Rare earth doped hydroxyfluorapatite monocrystal nanometer wire and preparation method thereof

A fluorine-containing hydroxyapatite, single-crystal nanotechnology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problems of unseen, crystallinity, homogeneity, monodispersity, Nano-size and efficiency cannot achieve optimization and other problems, and achieve the effect of stable product quality, low cost and good process repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, the preparation of single crystal nanowire

[0027] (1) Mix 3mL of 0.28M calcium nitrate aqueous solution, 0.3mL of 0.28M ytterbium nitrate aqueous solution, 0.3mL of 0.28M sodium fluoride aqueous solution, 3mL of 0.16M sodium phosphate aqueous solution, 0.8g of sodium hydroxide, 8mL of anhydrous Add ethanol and 20mL of oleic acid into a 50mL polytetrafluoroethylene hydrothermal reaction kettle, and stir evenly. In the above reaction system, the molar ratio of sodium phosphate, sodium fluoride, ytterbium nitrate and calcium nitrate is 0.57:0.1: 0.1:1, the pH of the system is 6.5.

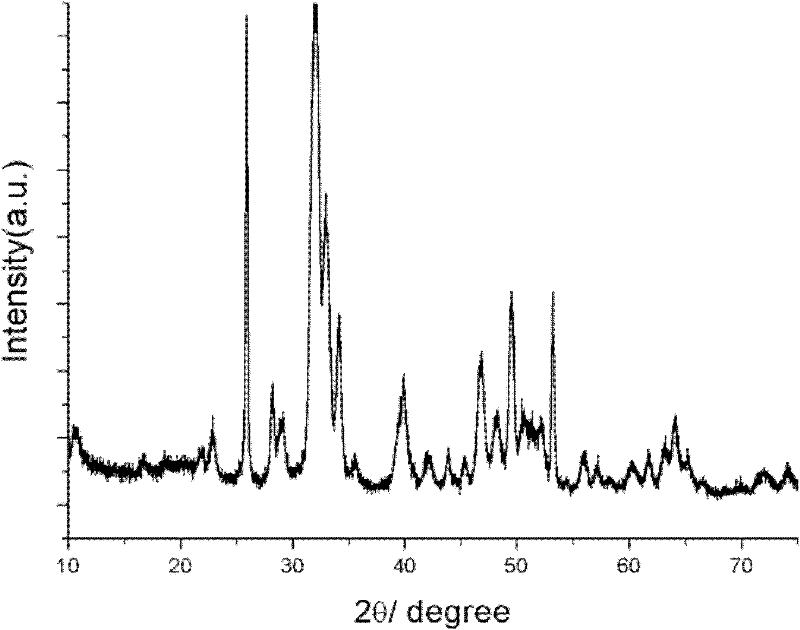

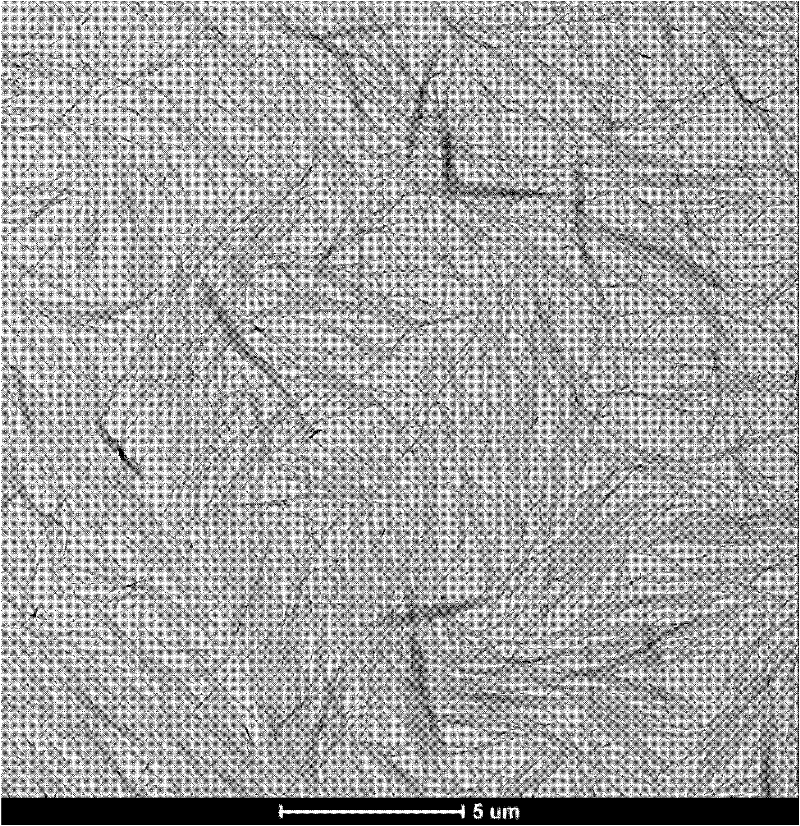

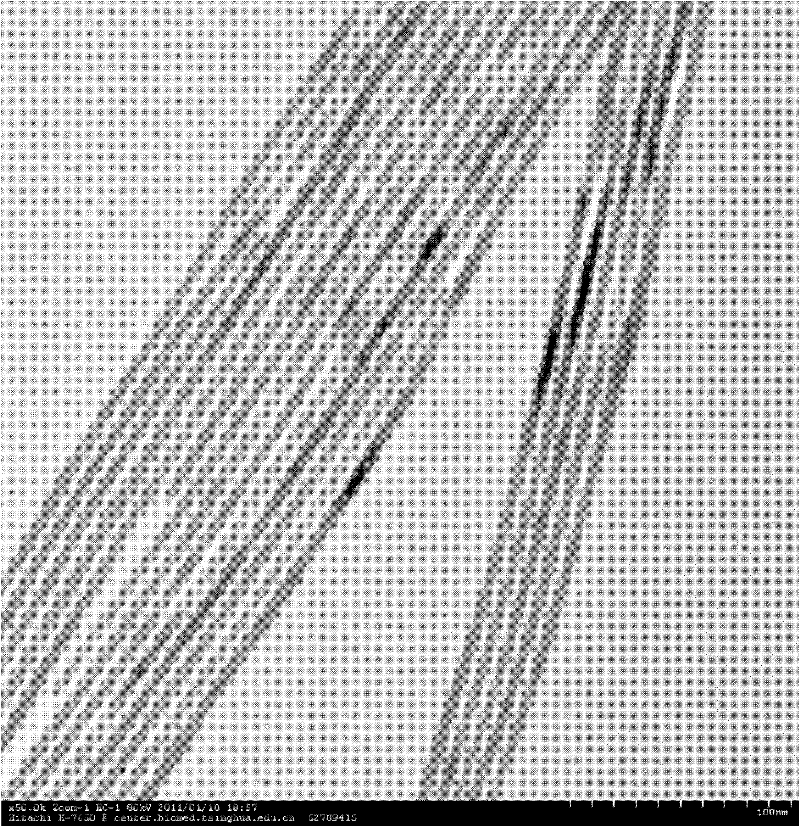

[0028] (2) Seal the reactor in (1), and react at 150° C. for 36 hours. Then cool to room temperature, open the reactor, wash with absolute ethanol and chloroform, and dry to obtain the product powder. The product is identified as hydroxyapatite by X-ray powder diffraction, and the powder X-ray diffraction results are as follows: figure 1 shown; the material morphology was obt...

Embodiment 2

[0029] Embodiment 2, the preparation of single crystal nanowire

