Long-life high-load metal working fluid and preparation method thereof

A metalworking fluid, high-load technology, used in additives, petroleum industry, base materials, etc., can solve the problems of affecting the smoothness of the processed parts, reducing the service life of the tool, and the pressure is not very large, so as to improve the storage stability and prolong the use. Longevity and effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

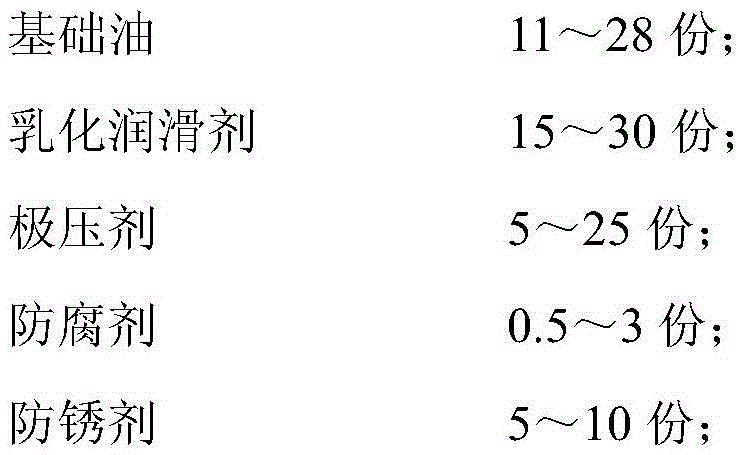

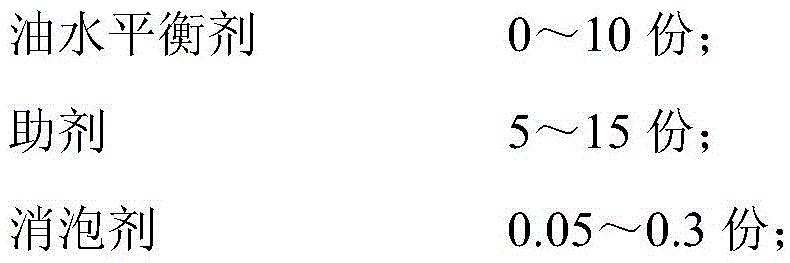

Method used

Image

Examples

Embodiment 1

[0021] First add 3kg epoxy soybean oil and 8kg class II hydrogenated oil (model 75N) into the blending kettle, then add 3kg chlorinated fatty acid, 22kg vulcanized lard, 6kg dimeric ricinoleic acid triethanolamine salt, 9kg castor oil polyoxygen Vinyl ether dioleate, 10kg sodium dodecylsulfonate and 5kg oleic acid diethanolamine borate, stirred at room temperature for 30 minutes, then added 2kg s-triazine, 0.5kg propyl p-hydroxybenzoate, 0.1kg sodium Tamycin, 0.4kg diazolidinyl urea, 0.5kg dodecenyl succinic acid diethanolamide, 0.5kg 2-alkyl branched chain C11 acid, 7kg triazine amino acid ester NEUF726, 1.5kg silicone ketone NEUF815 Stir with 0.5kg of 3-methyl-2thiazolethione for 20 minutes, then add 10.7kg of N,N-dimethylethanolamine and stir for 30 minutes, take a sample to observe the opacity, and use 7.8kg of polyethylene glycol monomethyl ether and 2.2kg of ISALCHEM145 to make it transparent. Finally, 0.3kg of XST-2015 organic silicon defoamer was added to obtain the pr...

Embodiment 2

[0023] First add 8kg epoxy rapeseed oil and 20kg class II hydrogenated oil (type 75N) into the blending kettle, then add 3kg sulfurized fatty acid, 8.45kg sulfurized lard, 6kg dimer ricinoleic acid triethanolamine salt, 9kg castor oil poly Oxyethylene ether dioleate, 10kg sodium dodecylsulfonate and 5kg oleic acid diethanolamine borate, stirred at room temperature for 30 minutes, then added 0.1kg s-triazine, 0.1kg propyl p-hydroxybenzoate, 0.2 kg natamycin, 0.1kg diazolidinyl urea, 1.5kg dodecenyl succinic acid diethanolamide, 0.5kg 2-alkyl branched chain C11 acid, 2kg triazine amino acid ester NEUF726, 0.5kg siloxane Ketone NEUF815 and 0.5kg of 3-methyl-2thiazolethione were stirred for 20 minutes, then 15kg of N,N-dimethylethanolamine was added and stirred for 30 minutes, the sample was observed to be opaque, and it was made transparent with 4.6kg of polyethylene glycol monomethyl ether and 5.4kg of ISALCHEM145 , and finally add 0.05kgXST-2015 silicone defoamer to obtain the ...

Embodiment 3

[0025] First add 8kg epoxy rapeseed oil and 20kg class II hydrogenated oil (type 75N) into the blending kettle, then add 2kg sulfurized fatty acid, 18kg sulfurized lard, 5kg dimeric ricinoleic acid triethanolamine salt, 7kg castor oil polyoxygen Vinyl ether dioleate, 10kg sodium dodecylsulfonate and 8kg oleic acid diethanolamine borate, stirred at room temperature for 30 minutes, then added 1kg s-triazine, 0.3kg propyl p-hydroxybenzoate, 0.1kg sodium Tamycin, 0.6kg diazolidinyl urea, 0.5kg dodecenyl succinic acid diethanolamide, 0.5kg 2-alkyl branched chain C11 acid, 5kg triazine amino acid ester NEUF726, 1.5kg silicone ketone NEUF815 Stir with 0.5kg of 3-methyl-2thiazolethione for 20 minutes, add 11.8kg of N,N-dimethylethanolamine and stir for 30 minutes, take a sample and observe it is transparent, and finally add 0.2kg of XST-2015 silicone defoamer to obtain the product. 2.5% cast iron scrap filter paper is rust-proof grade 0, 3% PB value is 109kg, 3% pH value is 9.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com