Photodynamic sterilization polymer as well as preparation method and application thereof

A polymer and photodynamic technology, applied in photodynamic therapy, chemical instruments and methods, luminescent materials, etc., can solve the problems of limited sterilization range, general sterilization effect, and inability to kill fungi, and achieves simple preparation method and strong killing ability. , the effect of low concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Preparation of polymer (I)

[0027] 1) In a 100mL round bottom flask, add 2.68g 2,5-dibromohydroquinone (10.0mmol), 32.8g1,12-dibromododecane (100mmol), 4.97g potassium carbonate (36.0 mmol) and 100 mL acetone. Under the catalytic amount of 18-crown-6 phase transfer catalyst, the reaction was stirred and heated to reflux for 5h. The reaction was stopped, after a large amount of solvent was spun off under reduced pressure, 200 mL of dichloromethane was added, and the obtained organic phase was washed 3 times with distilled water (3×100 mL), dried over anhydrous sodium sulfate, and the solvent was removed to obtain a crude product. The crude product is separated by column chromatography (eluent is dichloromethane / petroleum ether = 1 / 2, v / v) to obtain 1,4-dibromo-2,5-bis(12-bromododecyloxy)benzene (II) 2.68 g (35.1% yield). 1 H NMR(400MHz, CDCl 3 ,ppm)δ:1.23-1.49(m,32H),1.77-1.89(m,8H), 3.36(t,JJ=7.2Hz,4H), 3.94(t,JJ=8.0Hz,4H), 7.08(s ,2H); 13 C NMR(100MHz, CDCl ...

Embodiment 2

[0030] Example 2 Fluorescence emission spectrum and ultraviolet absorption spectrum test of polymer (I)

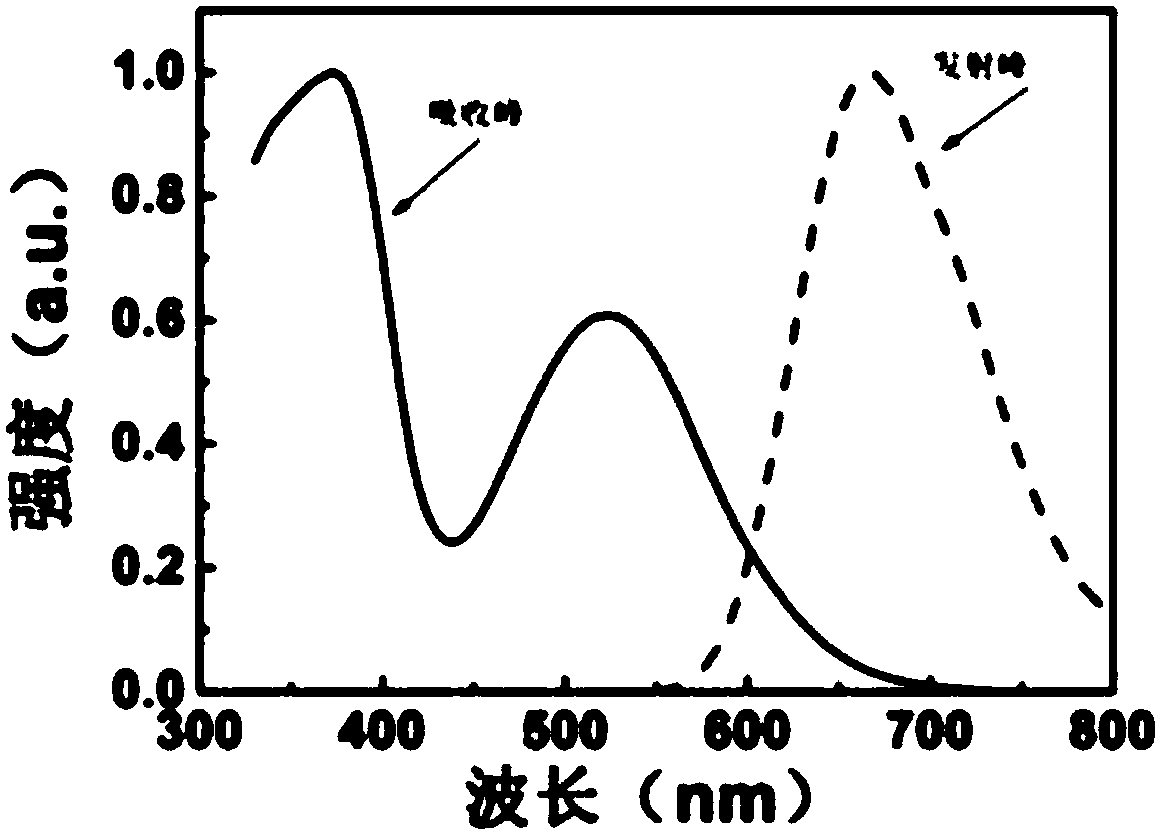

[0031] The polymer (I) was dissolved in DMSO to prepare a solution with a concentration of 0.02 mg / mL. Accurately pipet 2.0 mL of the above solution and add it to the UV sample cell. Using the DMSO solvent as a reference, measure it on the HITACHI UH5300 UV absorber. The maximum absorption peak is 540nm. Similarly, accurately pipette the above-mentioned DMSO solution with a concentration of 0.02mg / mL into a 2.0mL fluorescence sample cell and measure it on a HITACHI F-4600 fluorometer. The excitation and emission slit width is 5n, the excitation wavelength is 513nm, and the maximum emission wavelength is obtained. It is 665nm. The normalized map of the results obtained is shown in figure 1 .

