Patents

Literature

34results about How to "Orderly retractable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

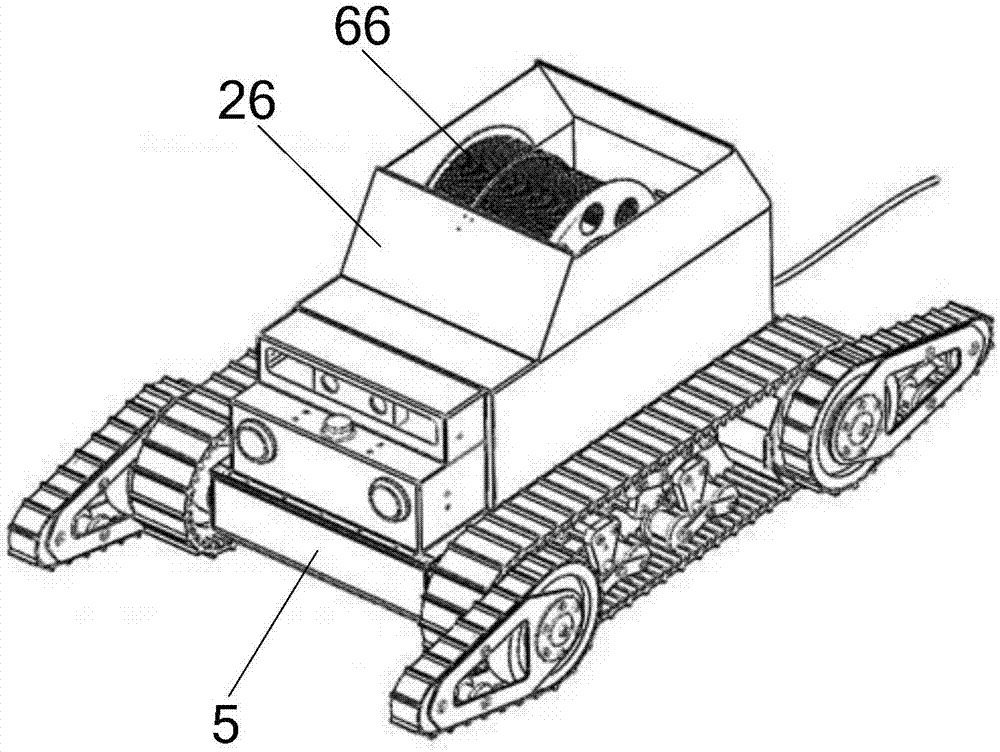

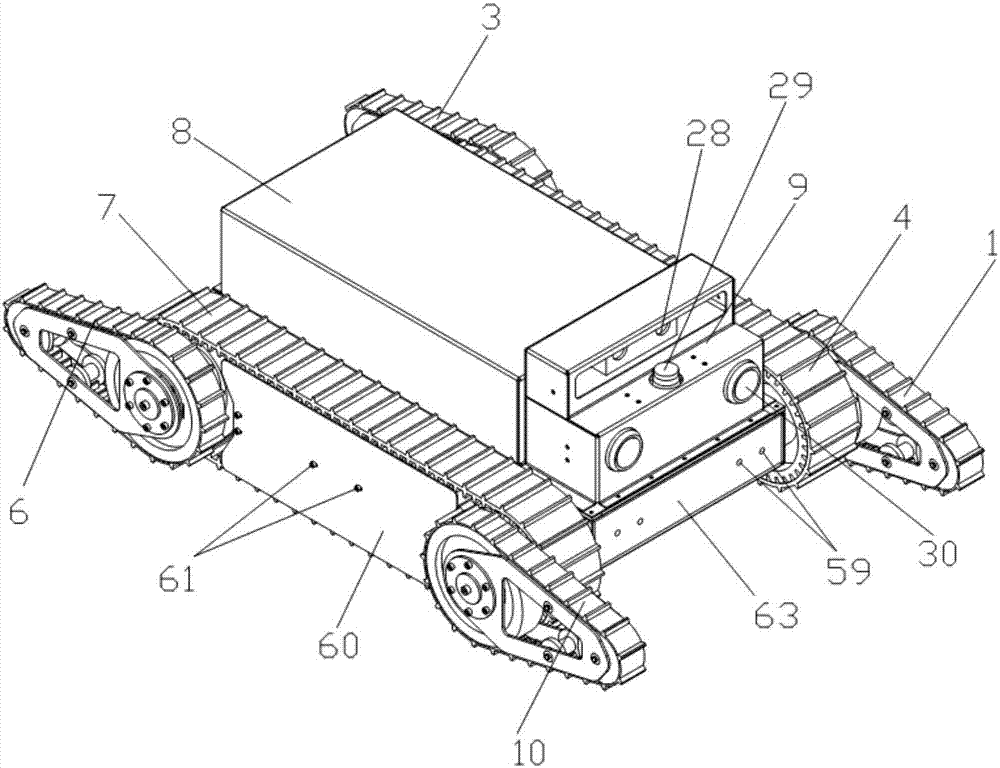

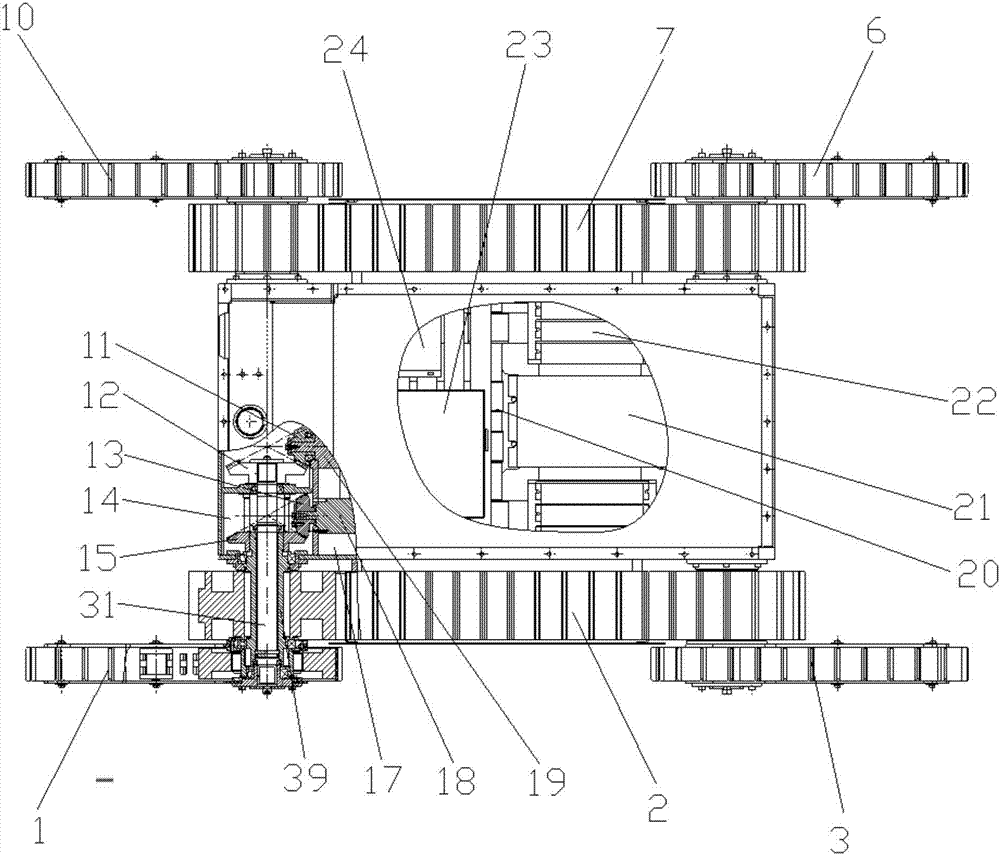

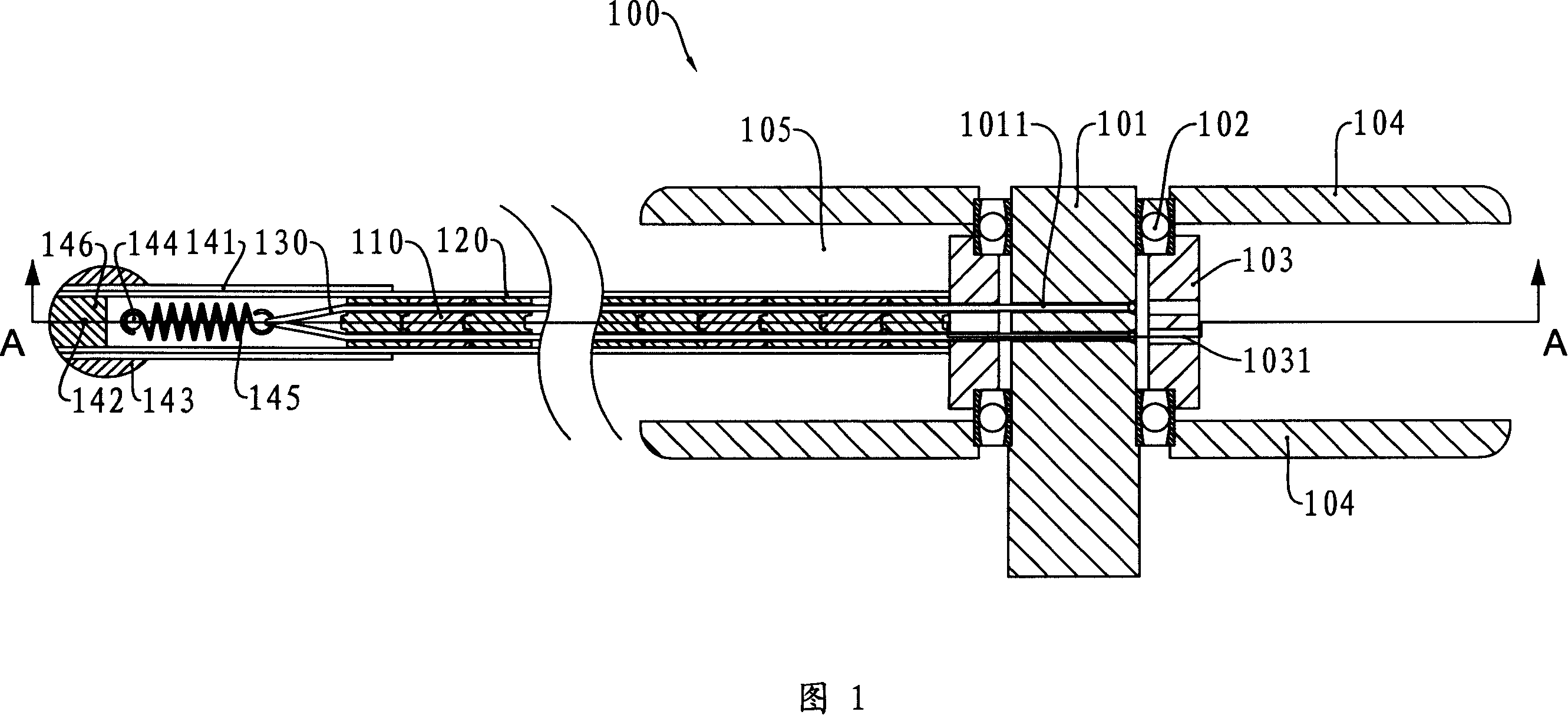

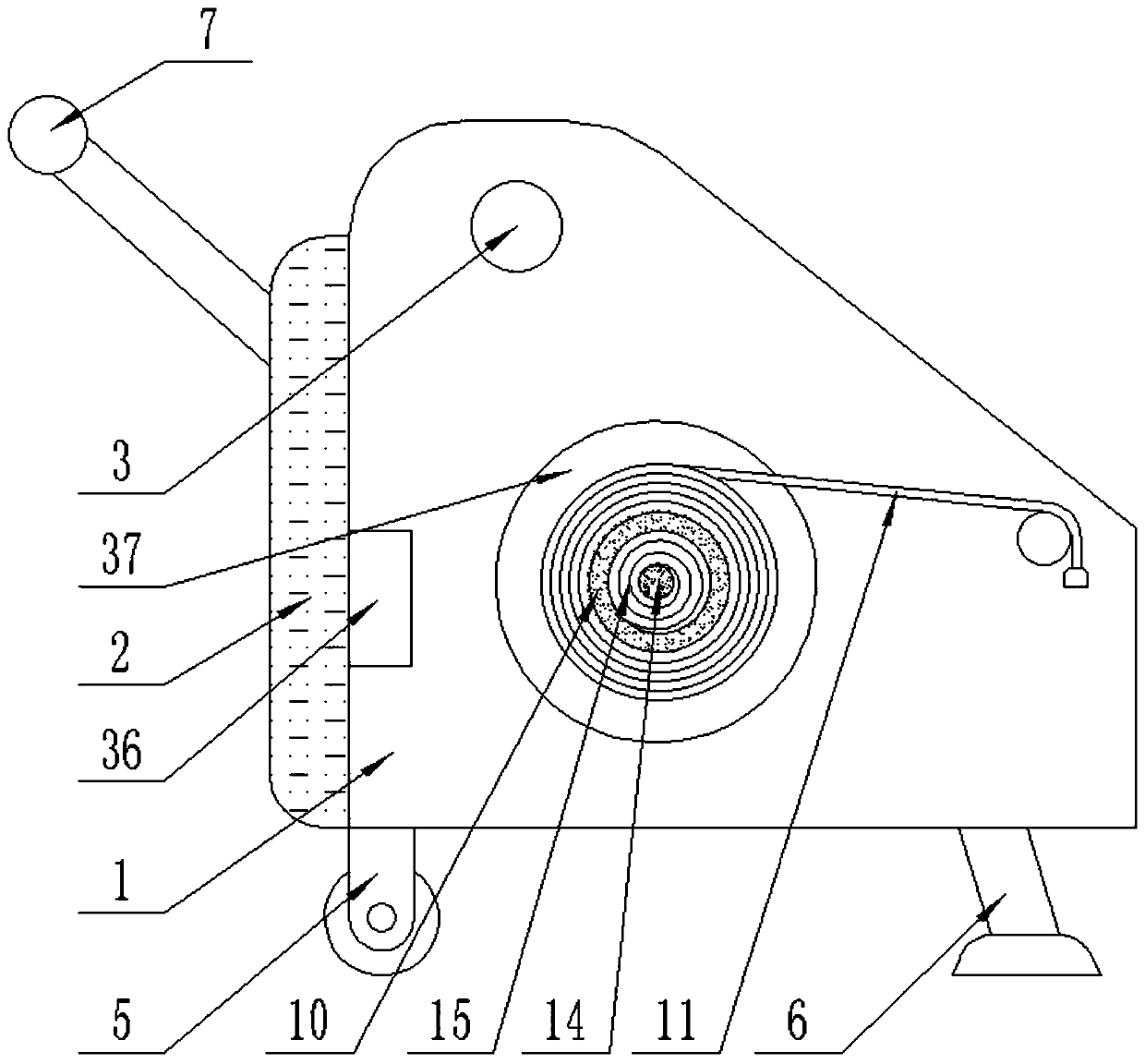

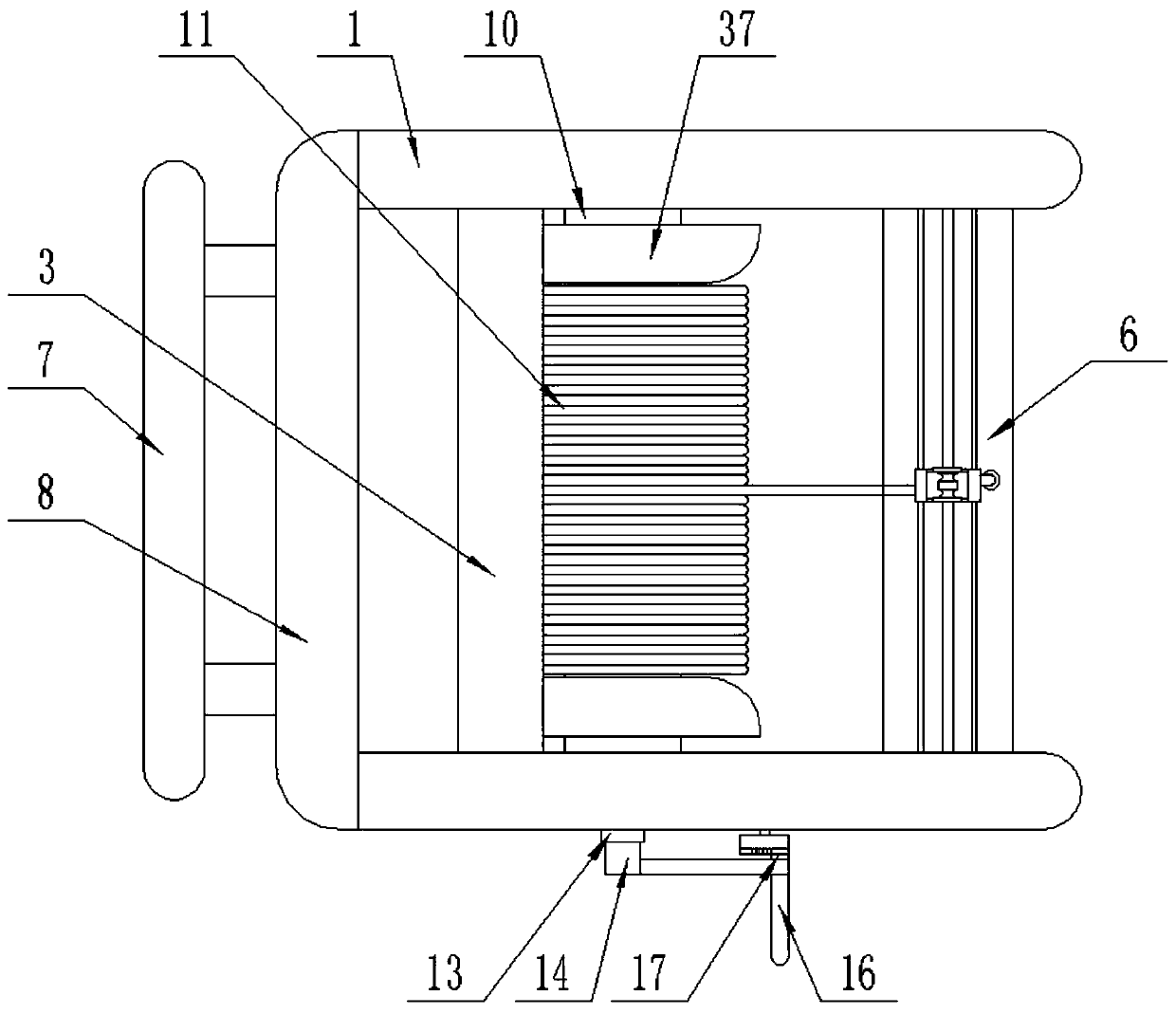

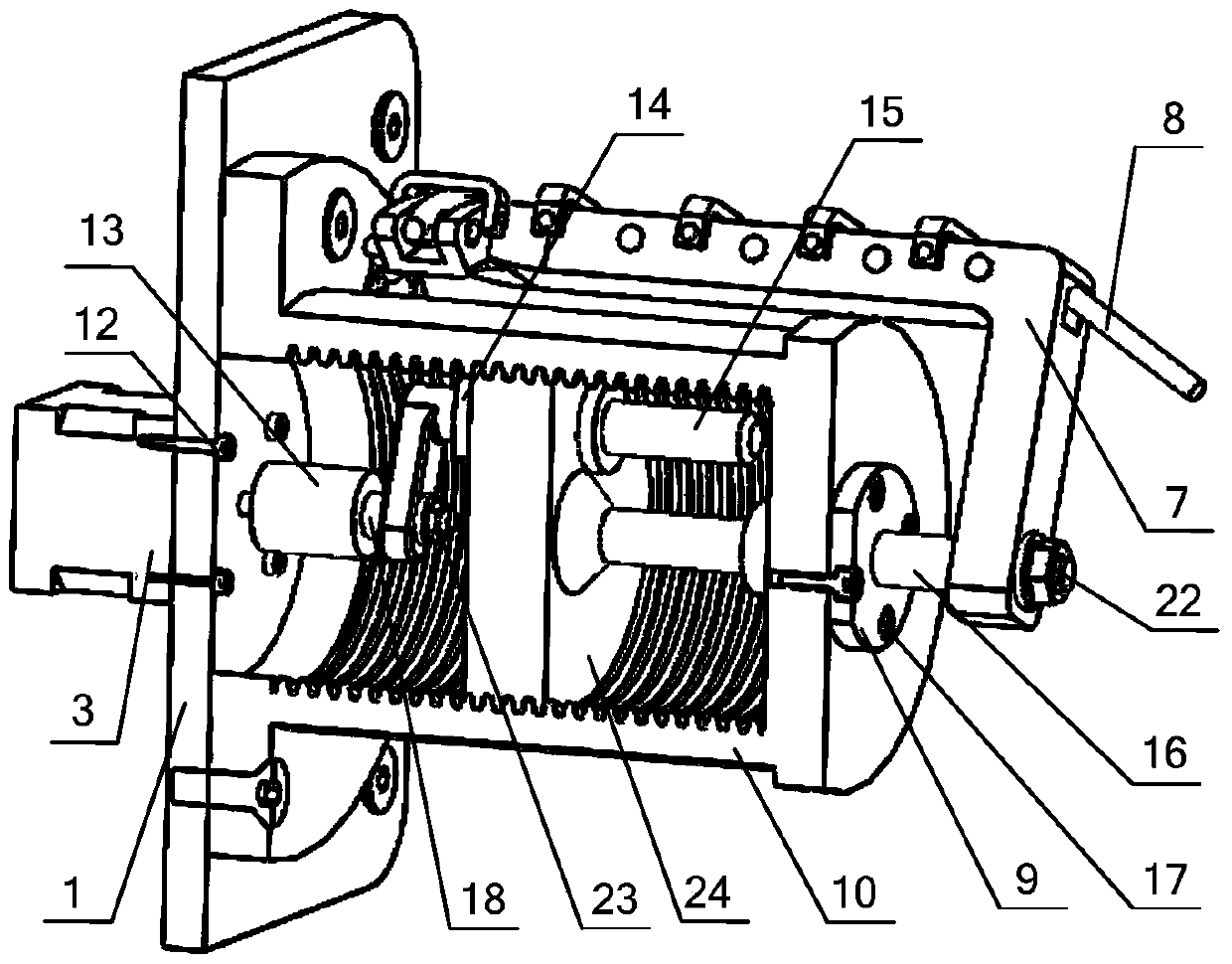

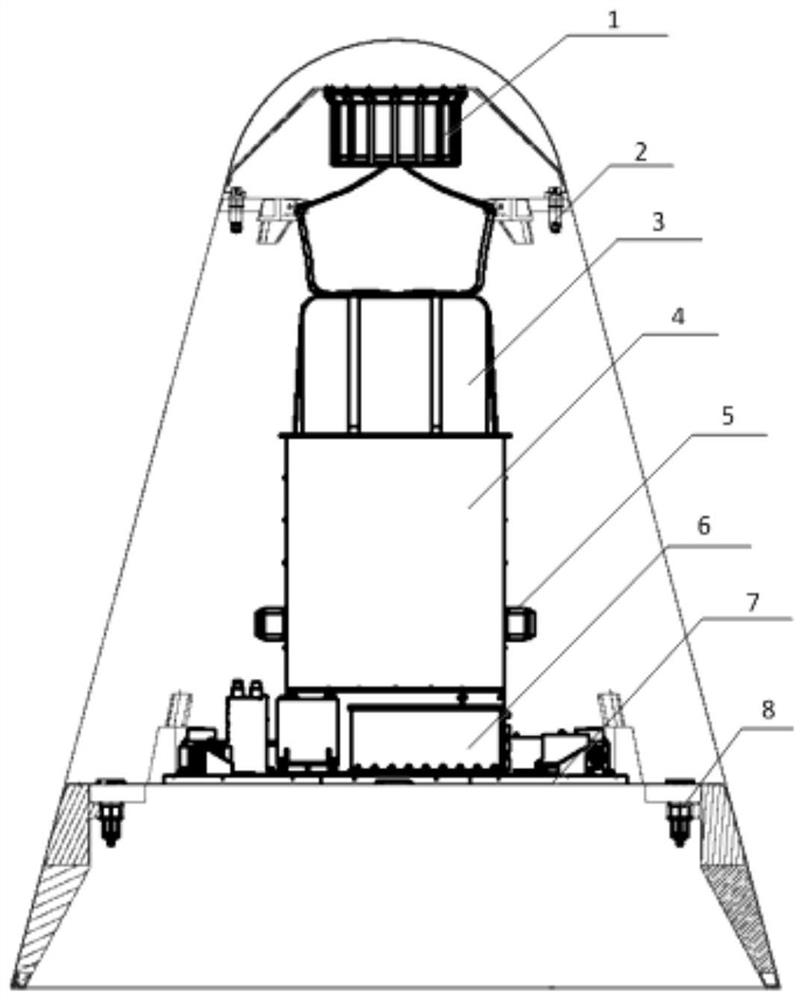

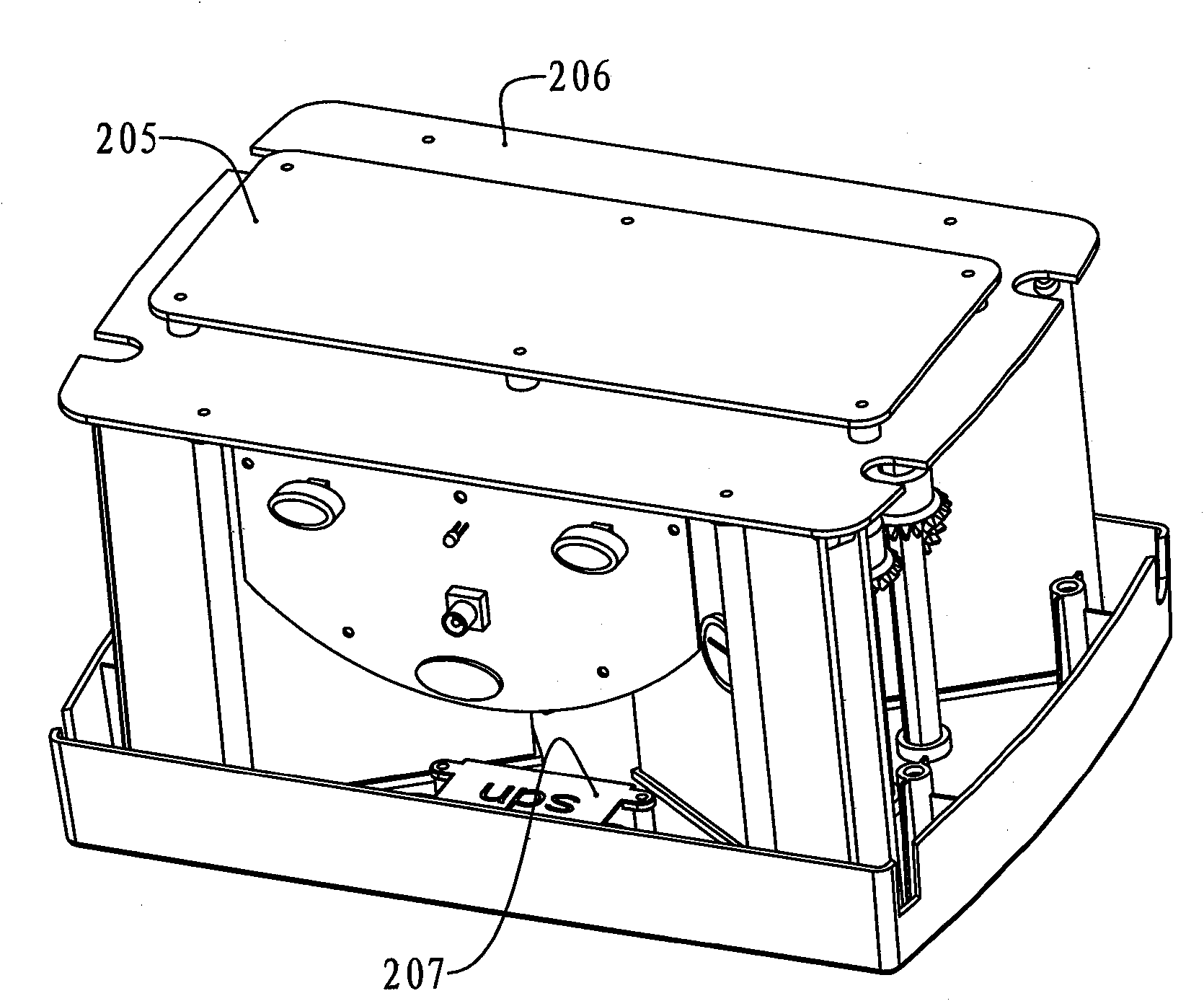

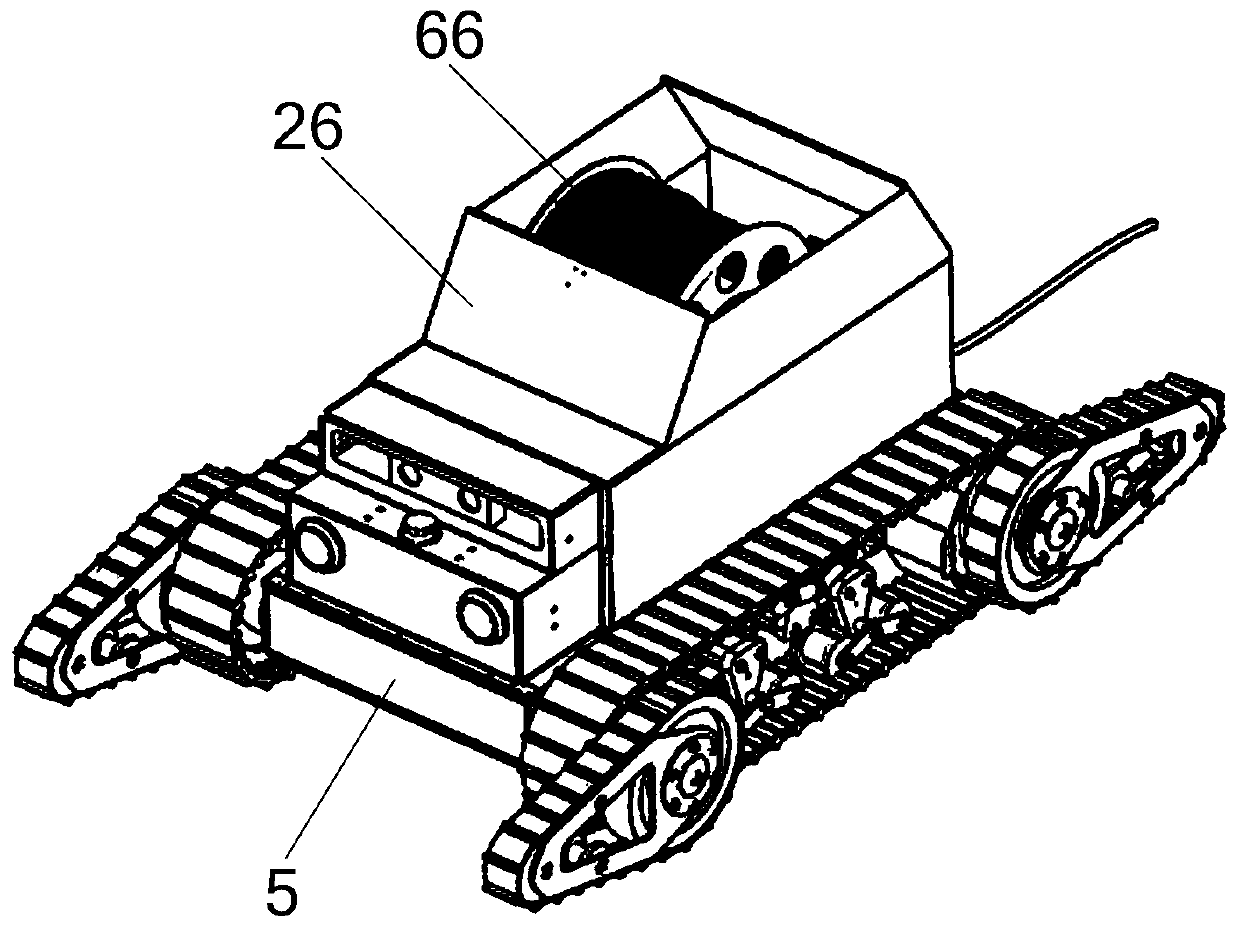

Wire-control coalmine rescue detection robot and cable extension and retraction method thereof

