A method for reducing and self-sulfiding roasting pretreatment jarosite slag

A alumina slag and pretreatment technology, applied in the field of metallurgy, can solve the problems of difficult flue gas treatment, complicated process, poor lead and zinc volatilization effect, etc., and achieve the elimination of treatment cost and secondary pollution, mild process conditions and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073]Using a jarosite slag as raw material, the contents of zinc, lead, iron, sulfur, silver, and indium in the slag are 4.07%, 1.96%, 22.47%, 13.52%, 74g / t, and 300g / t, respectively. Dry and grind the alumina slag to below 74 μm, then mix it with 15% wood charcoal powder (fixed carbon content is 73%) and 5% sodium carbonate with a mixer and press balls to obtain a diameter less than 50mm of mixed spheres.

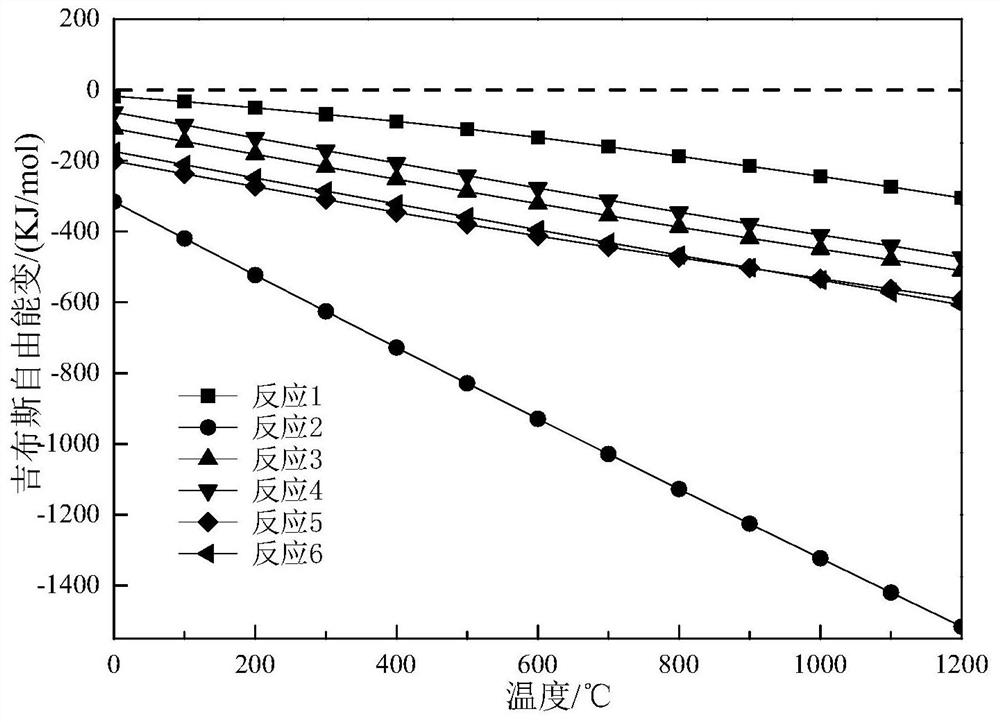

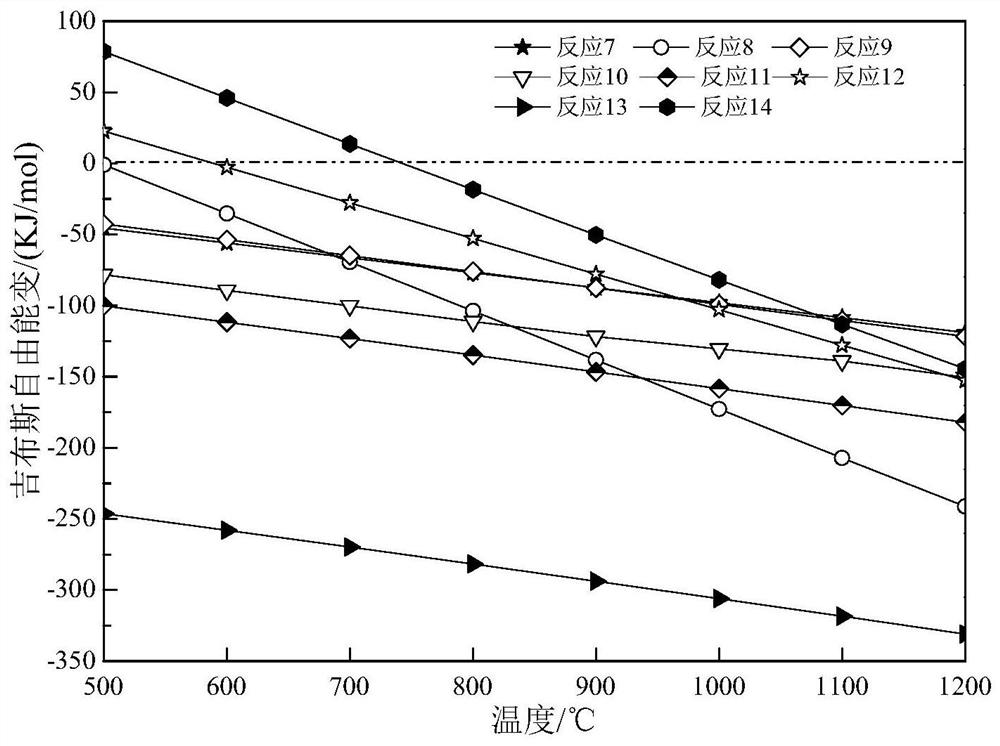

[0074] Take 100kg of the above-mentioned mixed spheres and put them into a rotary kiln, raise the temperature to 450°C and keep it for 90 minutes to carry out the roasting reaction of reduction and fixation of sulfur. The main reactions in this process are:

[0075] 1. KFe 3 (SO 4 ) 2 (OH) 6 =1 / 2Fe 2 (SO 4 ) 3 +Fe 2 o 3 +1 / 2K 2 SO 4 +3H 2 O;

[0076] 2. Fe 2 (SO 4 ) 3 +6C=3 / 2FeS 2 +1 / 2Fe+6CO 2 (g);

[0077] 3. ZnSO 4 +2C=ZnS+2CO 2 (g);

[0078] 4. PbSO 4 +2C=PbS+2CO 2 (g);

[0079] 5. Ag 2 SO 4 +2C=Ag 2 S+2CO 2 (g);

[0080] 6. CuSO 4 +2C=C...

Embodiment 2

[0099] Using jarosite slag as raw material, the contents of zinc, lead, iron, sulfur, silver, and indium in the slag are 3.25%, 2.36%, 26.36%, 14.52%, 112g / t, and 270g / t respectively. Bauxite slag is dried and ground to less than 74 μm, then mixed with 18% coke powder (fixed