Method for continuously and rapidly determining conventional elements and microelements in niobium and tantalum concentrates

A technology for rapid determination of trace elements, applied in the preparation of test samples, thermal excitation analysis, material excitation analysis, etc., can solve the problems of long analysis and test cycle, large amount of chemical reagents, cumbersome process, etc., and is conducive to technology promotion. and application, the effect of reducing sample pretreatment time and saving dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

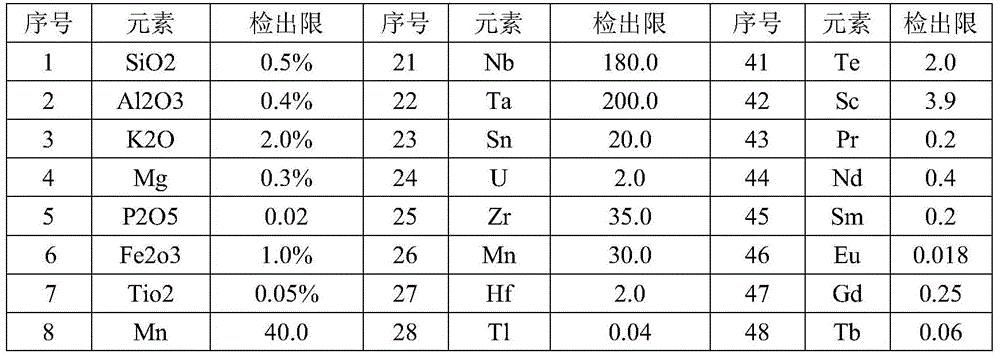

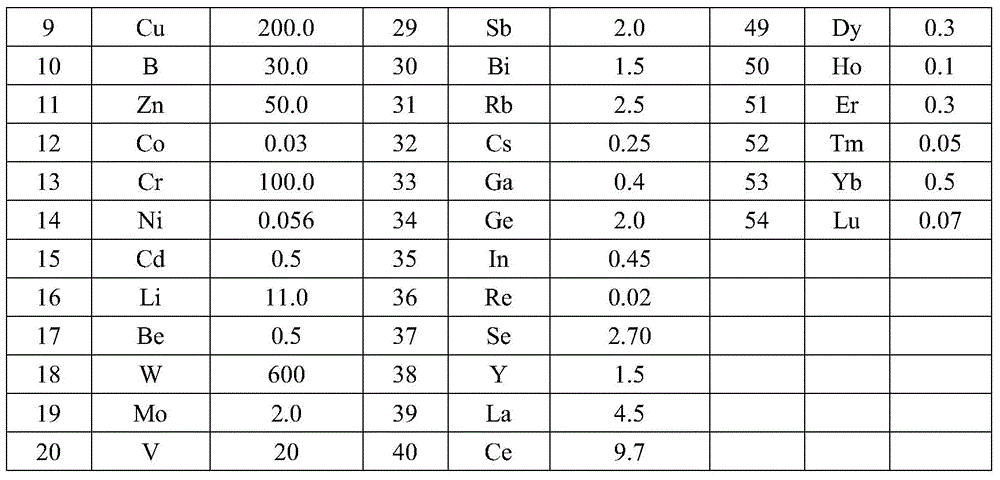

Method used

Image

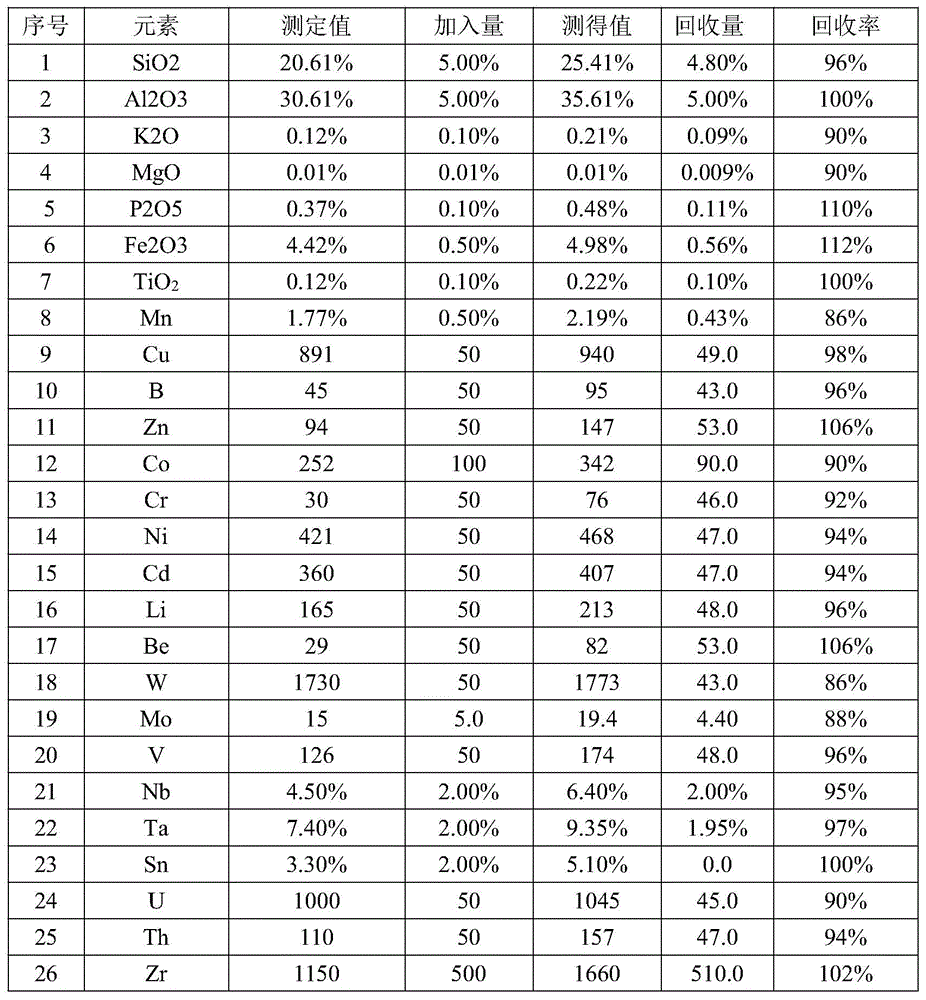

Examples

Embodiment 1

[0036] Source of samples for this experiment: 3 samples of niobium-tantalum ore concentrate in Yichun, Jiangxi. Analysis lot number: 2015Z123.

[0037] Other materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

[0038] experiment method:

[0039] Step 1 Accurately weigh 0.5000g sample into a 30mL graphite crucible, add 4gNaOH and 1.5gNa 2 o 2 Melt in a muffle furnace heated to 580°C for 20 minutes, and make sample blanks and management samples at the same time;

[0040] Step 2 Take it out and cool it slightly, put it into a 200mL plastic beaker with a cover, add 80-90mL of 150g / L NaCl solution, boil it on a heating plate for 3-5min, and wash out the crucible;

[0041] Step 3 Filter with medium-speed qualitative filter paper or fast centrifuge, transfer the filtrate into a 100mL volumetric flask, dilute to volume with 1% NaOH, and shake well;

[0042] Step 4 Take 5mL of clear liquid and transfer it into ...

Embodiment 2

[0059] The source of the sample for this experiment: a sample of ferroniobium concentrate from Pingell, Bauchi State, Nigeria. Analysis batch number: 2015Z021.

[0060] Other materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

[0061] experiment method:

[0062] Step 1 Accurately weigh 0.5000g sample into a 30mL graphite crucible, add 3gNaOH and 1gNa 2 o 2 Melt in a muffle furnace heated to 700°C for 20 minutes, and make sample blanks and management samples at the same time;

[0063] Step 2 Take it out and cool it slightly, put it into a 200mL plastic beaker with a cover, add 80-90mL of 150g / L NaCl solution, boil it on a heating plate for 3-5min, and wash out the crucible;

[0064] Step 3 Filter with medium-speed qualitative filter paper or fast centrifuge, transfer the filtrate into a 100mL volumetric flask, dilute to volume with 1% NaOH, and shake well;

[0065] Step 4 Take 5mL of clear liquid, dilut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com