ActiveCN107139159ACompact structureNovel and reasonable designManipulatorControl signalControl theory

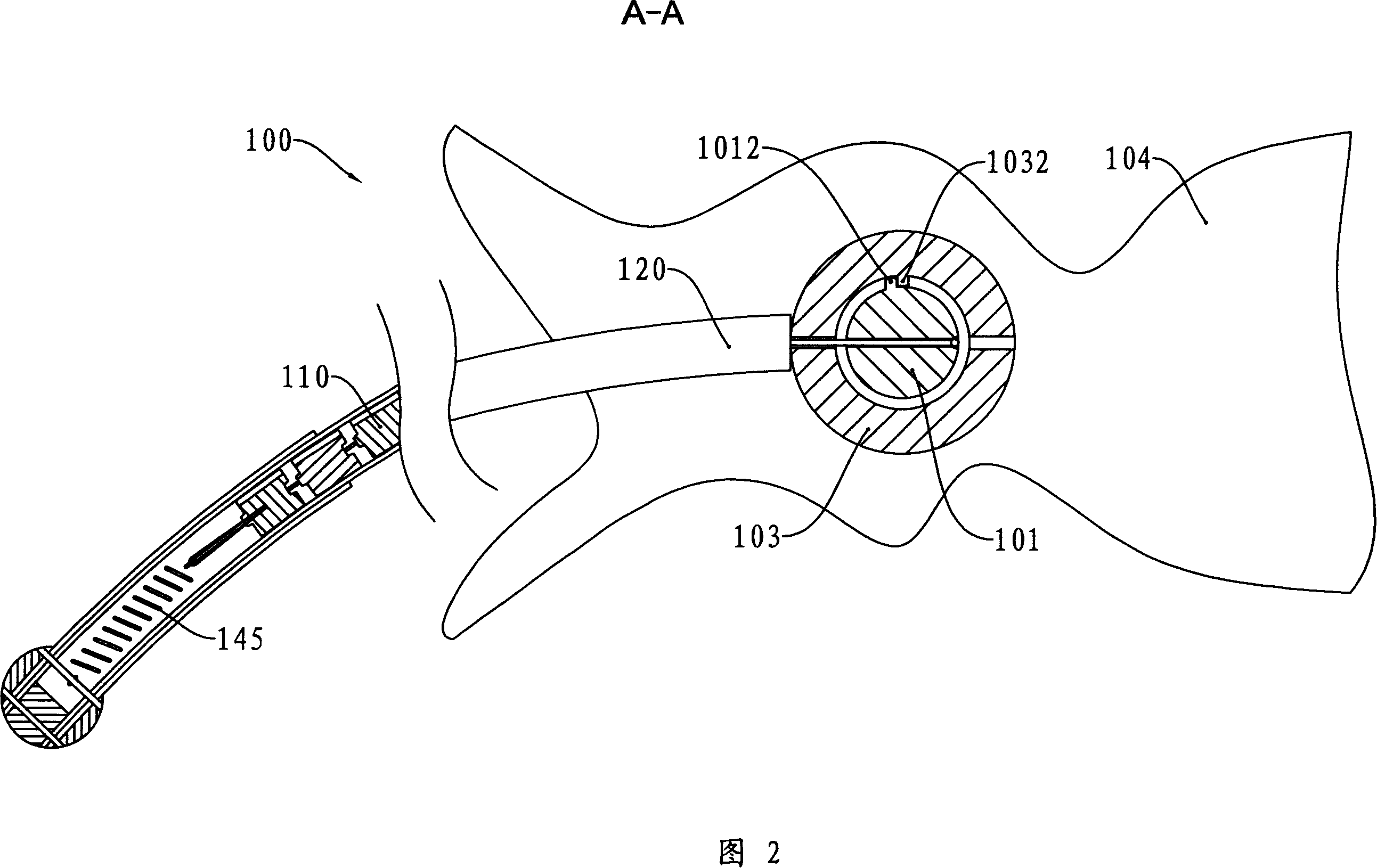

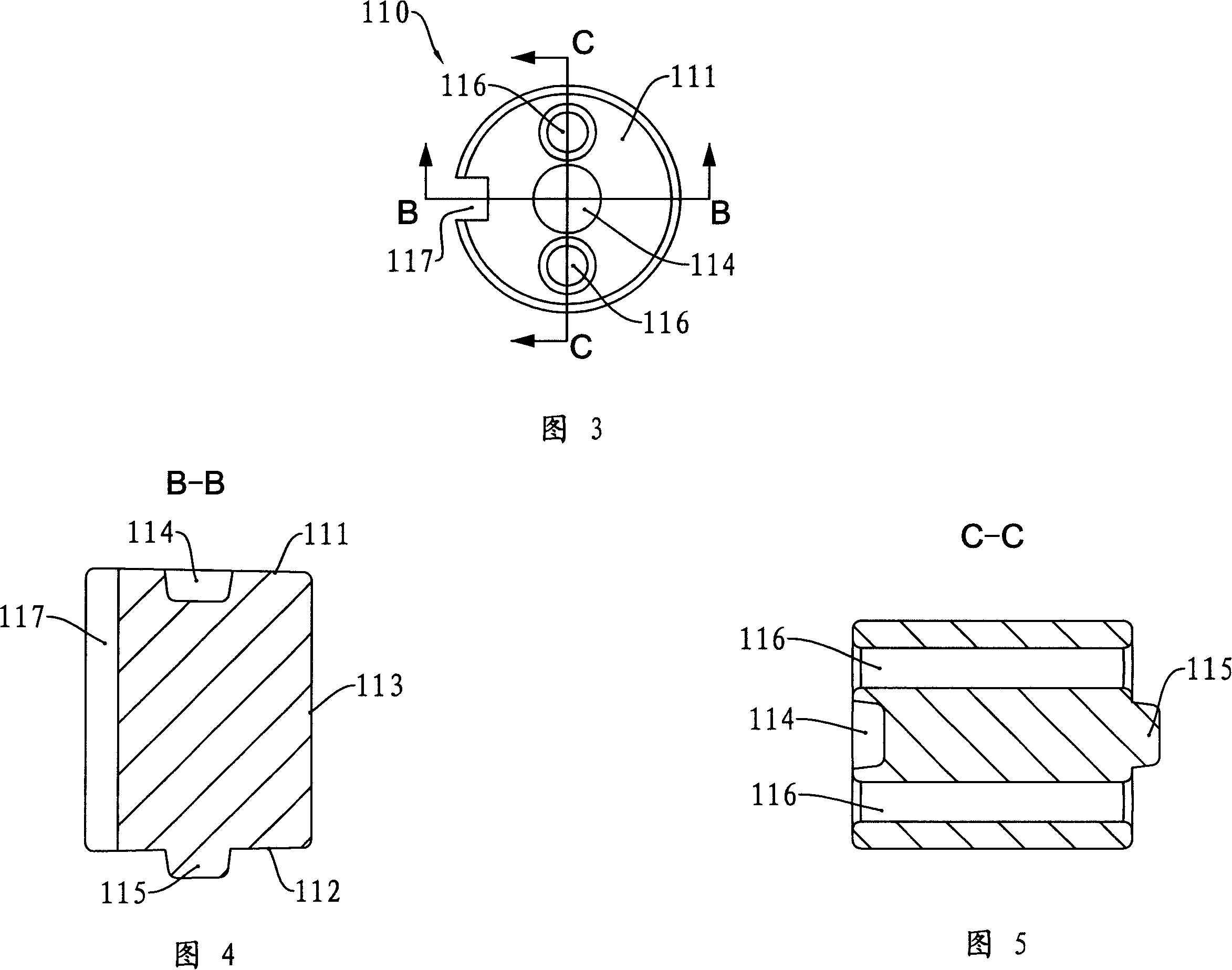

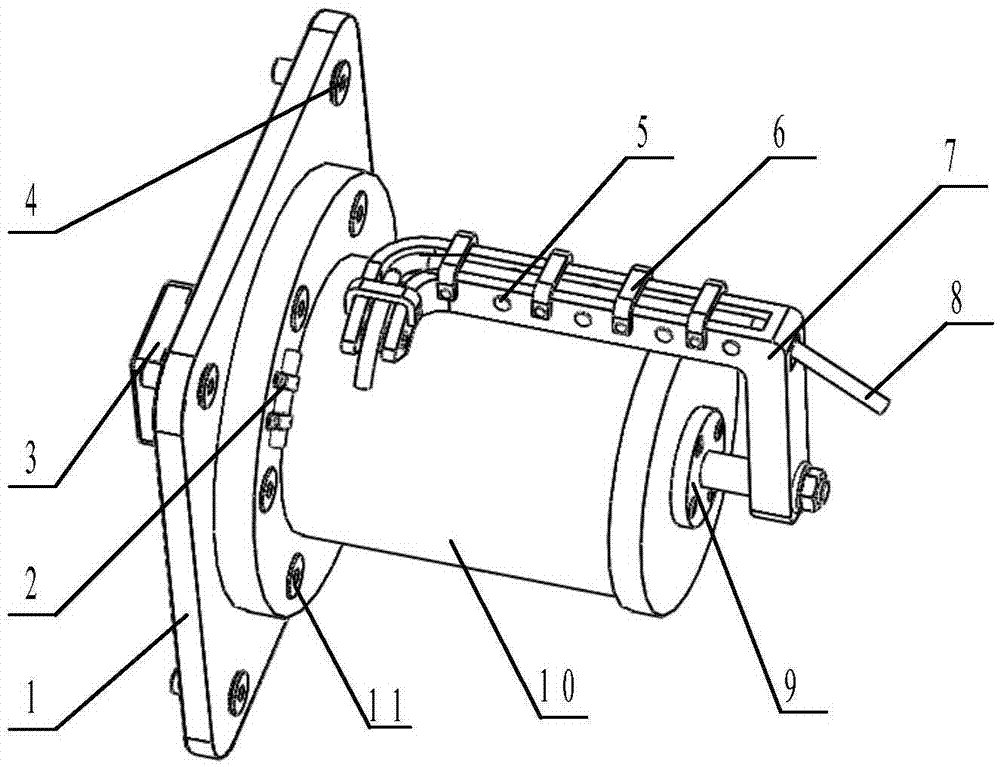

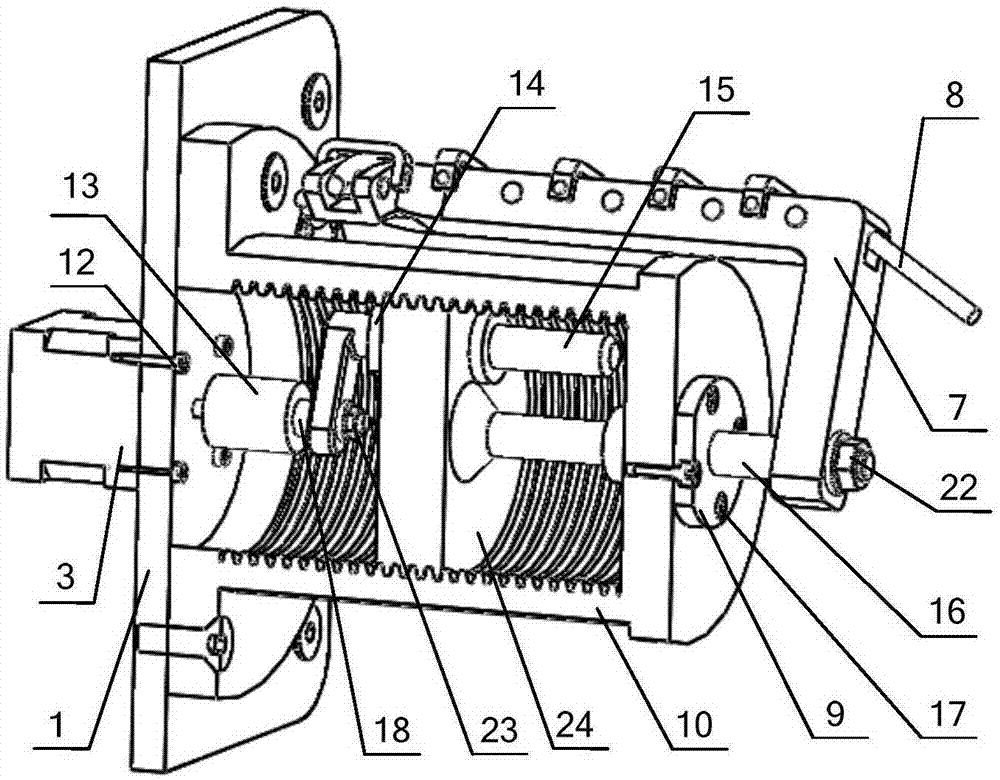

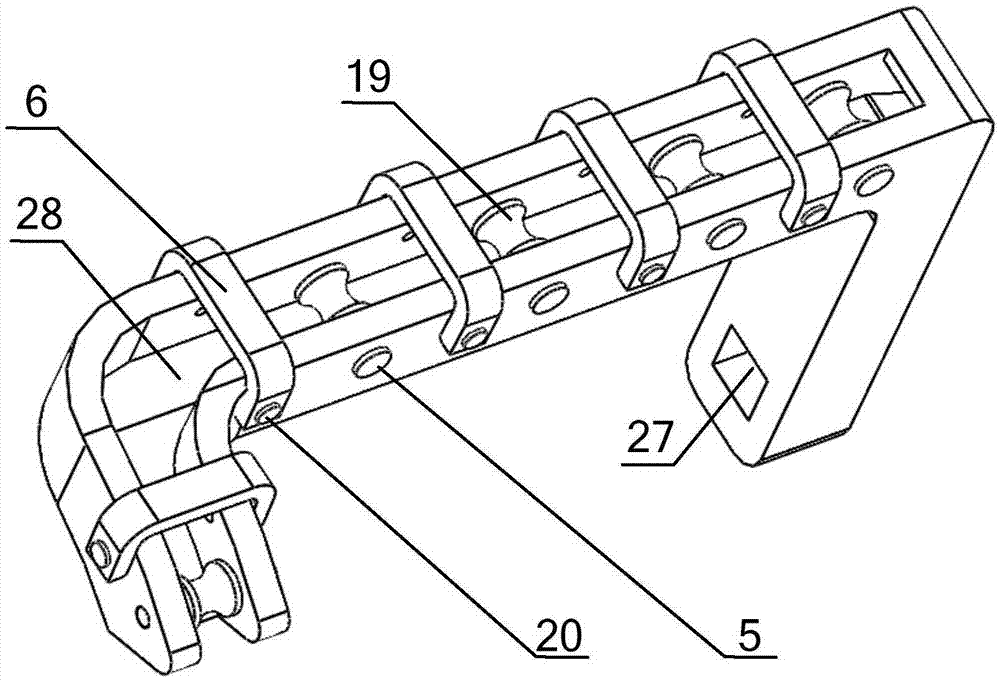

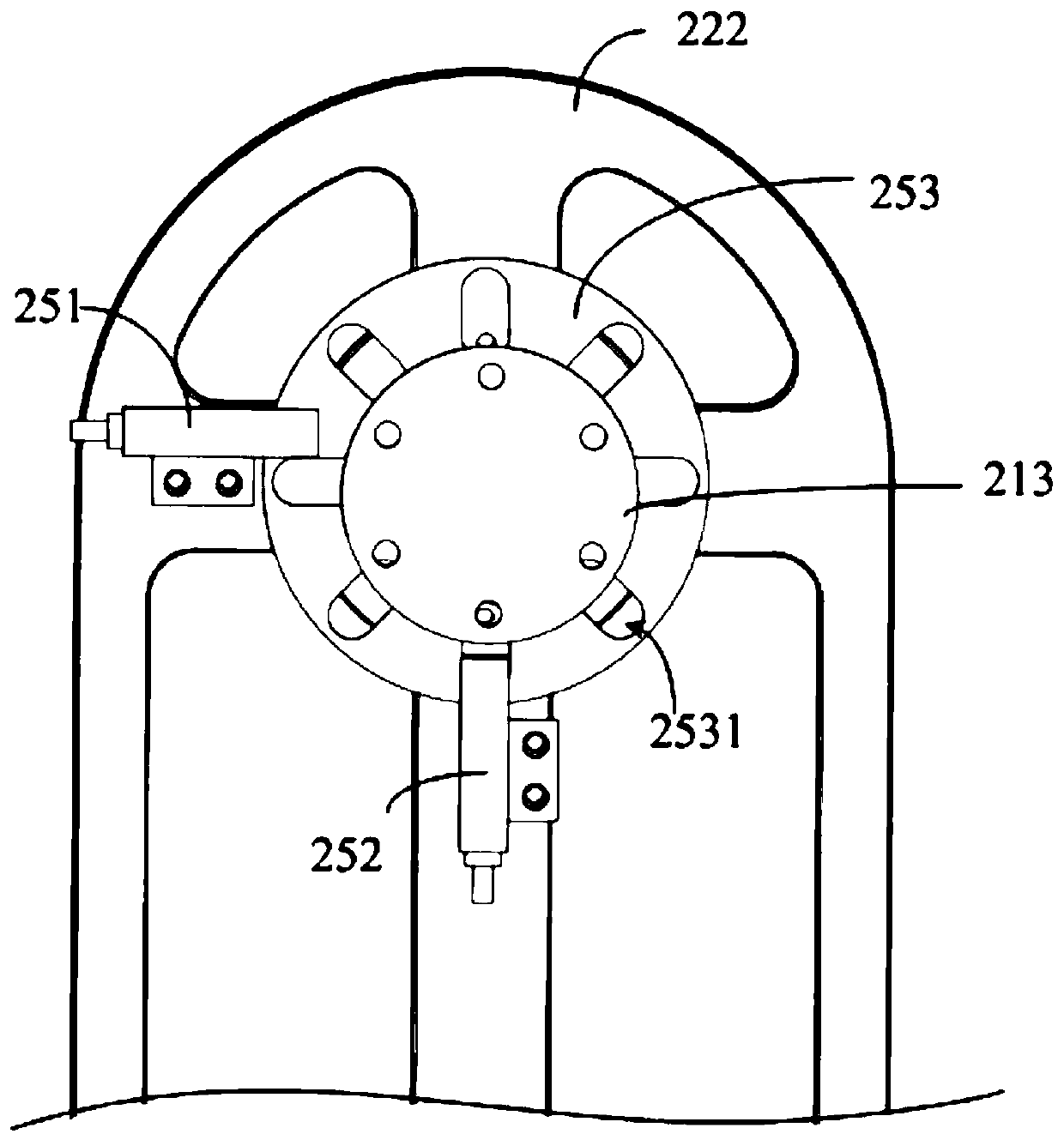

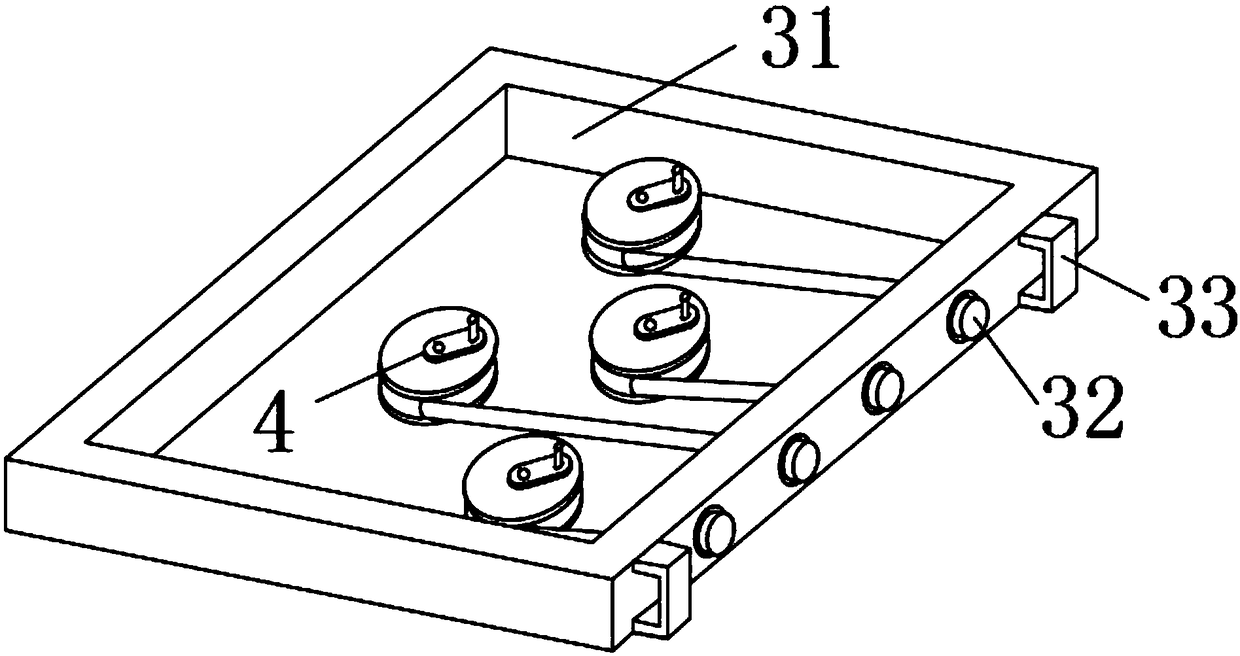

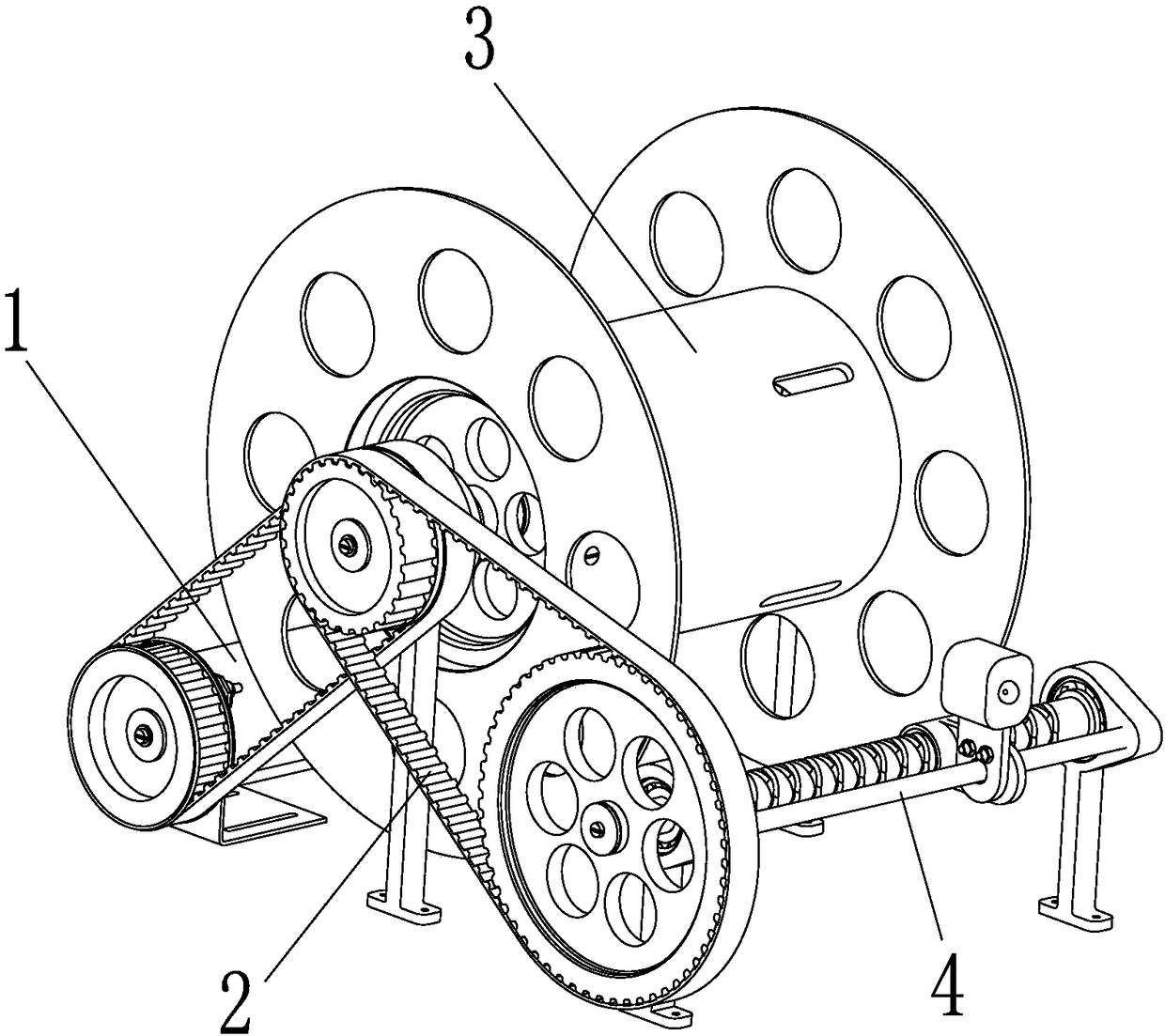

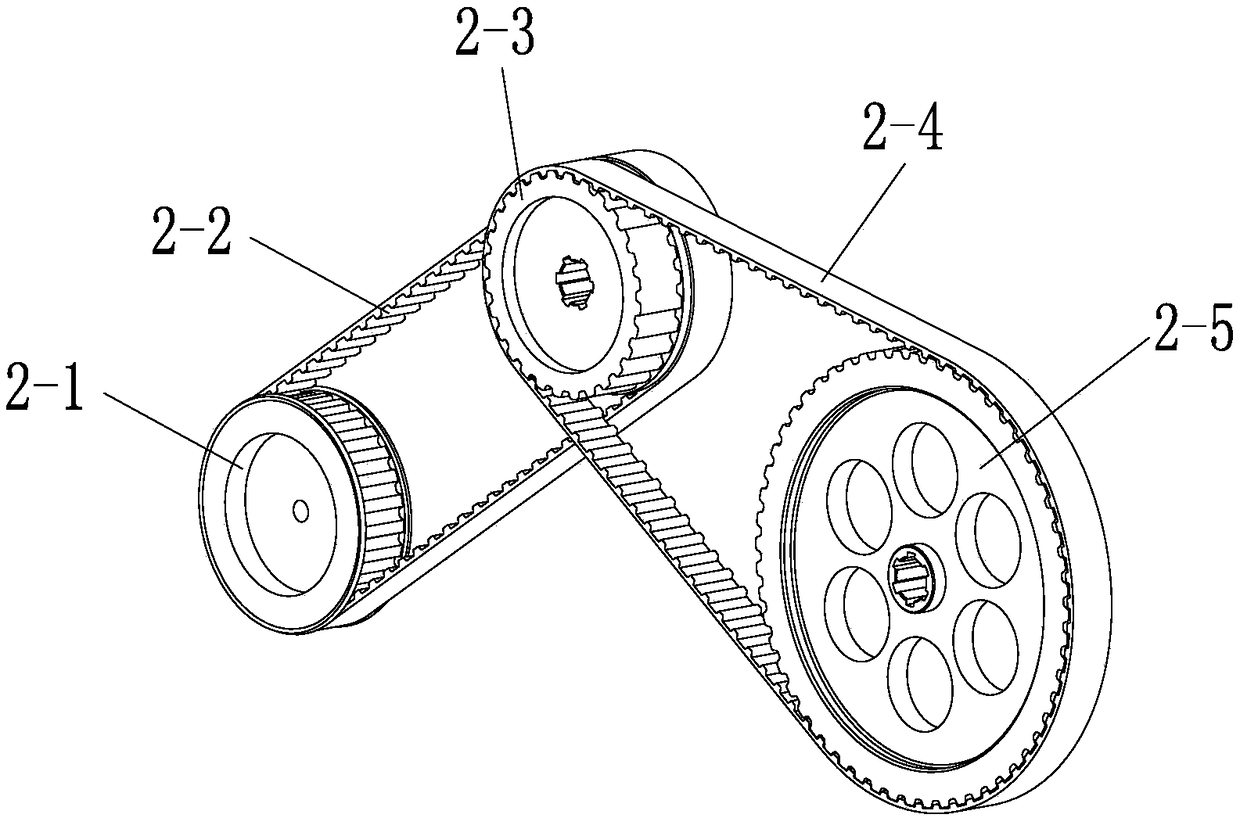

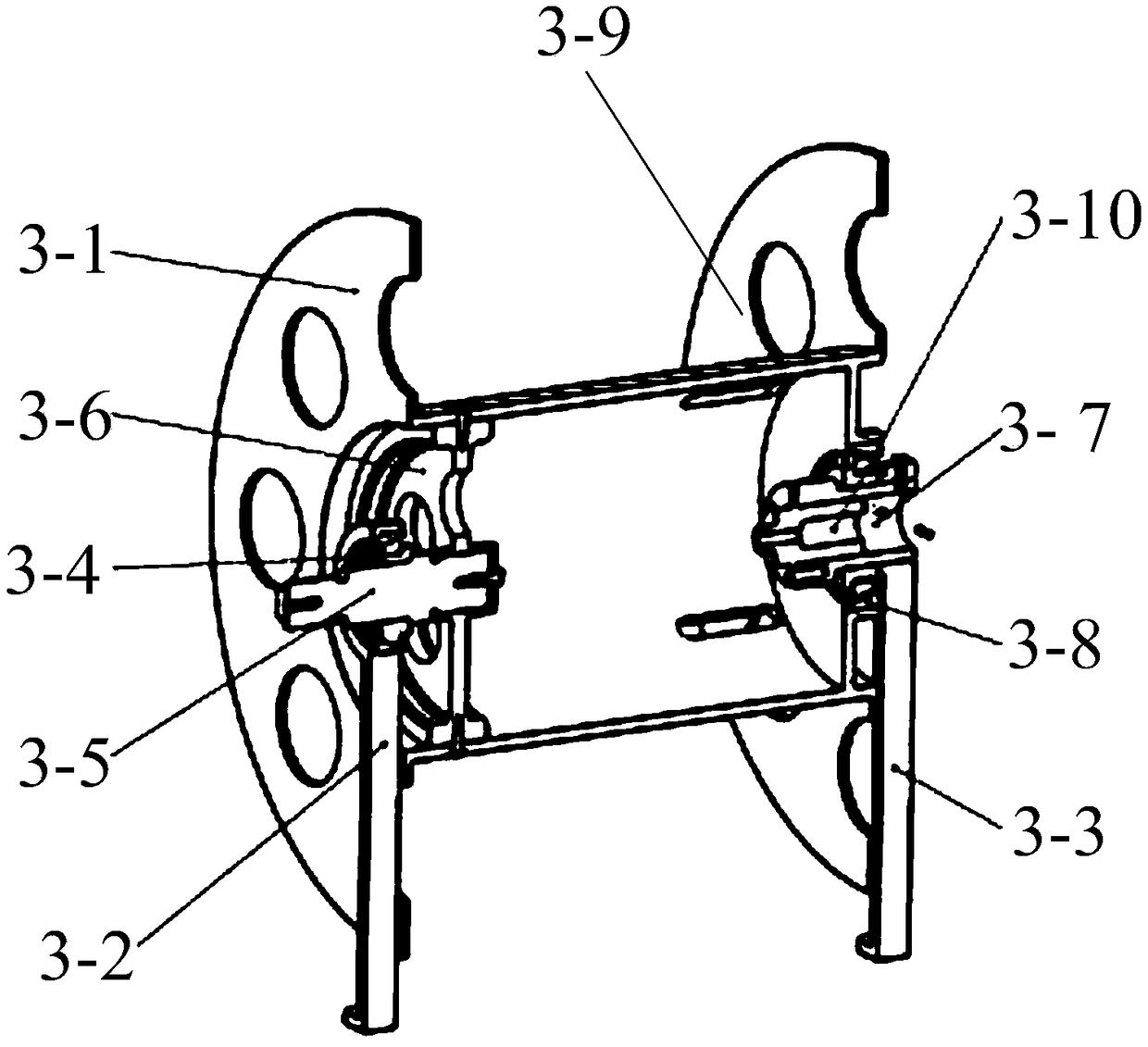

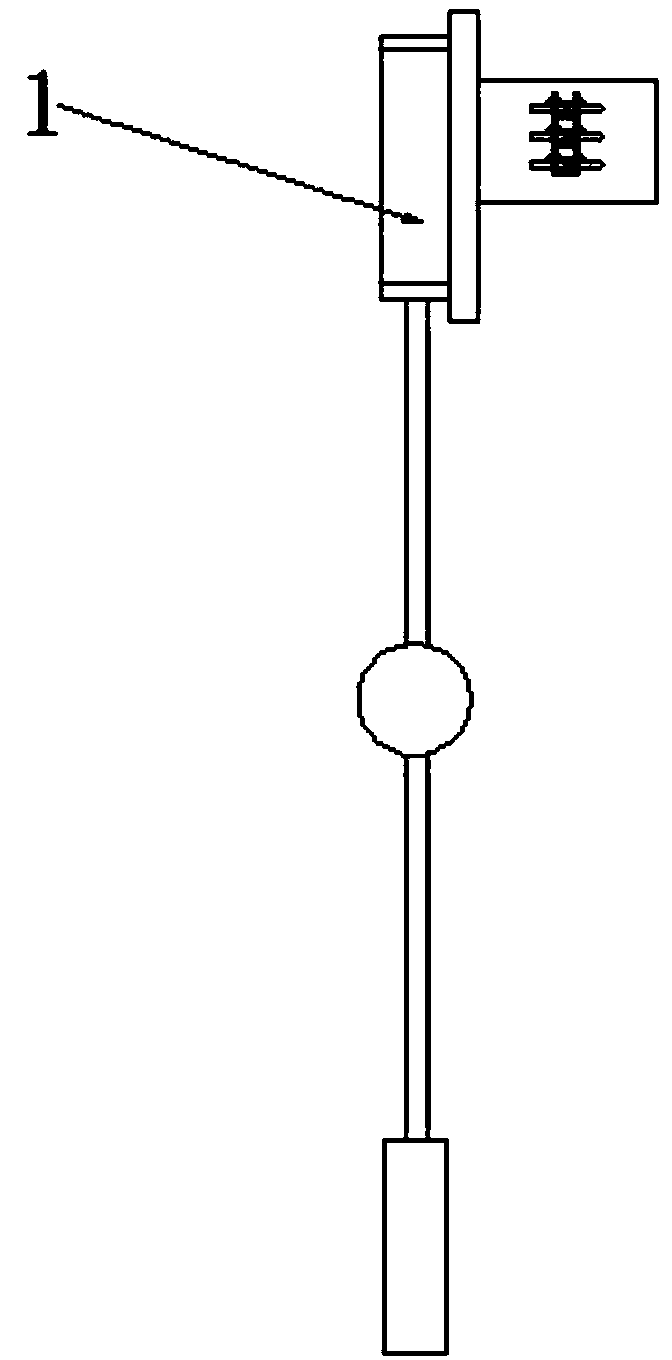

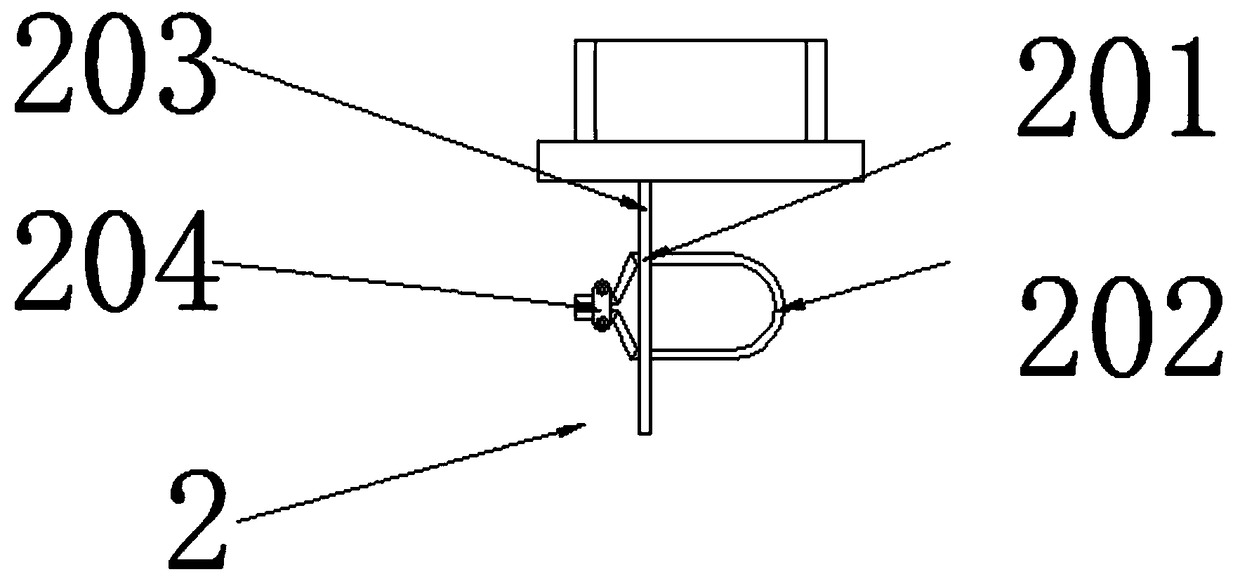

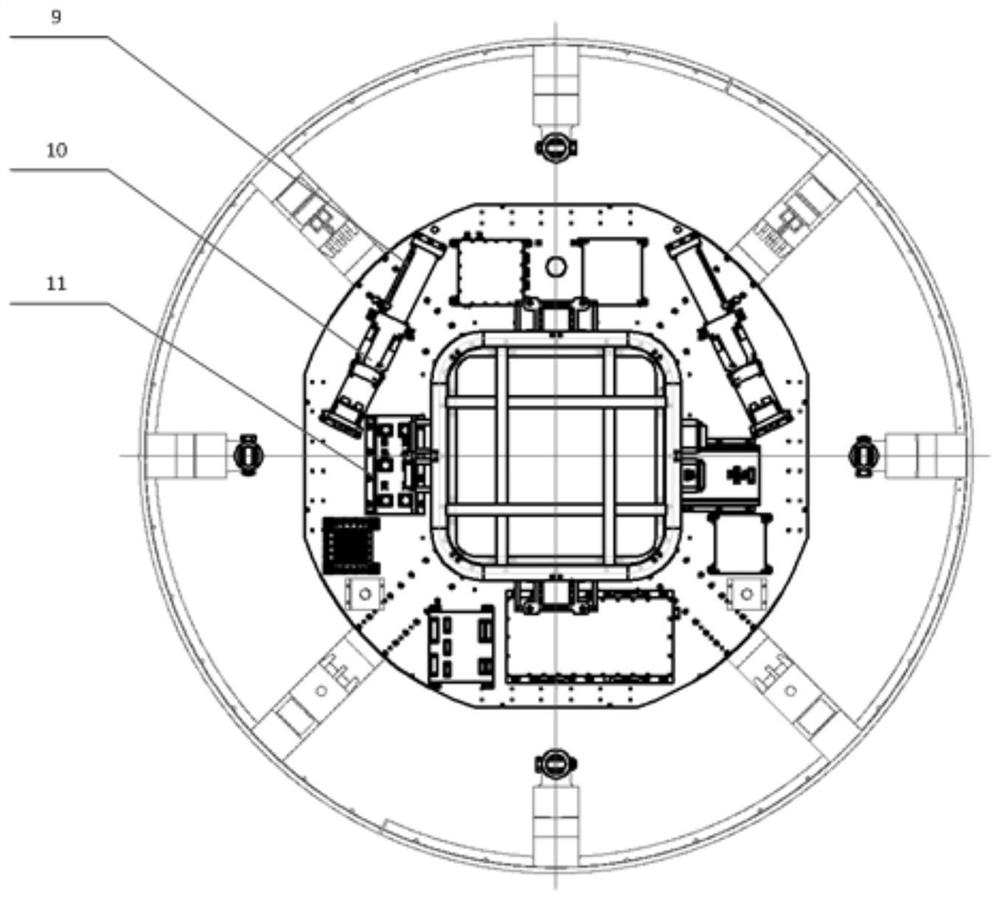

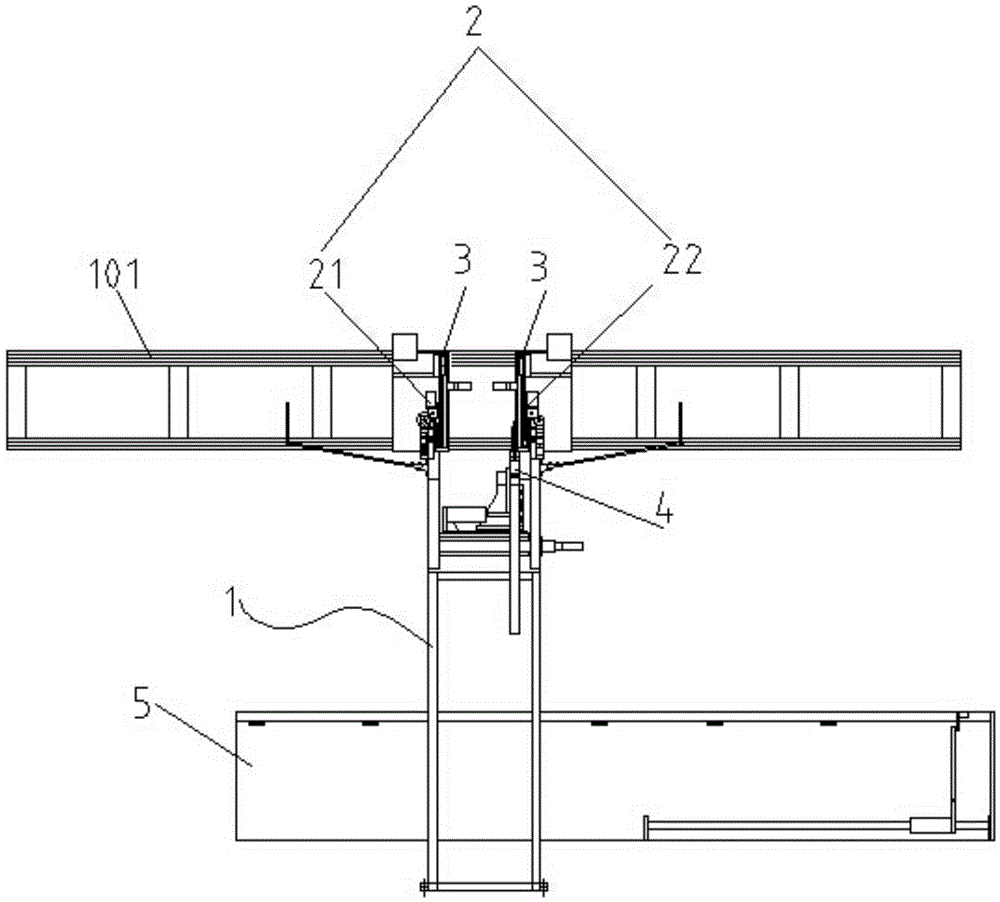

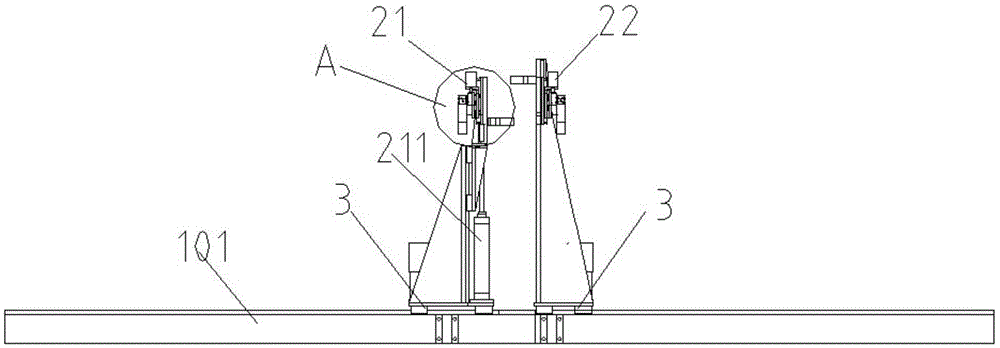

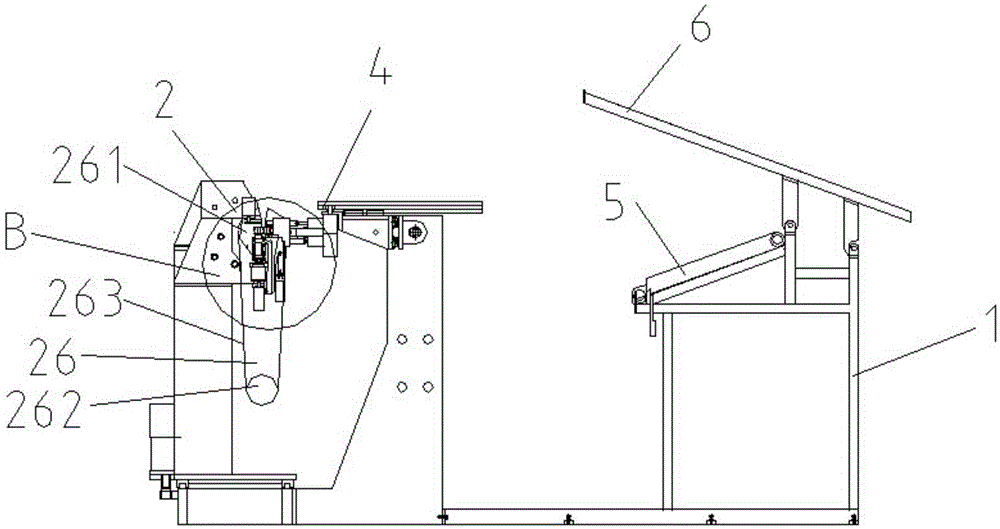

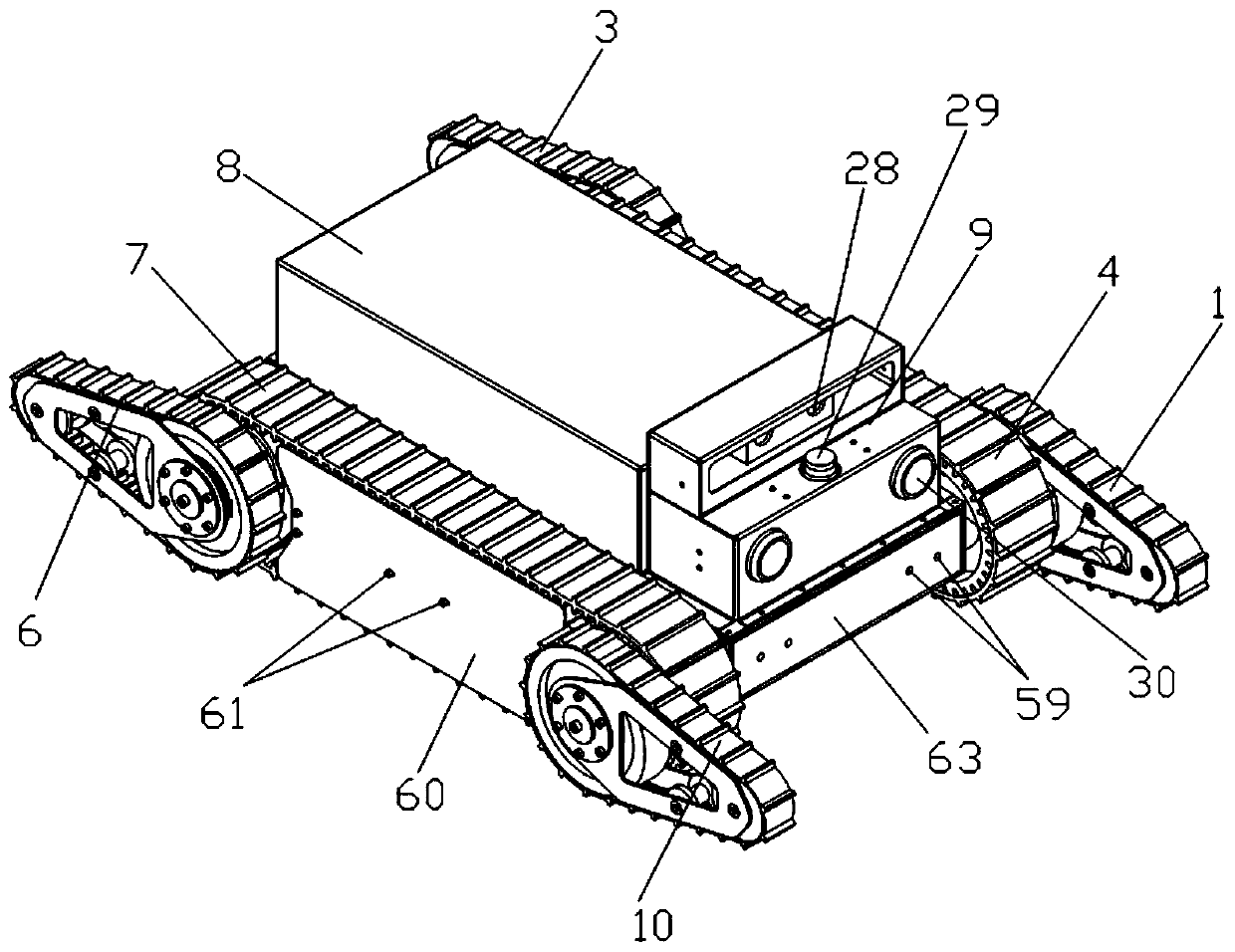

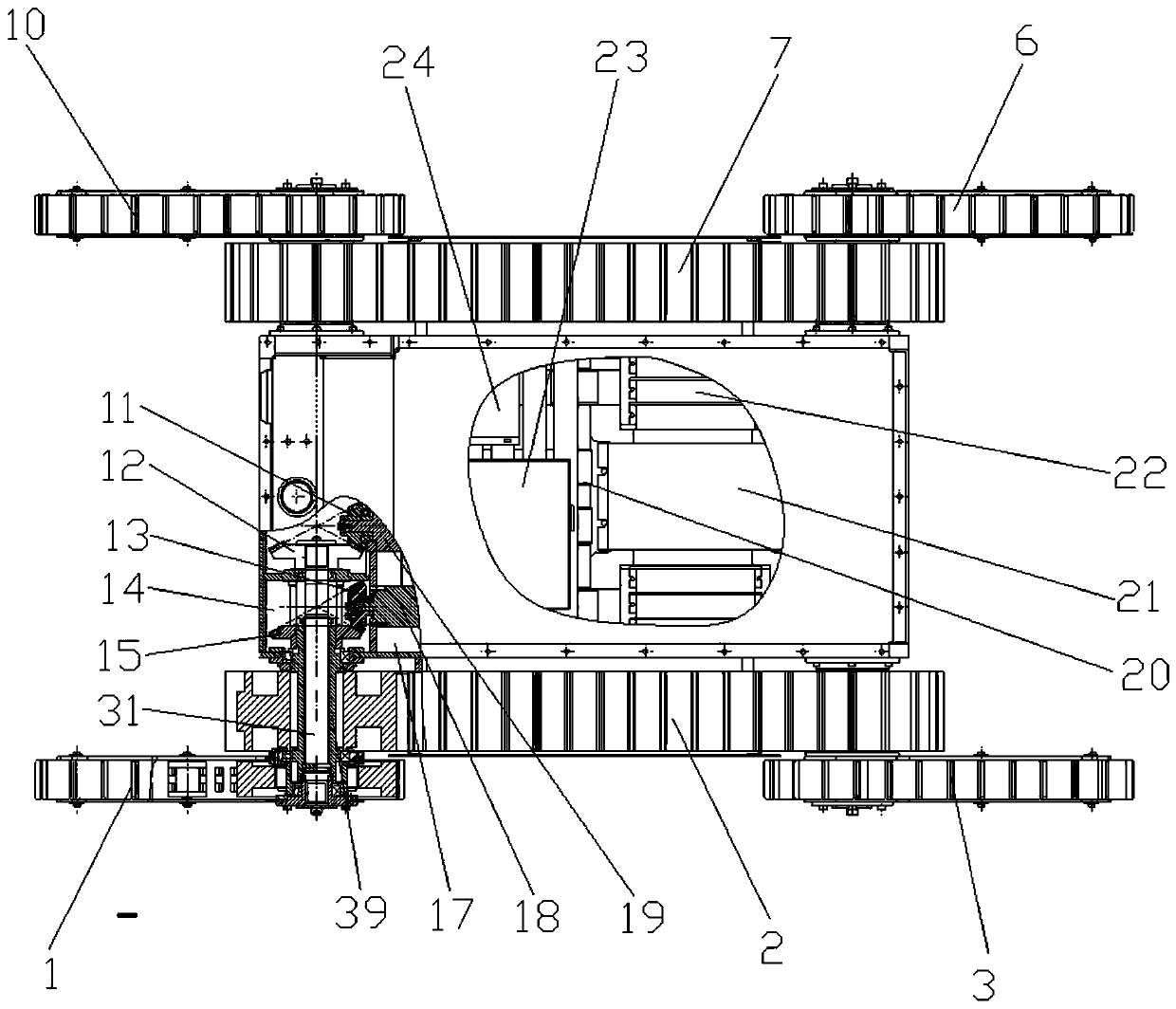

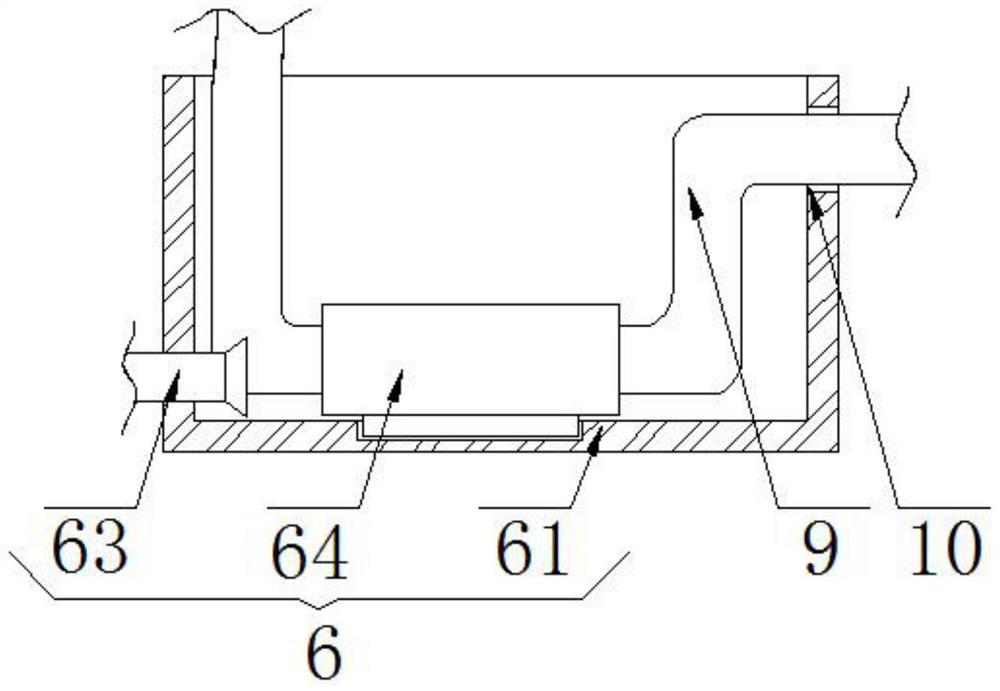

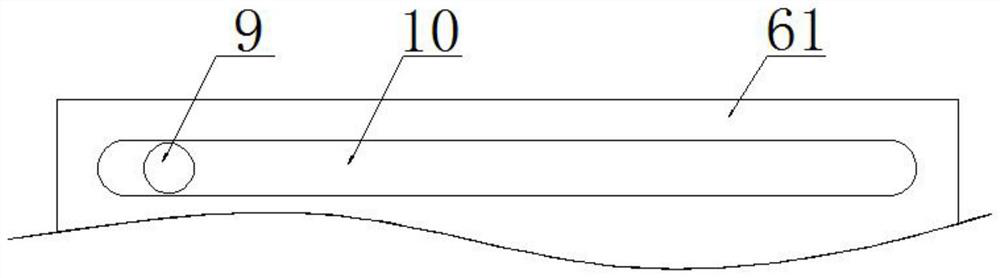

The invention discloses a wire-control coalmine rescue detection robot and a cable extension and retraction method thereof. The wire-control coalmine rescue detection robot comprises a robot body and a cable extension and retraction box arranged at the top of the robot body. A cable extension and retraction device is arranged in the cable extension and retraction box. The robot body comprise a robot body cabinet, two travelling track assemblies and four swinging arm track assemblies. The robot body cabinet comprises a lower cabinet cavity, an upper cabinet cavity, a sensor cavity, three gear cavities and two supporting wheel cavities. The cable extension and retraction device comprises a cable extension and retraction motor, a synchronous belt transmission mechanism connected with an output shaft of the cable extension and retraction motor, and a cable winding mechanism and a cable arranging mechanism which are both connected with the synchronous belt transmission mechanism. The cable extension and retraction method of the wire-control coalmine rescue detection robot comprises the steps of cable connection and cable extension and retraction. By adoption of the wire-control coalmine rescue detection robot and the cable extension and retraction method thereof, cables are extended and retracted in order and are appropriate in degree of tightness, cable entanglement and breaking are reduced, and stable transmission of control signals, relevant sensor information and a power supply can be guaranteed.