carbon content of 87%) and 10% sodium carbonate with a mixer and pressed into balls to obtain a mixture with a diameter of less than 50mm. For spheres, take 100kg of the above-mentioned mixed spheres and put them into a rotary kiln, raise the temperature to 600°C and keep it warm for 60 minutes, then continue to raise the temperature to 1100°C and keep it warm for 60 minutes. Indium volatilization rate, sulfur fixation rate, zinc, lead, iron, silver sulfidation conversion rate or metallization rate in alum slag. The results show that the volatilization rate of indium, the sulfidation conversion rate of zinc, lead and silver are 96.52%, 95.64%, 78.35% and 27.53% respectively, the metal rates of silver and i...

Embodiment 3

[0106] Using a certain silver-ferrite slag in Hunan as raw material, the contents of zinc, lead, iron, sulfur, silver, and indium in the alum slag are 8.75%, 4.47%, 20.35%, 15.76%, 656g / t, and 425g / t, respectively. Dry and grind the jarosite slag to below 74 μm, then mix it with 20% graphite powder below 74 μm (fixed carbon content is 93%) and 10% sodium carbonate with a mixer and press balls to obtain a diameter less than 50mm mixed spheres, put 100kg of the above mixed spheres into the rotary kiln, raise the temperature to 450°C and keep it for 90 minutes, then continue to raise the temperature to 850°C, keep it for 120 minutes, after the heat preservation is over, cool it naturally to room temperature, take out the roasted slag, and take a sample And calculate the volatilization rate of indium, the fixation rate of sulfur, the sulfidation conversion rate or metallization rate of zinc, lead, iron and silver in the alumina slag. The results show that the volatilization rate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com