Preparation method of quinoline feed additive with immunity improving function

A technology of feed additives and quinolines, which is applied in the field of synthesis of feed additives, can solve the problems of reducing the utilization rate of urea nitrogen, animal ammonia poisoning, matching production speed, etc., and achieve the effects of improving immunity and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

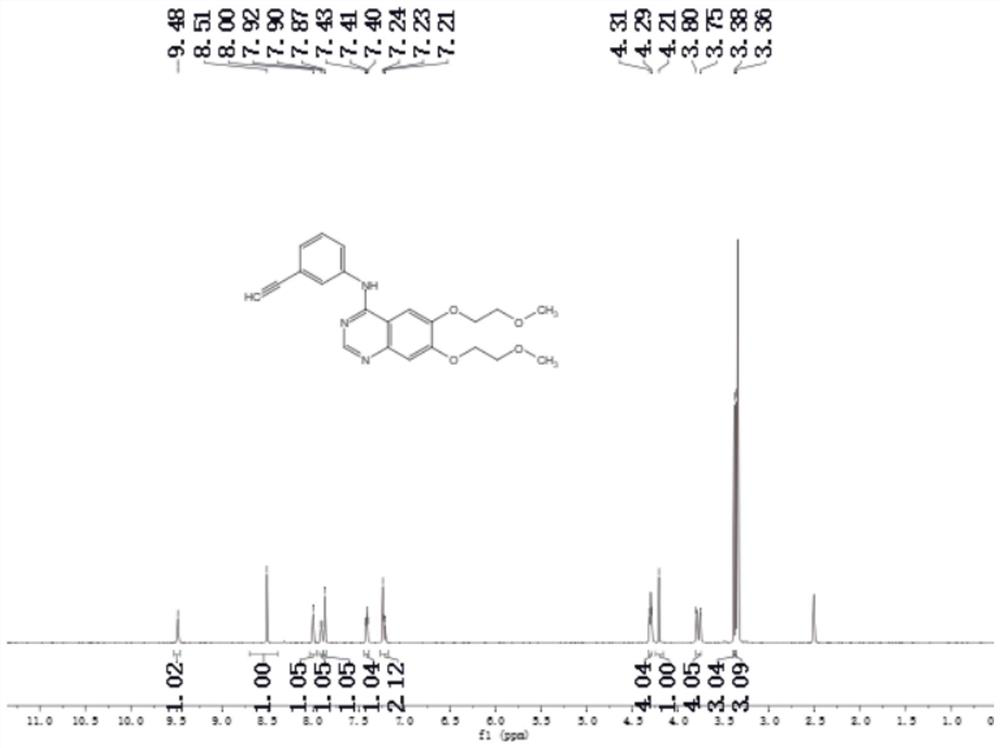

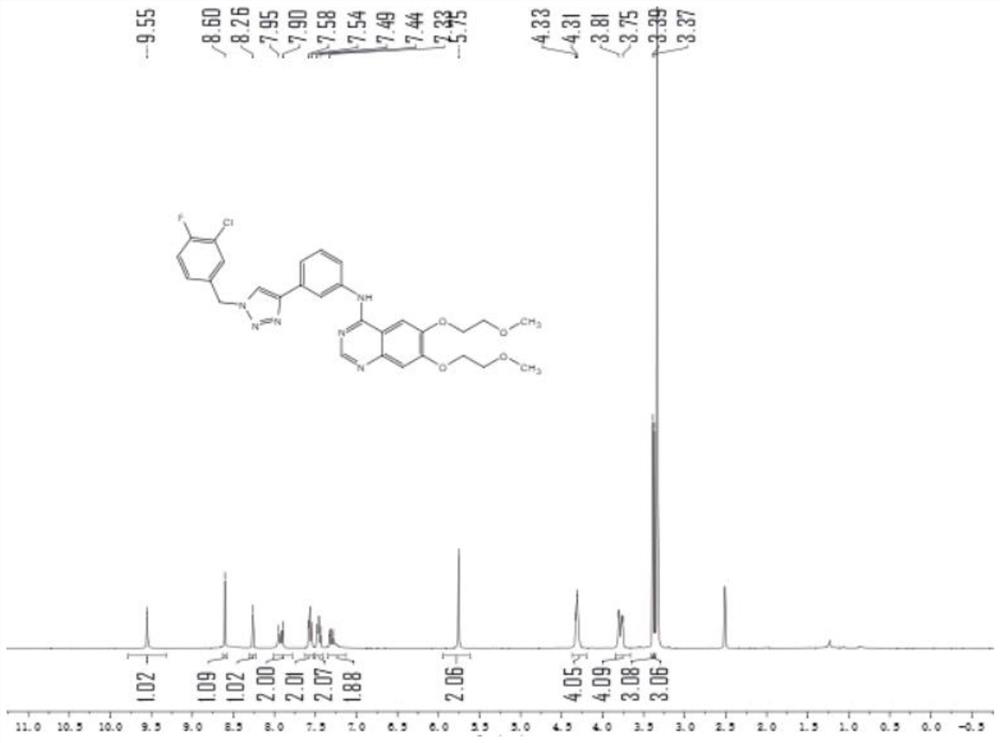

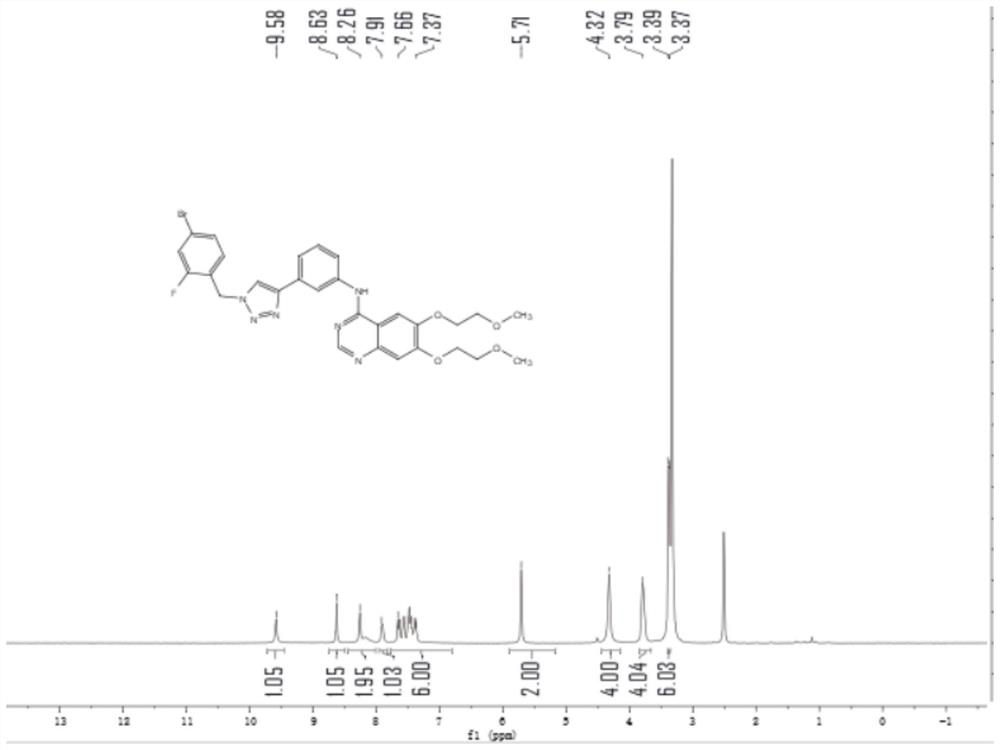

Image

Examples

Embodiment 1

[0020]

[0021]In a reaction flask, 23 g of N-Boc-3,4-dihydroxyaniline and 14 g of potassium carbonate were added to 400 mL of N,N-dimethylformamide, heated to 90°C and stirred for 30 min under nitrogen protection, and then slowly added Dissolved 25g of 2-chloroethyl methyl ether in 200mL of N,N-dimethylformamide solution, continue to react at 90°C for 14h, TLC monitors the complete reaction of N-Boc-3,4-dihydroxyaniline, use About 500 mL of N,N-dimethylformamide was evaporated in a vacuum with an oil pump, then the concentrate was added to 500 mL of dichloromethane, stirred evenly, and 500 mL of 2N hydrochloric acid was added at 0 to 10 °C, and the reaction was stirred for 5 h, and the organic The aqueous phase was extracted with 150 mL of dichloromethane for 4 times, the organic phases were combined, the organic phase was adjusted to pH 8 with saturated sodium hydroxide solution, the organic phase was separated, and the organic phase was dried and concentrated to obtain 3,...

Embodiment 2

[0023]

