Patents

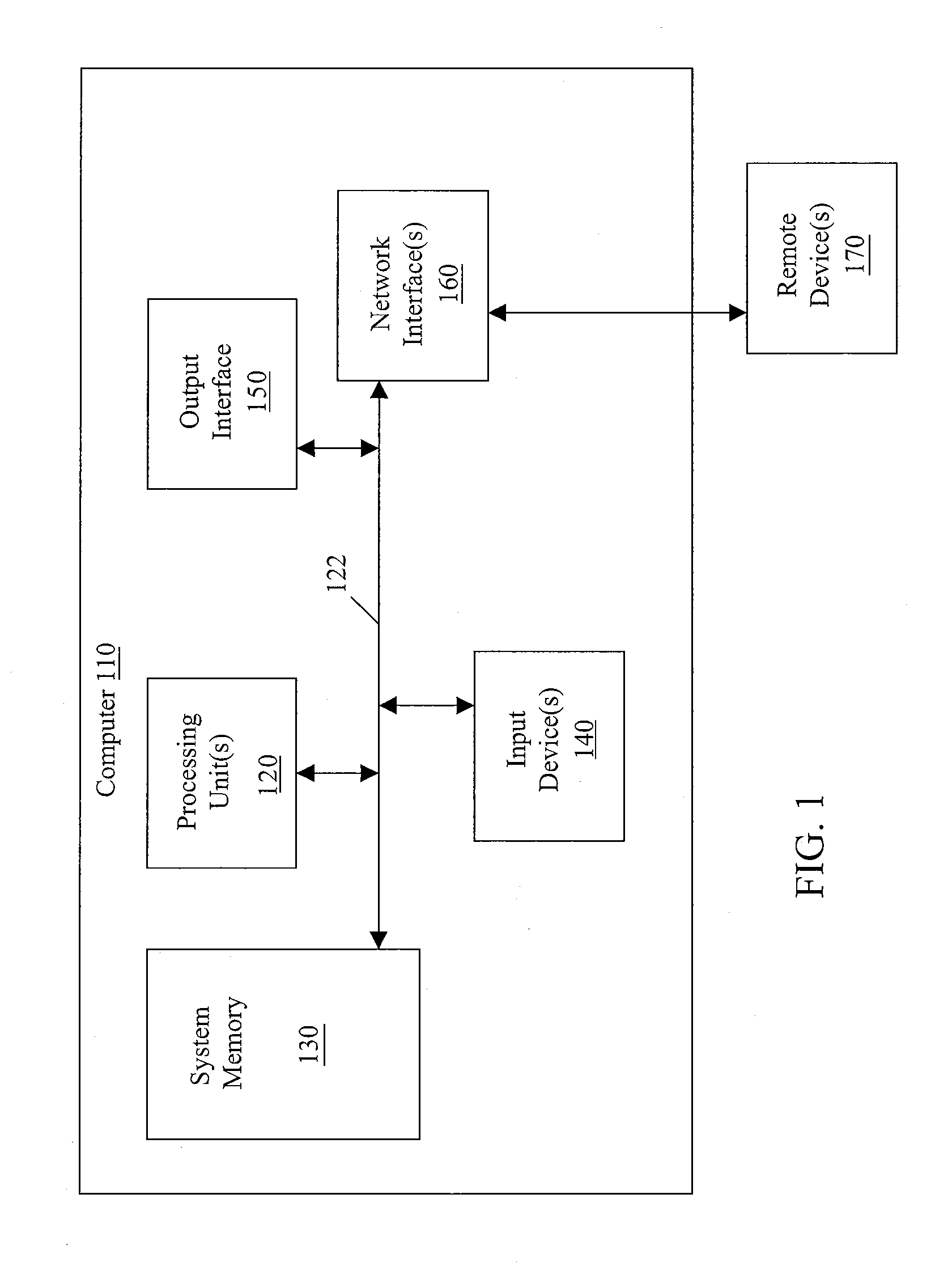

Literature

66 results about "Electrovibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

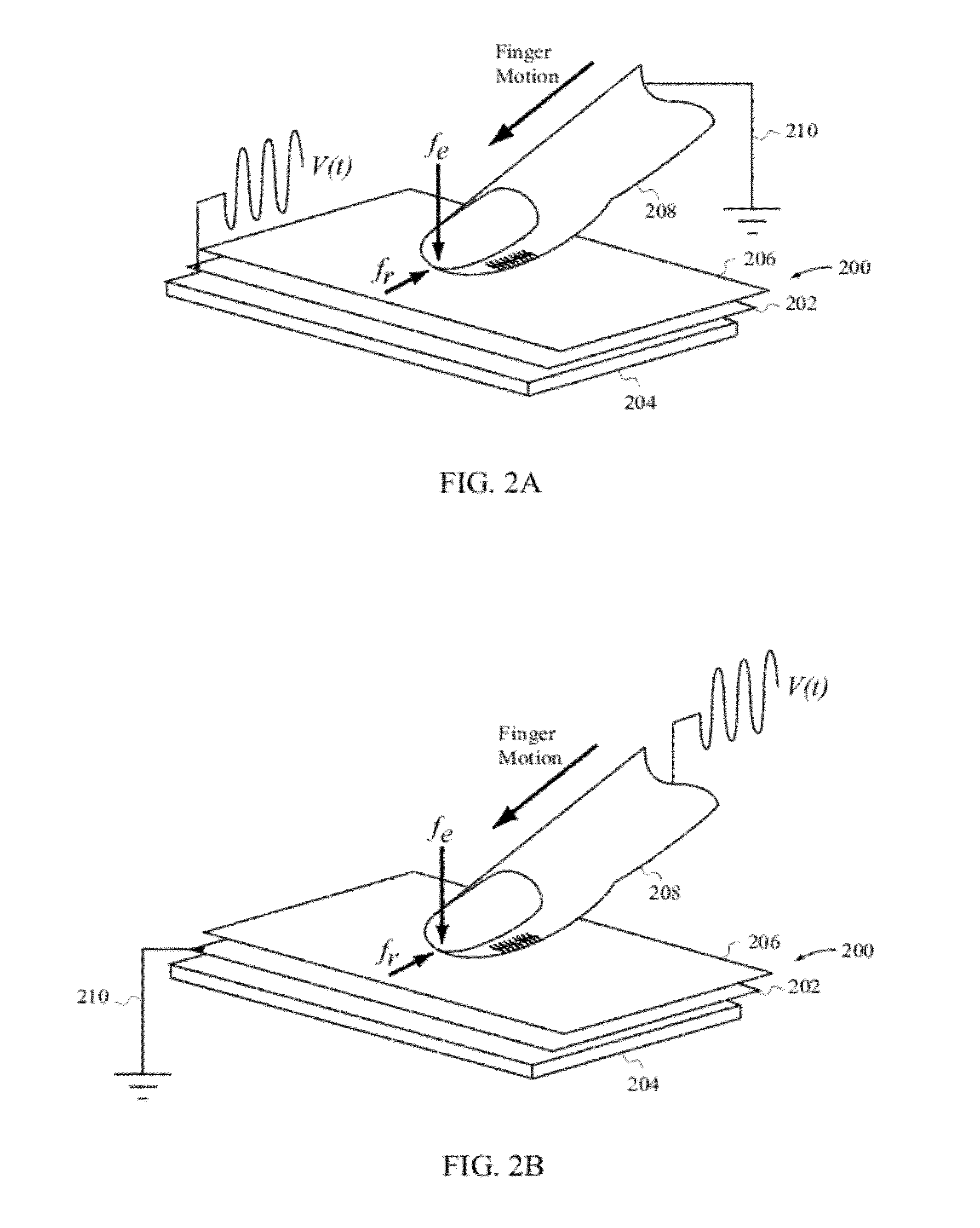

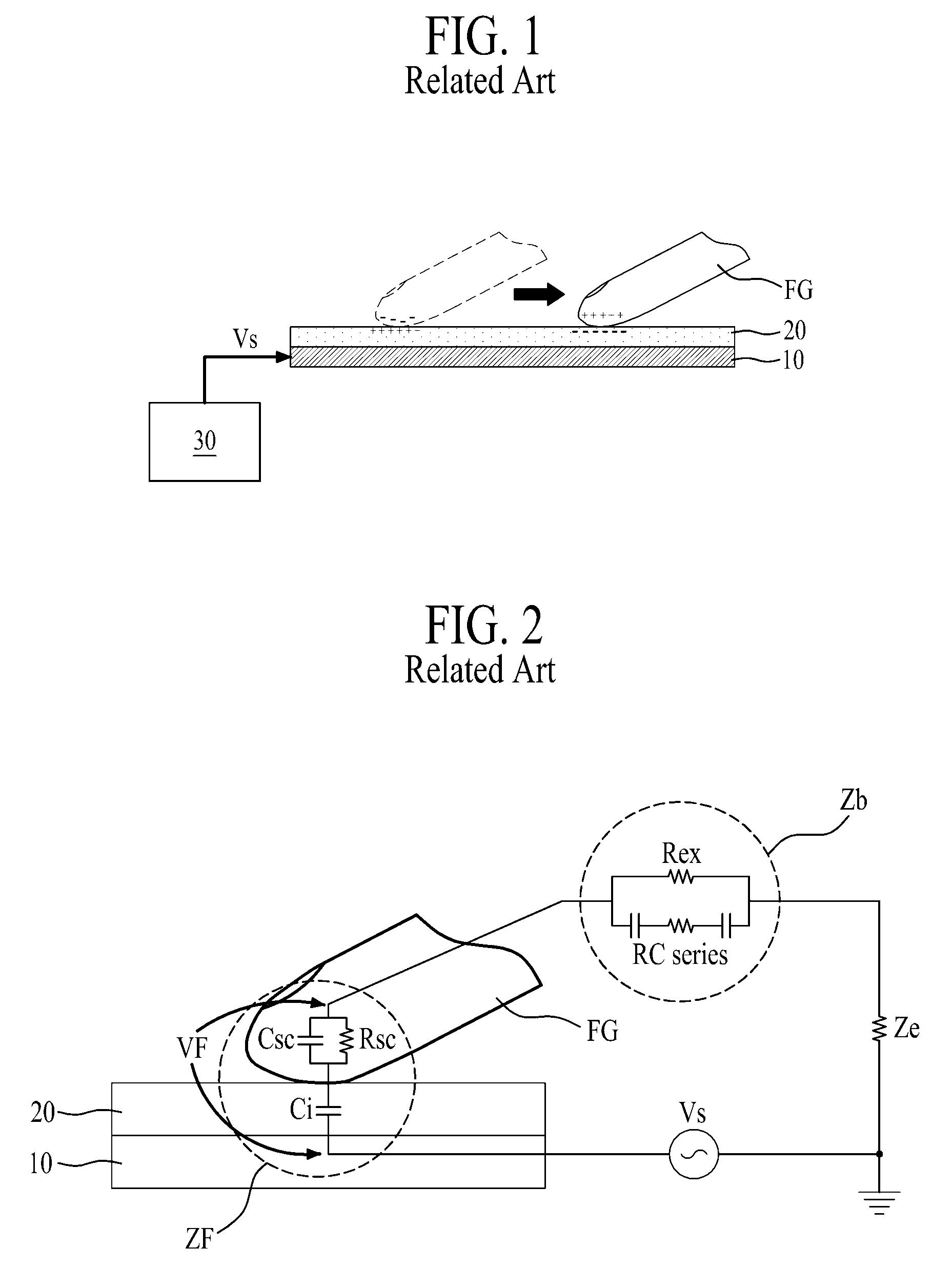

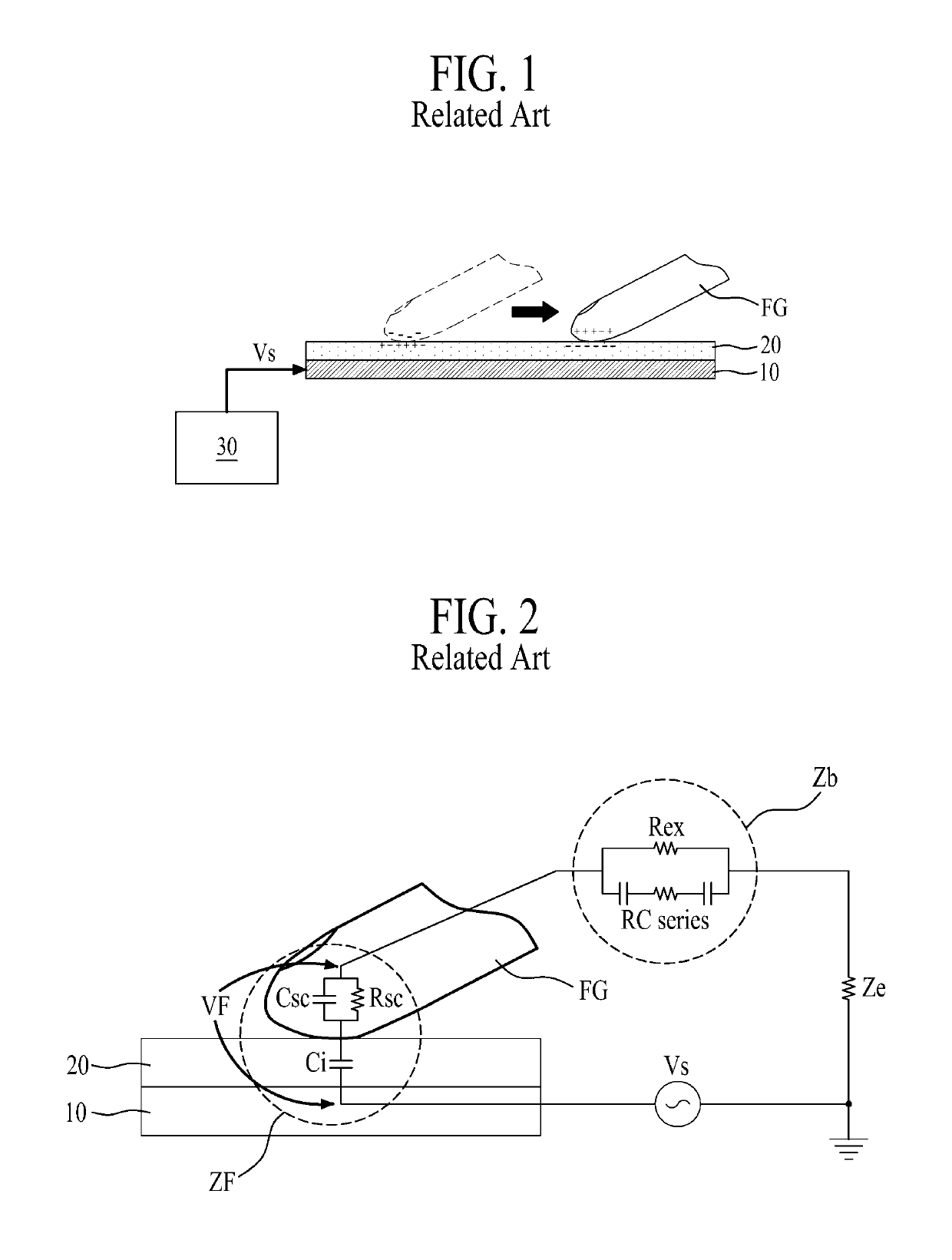

The history of electrovibration goes back to 1954. It was first discovered by accident and E. Mallinckrodt, A. L. Hughes and W. Sleator Jr. reported “... that dragging a dry finger over a conductive surface covered with a thin insulating layer and excited with a 110 V signal, created a characteristic rubbery feeling”. In their experiment, the finger and the metal surface create a capacitive setup. The attraction force created between the finger and the surface was too weak to perceive, but it generated a rubbery sensation when the finger was moving on the surface. This sensation was named "electrovibration" by the group. Today, Senseg and Disney Research are developing technology that could bring electrovibration to modern touchscreen devices.

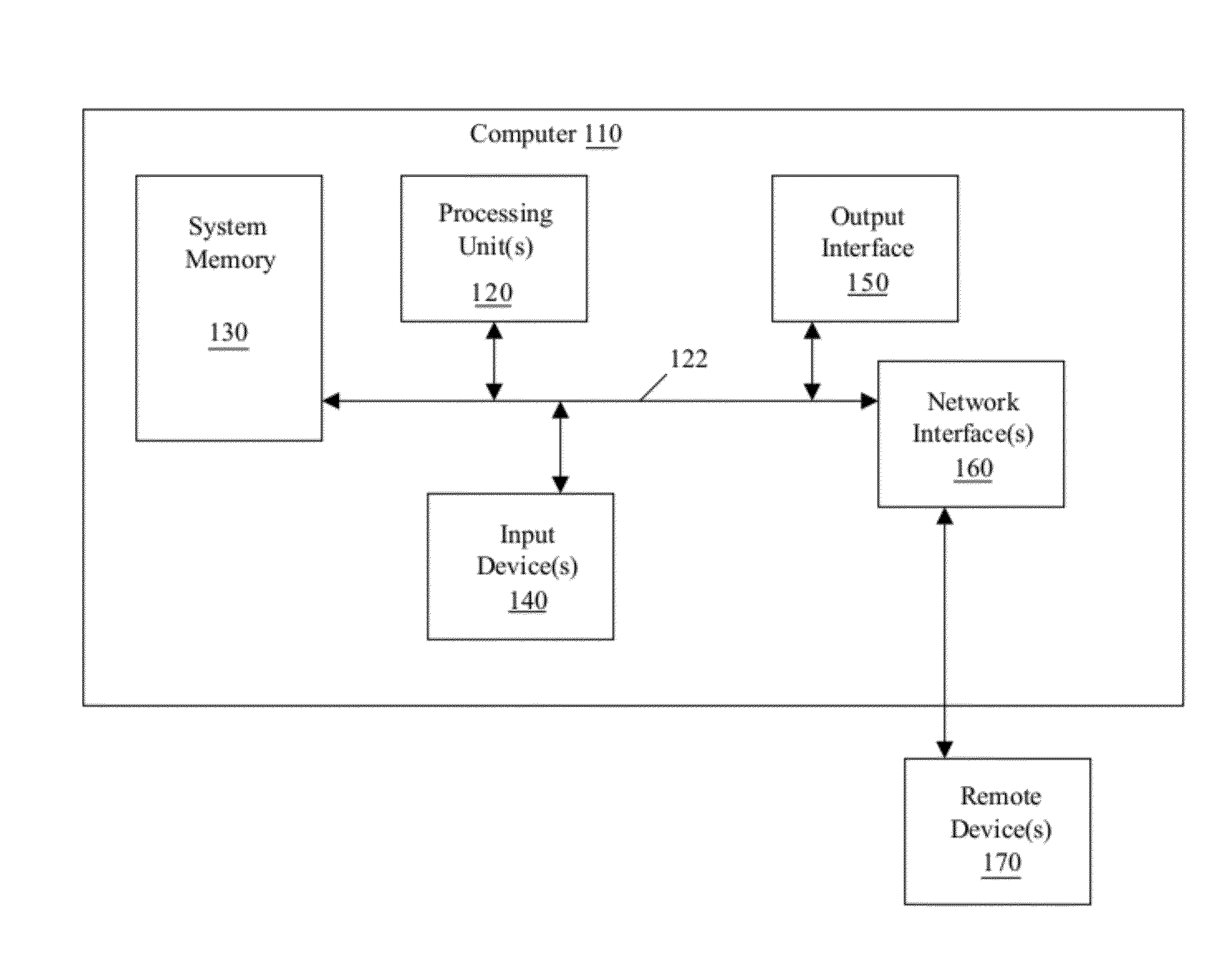

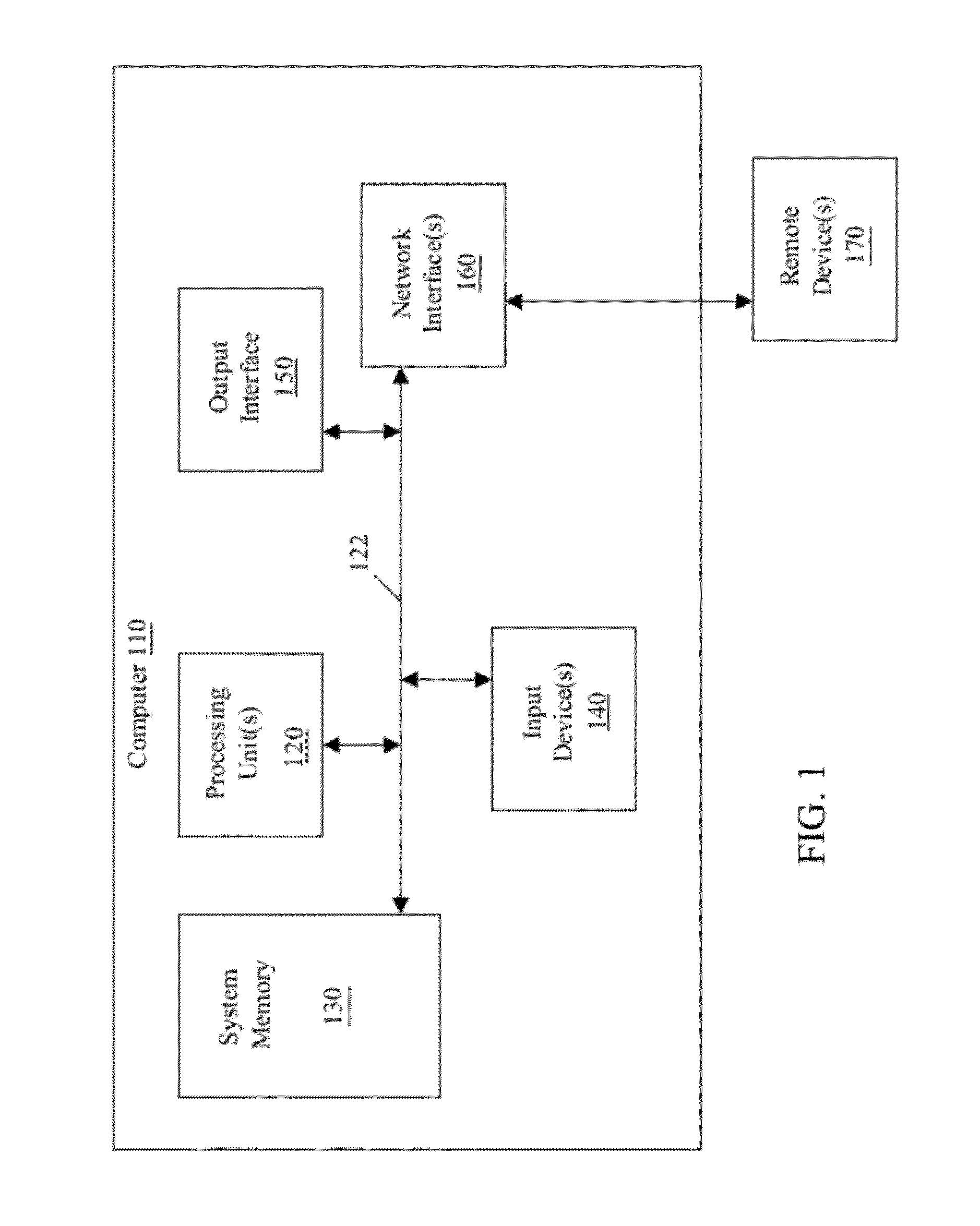

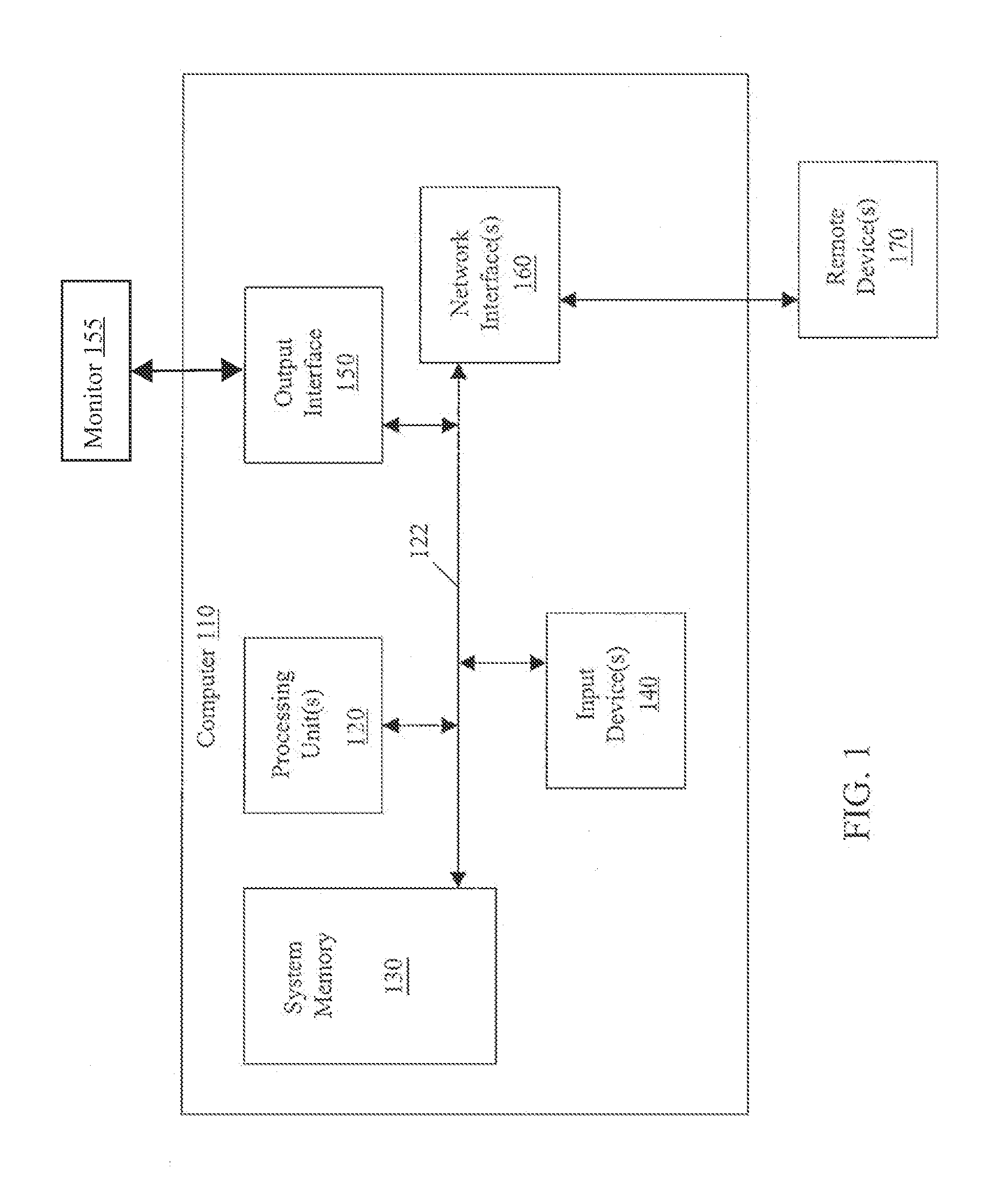

Using tactile feedback to provide spatial awareness

An image capturing device may be combined with a touch screen to generate a tactile map of an environment. The image capturing device captures an image of the environment which is then processed and used to correlate a point of user contact on a touch screen to a particular tactile sensation. The touch screen may then generate an electric signal (i.e., tactile feedback) corresponding to the tactile sensation which is felt by a user contacting the touch screen. By using the electrical signal as tactile feedback (e.g., electrovibration), the user may determine relative spatial locations of the objects in the environment, the objects' physical characteristics, the distance from the objects to the image capturing device, and the like.

