Preparation method and application of nano motor adsorbing material

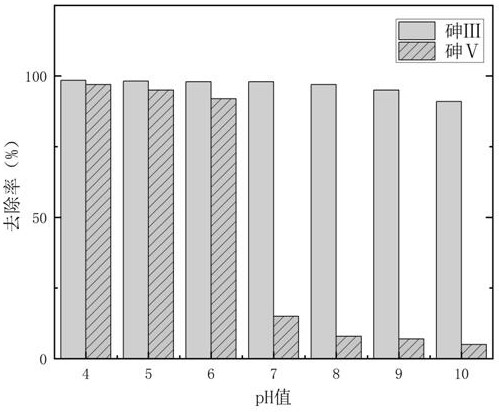

An adsorption material and motor technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, inorganic chemistry, etc., can solve the problems of low selectivity, secondary pollution, and poor recyclability of nanomaterials, and achieve a simple preparation process, removal of The effect of good effect and low cost of synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

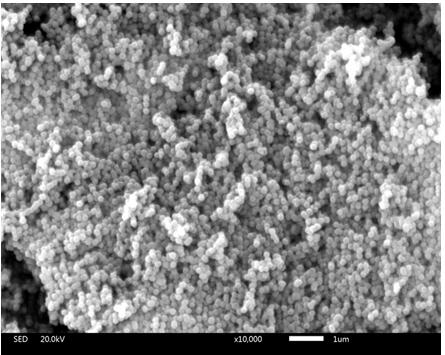

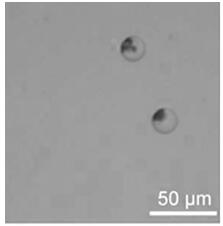

[0032] Embodiment 1: The preparation method of this nanomotor adsorption material is as follows:

[0033] (1) Weigh FeCl 2 2g and FeCl 3 Put 5.4g in a 100mL beaker, add 25mL of 2mol / L hydrochloric acid, fully dissolve and transfer to a 250mL three-necked flask, pass nitrogen into the solution to remove dissolved oxygen in the solution; then stir for 10min under the protection of nitrogen, the stirring speed is 300r / min, add ammonia water (28%, 40mL) while stirring; continue to stir for 1h after adding liquid, collect the solid and wash it with 60mL deionized water to obtain Fe 3 o 4 Nanoparticles;

[0034] (2) Fe 3 o 4 After ultrasonic treatment of nanoparticles in 0.1mol / L nitric acid solution for 10min, rinse with deionized water for 3 times, then disperse the rinsed particles in 0.5mol / L glucose aqueous solution, stir vigorously (450r / min) for 10min , transfer the suspension to an autoclave at 180°C for 6 hours, cool and separate it with a magnet, wash the solid wit...

Embodiment 2

[0038] Embodiment 2: The preparation method of this nanomotor adsorption material is as follows:

[0039] (1) Fe 3 o 4 Nanoparticles were ultrasonically treated in 1mol / L nitric acid solution for 20min, rinsed with deionized water for 4 times, then dispersed in 0.4mol / L glucose aqueous solution, stirred vigorously (450r / min) for 25min, Transfer the suspension to an autoclave at 200°C for 4 hours, cool and separate it with a magnet, wash the solid with deionized water and alcohol alternately for 4 times, and dry it in a vacuum oven at 80°C for 4 hours to obtain Fe 3 o 4 @C microsphere;

[0040] (2) Fe 3 o 4 @C microspheres dispersed in n-butyl titanate-ethanol mixed solution (n-butyl titanate and Fe 3 o 4 @C The mass ratio of microspheres is 5:0.8, the mass volume ratio of n-butyl titanate and ethanol is 1:7), after ultrasonic mixing, the nickel nitrate-ethanol mixture (cobalt nitrate and Fe 3 o 4 The mass ratio of @C microspheres is 4:1, the mass volume ratio of cobal...

Embodiment 3

[0042] Embodiment 3: The preparation method of this nanomotor adsorption material is as follows:

[0043] (1) Fe 3 o 4 Nanoparticles were ultrasonically treated in 0.2mol / L nitric acid solution for 9 minutes, rinsed with deionized water for 4 times, and then dispersed in 0.6mol / L glucose aqueous solution, stirred vigorously (450r / min) for 18min , transfer the suspension to an autoclave at 210°C for 3 hours, cool it and separate it with a magnet, wash the solid with deionized water and alcohol alternately for 4 times, and dry it in a vacuum oven at 80°C for 4 hours to obtain Fe 3 o 4 @C microsphere;

[0044] (2) Fe 3 o 4 @C microspheres dispersed in n-butyl titanate-ethanol mixed solution (n-butyl titanate and Fe 3 o 4 @C The mass ratio of microspheres is 8:0.6, the mass volume ratio of n-butyl titanate and ethanol is 1:8), after ultrasonic mixing, the nickel nitrate-ethanol mixture (nickel nitrate and Fe 3 o 4 The mass ratio of @C microspheres is 5:1, the mass volume ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com