[0024] In the reaction flask, 24 g of 3,4-bis(2-methoxyethoxy)aniline was added to 400 mL of formamide, and then 20 g of ammonium formate was added. Under a nitrogen atmosphere, slowly heated to 140 ° C, reacted for 16 h, and monitored by TLC for 3 ,4-bis(2-methoxyethoxy)aniline reacted completely, cooled to room temperature, added 800 mL of ethyl acetate and 600 mL of water to the reaction solution, stirred for 1 h, then separated the organic phase, and extracted with 200 mL of ethyl acetate The aqueous phase was mixed several times, and the combined organic phases were washed twice with 300 mL of saturated sodium chloride solution, dried over anhydrous magnesium sulfate, and concentrated under vacuum to obtain 3,4-bis(2-methoxyethoxy)benzyl Amidine 22.09g; LC-MS (ESI): m / z 269 [M+H] + .

Embodiment 3

[0026]

[0027] In a reaction flask with nitrogen protection and temperature control device, add 27 g of 3,4-bis(2-methoxyethoxy)benzamidine into 500 mL of chloroform, stir evenly, cool down to 0°C, and slowly dropwise add the solution 300 mL of chloroform containing 36 g of triphosgene, keeping the temperature stable, stirring for 1 h after the dropwise addition, concentrating the reaction solution, adding 200 mL of a mixed solution of cyclohexane and acetonitrile (volume ratio is 2:1) repeatedly, evaporated in vacuo And then remove the residual water in the reaction system and the by-product of triphosgene, finally add the mixed solution of tetrahydrofuran 400mL and ether 200mL to the concentrated reaction system, under nitrogen protection, add aluminum iodide 4.2g, 0~10 ℃ Under the conditions, keep the nitrogen atmosphere after stirring evenly, slowly add 100 mL of ether solution dissolved in 20 g of boron trifluoride diethyl ether dropwise, stir the reaction for 1 h afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com