Piglet fodder anti-stress additive as well as preparation method and application thereof

An anti-stress additive, material-to-liquid ratio technology, applied in the application, animal feed, animal feed, etc., can solve the problem of insignificant processing effect of crude fiber, reduce the content of salivary cortisol and increase the content of blood epinephrine, The effect of avoiding the generation of sulfate radicals and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

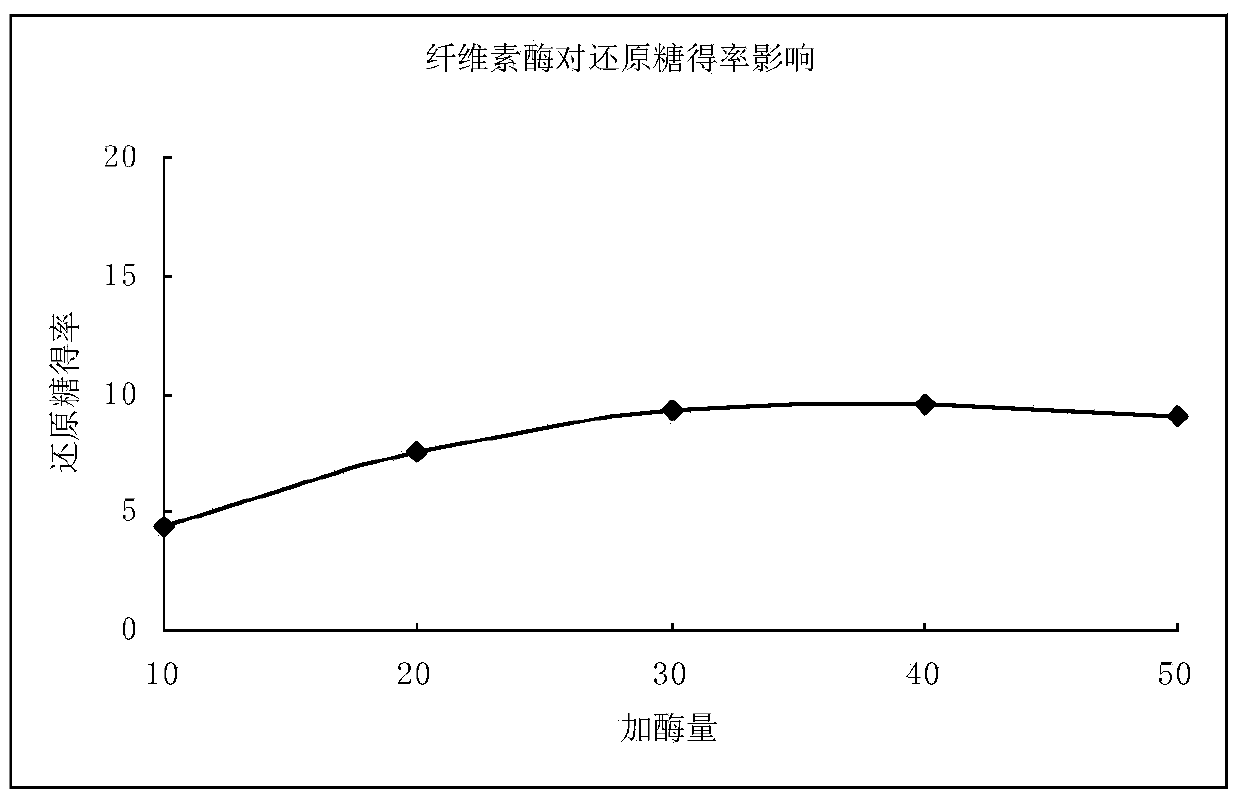

[0031] Example 1 The research on the hydrolysis of stalks into glucose

[0032] This example provides a method for hydrolyzing straw into glucose. After the straw is crushed, water is added according to the ratio of material to liquid at 1:0.5 for steam explosion treatment. The steam explosion pretreatment pressure is 1.5-2.0 MPa, and the retention time 120s; after blasting, use pH5.0 buffer to adjust the ratio of material to liquid to 1:5-1:10, add pectinase, hemicellulase and cellulase according to the weight of dry matter, and enzymolyze at 50°C for 24 Hours, after deactivating the enzyme, use a plate and frame filter press or centrifuge to obtain the supernatant; the steam explosion pretreatment pressure is 1.5-2.0MPa, and cannot exceed 2.0MPa, otherwise more furfural by-products will be produced. The reason for steam explosion is to Straw is pretreated. After blasting, the pH can be adjusted to about 5.0-6.0 with a small amount of phosphate buffer.