Owner:DISNEY ENTERPRISES INC

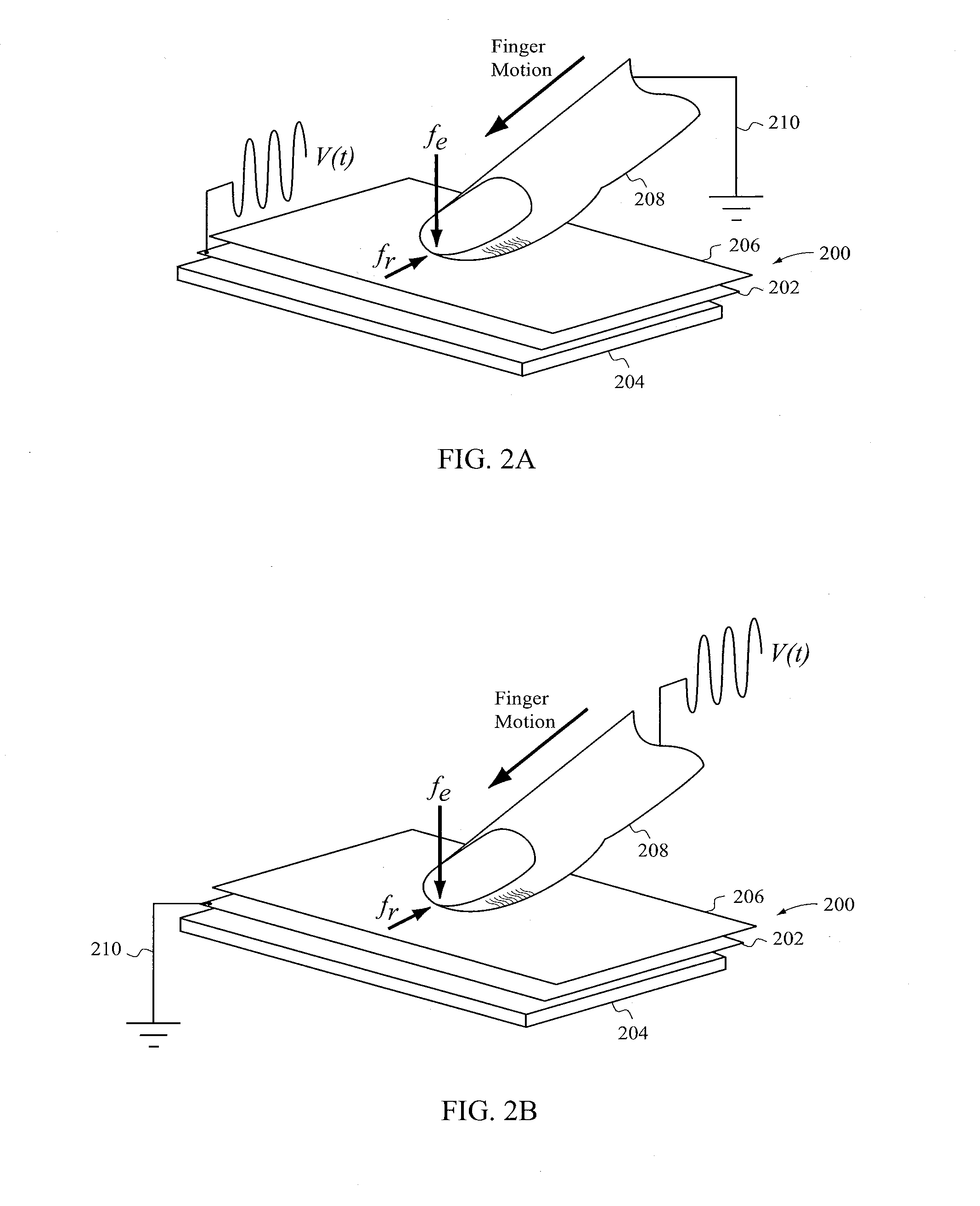

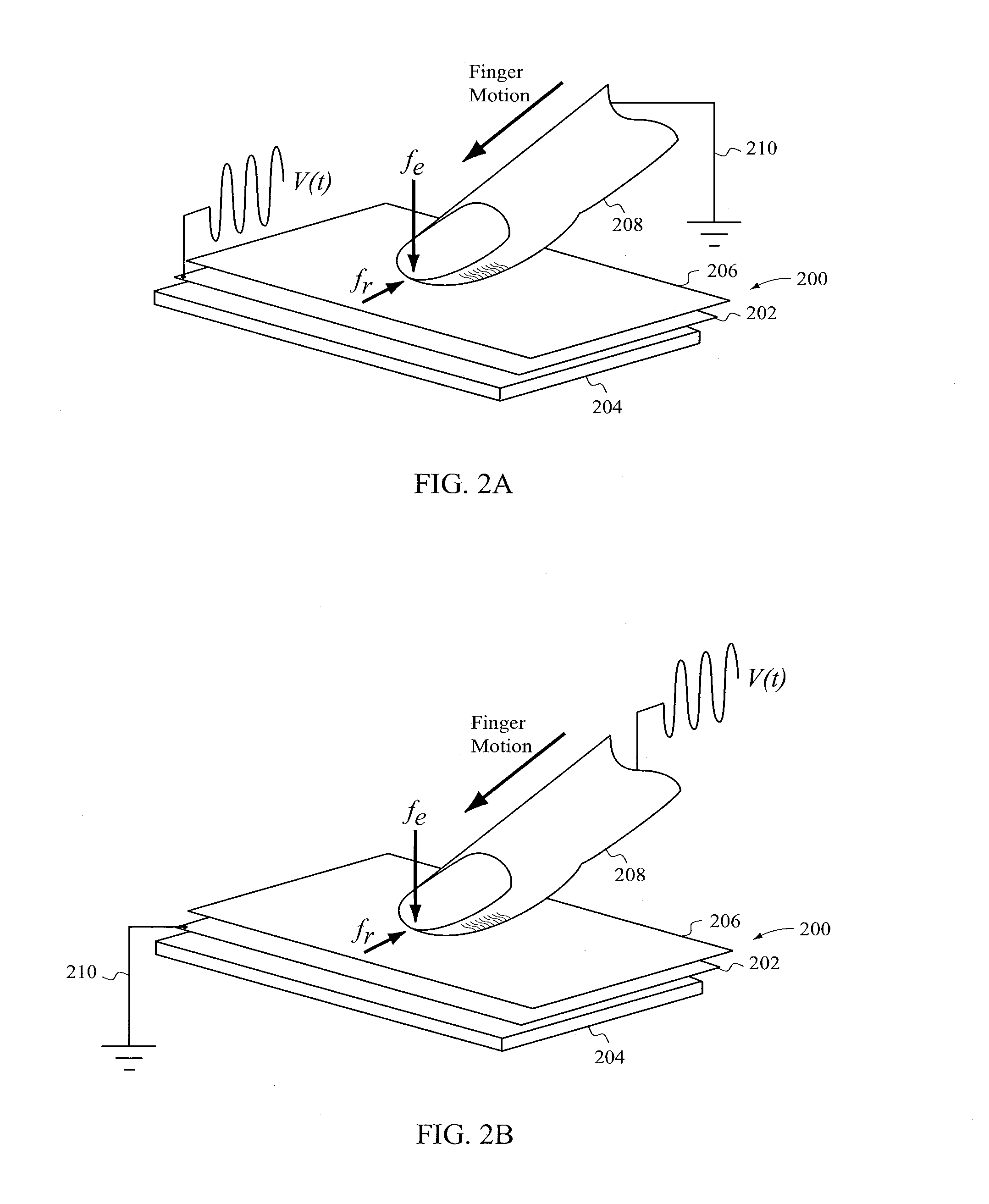

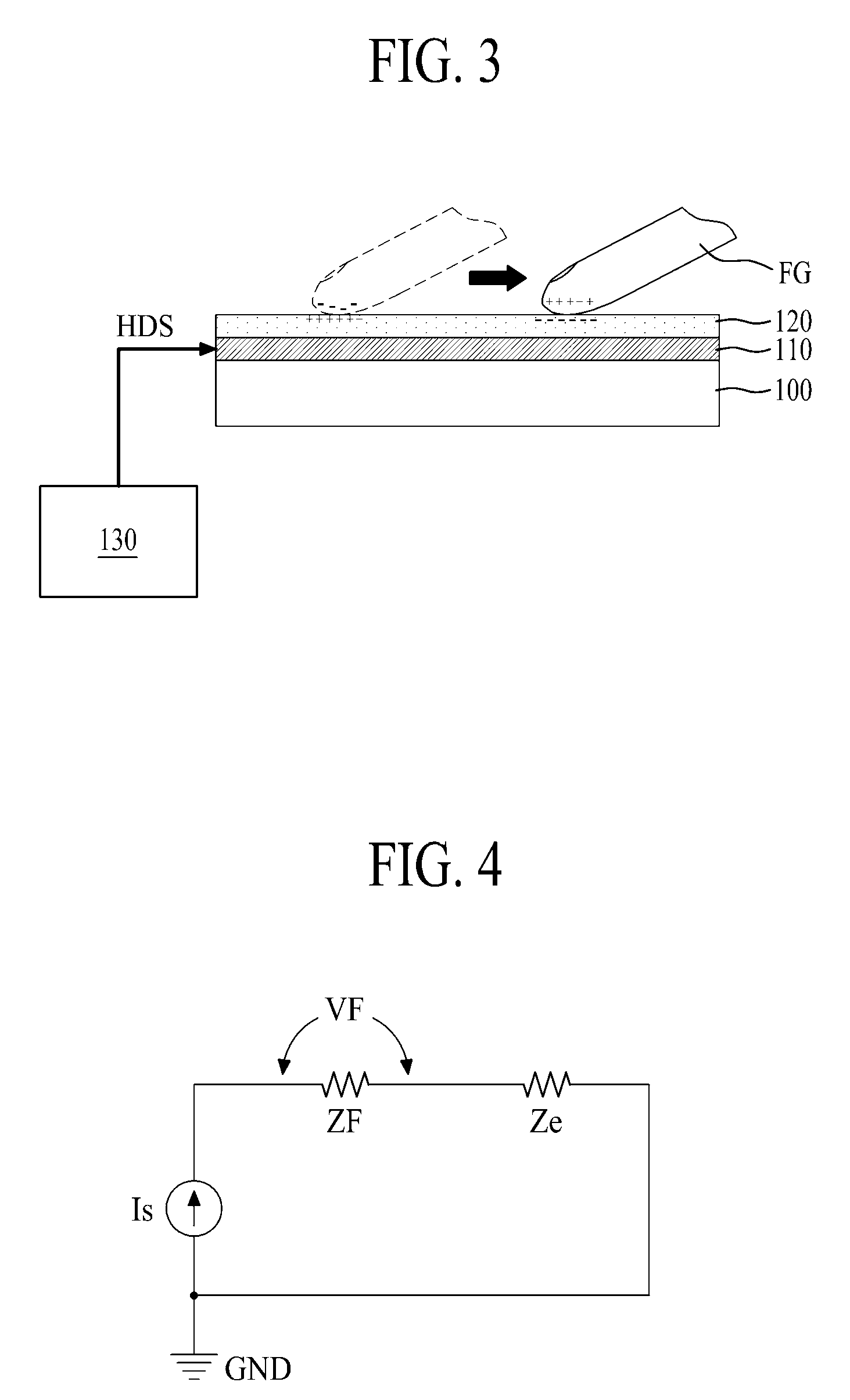

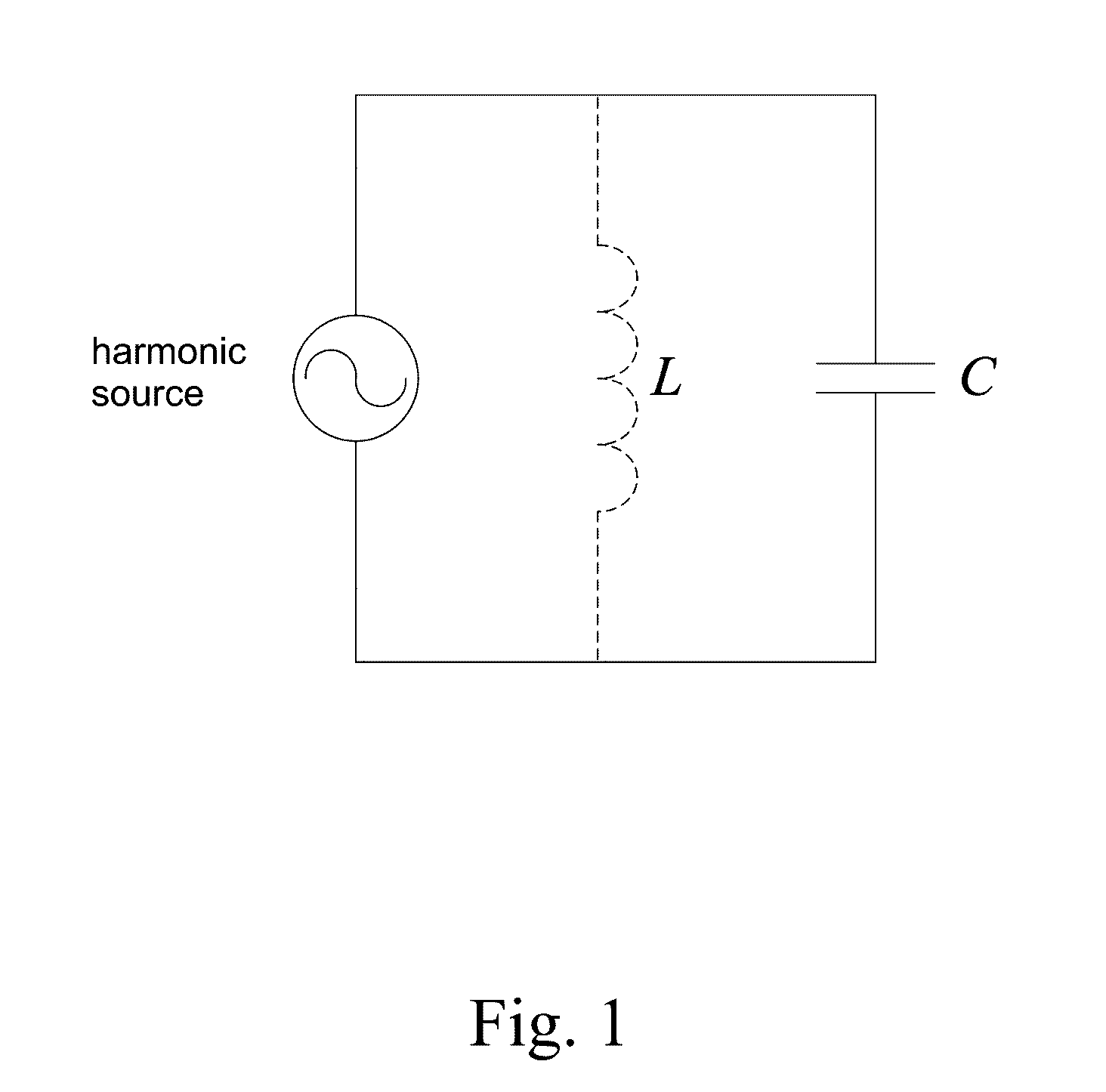

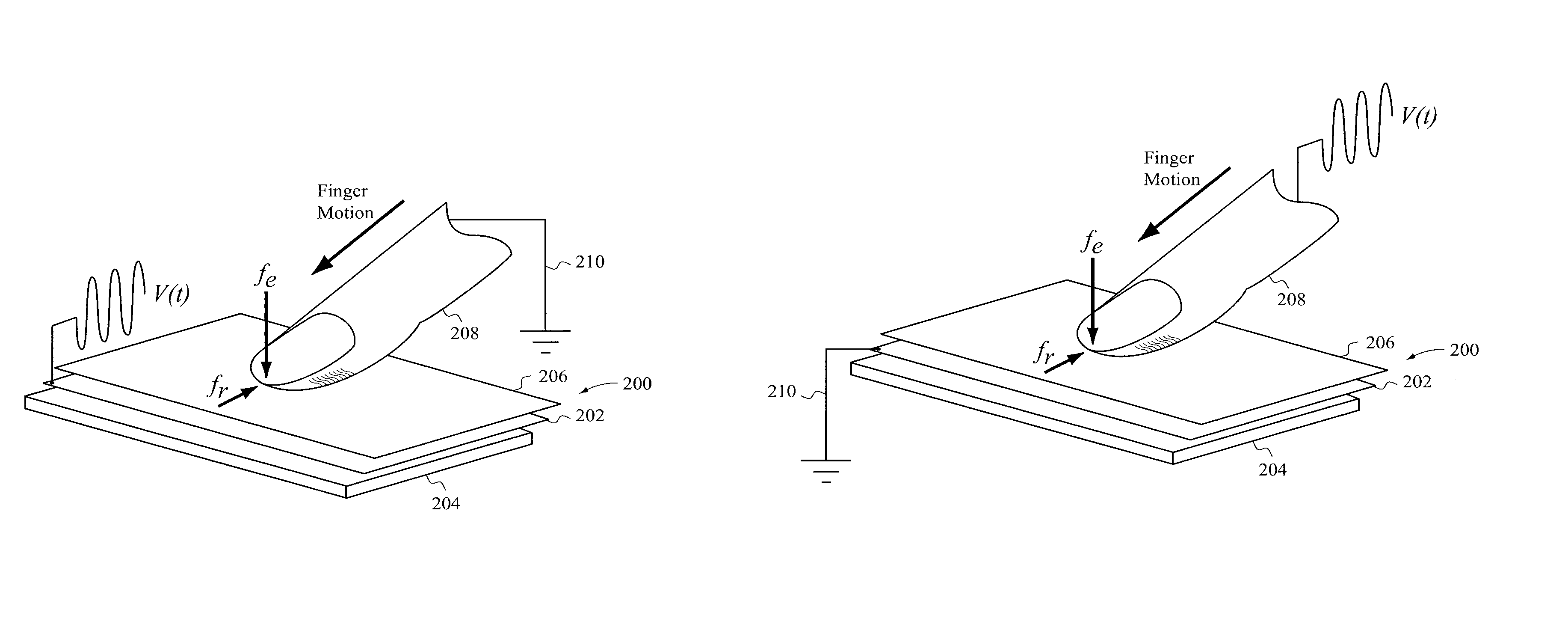

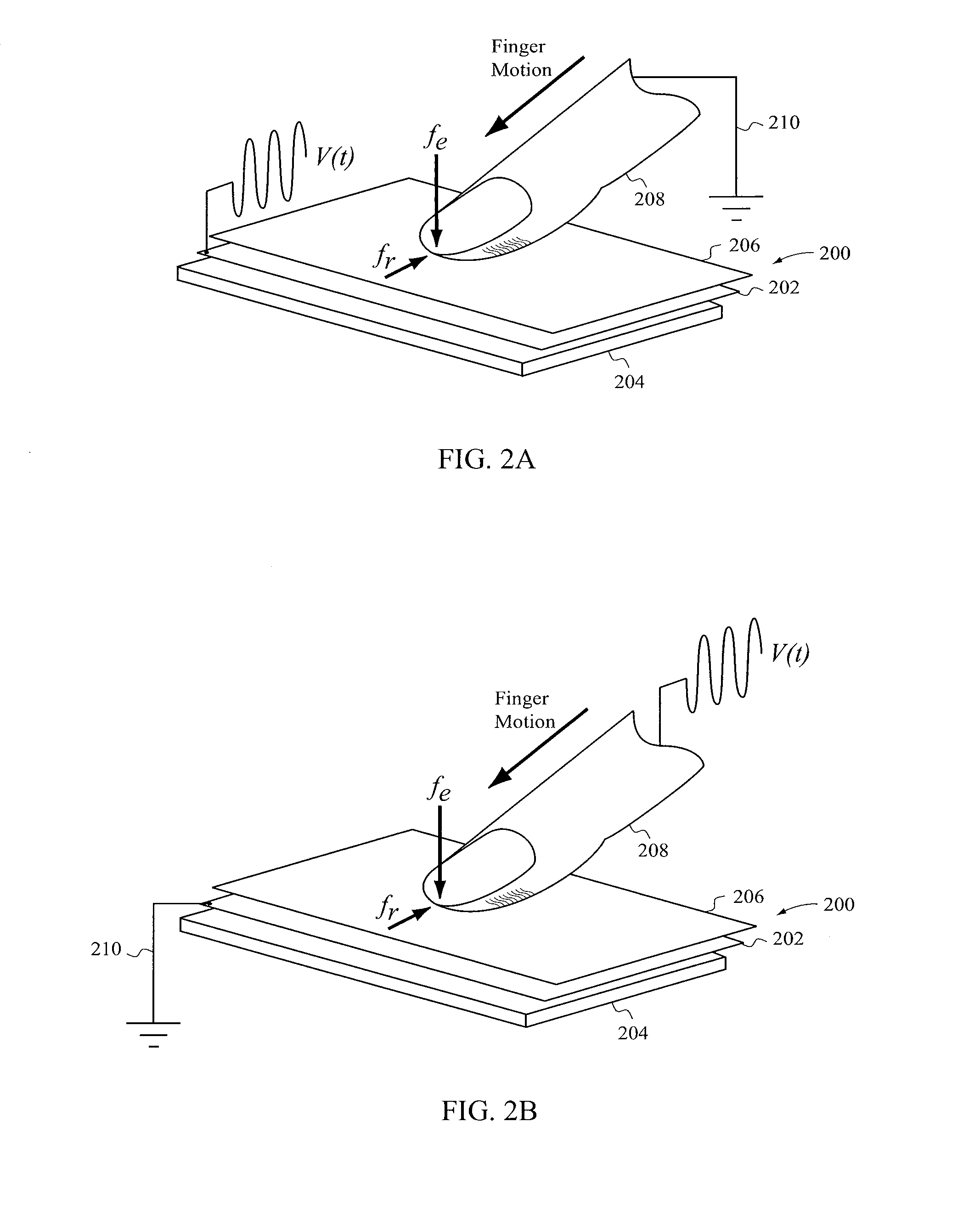

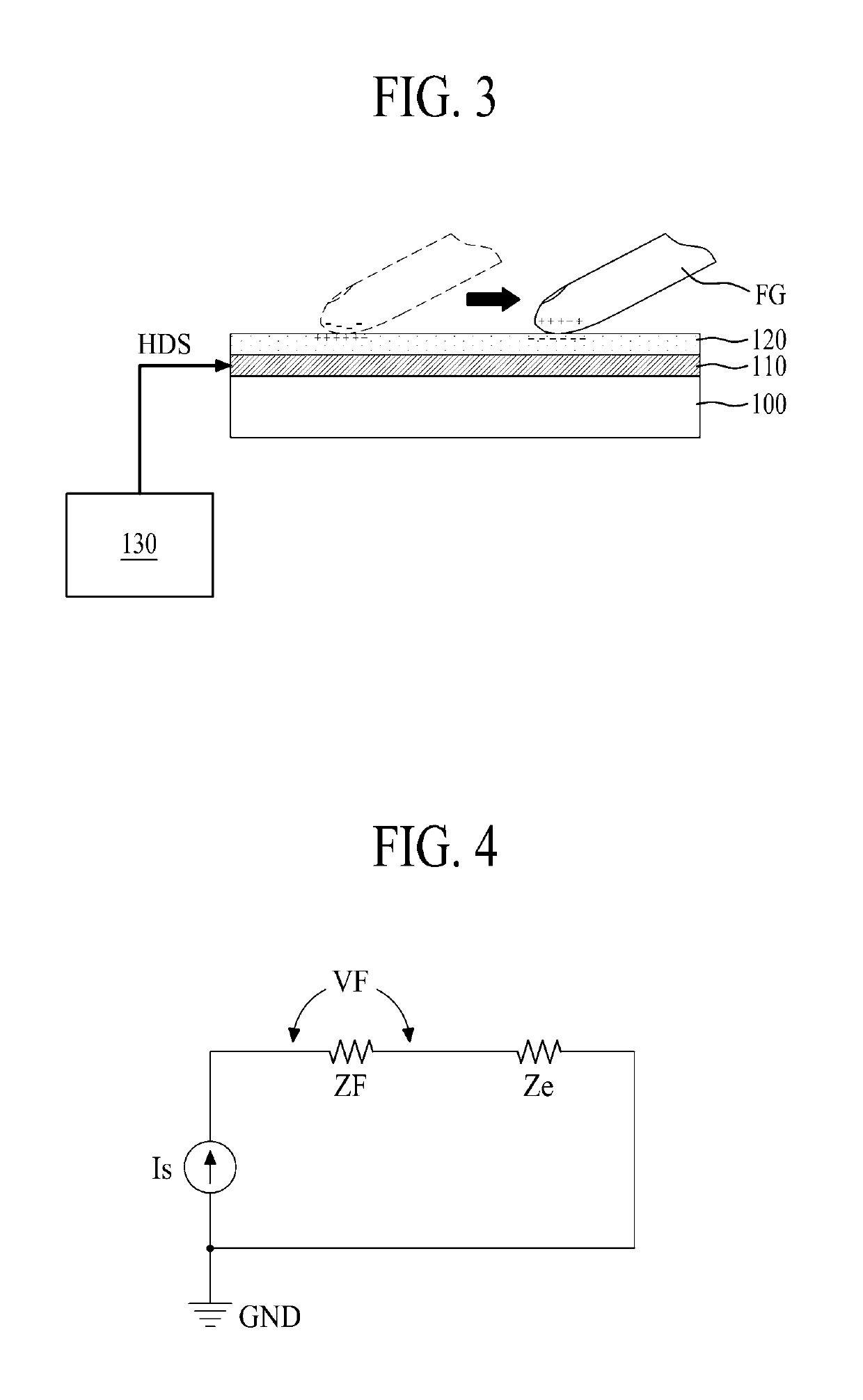

Electrovibration for touch surfaces

ActiveUS20110285667A1Input/output processes for data processingTactile sensationElectrical and Electronics engineering

An apparatus that includes a conductive surface and an insulation surface disposed on the conductive surface. The apparatus further includes a controller configured to cause a signal to be coupled to the conductive surface such that a tactile sensation is perceived in a digit that slides on the insulation surface.

Owner:DISNEY ENTERPRISES INC

Electrovibration for touch surfaces

InactiveUS20110285666A1Repeater circuitsInput/output processes for data processingElectricityTactile sensation

An apparatus that includes a conductive surface and an insulation surface disposed on the conductive surface. The apparatus further includes a controller configured to cause a signal to be coupled to the conductive surface such that a tactile sensation is perceived in a digit that slides on the insulation surface.

Owner:DISNEY ENTERPRISES INC

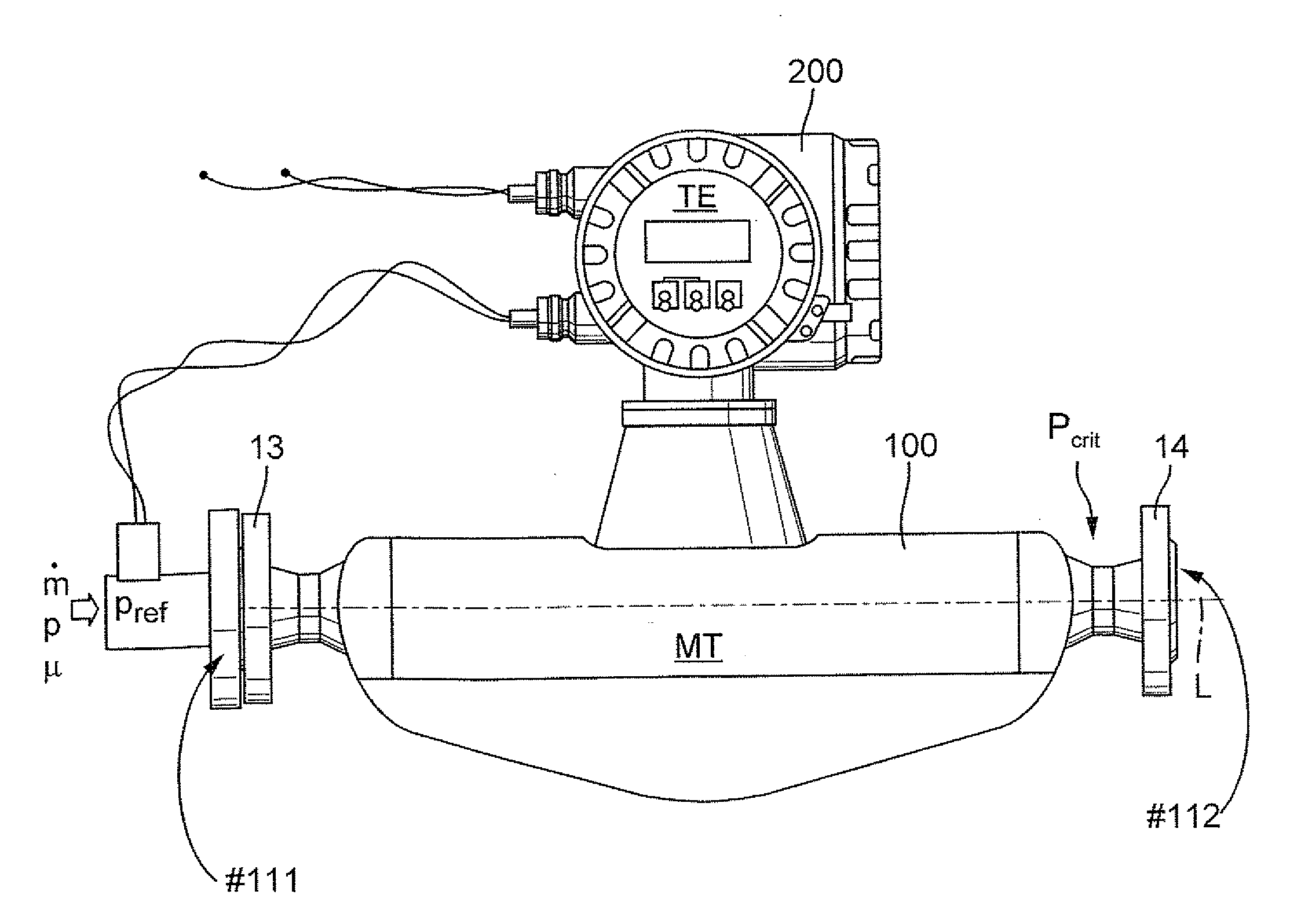

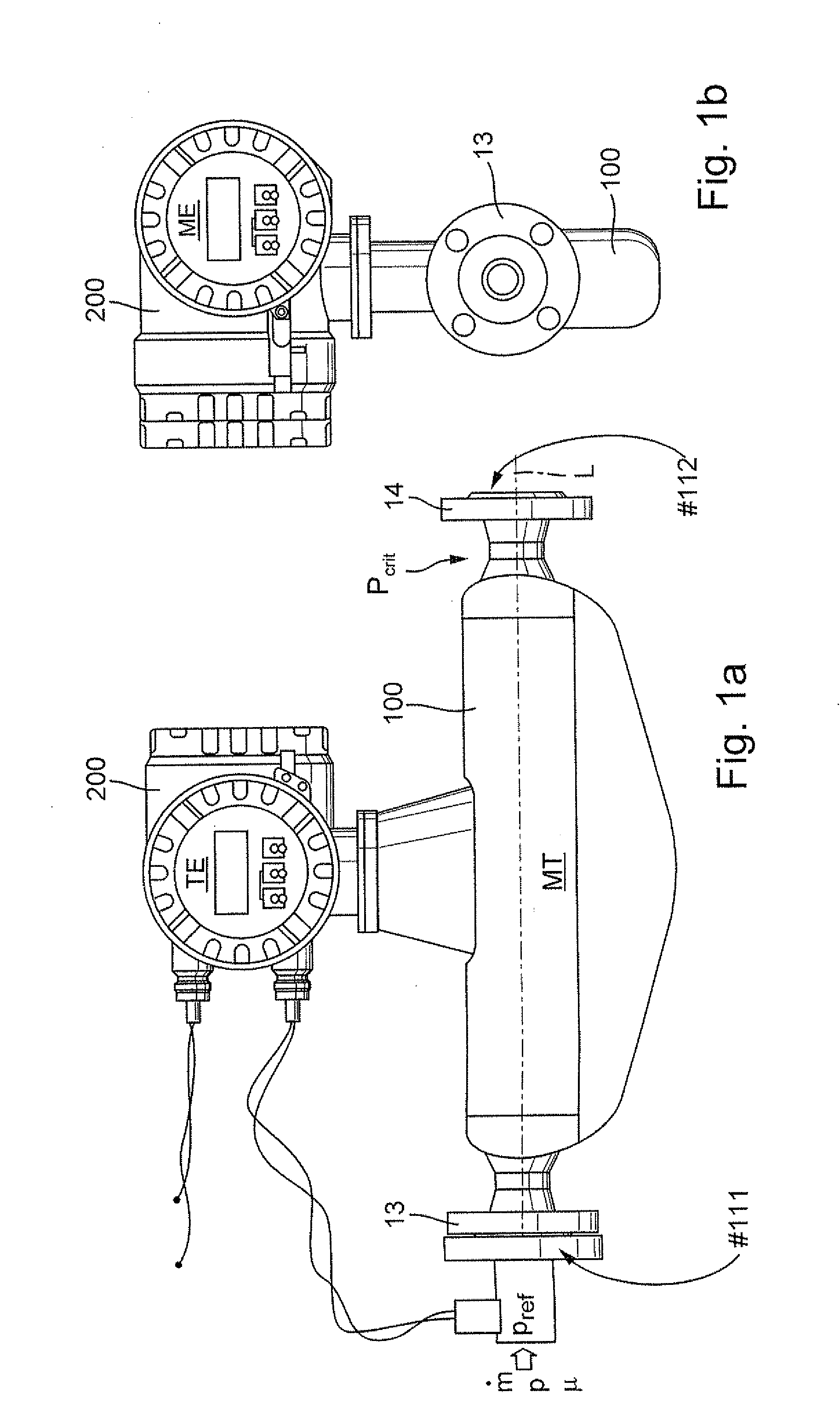

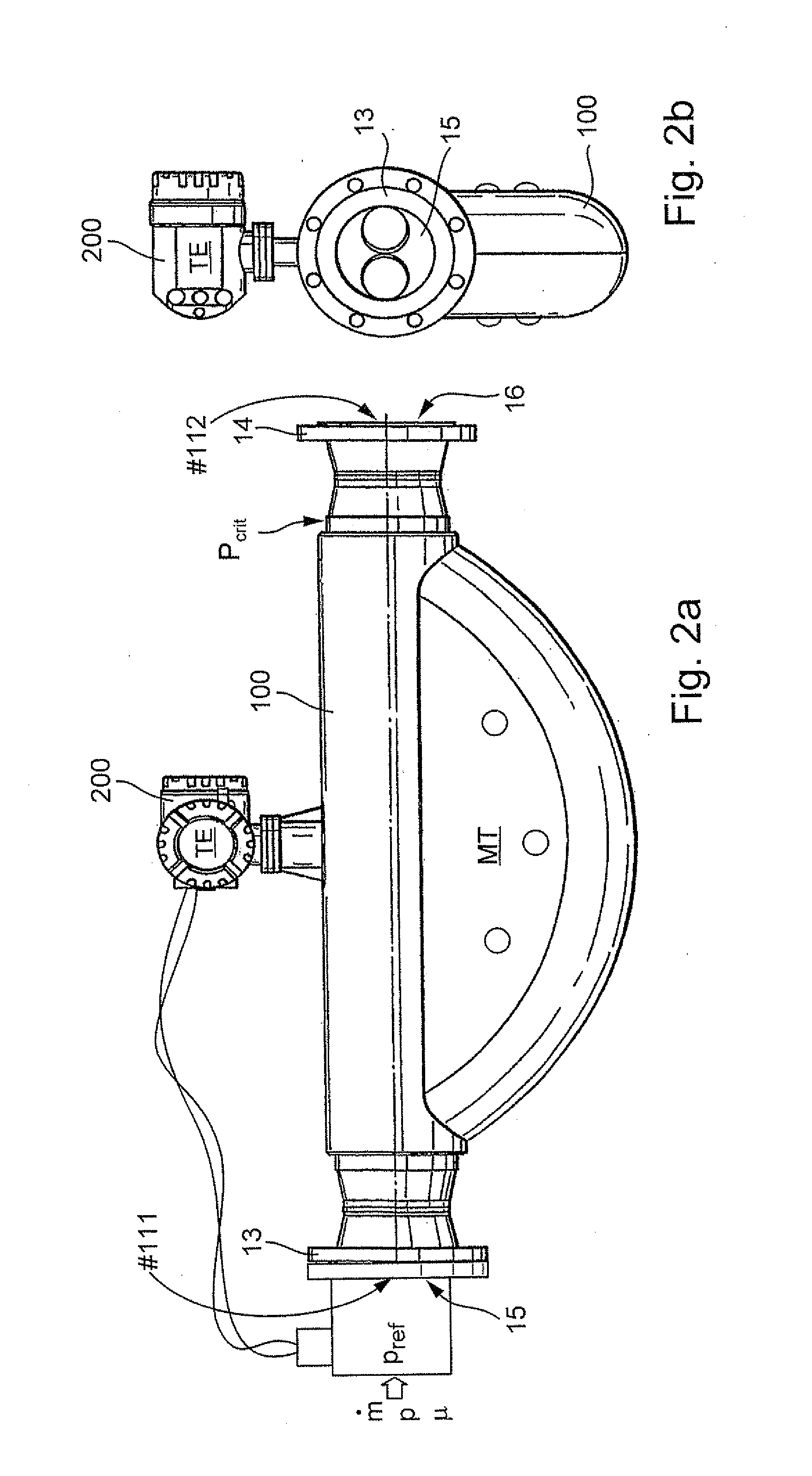

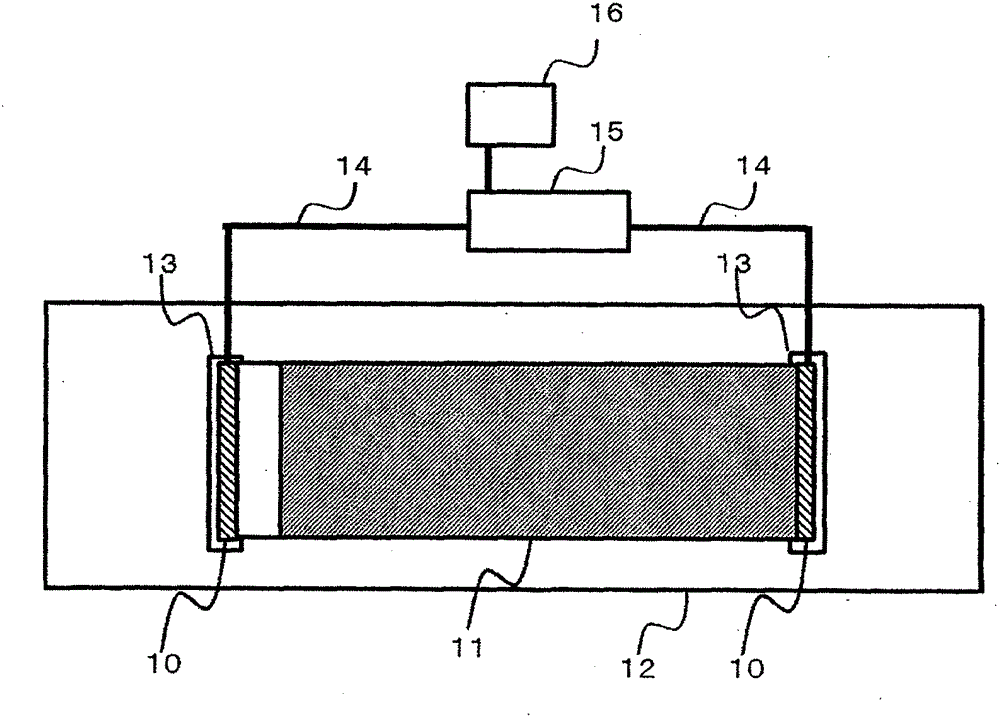

Measuring system having a measuring transducer of vibration-type

ActiveUS20110154912A1High measurement accuracyVolume/mass flow by dynamic fluid flow effectElectricityTransducer

The measuring system comprises: A measuring transducer of vibration-type, through which medium flows during operation and which produces primary signals corresponding to parameters of the flowing medium; as well as a transmitter electronics electrically coupled with the measuring transducer for activating the measuring transducer and for evaluating primary signals delivered by the measuring transducer. The measuring transducer includes: At least one measuring tube for conveying flowing medium; at least one electro-mechanical, oscillation exciter for exciting and / or maintaining vibrations of the at least one measuring tube; as well as at least a first oscillation sensor for registering vibrations at least of the at least one measuring tube and for producing a first primary signal of the measuring transducer representing vibrations at least of the at least one measuring tube. The transmitter electronics, in turn, delivers at least one driver signal for the exciter mechanism for effecting vibrations of the at least one measuring tube and generates, by means of the first primary signal, as well as with application of a damping, measured value, which represents an excitation power required for maintaining vibrations of the at least one measuring tube, and, respectively, a damping of vibrations of the at least one measuring tube as a result of inner friction in the medium flowing in the measuring transducer, a pressure difference, measured value, which represents a pressure difference occurring between two predetermined reference points in the flowing medium.

