Alkane-bridged lignin-based polymer as well as preparation method and application of lignin-based polymer

A lignin-based, polymer-based technology, applied in chemical instruments and methods, chemical/physical processes, liquid carbon-containing fuels, etc., can solve the problems of harsh reaction conditions, large dispersion, unfavorable industrial applications, etc., and achieve easy operation and control , Dispersion performance improvement, non-toxic molecular weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

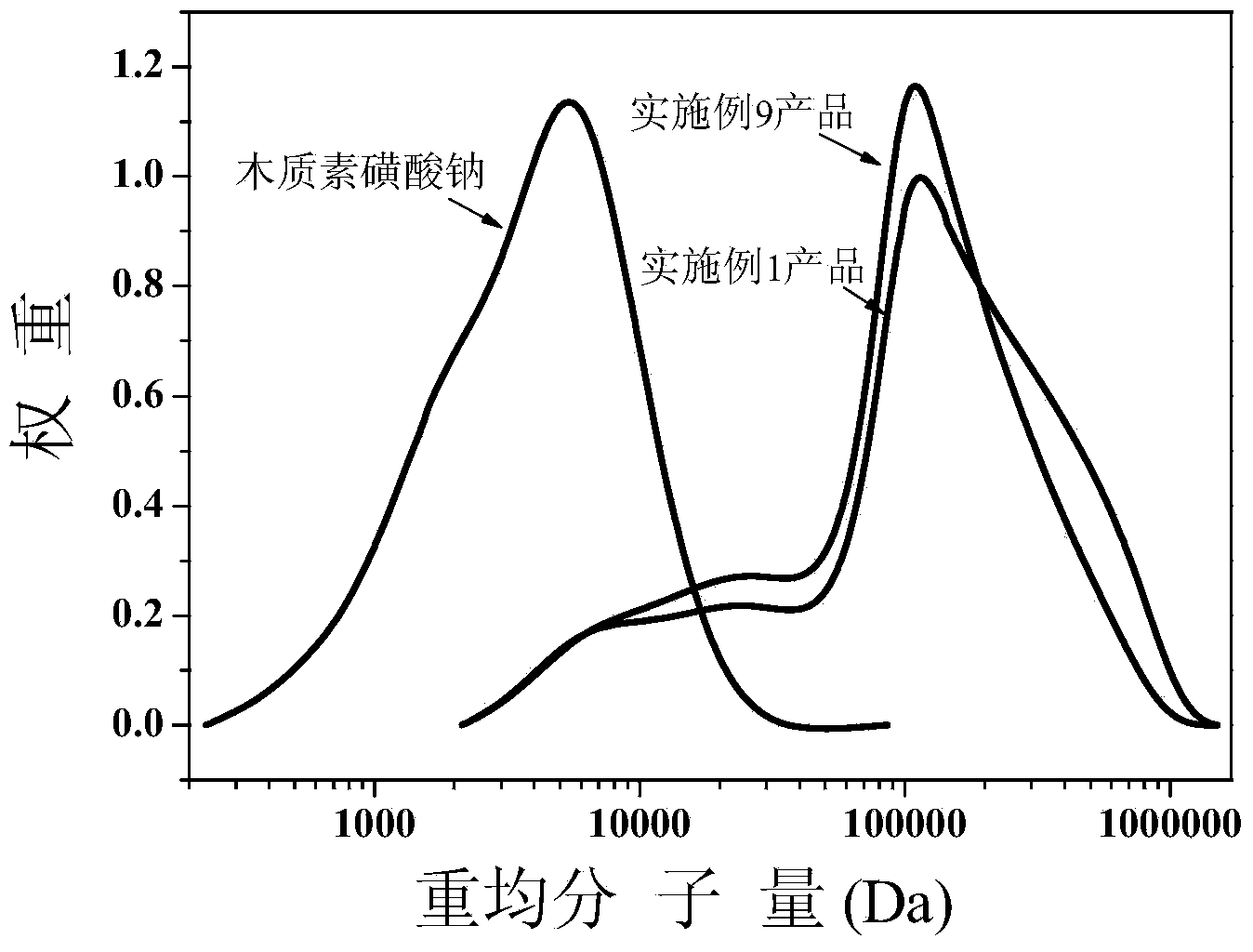

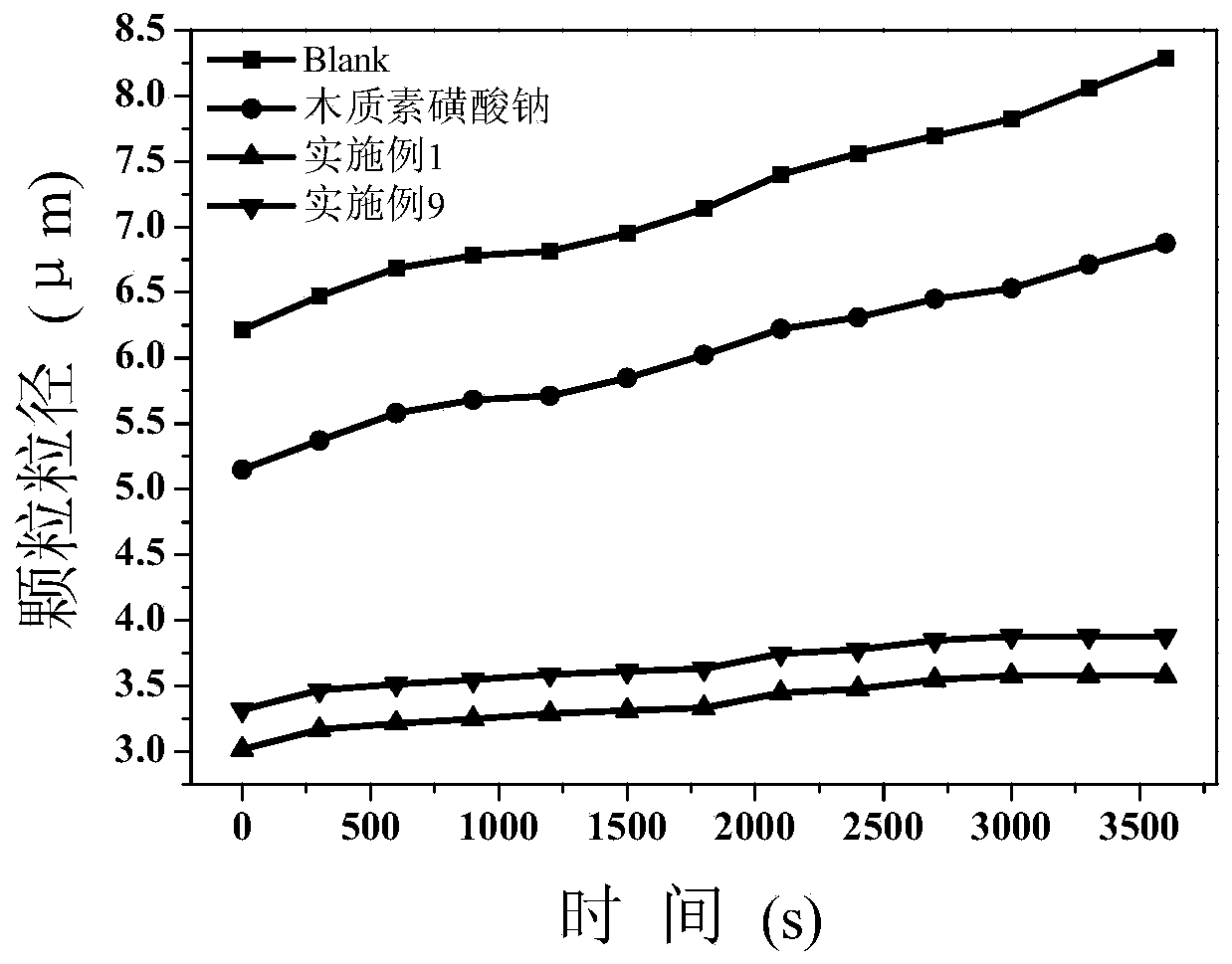

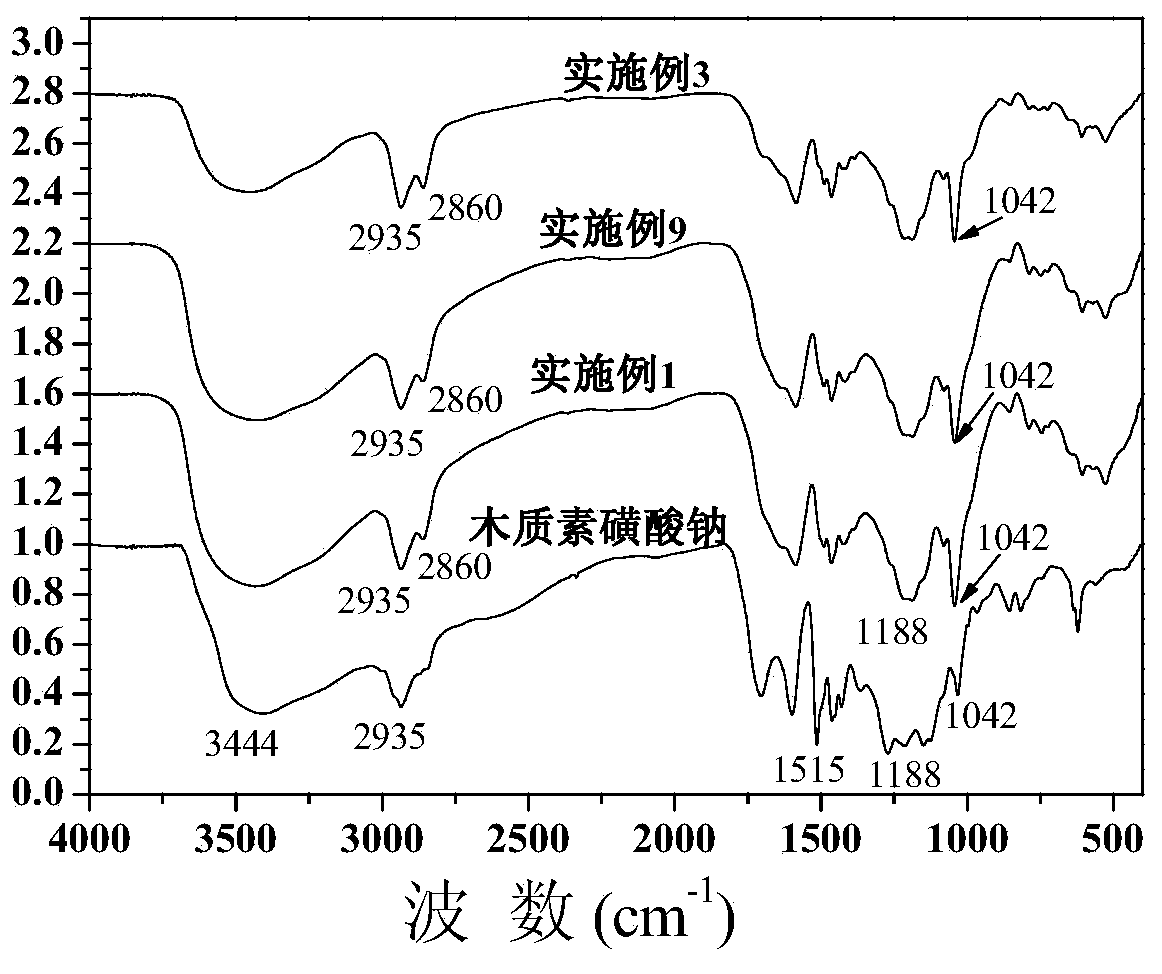

Embodiment 1

[0037] Take 20 grams of sodium lignosulfonate, add 2 grams of sodium hydroxide, add 0.5 grams of potassium iodide, raise the temperature to 60 ° C, slowly inject 100 grams of 1,2-dibromoethane with a syringe, and then react at 50 ° C for 24 Hours, after the reaction, cool to room temperature to obtain an alkane-bridged lignin-based polymer, which is then purified and dried to obtain a powdery product.

Embodiment 2

[0039] Take 20 grams of calcium lignosulfonate, add 4 grams of potassium hydroxide, and then 2 grams of sodium iodide, raise the temperature to 100 ° C, slowly inject 1 gram of 1,10-dibromodecane with a syringe, and then at 100 ° C React for 4 hours, cool after reaction, then purify and dry to obtain a powdery product.

Embodiment 3

[0041] Take 20 grams of sodium lignosulfonate, add 10 grams of potassium carbonate, and add 10 grams of tetrabutylammonium bromide to obtain intermediate reaction solution A. Take 10 grams of 1,6-dibromohexane into the reaction flask, slowly drop the reaction solution A into the constant pressure dropping funnel at 60°C, react at 90°C for 10 hours, cool to room temperature after the reaction, and then Purified and dried to obtain a powdered product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com