A method of using earthworms to process livestock and poultry manure waste to produce bio-organic fertilizer

A technology for bio-organic fertilizer and livestock and poultry manure, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, and organic fertilizers, can solve the problems of increased transportation costs, low nutrient content of vermicompost, and increased cumbersomeness and input costs of vermiculture. , to achieve good function and synergy, improve survival time and survival rate, and be beneficial to growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method of utilizing earthworms to process cow dung to produce bio-organic fertilizers, comprising the steps of:

[0040] The raw materials used in this method are as follows, parts by weight, and the following components are based on dry weight:

[0041] 80 parts of vermicompost, 10 parts of reed residue, 5 parts of biomass charcoal, 1 part of potassium fulvic acid, 1 part of amino acid, 1 part of medium and trace elements, 2 parts of microbial agent;

[0042] The amino acids described are animal source amino acids purchased from commercial sources. The amino acid is made from leftovers from various marine fish processing plants and cooking pulp water. It is processed by microbial fermentation, acid-base hydrolysis, and spray drying. It has moisture absorption and fermentation aroma. It contains 18 kinds of free amino acids, all amino acids The total amount is more than or equal to 70%, and it is easily soluble in water. The amino acids involved in the present invent...

Embodiment 2

[0070] A method of utilizing earthworms to process pig manure to produce bio-organic fertilizer, comprising the steps of:

[0071] The raw materials used in this method are as follows, parts by weight:

[0072] 75.5 parts of vermicompost, 15 parts of reed residue, 5 parts of biomass charcoal, 1 part of potassium fulvic acid, 1 part of amino acid, 0.5 parts of medium and trace elements, 2 parts of microbial agent;

[0073] The microbial agent is mixed with Bacillus subtilis, Bacillus licheniformis, Bacillus lateralis, and Bacillus colioids according to the number ratio of 2:1:1:1; the effective bacterial content of the microbial agent is ≥ 200 million / g;

[0074] The medium and trace elements are magnesium sulfate, zinc sulfate, borax, ferric sulfate, and ammonium molybdate mixed according to the mass ratio of 4:2:1:0.5:0.5;

[0075] In the process of preparing vermicompost, the components and proportions involved are as follows:

[0076] The weight ratio of earthworm speci...

Embodiment 3

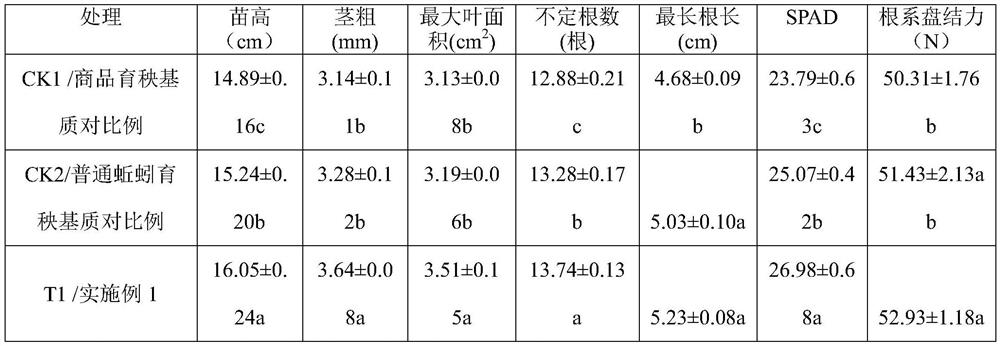

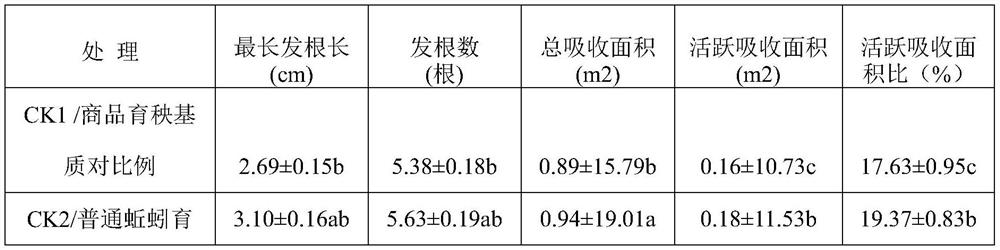

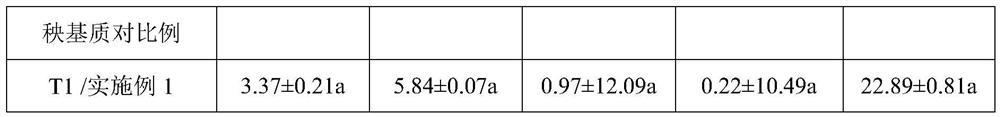

[0082] The bio-organic fertilizer produced in embodiment 1 is used as the application effect of rice seedling raising matrix raw material:

[0083] (1) Experimental design

[0084] The test was carried out in April 2018 in a small shed at the Mapoling Experimental Site of the Institute of Agricultural Environment and Ecology, Hunan Academy of Agricultural Sciences. The bio-organic fertilizer produced by vermicompost is used as the raw material of rice seedling raising matrix, and three treatments are set up:

[0085] Control one (CK1): the seedling raising substrate sold in the market;

[0086]Contrast 2 (CK2): 30% of vermicompost, 35% of reed foam, 20% of peat, 10% of vermiculite, 5% of organic fertilizer (mass ratio) intermixed seedling-raising substrate;

[0087] Treatment one (T1): a seedling-raising substrate in which 30% of bio-organic fertilizer, 35% of reed foam, 20% of peat, 10% of vermiculite and 5% of organic fertilizer (mass ratio) of the present invention are mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com