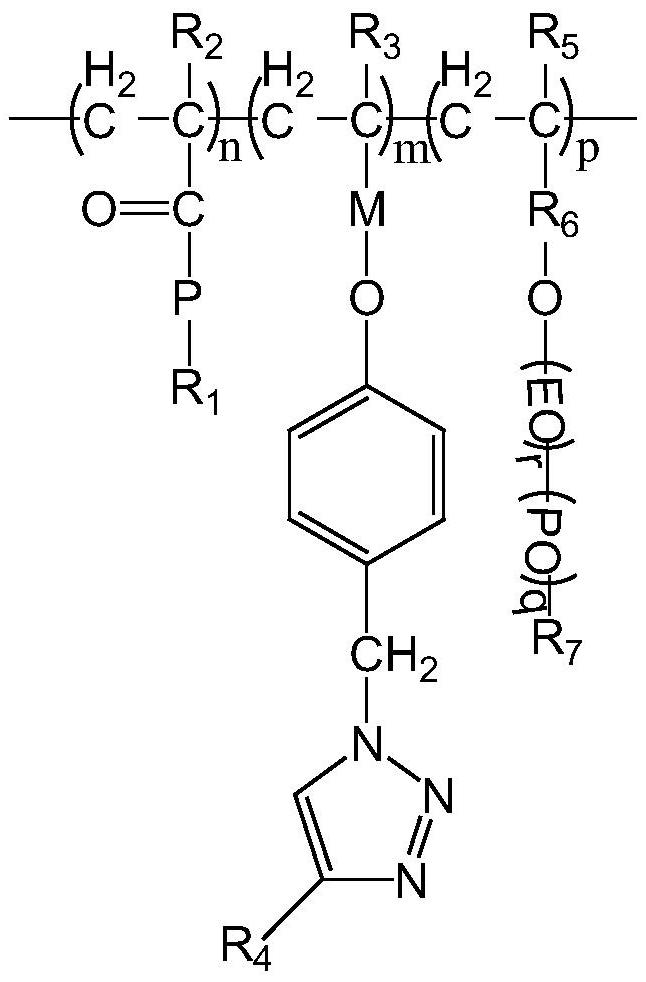

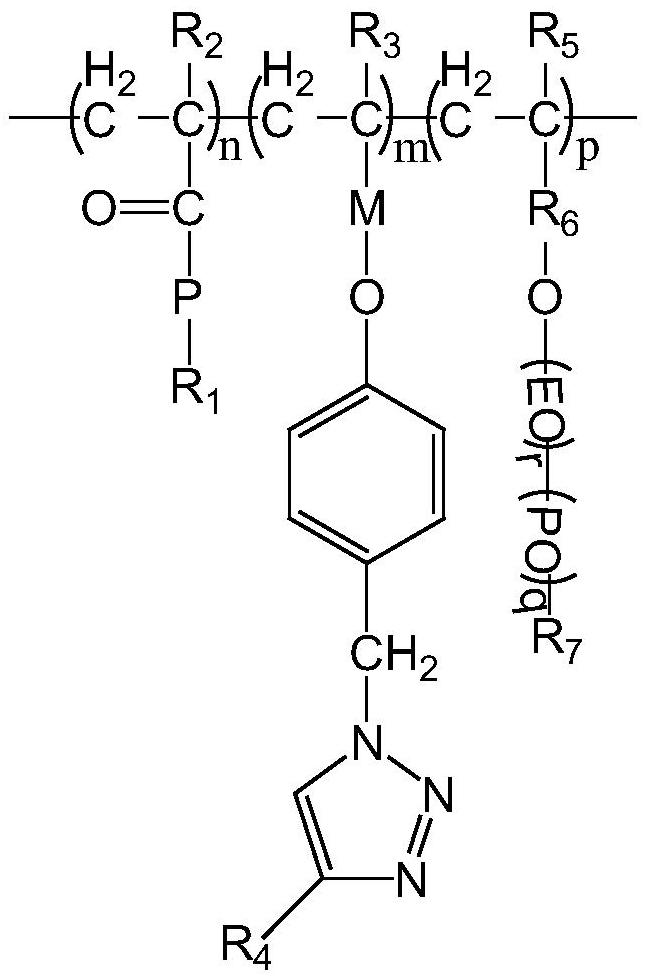

Antibacterial polycarboxylate superplasticizer and preparation method thereof

A technology of water reducing agent and polycarboxylic acid, applied in the field of antibacterial polycarboxylic acid water reducing agent and its preparation, can solve the problems of high cost restriction, environmental pollution, large usage amount of functional monomers, etc. Rich, excellent and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

