Beta mannosidase, its coding gene and application

A technology of mannase and gene, applied in the field of genetic engineering, can solve the problems of low energy utilization rate, achieve good anti-trypsin ability, reduce environmental pollution, and lower blood sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

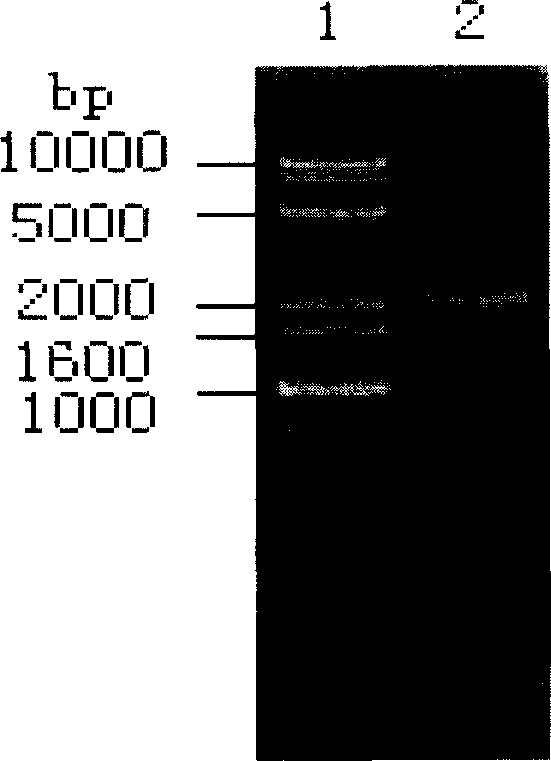

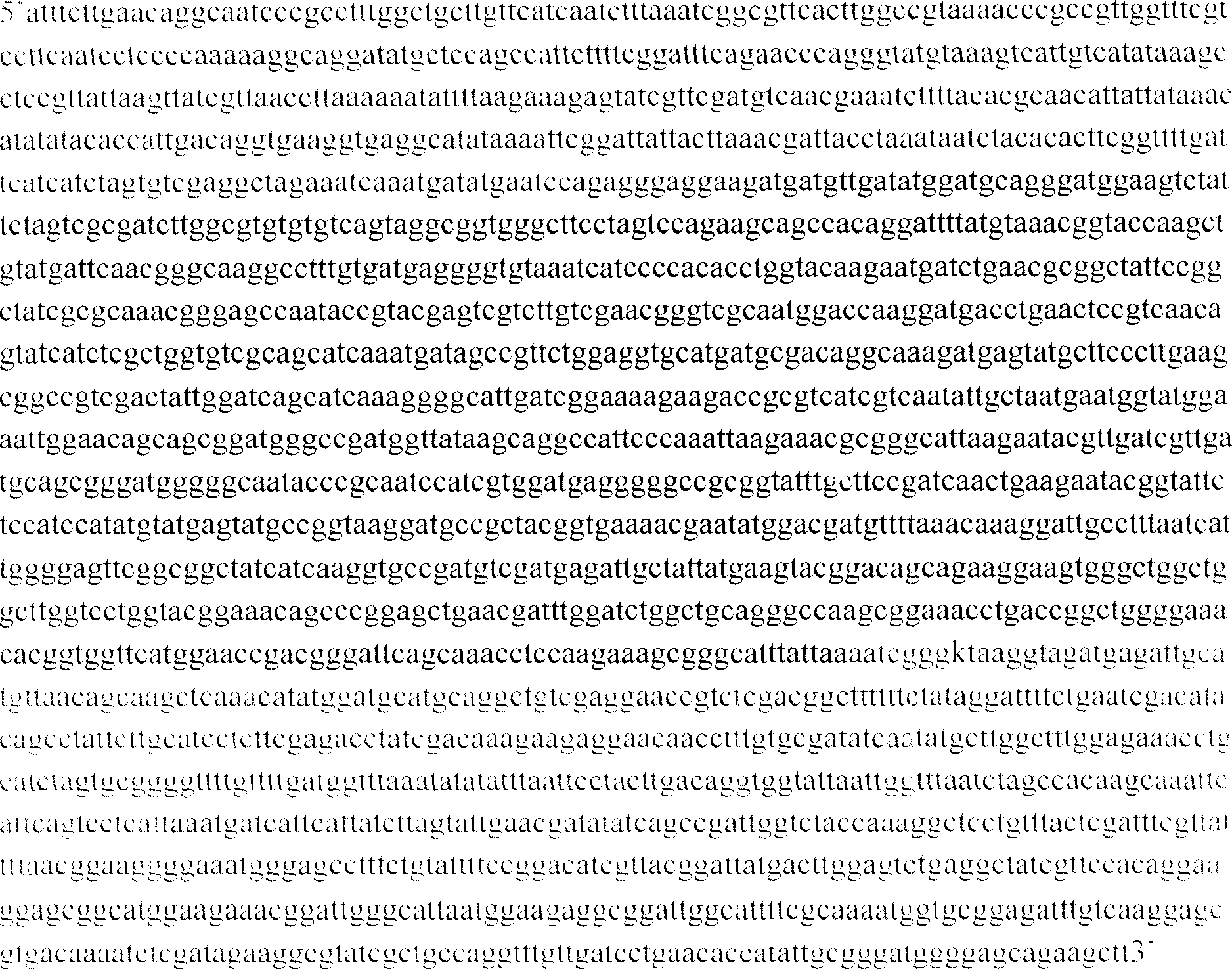

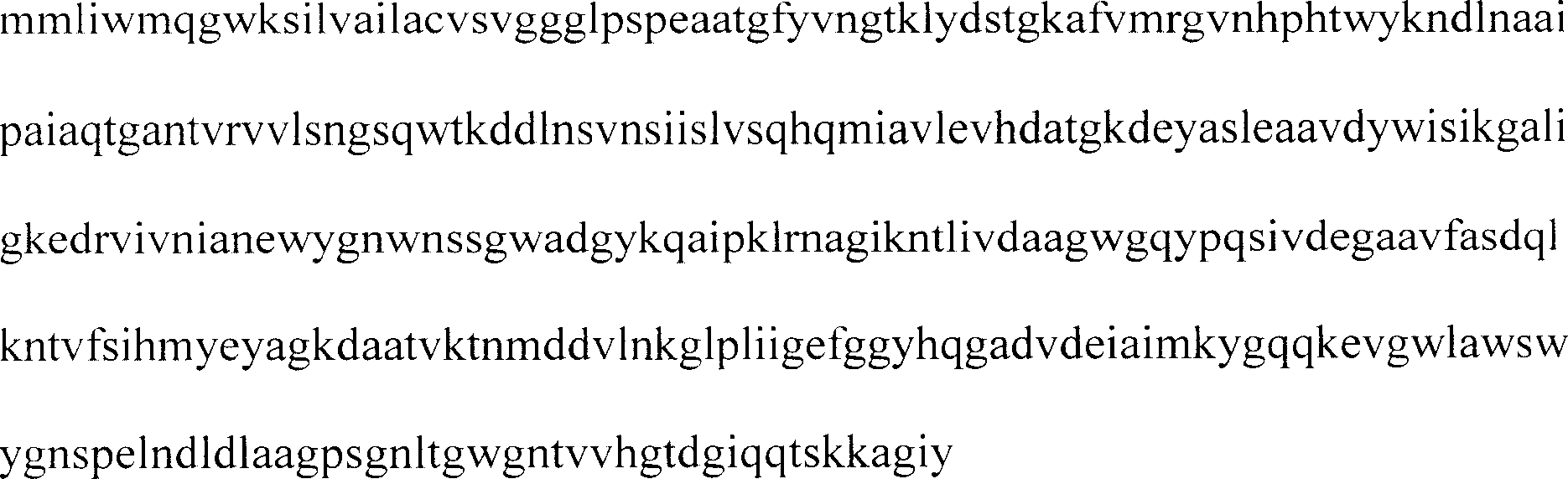

[0035] Example 1 Cloning of bacillus circulans beta-mannanase encoding gene manB48

[0036] Extraction of Bacillus circulans B48 genomic DNA: take the Bacillus circulans B48 bacterial liquid cultured at 30°C for 1 day and centrifuge at 10000rpm for 10min. Take 50 mg of bacteria sludge and add 500 μL of sterile water to wash, and centrifuge to get the precipitate. Resuspend the precipitate in 500 μL lysozyme mixture, incubate at 37°C for 30 minutes, add 100 μL of enzyme solution and continue to incubate at 40-50°C for 30 minutes until the bacterial solution is transparent, add 10% SDS to a final concentration of 2%, and stir for about After 5 minutes until the viscosity of the bacterial liquid drops significantly, centrifuge at 15,000 rpm for 10 minutes to remove debris. The supernatant was extracted sequentially with equal volumes of phenol, phenol-chloroform, and chloroform. Take the upper layer solution and add 0.6-1 times the volume of isopropanol to precipitate at room t...

Embodiment 2

[0048] Embodiment 2 Contains the recombinant enzyme preparation of β-mannanase coding gene manB48

