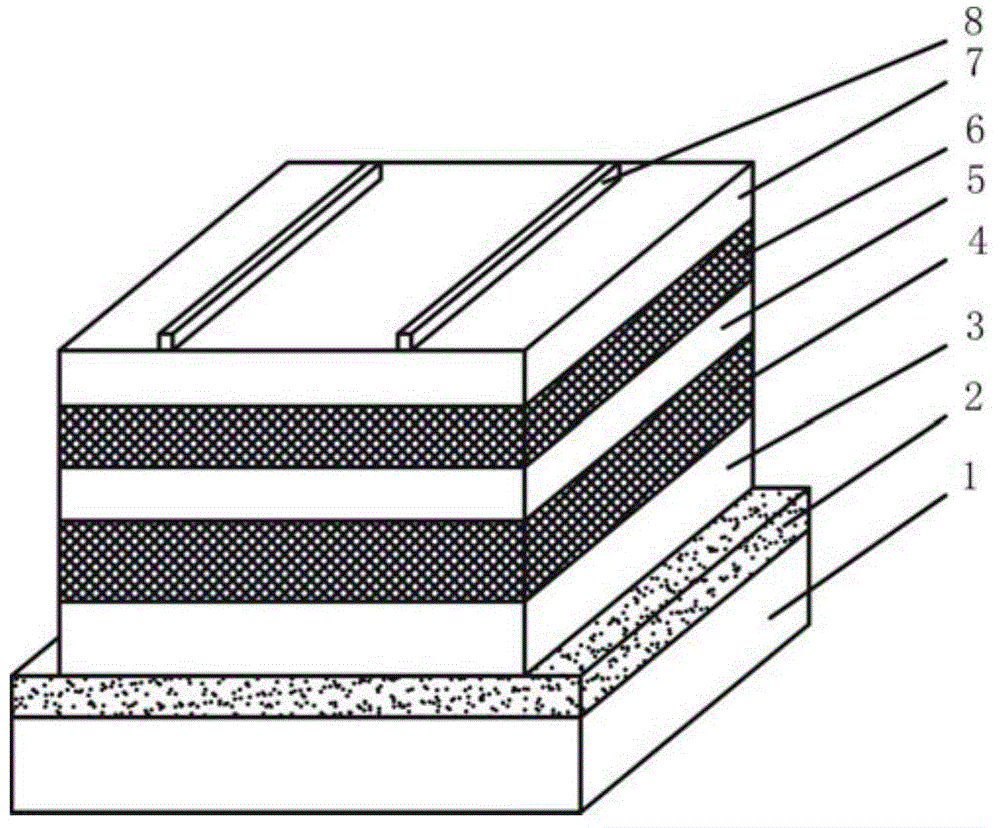

CZTSSe thin-film solar cell with upper conversion layer and manufacturing method of CZTSSe thin-film solar cell

A copper-zinc-tin-sulfur-selenide and solar cell technology, which is applied in the field of solar cells, can solve the problems of mismatch and low theoretical conversion rate, and achieve the effects of reducing preparation costs, making the preparation process green and environmentally friendly, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation method of the copper-zinc-tin-sulfur-selenium thin-film solar cell with an up-conversion layer is as follows:

[0054] a) The molybdenum (Mo) back electrode 2 of the thin-film solar cell is deposited on the glass substrate 1 by the method of magnetron sputtering, and its thickness is about 400nm;