Owner:ENDRESS HAUSER FLOWTEC AG

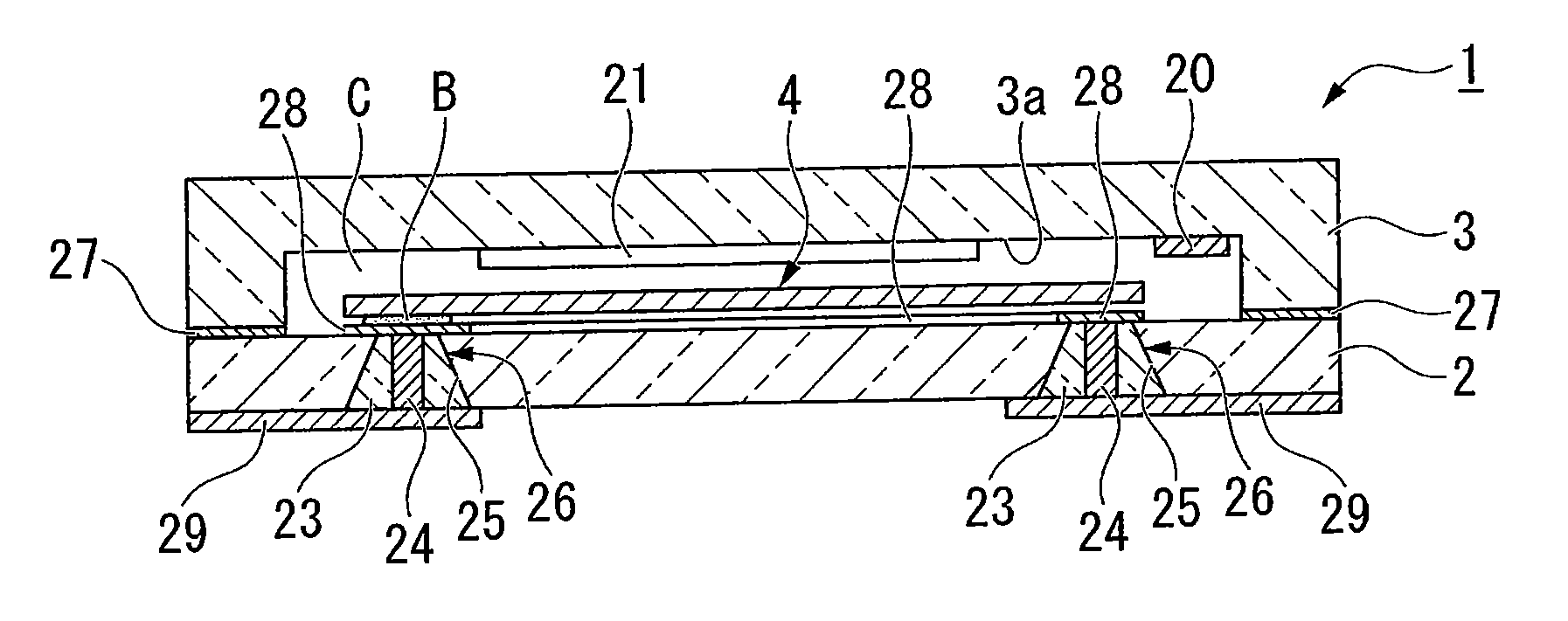

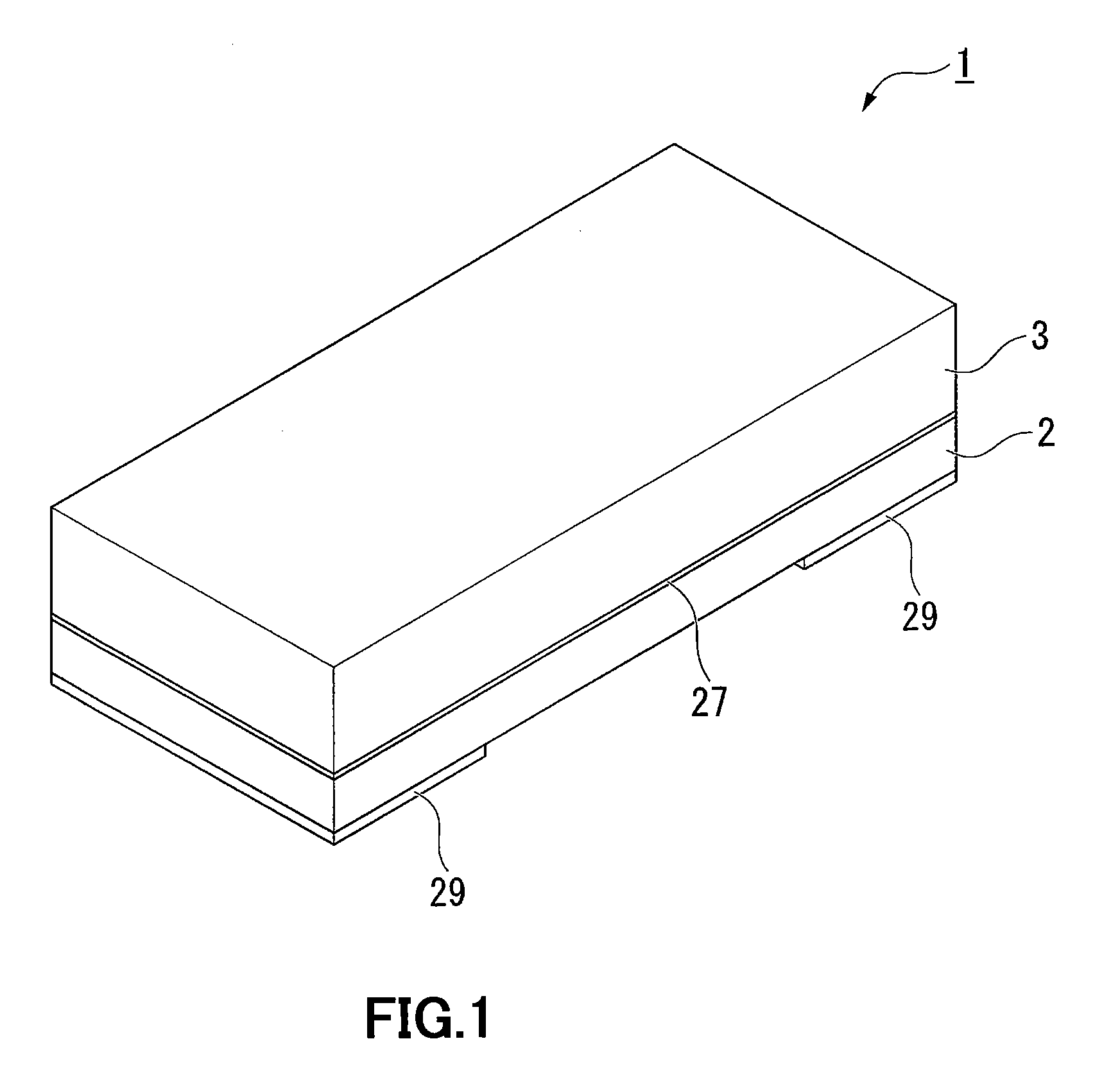

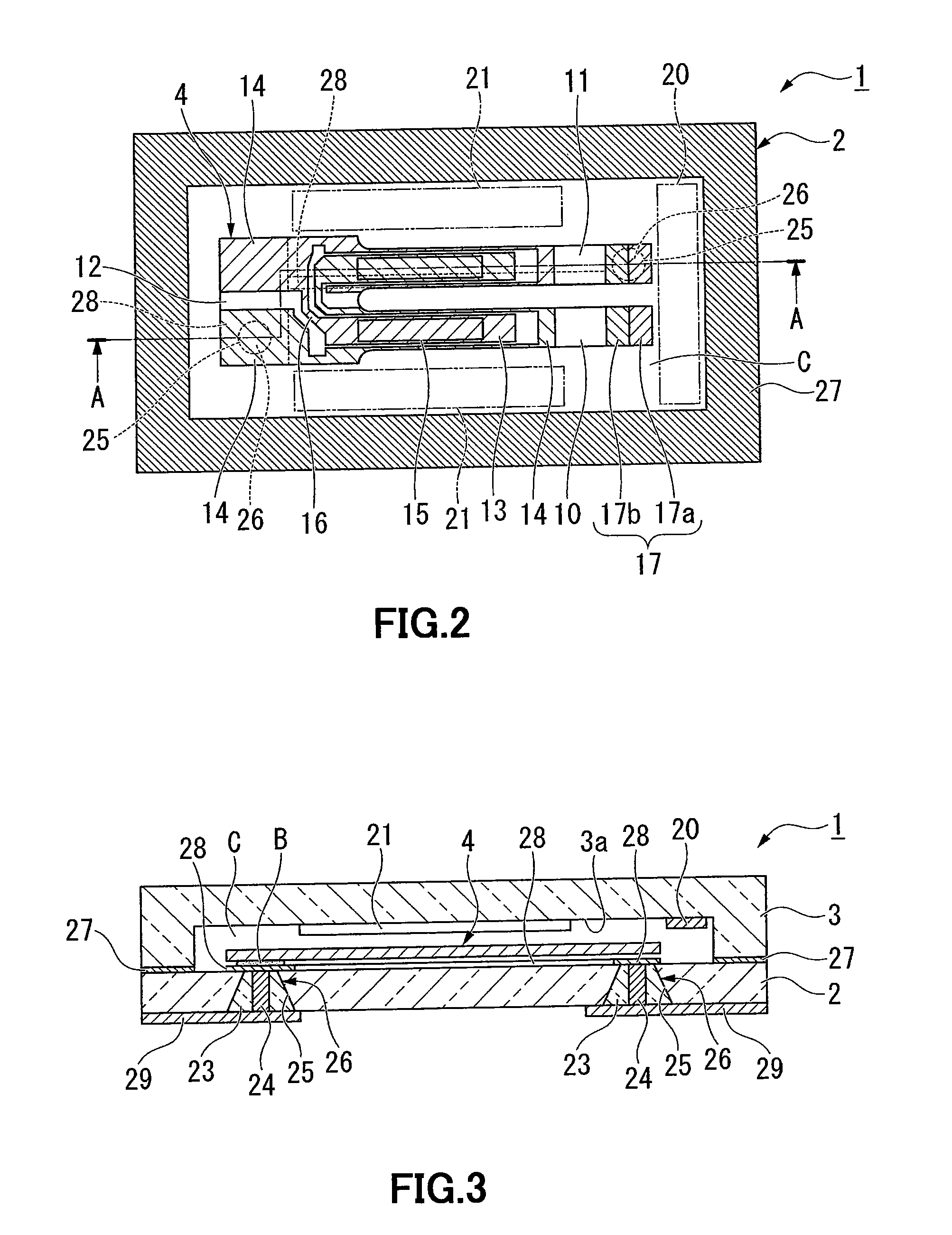

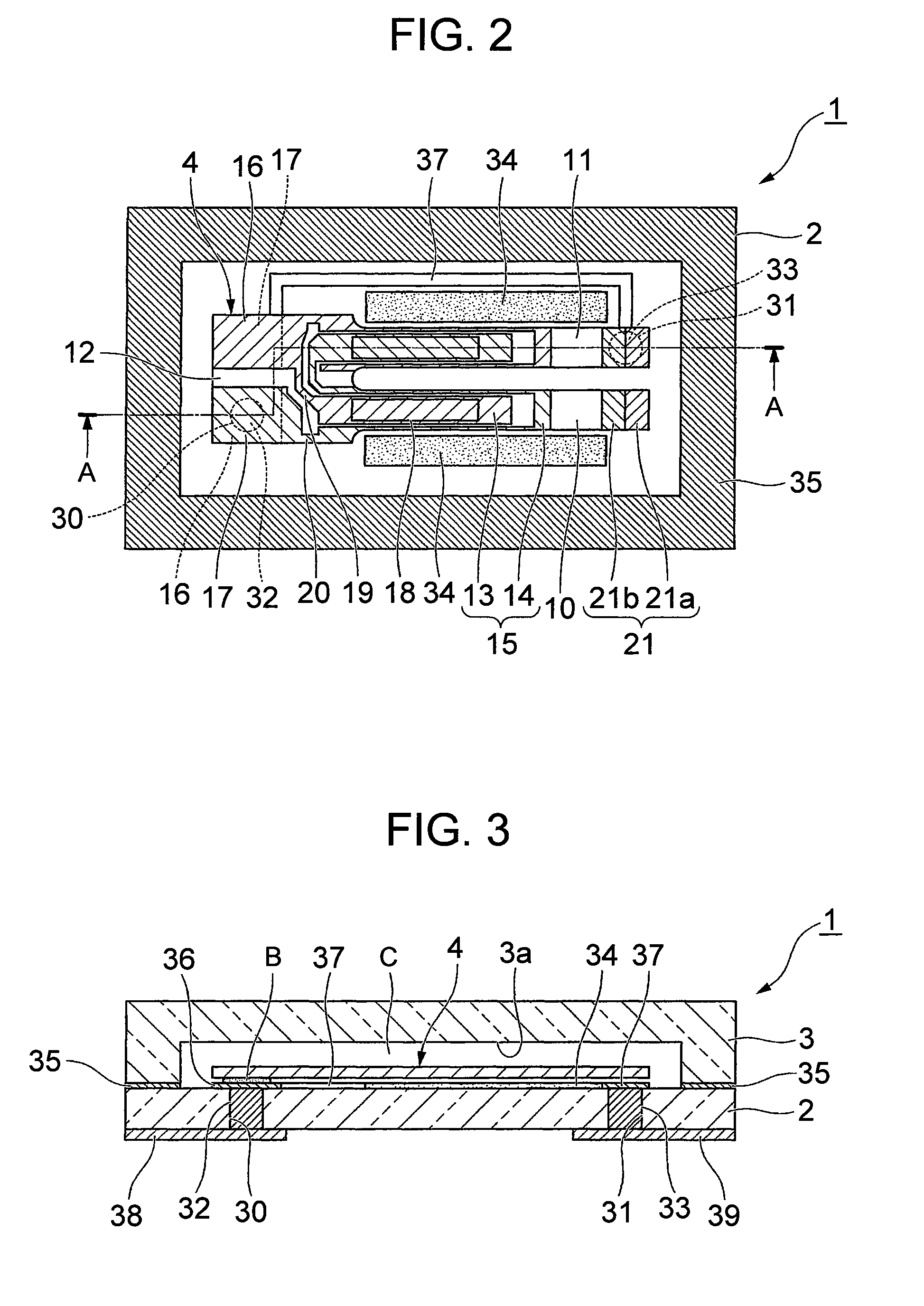

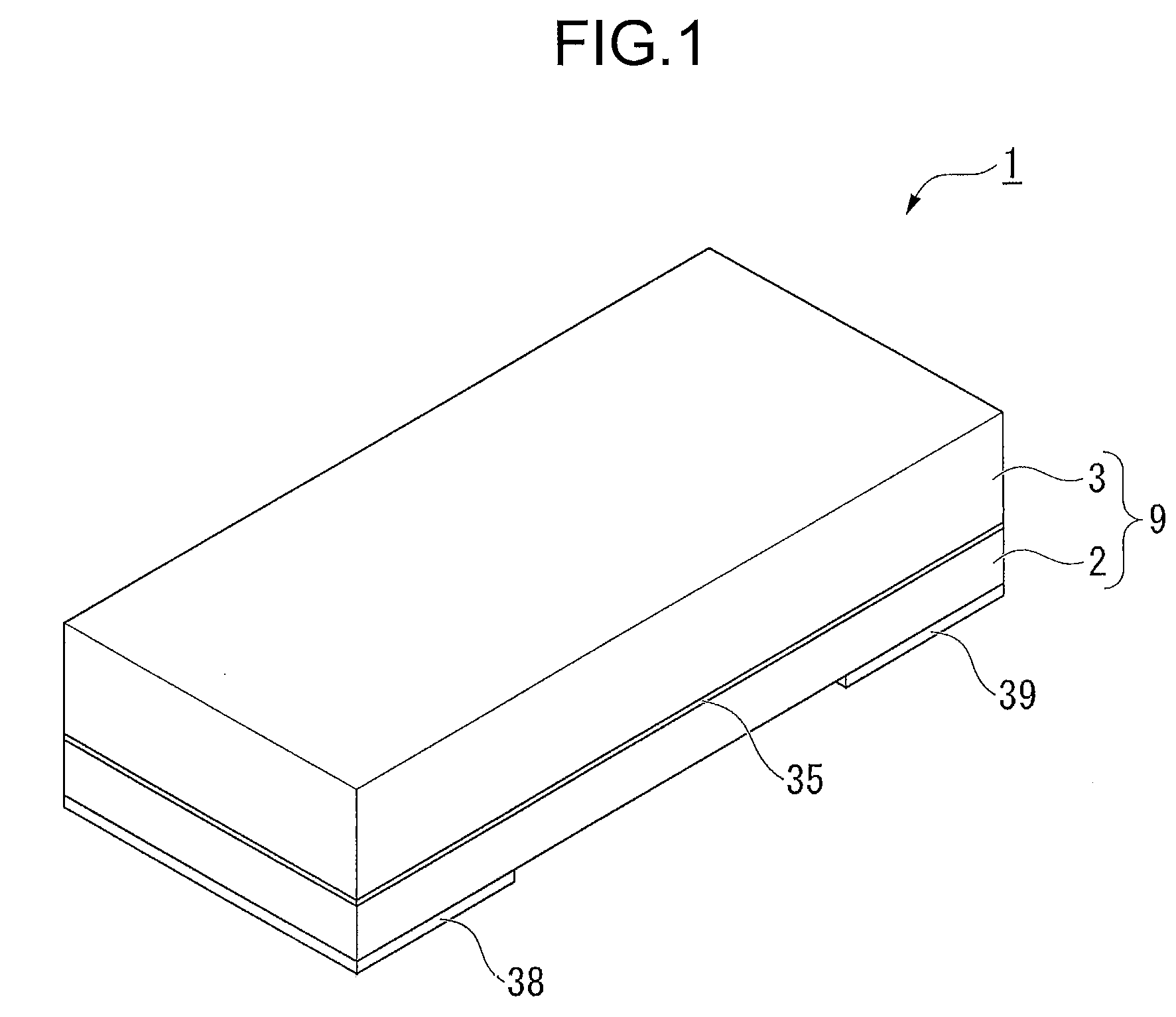

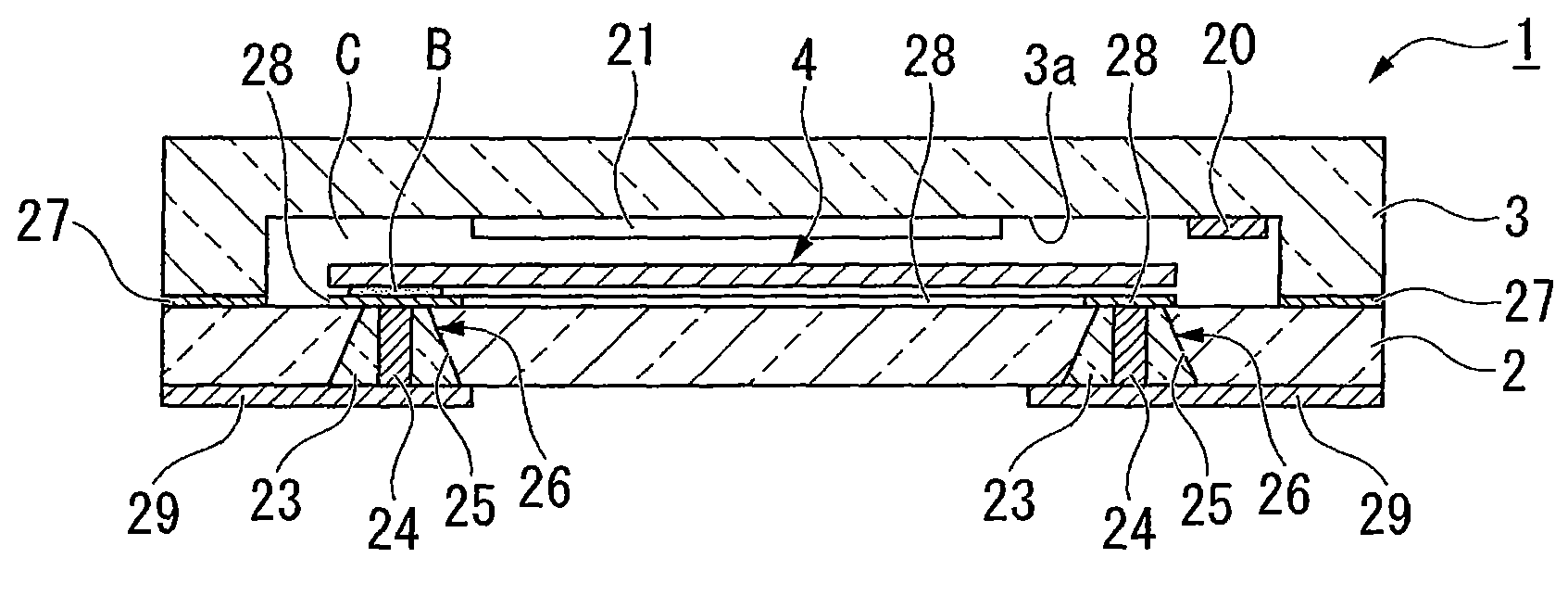

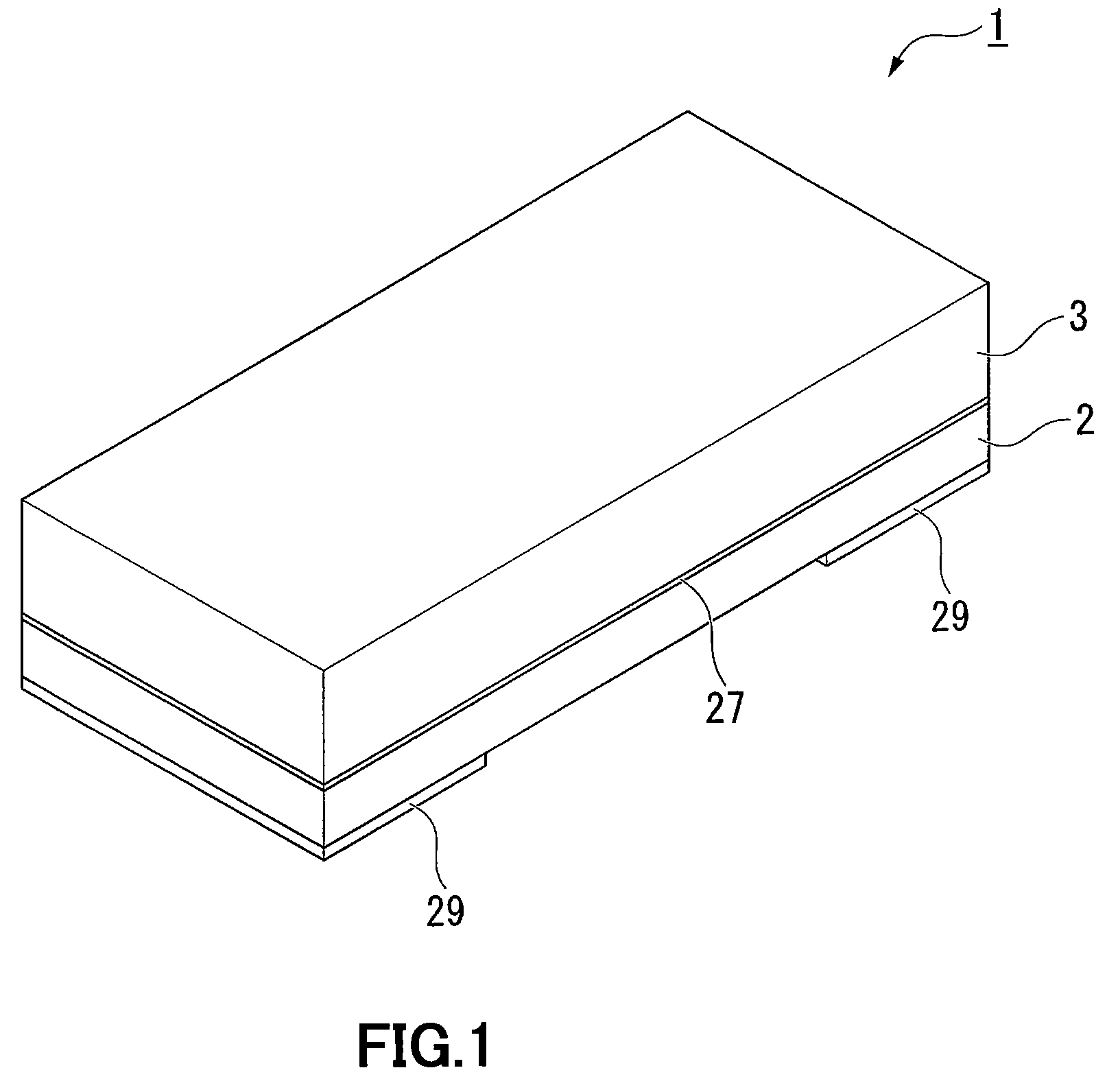

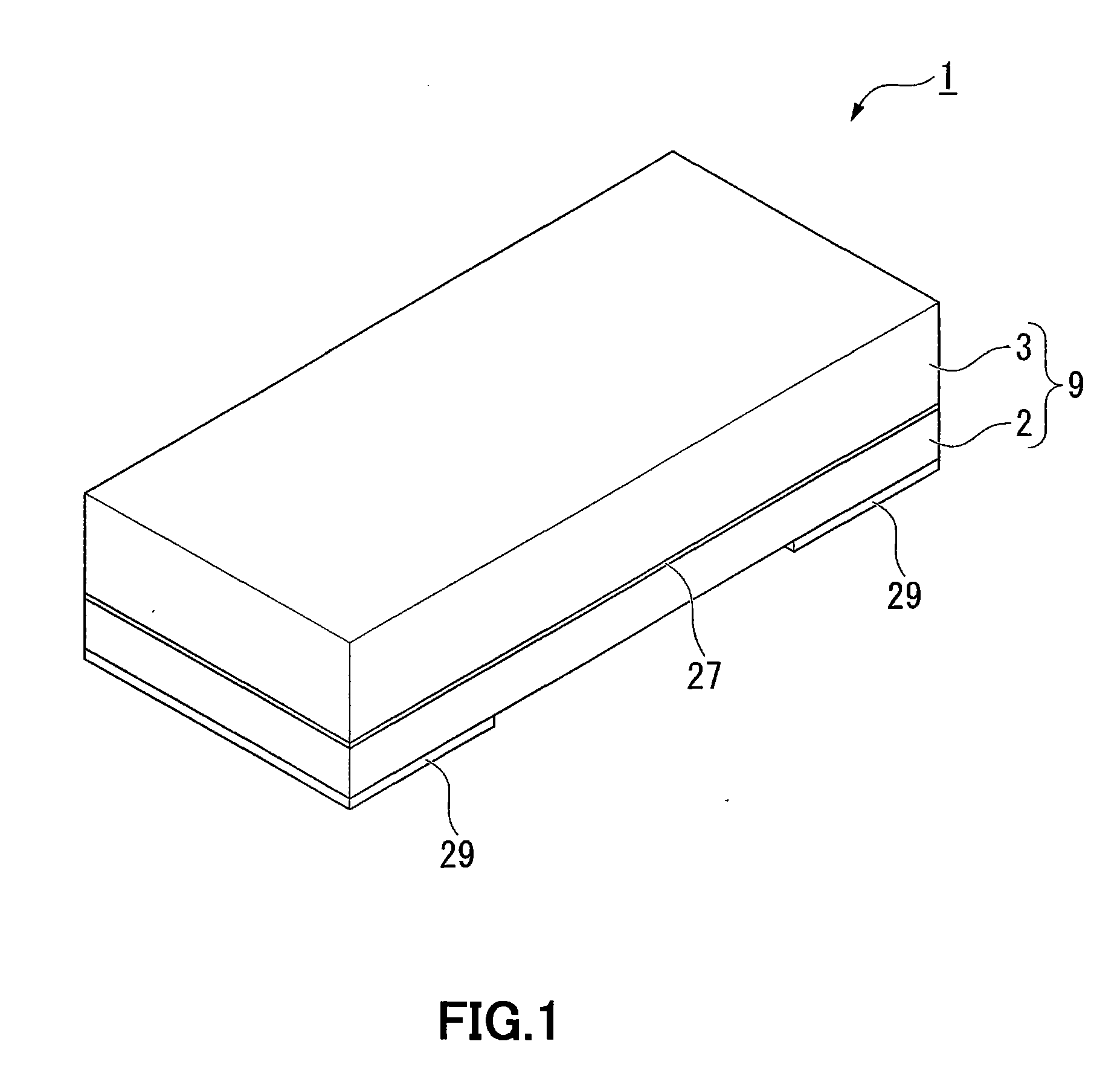

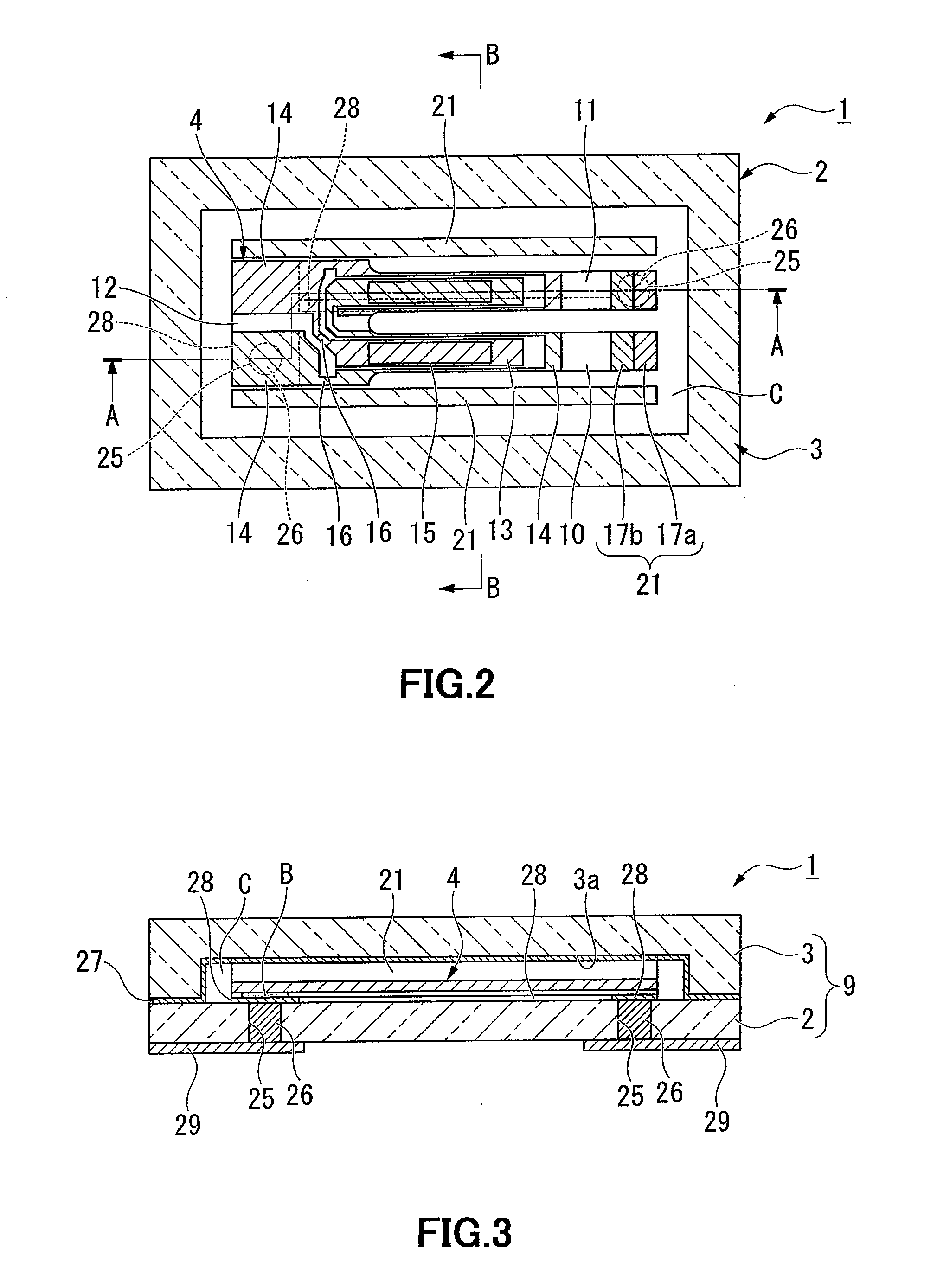

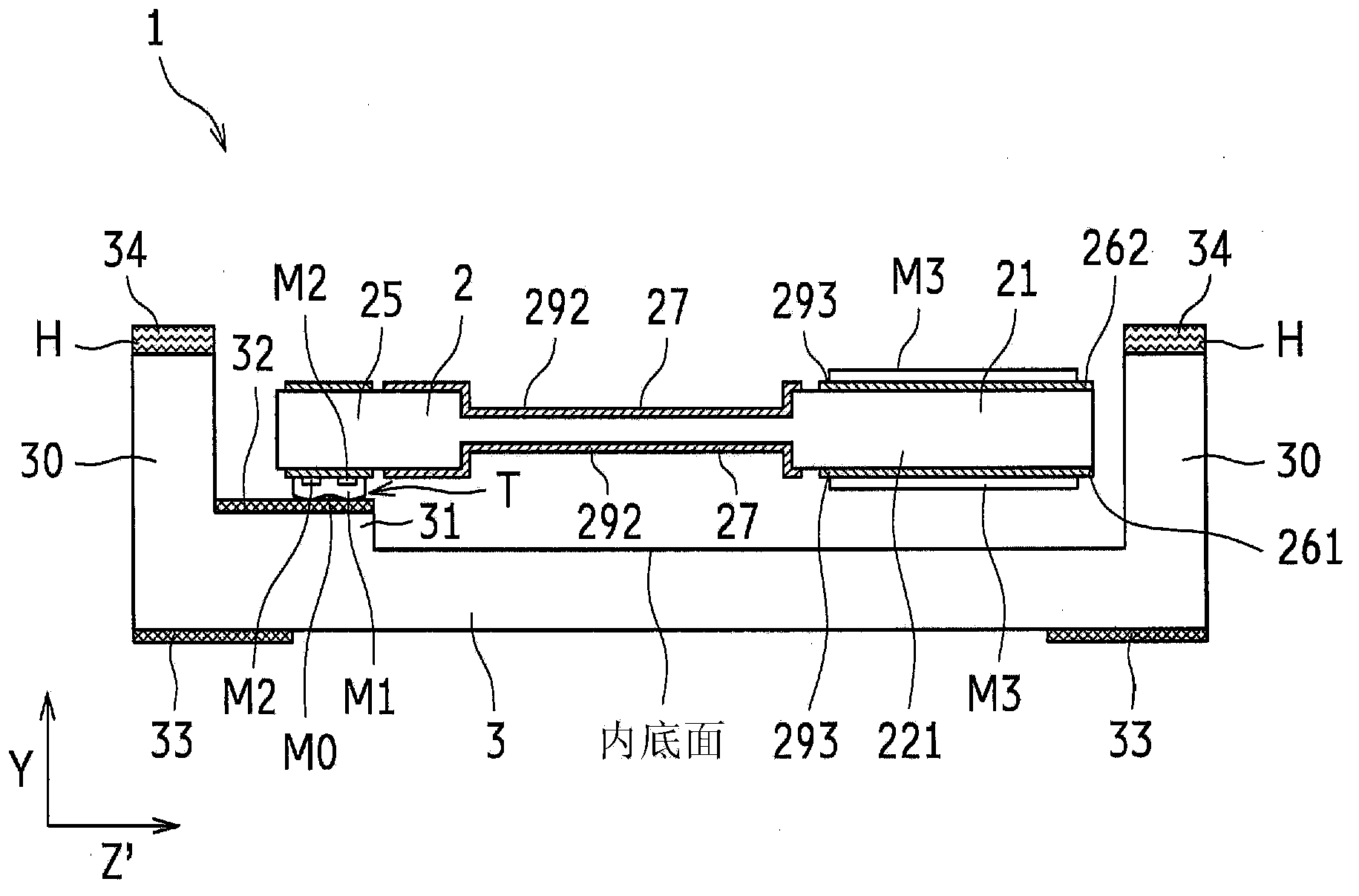

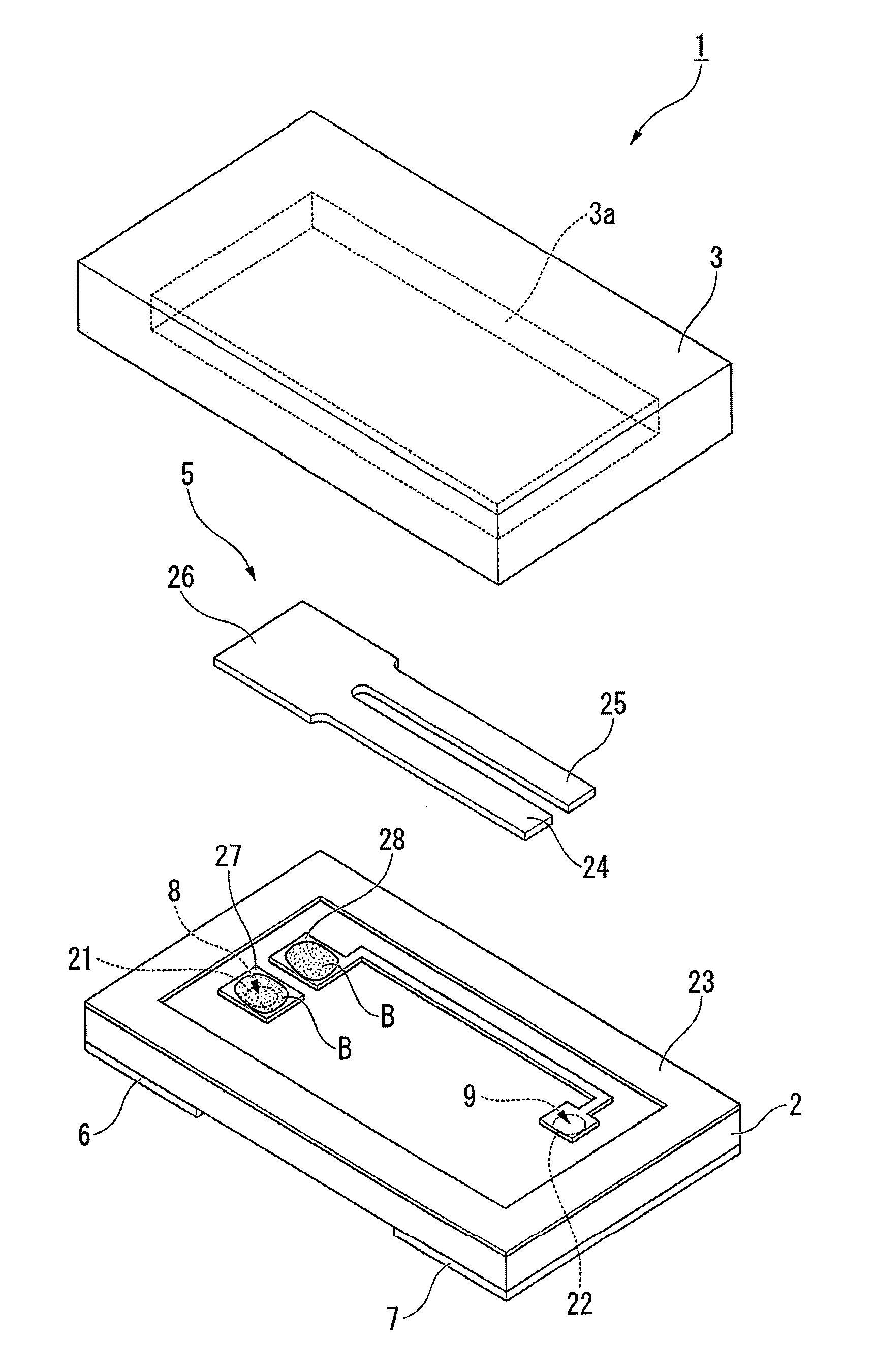

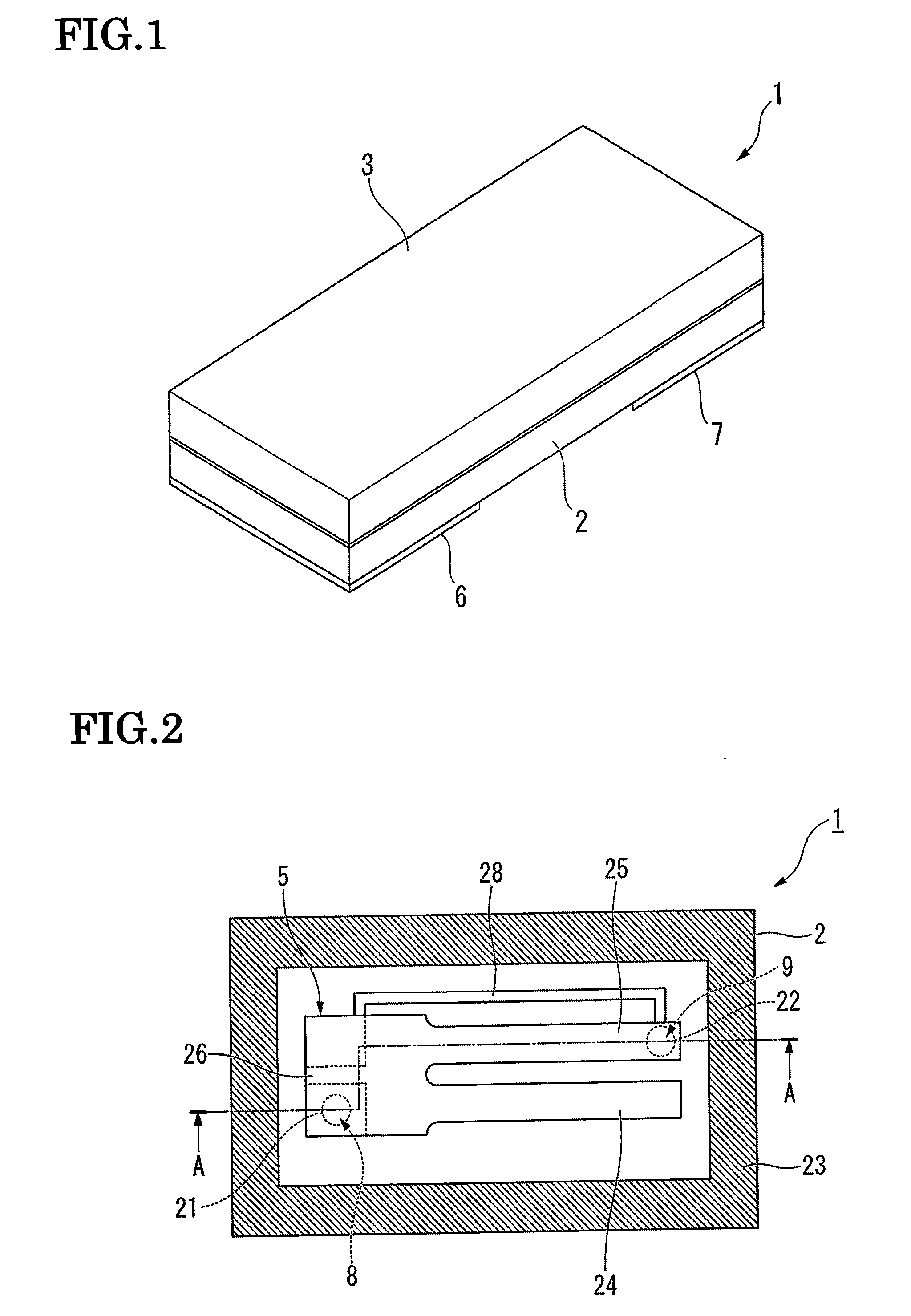

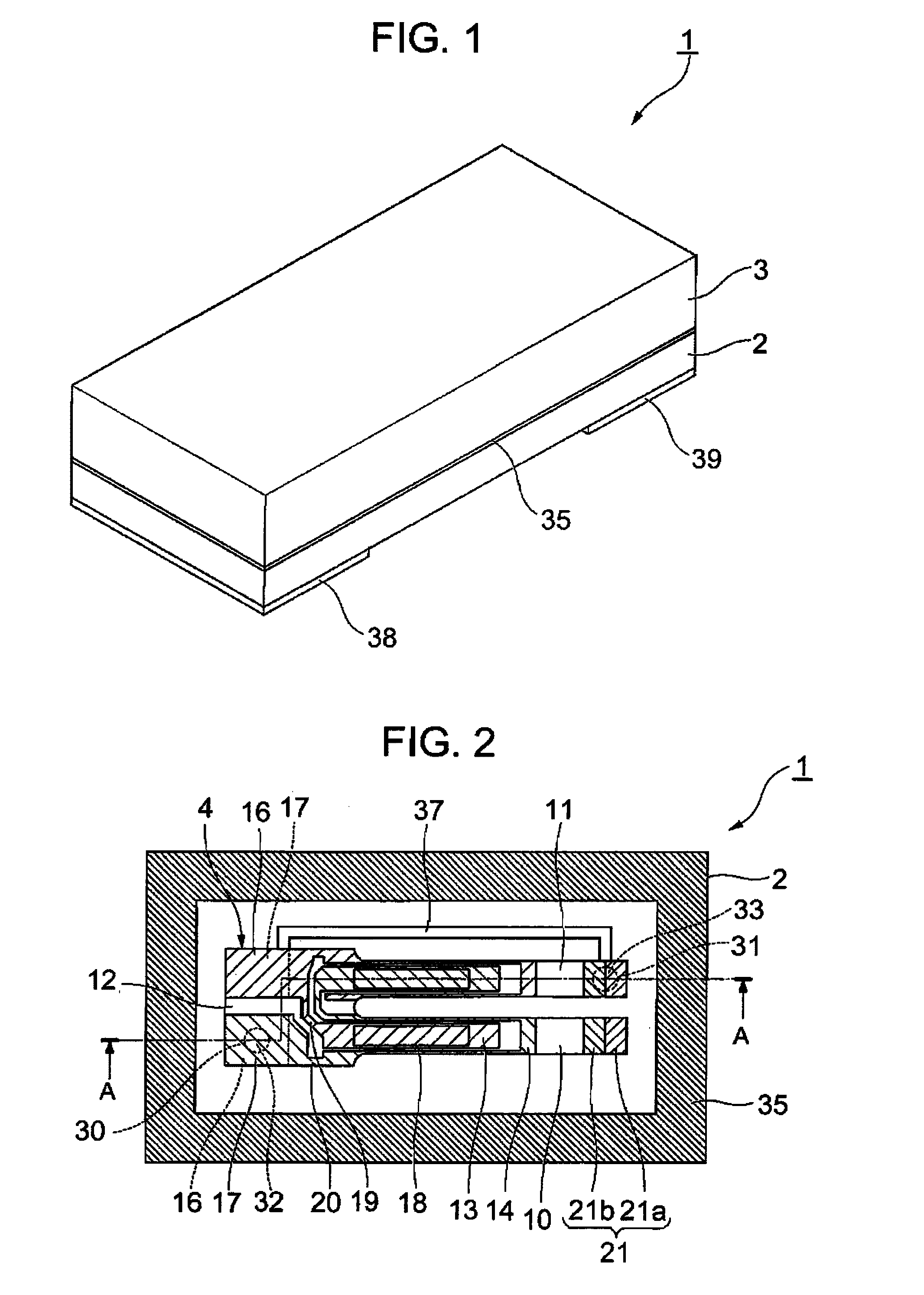

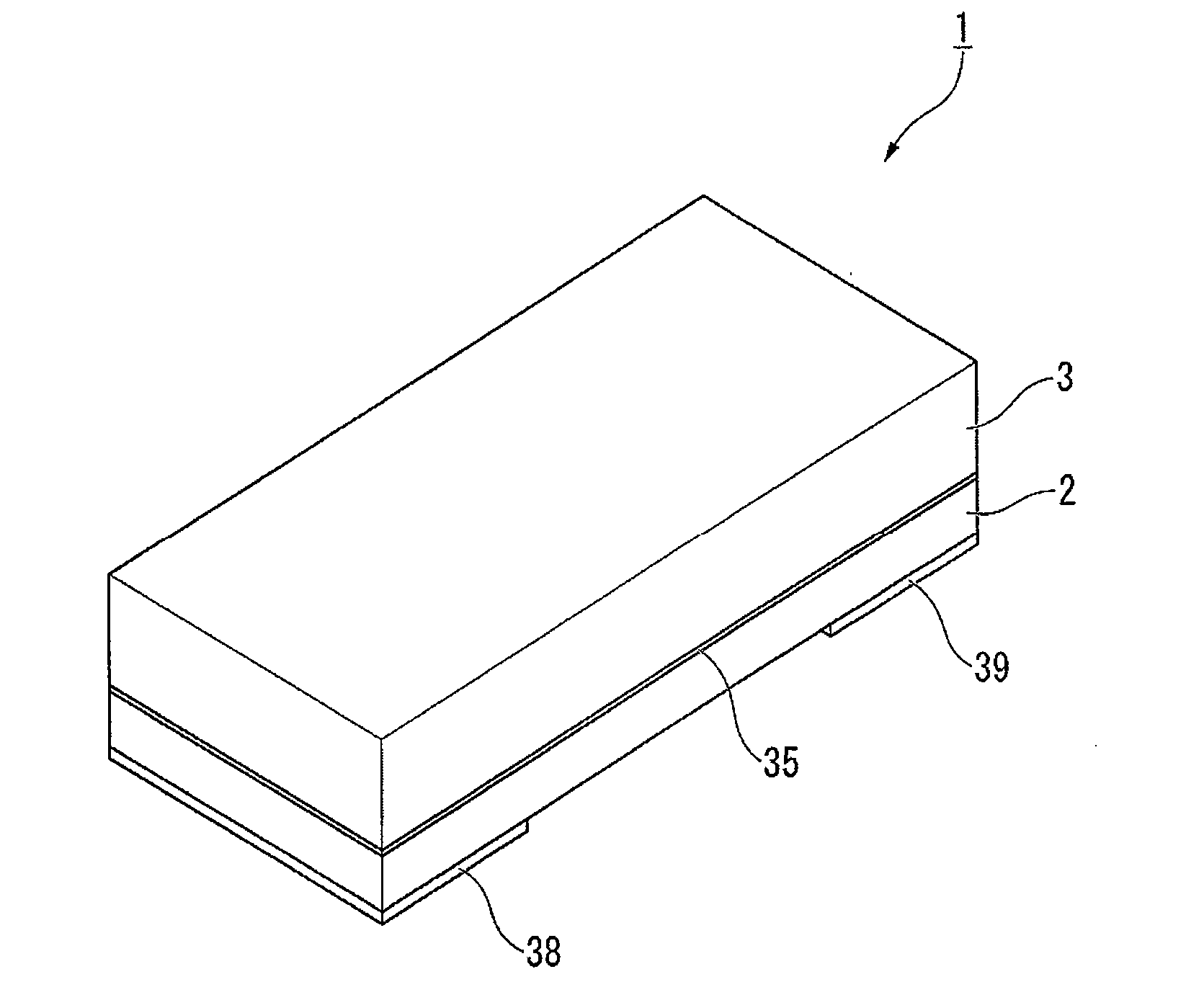

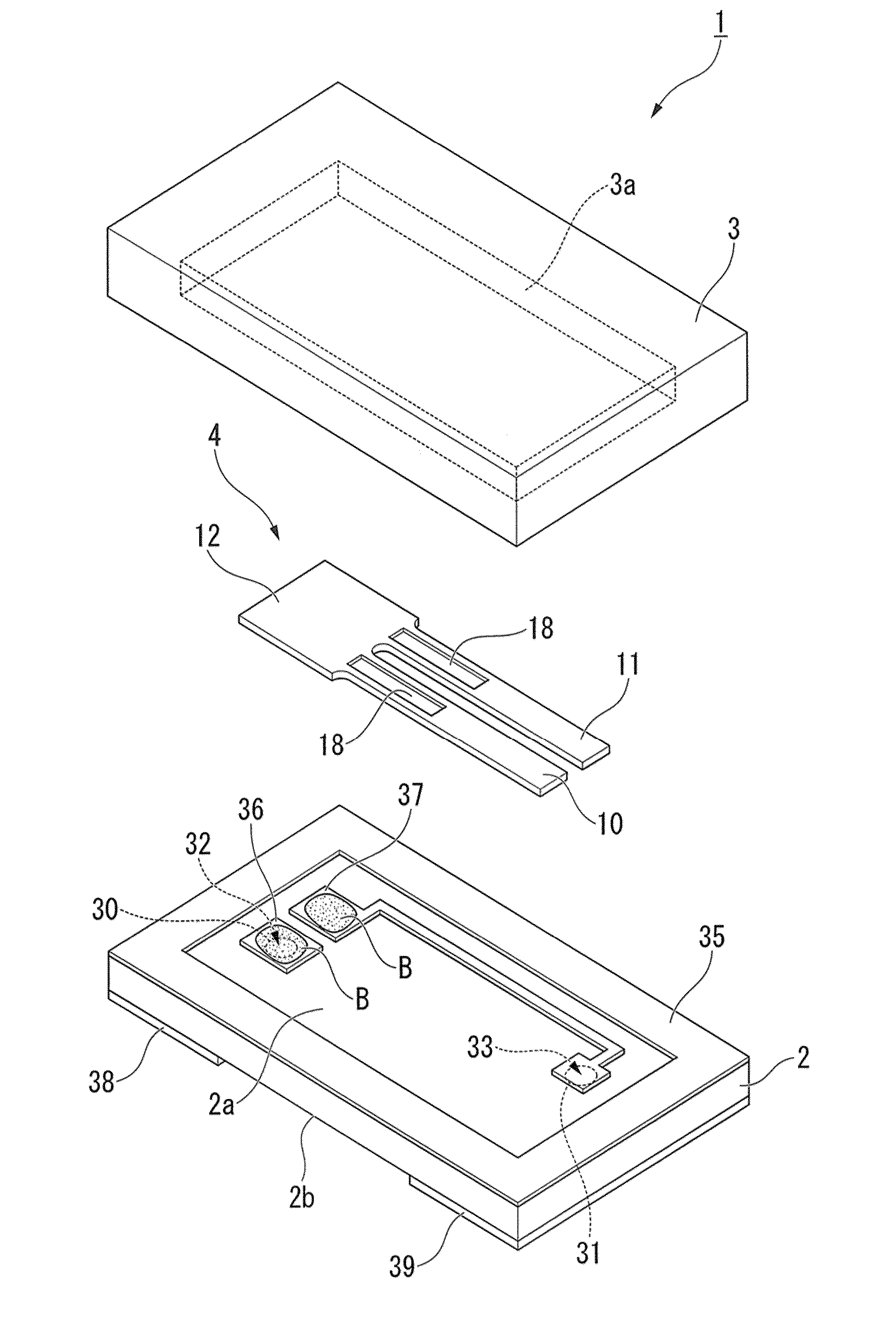

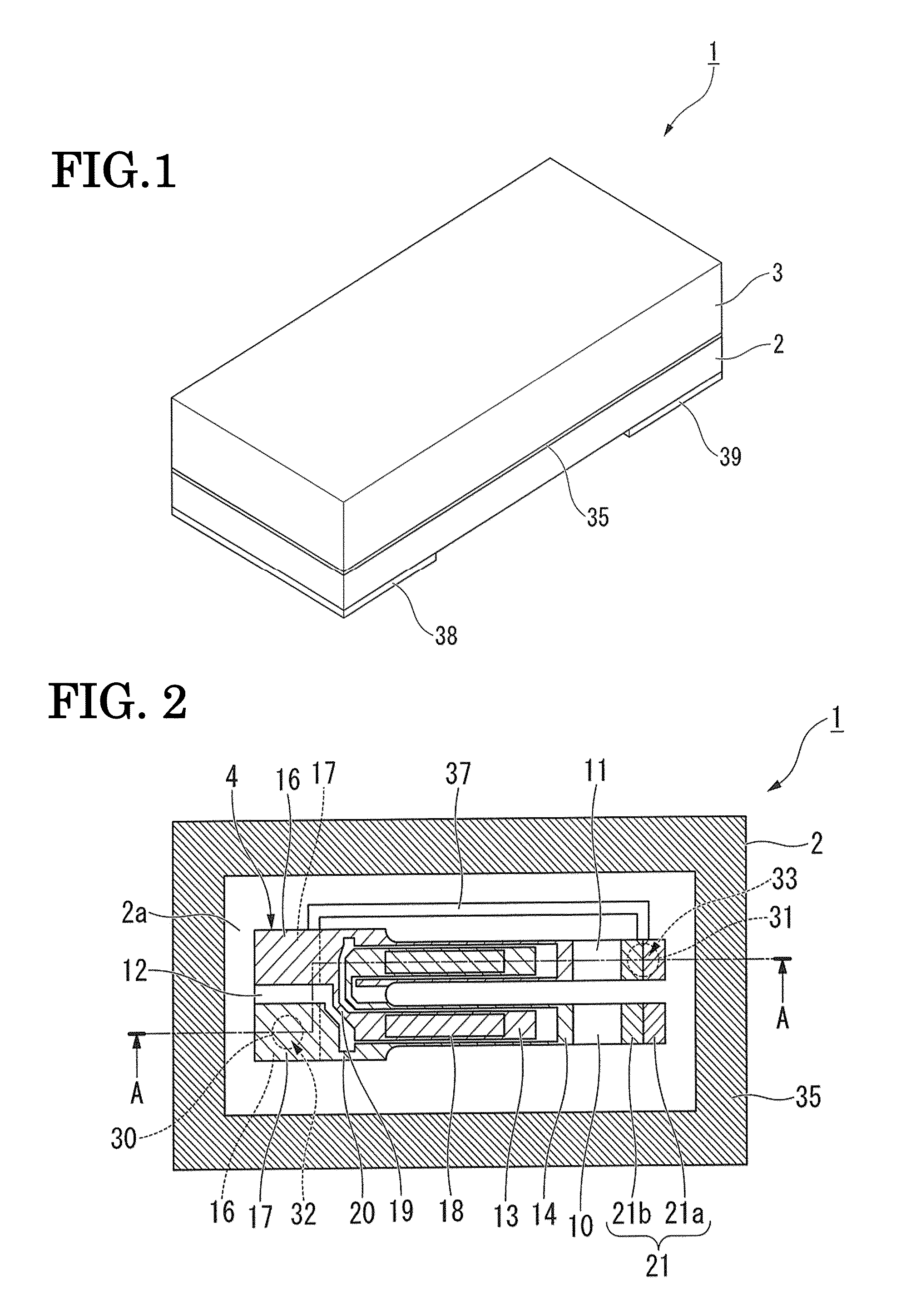

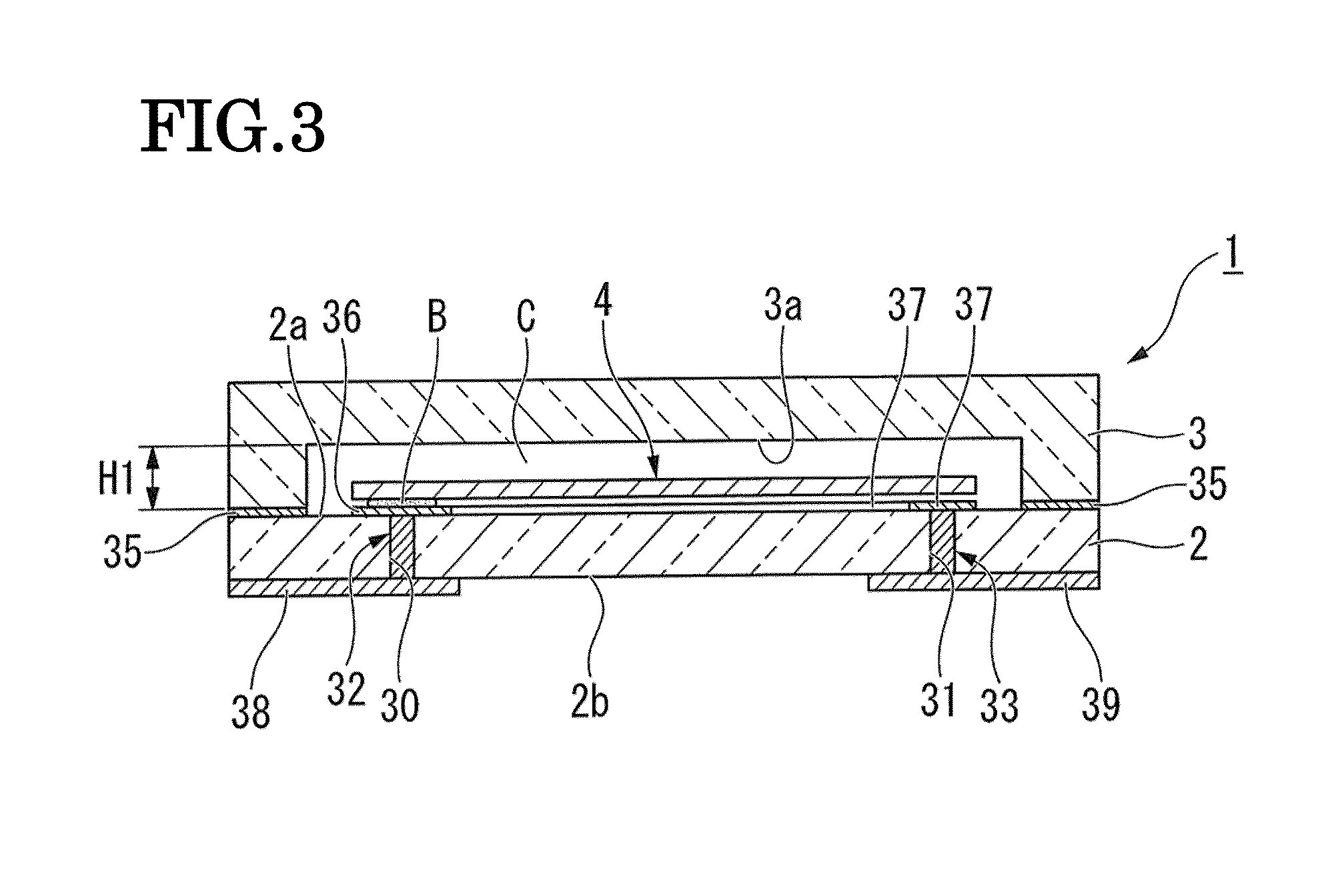

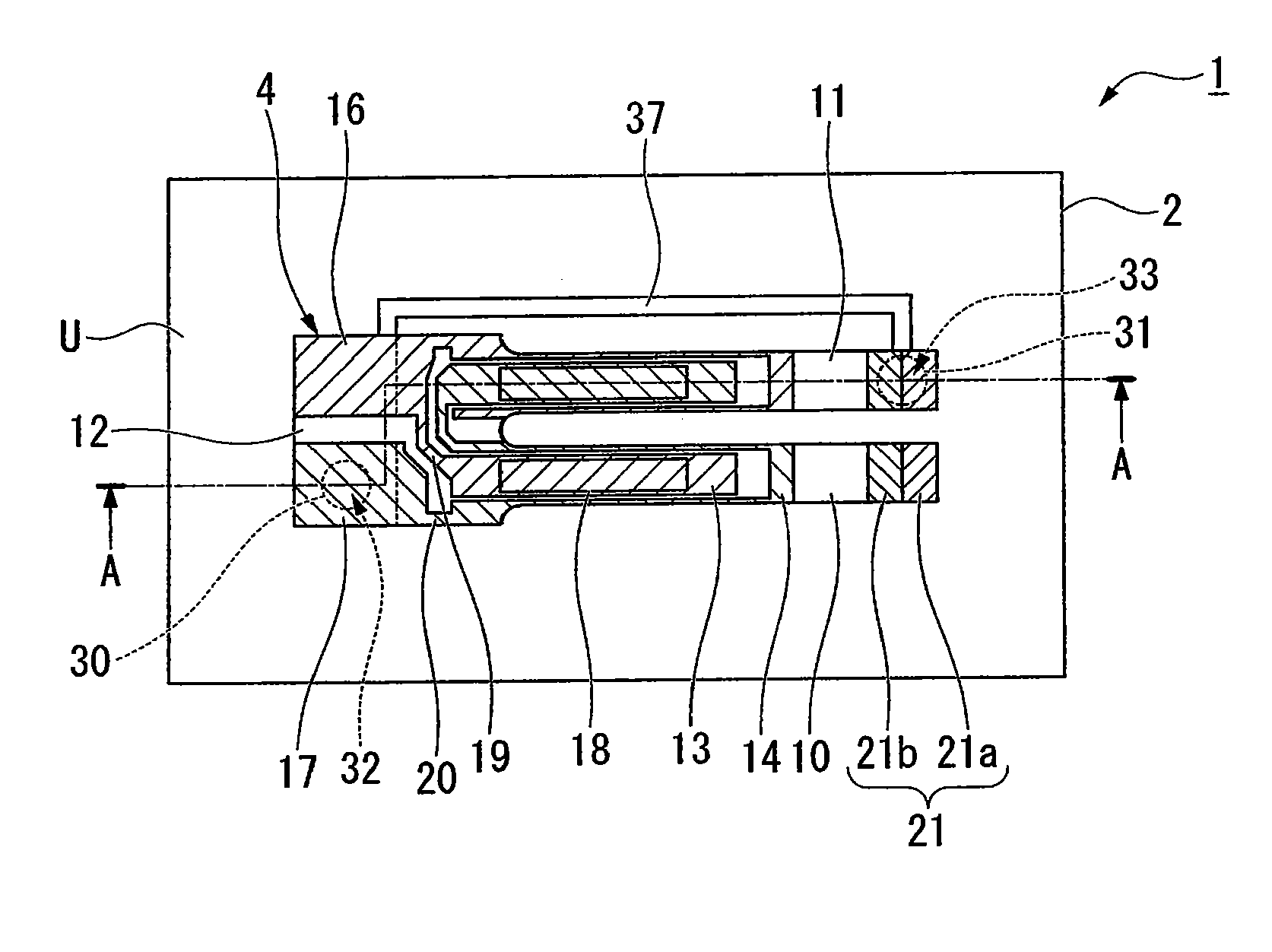

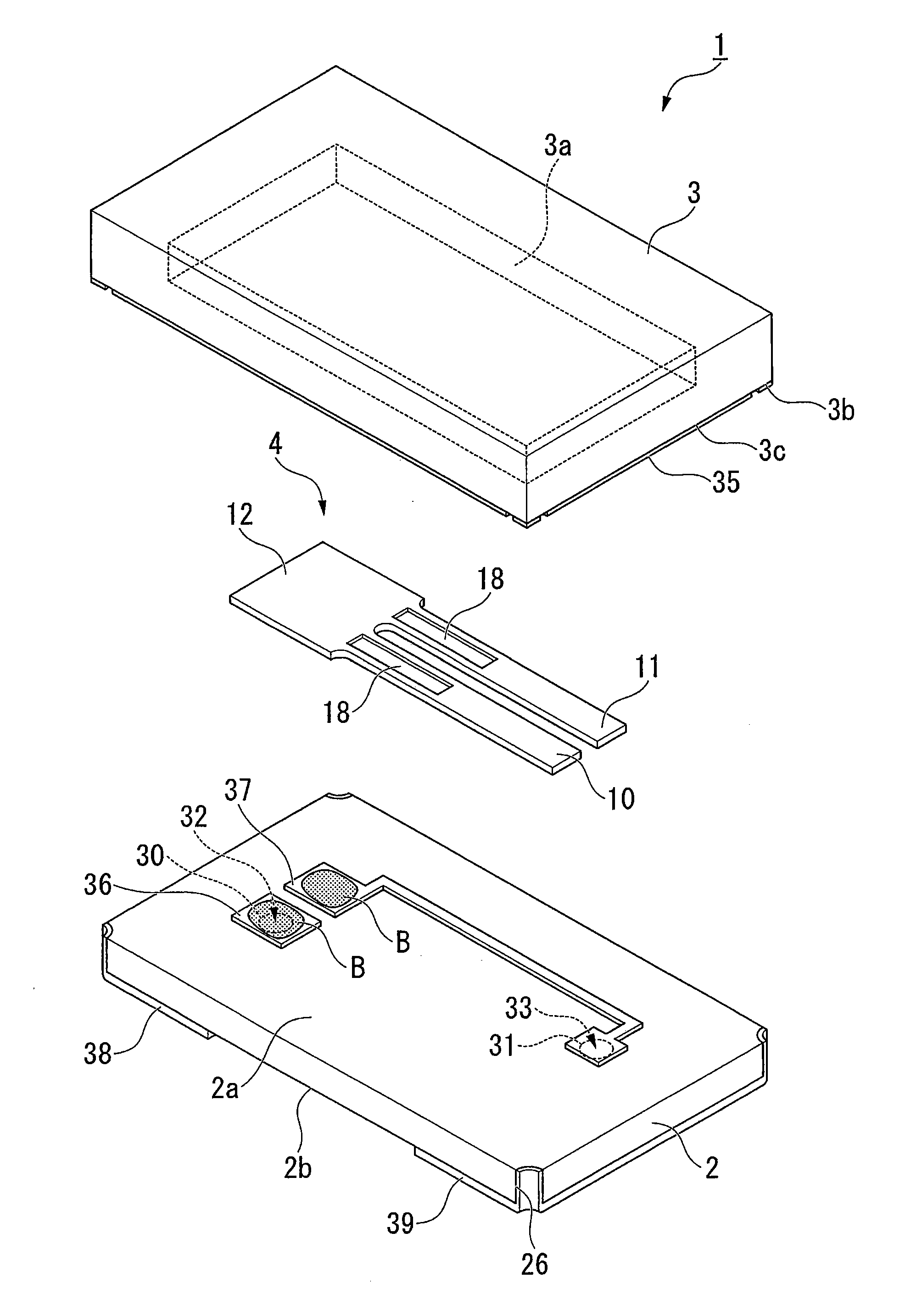

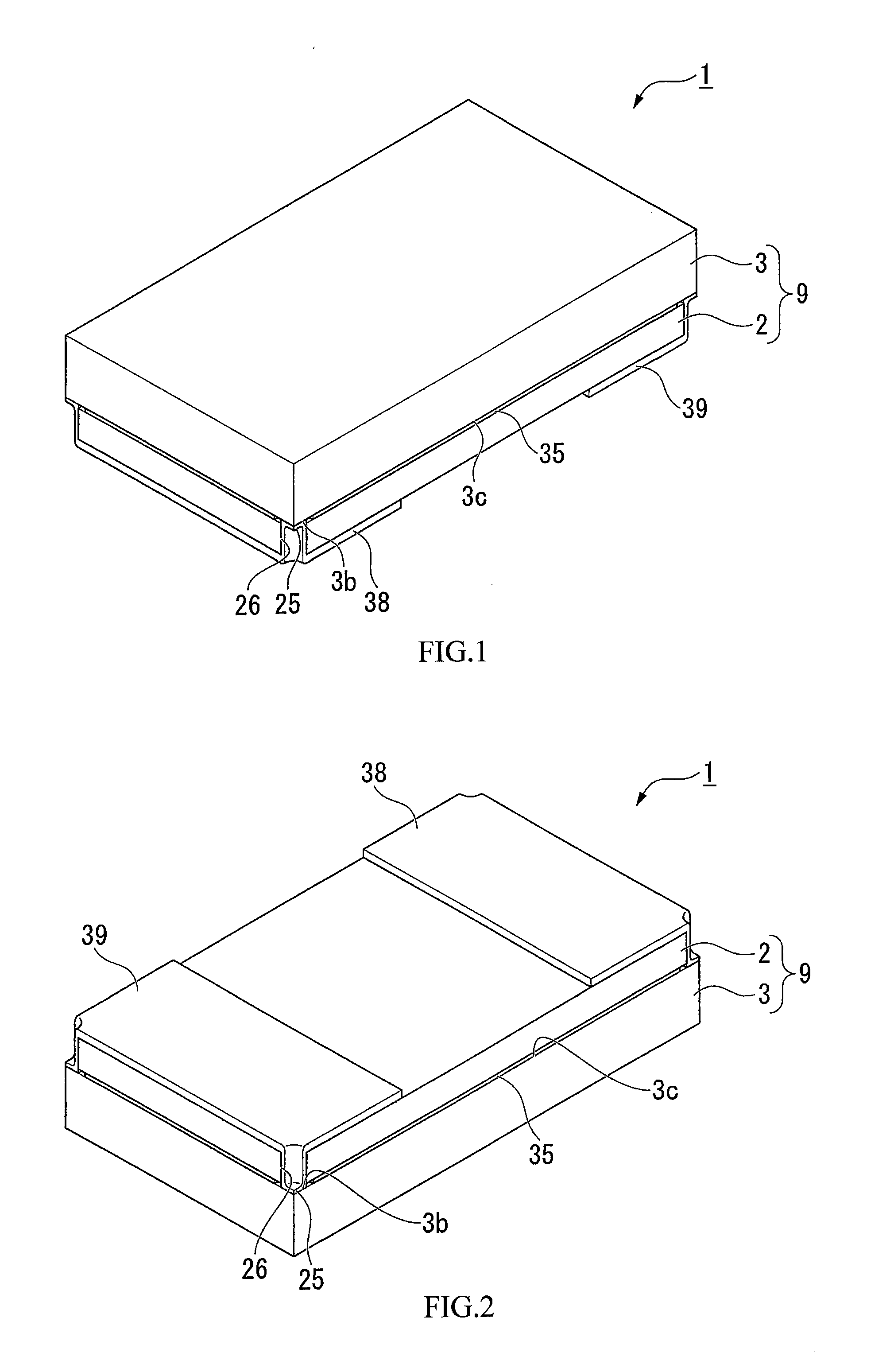

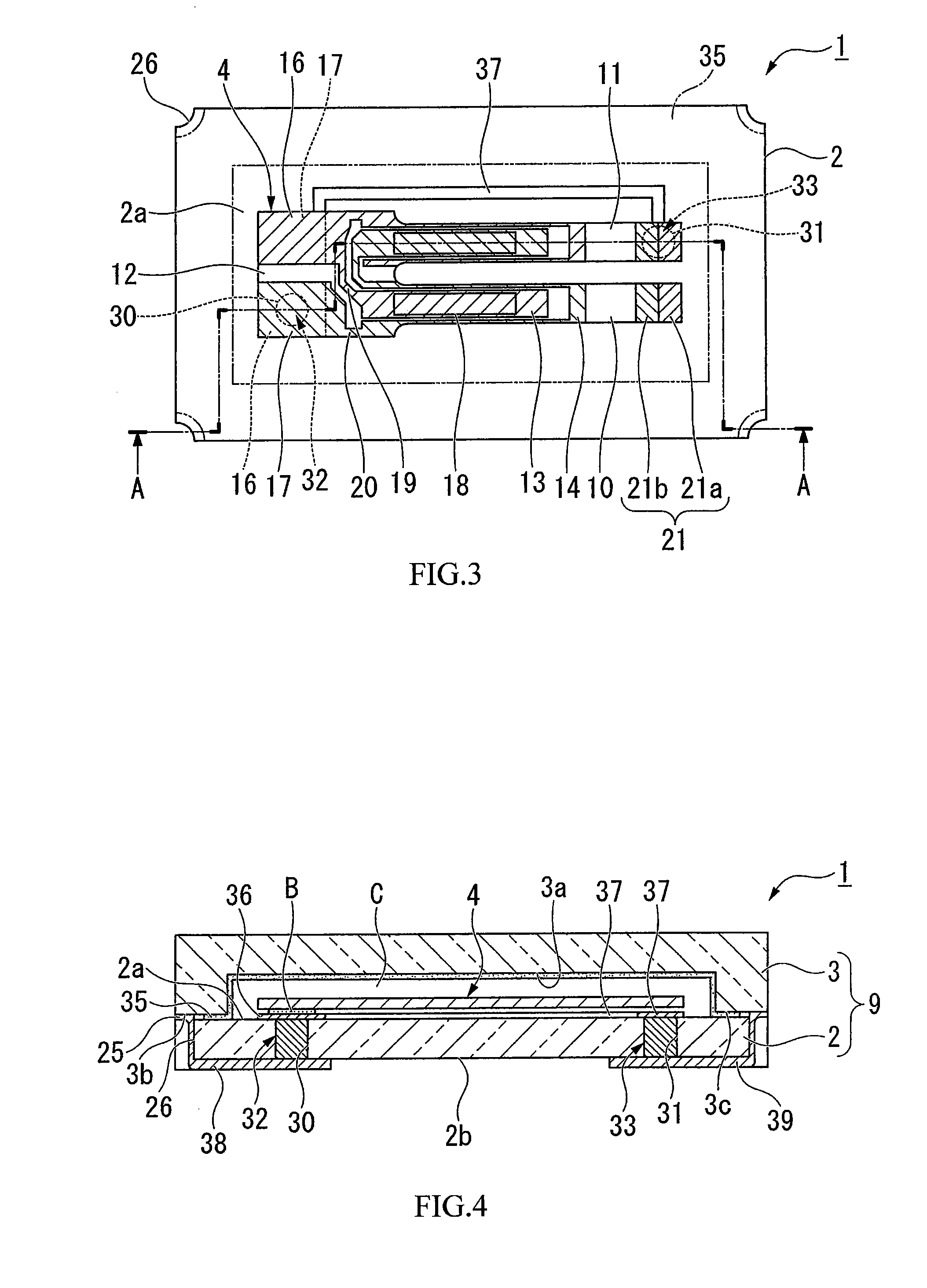

Package, method for manufacturing the same, piezoelectric vibrator, oscillator, electronic device, and radio-controlled timepiece

InactiveUS20110050045A1High degreeReduce the driving voltagePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsEngineering

Providing a package and a method for manufacturing the package capable of achieving improvement in the degree of vacuum in the cavity, and to provide a piezoelectric vibrator, an oscillator, an electronic device, and a radio-controlled timepiece. There is provided a package which includes a plurality of kinds of gettering materials 20, 21 having different activation temperatures and which are capable of being activated by heating is disposed in the cavity C.

Owner:SII CRYSTAL TECH

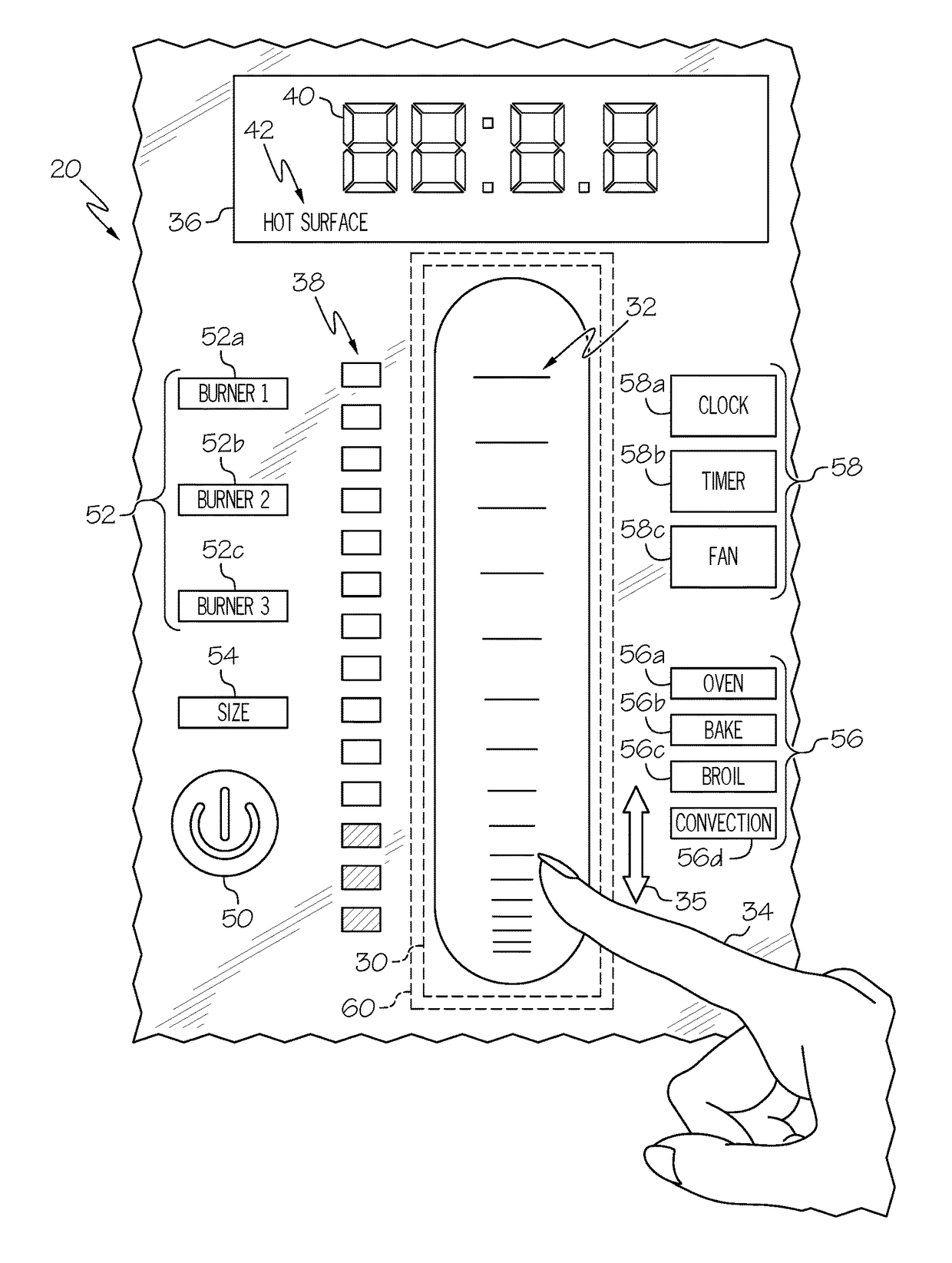

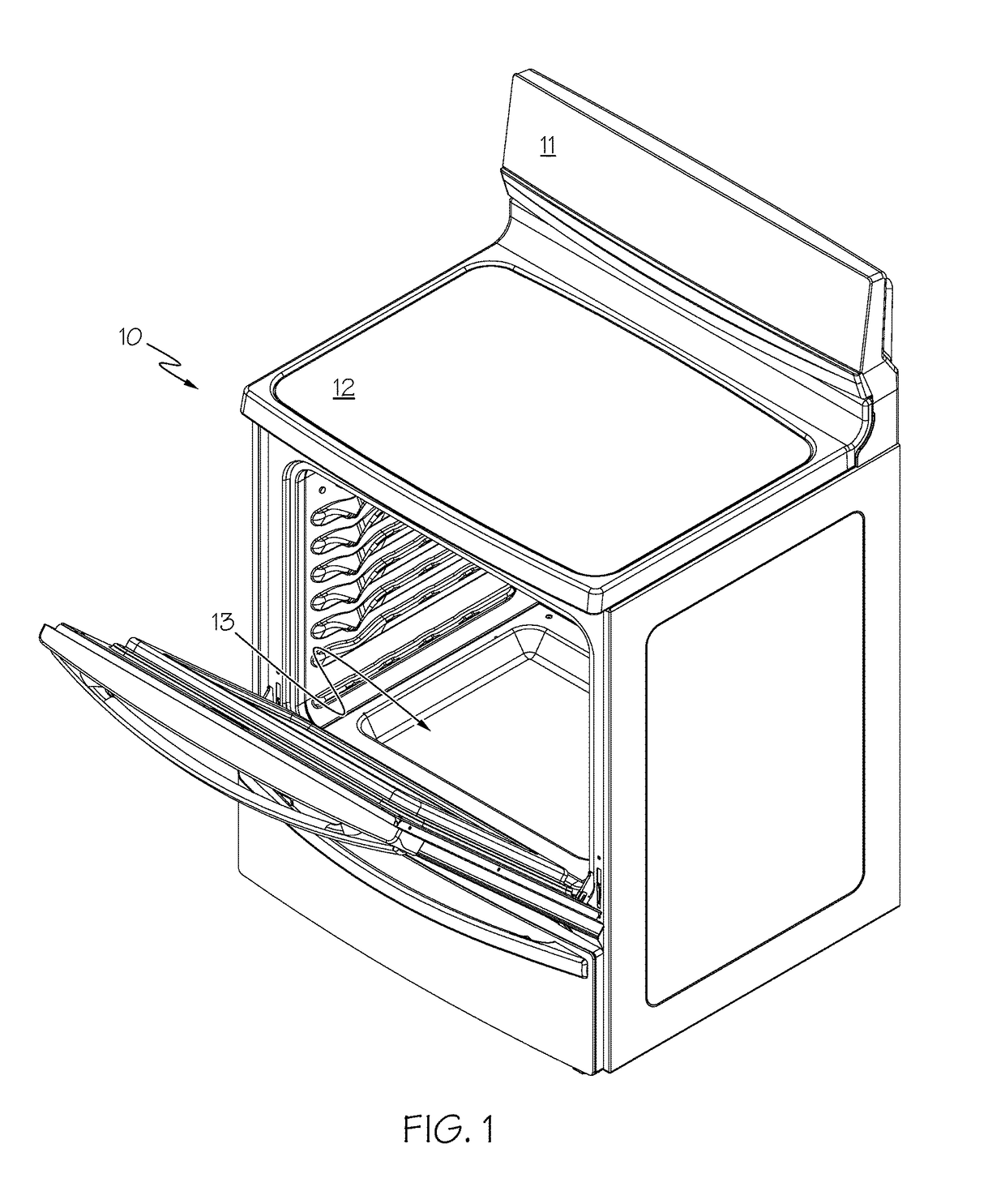

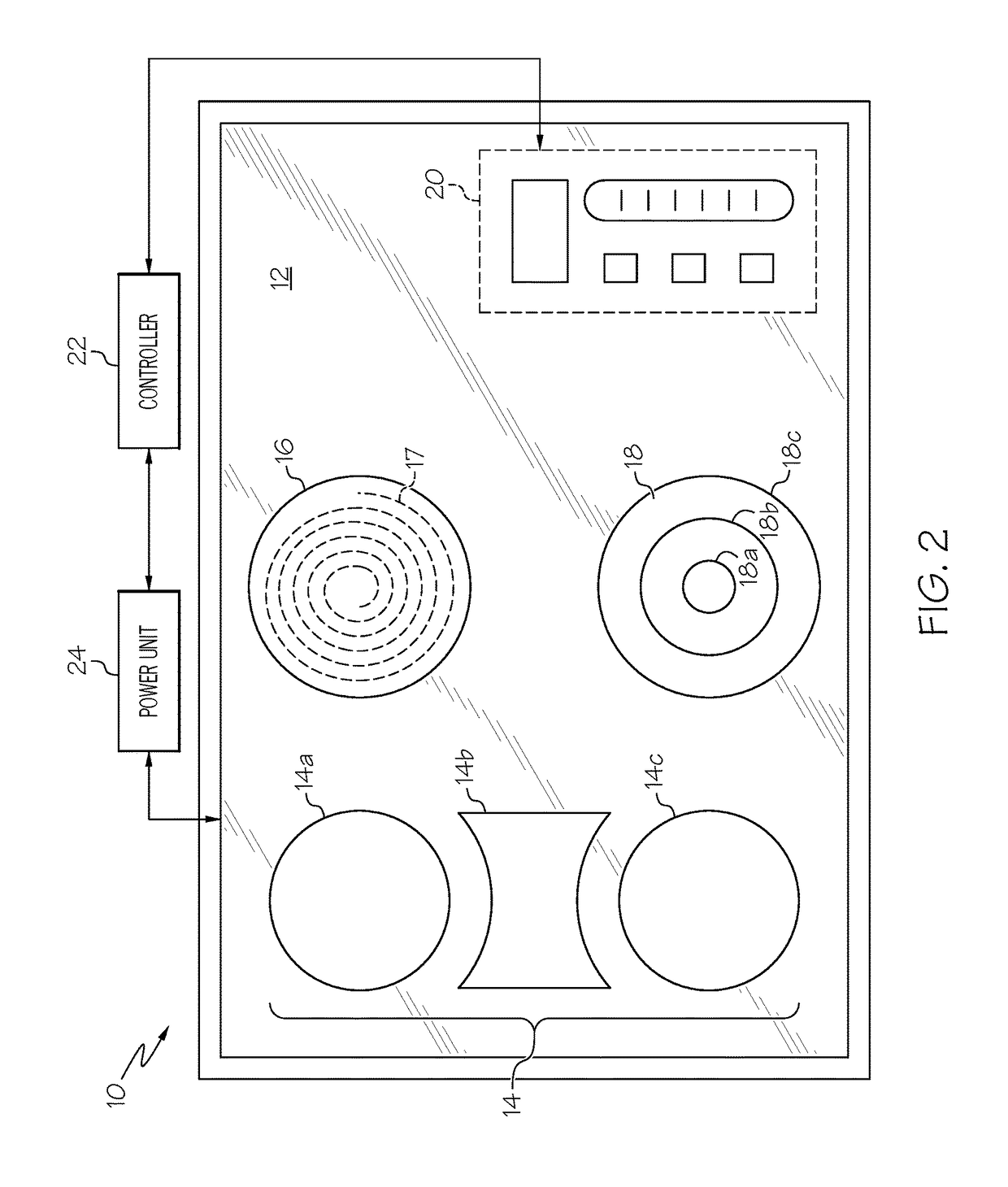

Appliance with electrovibration user feedback in a touch panel interface

A cooking appliance includes a plurality of electrically controlled heating elements operable to elevate a temperature of food items. A user interface includes a touch-sensitive circuit that is operatively-connected to an external surface of the cooking appliance for altering operational settings of the electrically controlled heating elements. An electrovibration feedback circuit is coupled to the external surface that generates a vibratory feedback that is sensible by the user's finger at the external surface in response to adjustments of the operational settings. The electrovibration feedback circuit creates an electrostatic force on the user's finger that simulates friction between the user's finger and the external surface.

