Core-shell structure silicon-carbon composite material for lithium ion battery, preparation method of core-shell structure silicon-carbon composite material and negative electrode

A silicon-carbon composite material, lithium-ion battery technology, applied in battery electrodes, carbon preparation/purification, nanotechnology for materials and surface science, etc., can solve poor conductivity, poor electrode cycle performance, and cannot be commercialized production and other problems, to achieve the effect of reducing impedance and polarization, improving electrochemical performance, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

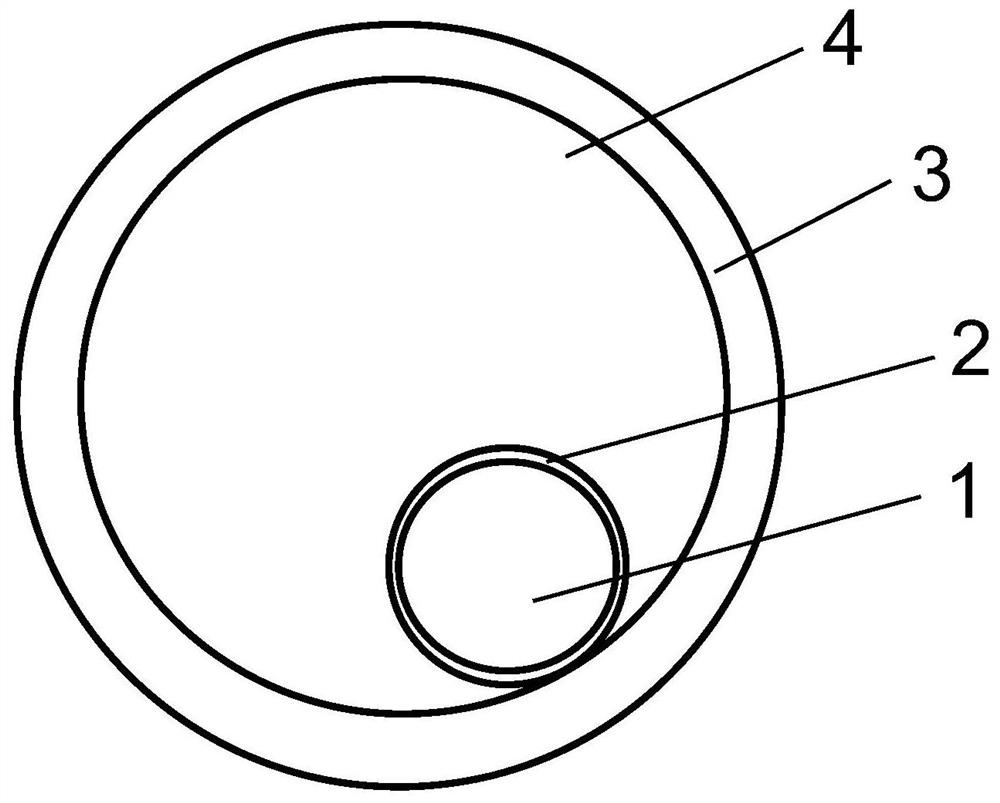

[0036] The preparation method of the core-shell structure silicon-carbon composite material for lithium-ion batteries provided by the invention uses phenol, aldehyde and polymer monomers to coat SiO x , and then by acid treatment and heat treatment, a core-shell structure silicon-carbon composite material for lithium-ion batteries is obtained; the preparation method comprises the following steps:

[0037] S1, the SiO x Evenly dispersed in the aqueous solution, add phenol and aldehyde, and after stirring, the phenolic resin-coated silicon-based composite material is obtained; in the process of forming phenolic resin from phenol and aldehyde, an alkaline catalyst is added to facilitate the coating of the thermosetting phenolic resin on the silicon-based composite material Surface; alkaline catalysts such as ammonia water, sodium hydroxide, etc.;

[0038] Of which SiO x Among them, the range of x is 0~2, SiO x One or more selected from elemental silicon, silicon monoxide, and si...

Embodiment 1

[0049] Add 1g of Si nanoparticles (50-150nm) to 500mL of water, stir for 3h to disperse evenly in the aqueous solution, add 300mg of resorcinol and 0.3mL of formaldehyde solution to the solution, add dropwise 0.2mL of ammonia solution, and stir to react After 60 min, the phenolic resin-coated silicon-based composite material was obtained; add 300 μL of pyrrole and 0.2 g of ammonium persulfate oxidant to the phenolic resin-coated silicon-based composite material, and stir for 3 hours at 30 °C at a stirring rate of 500 rpm Finally, the polypyrrole / phenolic resin-coated silicon-based composite material was obtained; then 1 mL of hydrochloric acid solution was added, stirred for 30 minutes to remove part of the phenolic resin, and the core-shell structure silicon-carbon composite material intermediate was obtained after filtering and drying; the core-shell structure silicon The carbon composite material intermediate is put into a tube furnace for heat treatment. Under an argon atmo...

Embodiment 2

[0051] Add 1g of SiO particles (2μm) to 500mL of water, stir for 3h to disperse evenly in the aqueous solution, add 200mg of 3-aminophenol and 0.2mL of formaldehyde solution to the solution, add dropwise 0.1mL of ammonia solution, and stir for 120min to obtain Phenolic resin-coated silicon-based composite material; add 500 μL of aniline and 0.25 g of ferric chloride oxidant to the phenolic resin-coated silicon-based composite material, and stir at 40 ° C at a rate of 300 rpm for 3 hours to obtain Polyaniline / phenolic resin coated silicon-based composite material; then add 0.5mL of phosphoric acid solution, stir for 30min to remove part of the phenolic resin, after filtering and drying to obtain the core-shell structure silicon-carbon composite material intermediate; core-shell structure silicon The carbon composite material intermediate is put into a tube furnace for heat treatment. Under a nitrogen atmosphere, the temperature rises to 750°C at a rate of 1°C / min. After 3 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com