Preparation method of vanadium nitride nanoparticle composite material for lithium-sulfur battery

A technology of vanadium nitride nanometer, lithium-sulfur battery, applied in nitrogen compounds, lithium storage batteries, chemical instruments and methods, etc., can solve the problems of ammonia corrosiveness and limit large-scale synthesis, and achieve the promotion of sulfur utilization efficiency and high energy density. And the effect of cycle stability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

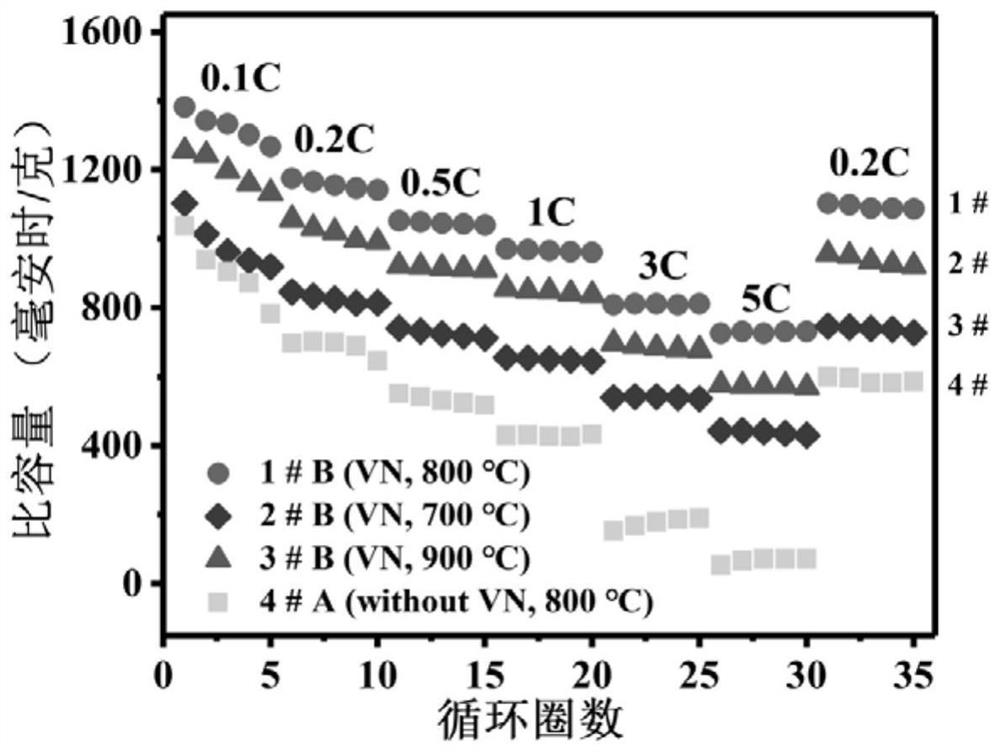

preparation example Construction

[0031] (2) Preparation of lithium-sulfur battery positive electrode and battery assembly: The sulfur positive electrode composite material in Example 1 was prepared using the traditional melt-diffusion method, and the obtained sulfur positive electrode composite material, conductive agent, polyvinylidene fluoride binder, and The ratio of 75:15:10 was stirred in N-methylpyrrolidone solvent to form a uniform slurry, which was coated on aluminum foil with a doctor blade, dried at 60 °C for 24 h, compacted with a roller press, and cut into 14mm circles The sheet is used as the positive electrode of lithium-sulfur battery. Lithium metal is used as the negative electrode, and Celgard 2400 polypropylene diaphragm is used. The electrolyte used is dissolved in 1,3-dioxolane and ethylene glycol dimethyl ether (volume ratio: 1:1) with a concentration of 1 mol L -1 Lithium bis(trifluoromethane)sulfonylimide solution. 1 wt% of anhydrous lithium nitrate was added as an additive, and the b...