Owner:ELECTROLUX HOME PROD CORP NV

Piezoelectric transducer, piezoelectric transducer manufacturing method, oscillator, electronic device, and radio clock

InactiveUS20100301954A1Reduce frequencyIncrease productionPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksTransducerRadio clock

Provided are: a piezoelectric oscillation piece which has a pair of oscillation arms disposed in parallel with each other with base ends of the oscillation arms fixed to a base of the piezoelectric oscillation piece and with weight metal films formed at the tips of the oscillation arms; a base substrate on the upper surface of which the piezoelectric oscillation piece is mounted; a lid substrate joined with the base substrate such that the mounted piezoelectric oscillation piece can be accommodated in a cavity; and a control film disposed in the vicinity of the pair of the oscillation arms as viewed in the plan view and formed at least on either of the substrates in such a manner as to extend from the base end side to the tip side in the longitudinal direction of the oscillation arms for increasing the degree of vacuum inside the cavity by heating. The control film is locally deposited on the side surfaces of the oscillation arms in the vicinity of the control film by heating.

Owner:SII CRYSTAL TECH

Method for manufacturing package, method of manufacturing piezoelectric vibrator, oscillator, electronic device, and radio-controlled timepiece

InactiveUS20110050043A1Improve energy efficiencyReliable anodic bondingPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsEngineering

Providing a method for manufacturing a package capable of achieving reliable anodic bonding between the bonding material 35 and a base board wafer 40 even when the bonding material 35 having a large resistance value is used. Providing a method for manufacturing a package by anodically bonding a bonding material 35, which is fixed in advance to an inner surface of a lid board wafer 50 made of an insulator, to an inner surface of a base board wafer 40 made of an insulator, the method including an anodic bonding step where an auxiliary bonding material 72 serving as an anode is disposed on an outer surface of the lid board wafer 50, a cathode 71 is disposed on an outer surface of the base board wafer 40, and a voltage is applied between the auxiliary bonding material 72 and the cathode 71, wherein the auxiliary bonding material 72 is made of a material that causes an anodic bonding reaction between the auxiliary bonding material 72 and the lid board wafer 50 in the anodic bonding step.

