N-doped carbon layer wrapped hollow-porous nickel oxide composite material and preparation method thereof

A hollow porous, nitrogen-doped carbon technology, used in nanotechnology for materials and surface science, electrochemical generators, electrical components, etc., can solve the problem of poor electronic conductivity and limit the electrochemical performance of nickel oxide. Battery cycle performance , low diffusion rate of lithium ions, etc., to achieve the effects of good discharge performance, easy promotion and large-scale production, and simple and effective preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

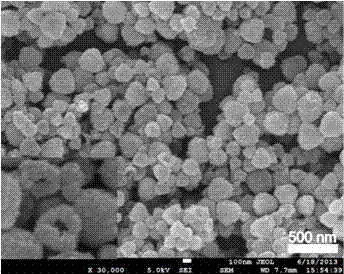

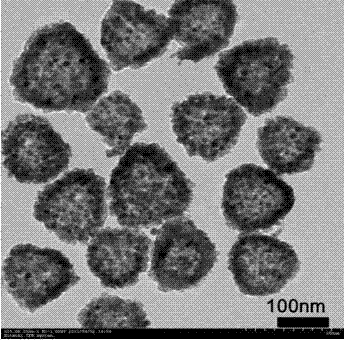

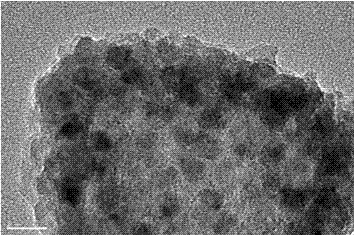

[0032] In 20 mL of ethylene glycol, add 0.895 g of nickel chloride hexahydrate, 1.23 g of sodium acetate, and 1.2 g of urea, respectively, and stir the mixture at 20-25 °C for 3-5 h. After mixing evenly, transfer it into a stainless steel reaction kettle lined with polytetrafluoroethylene, heat at 160-200 °C for 18-24 h, cool to room temperature, and centrifuge the product with ethanol and deionized water for 6-8 times Afterwards, vacuum-dry at 60-100 °C for 12-24 h in a drying oven to obtain precursor nickel bicarbonate nanoparticles with a particle size of about 200-300 nm. Add 30 mg of the precursor to 5 mL of 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid, and ultrasonically disperse for 5-15 min. Put the dispersed solution in a stainless steel reaction kettle lined with polytetrafluoroethylene, treat it with solvothermal method at 160-200 °C for 3-5 hours, cool to room temperature, centrifuge, and then heat it at 80-120 °C Dry under vacuum for 12-24 h. Place...

Embodiment 2

[0034] In 20 mL of ethylene glycol, 1.0 g of nickel chloride hexahydrate, 1.23 g of sodium acetate, and 0.8 g of urea were added respectively, and the mixture was stirred at 20-25 °C for 3-5 h. After mixing evenly, transfer it into a stainless steel reactor lined with polytetrafluoroethylene, heat at 160-200 °C for 18-24 h, and cool to room temperature. After the product was centrifuged and washed with ethanol and deionized water for 6 to 8 times, it was placed in a drying oven at 60 to 100 °C for 12 to 24 h under vacuum to obtain precursor nickel bicarbonate nanoparticles with a particle size of about 200 to 300 nm . 80 mg of the precursor was added to 10 mL of 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid, and ultrasonically dispersed for 5-15 min. Put the dispersed solution in a stainless steel reaction kettle lined with polytetrafluoroethylene, treat it with solvothermal method at 160-200 °C for 3-5 hours, cool to room temperature, centrifuge, and then heat i...

Embodiment 3

[0048] The hollow porous nickel oxide composite material wrapped by the nitrogen-doped carbon layer prepared in Example 1 was used to prepare a lithium ion battery according to the following method, and the performance test of the battery was performed on a constant current charge and discharge test system.

[0049] The mass ratio of 70%: 15%: 15% nitrogen-doped carbon layer wrapped hollow porous nickel oxide composite material, acetylene black, PVDF was mixed and ground in a mortar for 20 min, and 1-methyl-2- Pyrrolidone is used as a solvent, stirred to form a uniform slurry, and coated on the foamed copper to prepare a negative electrode sheet. In a glove box filled with argon, a metal lithium sheet was used as the positive electrode, and a 1 mol / L LiPF 6 / EC+DMC (1:1) organic solution is used as electrolyte, assembled into CR2025 button cell. The constant current charge and discharge test of the battery is carried out on the LAND-CT2001A battery test system (range 3.0V / 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com