Method and device for purifying, absorbing and recycling chlorinated gas in benzene chlorination process

A technology for chlorinating tail gas and benzene, applied in chemical instruments and methods, separation methods, chlorine/hydrogen chloride and other directions, can solve the problems of not realizing the effective utilization of hydrogen chloride, removing by-product hydrogen chloride gas, increasing processing costs, etc. The effect of improving the economic benefit of the enterprise, improving the product yield and saving the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

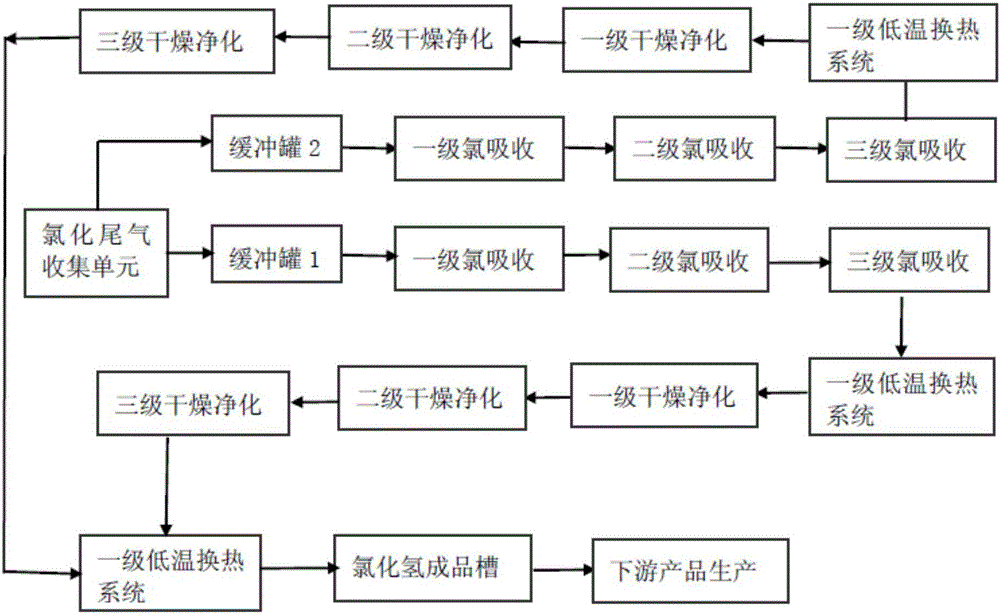

Method used

Image

Examples

Embodiment 1

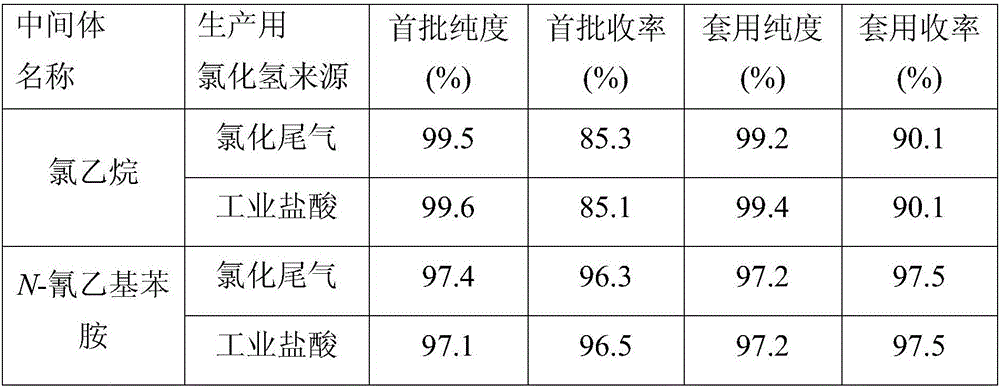

[0060] (1) Synthesis of ethyl chloride

[0061] The first batch: Add 107kg of alcohol and 224kg of water to the reactor, then add 600kg of zinc chloride, beat for 0.5h, and then pass in 102kg of hydrogen chloride gas obtained by purifying the chlorination tail gas, after the addition, slowly raise the temperature to 80°C for 3h, then raise the temperature Heat at 100°C for 3 hours, then raise the temperature to 110°C for 2 hours, and stop the reaction when the weight of the reaction pot remains basically unchanged. The mixed gas coming out of the reaction kettle is cooled to about 50°C by primary cooling, buffered, and cooled to 30°C by secondary cooling, first-stage water absorption, secondary water absorption, finished product cooling and condensation to about 0°C, and water separator separation. The finished product ethyl chloride has a content of 99.5% as detected by gas chromatography, and 128 kg of ethyl chloride is obtained by weighing, with a yield of 85.3%.

