A chemical polishing method for germanium flat mirrors using electric field effect to enhance the pH of the processing area

A processing area and chemical polishing technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as difficult to achieve non-destructive surface processing, achieve enhanced acidity value, enhanced corrosion, and improved polishing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

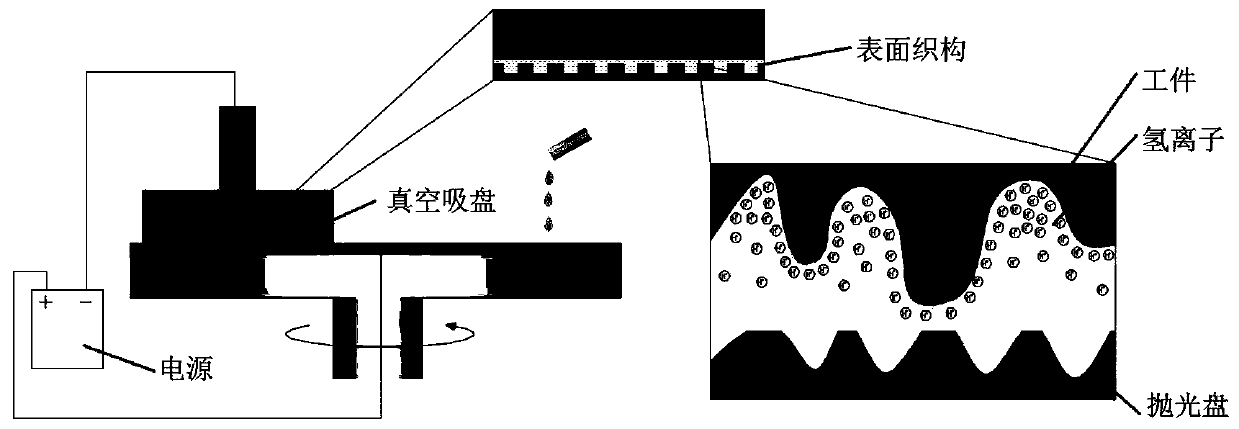

Method used

Image

Examples

Embodiment 1

[0035] Step 1, Preparation of Dielectric Ceramic Polishing Disc

[0036] Step 1.1: Dissolve 200g of aluminum isopropoxide as a precursor in 1.8kg of distilled water, heat the solution to 85°C for 1 hour under high-speed stirring, and then add 0.5g of nitric acid as a peptizer to prepare an aluminum sol; After the obtained aluminum sol is heated and aged, BaO-Ln with a particle size of 100nm is added 2 o 3 -TiO 2 Dielectric ceramic powder 2kg, mixed evenly to obtain a composite gel, dried the composite gel, and calcined at 1000°C to prepare alumina-dielectric ceramic composite powder;

[0037] Step 1.2: Add 180g of 5% PVA solution to the alumina-dielectric ceramic composite powder, use a ball mill to mix evenly, pass through a 200-mesh sieve, dry at room temperature for 12 hours, put it into a mold, and carry out when the molding pressure is 4Mpa Dry-press the polishing plate green body, use the laser beam to process the micro-texture of circular pits with a diameter of 0.1m...

Embodiment 2

[0048] The operation is basically the same as in Example 1, the difference is:

[0049] (1) The preparation method of chemical polishing liquid is changed to:

[0050] Add 1wt% alkylphenol polyoxyethylene ether surfactant, 1.5wt% triethanolamine corrosion inhibitor, 1wt% water-soluble alkylphenol polyoxyethylene ether zinc thiophosphate antiwear agent, add 3wt% polyethylene glycol 400 viscosity As a regulator, potassium hydroxide aqueous solution is added to prepare an alkaline chemical polishing solution with a pH value of 9, and 1 wt% hydrogen peroxide oxidant is added, wherein hydrogen peroxide is added dropwise to the polishing solution during the polishing process.

[0051] (2) The polishing method is changed to:

[0052] The soft and brittle material germanium sheet is vacuum adsorbed on the porous dielectric ceramic vacuum adsorption substrate, and placed in the fixture, and then the porous dielectric ceramic vacuum adsorption substrate that vacuum absorbs the workpiece ...