Owner:SEIKO INSTR INC

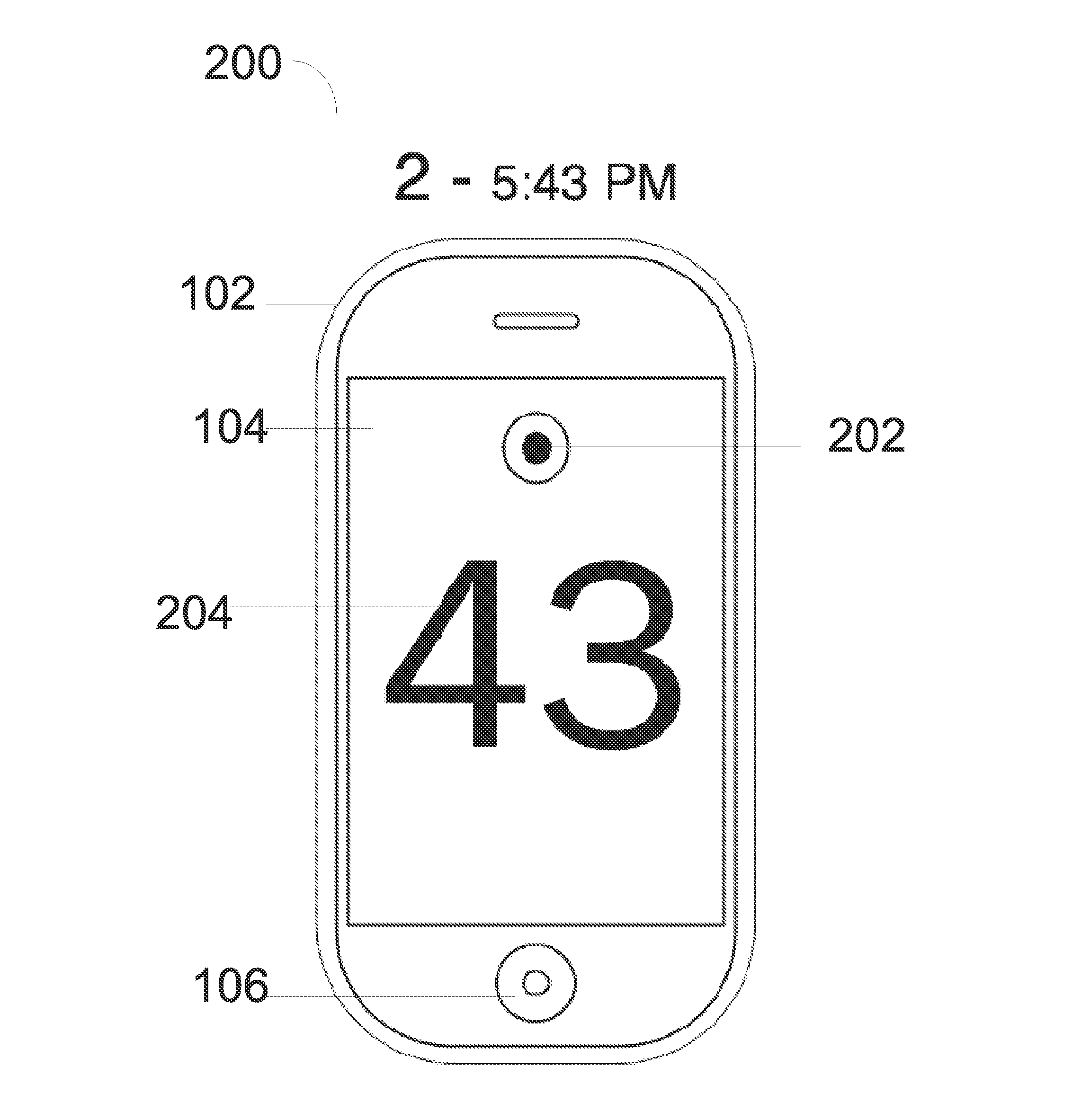

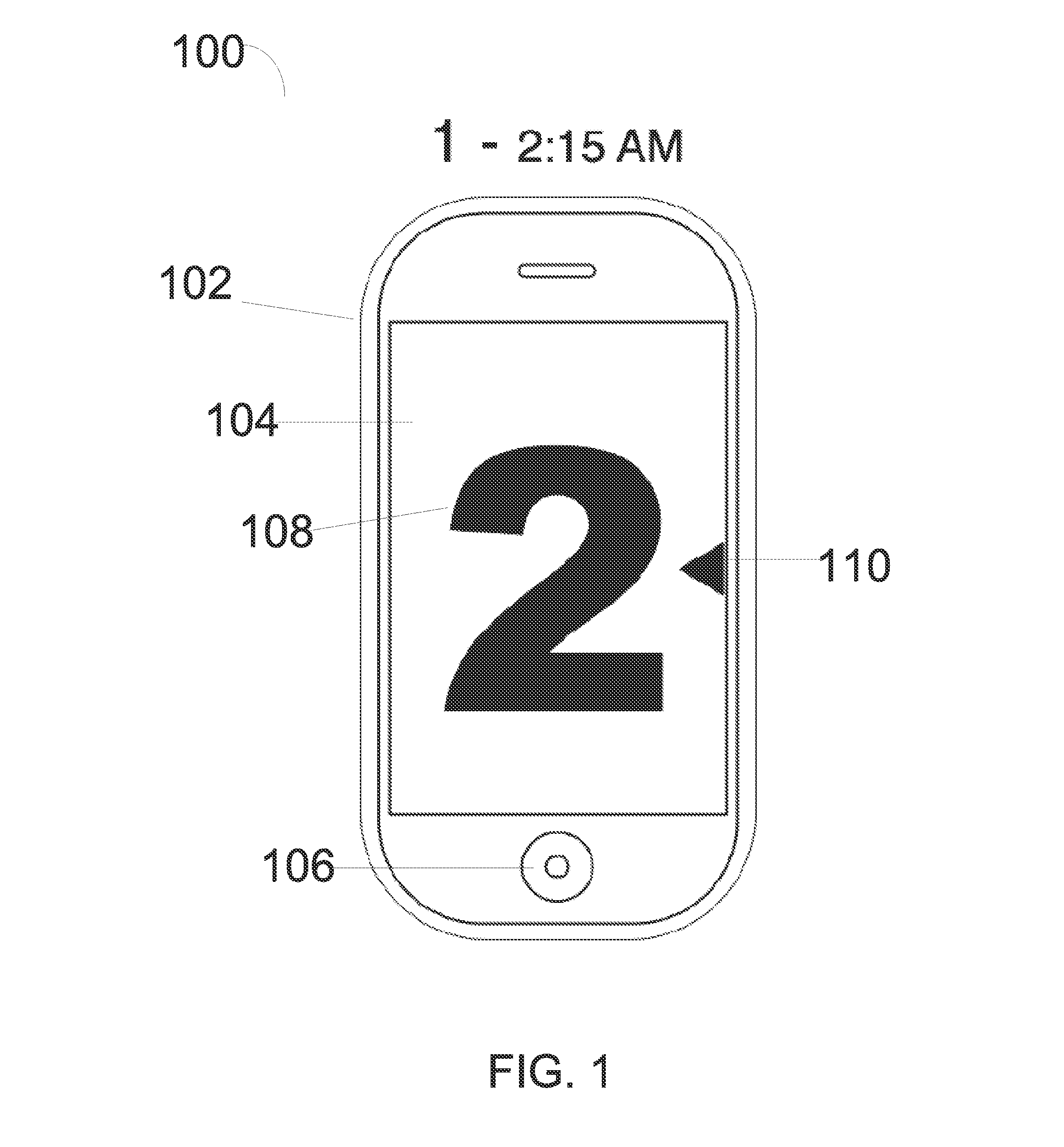

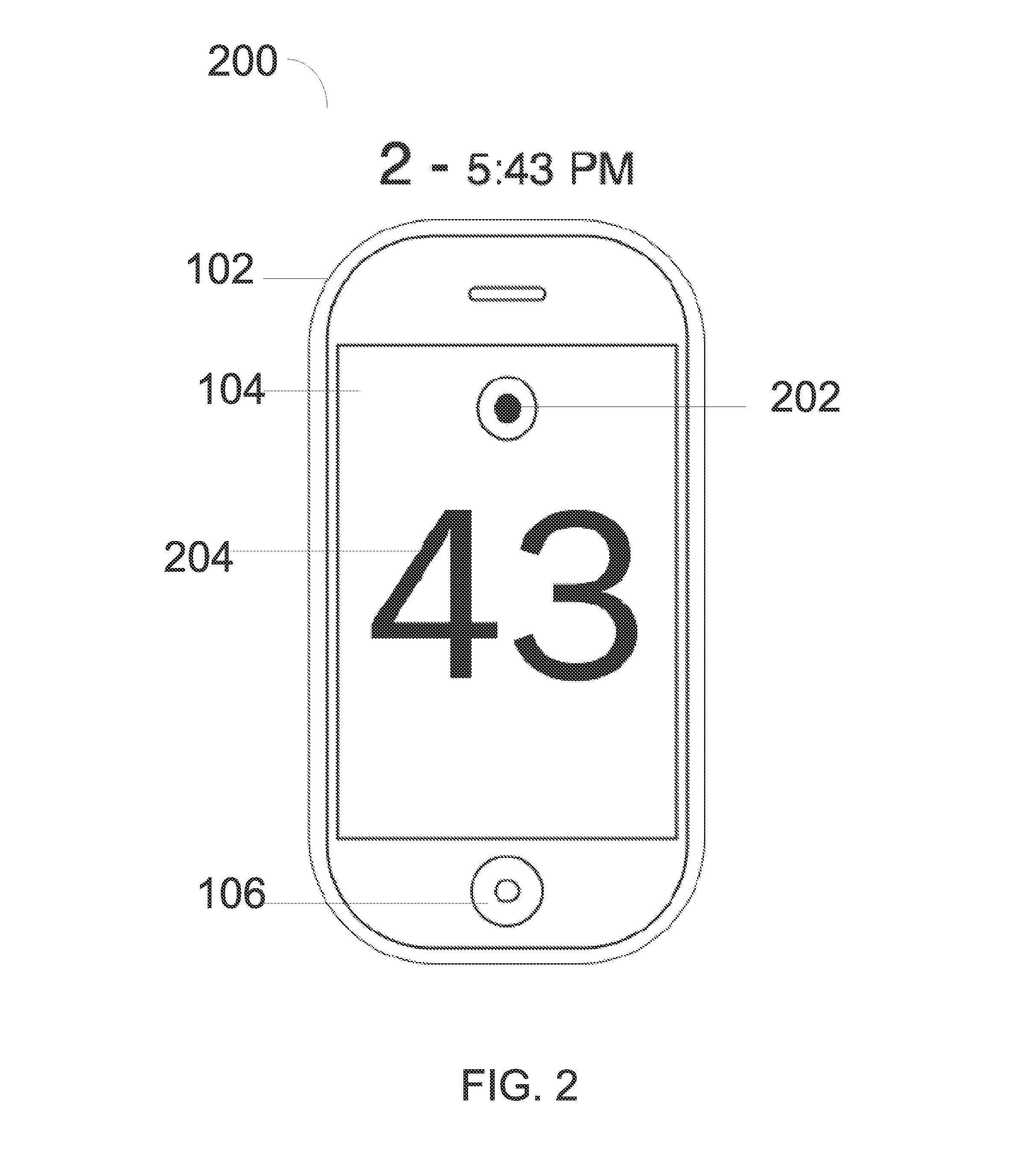

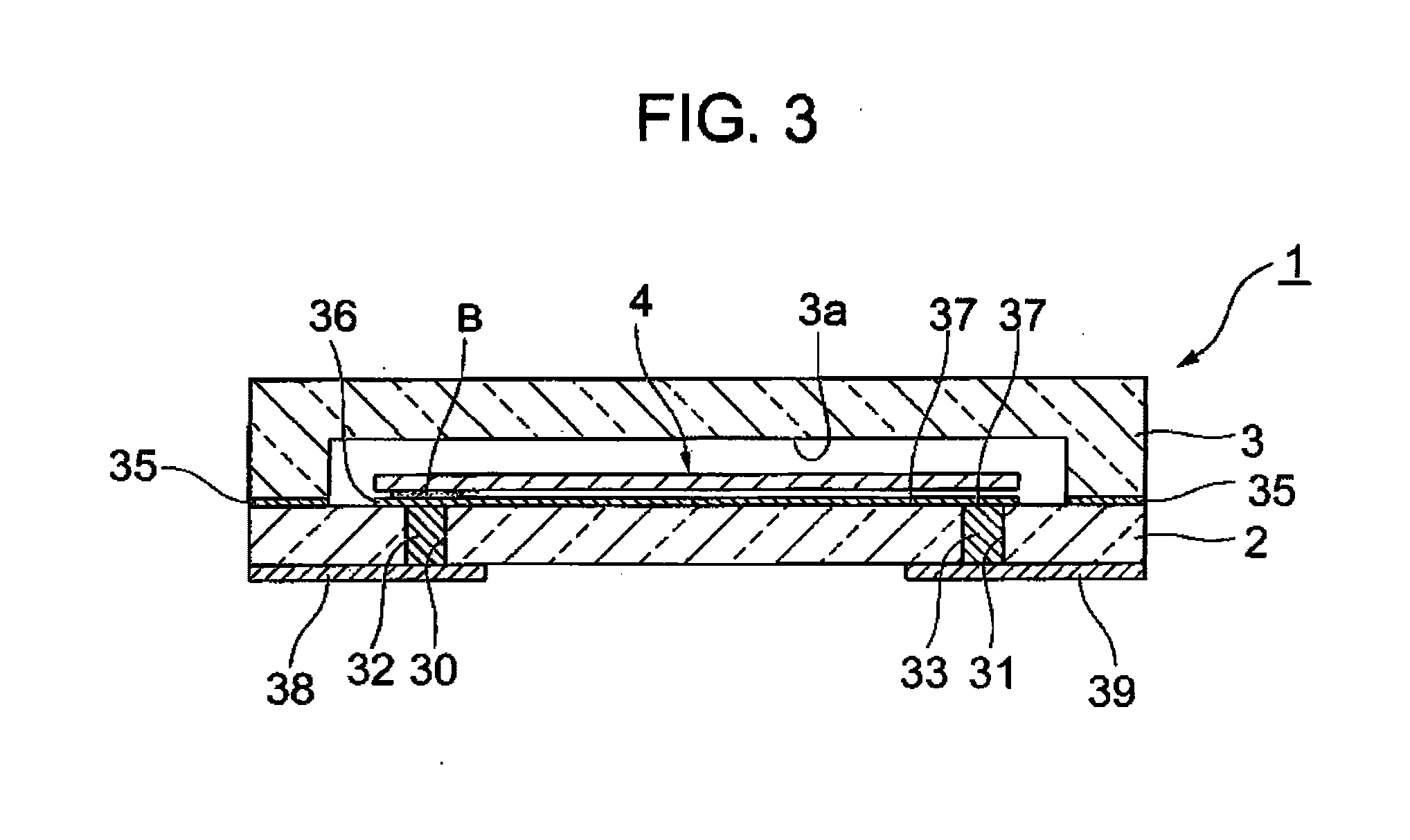

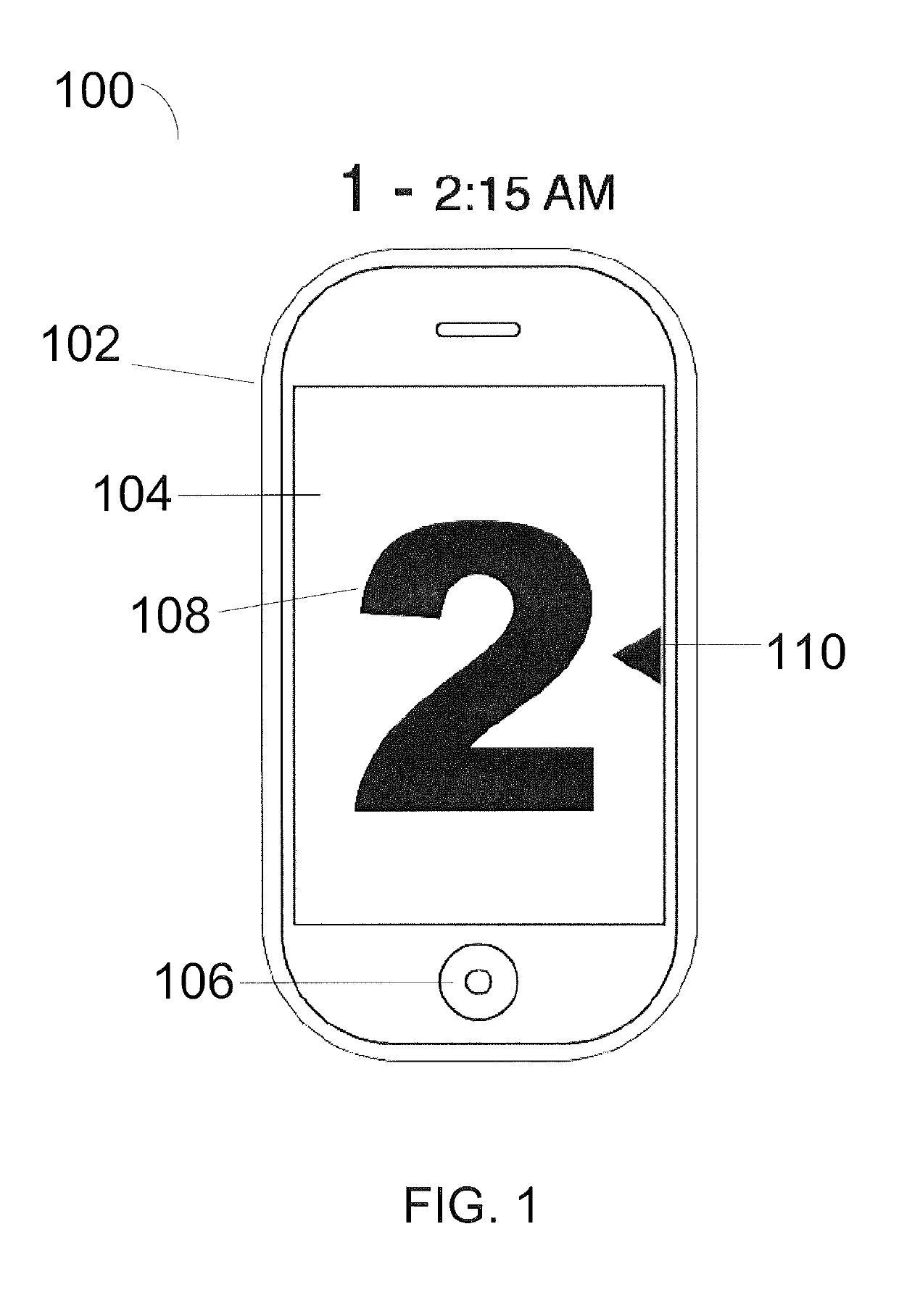

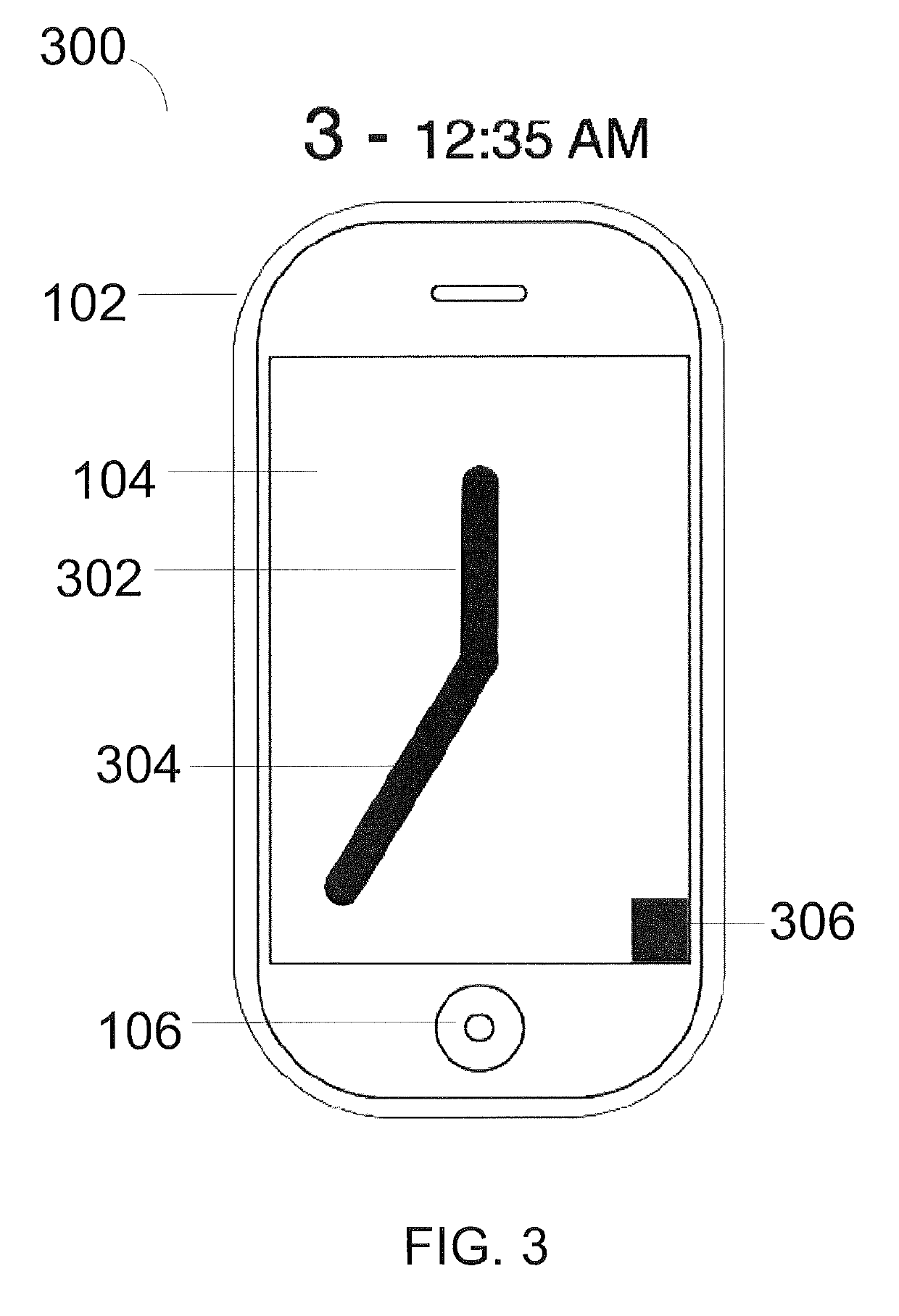

Method and device for tactilely reading time on a touch screen

ActiveUS9454229B1Avoids battery drainInput/output for user-computer interactionGraph readingElectrical impulseTouchscreen

The present invention relates to a device and method that generates a tactile presentation, which indicates time on a mobile device. The mobile device may include a touch screen, a processor, and a means for generating electrovibrations. The touch screen may include the functionality to be activated to electrovibrate in at least one portion of the touch screen. The processor may receive electrical signals specifying and displaying a current time on the touch screen. The means for generating electrovibrations generates electrovibrations that vary in response to the time to provide the tactile presentation of the time on the touch screen. The touch screen typically includes a glass plate that is topped with a transparent electrode and insulator. The insulator may be operable to receive contact from a user's finger and in response, generate electrical impulses to provide a tactile presentation as haptic feedback to the user.

Owner:WELLEN ALEXANDER

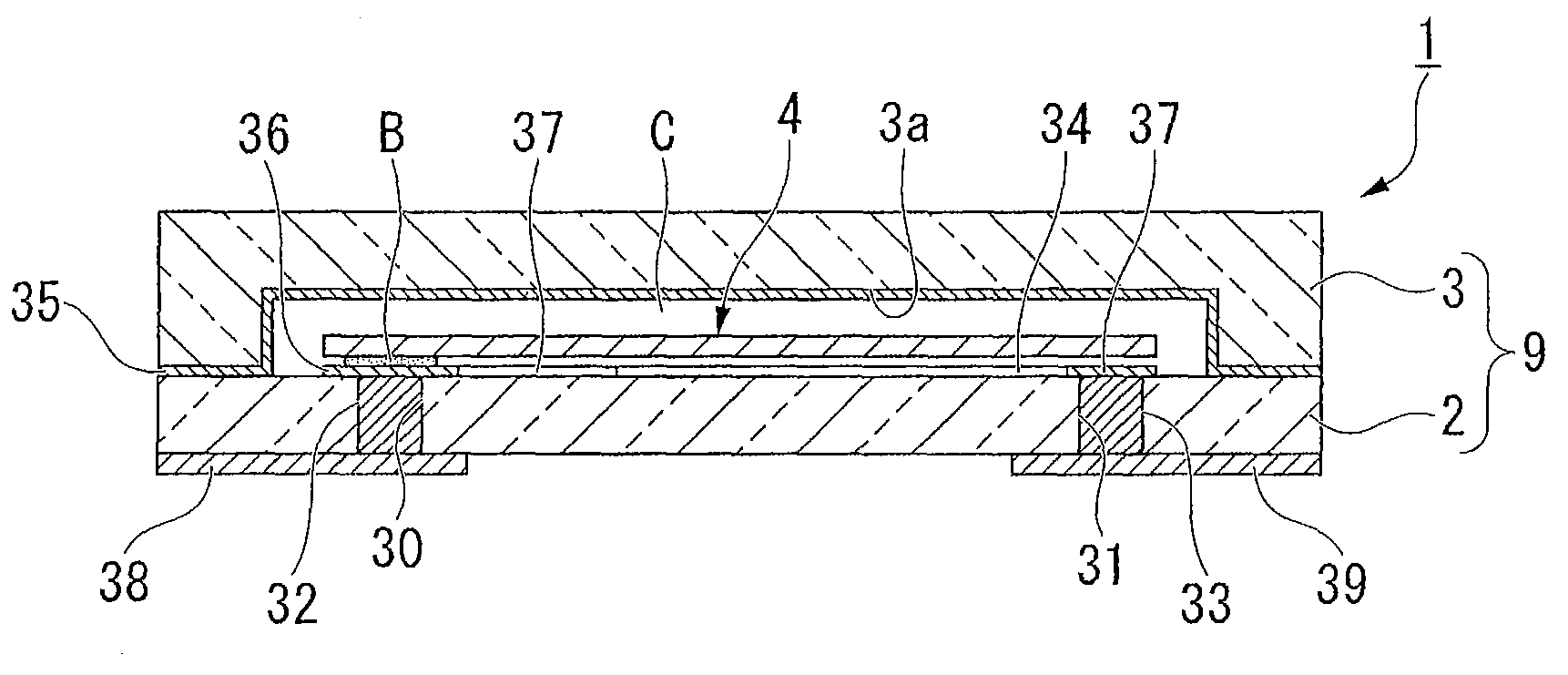

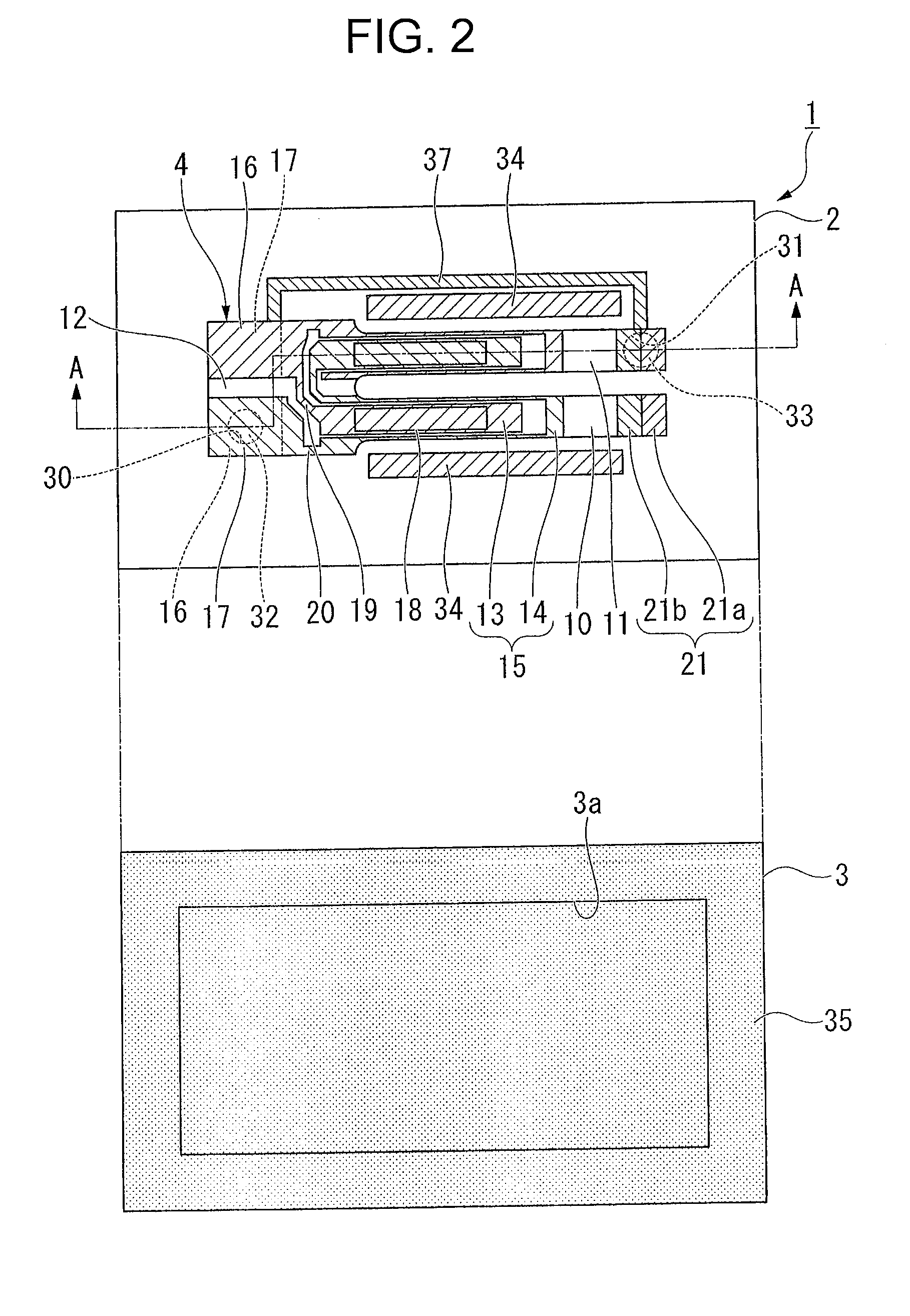

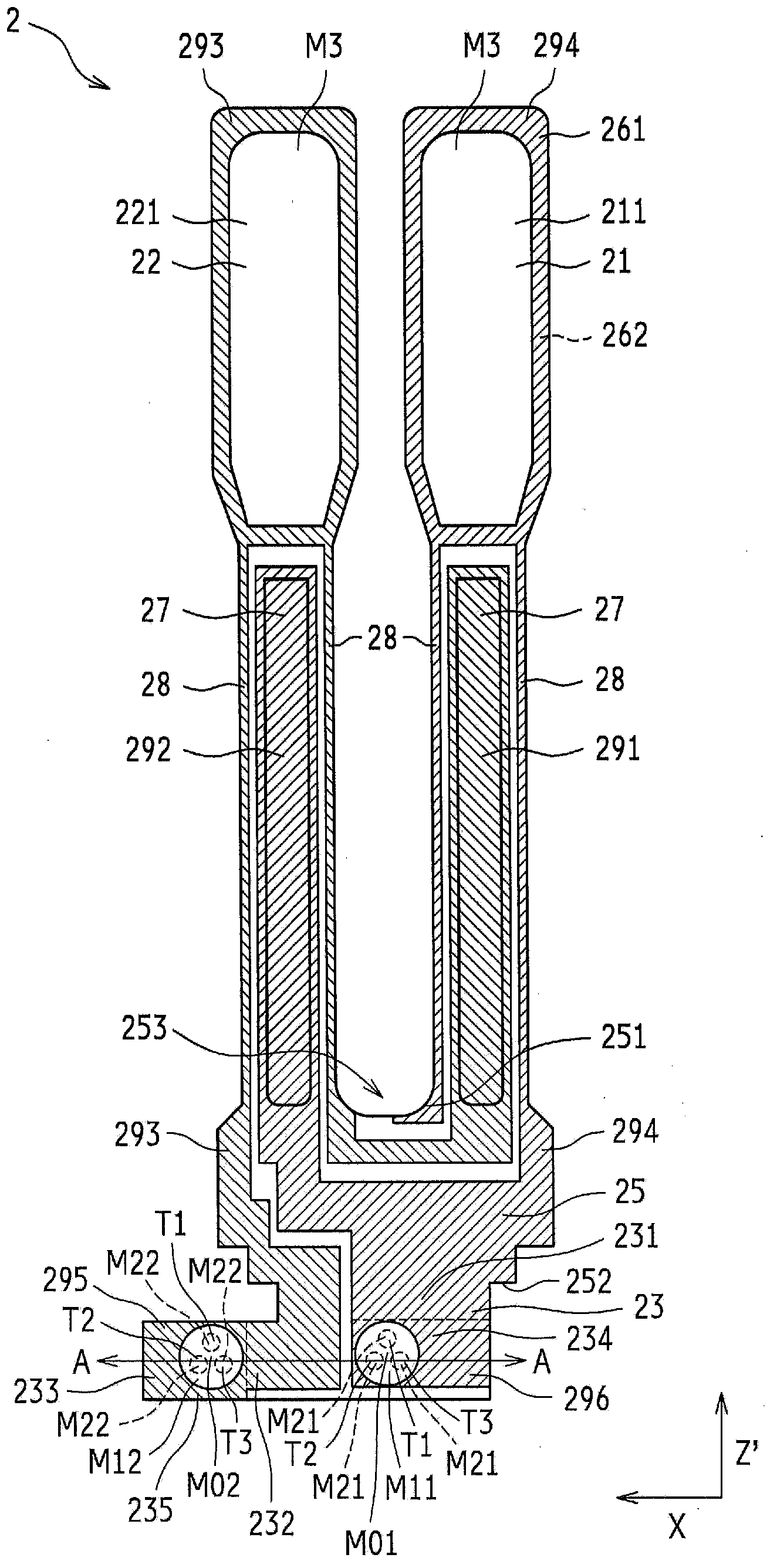

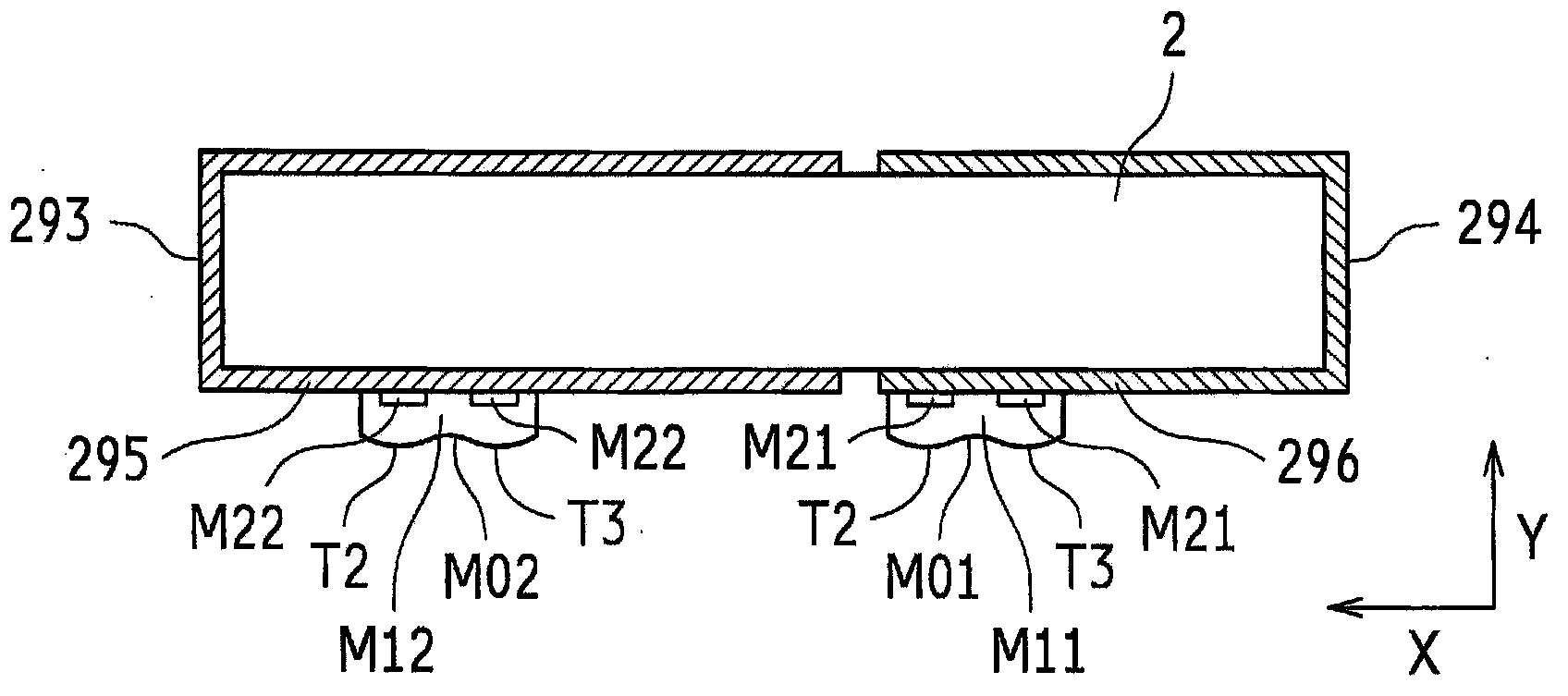

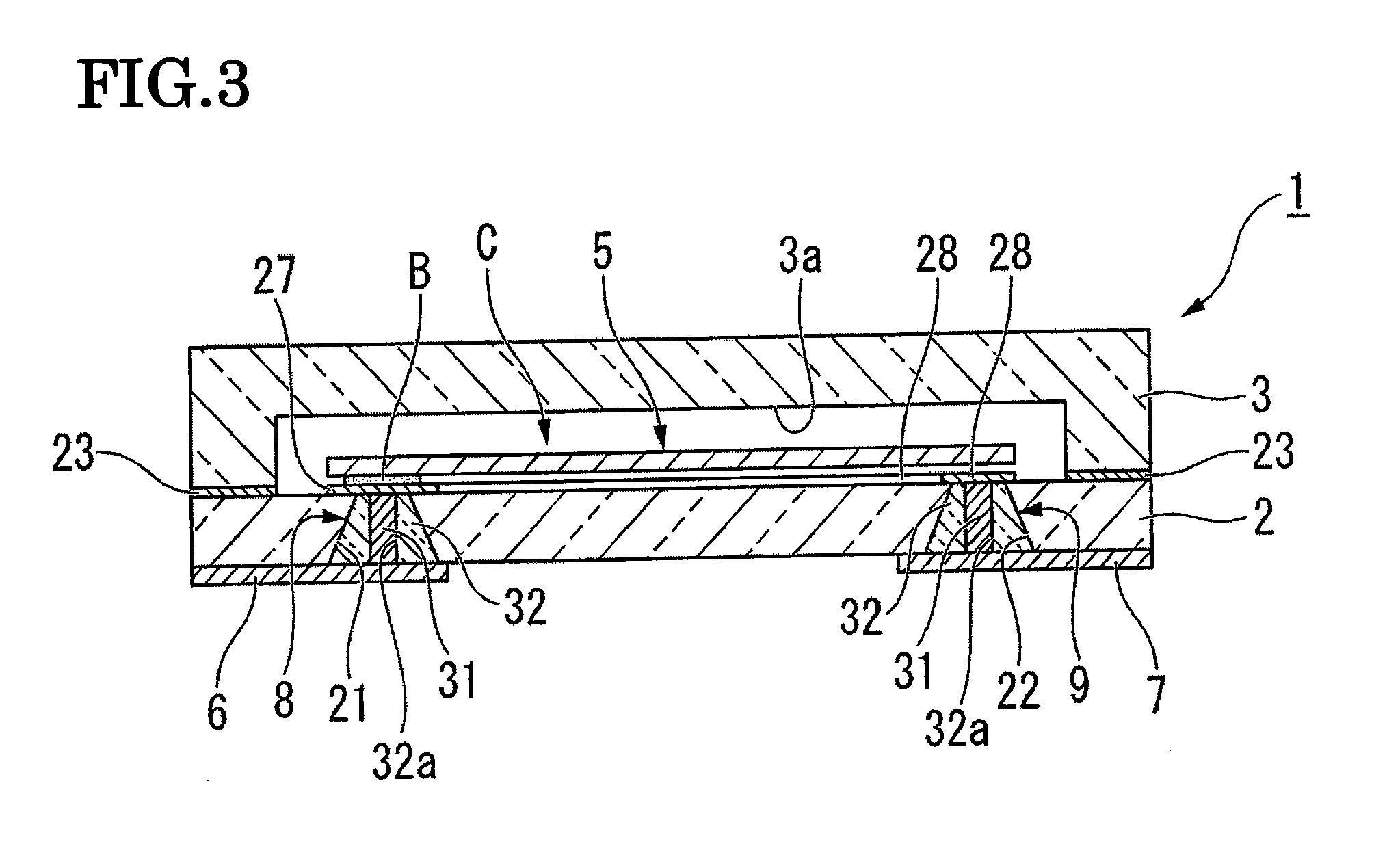

Piezoelectric vibrator, manufacturing method of piezoelectric vibrator, oscillator, electronic device, and radio-controlled clock

InactiveUS20110018398A1Decrease series resonance resistance valueSuppress production of productPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsEngineering

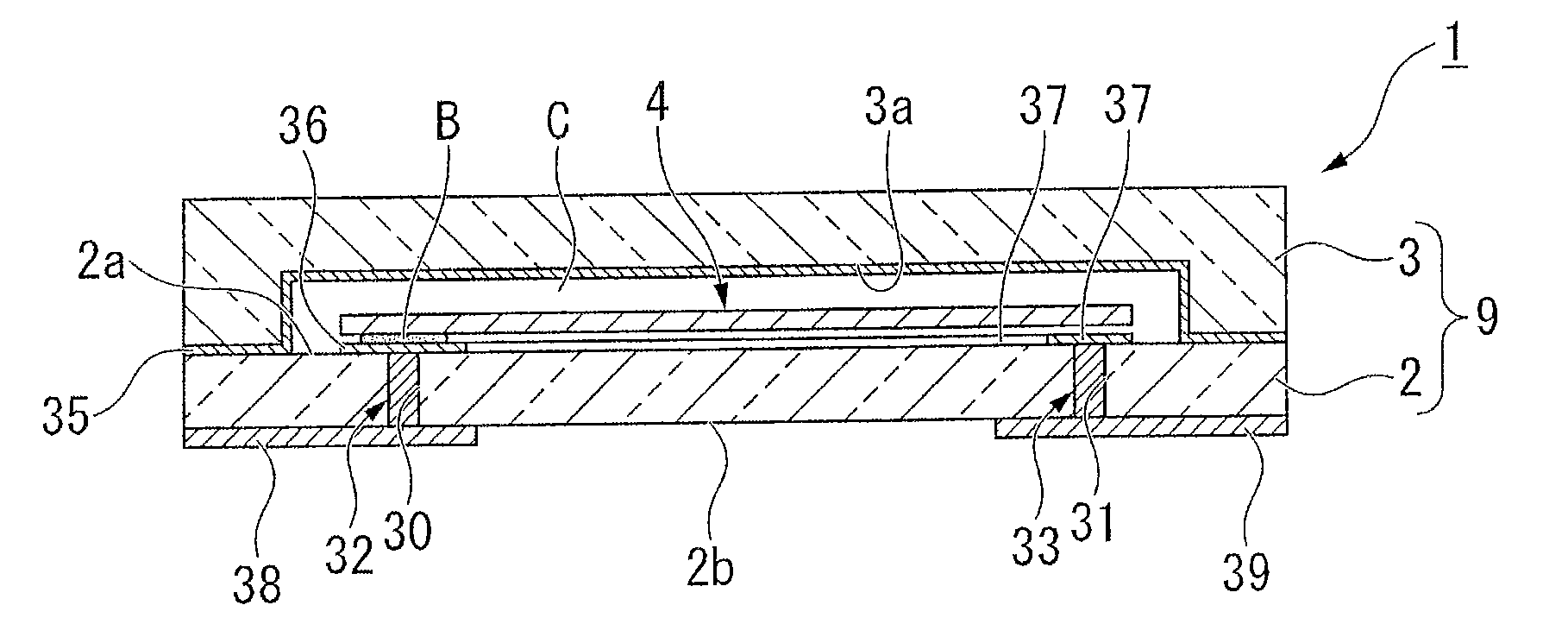

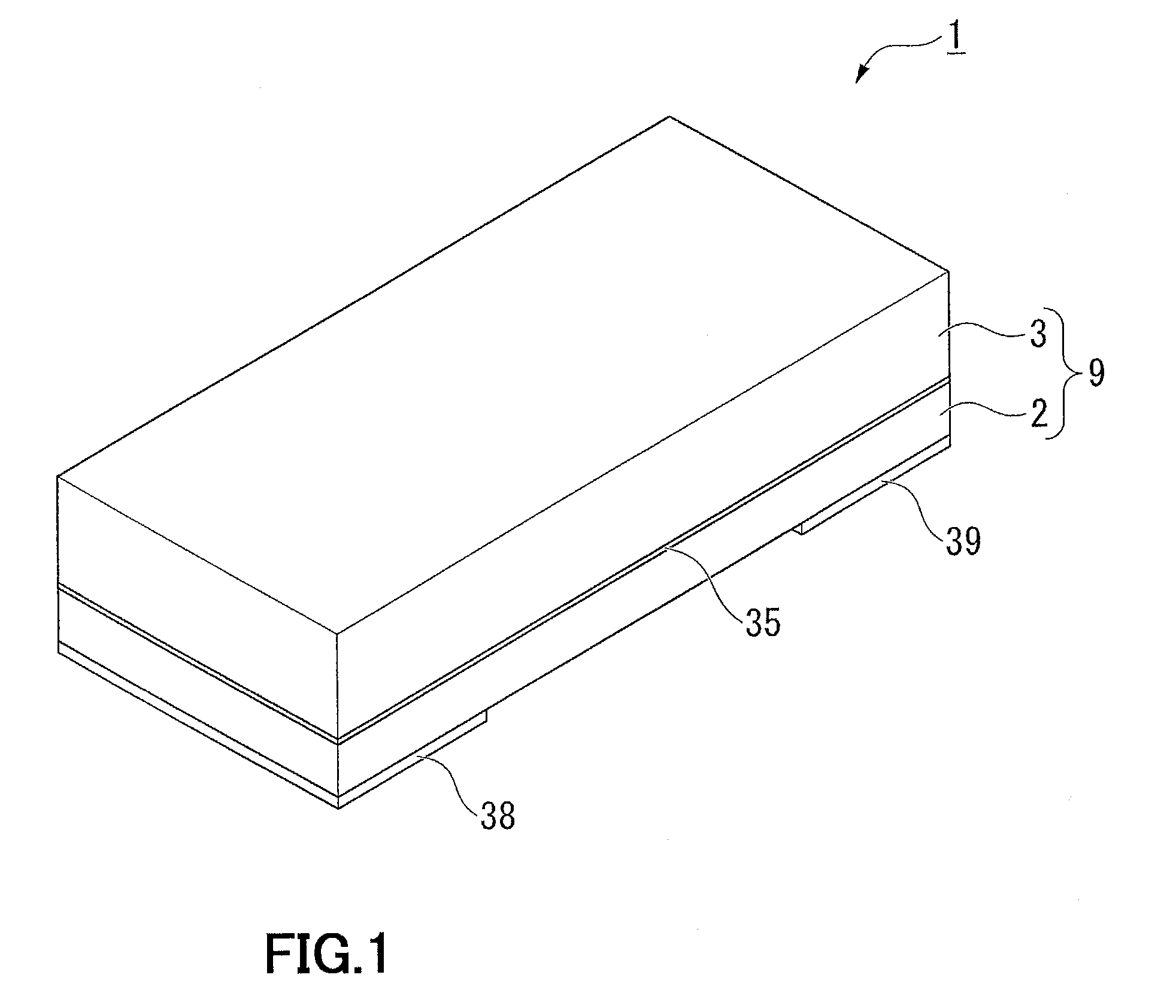

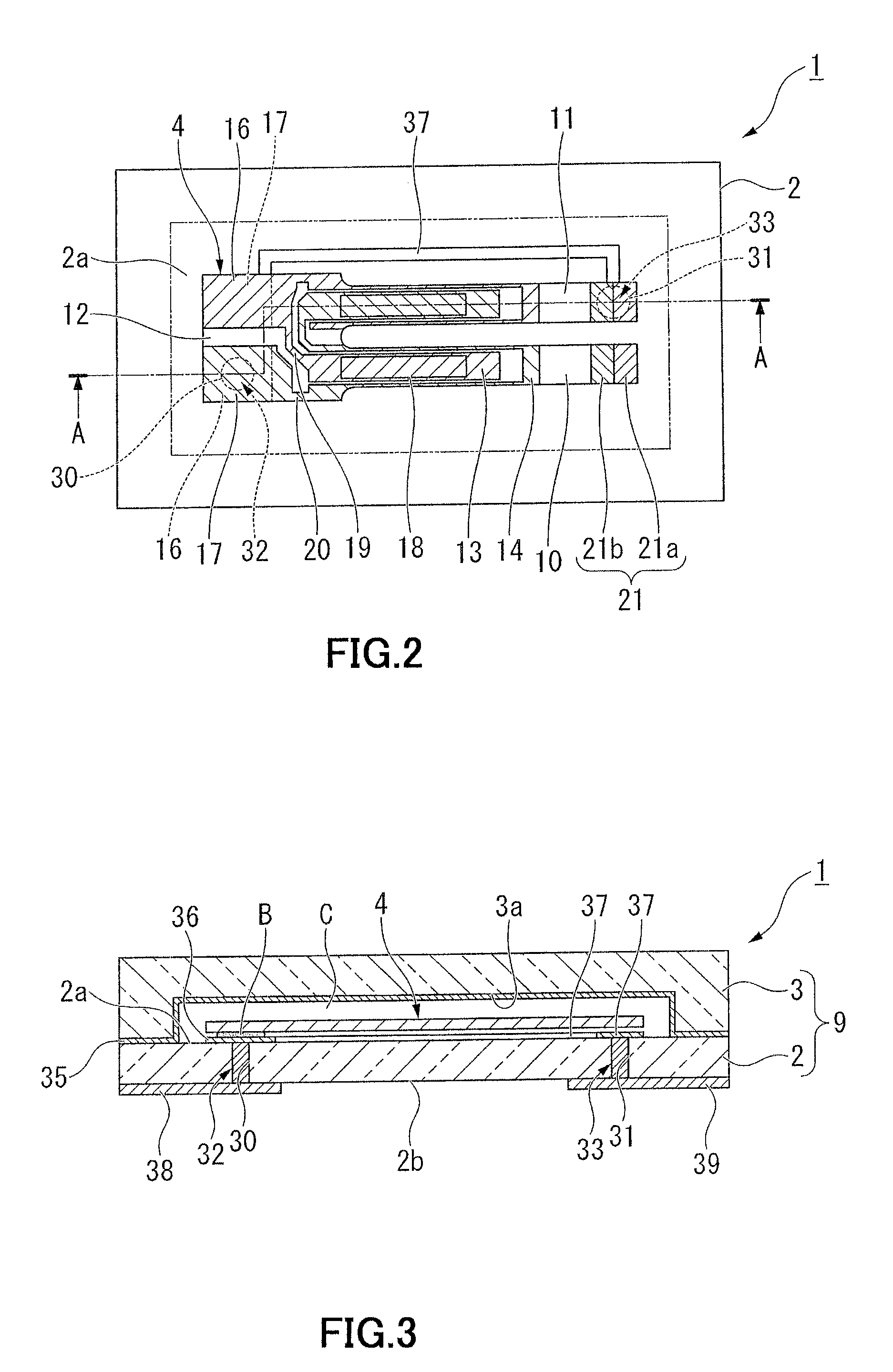

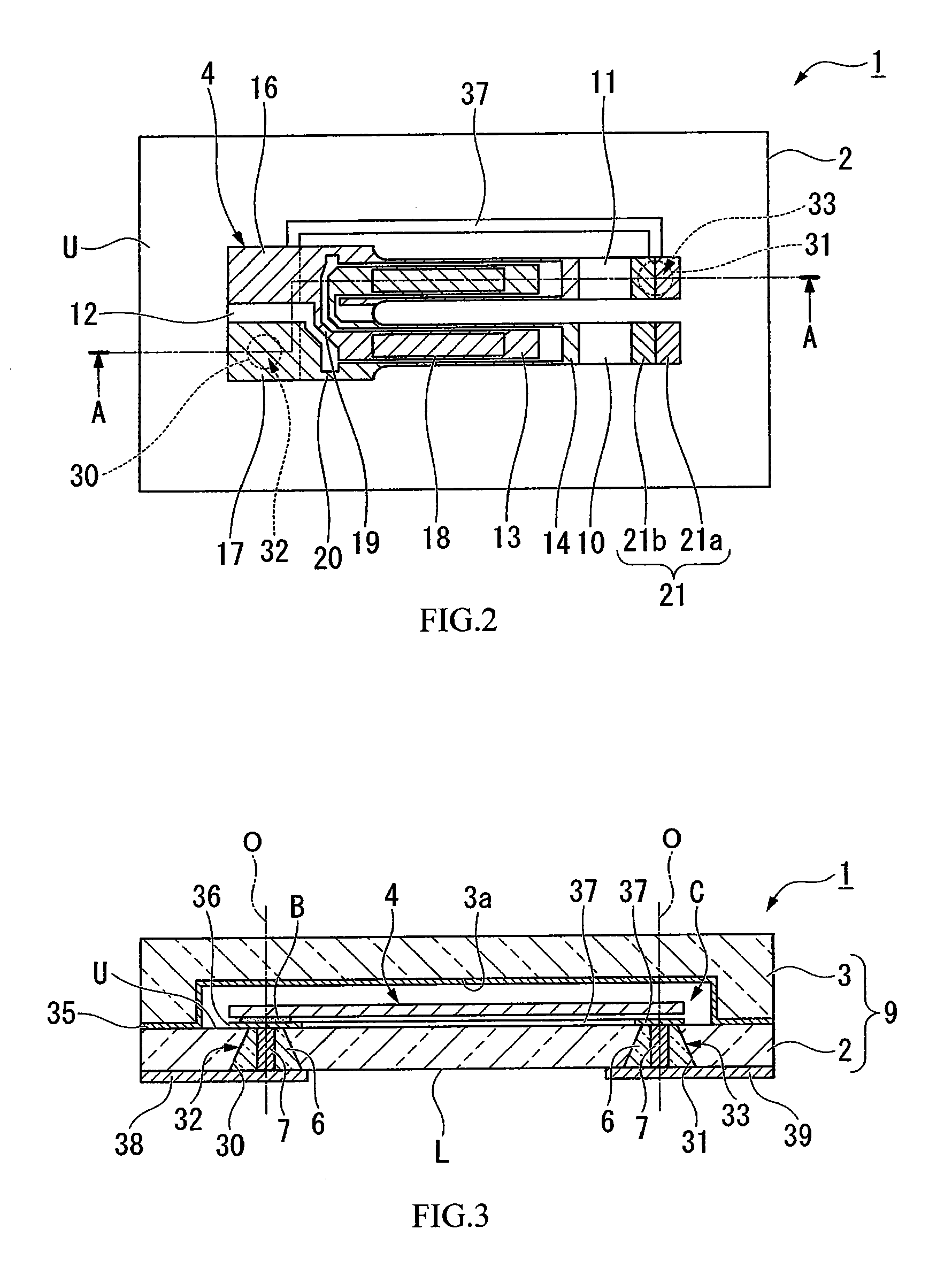

Providing a piezoelectric vibrator which is capable of securing the degree of vacuum in a cavity and can be manufactured with high efficiency and to provide a manufacturing method thereof. A piezoelectric vibrator 1 including: a base board 2 and a lid board 3 which are superimposed onto each other so as to form a cavity C therebetween; a piezoelectric vibrating reed 4 which is accommodated in the cavity and bonded to the base board; a gettering material 34 which is formed in the base board to be accommodated in the cavity; a bonding film 35 which is formed on the entire surface of the lid board facing the base board so as to bond both boards to each other at a portion thereof being in contact with the base board, wherein the bonding film is formed of a material which is capable of absorbing surrounding gas by being activated with laser irradiation.

Owner:SEIKO INSTR INC

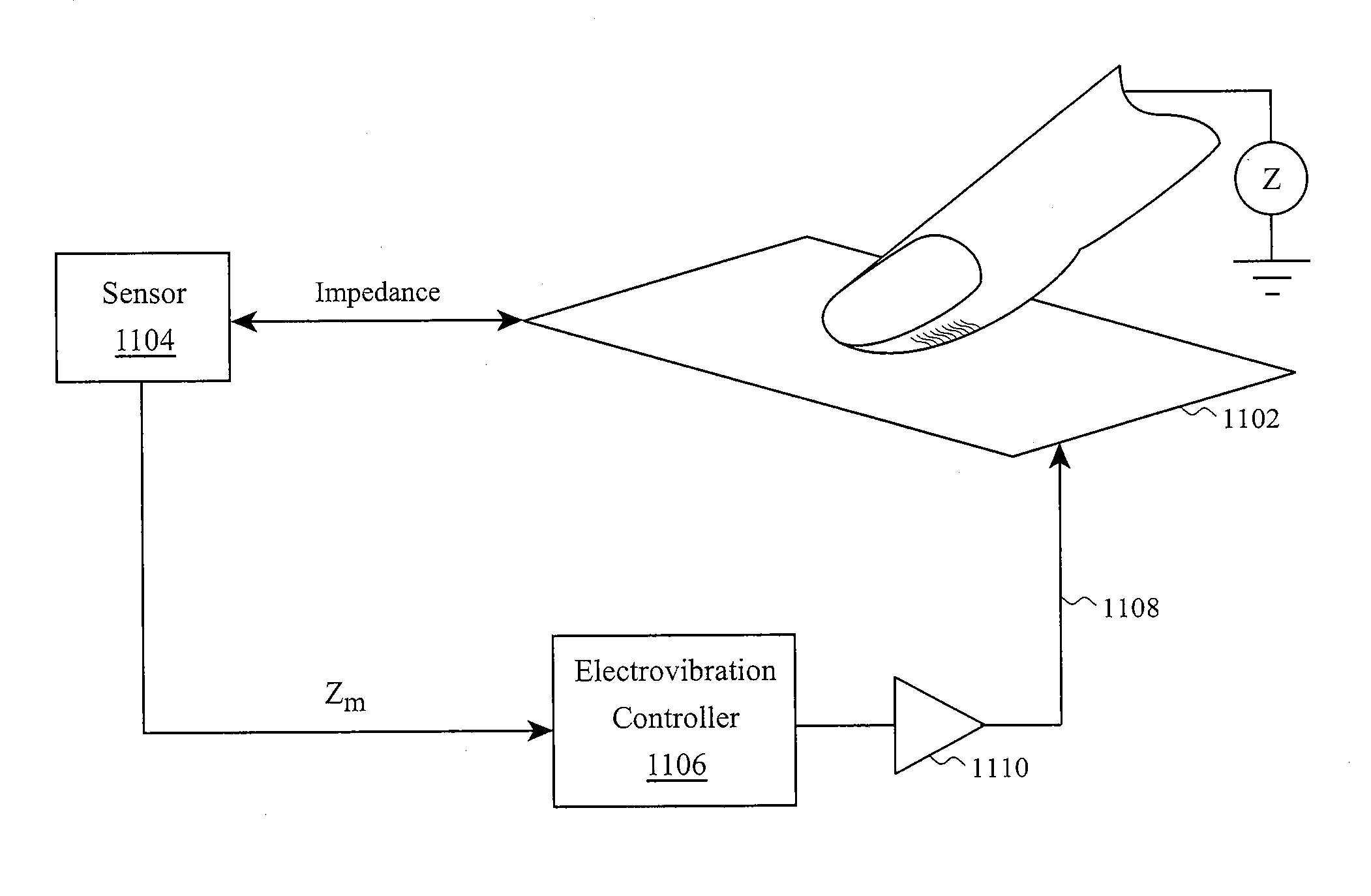

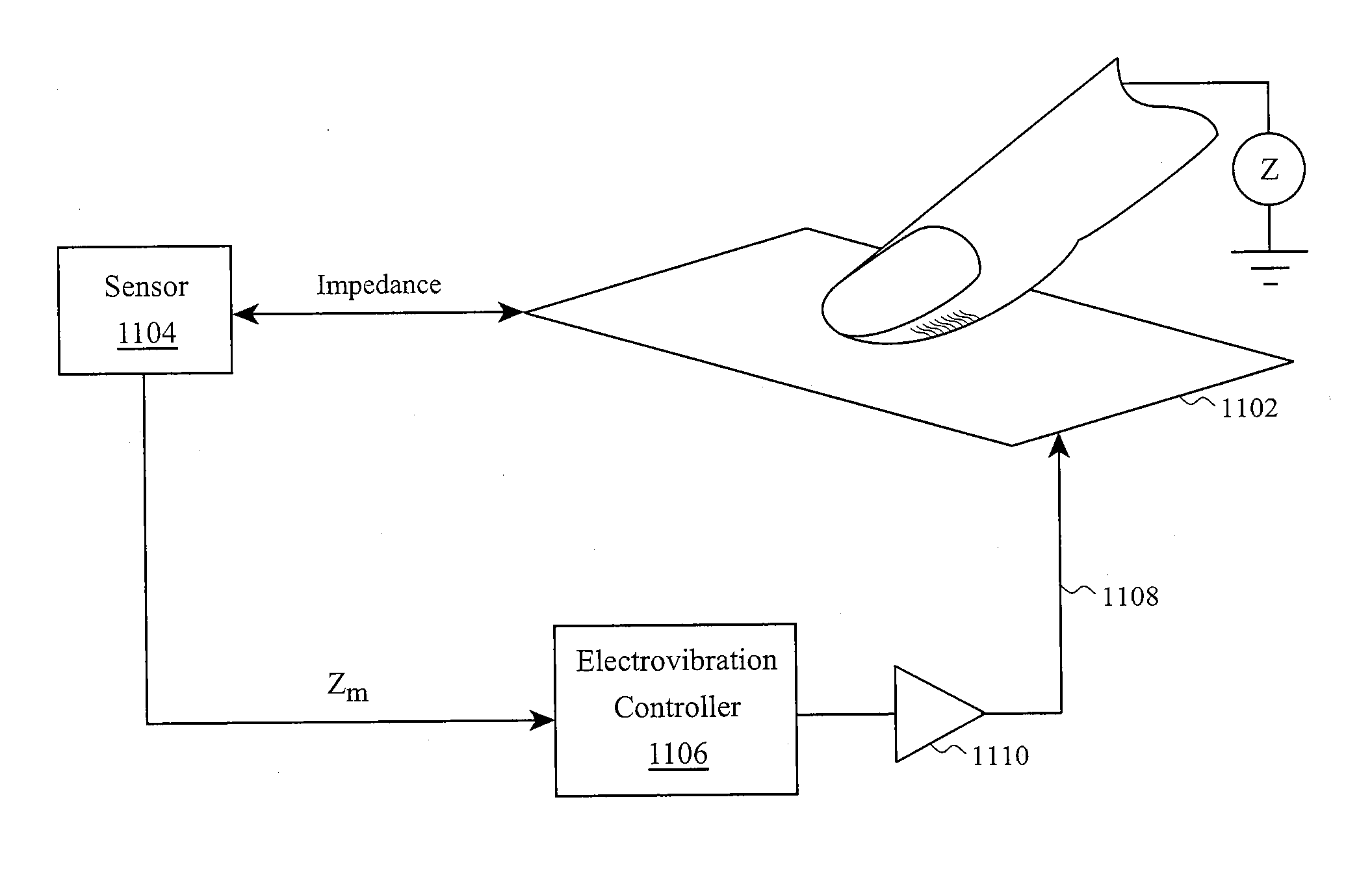

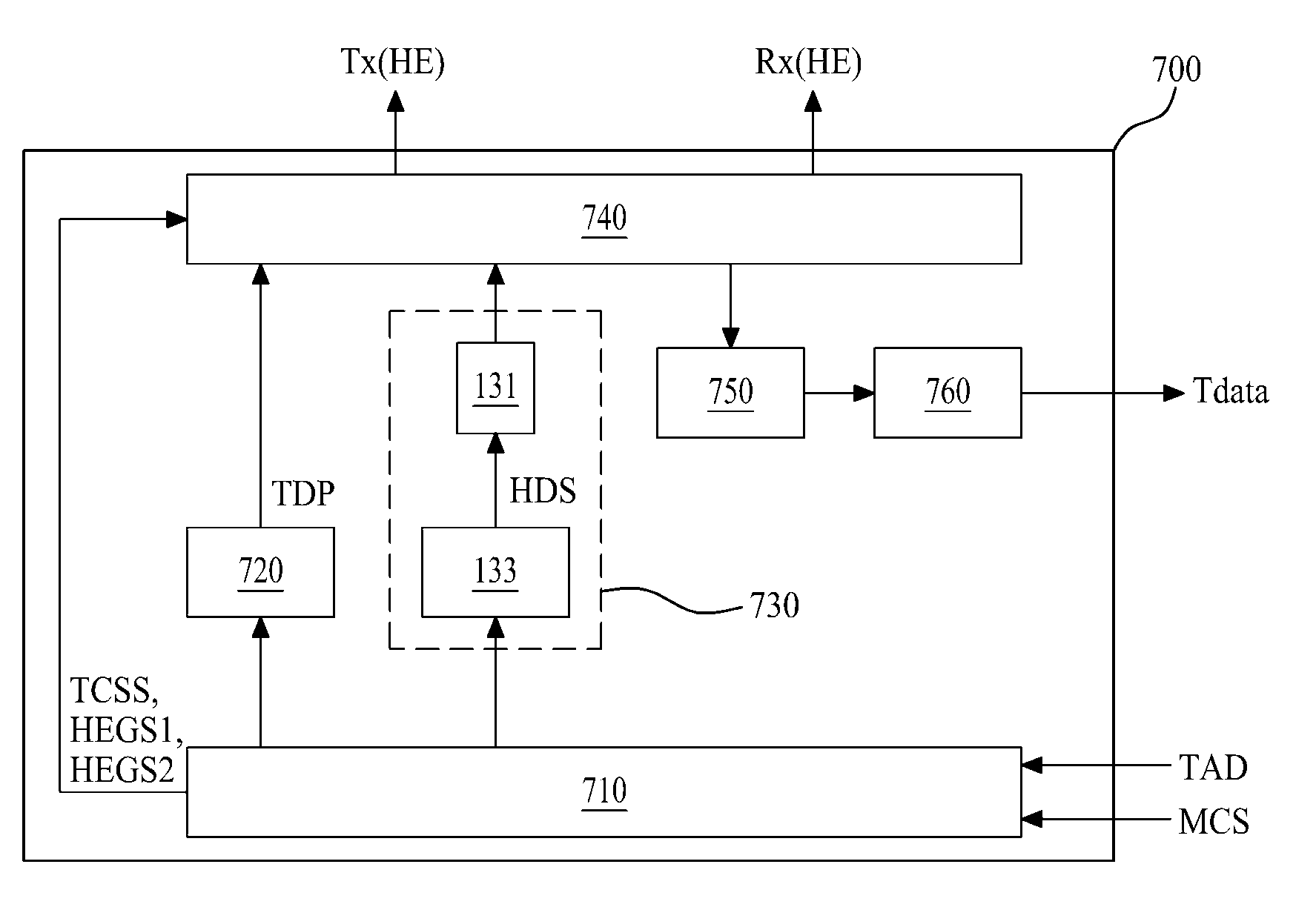

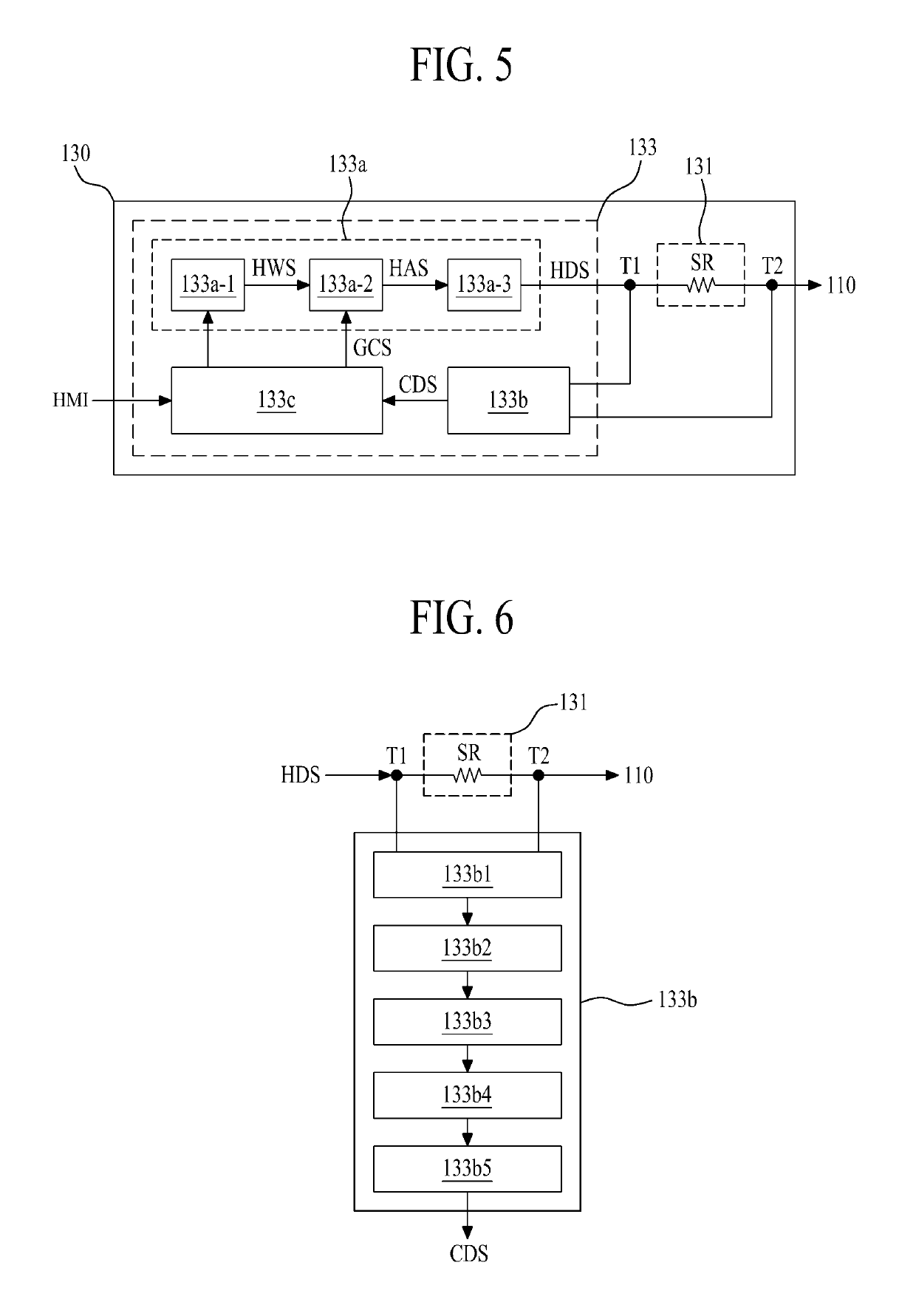

Haptic Driving Apparatus and Electronic Device Having Haptic Function

ActiveUS20160320901A1Input/output for user-computer interactionGraph readingEngineeringElectrical current

A haptic driving apparatus that may provide a user with electrovibration of certain strength regardless of a variance of a surrounding environment and an electronic device having a haptic function are disclosed. The haptic driving apparatus comprises a haptic electrode driver generating a haptic driving signal to supply the generated haptic driving signal to a haptic electrode through a current monitor and varying the haptic driving signal in accordance with the current supplied to the haptic electrode.

Owner:LG DISPLAY CO LTD +1

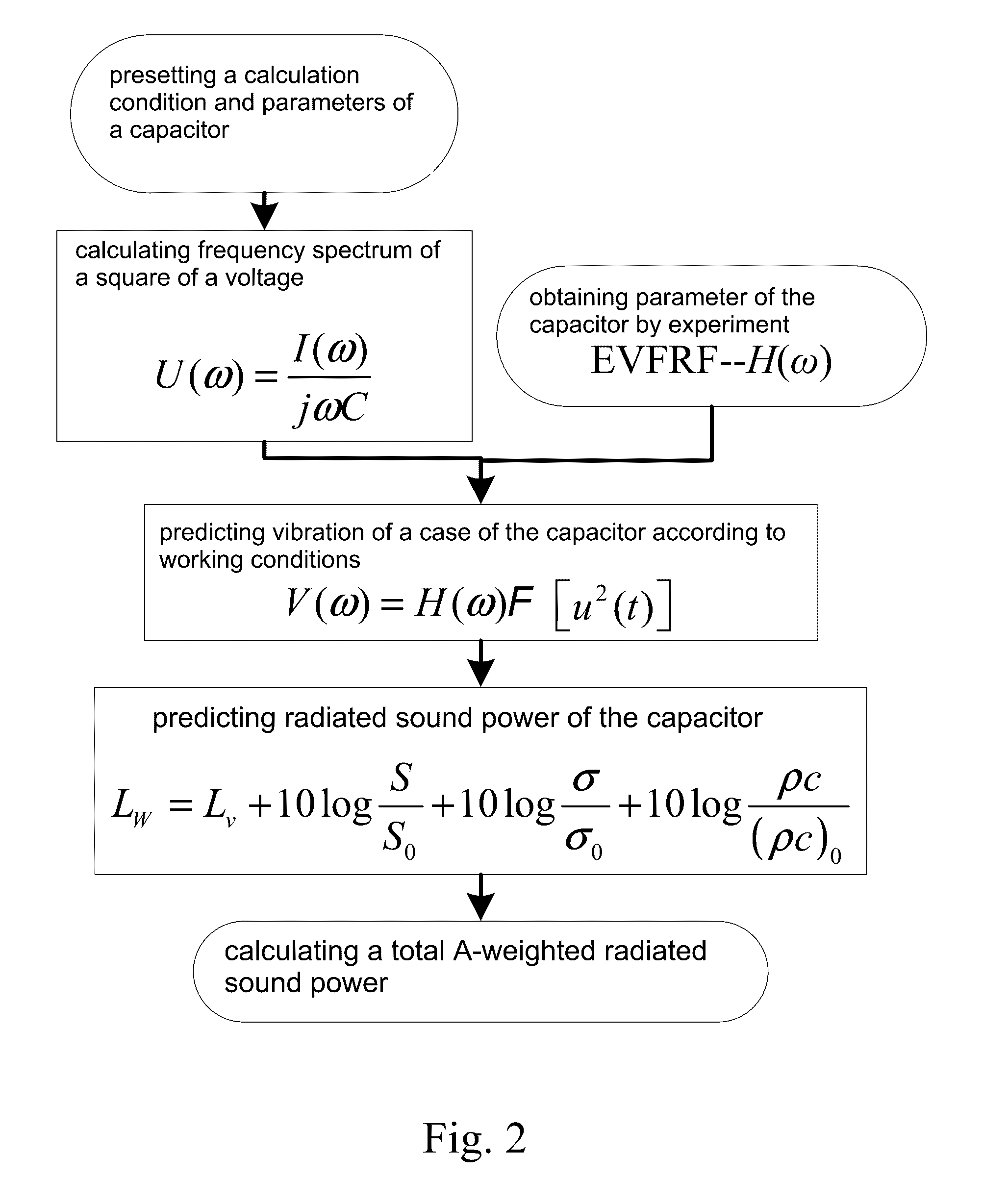

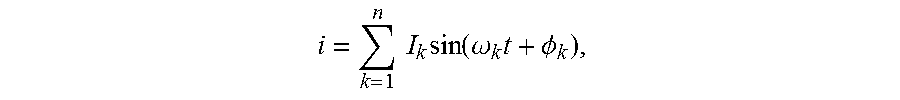

Frequency-sweep experimental method for predicting noise of power capacitor

ActiveUS20160349106A1Sufficient investmentSolve the real problemVibration measurement in solidsVibration measurement in fluidFrequency spectrumDouble Value

A frequency-sweep experimental method for predicting noise of a power capacitor, comprises steps of: (1) loading the capacitor with a sine voltage excitation with a loading frequency value of ½ to 50 times of a power frequency in sequence, at an increase of half of the power frequency for each time, and measuring vibration velocity at various points on a case of the capacitor; (2) under each loading frequency, dividing vibration velocity by a square of each voltage applied to obtain an electromechanical vibration frequency response function value corresponding to a double frequency which has a double value of each loading frequency mentioned above; (3) calculating frequency spectrum of a square of the voltage of the capacitor according to the voltage and a current of the capacitor; (4) multiplying the frequency spectrum of the square of the voltage of the capacitor by the electromechanical vibration frequency response function value of the capacitor to obtain a vibration velocity spectrum of the case of the capacitor; (5) calculating acoustical power of the noise radiated by the capacitor according to the vibration velocity spectrum of the case of the capacitor. The method of the present invention is capable of achieving the problems of lacking a simple and standard method for detecting noise in the capacitor industry, and lacking sufficient investment in noise reduction, so as to provide a fundamental for solving the problems in the capacitor noise.

Owner:XI AN JIAOTONG UNIV

Package, method for manufacturing the same, piezoelectric vibrator, oscillator, electronic device, and radio-controlled timepiece

InactiveUS8304965B2High degreeReduce the driving voltagePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksEngineeringMechanical engineering

Providing a package and a method for manufacturing the package capable of achieving improvement in the degree of vacuum in the cavity, and to provide a piezoelectric vibrator, an oscillator, an electronic device, and a radio-controlled timepiece. There is provided a package which includes a plurality of kinds of gettering materials 20, 21 having different activation temperatures and which are capable of being activated by heating is disposed in the cavity C.

Owner:SII CRYSTAL TECH

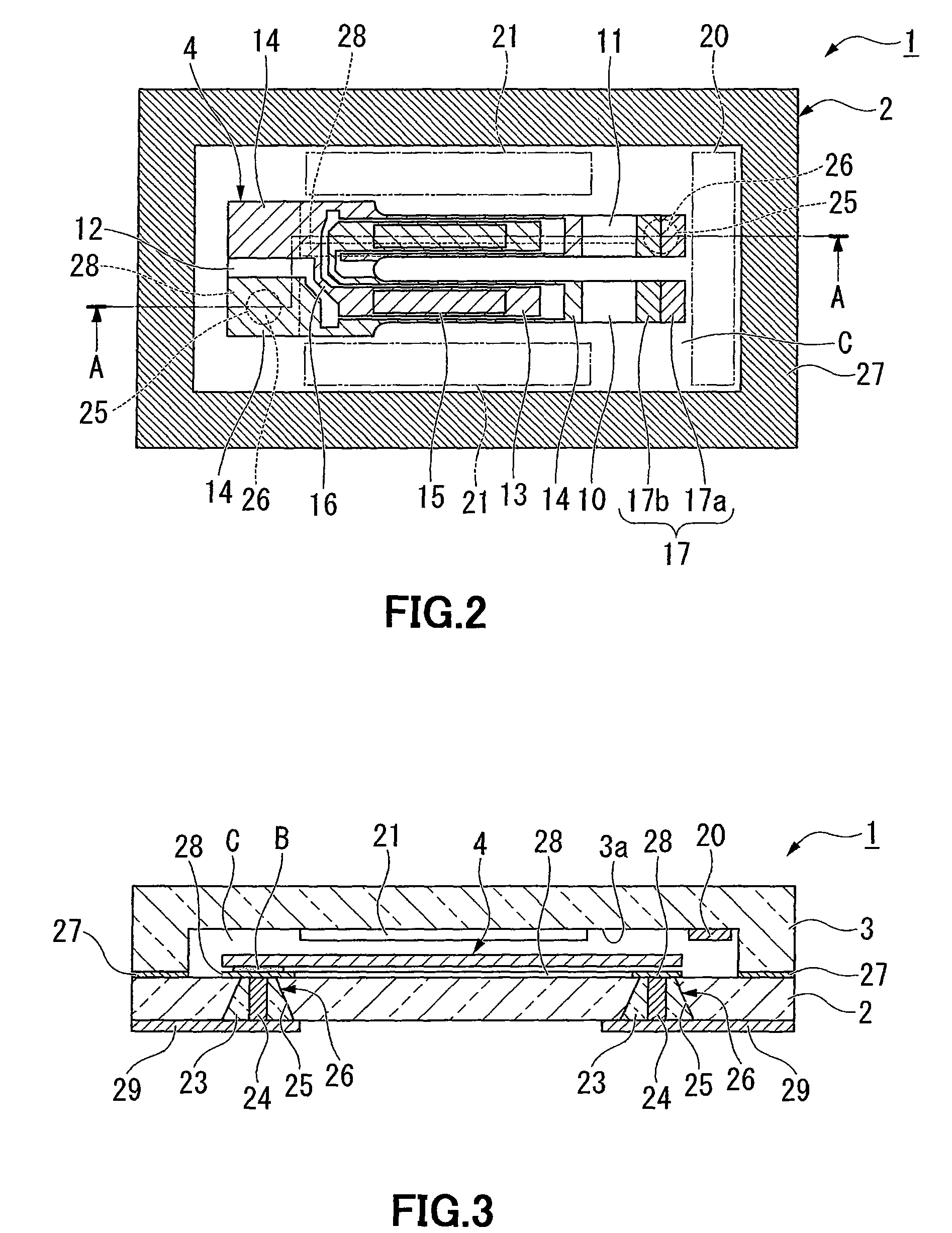

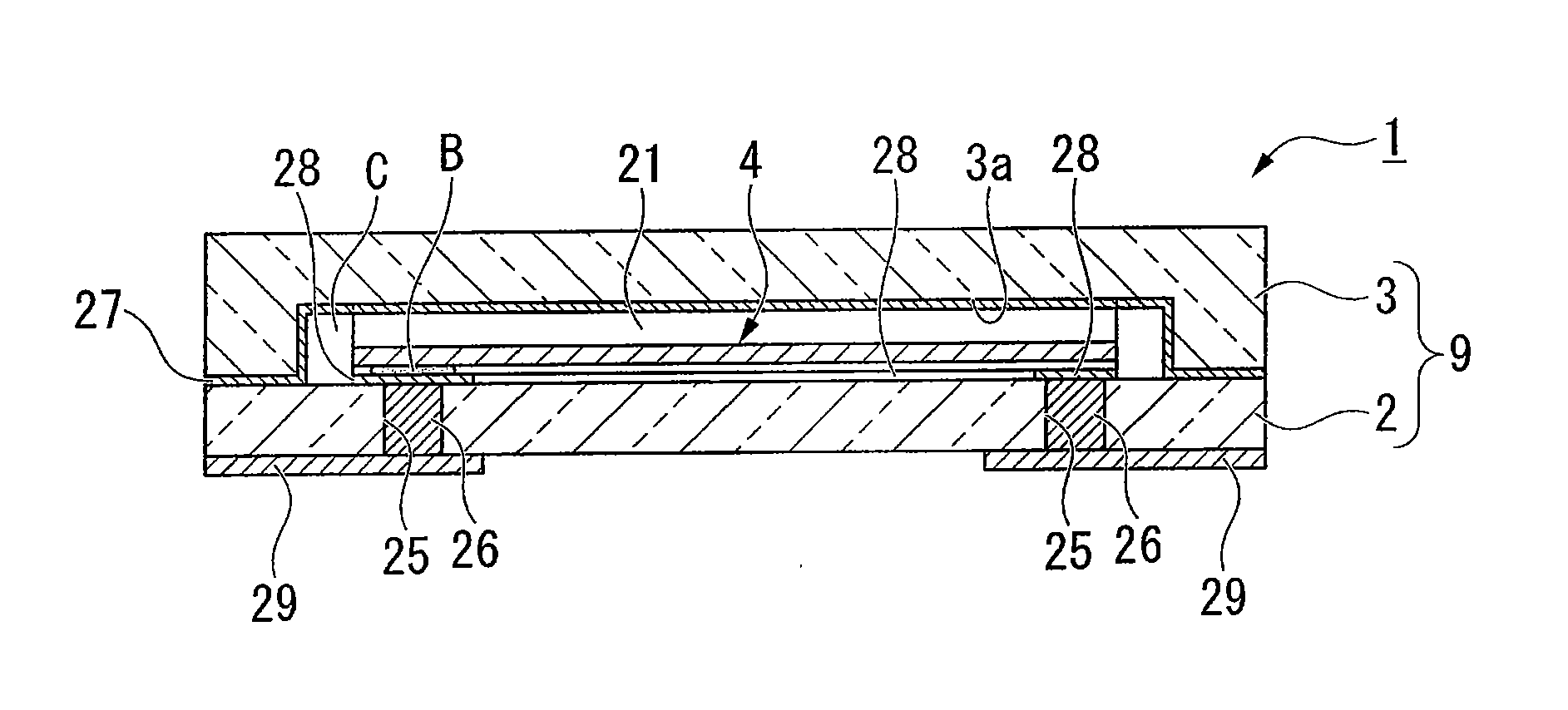

Piezoelectric vibrator, piezoelectric vibrator manufacturing method, oscillator, electronic device, radio-controlled timepiece

InactiveUS20110050046A1Suppresses frequency changesPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsEngineering

Providing a piezoelectric vibrator and a manufacturing method thereof which is capable of achieving gettering in a state where the frequency change of the piezoelectric vibrating reed is suppressed. Providing a piezoelectric vibrator 1 including: a package 9 having a base board 2 and a lid board 3 which are bonded in a superimposed state and a cavity C formed between both boards 2, 3; and a piezoelectric vibrating reed 4 and a gettering material 27 which are accommodated in the same cavity C, wherein a shielding wall 21 is provided in the cavity C so as to shield the piezoelectric vibrating reed 4 from the gettering material 27, and the shielding wall 21 is connected to both the base board 2 and the lid board 3.