Embodiment 1

[0036] (1) Mix 50 mg carbon nanotubes, 100 mg (0.22 mol) 1,2,4,5-tetrabromomethylbenzene and 70 mg (0.25 mol) 1,3,5-tris(1-imidazolyl)benzene Stir ultrasonically in 80 mL of DMF for 1 h, then heat at 110 °C for 12 h. The resulting solid powder was washed with DMF and ethanol several times, and after vacuum drying, a composite material of ionic polymer-coated carbon nanotubes was obtained;

[0037] (2) Add 150 mg of the composite material obtained in step (1) to 50 mL of an aqueous solution containing 750 mg of sodium metavanadate, stir at room temperature for 24 h, wash the solid powder with water, and freeze-dry to obtain metavanadate-containing A composite material of vanadate ion polymer coated carbon nanotubes;

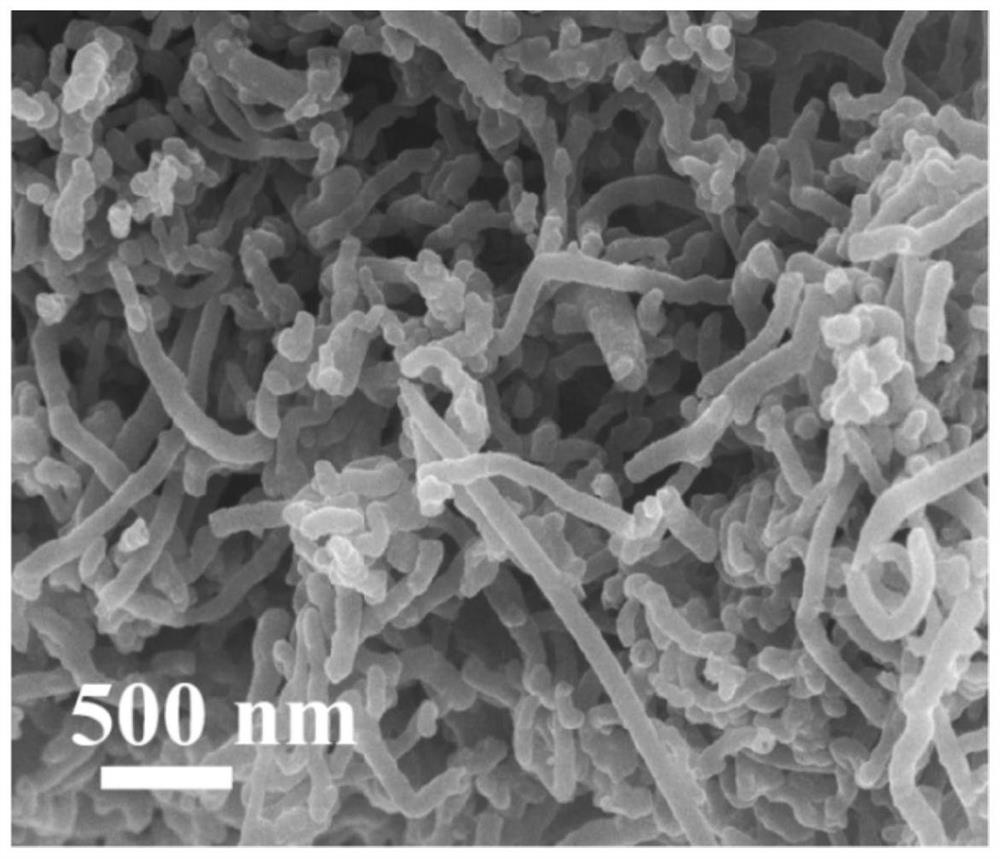

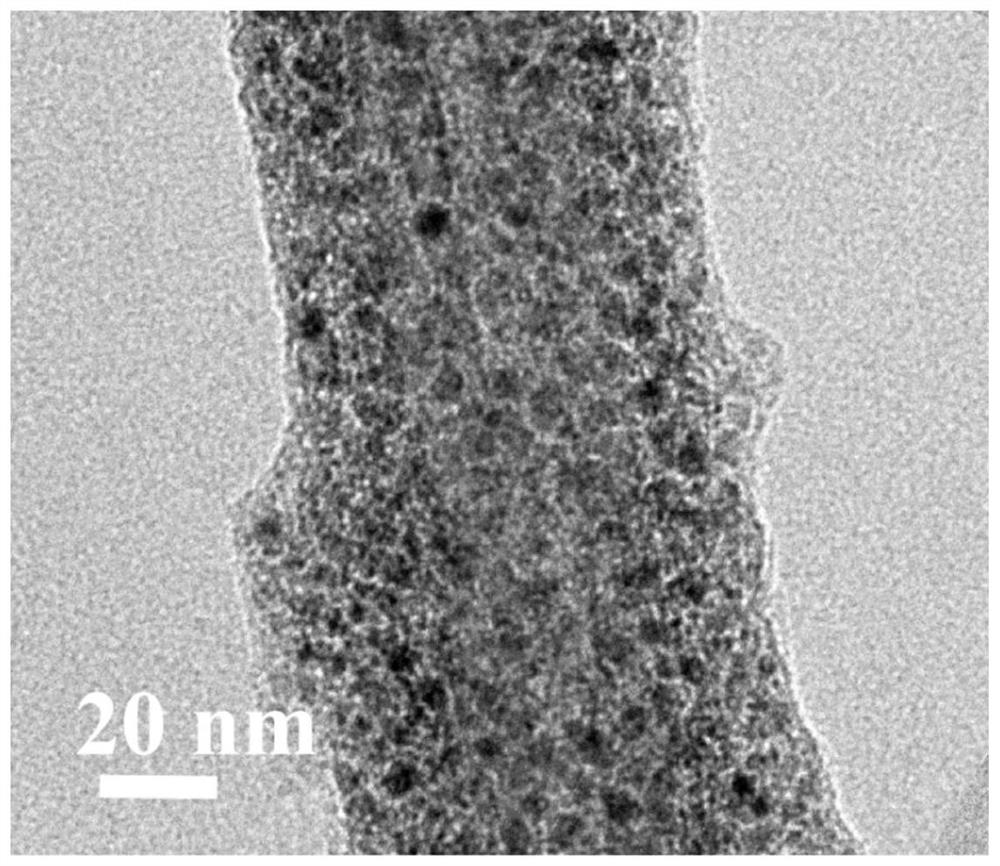

[0038](3) The composite material obtained in step (2) was placed in a porcelain boat and sealed in a quartz tube, and pyrolyzed at 800 °C for 2 h in a nitrogen atmosphere, and the vanadium nitride nanoparticle composite material was obtained after natural cooling...

Embodiment 2

[0044] (1) Mix 50 mg carbon nanotubes, 200 mg (0.44 mol) 1,2,4,5-tetrabromomethylbenzene and 100 mg (0.48 mol) 1,4-bis(1-imidazolyl)benzene in 100 mL DMF was stirred ultrasonically for 1 h, and then heated at 110 °C for 12 h. The resulting solid powder was washed with DMF and ethanol several times, and after vacuum drying, a composite material of ionic polymer-coated carbon nanotubes was obtained;

[0045] (2) Add 100 mg of the composite material obtained in step (1) to 80 mL of an aqueous solution containing 600 mg of sodium metavanadate, stir at room temperature for 24 h, wash the solid powder with water, and freeze-dry to obtain metavanadate-containing A composite material of vanadate ion polymer coated carbon nanotubes;

[0046] (3) Put the composite material obtained in step (2) into a porcelain boat and seal it in a quartz tube. o C and nitrogen atmosphere pyrolysis for 2 h, after natural cooling, the vanadium nitride nanoparticle composite material was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com