[0062] ...

Embodiment 2

[0068] Preparation of N-cyanoethylaniline

[0069] Add 2g of hydroquinone, 5g of tetraethylammonium chloride, and 855g of bottom water into a 3L reaction kettle, add 10.0g of crystalline aluminum trichloride and make a slurry, and slowly inject 25g of chlorinated tail gas after the aluminum trichloride is completely dissolved Purify the obtained hydrogen chloride gas, then slowly add 466g of aniline under stirring, raise the temperature to 45°C, slowly add 300g of acrylonitrile dropwise under stirring, slowly raise the temperature to 85°C after the dropwise addition, keep it for 12h, then raise the temperature to 90°C and keep it for 8h .

[0070] After the reaction was completed, the layers were separated after standing still for 1 hour. The organic phase was distilled to recover acrylonitrile, cooled and filtered, and the obtained solid was N-cyanoethylaniline product, and then the product was analyzed by liquid chromatography, aniline = 0.46%, N- Cyanoethylaniline=97.4%, N...

Embodiment 3

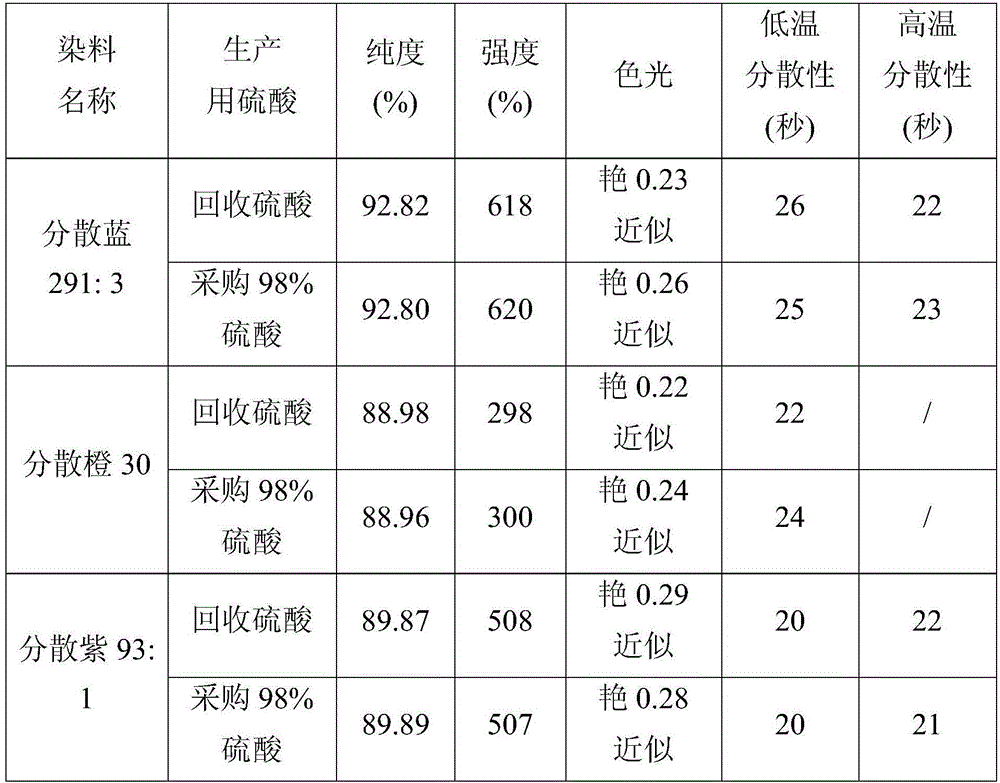

[0086] (1) Preparation of Disperse Blue 291:3 filter cake

[0087] Add 3800kg of nitrosyl sulfuric acid and 800kg of 98% sulfuric acid into the reactor, and add 2,4-dinitro-6-chloroaniline and 2,4-dinitro-6-bromoaniline with a mass ratio of 3:1 2000kg, stir to dissolve, control the temperature at 25-30°C to react, use starch potassium iodide test paper to detect the reaction end point, and obtain the diazonium salt solution. Add 2600kg (dried) 2-methoxy-5-acetylamino-N, N-diallylaniline and 5kg Pingpingjia O-15 to 32 tons of sulfuric acid aqueous solution with an acid value of 8%, beat for 2 hours use. Slowly add the above-prepared diazonium salt solution into the prepared coupling solution, add 20 tons of ice, and carry out the coupling reaction at -5 ~ 0°C. After the reaction is completed, press filter, and the filtrate is 46 tons of mother liquor water. The filter cake is washed with water until the neutral disperse blue 291:3 filter cake is 12 tons, and the water content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com