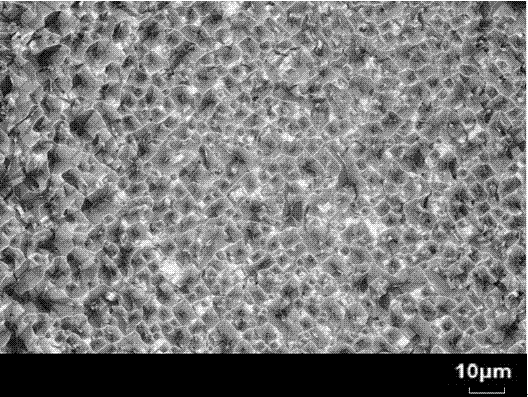

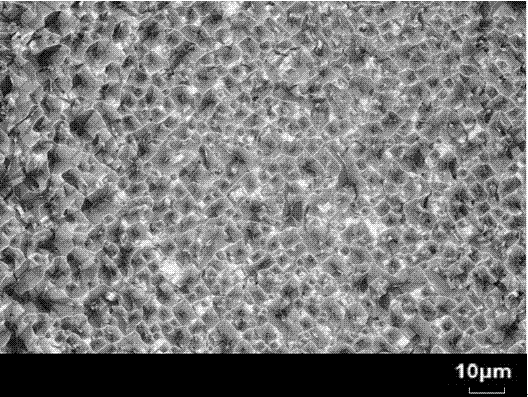

Texturing additive for inverted pyramid textured monocrystalline silicon wafer and application thereof

A single crystal silicon wafer and inverted pyramid technology, applied in the direction of single crystal growth, single crystal growth, sustainable manufacturing/processing, etc., can solve the problems of large environmental pollution control, high cost, inability to use both texturing equipment, etc. Inexpensive, simple to manufacture and use, the effect of reducing the chance of compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Prepare texturing additives: add 0.5g nonionic surfactant, 60g cationic surfactant, 10g polyethylene glycol, and 20g organic salt into the deionized solution, mix well to make 100g texturing additive solution;

[0031] The non-ionic surfactant is polyoxyethylene ether containing alkylphenol, high-carbon fatty alcohol polyoxyethylene ether, fatty acid polyoxyethylene ester, polyoxyethylene amine, alkyl alcohol amide, ethanolamine, sucrose ester, alkyl alcohol One of amides;

[0032] The cationic surfactants include fatty amine salts, ethanolamine salts, quaternary ammonium salts, imidazoline, polyethylene polyamine salts, morpholine guanidines, and triazine derivatives;

[0033] Described organic salt is two kinds in sodium acetate, pyridinium acetate, sodium ethylate;

[0034] The molecular weight of the polyethylene glycol is 200;

[0035] 2) Prepare the texturing liquid: add 100g of the texturing additive solution prepared in step 1) to 2Kg of the alkali solution...

Embodiment 2

[0039] 1) Prepare texturing additives: Add 50g of nonionic surfactant, 1g of cationic surfactant, 2g of polyethylene glycol, and 1g of organic salt into the deionized solution, mix well to make 100g of texturing additive solution;

[0040] The nonionic surfactants include polyoxyethylene ethers containing alkylphenols, polyoxyethylene ethers of high-carbon fatty alcohols, polyoxyethylene fatty acid esters, polyoxyethylene amines, alkanolamides, ethanolamines, sucrose esters, and alkyl alcohols. amides;

[0041] The cationic surfactant is one of fatty amine salts, ethanolamine salts, quaternary ammonium salts, imidazoline, polyethylene polyamine salts, morpholine guanidines, and triazine derivatives;

[0042] Described organic salt is the one in sodium acetate, pyridinium acetate, sodium ethylate;

[0043] The molecular weight of the polyethylene glycol is 2000;

[0044] 2) Configure the texturing liquid: add 100g of the texturing additive solution prepared in step 1) to 50Kg o...

Embodiment 3

[0048] 1) Configure texturing additives: add 20g nonionic surfactant, 25g cationic surfactant, 6g polyethylene glycol, and 12g organic salt into deionized solution, mix well to make 100g texturing additive solution;

[0049] The nonionic surfactants include polyoxyethylene ethers containing alkylphenols, polyoxyethylene ethers of high-carbon fatty alcohols, polyoxyethylene fatty acid esters, polyoxyethylene amines, alkanolamides, ethanolamines, sucrose esters, and alkyl alcohols. Five of the amides;

[0050] The cationic surfactants include three types of fatty amine salts, ethanolamine salts, quaternary ammonium salts, imidazoline, polyethylene polyamine salts, morpholine guanidines, and triazine derivatives;

[0051] Described organic salt comprises sodium acetate, pyridinium acetate, sodium ethylate;

[0052] The molecular weight of the polyethylene glycol is 1200;

[0053] 2) Configure the texturing liquid: add 100g of the texturing additive solution prepared in step 1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com