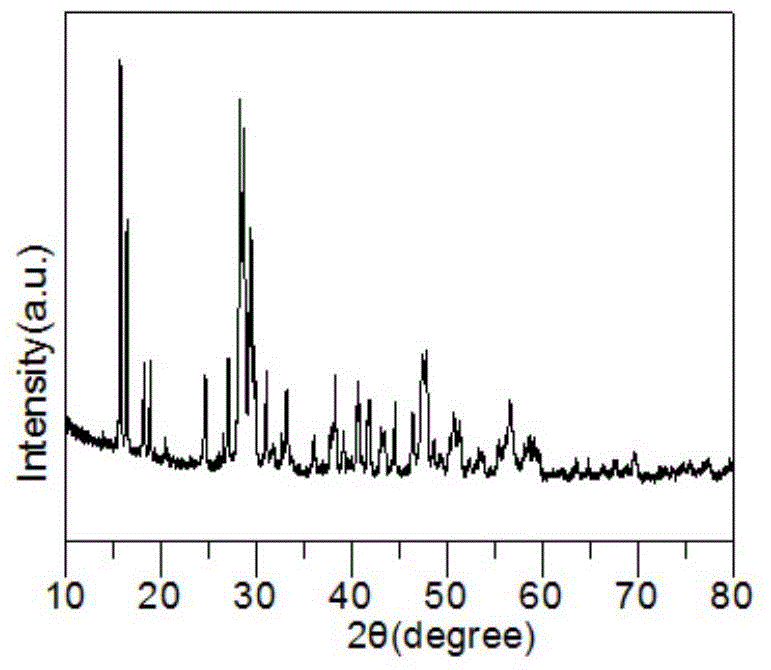

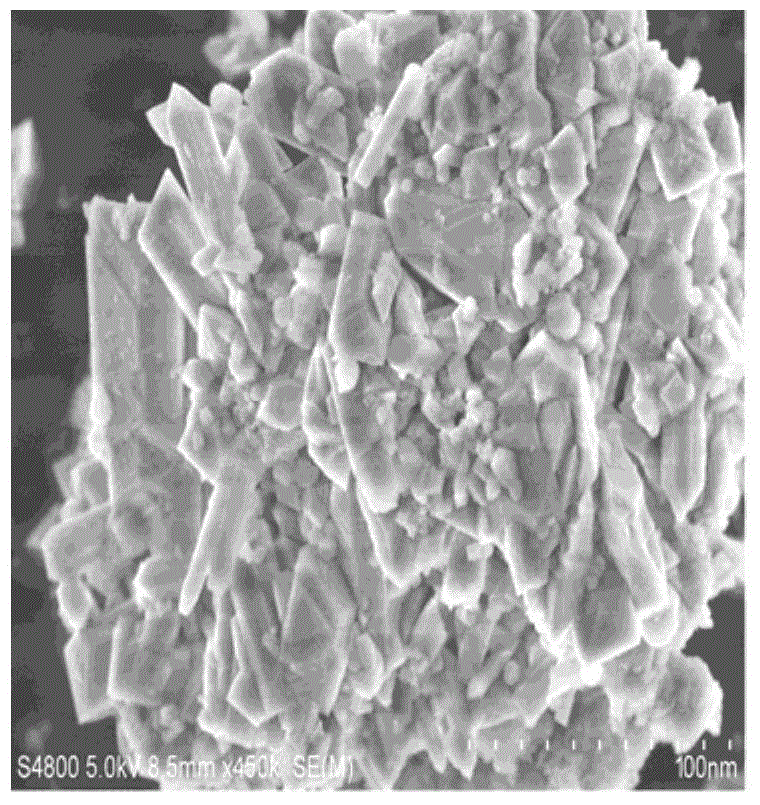

[0055] b) Up-conversion layer K of thin-film solar cells 2 YF 5 Film 3 is a fluoride film material prepared by a two-step method. The two-step method is to first prepare fluoride up-conversion nanocrystals by thermal injection, and then use the sol-gel method to pass the prepared nanocrystal ink on the Mo-plated surface. Deposit a layer of fluoride film on the substrate, the process steps are as follows:

[0056] b1) Weigh 0.39mmol of yttrium oxide (Y 2 o 3 ) and 4mmol of potassium bifluoride (KHF 2 ), put into the airtight three-necked flask of 50ml, and vacuumize 5min at normal temperature, then inject volume ratio and be 0.5, total solvent amount is the ...

Embodiment 2

[0075] The preparation method of the copper-zinc-tin-sulfur-selenium thin-film solar cell with an up-conversion layer is as follows:

[0076] Steps a)-b) are the same as in Example 1;

[0077] Preparation of photoelectric conversion layer CZTSe film

[0078] c1) First weigh 2mol of anhydrous cuprous chloride (CuCl), 1mol of anhydrous tin chloride (SnCl) 4 ) and 1mol of ammonium chloride (NHCl 4 ) is a reaction raw material, adding 1mol of 3-mercapto-1-propanesulfonate sodium (C 3 h 7 NaO 2 S 2 ) to promote Cu + and Sn 4+ Dissolve, add 3mol of selenium powder at the same time, put it into a 50ml three-necked flask, and vacuumize it at room temperature for 5min, then inject 10ml of oleic acid / oleylamine solvent system with a volume ratio of 1:2, and the solution immediately becomes dark. Yellow; at the same time, argon gas is introduced, and the temperature of the solution is raised to 300°C at the heating rate and stirring rate of 30°C / min and 400rpm / min respectively, a...

Embodiment 3

[0085] The preparation method of the copper-zinc-tin-sulfur-selenium thin-film solar cell with an up-conversion layer is as follows:

[0086] Steps a)-b) are the same as in Example 1;

[0087] Preparation of photoelectric conversion layer CZTS film

[0088] c1) First weigh 2mol of anhydrous cuprous chloride (CuCl), 1mol of anhydrous tin chloride (SnCl) 4 ) and 1mol of ammonium chloride (NHCl 4 ) is a reaction raw material, adding 1mol of 3-mercapto-1-propanesulfonate sodium (C 3 h 7 NaO 2 S 2 ) to promote Cu + and Sn 4+ Dissolve, add 3mol of sublimated sulfur into a 50ml three-neck flask to form a closed system, and vacuumize at room temperature for 5 minutes, close the vacuum valve, and then inject 10ml of oleic acid / oil with a volume ratio of 1:2 amine, the solution turns dark yellow; at the same time, argon gas is introduced, and the temperature is raised to 300°C at a heating rate of 30°C / min and a stirring rate of 400rpm / min, and is kept for 30min, finally forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com