Owner:XIAN UNIV OF SCI & TECH

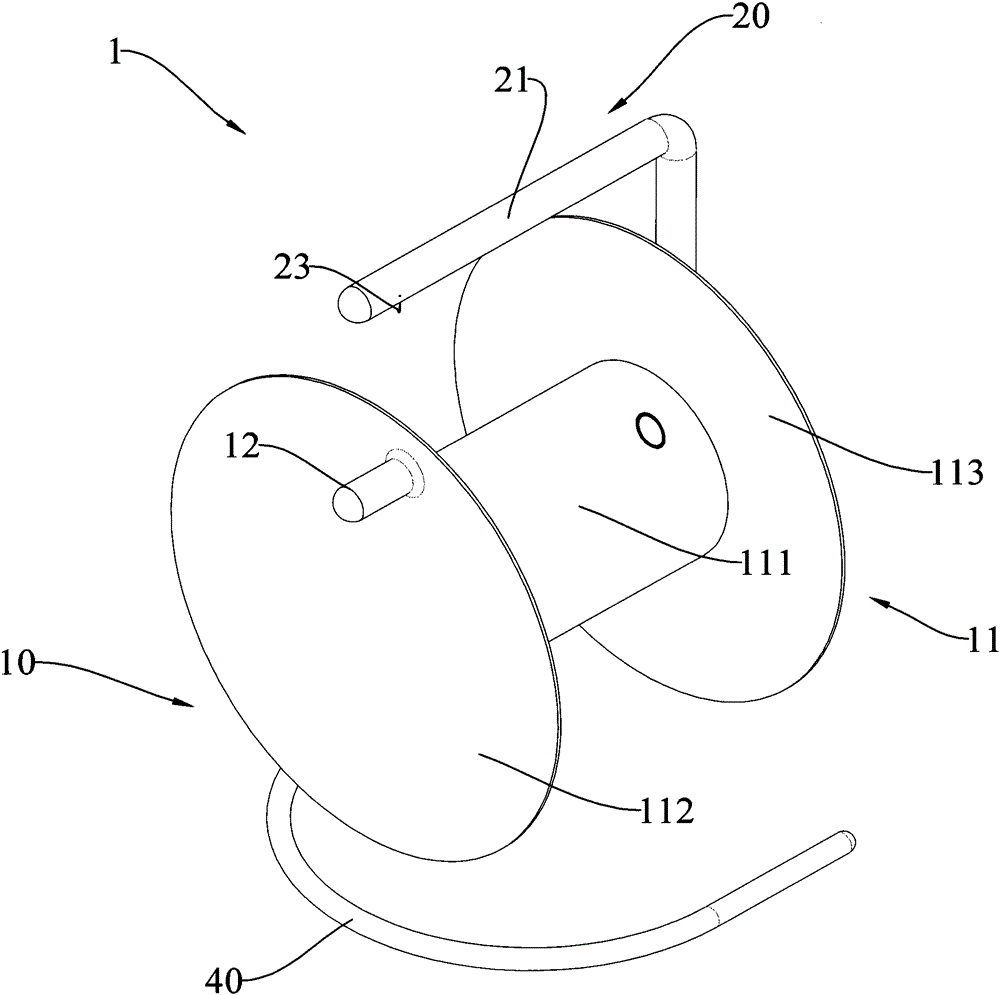

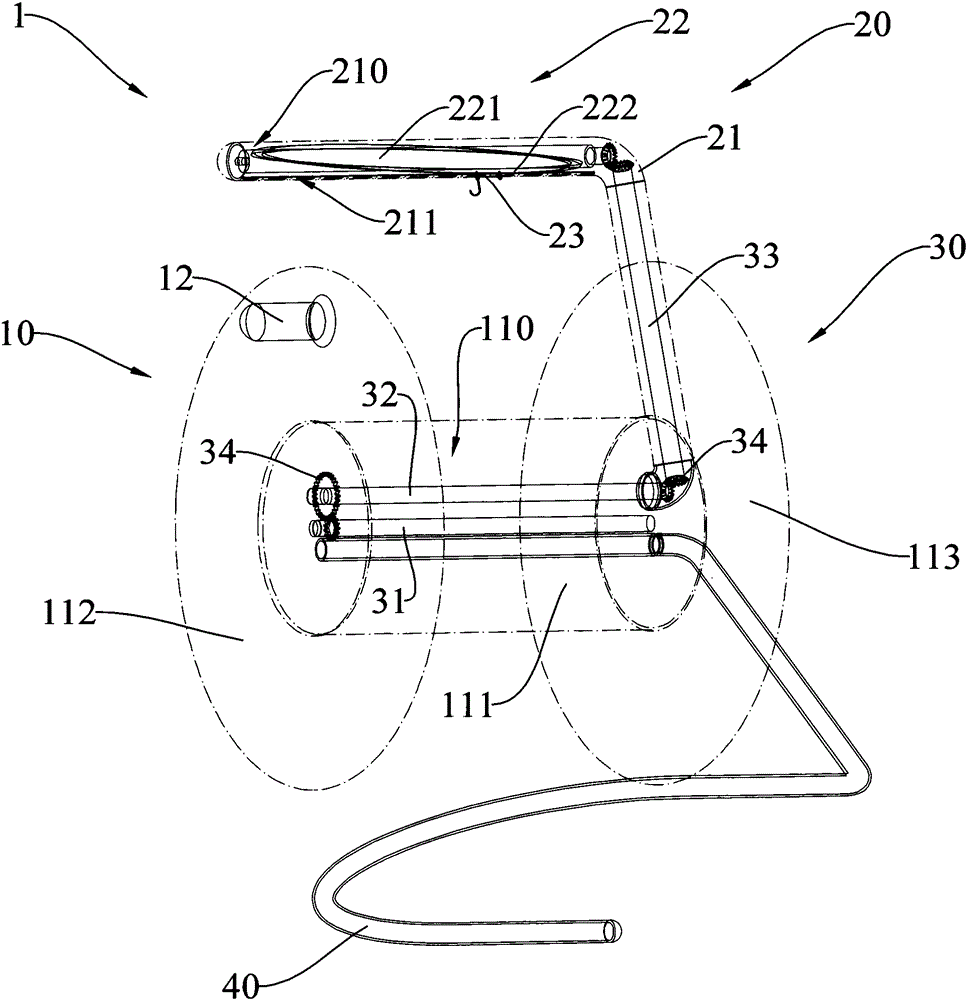

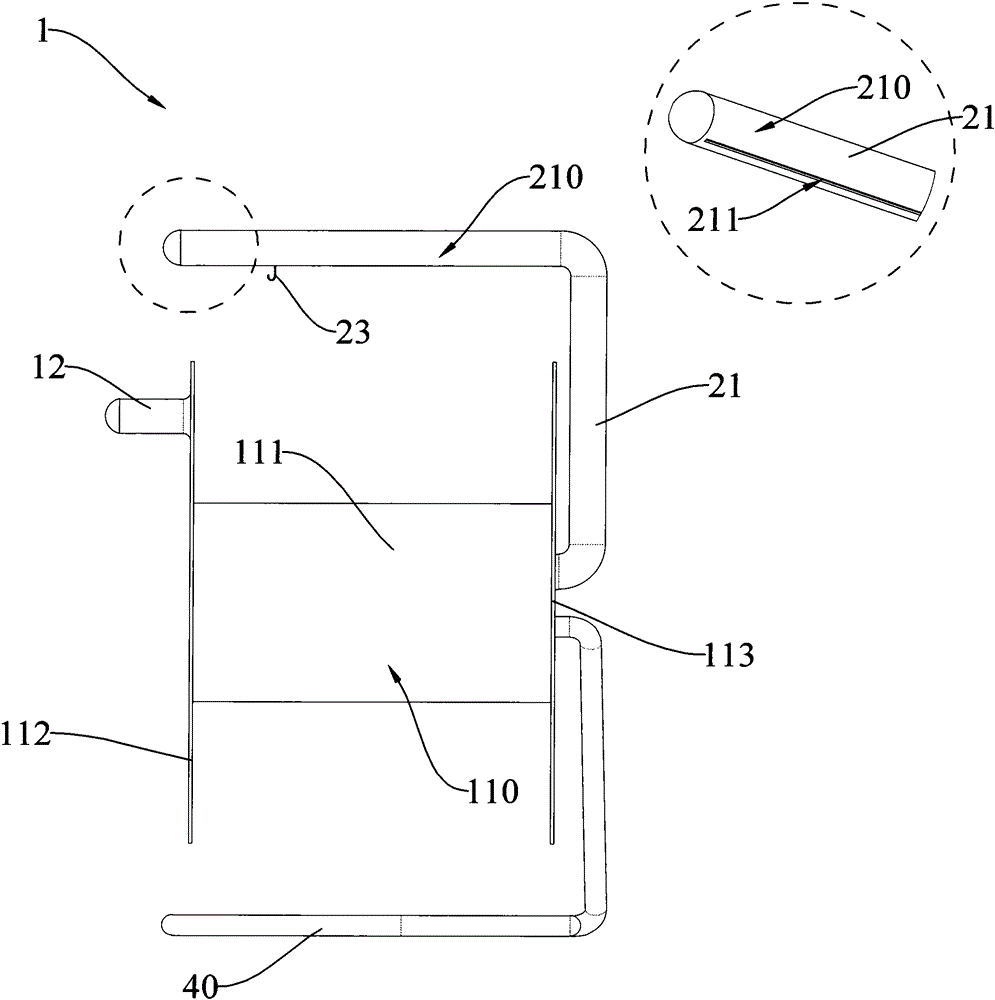

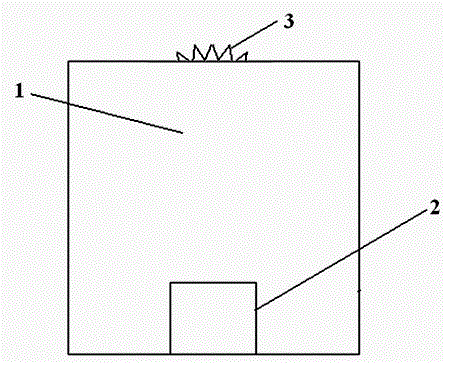

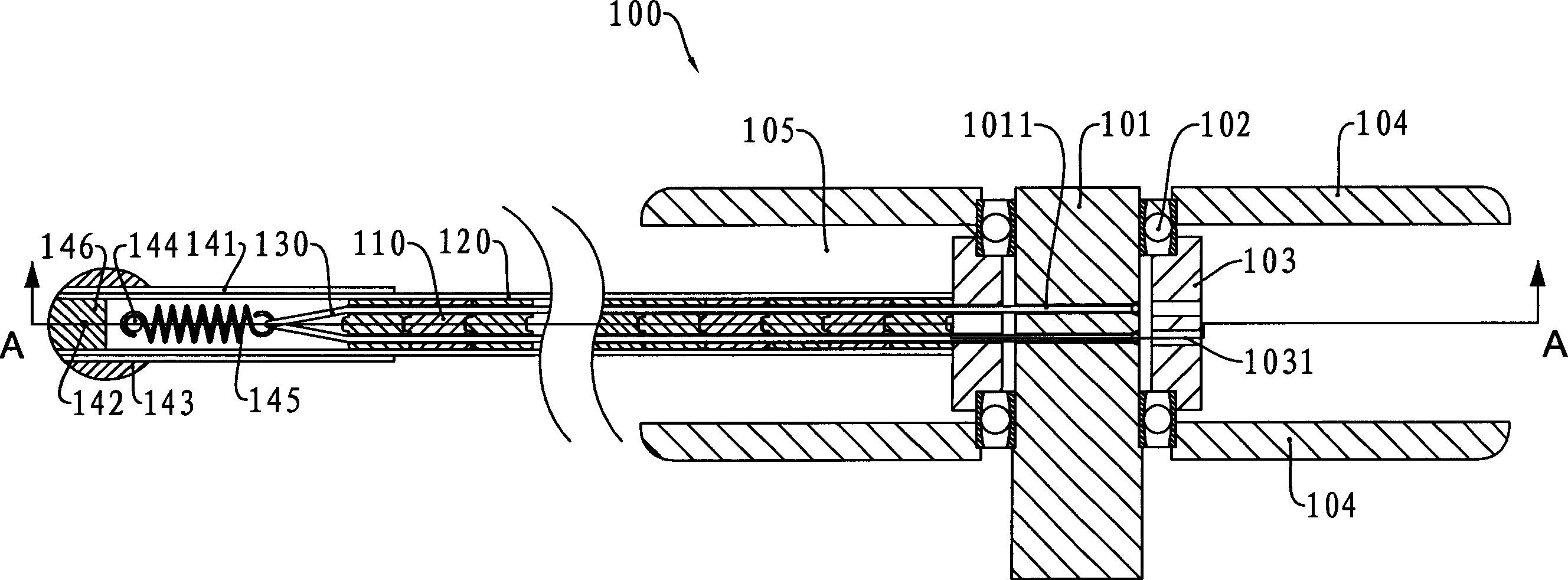

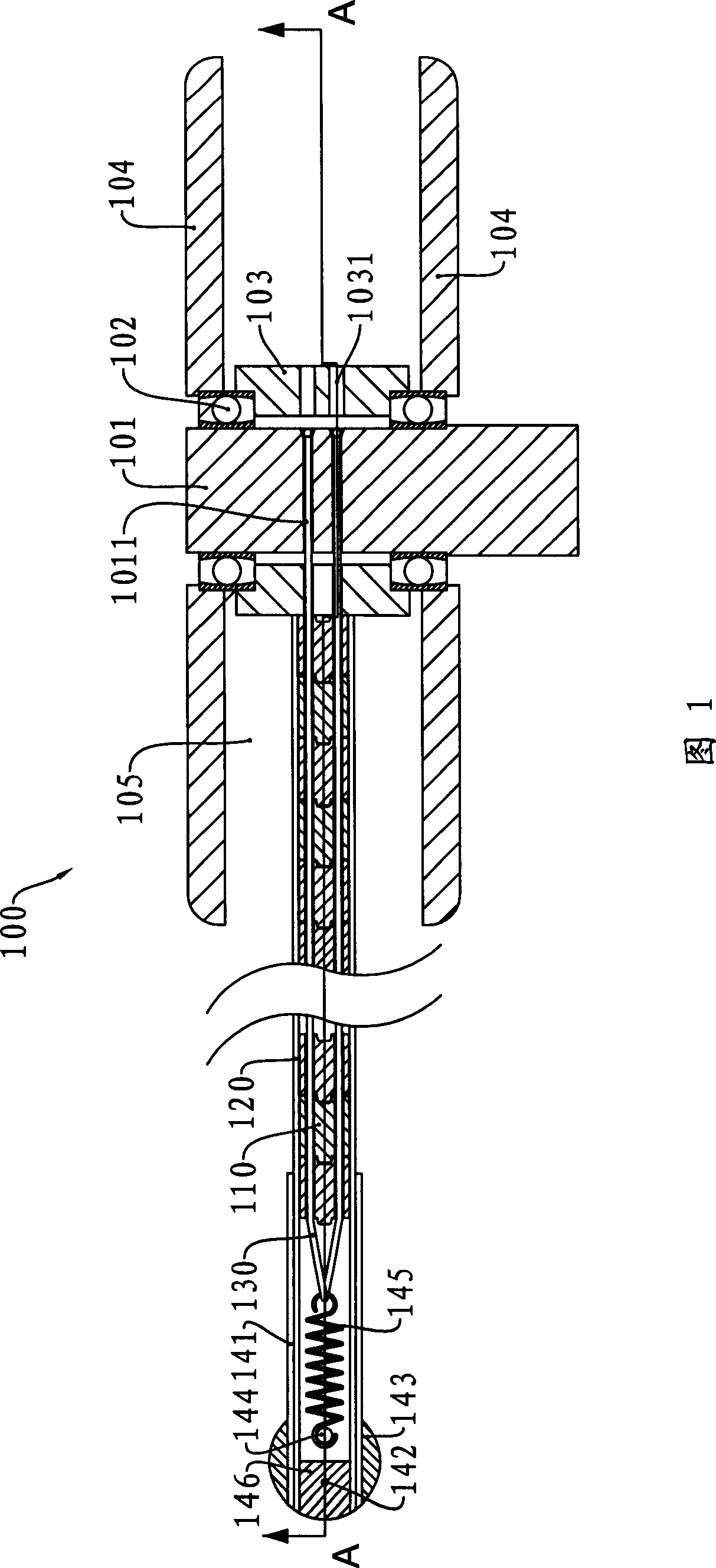

Retraction lever and tent

InactiveCN101109242ARigid-flexible conversion is convenientOrderly retractableTents/canopiesEngineeringMechanical engineering

The invention relates to a shrinkage rod and a tent made with the shrinkage rod. The shrinkage rod comprises a plurality of rigid skeleton-joints with two axial ends and sides, the concave and convex parts of all skeleton-joints are connected in series along the through holes by two flexible ropes sequentially; the shrinkage rod additional comprises a storage section located at one end of the rod for storing the rod in a coiled way. The storage section is provided with a rotatable rotary shaft, and a rod-storage sleeve is fixed on the rotary shaft in linkage way in form of intermittent drive; one end of the two flexible ropes pass the rod-storage sleeve and are fixed on the rotary shaft; the rod-storage sleeve is borne rotatably between two rope-protecting boards at two ends of the sleeve; a tension part is provided at another end of the shrinkage rod; another end of the two flexible ropes are fixed on the tensioning part. The shrinkage rod can be retracted and released sequentially, a tent made with the rod has the advantage of the smaller retracted size comparing with a prior tent.

Owner:陈想年

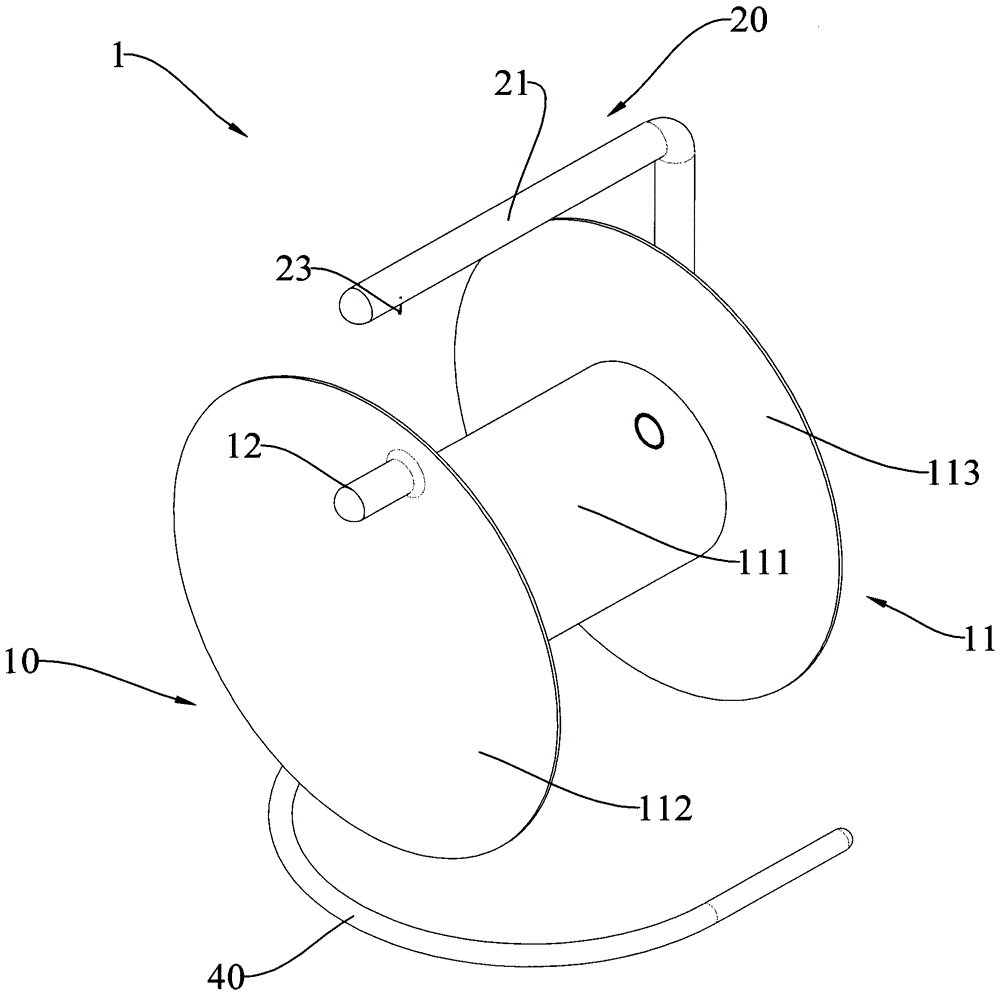

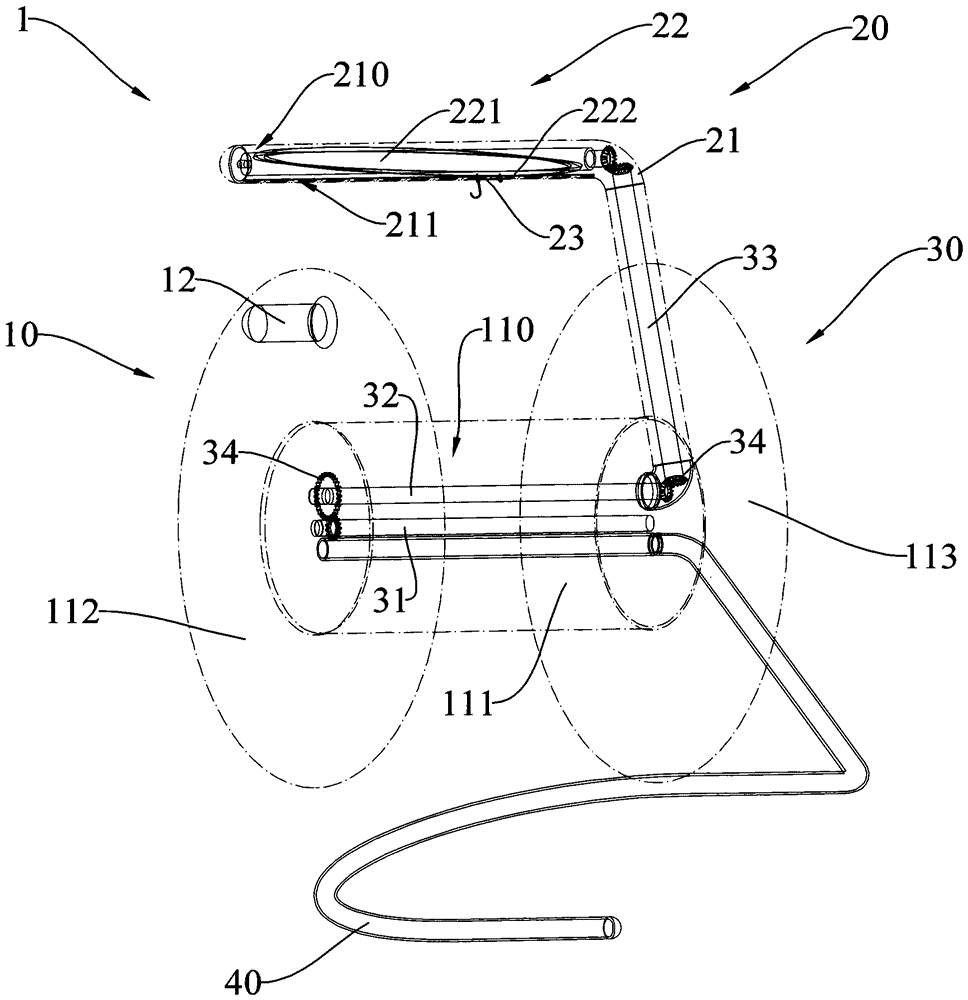

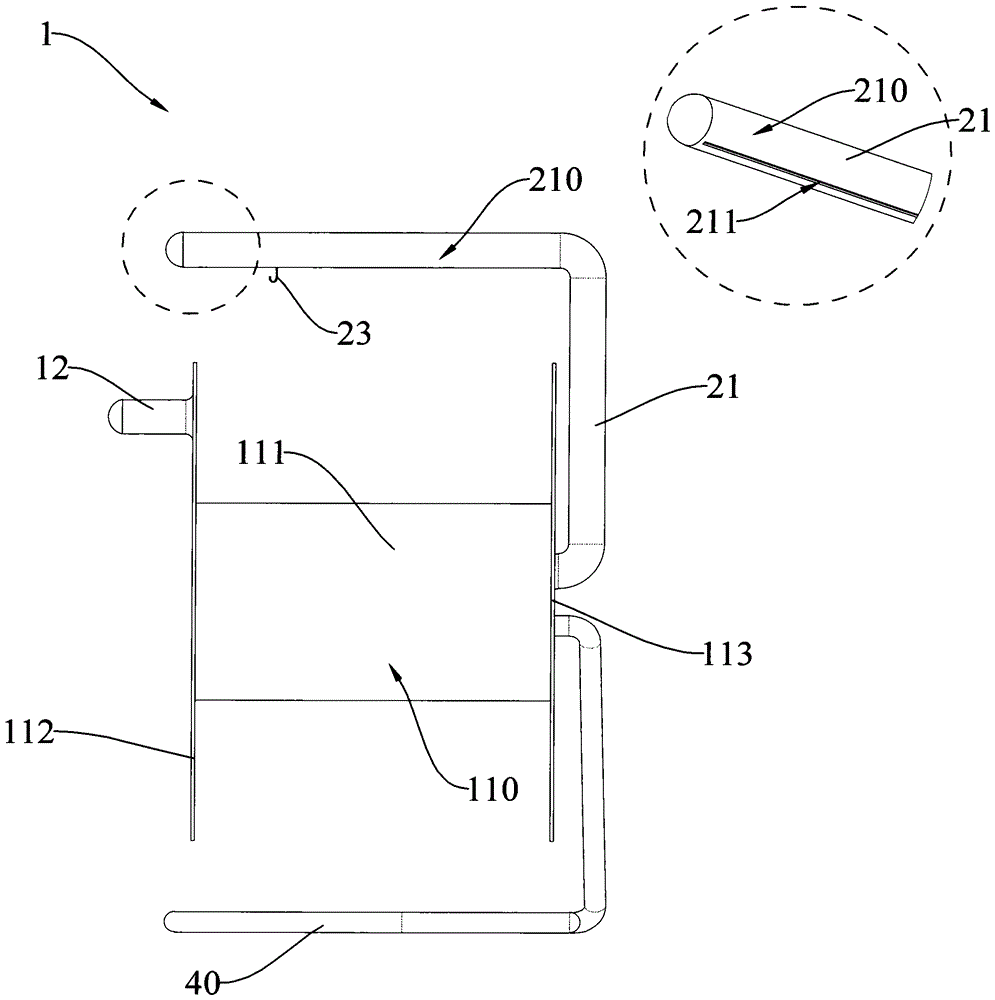

Novel winding device and use method thereof

ActiveCN105173926AReduce the difficulty of operationReduce manufacturing costFilament handlingConductor CoilMechanical engineering

The invention discloses a novel winding device and a use method for the novel winding device. The winding device comprises a winding mechanism, a wire arranging mechanism, a guiding part and a sliding part. The winding mechanism comprises a winding pipe. The winding pipe comprises a winding pipe body, a movable side plate and a fixed side plate, wherein the winding pipe body can be rotationally jointed between the movable side plate and the fixed side plate. The wire arranging mechanism comprises a wire arranging pipe. The wire arranging pipe is provided with a wire arranging pipe cavity and a guiding groove, and the guiding groove is communicated with the wire arranging pipe cavity and the outside and downwards faces the winding pipe body. The guiding part is horizontally installed in the wire arranging pipe cavity. The guiding part comprises a guiding shaft and a protruding ridge part which protrudes out of the guiding shaft and integrally extends in a ring shape. A preset route is formed between the protruding ridge part and the guiding groove. The sliding part is reversely arranged in the guiding groove and extends towards the winding pipe body from the guiding part so as to be used for conducting reciprocating wire arranging. The two sides of the sliding part are transversely internally tangent to the inner side and the outer side of the protruding ridge part respectively so that the sliding part can slide along the preset route to conduct reciprocating wire arranging relative to the rotation of the winding pipe.

