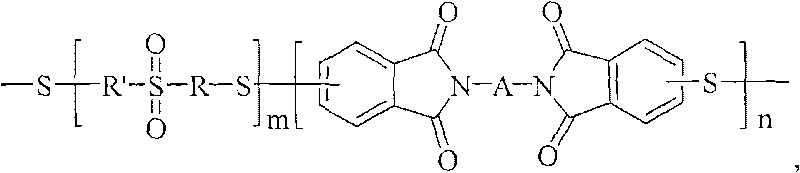

PASSI terpolymer and preparation method thereof

A sulfonimide terpolymer and terpolymer technology, applied in the field of preparation of the polysulfide sulfoneimide polymer, can solve the problems of narrow processing window, little industrial significance, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

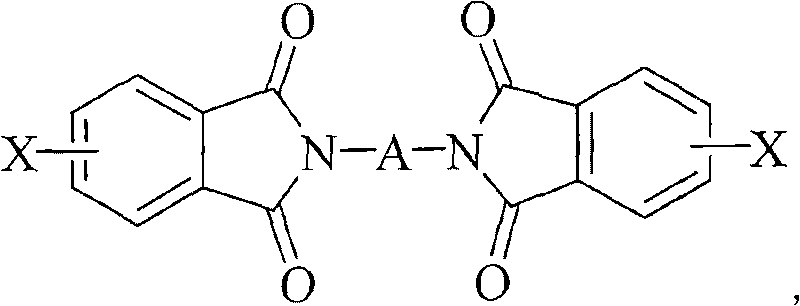

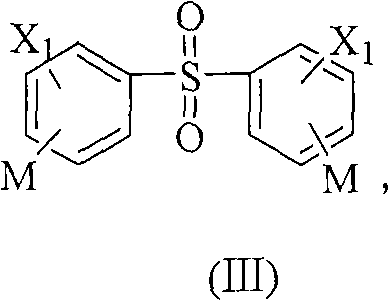

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Add 5.29g (0.01mol) 4,4'-bis(4-chloroimide) diphenyl ether, 2.87g (0.01mol) 4'4-dichlorodiphenyl sulfone in a 250ml three-necked flask , 0.67g (0.021mol) sulfur, 5.67g (0.063) paraformaldehyde, 1.68g sodium hydroxide, 0.25g calcium chloride, add 100mlN-methylpyrrolidone (solid content: 8%) after logical nitrogen deoxygenation three times, After heating to 150° C. for 5 hours, cooling to room temperature, adding 0.11 g of chlorobenzene, heating to 180° C. for 3 hours, and cooling the reaction solution to room temperature for aftertreatment.

[0050] Slowly pour the reaction solution into methanol and stir for 2 hours, filter and boil with water for 1 hour, filter, wrap the filter cake with filter paper, extract in a Soxhlet extractor with a mixed solution of ethanol and acetone for 24 hours, and then The obtained polymer was baked in a vacuum oven at 200° C. for 48 hours.

[0051] The intrinsic viscosity of the obtained polymer in m-cresol at 30°C is 0.65dL / g...

Embodiment 2

[0052] Example 2: Add 54.85g (0.100mol) 3,4'-bis(4-nitroimide) diphenylmethane and 48.04g (0.100mol) 3,3'-bis(3- Fluoroimide) biphenyl mixture, 30.83g (0.100mol) 4,4'-dinitrodiphenyl sulfone, 9.14g (0.285mol) sulfur, 21.56g (0.57mol) sodium borohydride, 41.46g carbonic acid Potassium, 5.23g sodium iodide, 4000ml dimethyl sulfoxide and 1000ml xylene (solid content: 14%) were added after argon deoxygenation three times, heated to 180°C and reacted for 20 hours, cooled to room temperature and added 3 -The nitrobenzophenone was heated to 200° C. for 1 hour to react, and the reaction solution was cooled to room temperature for aftertreatment.

[0053] Slowly pour the reaction solution into ethanol and stir for 2 hours, filter and boil with water for 2 hours, filter, wrap the filter cake with filter paper, extract it with a mixed solution of ethanol and acetone in Soxhlet extraction for 24 hours, and then extract The obtained polymer was baked in a vacuum oven at 200° C. for 48 hou...

Embodiment 3

[0055] Example 3: Add 22.22g (0.04mol) 2,2'-(4,4'-bis(3-chloroimide) diphenyl)isopropane and 16.33g (0.03mol) in a 500ml there-necked flask 3,3'-bis(3-fluoroimide) diphenylsulfone mixture, 2.56g (0.01mol) 3,3'-difluorodiphenylsulfone and 5.19g (0.01mol) bis(4-(4 -Mixture of chlorophenylsulfone group) phenyl) ether, 2.88g (0.09mol) sulfur, 5.04g (0.09) reduced iron powder, 9.07g sodium bicarbonate, 0.3g18-crown-6, pass argon to deoxygenate three times Then add 300ml of N,N-dimethylformamide, heat to 180°C and react for 20 hours, then add 20ml of oxalic acid to quench the polymerization reaction.

[0056] The reaction solution was slowly poured into water and stirred for 2 hours, filtered, boiled in water for 2 hours, filtered, and the filter cake was baked in a vacuum oven at 200°C for 48 hours.

[0057] The intrinsic viscosity of the obtained polymer in m-cresol at 30°C was 0.41 dL / g, and the glass transition temperature (Tg) was 249°C. The heat distortion temperature is 216...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com