Owner:SII CRYSTAL TECH

Piezoelectric vibrating body

ActiveCN104956692APlane diaphragmsPiezoelectric/electrostrictive/magnetostrictive devicesSound waveHaptic sensation

The purpose of the present invention is to provide a piezoelectric vibrating body that is capable of instantaneously generating vibrations for causing what is referred to as a haptic sensation by effectively generating sound waves when a voltage is applied thereto. This piezoelectric vibrating body comprises a piezoelectric laminated body, for which oriented film layers made of a polylactic acid and conductive layers are alternatingly laminated, and grippers for gripping either end of the piezoelectric laminated body, wherein (i) one of conductive layers adjoined across a respective oriented film layer is short-circuited to a negative electrode, and the other to a positive electrode, and the oriented film layers sandwiched by the respective conductive layers are laminated so as to expand / contract in the same direction when a current is applied thereto, (ii) the piezoelectric laminated body has two parallel surfaces that are parallel to the plane direction of the oriented film layers and two end faces A and B that are sandwiched by the parallel surfaces and arranged parallel to each other, and (iii) the gripped ends respectively include end face A and end face B, and the portion of the piezoelectric laminated body between the end faces A and B is stressed by the grippers.

Owner:MURATA MFG CO LTD +1

Piezoelectric vibrating reed, piezoelectric vibrator, method for manufacturing piezoelectric vibrating reed, and method for manufacturing piezoelectric vibrator

ActiveCN103430450ANo locationWill not happenPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksSurface roughnessMetal

A piezoelectric resonator plate includes at least a pair of excitation electrodes and at least a pair of extraction electrodes. The pair of extraction electrodes are respectively extracted from the pair of excitation electrodes to electrically and mechanically bond the pair of excitation electrodes to an external electrode. The pair of extraction electrodes each include a distal end portion. The distal end portion includes a connecting electrode extracted to a vicinity of one end portion on one principal surface of the piezoelectric resonator plate. The connecting electrodes each include a top surface where a first metal film to be bonded to the external electrode is formed. The first metal film includes a top surface with two or more protruding portions. The first metal film has a larger surface roughness and a smaller area compared with the respective connecting electrodes. The protruding portions are formed with cross-sections in curvature shapes.

Owner:DAISHINKU CORP

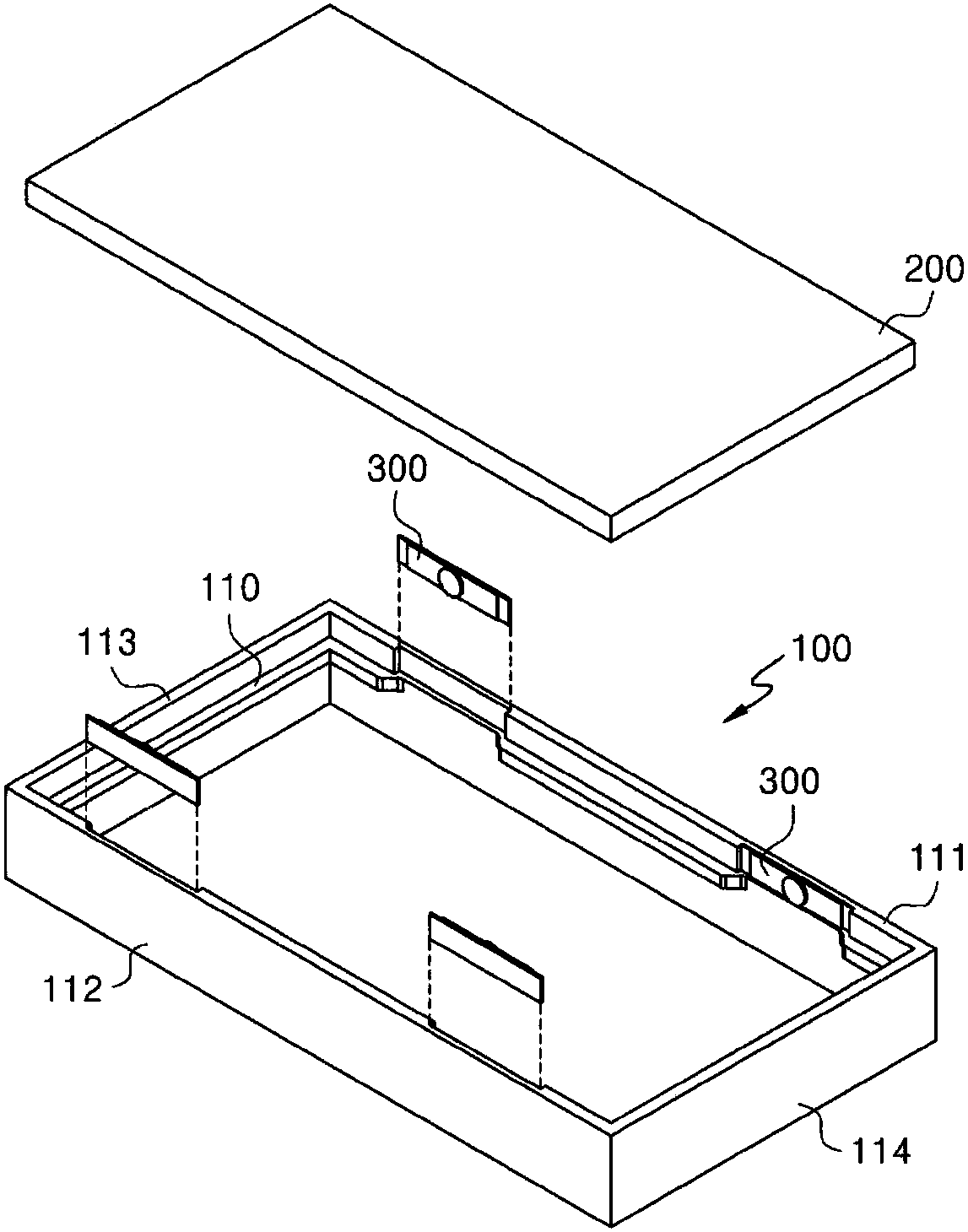

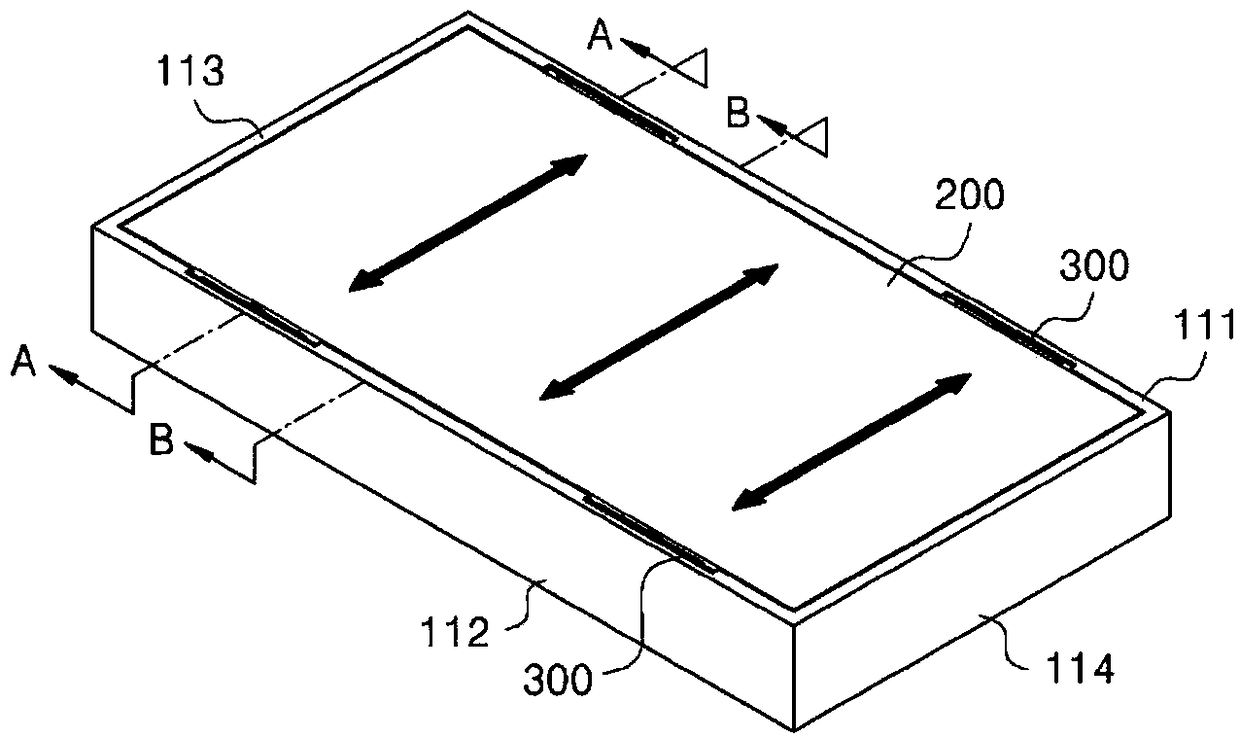

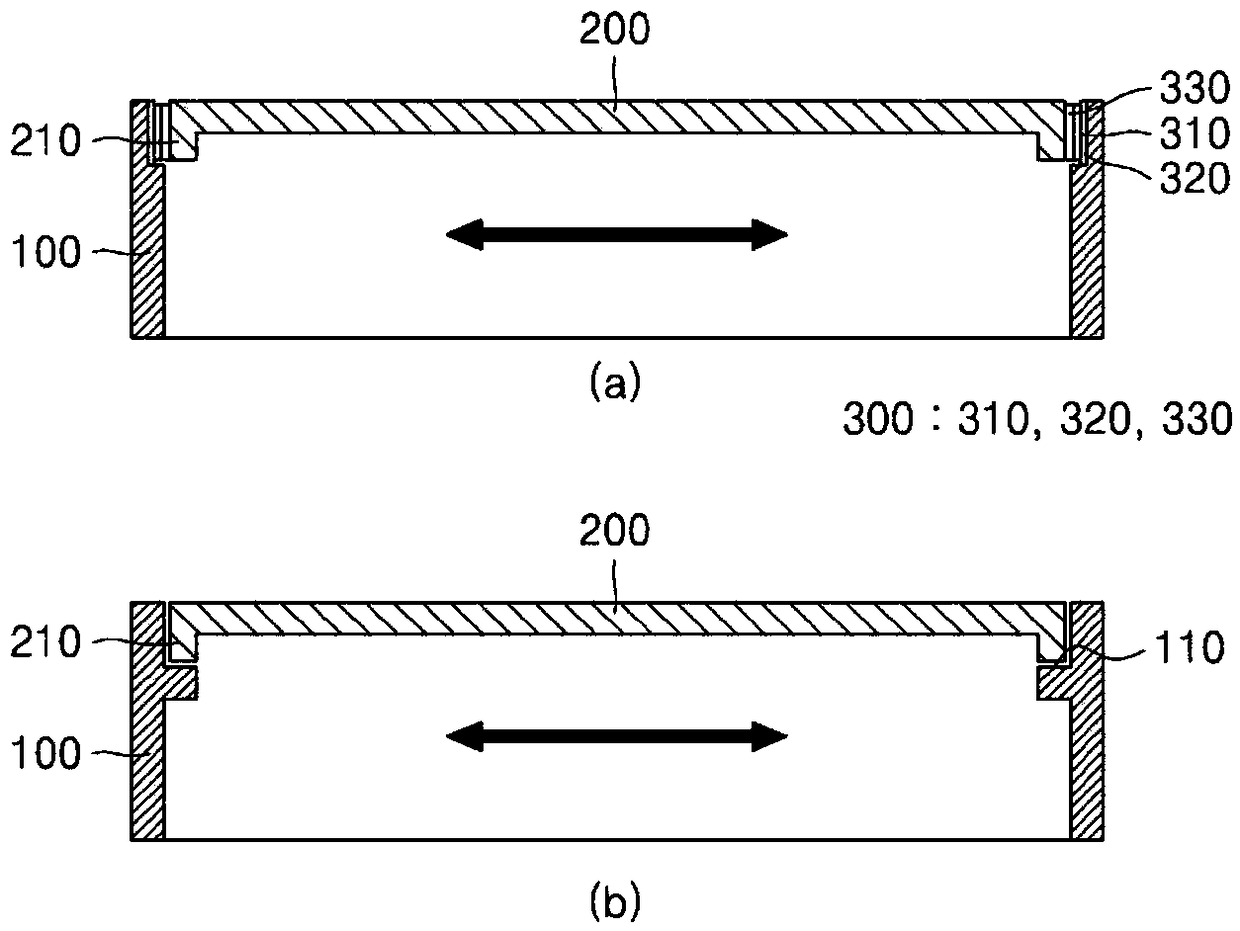

Touch screen device

InactiveCN108292180AStrong vibrationUniform vibration forceInput/output for user-computer interactionGraph readingEngineeringTouchscreen

The present invention presents a touch screen device which comprises: a frame; a touch screen panel arranged in the frame; and a piezoelectric vibration member arranged between the frame and the touchscreen panel, wherein the piezoelectric vibration member vibrates in a horizontal direction of the touch screen panel.

Owner:MODA INNOCHIPS CO LTD

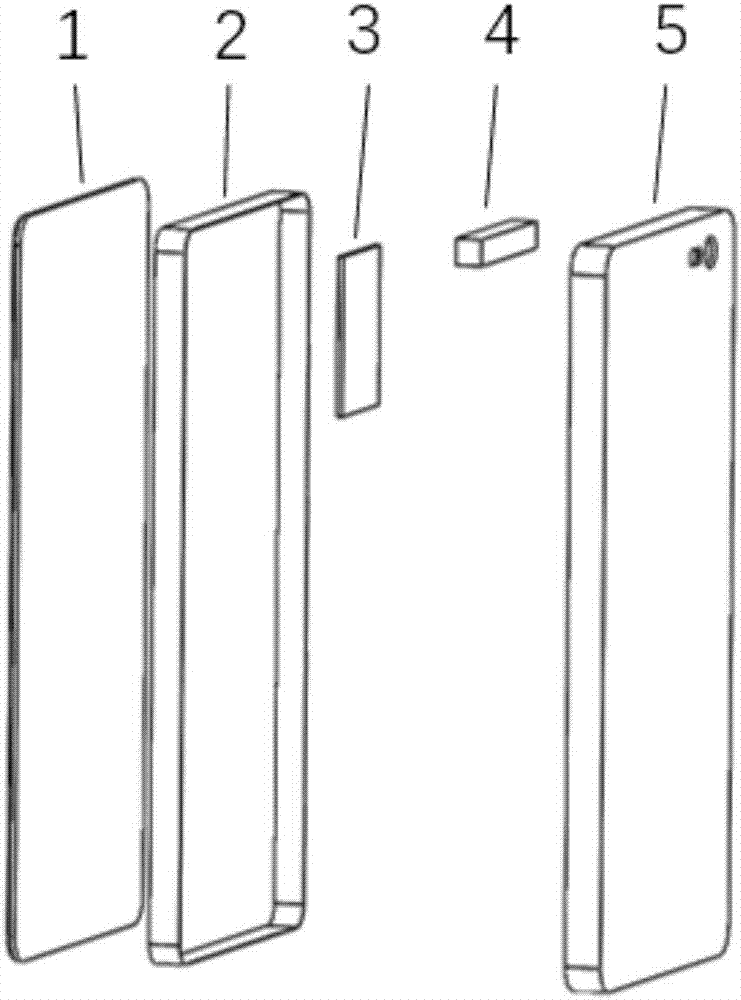

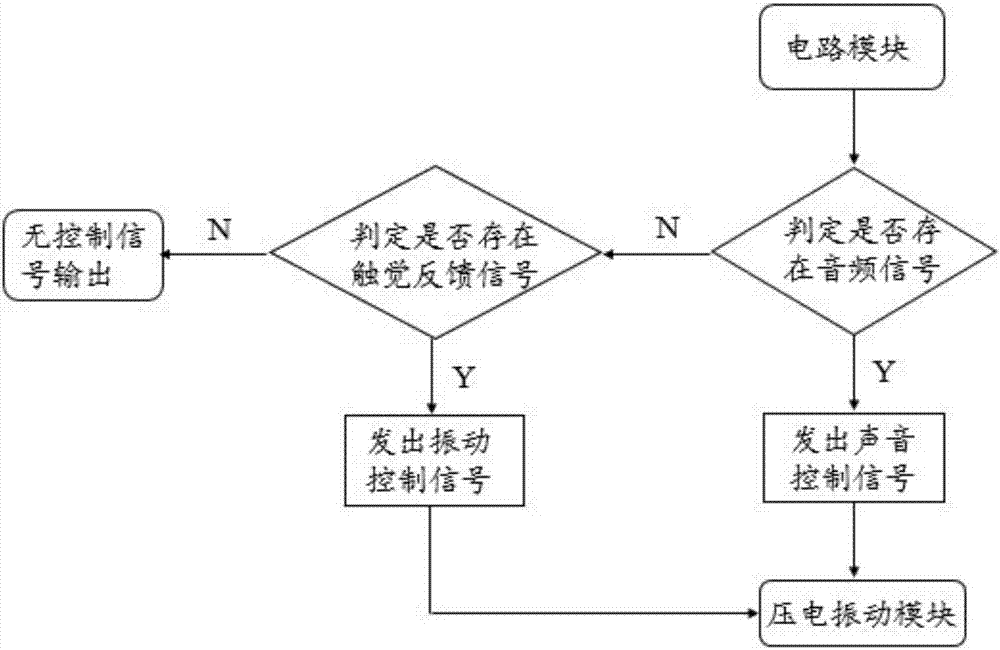

Mobile terminal equipment, tactile feedback and audio control method and system

PendingCN106980373AMiniaturizationLight in massInput/output for user-computer interactionGraph readingTerminal equipmentSound production

The invention relates to the technical fields of tactile feedback and screen sound production, and in particular to mobile terminal equipment, a tactile feedback and audio control method and a tactile feedback and audio control system so as to solve the technical problems in prior art that an audio module and a tactile feedback module of the mobile terminal equipment are relatively large in size, relatively heavy in mass and relatively high in thickness and the system is relatively complicated. The mobile terminal equipment comprises a display panel, a housing, a middle frame, a circuit module and a piezoelectric vibration module, wherein the housing is located at the back surface of the display panel; the middle frame is internally placed in a space formed by the panel and the housing; the circuit module and the piezoelectric vibration module are located between the middle frame and the housing; and the piezoelectric vibration module is used for tactile feedback and sound production. The light weight and microminiaturization of the mobile terminal equipment are realized, the mass, thickness and size of the mobile terminal equipment can be remarkably reduced and the system is simplified.

Owner:SUZHOU PANT PIEZOELECTRIC TECH

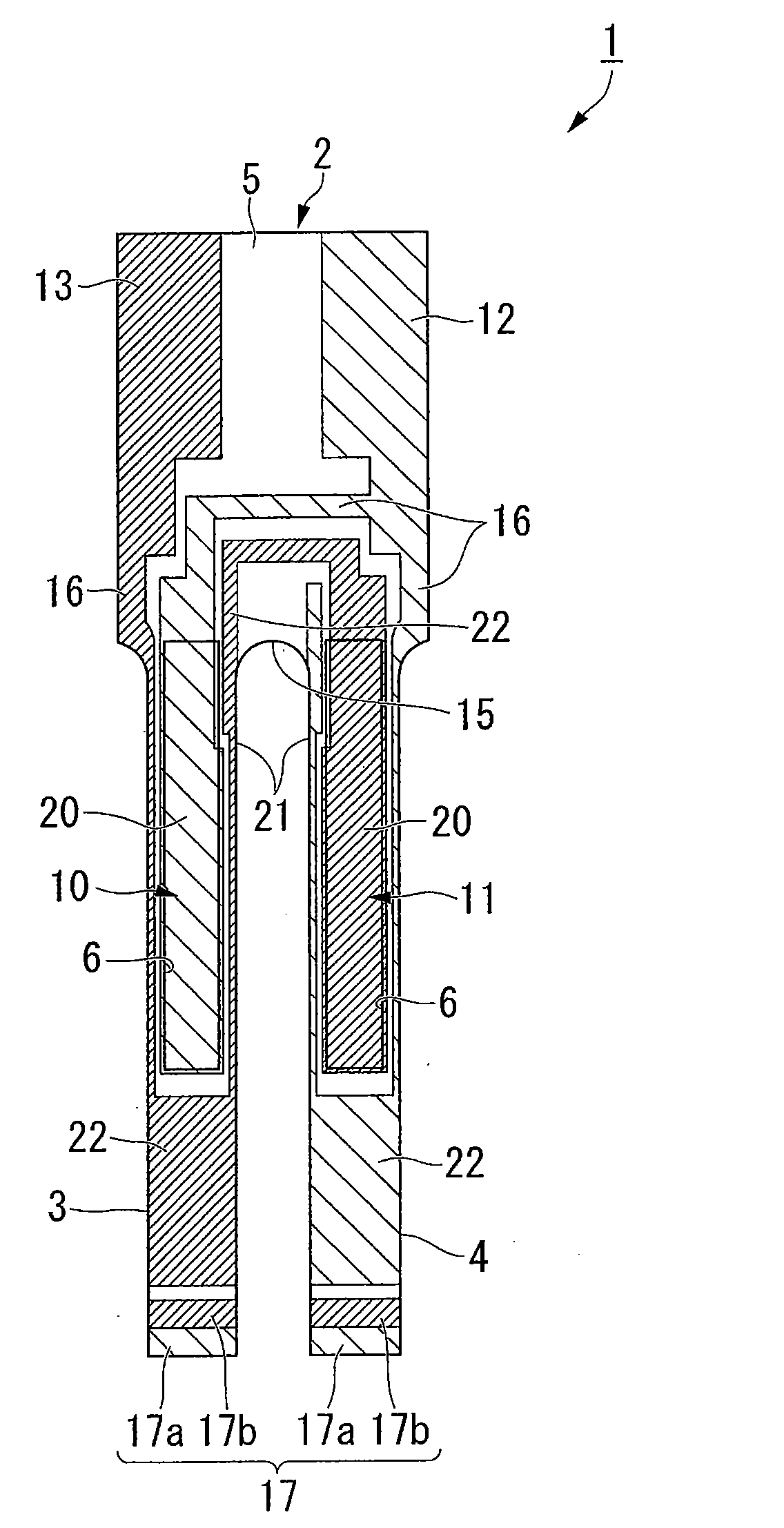

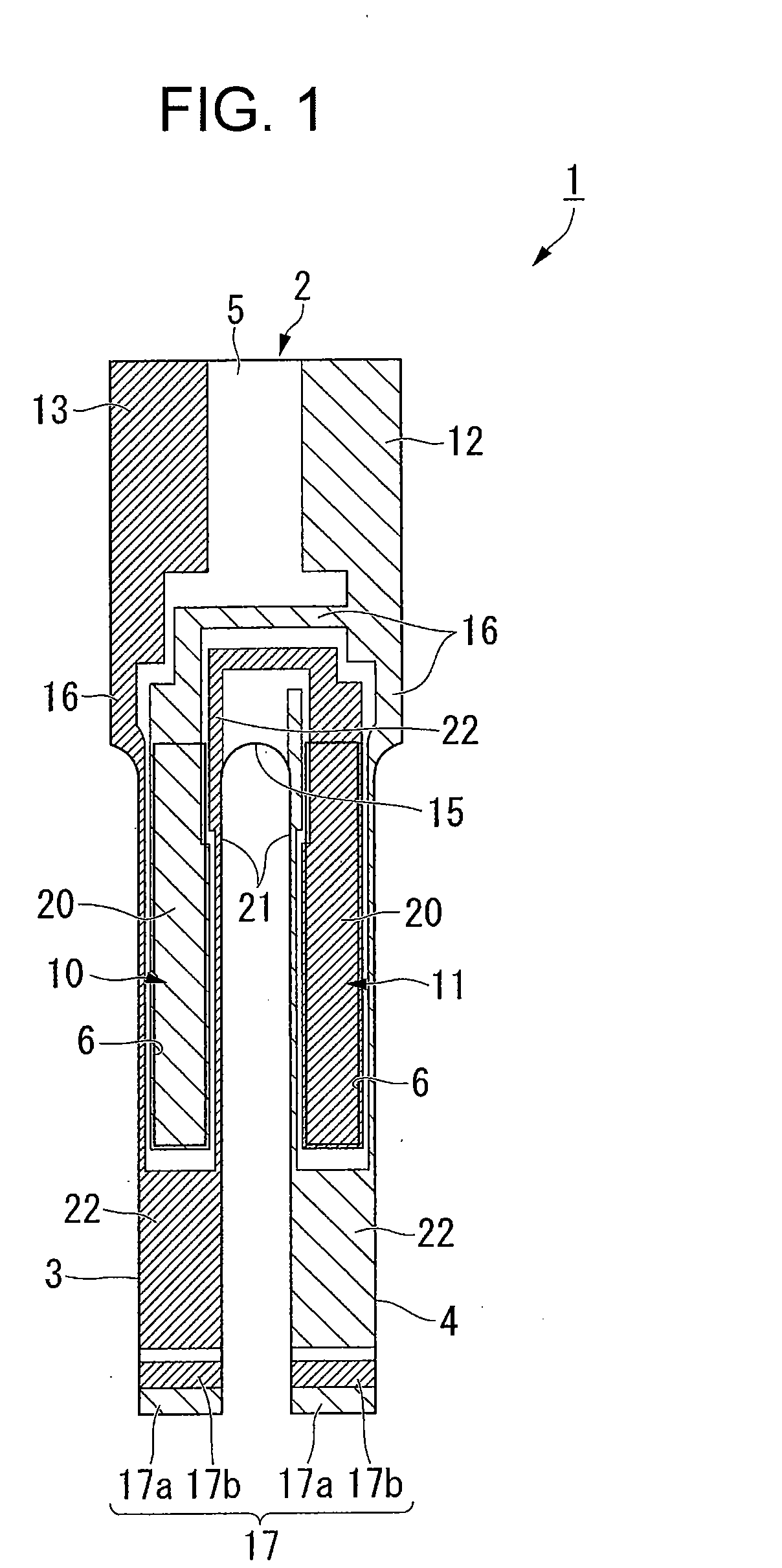

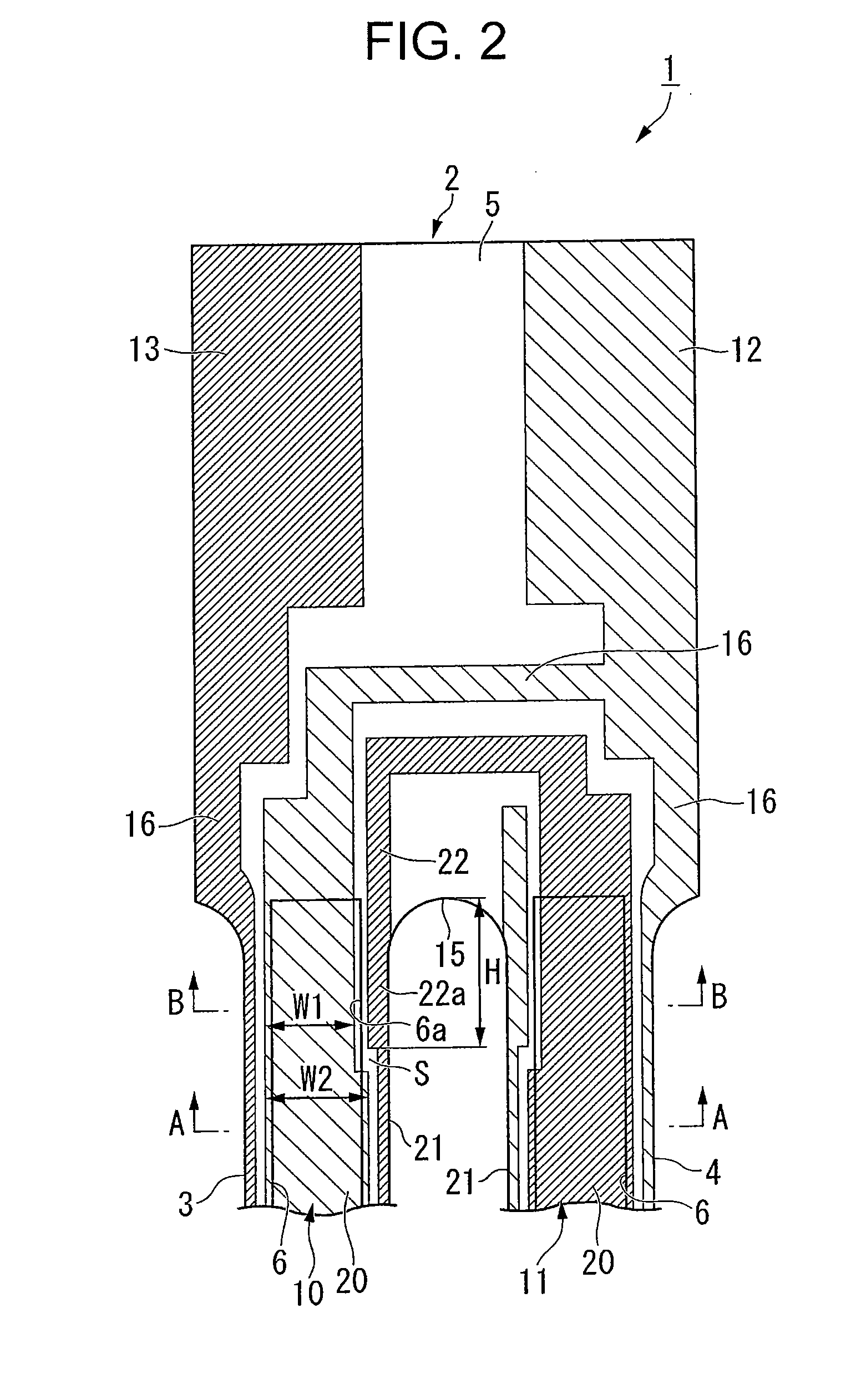

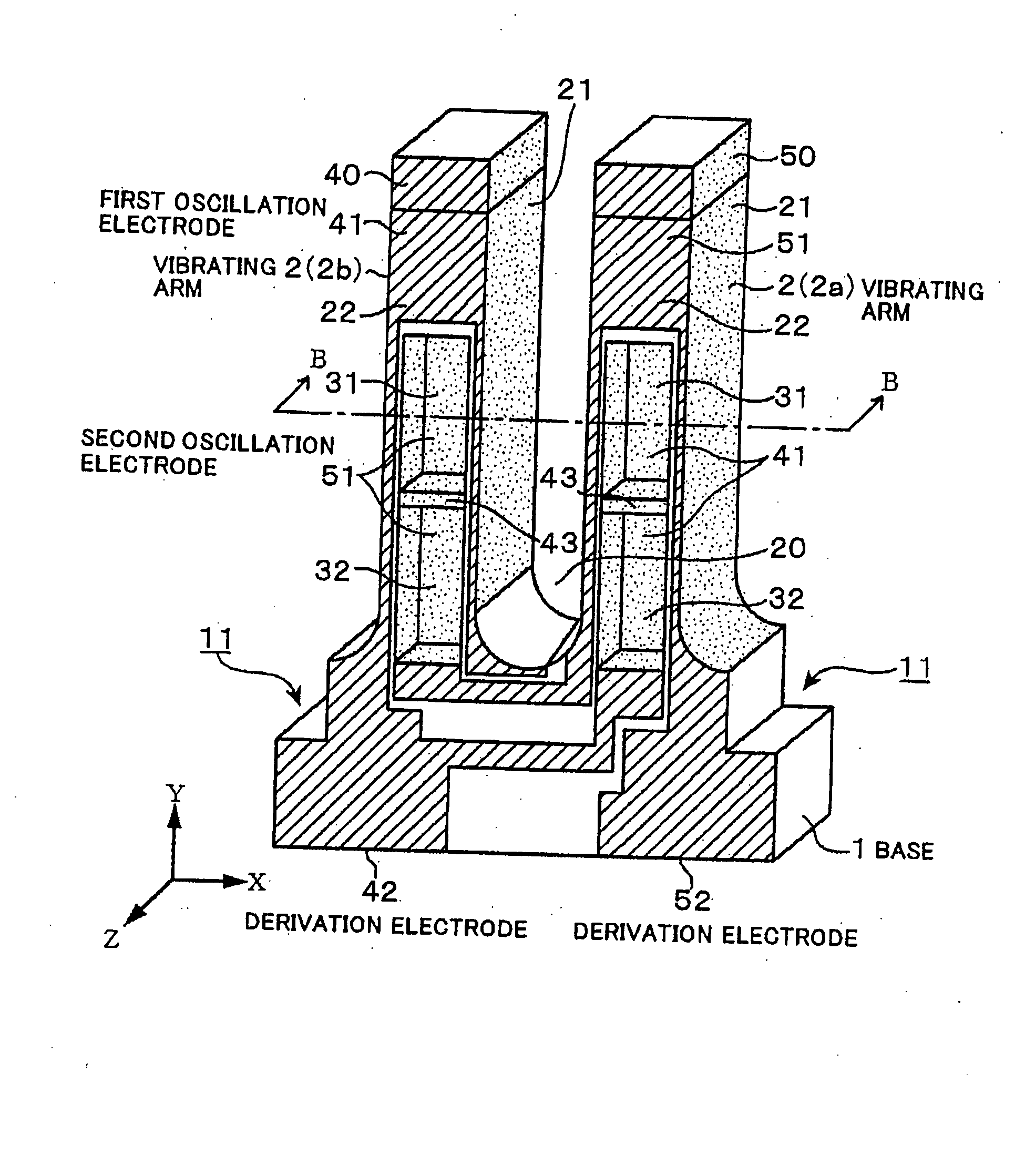

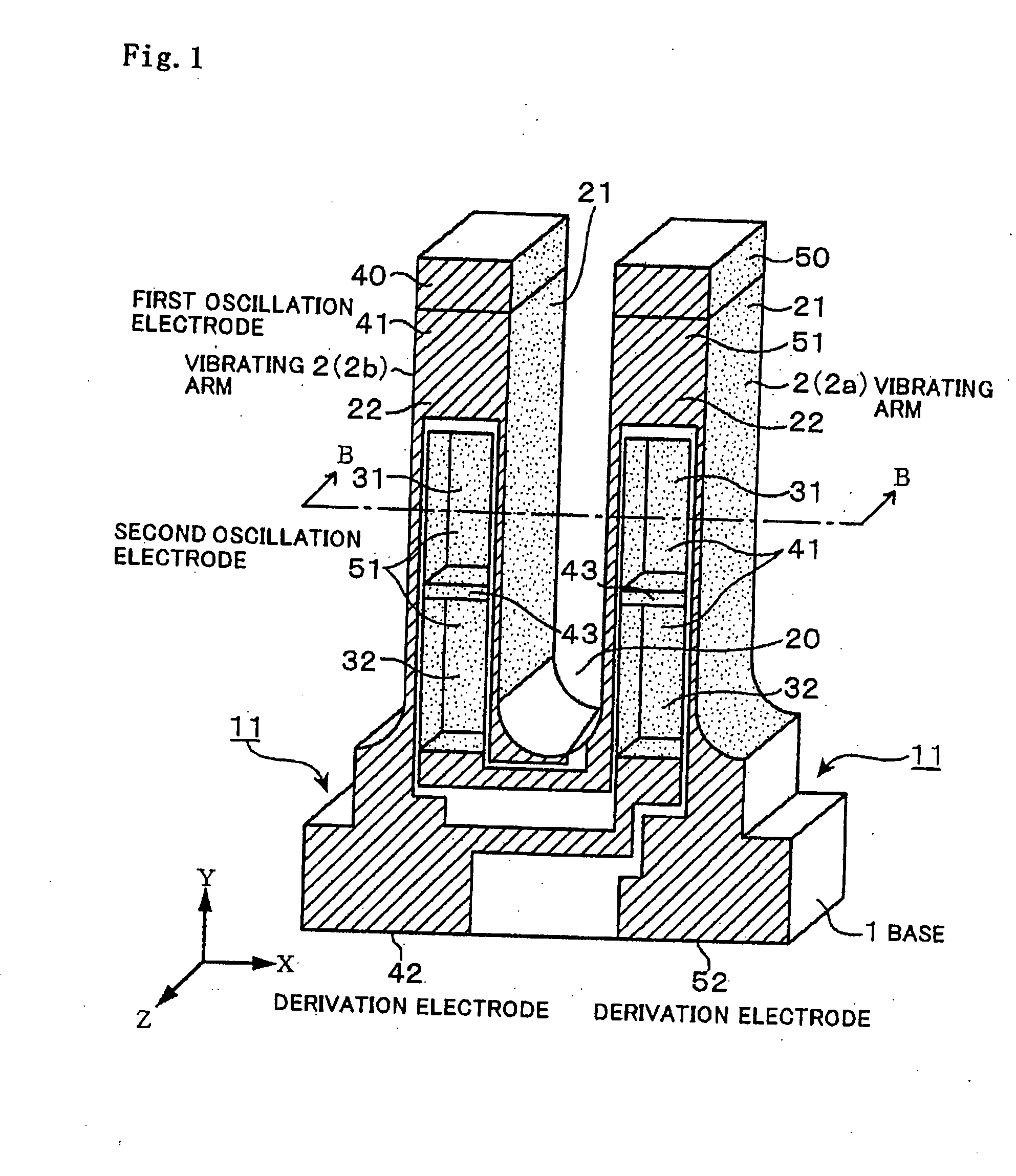

Piezoelectric vibrating reed, piezoelectric vibrator, oscillator, electronic device, radio-controlled clock, and method for manufacturing piezoelectric vibrating reed

ActiveUS20110018402A1Improve reliabilityQuality improvementPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectricityMechanical engineering

Providing a piezoelectric vibrating reed which has low disconnection possibility and ensures reliability for stable operation without requiring strict exposure position accuracy. A piezoelectric vibrating reed 1 including: a piezoelectric plate which includes vibrating arms 3 and 4, a base portion 5 to which base ends of vibrating arms are integrally fixed, and groove portions 6 which are formed on principal surfaces of vibrating arms; and excitation electrodes 10 and 11 to which vibrating arms are vibrate, wherein the excitation electrodes each include: a principal electrode portion 20, a side electrode portion 21 and a connection electrode portion 22, wherein the principal electrode portions are formed such that a horizontal width W1 on the base end sides of the vibrating arms is smaller than a horizontal width W2 in other portions so that a vacant area S is secured on a portion of the principal surface of each of the vibrating arms in the vicinity of a fork portion 15, and wherein the connection electrode portion is formed to have a large width on the principal surface of each of the vibrating arms so as to come close to an opening end side of each of the groove portions by occupying the vacant area.

Owner:SII CRYSTAL TECH

Electrovibration for touch surfaces

ActiveUS9501145B2Input/output for user-computer interactionGraph readingTactile sensationEngineering

An apparatus that includes a conductive surface and an insulation surface disposed on the conductive surface. The apparatus further includes a controller configured to cause a signal to be coupled to the conductive surface such that a tactile sensation is perceived in a digit that slides on the insulation surface.

Owner:DISNEY ENTERPRISES INC

Glass substrate polishing method, package manufacturing method, piezoelectric vibrator, oscillator, electronic device and radio timepiece

InactiveUS20110248788A1Improve surface accuracyKeep airtightPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksPiezoelectric actuatorsMetallurgy

A glass substrate polishing method having polishing processes for polishing a glass substrate surface while supplying a polishing agent. The glass substrate polishing method is characterized in that the polishing processes include a first polishing process in which the surface of the glass substrate is polished using a first polishing pad made from a polishing cloth and a second polishing process in which the surface of the glass substrate is polished using a second polishing pad made from urethane foam.