Owner:JUNHE PUMPS HLDG

Power supply reel capable of taking up cable automatically

The invention discloses a power supply reel capable of taking up a cable automatically. The power supply reel comprises two fixing plates. A support seat device is arranged between the two fixing plates. A rotating device is arranged on the support seat device. A cable arrangement device is arranged at one side of the rotating device. The cable is detected through a 360-degree rotating electric coupler, so that electric shock is prevented. The elasticity of a back-coil spring is adjusted through a handle, and thus, the cable can be automatically rotated onto a cable winding shaft. A reciprocating lead screw is matched with a rotating seat, so that the cable is taken up and released, and the rotating seat is driven to perform reciprocating motion on the reciprocating lead screw; and thus, when being released and taken up, the cable can move at a certain rule; and it is guaranteed that the cable is wound neatly. The power supply reel has the beneficial effects of being simple in structure and great in practicability.

Owner:国网安徽省电力有限公司亳州供电公司 +2

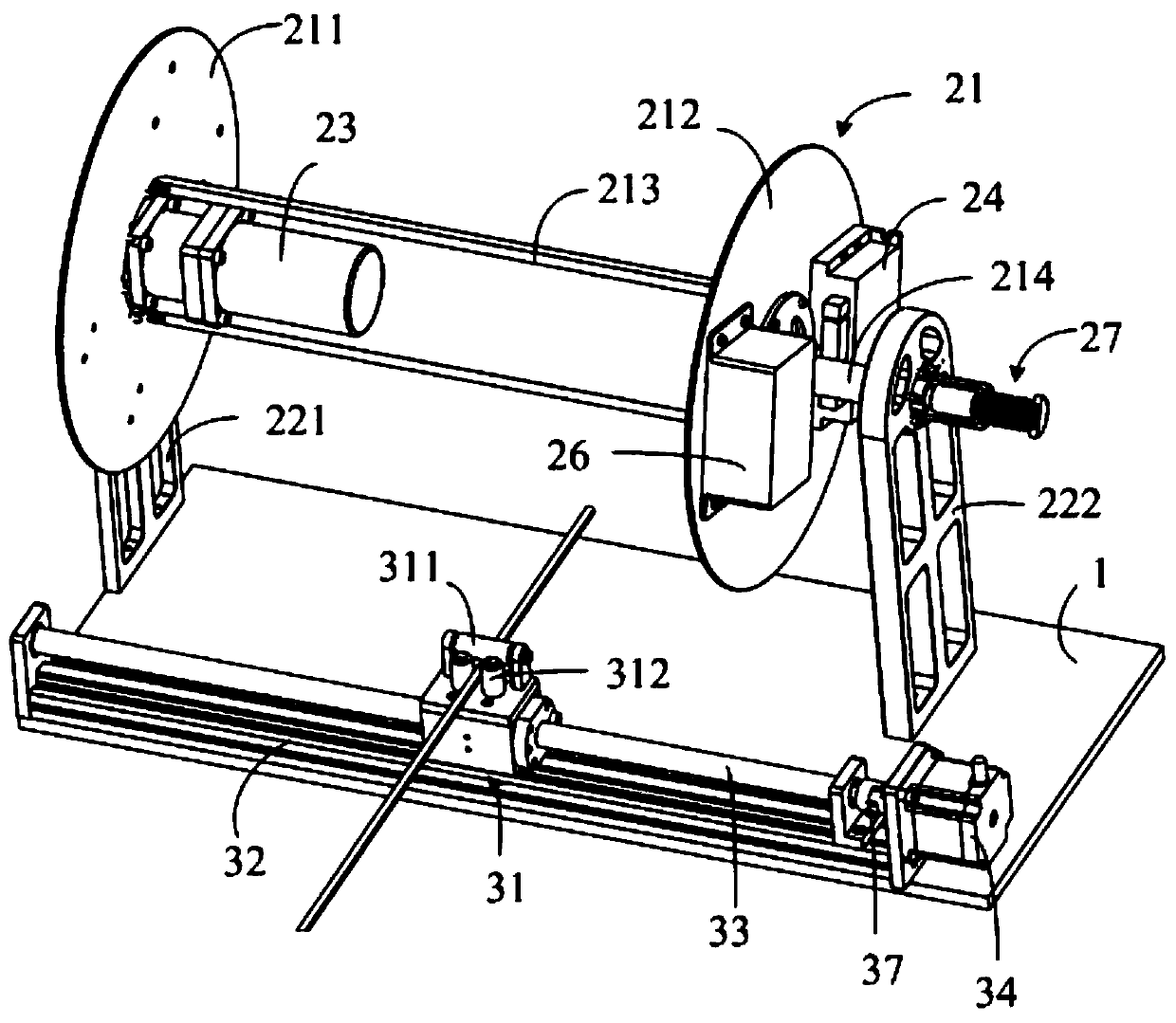

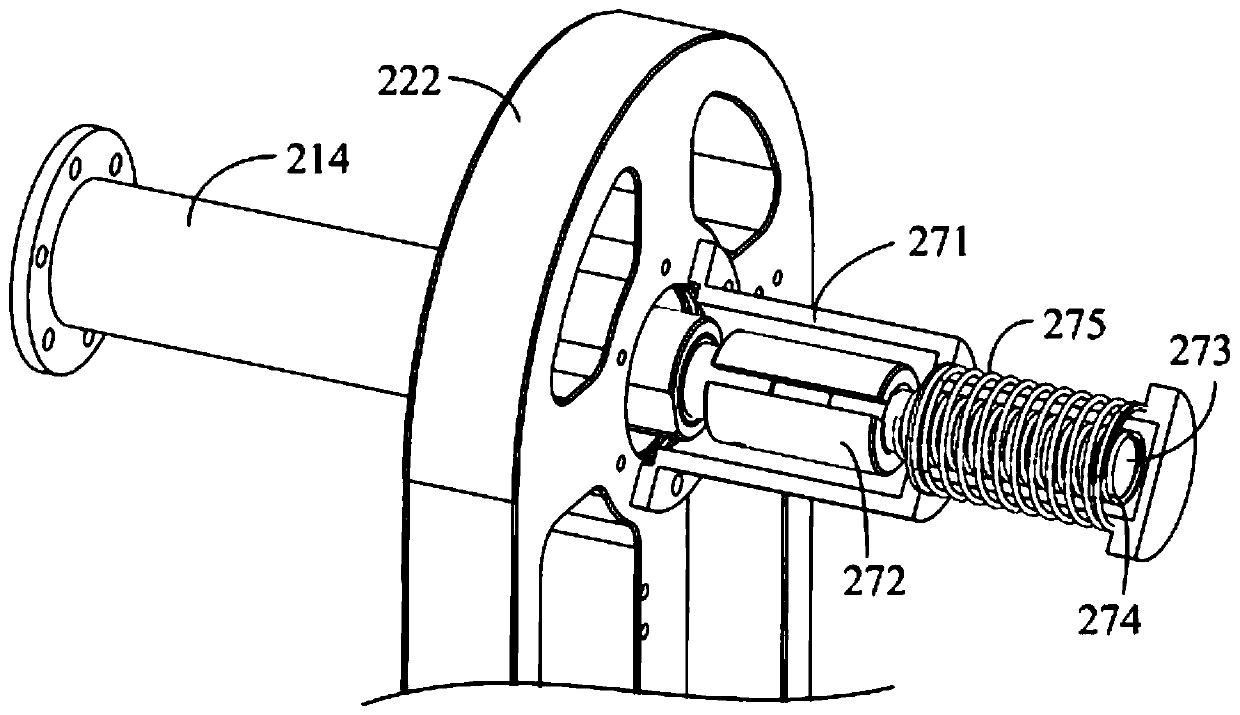

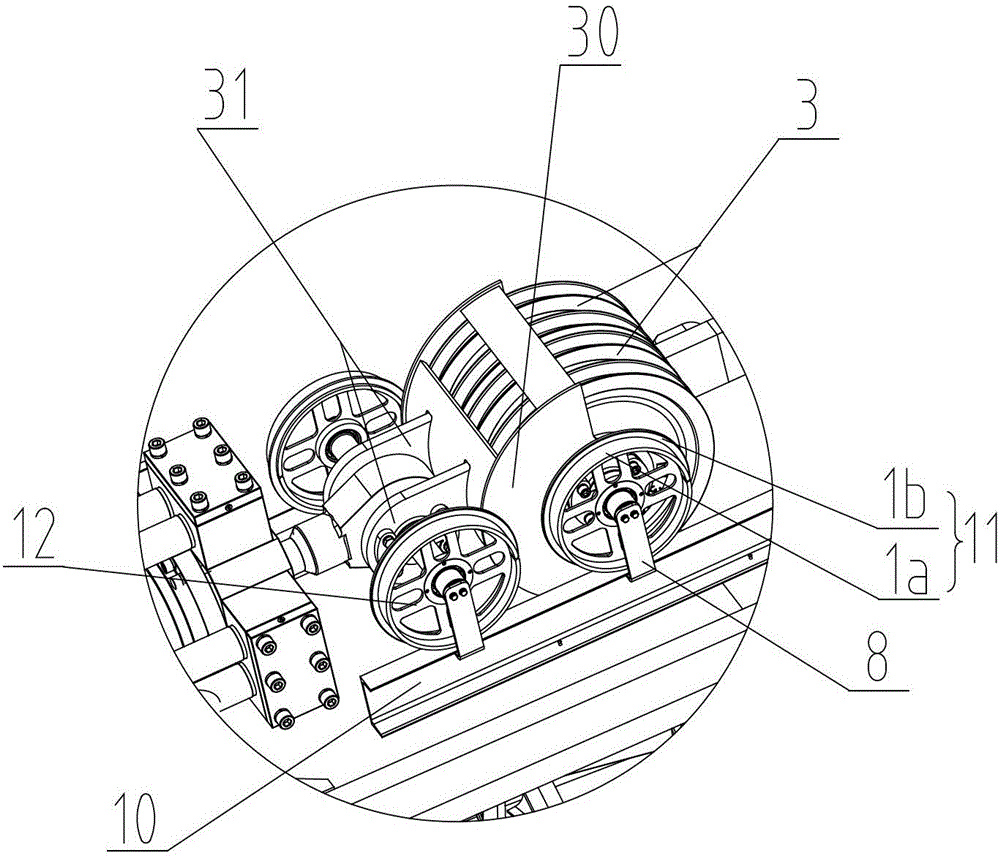

Winding type automatic take-up and pay-off mechanism

The present invention relates to a winding type automatic take-up and pay-off mechanism. One end of a winding drum is mounted on a mechanism mounting plate. A winding arm driving shaft is mounted at the other end of the winding drum in a manner of relatively moving in an axial direction. One end of the winding arm driving shaft is in threaded connection with the inner wall of the winding drum, and the other end of the same is connected to a winding arm with a cable guiding groove. One end of a cable is fixed to one end of the winding drum, and the other end of the same extends out of the cable guiding groove. A rocker is located in the winding drum and connected to the other end of the winding arm driving shaft in such a manner of relatively moving in the axial direction. Moreover, the rocker is connected to a driving motor mounted on the mechanism mounting plate and driven by the driving motor to rotate around an axial center line of the winding drum. The winding arm driving shaft and the winding arm rotate along with the rocker, and the winding arm driving shaft is in threaded connection with the inner wall of the winding drum so as to drive the winding arm to move in the axial direction. The winding type automatic take-up and pay-off mechanism is compact in structure and uniform in cable winding pitch, and may achieve automatic, ordered and uniform take-up and pay-off of a short cable.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

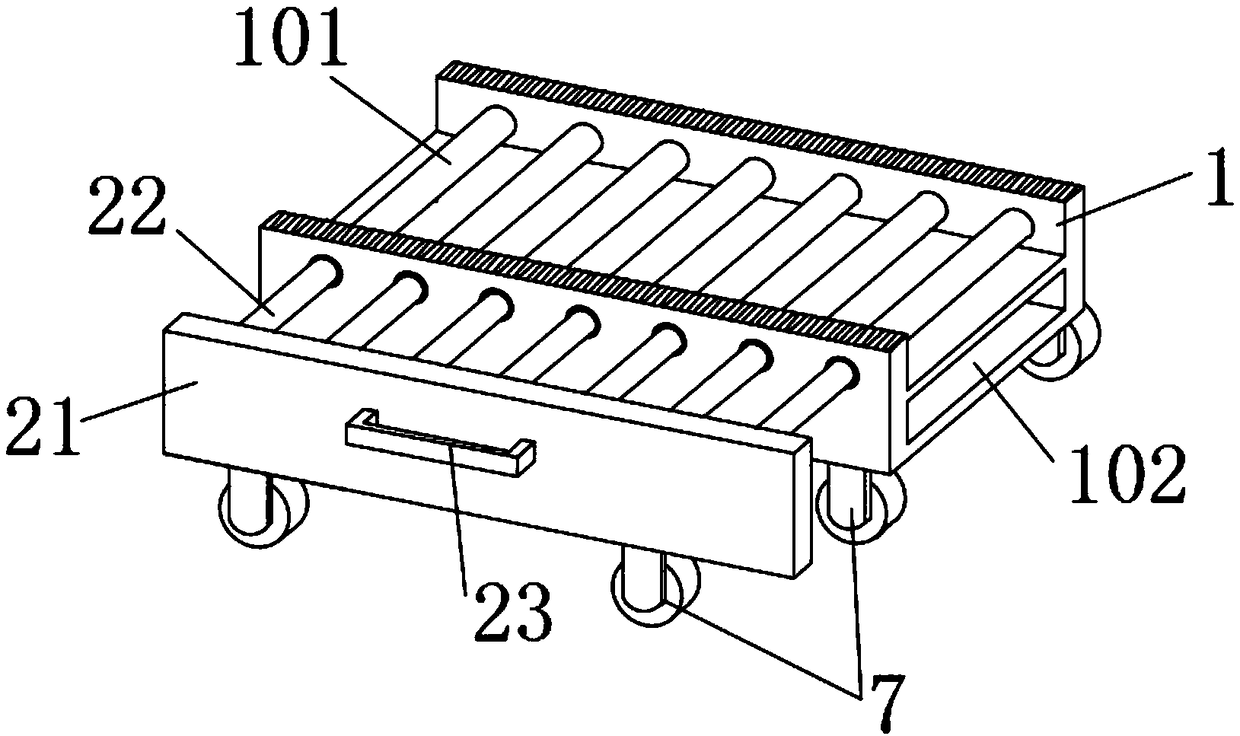

Automatic wire cable winding device

PendingCN111285279ASolve the problem of not being able to unwind smoothly from the rollOrderly coiledWinding mechanismsStructural engineeringElectrical and Electronics engineering

The invention relates to an automatic wire cable winding device. The automatic wire cable winding device is used for winding a wire cable onto a roller or unwinding the wire cable out of the roller. The wire cable winding device comprises a base, the roller rotationally installed on the base, a first drive assembly arranged on the roller and driving the roller to rotate, and a wire cable arrangement mechanism movably arranged on the base, wherein a penetrating hole allowing the wire cable to penetrate through is formed in the wire cable arrangement mechanism; the wire cable arrangement mechanism is capable of moving in the length direction of the roller, and driving the wire cable to move in the length direction of the roller, and then the operation of orderly winding the wire cable onto the roller or unwinding the wire cable out of the roller is realized in cooperation with the rotation of the roller. According to the wire cable winding device, the wire cable can be driven to be automatically and orderly wound, unwound and arranged in the length direction of the roller through the wire cable arrangement mechanism, so that the problem that the wire cable cannot be smoothly wound and unwound because of being disorderly wound onto the roller is avoided.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD. +2

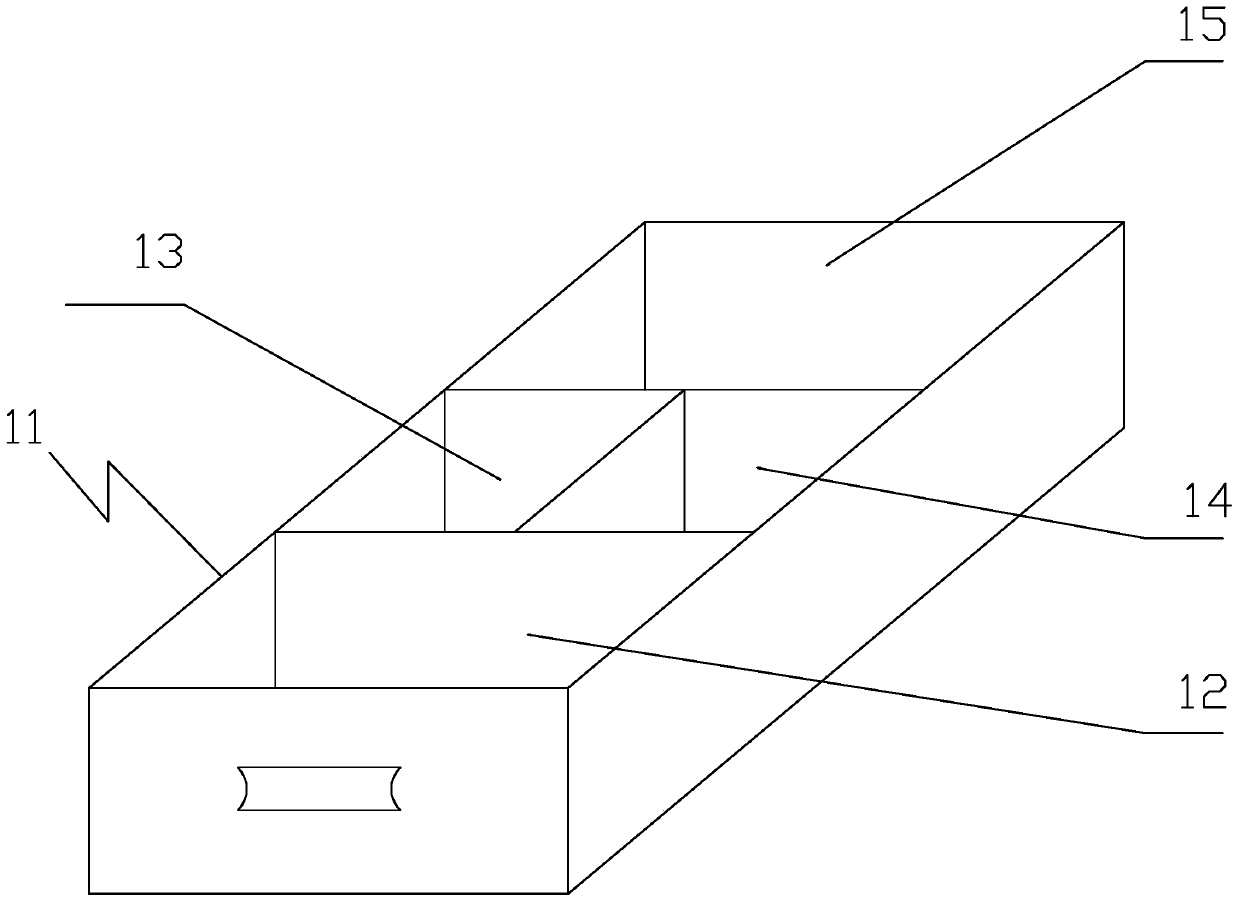

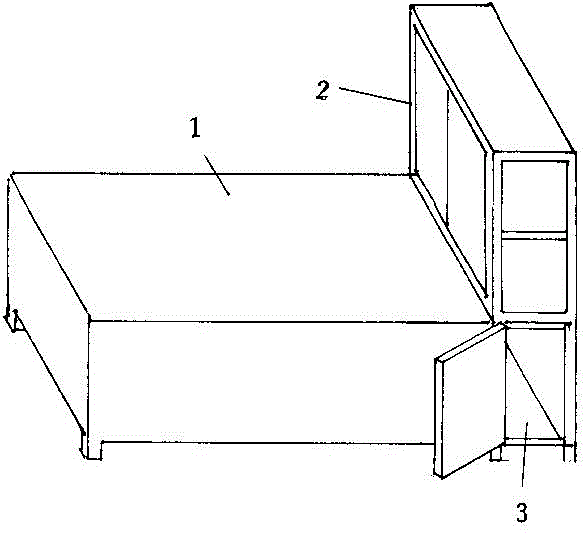

Bed with wardrobe

InactiveCN103799757AOrderly retractableAvoid the phenomena that affect the delay in getting up in the morningWardrobesLighting elementsEngineeringCushion

The invention provides a bed with a wardrobe. One end of a bed body is connected with a wardrobe which is concurrently used as a back cushion, a shoe cabinet is arranged below the wardrobe, a lighting lamp tube is arranged above the wardrobe, so that through the device, when users go to bed, wearing clothes can be taken off and put into the wardrobe, and then when the users get up in the morning, the users can get dressed conveniently and timely, and therefore, a phenomenon that after users get up in the morning, the careless throwing of clothing causes delay in work or business is avoided, and the clothing can be arranged orderly.

Owner:ZHUGELIANG MIDDLE SCHOOL

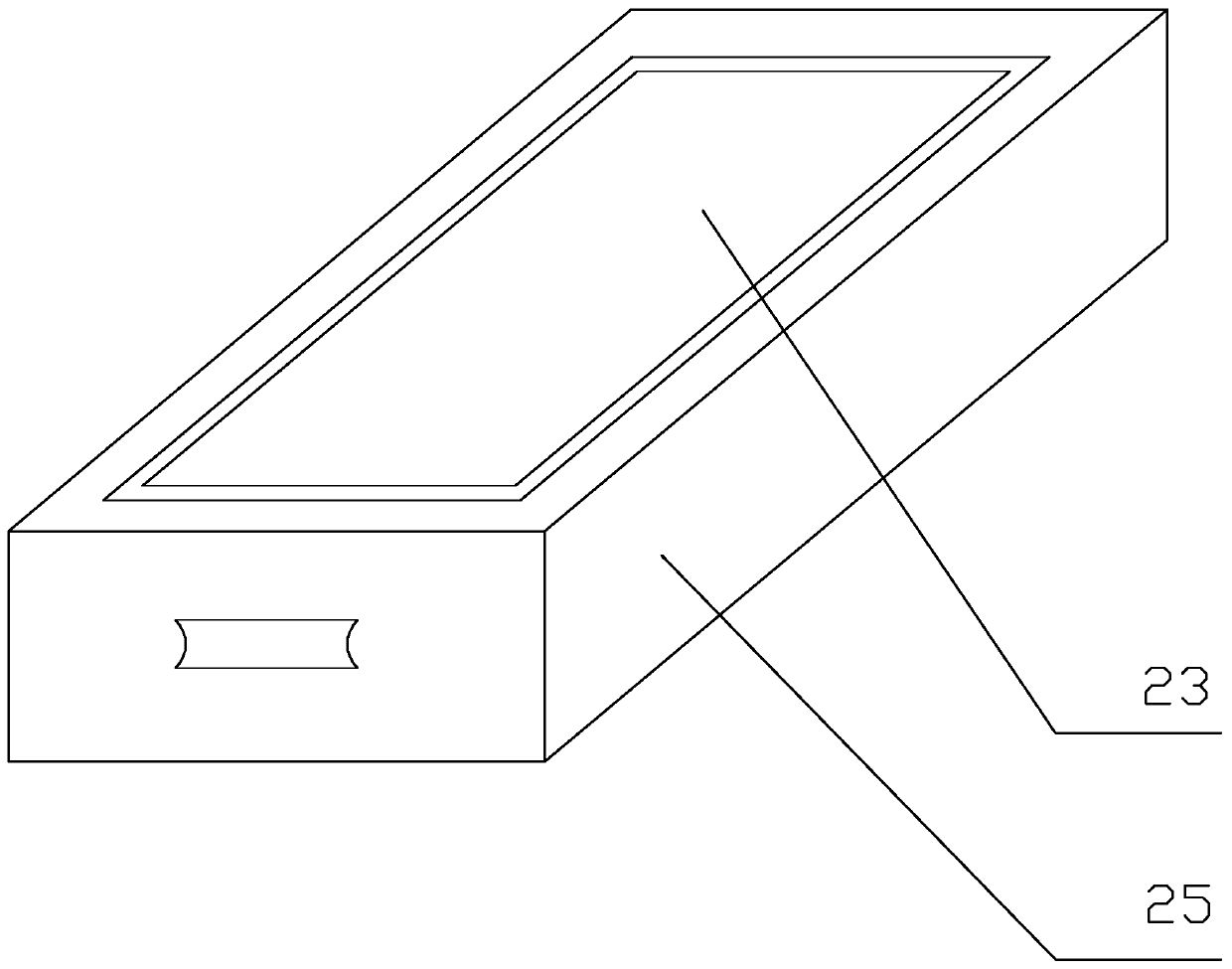

Intelligent sterilization cabinet

PendingCN110170062AFacilitated DiffusionDoes not affect normal useLavatory sanitoryTextile treatment by spraying/projectingBackplaneElectricity

The invention discloses an intelligent sterilization cabinet, which further includes a cabinet body, a plurality of compartments arranged on the cabinet body and first drawers, wherein the first drawers are slidably fitted in the compartments, and the first drawers are internally provided with an electric control board, an ozone generator, a first air pump and a first pipe respectively; the electric control board is electrically connected to the ozone generator, and the input end of the first air pump is connected to the ozone generator; the output end of the first air pump is connected to theinput end of a first pipe, and the first pipe is built in a back plate of the cabinet body. The invention provides an intelligent sterilization system with good sterilization effect.

