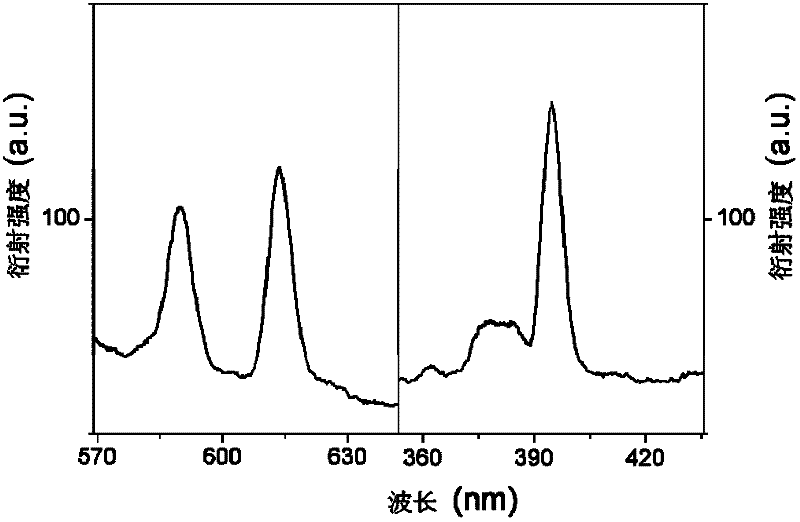

Graphene/rare earth fluoride nanoscale composite material and intercalation stripping synthesis method thereof

A nano-composite material, rare earth fluoride technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of eye irritation, poor production safety, delayed inflammation, etc., and achieve uniform appearance, low cost, and equipment. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific Embodiment 1: In this embodiment, the graphene / rare earth fluoride nanocomposite material is made of rare earth salt solution, expanded graphite, surfactant solution and fluorine source solution; wherein rare earth salt solution, expanded graphite, surfactant solution and fluorine The molar ratio of the source solution is 1:(0.01~10):(0.1~10):(0.1~5); the concentration of the rare earth solution is 0.05~2mol / L; the concentration of the surfactant solution is 0.05~2mol / L; The concentration of the fluorine source solution is 0.05-2mol / L; the rare earth solution is a rare earth nitrate solution or a rare earth chloride solution; the solute in the rare earth nitrate solution is yttrium nitrate, scandium nitrate, lanthanum nitrate, cerium nitrate, praseodymium nitrate, Samarium nitrate, europium nitrate, gadolinium nitrate, terbium nitrate, dysprosium nitrate, holmium nitrate, erbium nitrate, thulium nitrate, ytterbium nitrate, lutetium nitrate or a mixture of them, ...

specific Embodiment approach 2

[0018] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the solute in the anionic and cationic surfactant solution with fixed hydrophilic and lipophilic groups is cetyltrimethylammonium bromide, cetyl Dimethyl benzyl ammonium bromide, cetyl polyoxyethylene ether dimethyl octyl ammonium chloride, lauryl polyoxyethylene ether dimethyl methyl ammonium chloride, octylphenol polyoxyethylene Ether dimethyl decyl ammonium bromide, octylphenol polyoxyethylene ether dimethyl decyl ammonium chloride, cetyl alcohol polyoxyethylene ether dimethyl octyl ammonium chloride, dodecyl ammonium Sodium Alkyl Sulfate, Sodium Lauryl Sulfonate, Sodium Cetyl Benzene Sulfonate, Sodium Octadecyl Sulfate, Sodium N-Oleoyl Polypeptide, Sodium Fatty Alcohol Polyoxyethylene Ether Sulfate, Fatty Alcohol Polyoxyethylene Sulfate One or a mixture of disodium oxyethylene ether sulfosuccinate monoester, and the solvent is one or a mixture of water, ethanol, and e...

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the solute in the zwitterionic surfactant solution is EO 20 PO 70 EO 20 (P123), EO 106 PO 70 EO 106 (F127), lauryl dimethyl amine oxide, coco alkyl dimethyl amine oxide, lauryl dimethyl amine oxide, dodecyl dihydroxyethyl amine oxide, tetradecyl dihydroxyethyl amine oxide amine oxide, hexadecyl dihydroxyethyl amine oxide, octadecyl dimethyl amine oxide, octadecyl dihydroxyethyl amine oxide or a mixture of several, the solvent is water, ethanol , One or more mixtures of ethylene glycol. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com