[0049] The expression vector pET-22b(+) was double-enzymatically digested (NcoI+HindIII), and the gene manB48 of Bacillus circulansB48 was double-enzymatically digested (NcoI+HindIII) to cut out a part of the gene fragment encoding mature mannanase and the expression vector The pET-22b(+) was ligated to obtain the recombinant plasmid pET-22b(+)-manB48 containing the mannanase gene manB48 of Bacillus circulatus, and transformed into Escherichia coli BL21 to obtain the recombinant Escherichia coli strain BL21MAN48.

[0050] Take the BL21 strain containing the recombinant plasmid and the BL21 strain containing the pET-22b(+) empty plasmid (as a control), inoculate them in 5 mL of LB (with 100 μg / mL of ampicillin) culture solution, and culture with rapid shaking at 37°C overnight . Add 100 μL overnight culture solution to 8 mL LB culture solution (1% inoculum size) containing 100 μ...

Embodiment 3

[0052] Example 3 Purification of β-mannanase MANB48

[0053] After culturing Bacillus circulans B48 with the enzyme-inducing medium for 2 days, centrifuge the culture solution at 10,000rpm for 30 minutes to remove the bacteria, take the supernatant as the crude enzyme solution, put the crude enzyme solution in an ice bath, and slowly Add ammonium sulfate to 30% saturation, ice bath for 2 hours, then centrifuge at 13000rpm for 20min, continue to precipitate the supernatant with ammonium sulfate to 80%, centrifuge at 13000rpm for 20min, take the precipitate, and redissolve it with citric acid-sodium hydroxide buffer. The concentrated enzyme solution was obtained and further purified by HPLC (KTA FPLC, Pharmacia Company).

[0054] After being precipitated by ammonium sulfate, it was loaded on HiTrap_Q_Sepharose_XL (amersham pharmaciabiotech prepacked column) anion column. Add 2 mL of sample, first elute the equilibrated column with pH 8.0, 0.02 mol / L Tris-HCl buffer solution, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com