Owner:佛山市斗拱建材科技有限公司

A winding type automatic take-up and pay-off mechanism

The present invention relates to a winding type automatic take-up and pay-off mechanism. One end of a winding drum is mounted on a mechanism mounting plate. A winding arm driving shaft is mounted at the other end of the winding drum in a manner of relatively moving in an axial direction. One end of the winding arm driving shaft is in threaded connection with the inner wall of the winding drum, and the other end of the same is connected to a winding arm with a cable guiding groove. One end of a cable is fixed to one end of the winding drum, and the other end of the same extends out of the cable guiding groove. A rocker is located in the winding drum and connected to the other end of the winding arm driving shaft in such a manner of relatively moving in the axial direction. Moreover, the rocker is connected to a driving motor mounted on the mechanism mounting plate and driven by the driving motor to rotate around an axial center line of the winding drum. The winding arm driving shaft and the winding arm rotate along with the rocker, and the winding arm driving shaft is in threaded connection with the inner wall of the winding drum so as to drive the winding arm to move in the axial direction. The winding type automatic take-up and pay-off mechanism is compact in structure and uniform in cable winding pitch, and may achieve automatic, ordered and uniform take-up and pay-off of a short cable.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

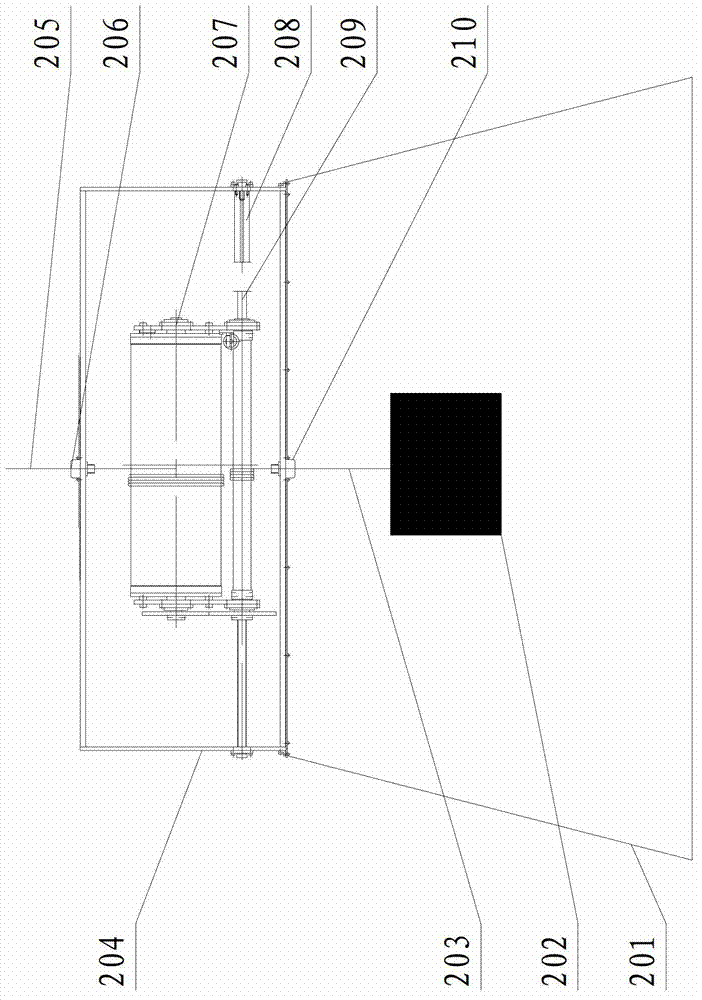

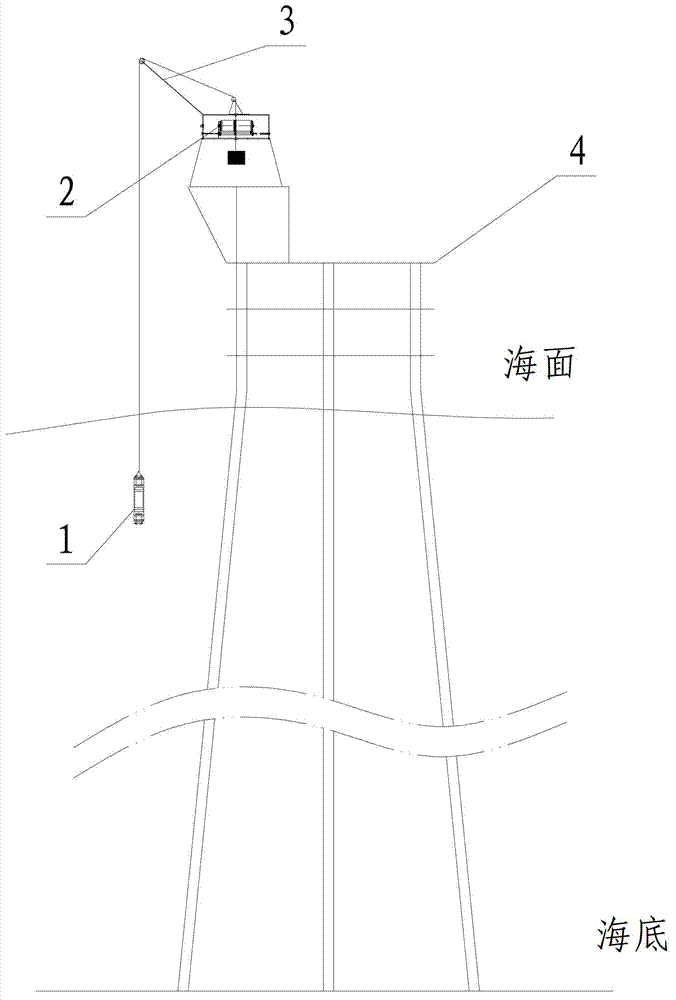

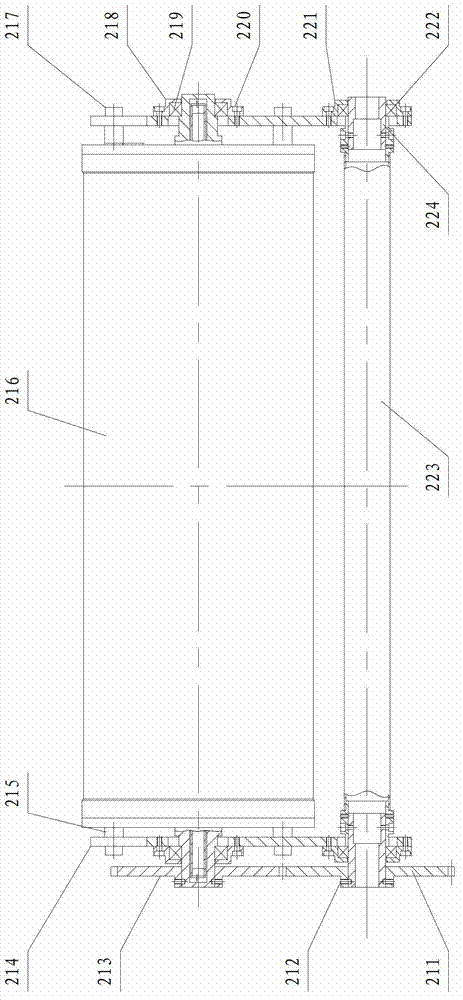

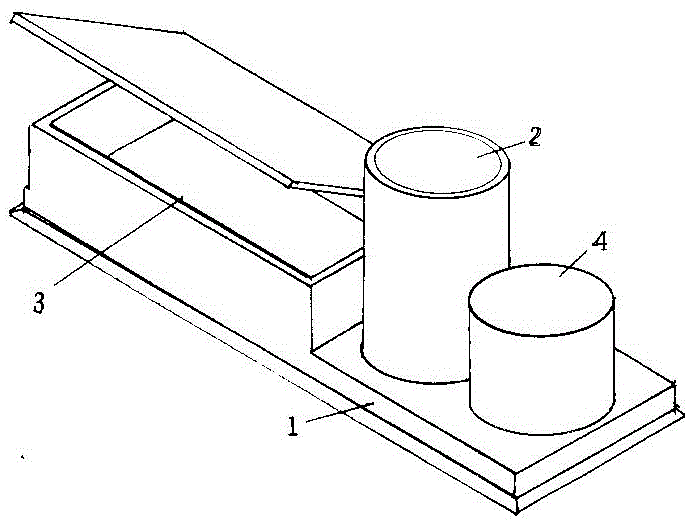

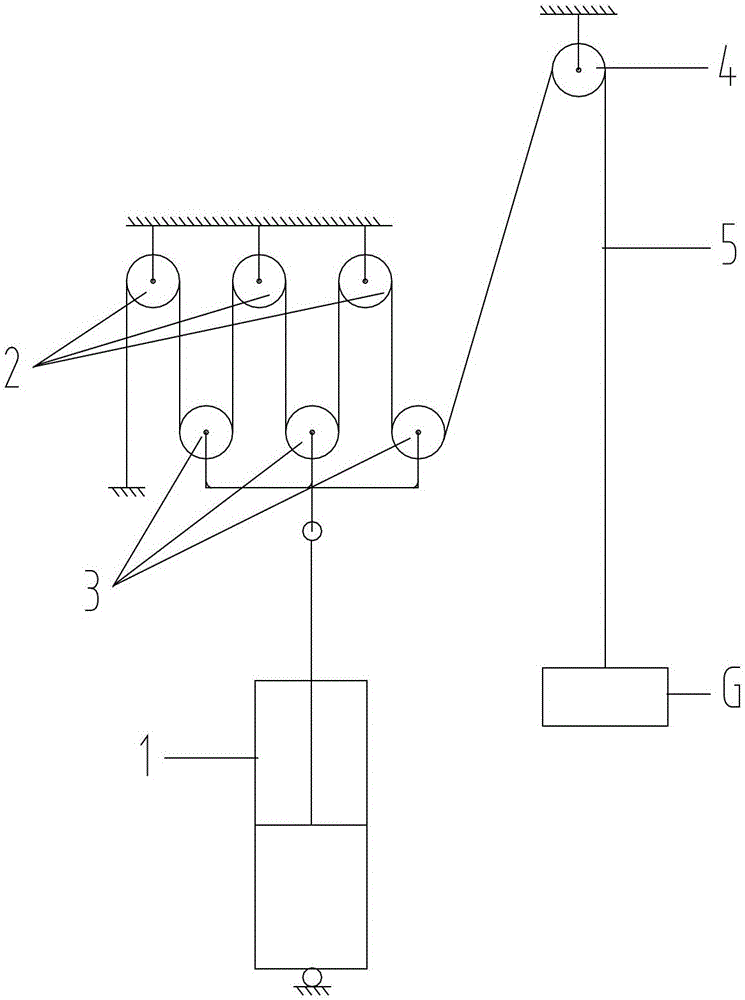

Moment balanced type hydrographic winch for marine oil platform

InactiveCN103588136ARealize Stereoscopic ObservationTimed Vertical Profile MeasurementWinding mechanismsPull forceGear wheel

The invention belongs to the field of marine environment three-dimensional monitoring and particularly relates to a moment balanced type hydrographic winch for a marine oil platform. The moment balanced type hydrographic winch is arranged on the marine oil platform and comprises a base, a supporting frame and a moment balanced type winding roller group, wherein the supporting frame is arranged on the marine oil platform through the base, and the moment balanced type winding roller group comprises a large driving roller and a small driven roller. The large driving roller and the small driven roller perform synchronous rotation through a pair of gears in a meshing mode, one end of a signal cable is wound on the large roller, the other end of the signal cable is connected with an observing device, one end of a bearing cable is wound on the small roller, the other end of the bearing cable is connected with a counter weight, rotation directions of the large roller and the smaller roller are opposite, the large roller and the smaller roller are respectively used for collecting and releasing the signal cable and the bearing cable, and the moment of the large roller borne the pull force of the signal cable and the moment of the smaller roller borne the pull force of the bearing cable are balanced. By means of the principles of moment balance and system energy conservation, the moment balanced type hydrographic winch for the marine oil platform can achieve three-dimensional observation of marine elements from the seabed to the sea surface with small driving force.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Combined writing case with pedestal

InactiveCN104621935AEasy to useImprove work and study efficiencyPursesLuggageEngineeringMechanical engineering

Owner:YICHENG NO 3 SENIOR HIGH SCHOOL

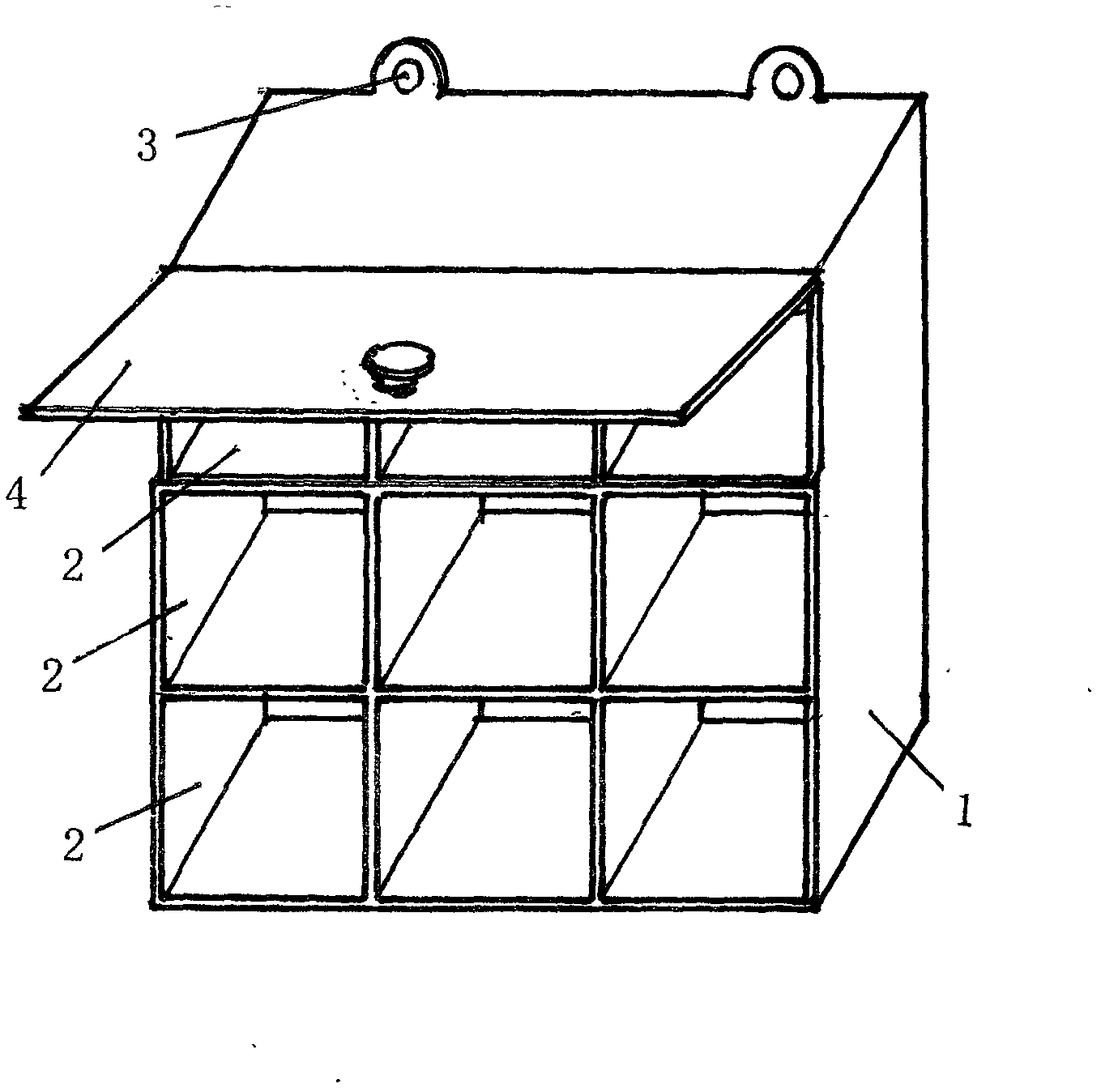

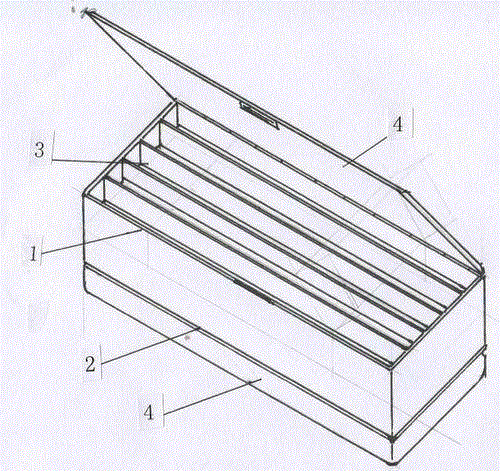

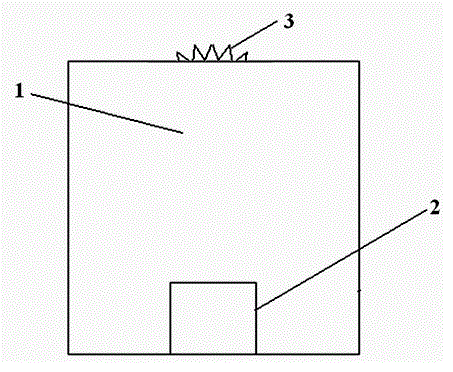

Small article collecting box

InactiveCN102991823AOrderly retractableNon-removalbe lids/coversExternal fittingsEngineeringDomestic environment

The invention provides a small article collecting box. A plurality of collecting cases are arranged in a square box body of the collecting box, a fixing hanging ring is arranged on the rear side above the box body, and a turning cover is arranged on the collecting cases on the upper portion of the box body. During using, the box body is fixed on the wall through the fixing hanging ring so that small household articles can be placed in the collecting cases, the collecting cases with the turning cover on the upper portion can be used for placing valuables and articles required to be protected from light, ordered collecting of the small household articles is facilitated, and tidy domestic environment is guaranteed.

Owner:郭云菲

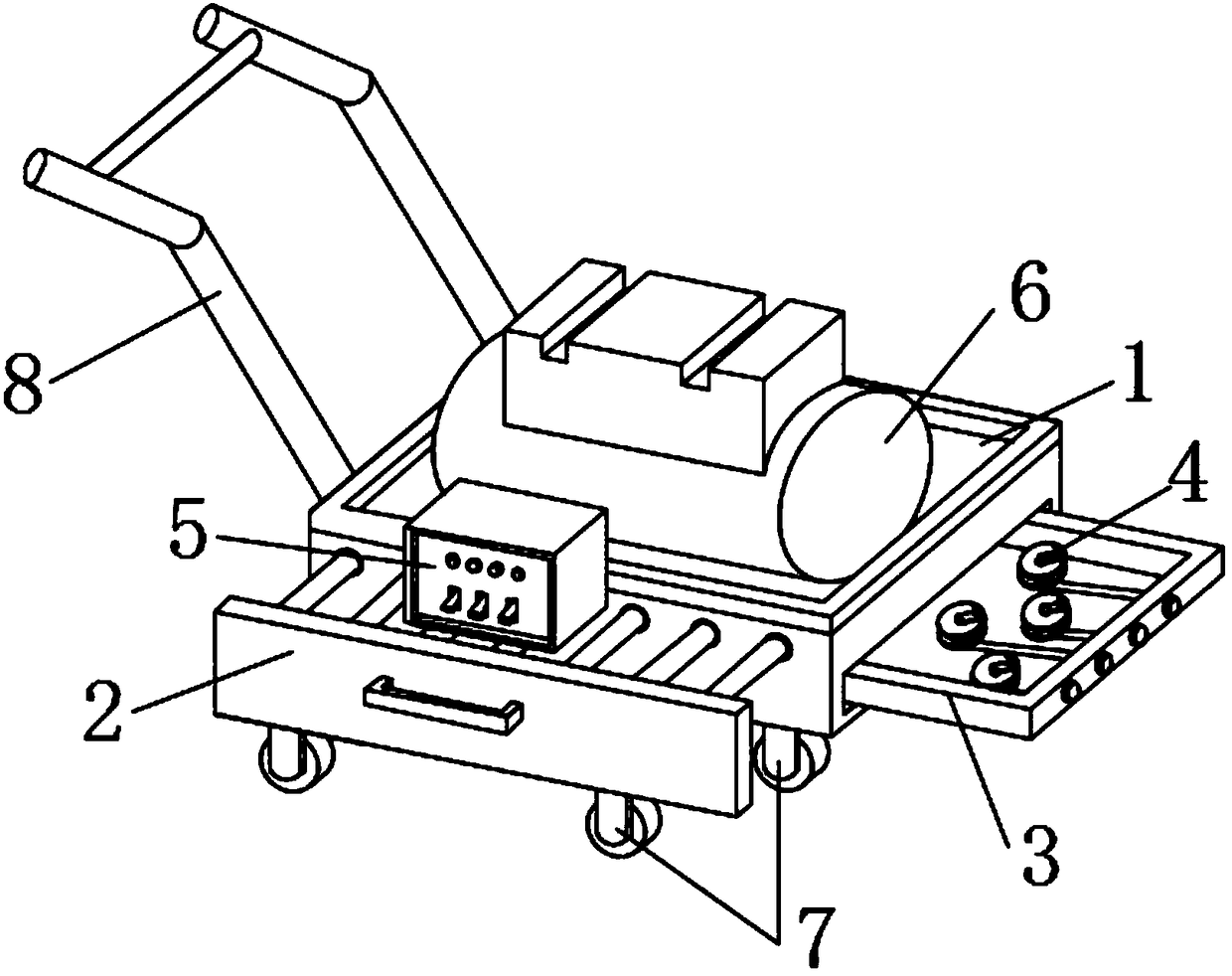

Floor heating cleaning device

InactiveCN108163648APrevent the phenomenon of being entangled and inconvenient to useEasy to useEngineeringAir compressor

The invention discloses a floor heating cleaning device. The floor heating cleaning device comprises a vehicle bottom plate, an air compressor and a digital pulse generating power supply. The inner side of the side surface of the vehicle bottom plate is slidably provided with a side pulling rack, and a main pulling rack is slidably arranged at the end surface of the vehicle bottom plate, the mainpulling rack is positioned below the side pulling rack. The digital pulse generating power supply is fixed on the upper side of the side pulling rack, and the air compressor is fixed on the upper surface of the vehicle bottom plate. Several sets of winding plates are fixed inside the main pulling rack. A pushing hand is fixed on the side opposite to the main pulling rack on the vehicle bottom plate, and a plurality of universal wheels are fixed below the vehicle bottom plate and the side pulling rack. The floor heating cleaning device has the advantages of simple structure, convenient use, orderly use of the floor heating cleaning device, prevention of chaos in the cleaning process, and orderly and reasonable collection and release of the cleaning pipeline.

