Chitosan microspheres as well as preparation method and application thereof

A technology of chitosan microspheres and chitosan derivatives is applied in pharmaceutical formulations, medical preparations with inactive ingredients, and medical preparations containing active ingredients, which can solve the problems of short degradation cycle and frequent injections, etc. To achieve the effects of mild preparation process, improved drug loading capacity, uniform and controllable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

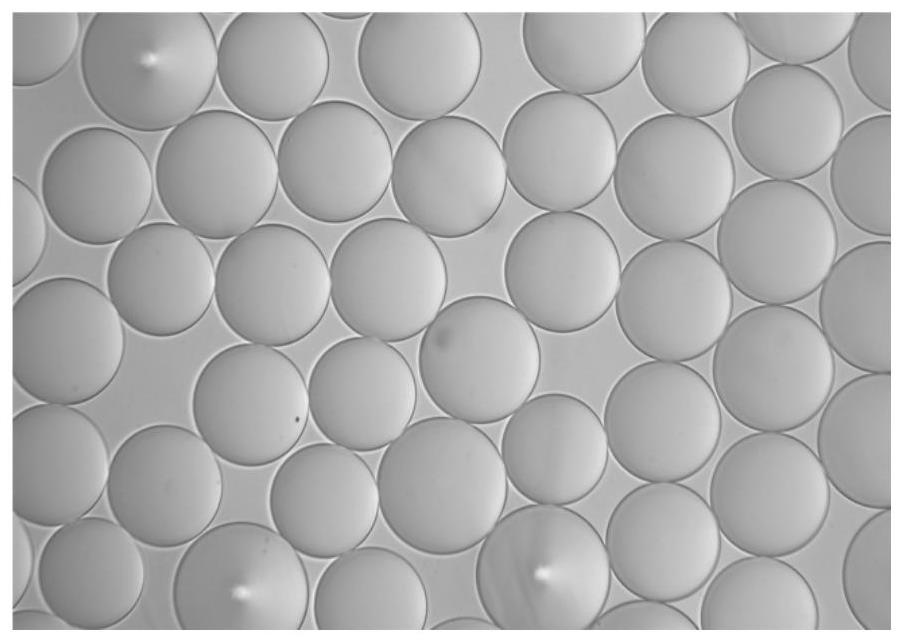

[0045] (1) Weigh 6g of carboxymethyl chitosan and add it to 100ml of deionized water, then add 10mL of sodium hydroxide solution with a mass concentration of 20%, stir evenly, cool down to -5°C to 10°C, and then add 2g After the dropwise addition of acryloyl chloride, react for another 0.5 h, then use deionized water to dialyze to remove impurities, and then freeze-dry to obtain an acryloyl chitosan intermediate.

[0046] (2) Dissolve 5g of acryloyl chitosan intermediate in 20ml of deionized water, then add 0.1g of N,N'-methylenebisacrylamide, 0.5g of (2-aminoethyl) allyl carbamate hydrochloride Salt, 0.01g potassium persulfate to prepare a polymer monomer solution; 5g Span 80 was added to 200mL liquid paraffin to form an oil phase mixture; the polymer monomer solution was added to the oil phase mixture, dispersed by mechanical stirring, Control the temperature at 50°C, then add 0.1g of tetramethylethylenediamine to initiate the polymerization reaction for 6 hours, and generat...

Embodiment 2

[0049] (1) Weigh 1.0g of hydroxypropyl chitosan and add it to 100ml of deionized water, then add 10mL of 1% pyridine solution, stir evenly, cool down to -5°C to 10°C, and then add 0.1g After the dropwise addition of methacryloyl chloride, react for another 0.5 h, then use deionized water to dialyze to remove impurities, and freeze-dry to obtain the acryloyl chitosan intermediate.

[0050] (2) Dissolve 1.0g of acryloyl chitosan intermediate in 10ml of deionized water, then add 0.1g of polyethylene glycol dimethacrylate, 0.1g of sodium 2-acrylamide-2-methylpropanesulfonate , 0.01g sodium persulfate to prepare a polymer monomer solution; 1g of polyoxyethylene fatty alcohol ether was added to 100mL of n-hexane to form an oil phase mixture; the polymer monomer solution was added to the oil phase mixture, and stirred by mechanical Disperse, control the temperature at 50°C, then add 0.05g of tetramethylethylenediamine to initiate the polymerization reaction for 6 hours, and generate ...

Embodiment 3

[0053] (1) Weigh 10g of hydroxyethyl chitosan and add it to 100ml of deionized water, then add 20mL of triethylamine solution with a mass concentration of 20%, stir evenly, cool down to -5°C to 10°C, and then add 5g Ethacryloyl chloride, after the dropwise addition, was reacted for 1.0 h, and then was dialyzed with deionized water to remove impurities, and then freeze-dried to obtain an acryloyl chitosan intermediate.

[0054] (2) Dissolve 10g of acryloyl chitosan intermediate in 20ml of deionized water, then add 1.0g of hydroxyethyl methacrylate, 2.0g of 2-(diethylamino)ethyl methacrylate, 0.05g of persulfuric acid ammonium to prepare a polymer monomer solution; add 20g ABIL EM 90 to 250mL petroleum ether to form an oil phase mixture; add the polymer monomer solution to the oil phase mixture, disperse by mechanical stirring, control the temperature at 50 ° C, and then Add 0.5g tetramethylethylenediamine to initiate the polymerization reaction for 6h to generate porous chitosa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com