[0033] The samples ...

Embodiment 2

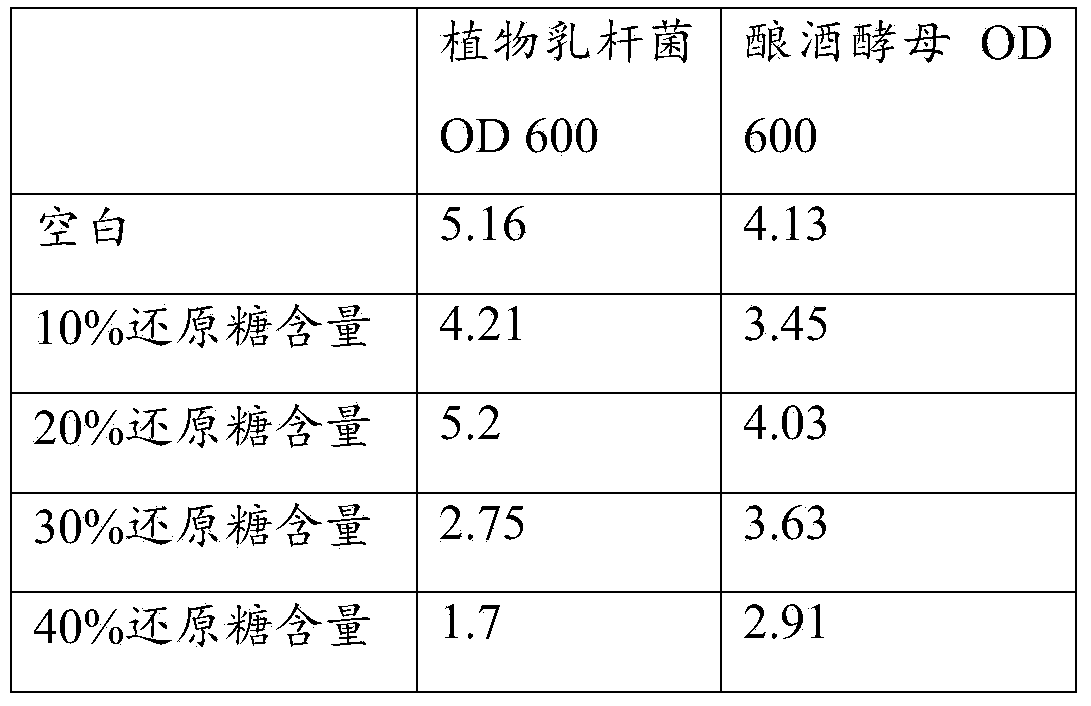

[0034]Example 2 Effect of reducing sugar concentration of straw hydrolyzate on the growth of fermentation strains

[0035] The enzymatic solution was diluted to obtain sugar solutions with different reducing sugar contents. When the blank was cultured with Lactobacillus plantarum or yeast alone, the OD value was measured with a spectrophotometer. The results are shown in Table 1. It can be seen from Table 1 that when the reducing sugar content of the enzymatic hydrolyzate is higher than 20%, the growth of Lactobacillus plantarum will be significantly affected. The possible reason is that the by-products produced during straw hydrolysis inhibit the growth of Lactobacillus plantarum. After enzymatic hydrolysis, the reducing sugar concentration is maintained below 20% by means of dilution.

[0036] The influence of table 1 reducing sugar concentration on the growth of fermented bacteria

[0037]

Embodiment 3

[0038] Embodiment 3 Lactobacillus plantarum and saccharomyces co-culture research

[0039] Lactobacillus plantarum was purchased from the American Standard Species Bank ATCC number Lactobacillus plantarum ATCC 14917. The strain was frozen in 15% glycerol (minus 70-80 degrees Celsius), and after the freeze-dried tube was taken out, it was activated on the MRS slant solid medium to select a single colony , and then activated in MRS liquid medium for two generations, and then inoculated into the detoxified sugar solution after enzymatic hydrolysis.

[0040] Preparation of Saccharomyces cerevisiae seed medium: transfer Saccharomyces cerevisiae strains to Saccharomyces cerevisiae seed medium for activation, and culture at 30°C for 24 hours; pick activated Saccharomyces cerevisiae strains to inoculate 5mL of Saccharomyces cerevisiae liquid medium, and culture at 30°C for 24 hours , followed by 10% inoculum size expansion. The composition of the seed medium: yeast extract 5g, pepton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com