Owner:四川德顿郎陈暖通设备有限公司

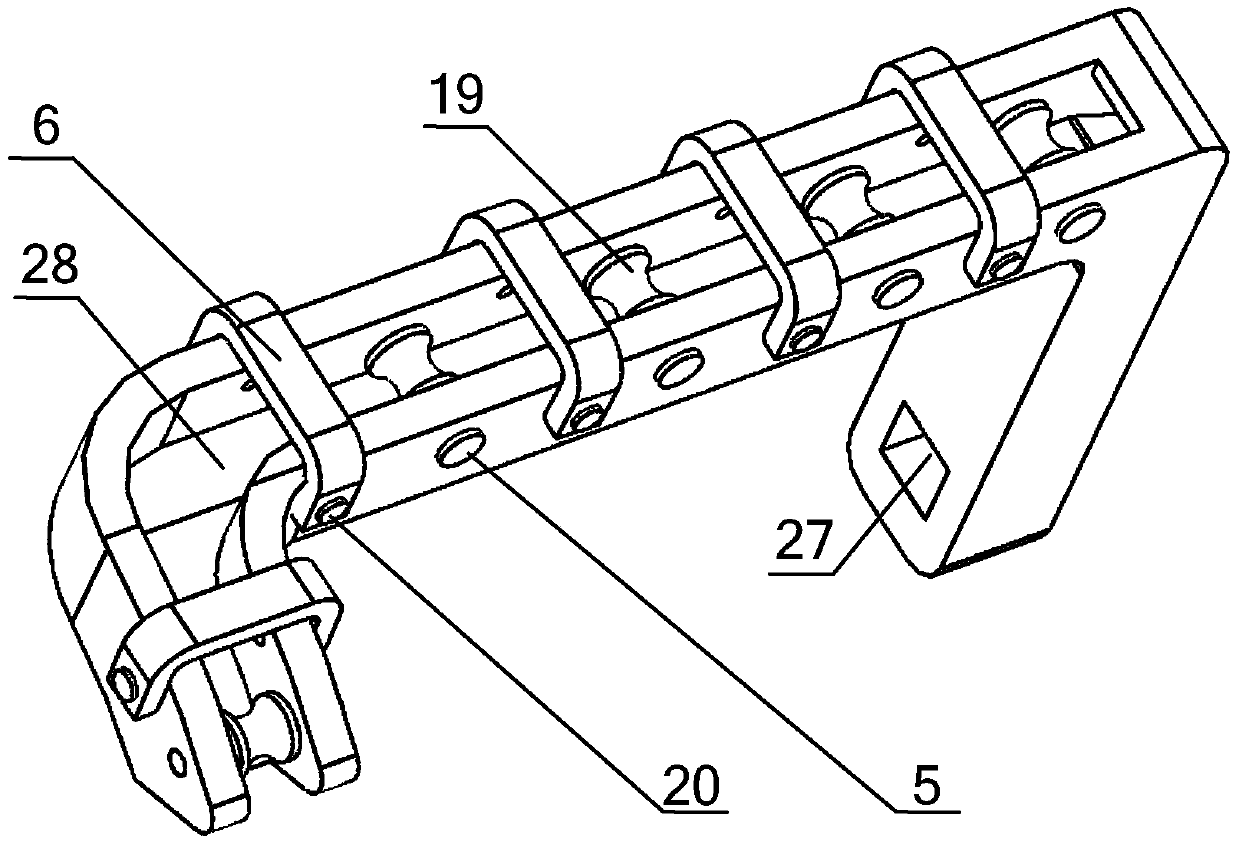

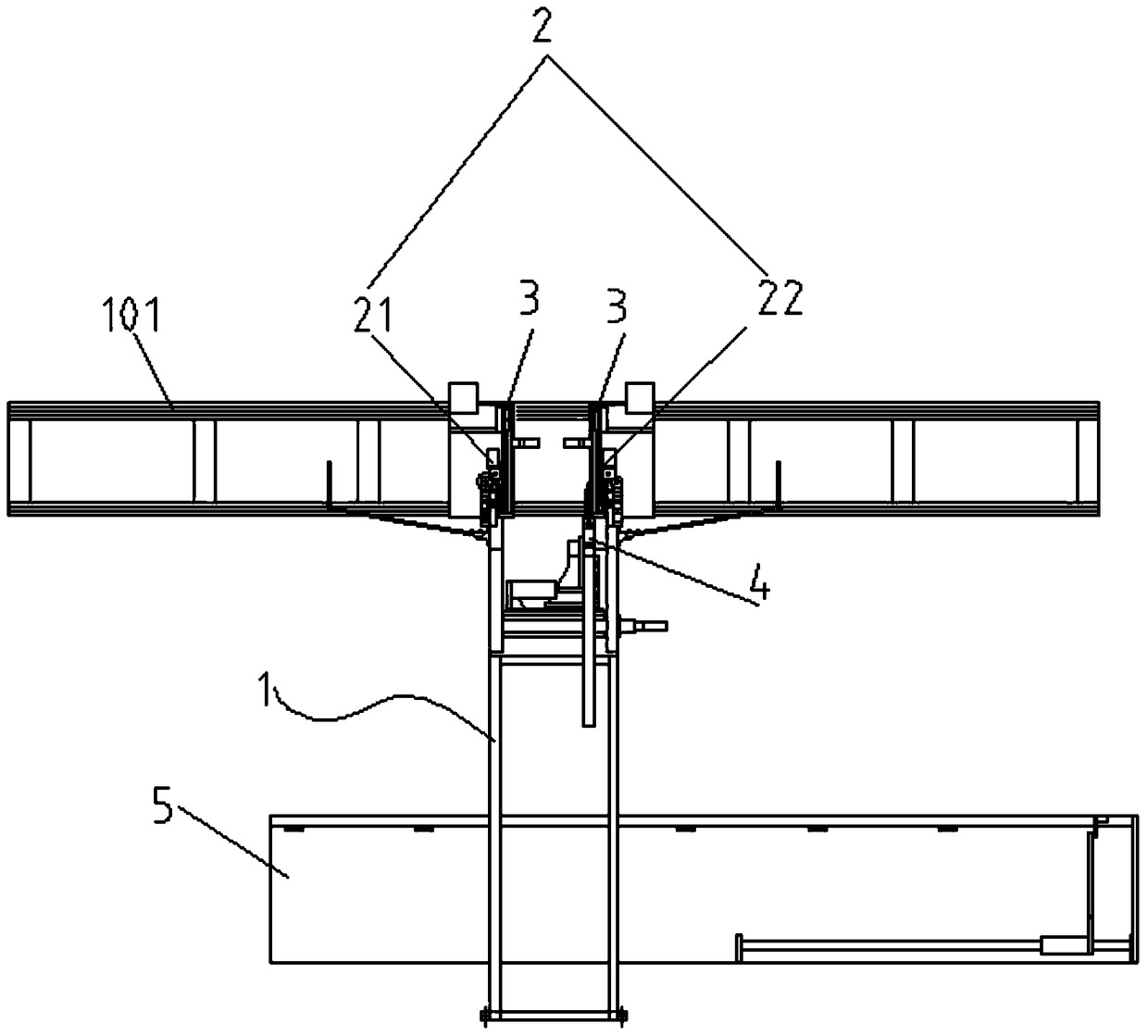

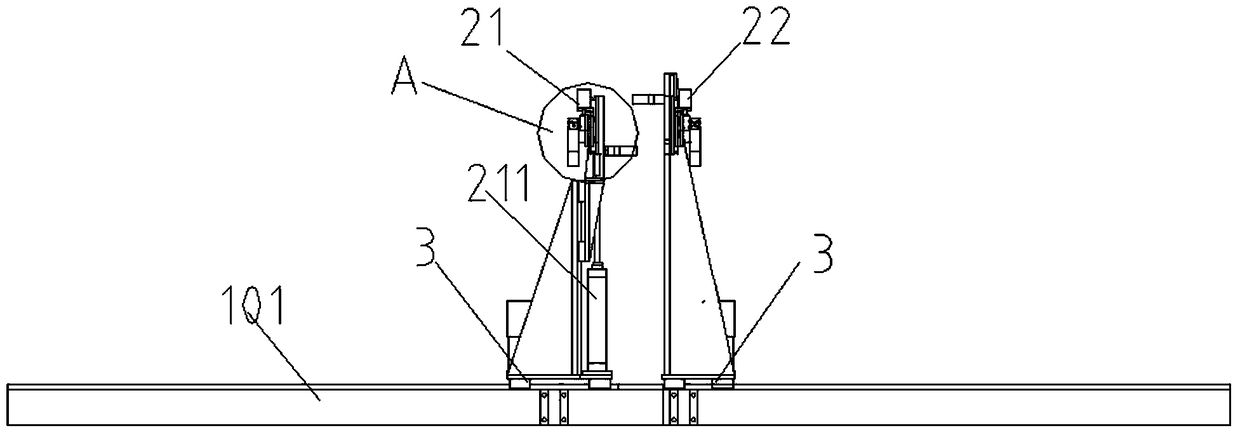

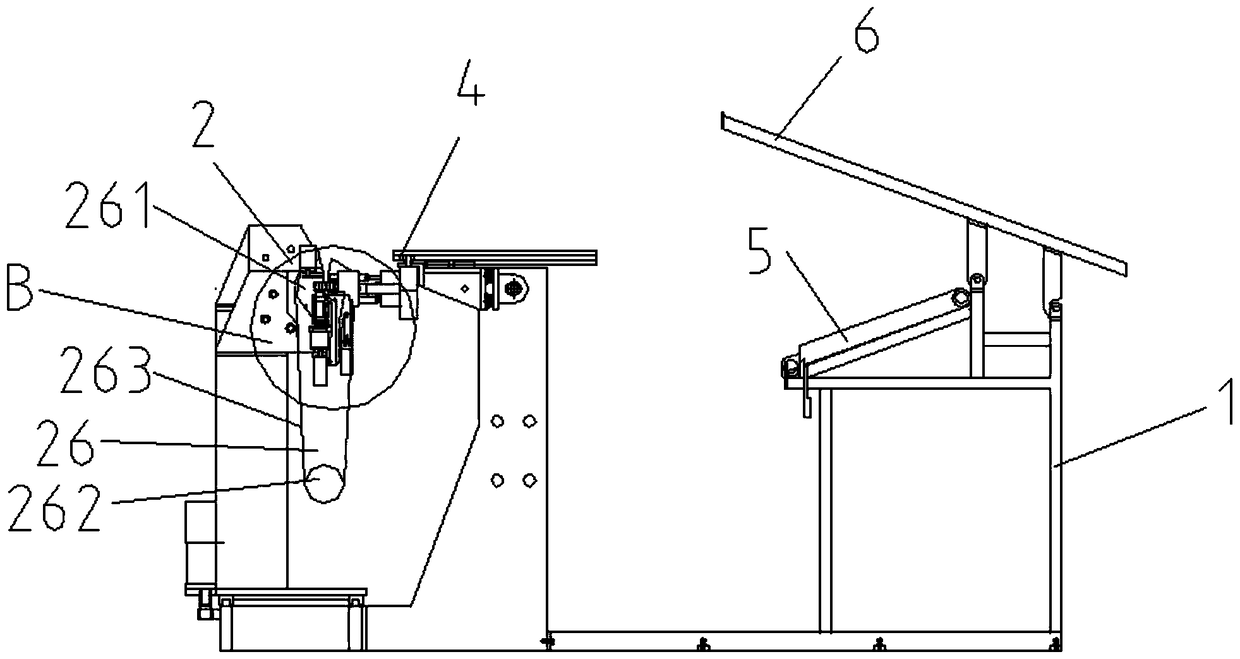

Cable retracting device for wired control robot and cable retracting method

Owner:XIAN UNIV OF SCI & TECH

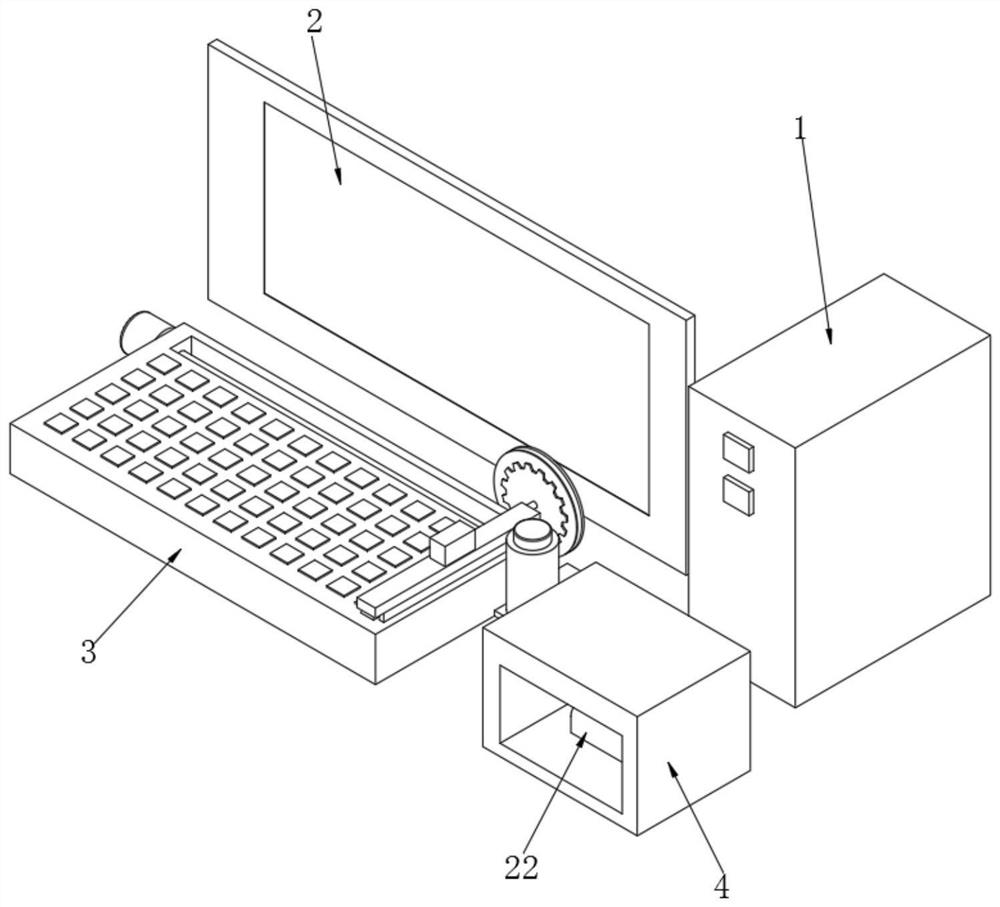

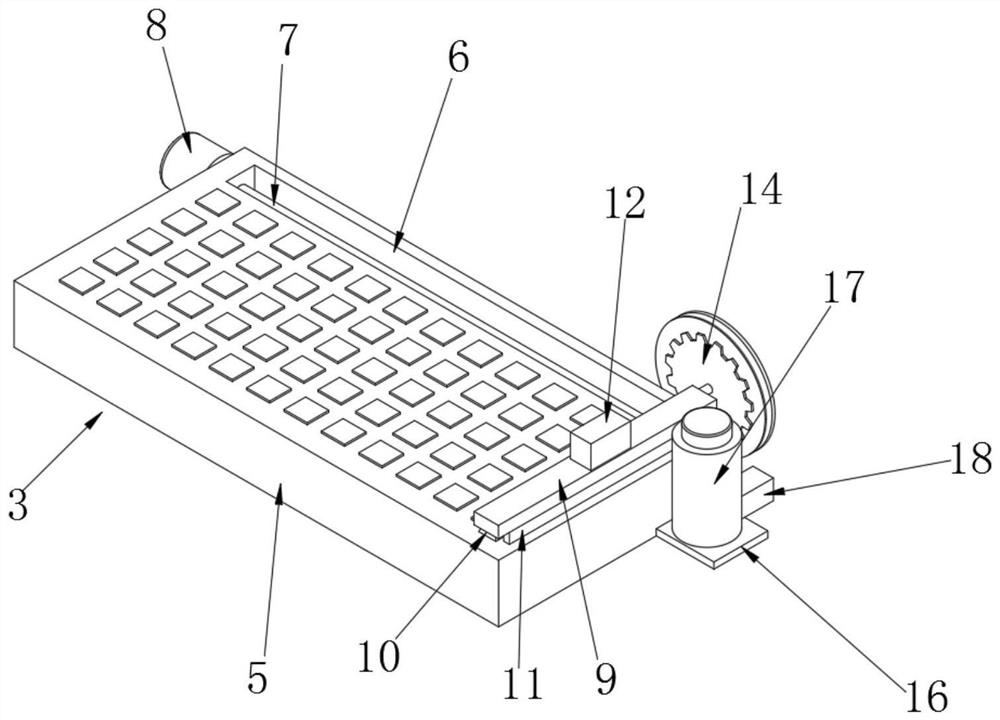

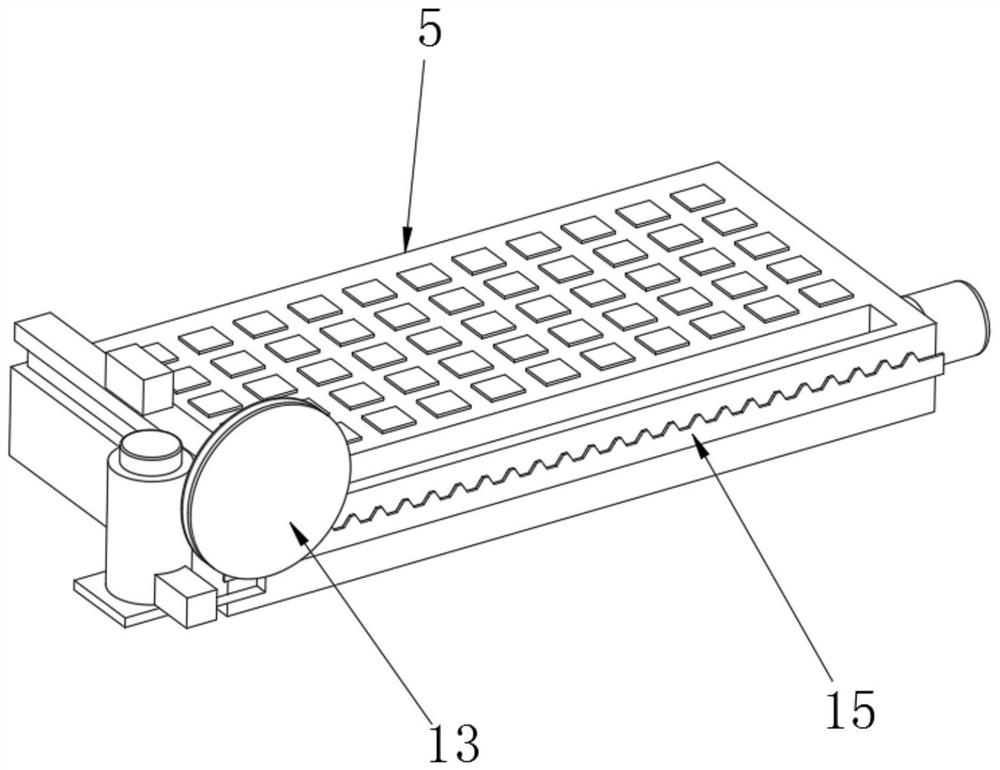

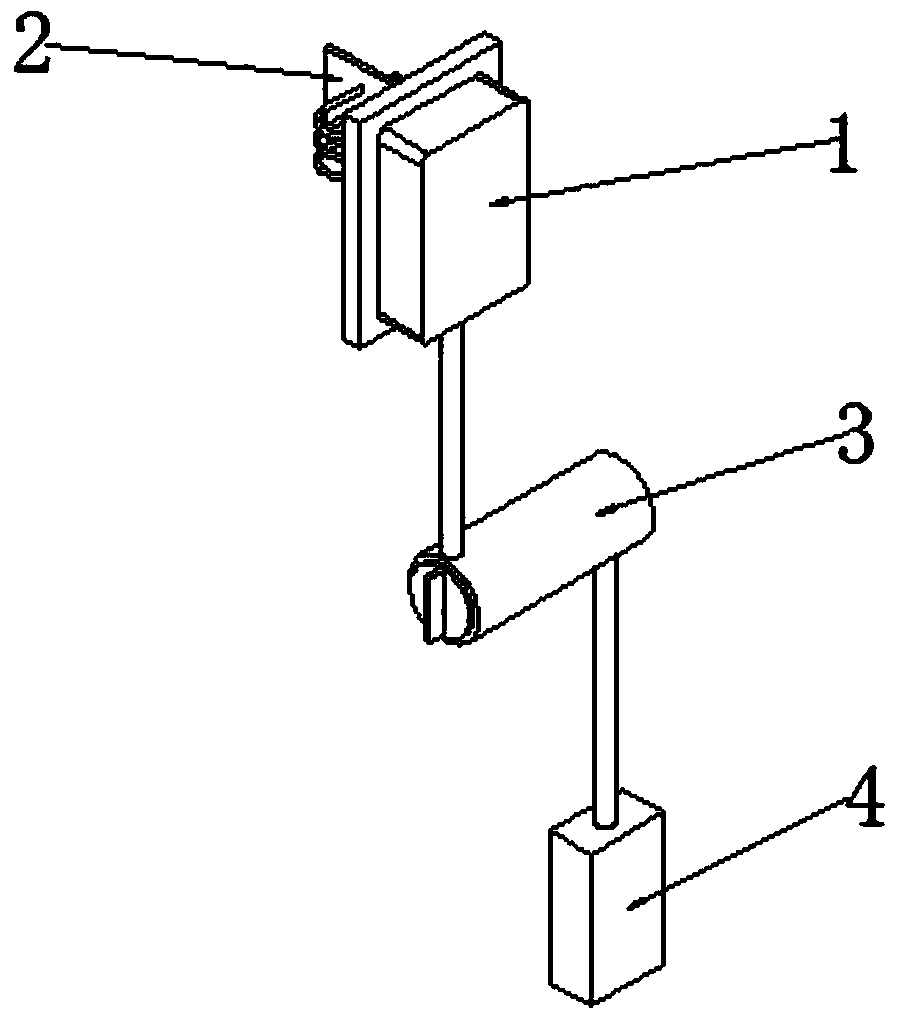

Employment and entrepreneurship teaching system and device

InactiveCN114003132AAvoid indirect contactGuaranteed safe useInput/output for user-computer interactionDrying gas arrangementsPhysicsElectric machinery

The invention relates to an employment and entrepreneurship teaching device which comprises a host, a display screen, a first operating mechanism and a second operating mechanism. A motor works to drive a threaded rod to rotate, then a supporting sliding arm is driven to move from one end of a side groove, and when moving, a liquid pump works to convey disinfectant fluid in a liquid storage box into a groove hole of a rotating rod through a guide pipe, and finally the disinfectant fluid enters a first spraying base through a connecting channel to be sprayed out to disinfect a keyboard, when the supporting sliding arm starts to return to the original position, the liquid pump stops working, the first air heater starts to work to convey hot air into the second spraying base to be sprayed out, the surface of the keyboard is dried, and after the mouse is used, the liquid pump works to convey disinfectant fluid to the spraying head through the internal channel to be sprayed out, so that the mouse is disinfected and cleaned; and then, a second air heater works to convey hot air to a spray head through an internal channel to be sprayed out, the mouse is dried, disinfection of the keyboard and the mouse is completed, indirect contact of a user is avoided, and safe use is guaranteed.

Owner:河南工学院

Wireless network bridge convenient to install and operate

InactiveCN109246489AOrderly retractableEasy to operateNetworks interconnectionSelection arrangementsArchitectural engineeringWireless network

The invention discloses a wireless network bridge convenient to install and operate, and the wireless network bridge comprises a wireless network bridge main body, an installation structure, a connecting mechanism, a power supply box, a power interface, a first network port, and a second network port. One side of the wireless network bridge main body is provided with the installation mechanism, and the bottom of the wireless network bridge main body is provided with the connecting mechanism. The bottom of the connecting mechanism is provided with the power supply box, and the installation mechanism comprises a connecting plate, through holes, a steel rope and a rope clamp. One body of the wireless network bridge main body is provided with the connecting plate, and one side of the connecting plate is symmetrically provided with through holes in a uniform manner. Two ends of the steel rope pass through the through holes, and an outer side of the steel rope is provided with the rope clampat an outside of the connecting plate in a sleeving manner. The wireless network bridge can be adjusted for installation according to the supports in different sizes through the steel rope of the installation mechanism, so the wireless network bridge is wide in application range, and is convenient to operate. Meanwhile, the connecting mechanism can achieve the ordered winding and unwinding of a wire, thereby facilitating the actual operation and application.

Owner:合肥超必达网络技术服务有限公司

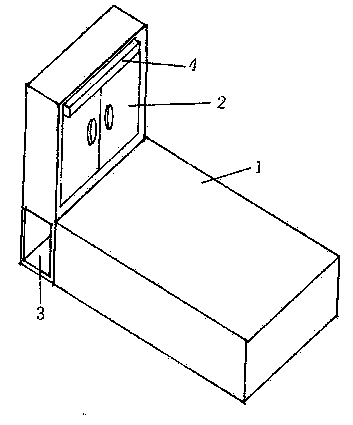

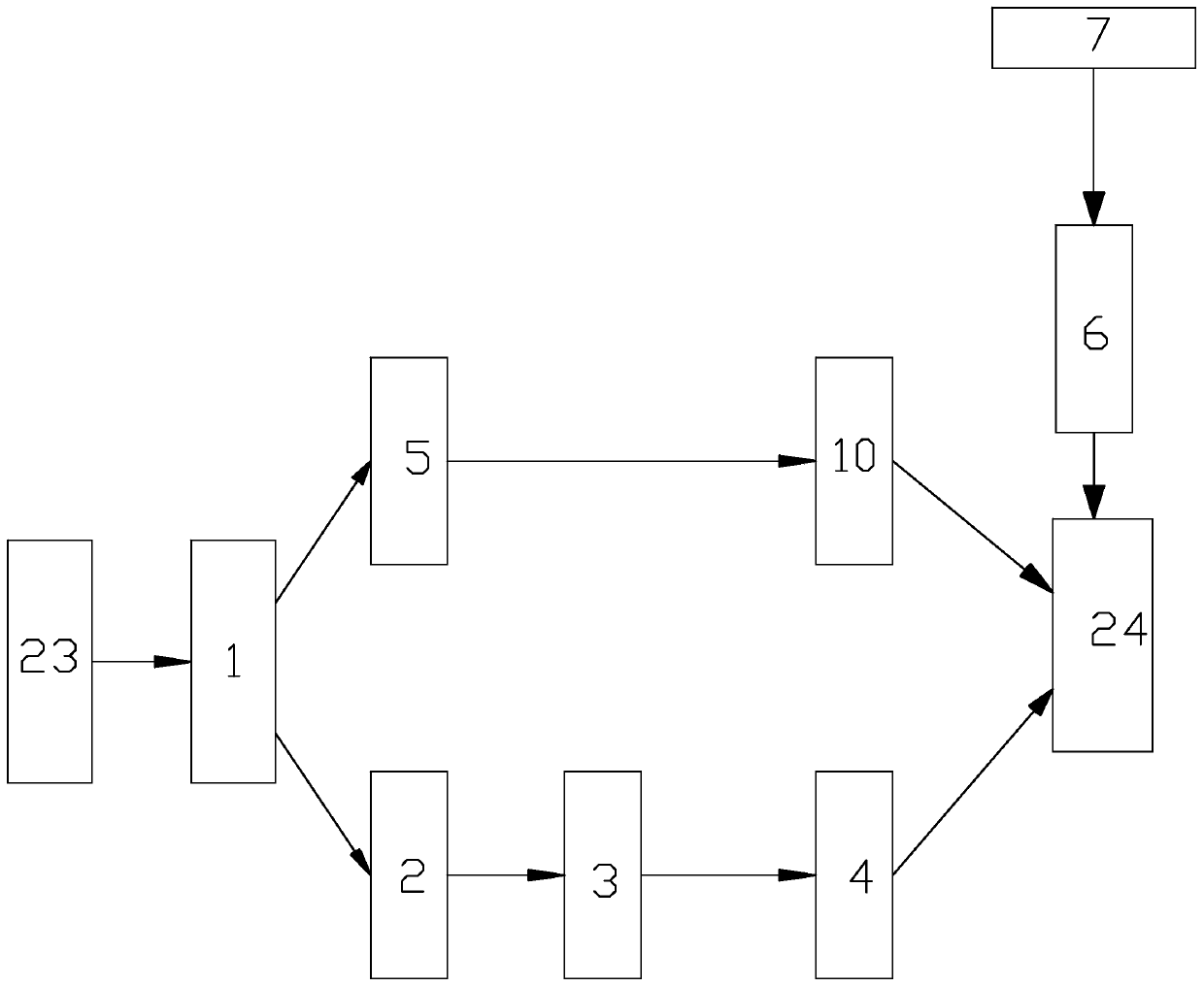

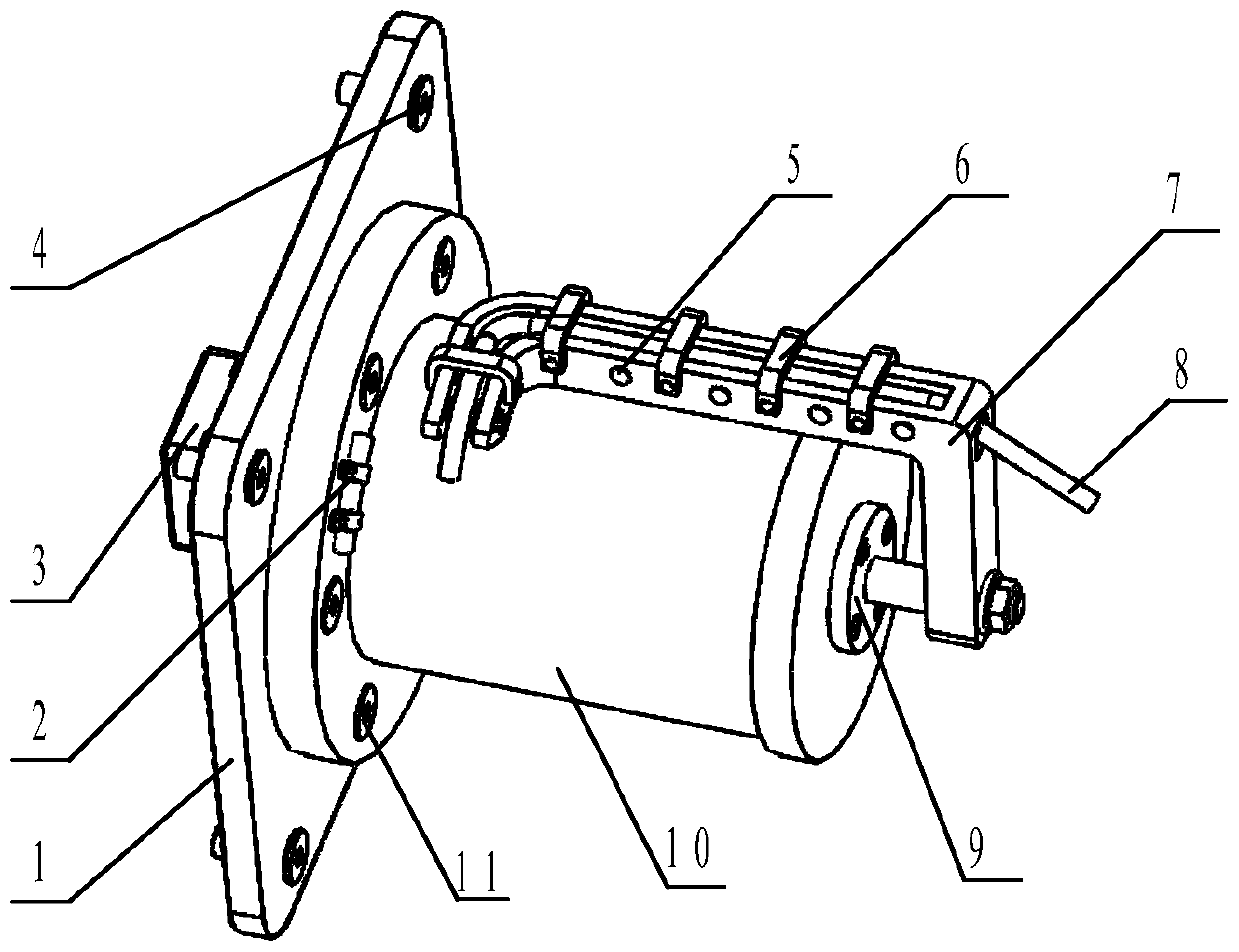

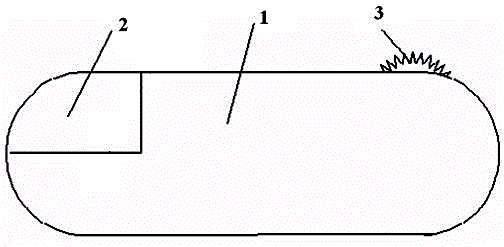

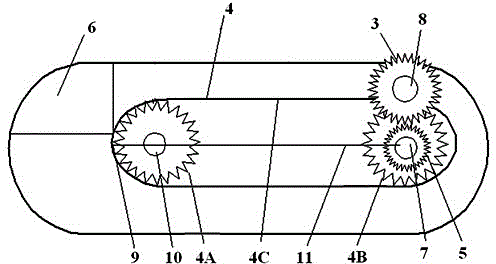

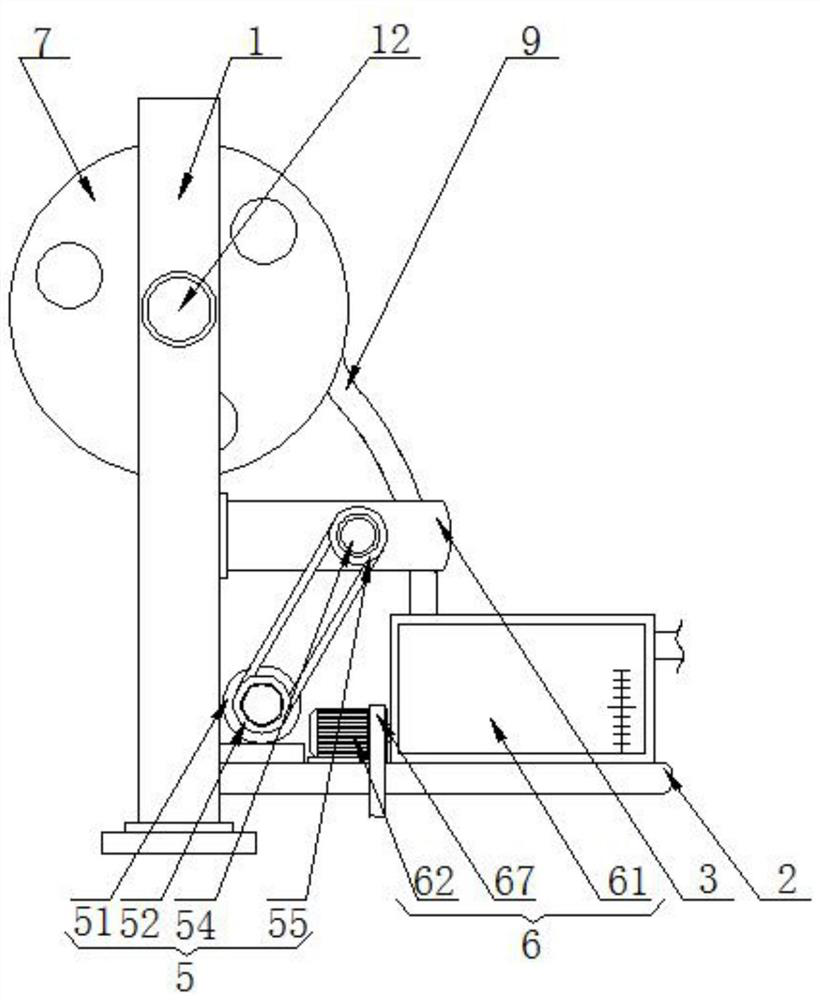

Earphone built-in structure and corresponding device

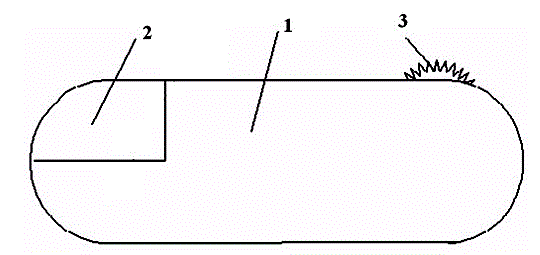

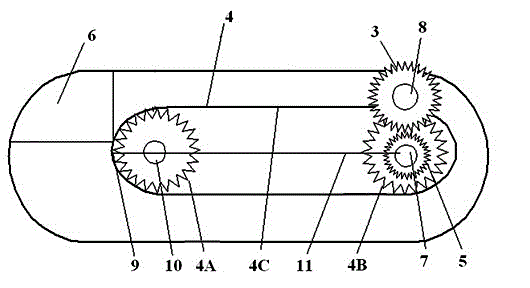

InactiveCN102917293ASolve carrying problemsExtended service lifeEarpiece/earphone attachmentsEngineeringHeadphones

The invention provides an earphone built-in structure which comprises a first back cover (1) closely containing internal space of a casing of the earphone built-in structure, a second back cover (2) closing an earphone slot, a manual gear (3) at least partially exposed, a rotatable part (4) for an earphone wire to wind, a transmission gear (5) meshed with the manual gear (3) and driving the rotatable part (4) to rotate to achieve winding-up and paying-off of the earphone wire, the earphone slot (6) used for containing an earphone receiver and an earphone jack (7) capable of containing a whole earphone plug. An electronic device with the earphone built-in structure is further provided. The structure achieves the effect that an earphone is built in the internal space of the casing of the electronic device, resolves the carrying problem of the earphone, is capable of orderly conducting winding-up and paying-off of the earphone wire and is favorable for prolonging service life of the earphone.