[0030] (1) 0.28M calcium nitrate aqueous solution 3mL, 0.28M lanthanum nitrate aqueous solution 0.3mL, 0.28M sodium fluoride aqueous solution 0.45mL, 0.16M sodium hydrogen phosphate aqueous solution 3mL, 1.2g sodium hydroxide, 8mL anhydrous Add water ethanol and 20mL of oleic acid into a 50mL polytetrafluoroethylene hydrothermal reaction kettle, and stir evenly. In the above reaction system, the molar ratio of sodium phosphate, sodium fluoride, lanthanum nitrate and calcium nitrate is 0.57:0.15 : 0.1: 1, the pH of the system is 7.5.

[0031] (2) Seal the reactor in (1), and react at 120° C. for 48 hours. Then cool to room temperature, open the reactor, wash with absolute ethanol and chloroform, and dry to obtain the product powder. The resulting product is identified by X-ray powder diffraction and transmission electron microscopy and component analysis (similar to the single crystal nanowire prepared in Examp...

Embodiment 3

[0032] Embodiment 3, the preparation of single crystal nanowire

[0033] (1) Mix 3mL of 0.28M calcium nitrate aqueous solution, 0.3mL of 0.28M cerium nitrate aqueous solution, 0.45mL of 0.28M sodium fluoride aqueous solution, 3mL of 0.16M sodium dihydrogen phosphate aqueous solution, 1.8g of sodium hydroxide, 10mL of Add absolute ethanol and 20mL of oleic acid into a 50mL polytetrafluoroethylene hydrothermal reaction kettle and stir evenly. In the above reaction system, the molar ratio of sodium dihydrogen phosphate, sodium fluoride, cerium nitrate and calcium nitrate is 0.57:0.15:0.1:1, the pH of the system is 8.0.

[0034] (2) Seal the reactor in (1), and react at 180° C. for 24 hours. Then cool to room temperature, open the reactor, wash with absolute ethanol and cyclohexane, and dry to obtain the product powder. The resulting product is identified by X-ray powder diffraction and transmission electron microscopy and component analysis (similar to the single crystal nanowi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com