Preparation method of industrial sewage treatment fungicide

A technology for industrial sewage and sewage treatment, applied in the field of water treatment, can solve problems such as poor treatment effect of physical methods, hazards to human physical and mental health, complex components of industrial wastewater, etc., achieve excellent bioaugmentation effect, improve bioaugmentation effect, and improve The effect of degree removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

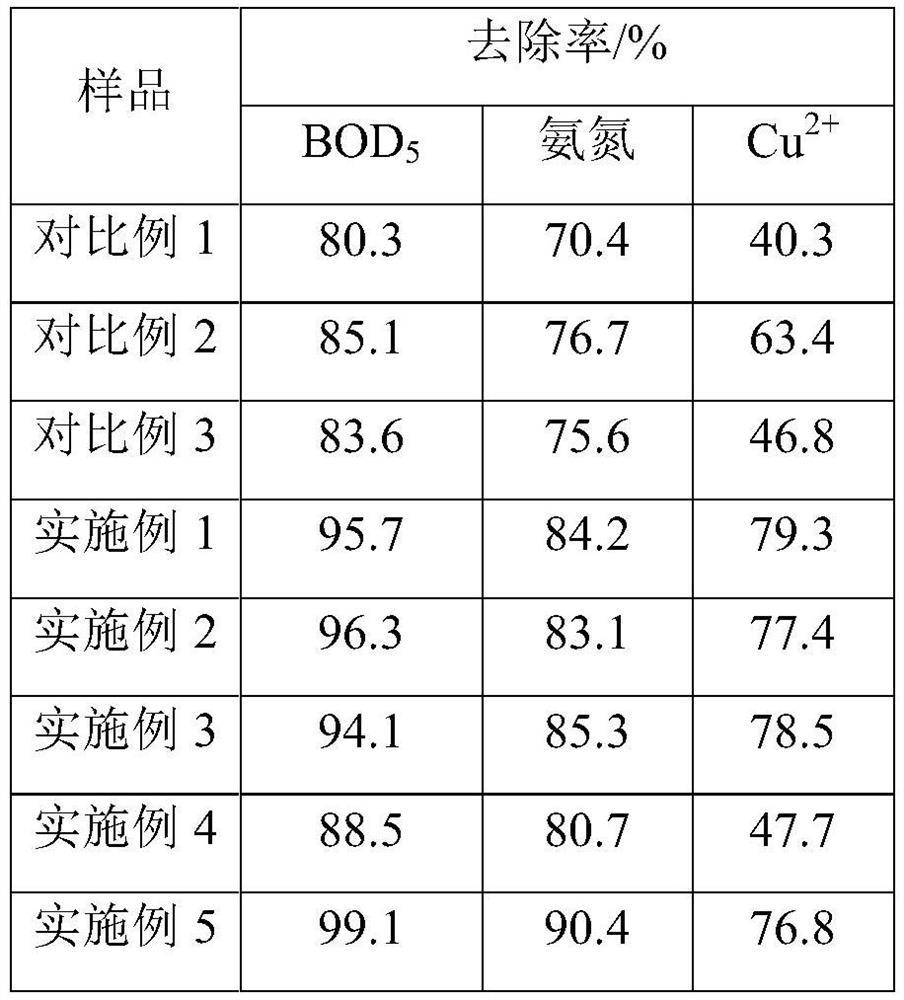

Embodiment 1

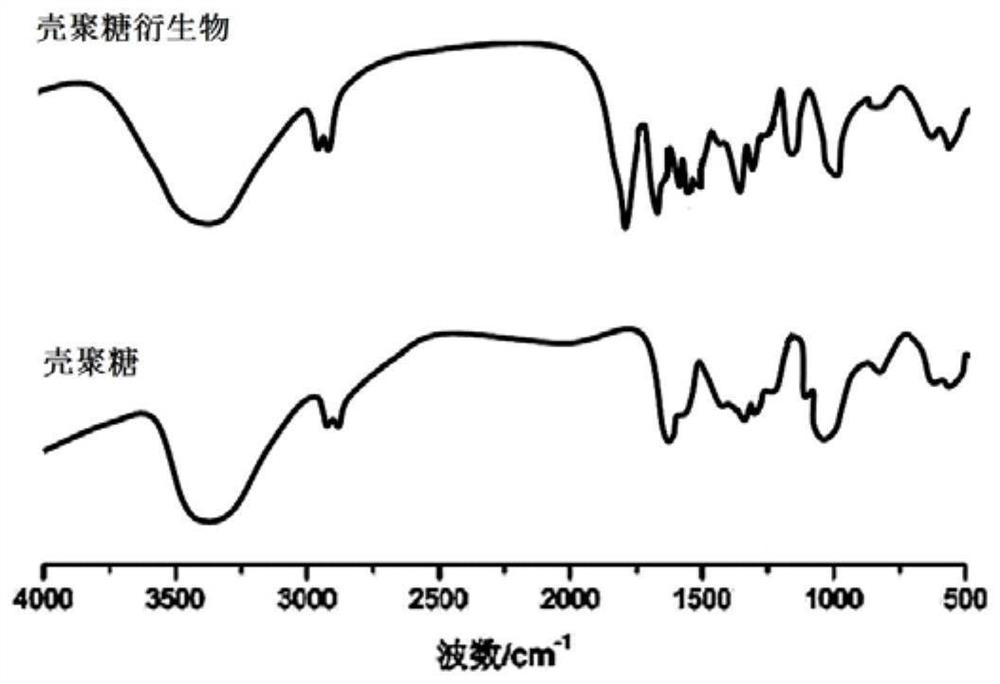

[0050] Preparation of chitosan derivatives:

[0051] Dissolve chitosan in 1% acetic acid and stir until completely dissolved. Add 4-amino-2-nitrodiphenylamine-2'-formic acid according to the molar ratio of 4-amino-2-nitrodiphenylamine-2'-formic acid to chitosan as 1.38:1; then N-hydroxyl Succinimine (the molar ratio of N-hydroxysuccinimine to chitosan is 1.1:1) was dissolved in 1.5 mg / mL of EDC, then added to the above mixed solution, continued to stir until completely dissolved, then adjusted the pH to 8.5, then Stir for 24h. Then put the solution into a dialysis bag and put it into distilled water for dialysis for 3 days, during which time the distilled water was replaced. Then the dialysis bag was transferred to PEG solution to concentrate for 2 days. Then take the concentrated solution and add acetone (1:2) to precipitate the modified chitosan for 10 hours. The solution was centrifuged (15000 rpm), and the precipitated part was washed with absolute ethanol for 3 times,...