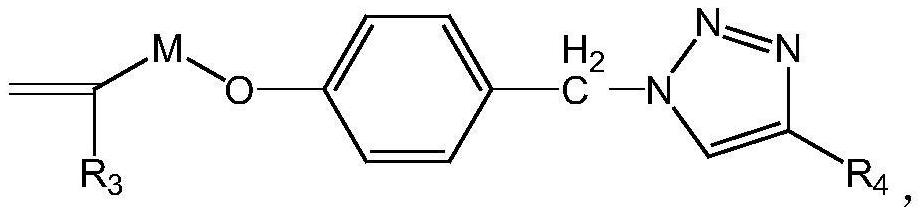

[0040] 1) Stir 1mol of 4-hydroxybenzyl chloride and 1.1mol of sodium azide in 100mL of DMF solvent, and react at room temperature for 12h to obtain p-hydroxyl azide; p-hydroxyl azide (1mol), propyne (1.1 mol), cuprous iodide (0.03mol), and triethylamine (0.1mol) were reacted in tert-butanol / water (90mL, v / v=1 / 2) and acetonitrile (2mL) at room temperature for 8h to obtain 1, Phenolic compounds with 2,3-triazole structure; add 3-chloropropene (1.1mol) dropwise to DMF containing the above phenolic compounds (1mol) and potassium hydroxide (0.2mol) within 2h through a reflux condensing device In the mixed solution, the reaction was continued at 50°C for 6 hours to obtain the unsaturated monomer 1 containing 1,2,3-triazole;

[0041] 2) Acrylic acid (4mol), 1,2,3-triazole-containing unsaturated monomer 1 (0.15mol), allyl polyethylene glycol (1mol, M w =1000g / mol) Under the combined action of ammonium persulfate (0.07mol), sodium sulfite (0.1mol) and mercaptoethanol (0.05mol), free r...

Embodiment 2

[0046] 1) Stir 1mol of 4-hydroxybenzyl bromide and 1.1mol of sodium azide in 100mL of ethanol solvent, react at room temperature for 12h to obtain p-hydroxyl azide; mix p-hydroxyl azide (1mol), 3-phenyl -1-propyne (1.1mol), copper iodide (0.04mol), diethylamine (0.1mol) were reacted in ethanol / water (90mL, v / v=1 / 2) and acetamide (2mL) at room temperature for 8h , to obtain a phenolic compound containing 1,2,3-triazole structure; through a reflux condensing device, 3-bromopropene (1.1mol) was added dropwise to the above-mentioned phenolic compound (1mol) and sodium hydroxide ( 0.2mol) in ethanol mixed solution, continue to react at 50°C for 6h to obtain unsaturated monomer 2 containing 1,2,3-triazole;

[0047] 2) Acrylamide (3.5mol), 1,2,3-triazole-containing unsaturated monomer 2 (0.25mol), methallyl polyoxyethylene ether (1mol, M w =500g / mol) Under the joint action of hydrogen peroxide (0.08mol), dimple (0.06mol) and 3-mercaptopropionic acid (0.04mol), the antibacterial poly...

Embodiment 3

[0052] 1) 1mol of 4-hydroxybenzyl chloride and 1.1mol of sodium azide were stirred in 100mL of chloroform solvent, and reacted at room temperature for 12h to obtain p-hydroxyazide; p-hydroxyazide (1mol), phenylacetylene (1.1 mol), copper bromide (0.03mol), DMAP (0.15mol) in n-butanol / water (90mL, v / v=1 / 2) and ethanesulfonyl acetonitrile (2mL) at room temperature for 8h, to obtain 1, The phenolic compound of 2,3-triazole structure; Through the reflux condensation device, 3-chloro-1-butene (1.1mol) is added dropwise to the above-mentioned phenolic compound (1mol) and silver hydroxide (0.2 mol) in chloroform mixed solution, continue to react at 50°C for 6h to obtain unsaturated monomer 3 containing 1,2,3-triazole;

[0053] 2) Mix methacrylic acid (4mol), 1,2,3-triazole-containing unsaturated monomer 3 (0.2mol), methallyl polyoxyethylene ether (1mol, M w =1500g / mol) under the joint action of potassium persulfate (0.07mol), sodium bisulfite (0.1mol) and 2-mercaptopropionic acid (0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com