Embodiment 3

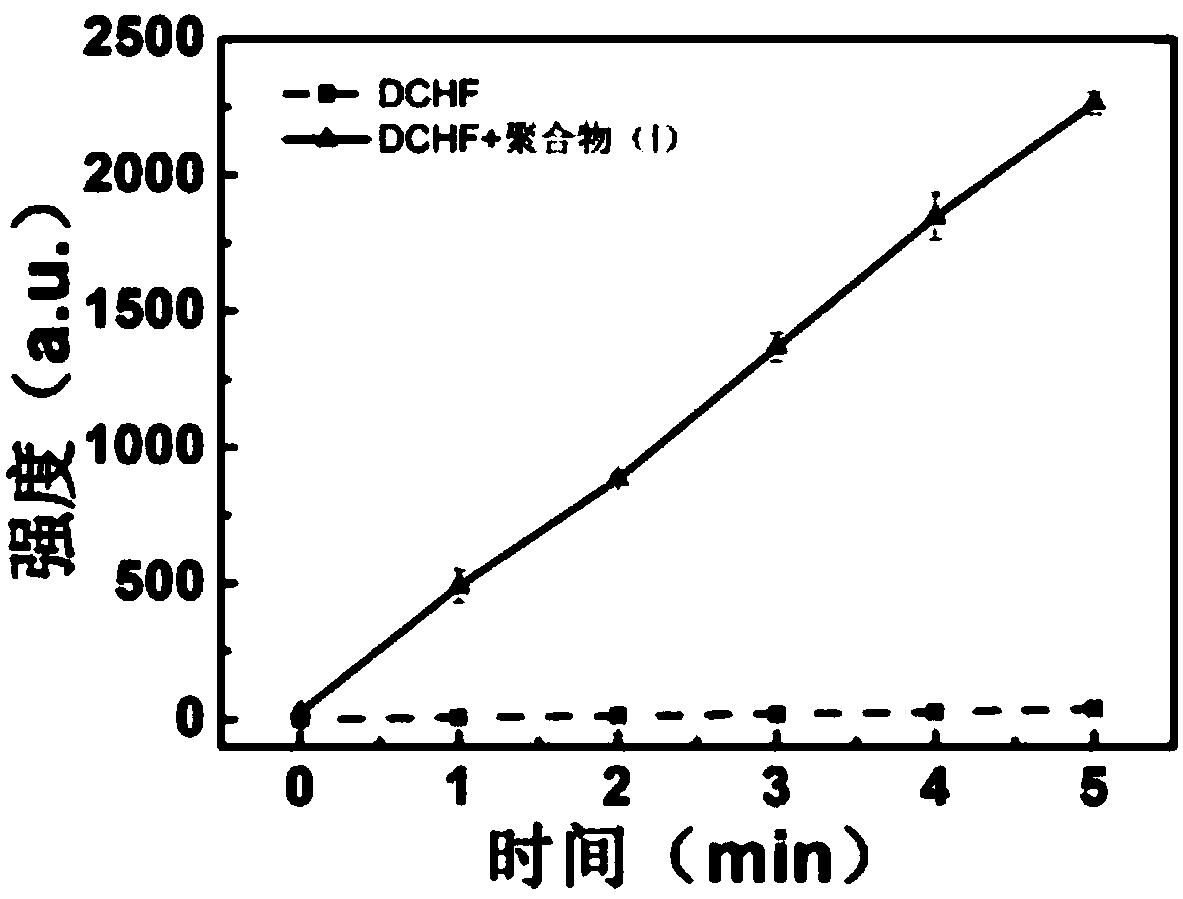

[0032] Example 3 Active oxygen generation ability test of polymer (I)

[0033] Take 50μL of 10.0mM 2,7-dichlorofluorescein diacetate ethanol solution, add 450μL of ethanol to dilute, then add 2.0mL of 0.01M NaOH aqueous solution, and activate at room temperature for 30min in the dark. After activation, add 10 mL of 1×PBS buffer solution, and the final concentration of the mixed DCFH solution is 40 μM.

[0034] Add 1.0mL of activated DCFH (40μM) solution and 52.4μL of polymer (I) (100μM) aqueous solution into the cuvette, mix well, and place the resulting solution in white light (1.0mW / cm). 2 ) Irradiate for 5 min, and record the fluorescence emission spectrum of DCFH solution with excitation wavelength of 488nm at 500-700nm every minute. The blank group is the DCFH solution (40μM) without any activation to be tested. After the same illumination treatment, use the same method to detect Its fluorescence emission spectrum. See the test results figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com