Embodiment 3

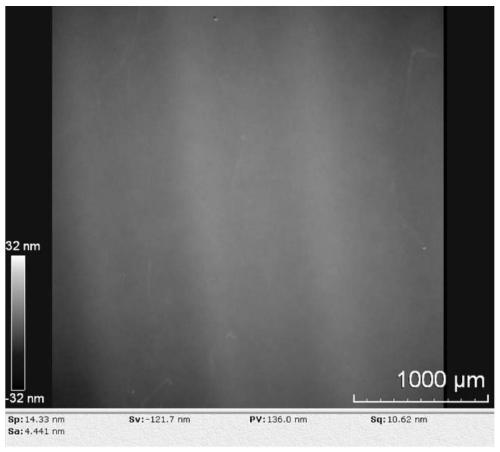

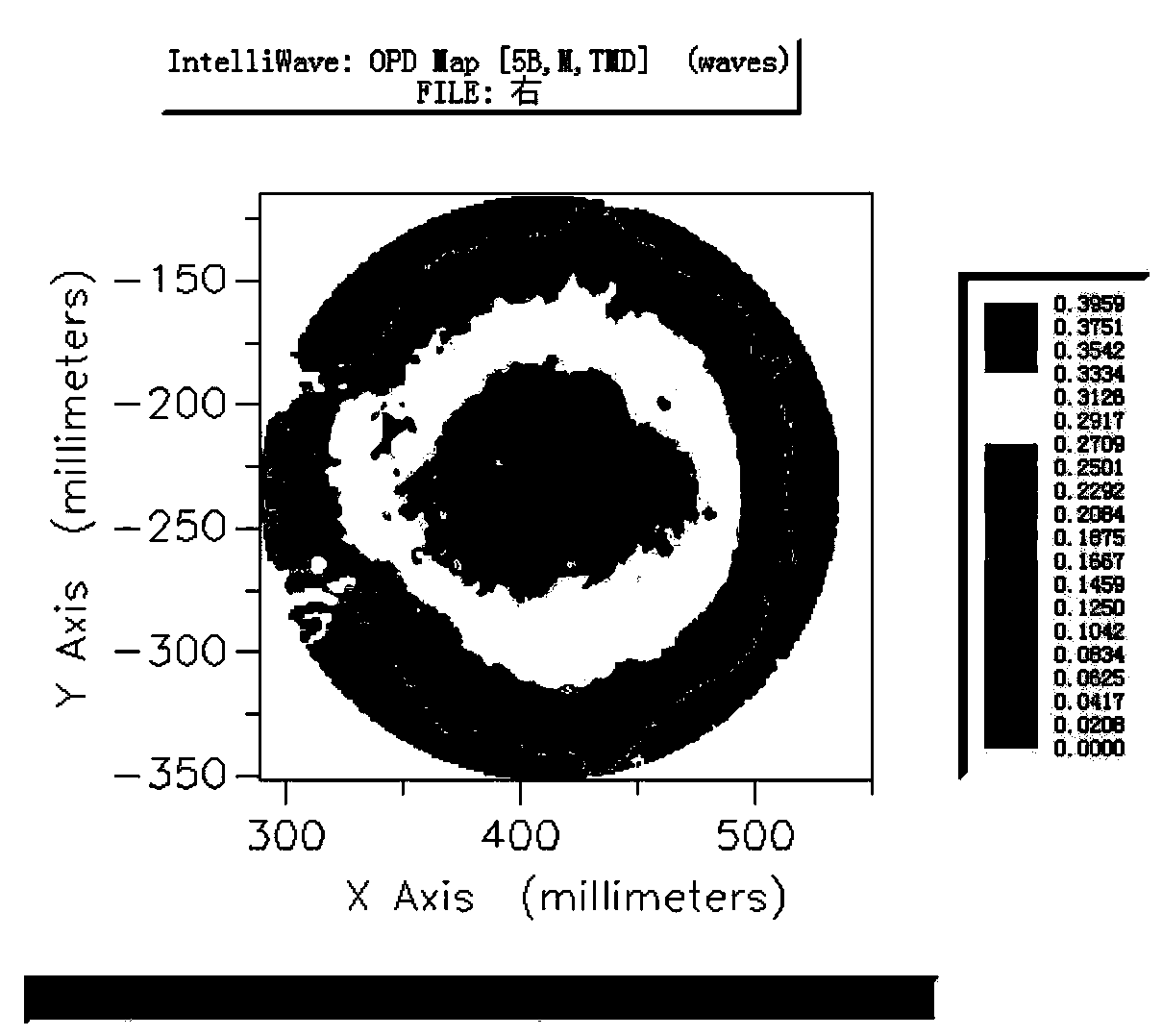

[0054] Polishing comparison test: use IC1000 polyurethane polishing pad and silicon dioxide polishing liquid to polish the germanium flat mirror. There are many corrosion pits on the surface of the germanium flat mirror polished with polyurethane polishing pad and silicon dioxide polishing liquid, especially the polishing liquid on the grain boundary. The corrosion pits at the place are obvious, and the surface roughness and flatness comparison diagrams of the germanium wafers obtained by polishing in Examples 1, 2, and 3 are as follows Figure 4 It can be seen from the figure that the polishing method using the electric field effect to enhance the pH of the processing area has lower roughness and better surface quality than the traditional polyurethane polishing pad polishing method. At the same time, the polishing process can be understood as the copy of the workpiece to the surface of the polishing disc. , Since the hardness of the ceramic-based polishing disc is greater tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com