Owner:BEIJING UNION UNIVERSITY

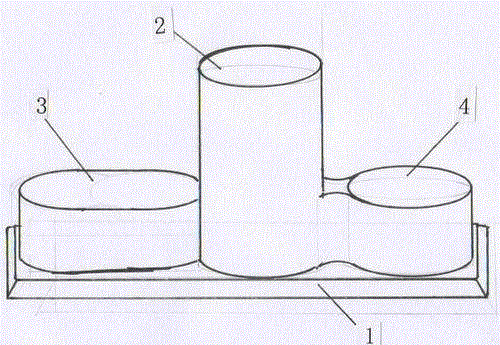

Seat type stationery assembly

InactiveCN105751788AAvoid accidental spillsOrderly retractableWriting accessoriesBottle holdersIndustrial engineering

The invention provides a seat type stationery assembly; a rectangular pedestal is fixedly provided with a pen container, a writing case and a cup sleeve; the writing case, the pen container and the cup sleeve used for placing the cup use the same pedestal as one body, so various stationery and writing pens can be well sorted and placed in order, and the cup can be stably placed on the pedestal; the seat type stationery assembly is convenient in usage, can improve work and learning efficiency, and can prevent the cup from carelessly spilling.

Owner:ZHUGELIANG MIDDLE SCHOOL

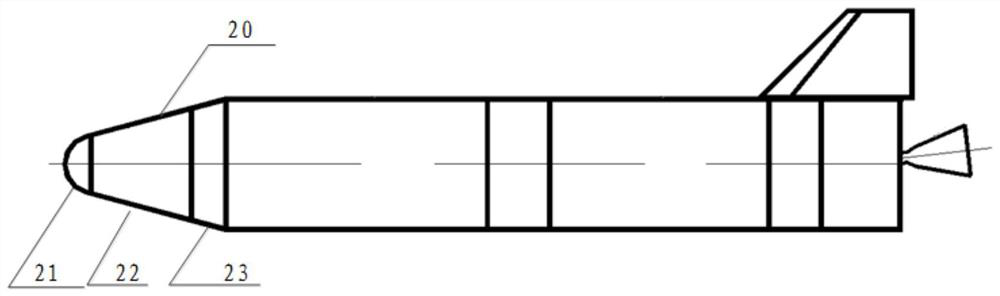

Precise parafoil recovery system and method for safety control of landing area of booster

PendingCN114476142ATroubleshoot structural adaptationsDeceleration attitudeSystems for re-entry to earthCosmonautic landing devicesAutomatic controlSafety control

The invention provides an accurate parafoil recovery system and method for safety control of a booster falling area, a sectional connection and separation and centralized layout design is adopted, an original integrated booster nose cone is divided into an end cap, a nose cone middle section and a nose cone bottom section, a stabilizing parachute is mounted in the end cap, and the stabilizing parachute is mounted in the nose cap. Other products of the recovery system are intensively mounted on the nose cone bottom section through a bearing structure, so that the problem of structural adaptability change of an existing booster is solved; the recovery system adopts a segmented homing control strategy of multiple target points and multiple obstacle avoidance areas, the drop point precision under the obstacle avoidance condition is improved, obstacle avoidance and accurate landing of the booster are achieved, meanwhile, the recovery system has two control modes, namely an automatic control mode and a ground manual control mode, redundant backup is achieved, and the system reliability is improved.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

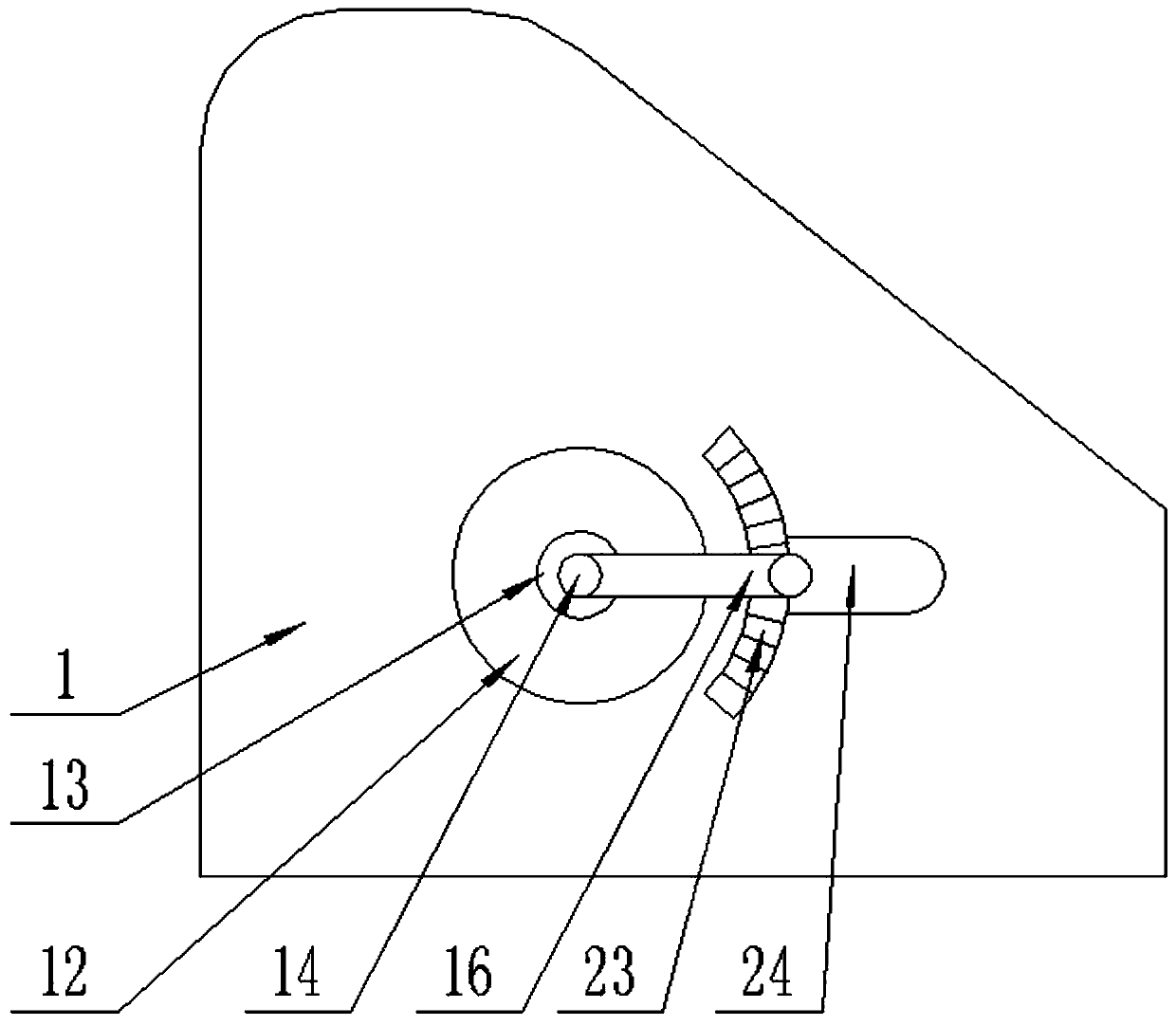

Pipe bending machine

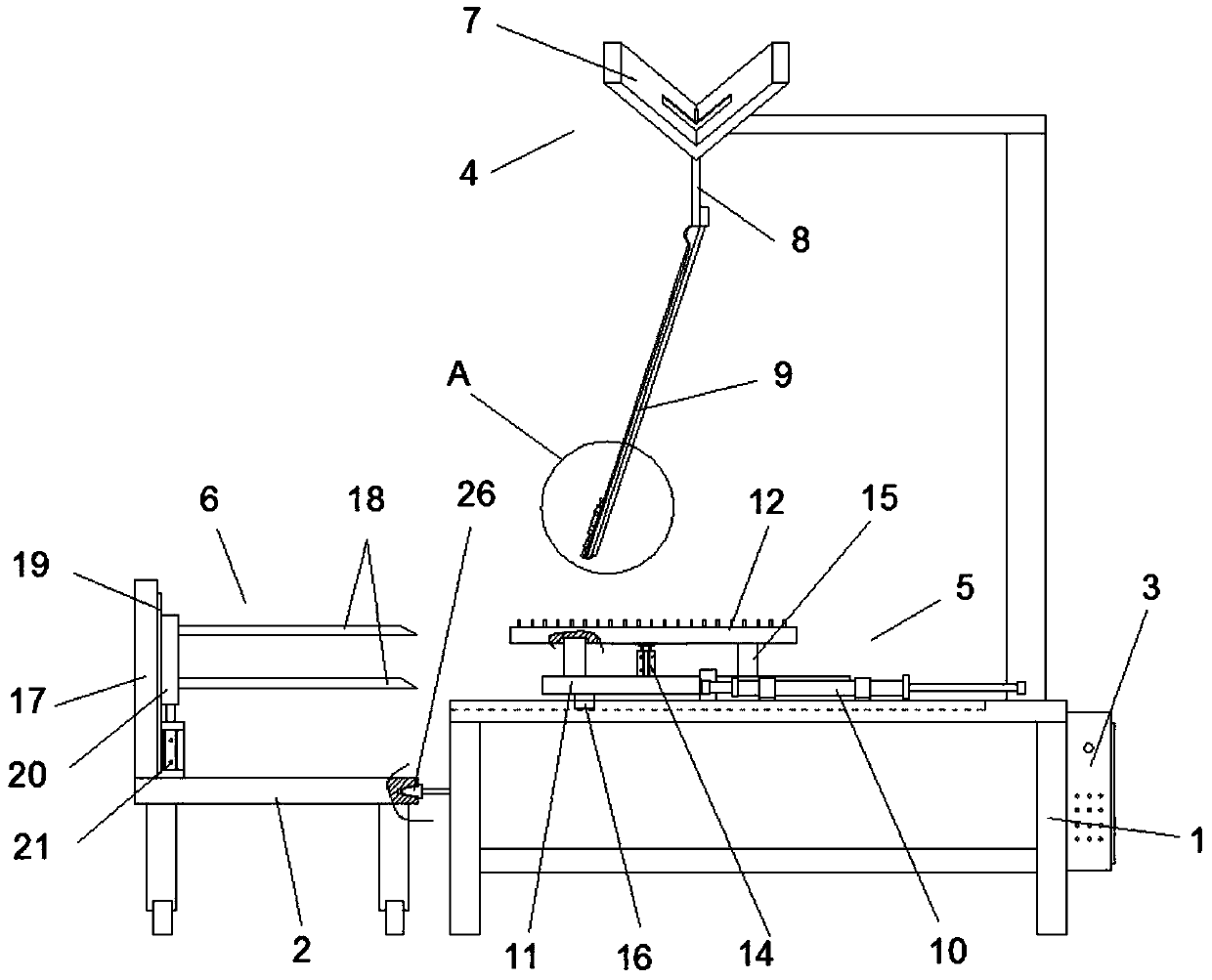

ActiveCN106825156AImprove work efficiencyLow costMetal-working feeding devicesPositioning devicesElectric machineryGear transmission

The invention discloses a pipe bending machine. The pipe bending machine comprises a machine body, a machine head, a moving base, a feeding device, a servo motor, a pneumatic control power system and a PLC control system. The machine body comprises a longitudinal guide rail, and the moving base slides on the longitudinal guide rail. The machine head comprises an open type disc dual-gear transmission structure and an XY plane 180-degree pipe bending mechanism. The open type disc dual-gear transmission structure comprises an XZ plane 360-degree rotating mechanism and a pipe receiving device. The XY plane 180-degree pipe bending mechanism can rotate relative to the XZ plane 360-degree rotating mechanism. The XZ plane 360-degree rotating mechanism can drive the XY plane 180-degree pipe bending mechanism to rotate together. The XZ plane 360-degree rotating mechanism comprises a V-shaped opening. The machine head comprises a left machine head body and a right machine head body which are arranged on two sides of the longitudinal guide rail. At least one machine head body is provided with an up-down adjusting mechanism. The left machine head body and the right machine head body can bend pipes simultaneously according to different paths through PLC control. The two machine head bodies are used for automatically bending pipes at the same time, so that efficiency is high. The machine head on one side can be vertically adjusted to achieve avoidance, interference is avoided, and the shortest linear section of the middle of a bent pipe is obtained.

Owner:SHANGHAI LEAO MACHINERY DESIGN CO LTD

Writing case capable of conveniently storing multiple pens

Owner:YICHENG NO 3 SENIOR HIGH SCHOOL

a pipe bending machine

ActiveCN106825156BImprove work efficiencyImprove management efficiencyMetal-working feeding devicesPositioning devicesControl powerControl system

The invention discloses a pipe bending machine. The pipe bending machine comprises a machine body, a machine head, a moving base, a feeding device, a servo motor, a pneumatic control power system and a PLC control system. The machine body comprises a longitudinal guide rail, and the moving base slides on the longitudinal guide rail. The machine head comprises an open type disc dual-gear transmission structure and an XY plane 180-degree pipe bending mechanism. The open type disc dual-gear transmission structure comprises an XZ plane 360-degree rotating mechanism and a pipe receiving device. The XY plane 180-degree pipe bending mechanism can rotate relative to the XZ plane 360-degree rotating mechanism. The XZ plane 360-degree rotating mechanism can drive the XY plane 180-degree pipe bending mechanism to rotate together. The XZ plane 360-degree rotating mechanism comprises a V-shaped opening. The machine head comprises a left machine head body and a right machine head body which are arranged on two sides of the longitudinal guide rail. At least one machine head body is provided with an up-down adjusting mechanism. The left machine head body and the right machine head body can bend pipes simultaneously according to different paths through PLC control. The two machine head bodies are used for automatically bending pipes at the same time, so that efficiency is high. The machine head on one side can be vertically adjusted to achieve avoidance, interference is avoided, and the shortest linear section of the middle of a bent pipe is obtained.

Owner:SHANGHAI LEAO MACHINERY DESIGN CO LTD

Bed provided with wardrobe

InactiveCN105640139AOrderly retractableAvoid the phenomena that affect the delay in getting up in the morningBedstandsEngineering

The present invention provides a bed provided with a wardrobe, wherein the side end of the bed body is provided with the wardrobe adopted as the backrest, and a shoe cabinet is connected below the wardrobe. With the arrangement of the present invention, when people goes to bed, the worn clothes are undressed and can be placed into the wardrobe, such that the clothes can be worn conveniently and timely during getting-up in the morning, the phenomenon that the clothes littering affects the getting-up in the morning to cause the delay can be avoided, and the clothes can be placed and received orderly.

Owner:YICHENG NO 3 SENIOR HIGH SCHOOL

Earphone built-in structure and corresponding device

InactiveCN102917293BSolve carrying problemsExtended service lifeEarpiece/earphone attachmentsMechanical engineeringElectronic equipment

Owner:BEIJING UNION UNIVERSITY

Retraction lever and tent

InactiveCN101109242BRigid-flexible conversion is convenientOrderly retractableTents/canopiesEngineeringMechanical engineering

The invention relates to a shrinkage rod and a tent made with the shrinkage rod. The shrinkage rod comprises a plurality of rigid skeleton-joints with two axial ends and sides, the concave and convex parts of all skeleton-joints are connected in series along the through holes by two flexible ropes sequentially; the shrinkage rod additional comprises a storage section located at one end of the rodfor storing the rod in a coiled way. The storage section is provided with a rotatable rotary shaft, and a rod-storage sleeve is fixed on the rotary shaft in linkage way in form of intermittent drive;one end of the two flexible ropes pass the rod-storage sleeve and are fixed on the rotary shaft; the rod-storage sleeve is borne rotatably between two rope-protecting boards at two ends of the sleeve; a tension part is provided at another end of the shrinkage rod; another end of the two flexible ropes are fixed on the tensioning part. The shrinkage rod can be retracted and released sequentially, a tent made with the rod has the advantage of the smaller retracted size comparing with a prior tent.

Owner:陈想年

Cable retracting method for wired control coal mine rescue detection robot

ActiveCN107139159BCompact structureNovel and reasonable designManipulatorControl signalElectric machinery

The invention discloses a wire-control coalmine rescue detection robot and a cable extension and retraction method thereof. The wire-control coalmine rescue detection robot comprises a robot body and a cable extension and retraction box arranged at the top of the robot body. A cable extension and retraction device is arranged in the cable extension and retraction box. The robot body comprise a robot body cabinet, two travelling track assemblies and four swinging arm track assemblies. The robot body cabinet comprises a lower cabinet cavity, an upper cabinet cavity, a sensor cavity, three gear cavities and two supporting wheel cavities. The cable extension and retraction device comprises a cable extension and retraction motor, a synchronous belt transmission mechanism connected with an output shaft of the cable extension and retraction motor, and a cable winding mechanism and a cable arranging mechanism which are both connected with the synchronous belt transmission mechanism. The cable extension and retraction method of the wire-control coalmine rescue detection robot comprises the steps of cable connection and cable extension and retraction. By adoption of the wire-control coalmine rescue detection robot and the cable extension and retraction method thereof, cables are extended and retracted in order and are appropriate in degree of tightness, cable entanglement and breaking are reduced, and stable transmission of control signals, relevant sensor information and a power supply can be guaranteed.

Owner:XIAN UNIV OF SCI & TECH

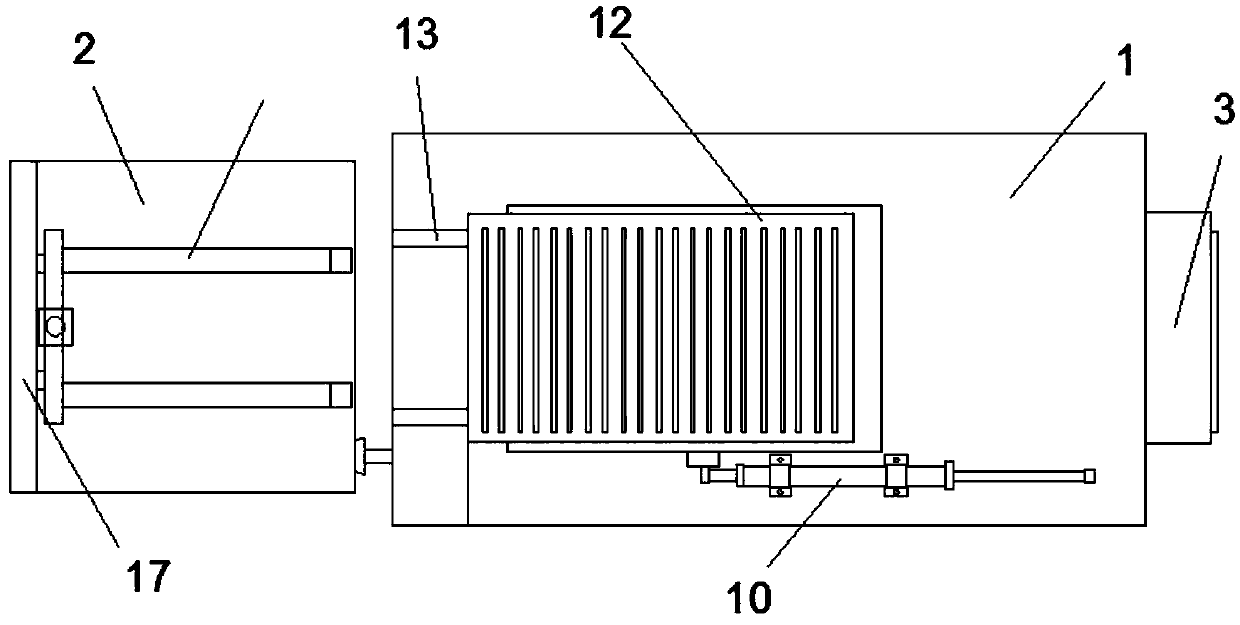

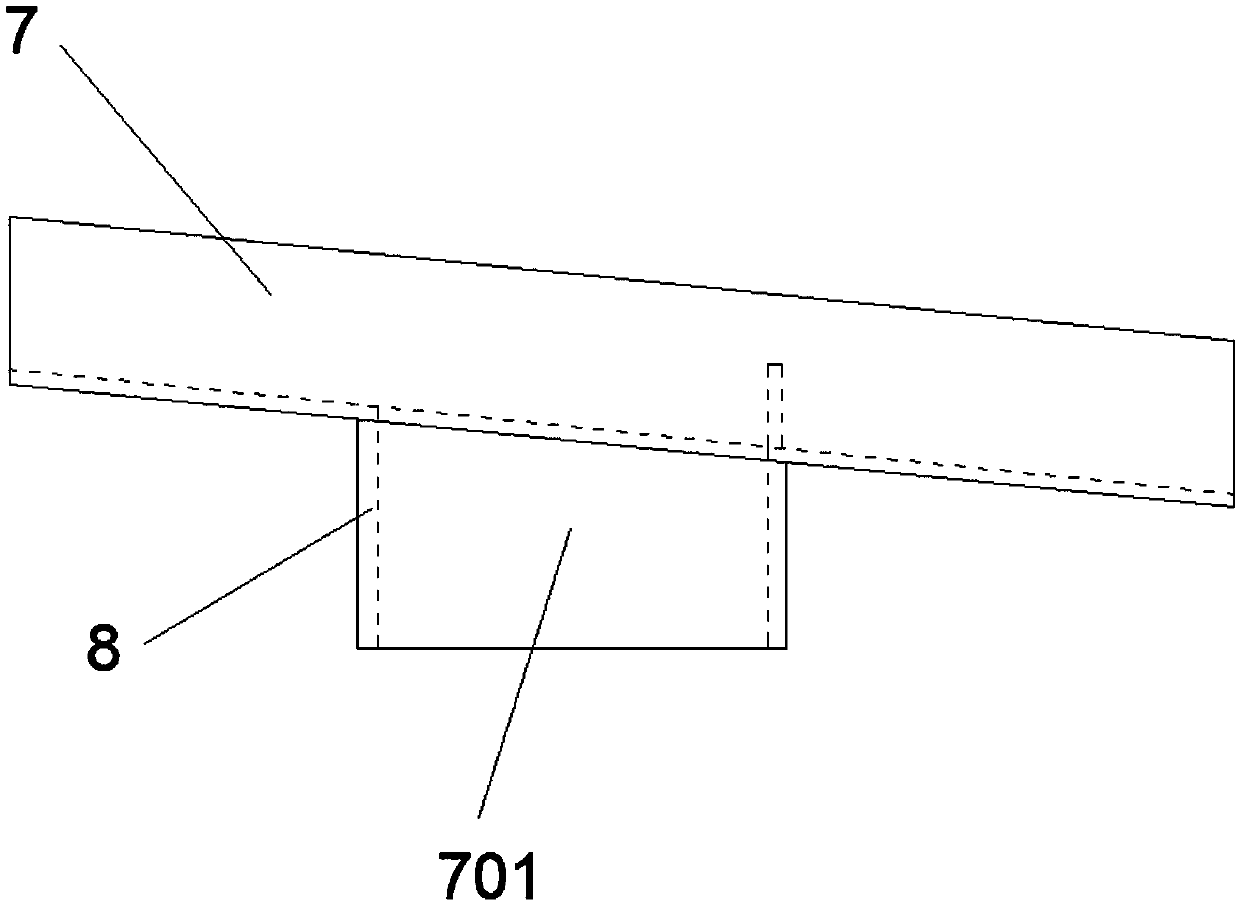

An oil seal spring automatic blanking finishing mechanism

ActiveCN107662808BOrderly retractableReduce defective rateConveyor partsLeveling mechanismEngineering

The invention relates to the field of automation equipment, and provides an oil seal spring dropped material automatic arrangement mechanism. The mechanism comprises a first support base, a second support base and an electric control cabinet, and further comprises a dropped material leveling mechanism; a placing and conveying mechanism is installed on the first support base, a material disc replacing mechanism is installed at the top of the second support base, the dropped material leveling mechanism comprises a V-shaped material plate, a reshaping plate and an arranging structure, the V-shaped material plate is fixed on the first support base through a support, the reshaping plate is vertically fixed to the top of the V-shaped material plate, the arranging structure is aslant installed atthe bottom of the reshaping plate, and a dropped material groove is formed in the center of the top of the V-shaped material plate and runs through the reshaping plate; the placing and conveying mechanism comprises a feeding air cylinder, a mobile plate and a material disc, and slide grooves are symmetrically formed in the top of the first support base. Through the oil seal spring dropped material automatic arrangement mechanism, the problem in the prior art is solved that oil seal springs are usually stored together in a box body after being shaped through processing machinery, thus the oilseal springs are crossed together, and the defective percentage is increased and the usage in the next procedure is inconvenient.

Owner:ANHUI HONGQIAO METAL MFG

Novel winding device and method of use thereof

ActiveCN105173926BReduce the difficulty of operationReduce manufacturing costFilament handlingEngineeringConductor Coil

The invention discloses a novel winding device and a use method for the novel winding device. The winding device comprises a winding mechanism, a wire arranging mechanism, a guiding part and a sliding part. The winding mechanism comprises a winding pipe. The winding pipe comprises a winding pipe body, a movable side plate and a fixed side plate, wherein the winding pipe body can be rotationally jointed between the movable side plate and the fixed side plate. The wire arranging mechanism comprises a wire arranging pipe. The wire arranging pipe is provided with a wire arranging pipe cavity and a guiding groove, and the guiding groove is communicated with the wire arranging pipe cavity and the outside and downwards faces the winding pipe body. The guiding part is horizontally installed in the wire arranging pipe cavity. The guiding part comprises a guiding shaft and a protruding ridge part which protrudes out of the guiding shaft and integrally extends in a ring shape. A preset route is formed between the protruding ridge part and the guiding groove. The sliding part is reversely arranged in the guiding groove and extends towards the winding pipe body from the guiding part so as to be used for conducting reciprocating wire arranging. The two sides of the sliding part are transversely internally tangent to the inner side and the outer side of the protruding ridge part respectively so that the sliding part can slide along the preset route to conduct reciprocating wire arranging relative to the rotation of the winding pipe.

Owner:JUNHE PUMPS HLDG

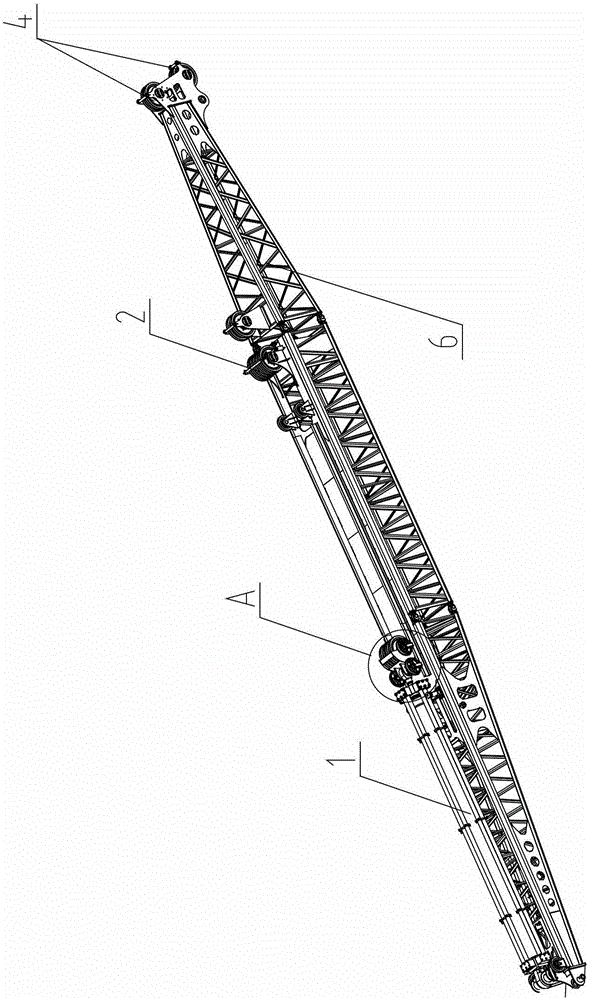

A dynamic compaction machine and its guideable lifting mechanism

ActiveCN103205960BStable supportEffective constraintsSoil preservationMaintainabilityBlock and tackle

Owner:SANY HEAVY IND CO LTD (CN)

Pipe arrangement device for suction reel of combined sewage suction truck

InactiveCN111794361AImprove work efficiencyAvoid affecting retraction workSewer systemsCouplingElectric machinery

The invention discloses a pipe arrangement device for a suction reel of a combined sewage suction truck, and belongs to the technical field of sewage suction trucks. The pipe arrangement device for the suction reel of the combined swage suction truck comprises a cross beam and a fixing plate fixedly connected to the bottom of one side of the cross beam, a first vertical plate and a second verticalplate are fixedly connected to a front side and a back side of one side of the fixing plate respectively, a pipe arrangement assembly is disposed at the top of the fixing plate, and a cleaning assembly is fixedly connected to the other side of the top of the fixing plate; and the pipe arrangement assembly comprises a motor, the bottom of the motor is fixedly connected with one side of the top ofthe fixing plate through a connecting block, and a first belt wheel is fixedly connected to one end of an output shaft of the motor through a coupling. According to the pipe arrangement device for thesuction reel of the combined sewage suction truck, sewage suction pipes can be stretched and withdrawn in order through the pipe arrangement assembly when stretched and withdrawn, the situation thatthe flexible pipes are wound and stacked on the reel and consequentially affect subsequent stretching and withdrawing is avoided, time and labor are saved, and the working efficiency of the sewage suction truck in the subsequent stage is improved.

Owner:武汉运盛特种汽车制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com