Embodiment 2

[0059] The preparation of chitosan derivative is identical with embodiment 1.

[0060] A bacterial agent for industrial sewage treatment, comprising, as main ingredients, by weight parts, 11 parts of Chryseobacterium indole-producing, 7 parts of Pseudomonas putida, 4 parts of Nitrosoma, and 4 parts of Acinetobacter ruckeri.

[0061] Nutrient ingredients, in parts by weight, include 4 parts of sodium ascorbate and 0.7 part of riboflavin.

[0062] Solid matrix, in parts by weight, 17 parts of perlite and 7 parts of chitosan derivatives.

[0063] The preparation of the bacterial agent for industrial sewage treatment was the same as in Example 1.

Embodiment 3

[0065] The preparation of chitosan derivative is identical with embodiment 1.

[0066] A bacterial agent for industrial sewage treatment, comprising, in parts by weight, 9 parts of Chryseobacterium indolegenes, 6 parts of Pseudomonas putida, 6 parts of nitrosobacter, and 5 parts of Acinetobacter ruckeri.

[0067] Nutrient ingredients, in parts by weight, include 4 parts of sodium ascorbate and 0.6 part of riboflavin.

[0068] Solid matrix, in parts by weight, 19 parts of perlite and 6 parts of chitosan derivatives.

[0069] The preparation of the bacterial agent for industrial sewage treatment was the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com