Owner:SEIKO INSTR INC

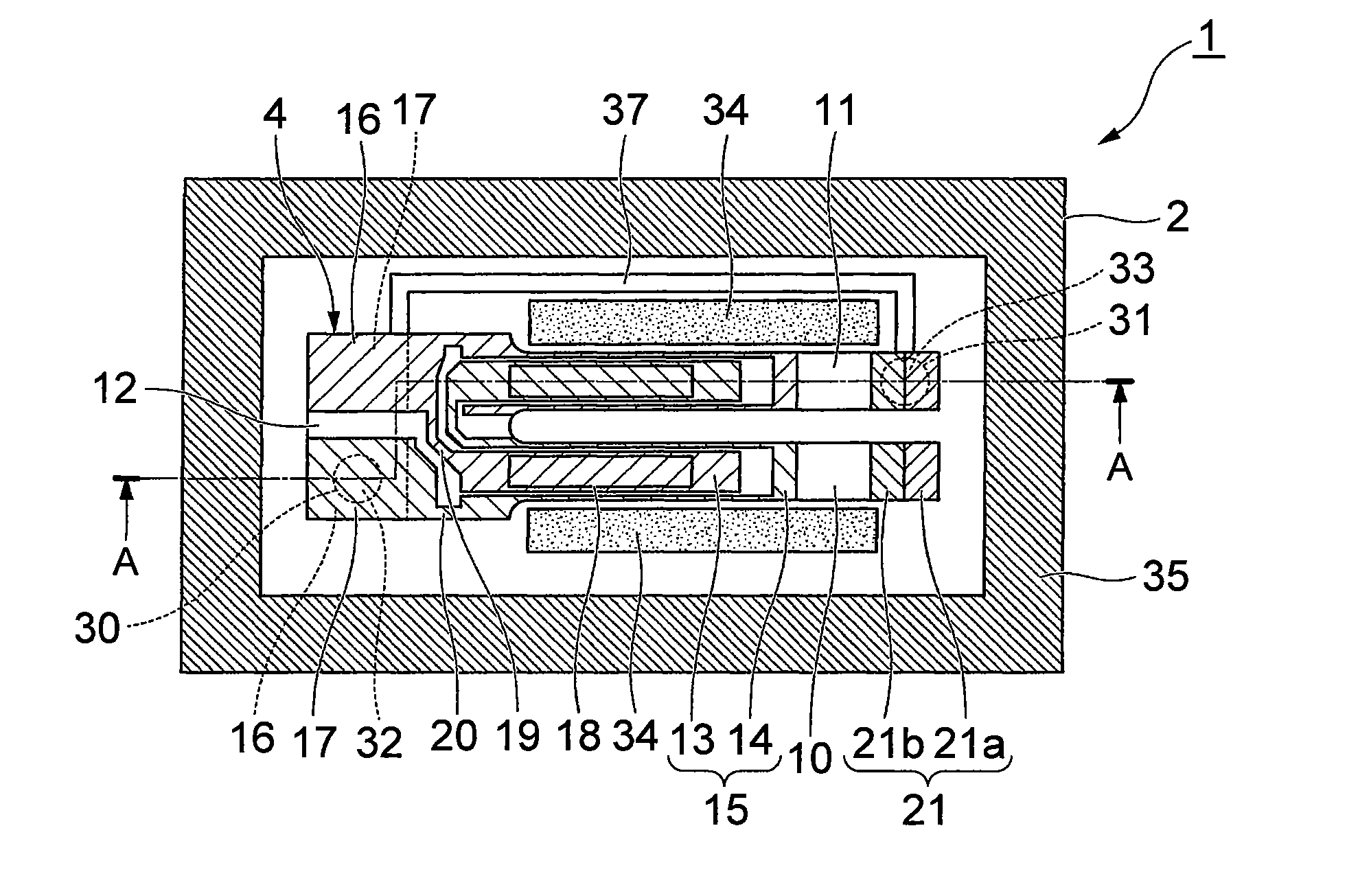

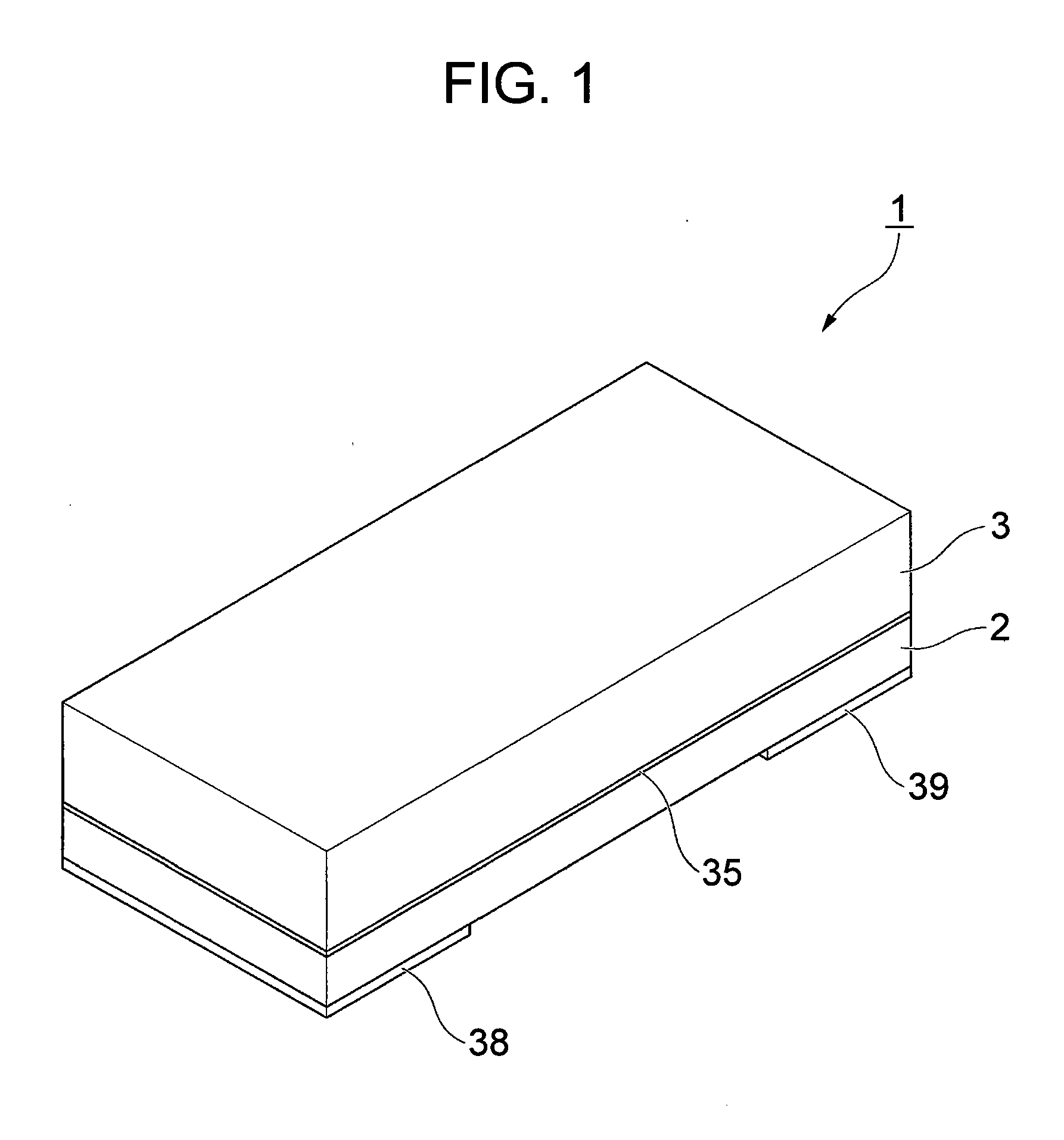

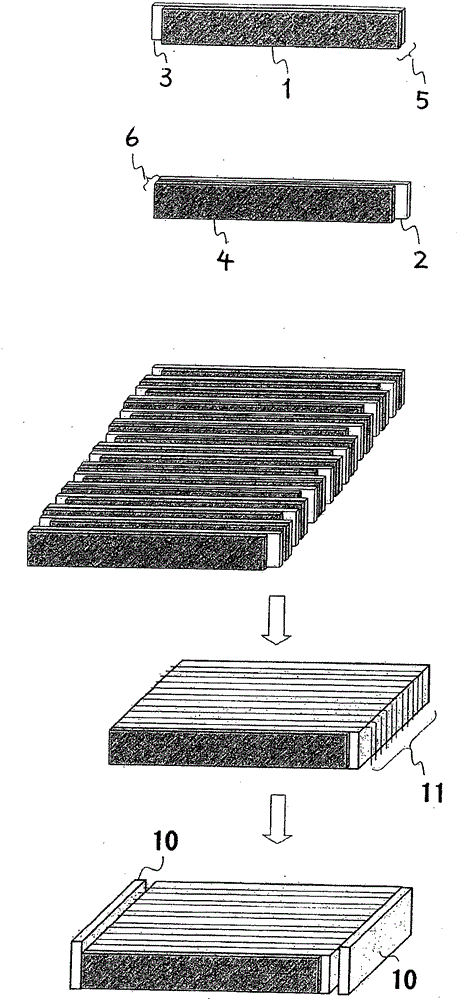

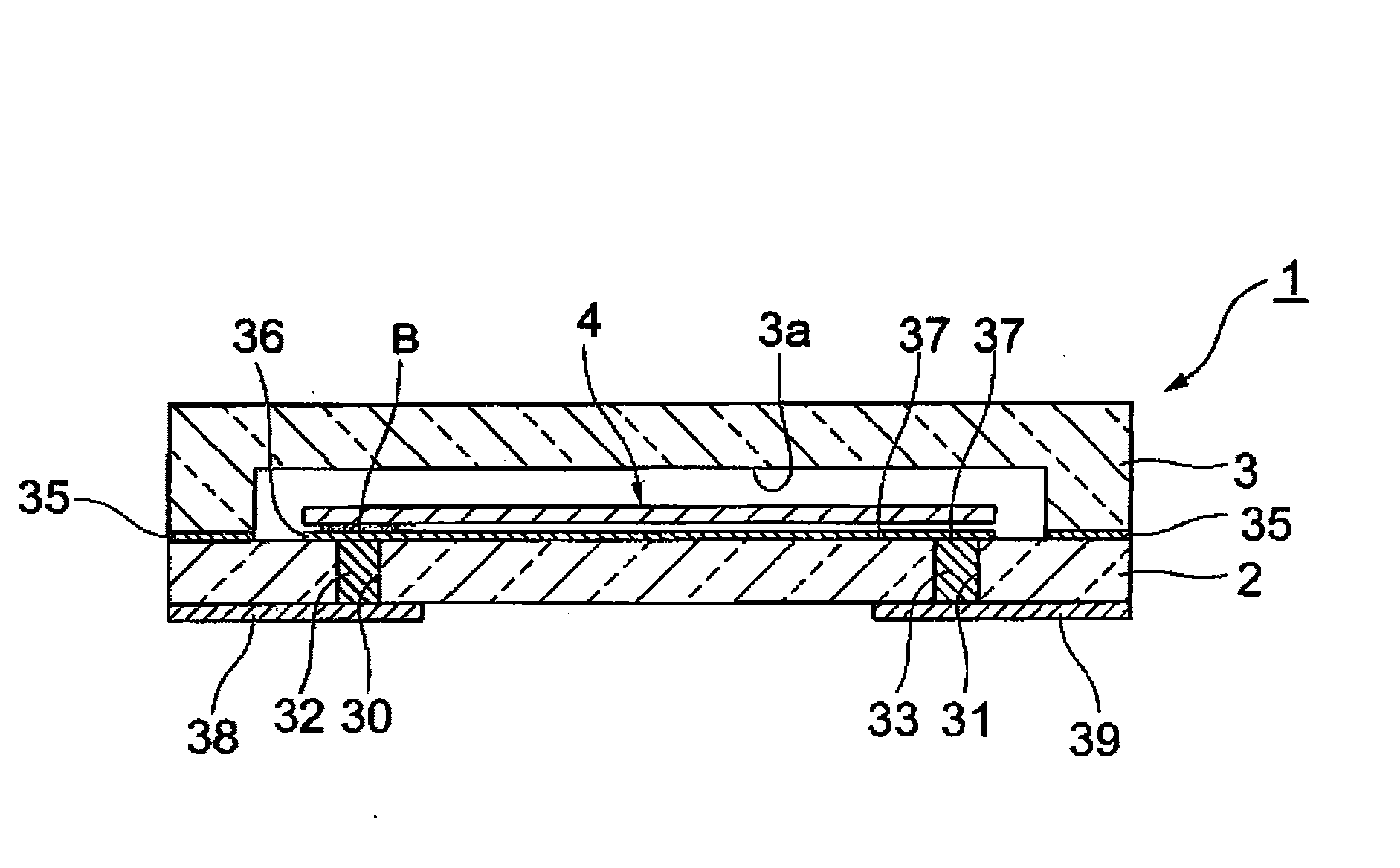

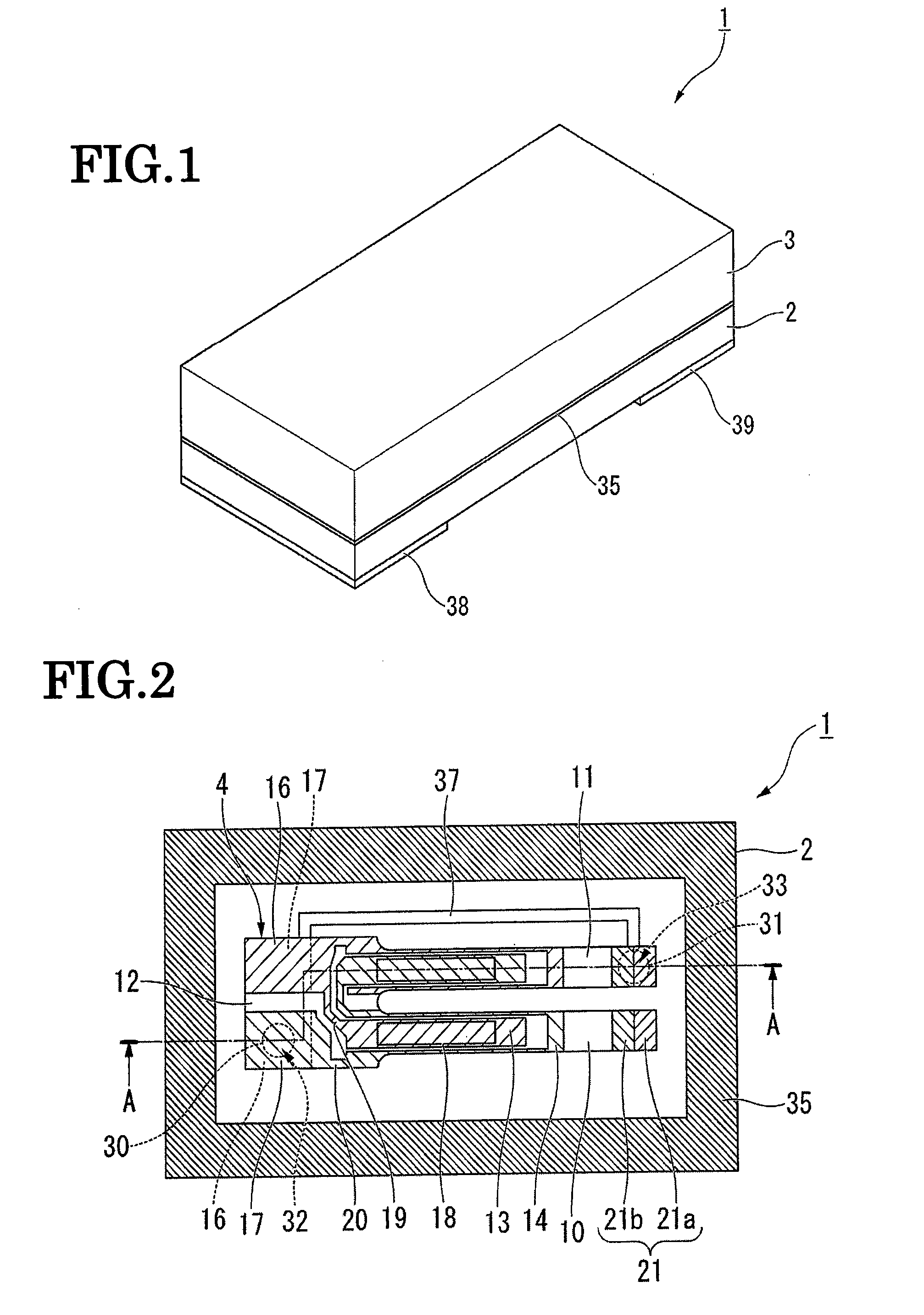

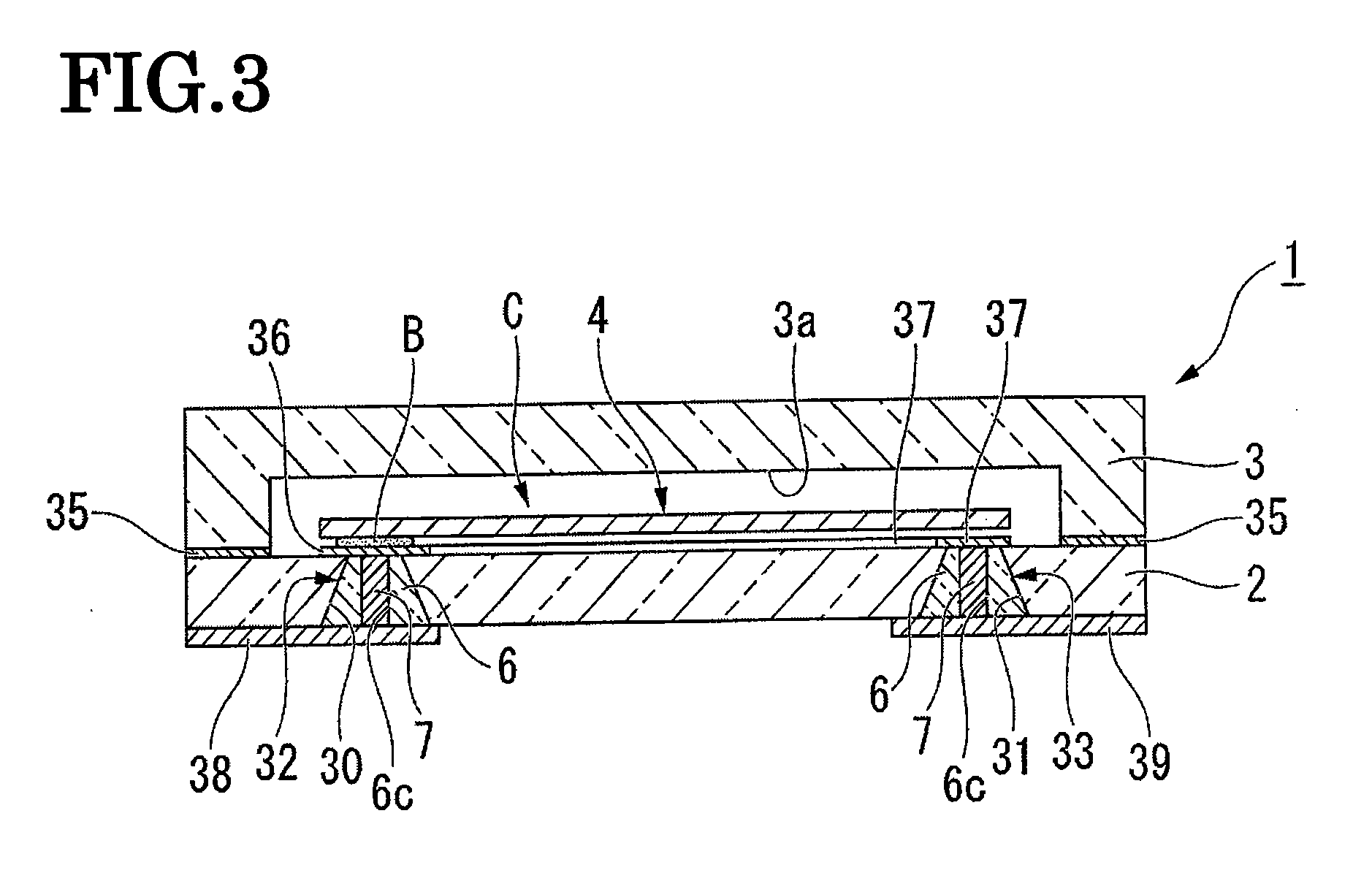

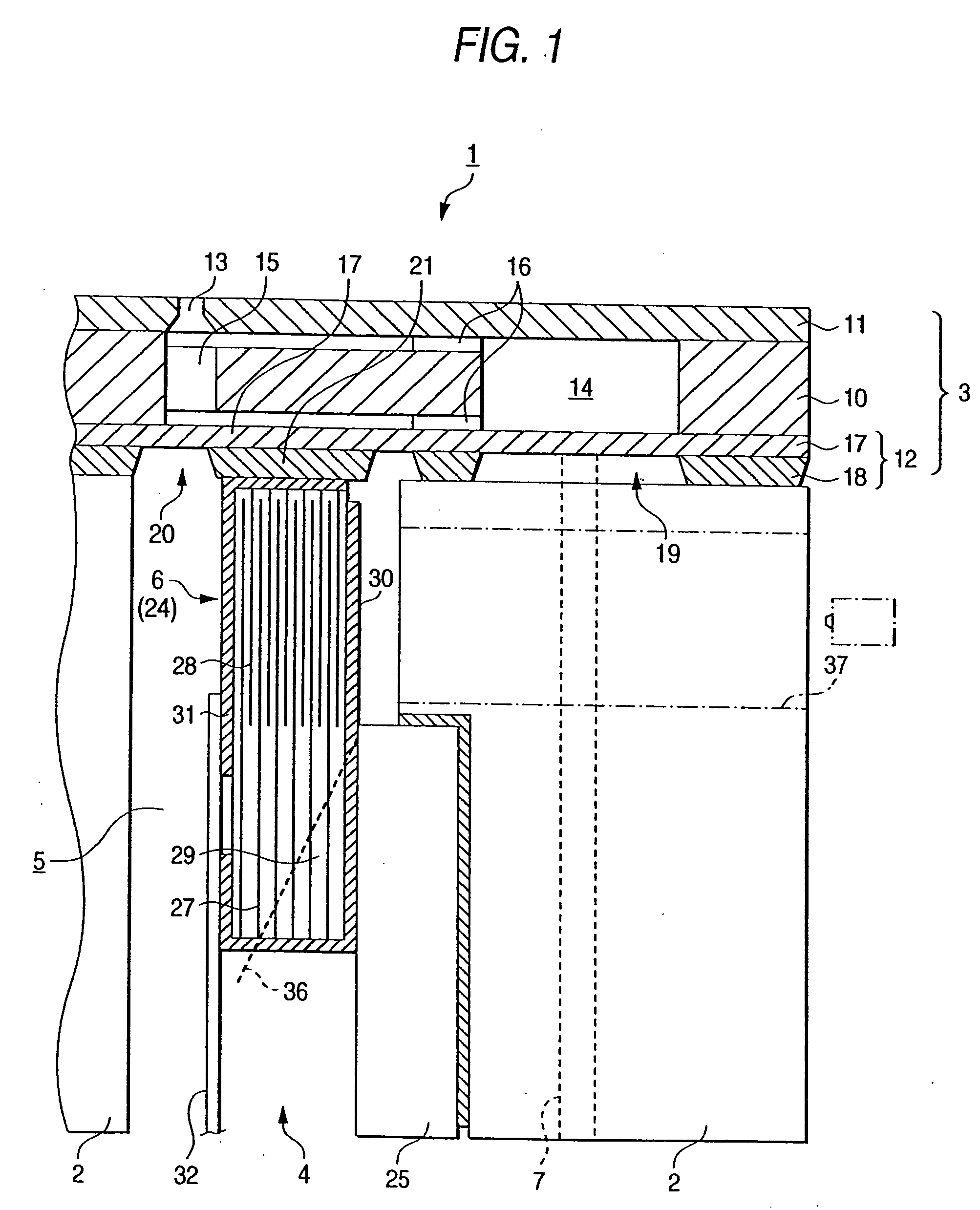

Method of manufacturing piezoelectric vibrator, piezoelectric vibrator, oscillator, electronic device, and radio clock

InactiveUS20100301709A1Improve air tightnessImprove reliabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsRadio clock

There is provided a piezoelectric vibrator 1 that includes a base substrate 2, a lid substrate 3, a piezoelectric vibrating reed 4, a pair of external electrodes 38 and 39, a pair of through electrodes 32 and 33, and routing electrodes 36 and 37. Both surfaces of the base substrate 2 are polished. The lid substrate 3 includes a recess 3a for a cavity C and is bonded to the base substrate. The piezoelectric vibrating reed 4 is bonded to the upper surface of the base substrate so as to be received in a cavity that is formed between the base substrate and the lid substrate. The pair of external electrodes 38 and 39 is formed on the lower surface of the base substrate. The pair of through electrodes 32 and 33 is formed so as to pass through the base substrate, maintains airtightness in the cavity, and is electrically connected to the pair of external electrodes, respectively. The routing electrodes 36 and 37 are formed on the upper surface of the base substrate and electrically connect the pair of through electrodes to the bonded piezoelectric vibrating reed. The through electrodes are formed by the hardening of paste that contains a plurality of nonspherical metal fine particles.

Owner:SII CRYSTAL TECH

Method and device for tactilely reading time on a touch screen

PendingUS20190332173A1Avoids battery drainInput/output for user-computer interactionAcoustic time signalsTouchscreenMobile device

The present invention relates to a device and method that generates a tactile presentation, which indicates time on a mobile device. The mobile device includes a touch screen, a processor, and the functionality to be activated to electrovibrate in at least one portion of the touch screen. The processor receives electrical signals specifying and displaying a current time on the touch screen. The touch screen generates electrovibrations that vary in response to the time to provide the tactile presentation of the time on the touch screen. The haptic feedback is configured to emulate shapes such as a numeric character or other discernable shape in a location on a portion of the touch screen, so that a user by contacting the touch screen can sense the numeric character or shape generated by the haptic feedback and determine the time elapsed within an hour without having to view the touch screen.

Owner:WELLEN ALEXANDER

Package manufacturing method, piezoelectric vibrator, oscillator, electronic device, and radio-controlled timepiece

InactiveUS20110255378A1Increase productionPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringElectronic component

A method of manufacturing a package capable of sealing an electronic component in a cavity formed between a plurality of substrates bonded to each other includes a penetration electrode forming step of forming a penetration electrode which passes through a first substrate of the plurality of substrates in the thickness direction and which electrically connects the inside of the cavity and the outside of the package to each other. The package manufacturing method is characterized in that the penetration electrode forming step includes a through hole forming step of forming a through hole for disposing the penetration electrode in the first substrate and a filling step of filling a filler into the through hole under a decompressed atmosphere.

Owner:SEIKO INSTR INC

Package manufacturing method, piezoelectric vibrator manufacturing method, oscillator, electronic device, and radio-controlled timepiece

InactiveUS20110249534A1Improve flexural strengthPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksEngineeringGlass material

A package manufacturing method of the present invention is a method of manufacturing a package with a recessed cavity formed in at least one of first and second substrates formed of a glass material and includes a cavity forming step of forming the cavity by performing press molding on at least one molded substrate of the first and second substrates and a heat treatment step of heating the molded substrate formed with the cavity.

Owner:SII CRYSTAL TECH

Method of manufacturing package, piezoelectric vibrator, oscillator, electronic apparatus, and radio-controlled timepiece

InactiveUS20110203084A1Low costPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksRadio equipmentFrit

Provided are a method of manufacturing a package capable of forming a penetration electrode at a low cost without conduction defects while maintaining the airtightness of a cavity, a piezoelectric vibrator manufactured by the manufacturing method, and an oscillator, an electronic apparatus, and a radio-controlled timepiece each having the piezoelectric vibrator. In a glass frit application step, a glass frit is applied onto a first surface so that a first opening on the first surface side of a penetration hole is blocked under a depressurized atmosphere in a state where a second surface side of the penetration hole is blocked. In a glass frit filling step, an atmospheric pressure is increased so that the glass frit is filled in the penetration hole by a pressure difference which is generated between the inside of the penetration hole and the outside of the penetration hole.

Owner:SEIKO INSTR INC

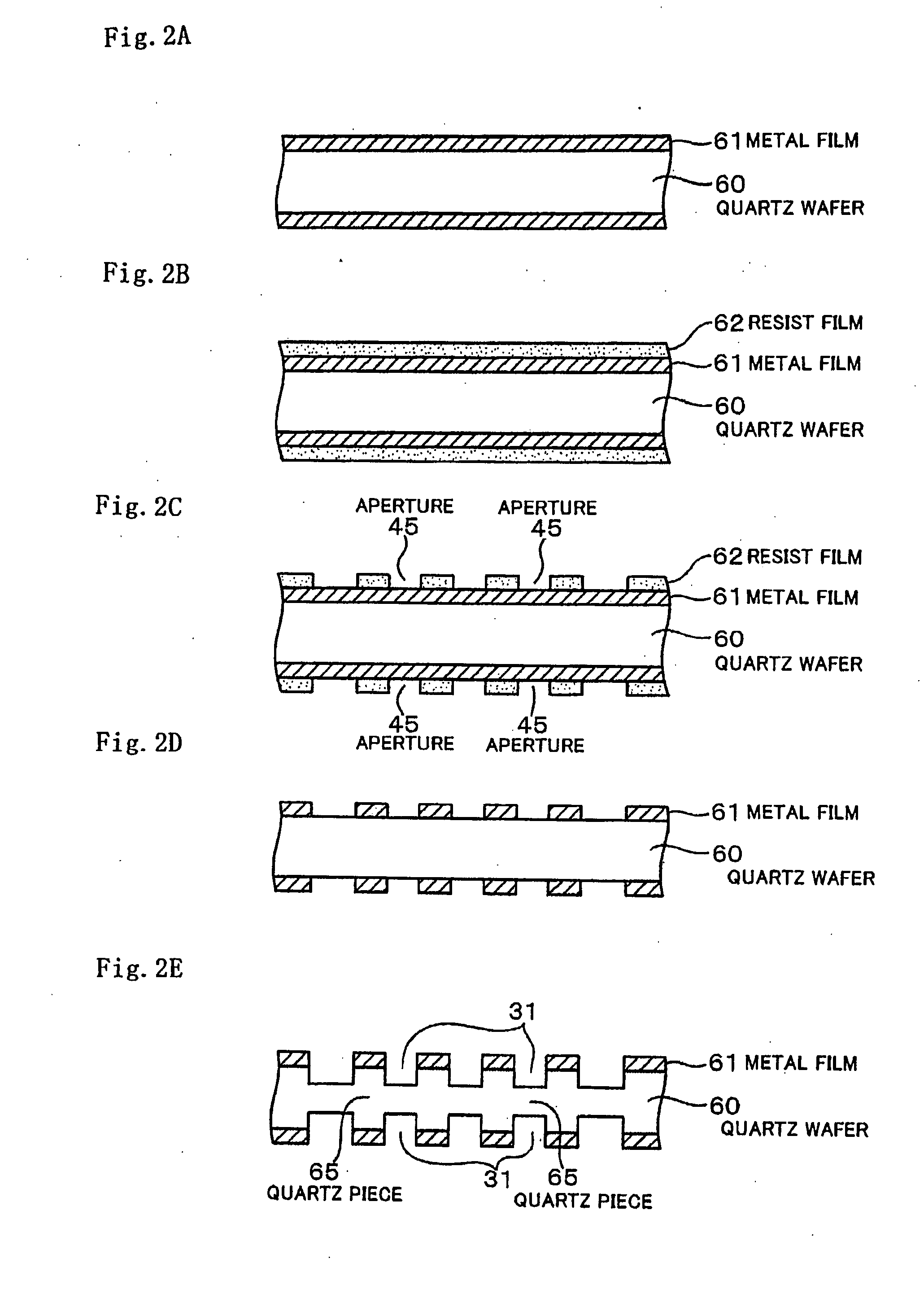

Method for manufacturing piezoelectric resonator

InactiveUS20080016666A1Etch rate reductionImprove accuracyPiezoelectric/electrostrictive device manufacture/assemblyRecord carriersEngineeringMetal membrane

To provide a method for manufacturing a piezoelectric resonator which can conduct frequency matching with high reliability when performing rough adjustment of the frequency by adjusting the shape of a piezoelectric oscillating piece before forming an electrode film, and thereby it becomes possible to avoid reduction of the yield. Etching for forming the shape of a piezoelectric oscillating piece, and etching for forming grooves are conducted simultaneously, and after forming the grooves, the shape formation of the piezoelectric oscillating piece is started again from the same depth as the groove in a state of covering the groove with a metal film, and after the shape formation, matching of frequency is conducted by etching the side surface of the piezoelectric oscillating piece in succession. By composing such a structure, it is possible to conduct rough adjustment of frequency at a low etching rate so that the frequency matching can be performed with no due difficulty and with high accuracy.

Owner:NIHON DEMPA KOGYO CO LTD

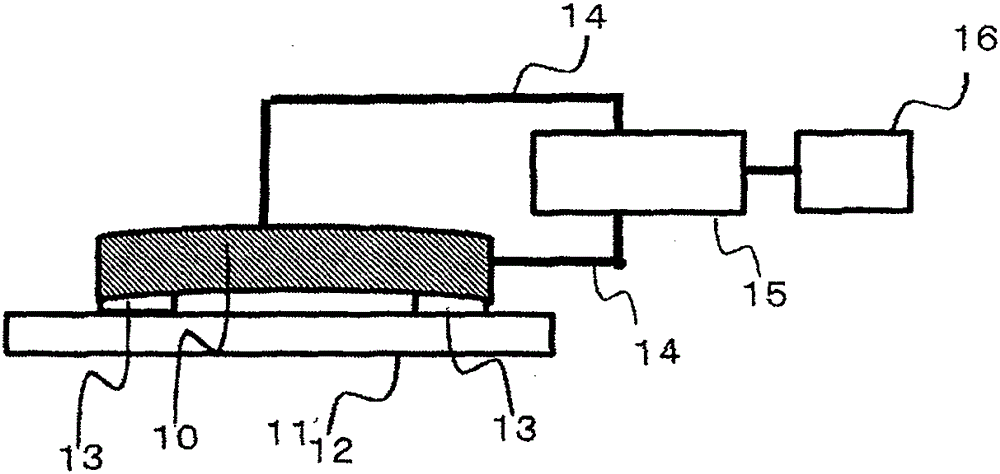

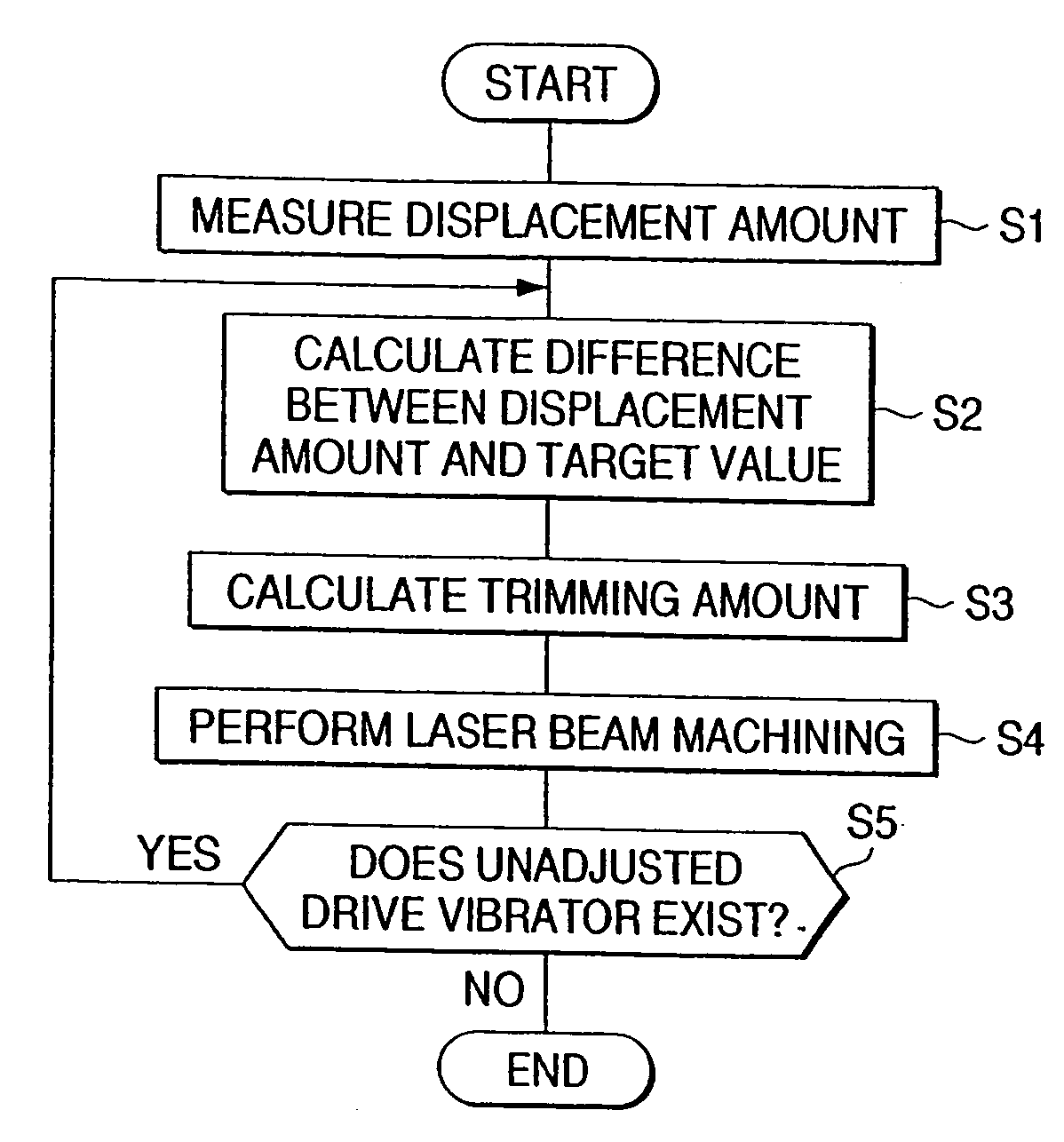

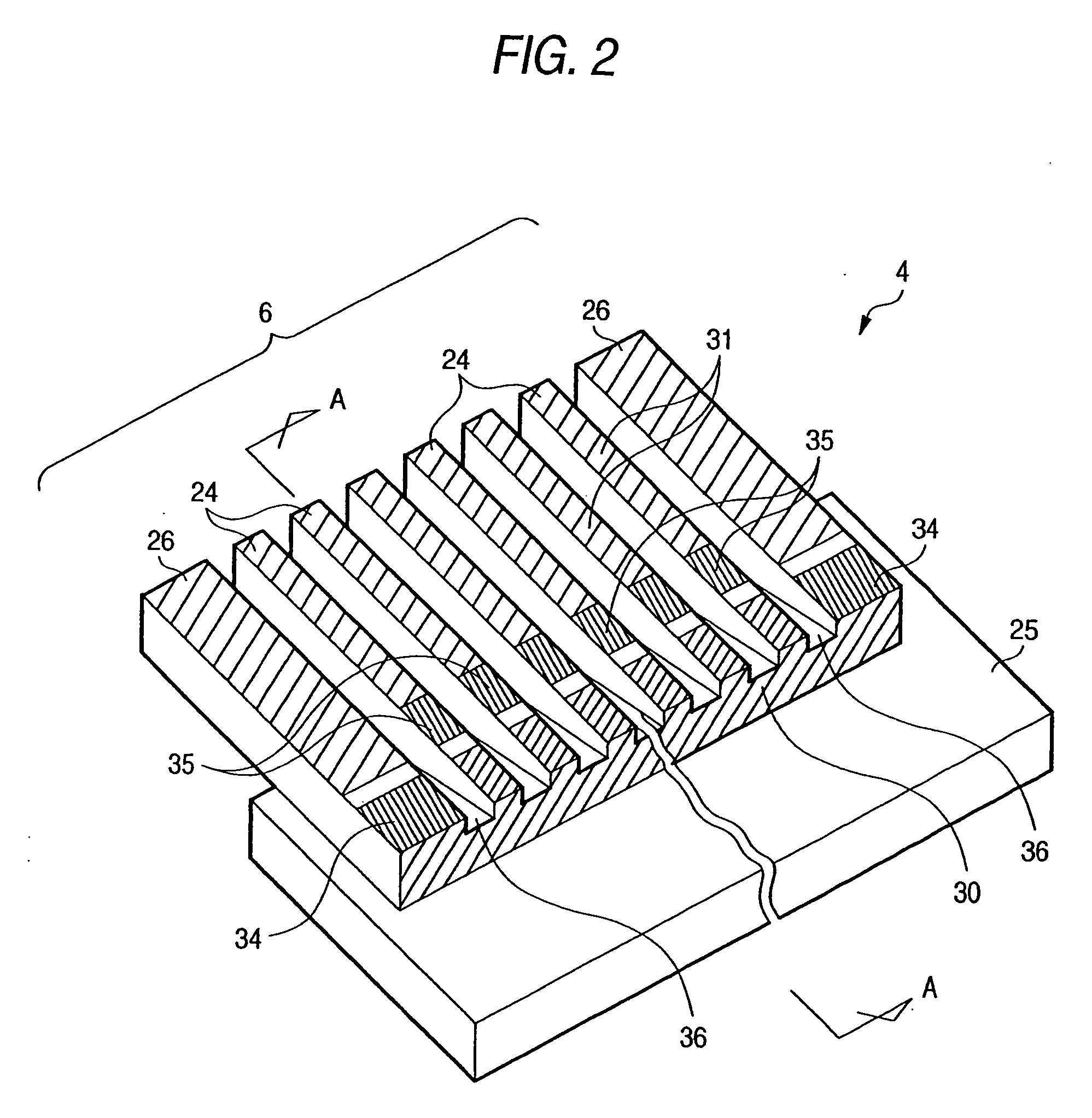

Manufacturing method of piezoelectric vibrator unit, manufacturing method of liquid jet head, piezoelectric vibrator unit, and liquid jet head

InactiveUS20060010670A1Piezoelectric/electrostrictive device manufacture/assemblyWriting implementsLiquid jetPotential difference

Common internal electrodes 27 and segment internal electrodes 28 are laminated alternately with a piezoelectric material 29 between and a common external electrode 30 and a segment external electrode 31 are provided on the surface, forming a drive vibrator 24. A free end part 24a of the drive vibrator 24 is formed with an active region L and can be expanded and contracted in the length direction of the vibrator. A piezoelectric material 29 of the outermost layer in the free end part 24a can be operated based on the potential difference between the external and internal electrodes and a portion of the active region L in the external electrode is used as a trimming portion with an effective length x varied by trimming.

Owner:SEIKO EPSON CORP

Vacuum package, method for manufacturing vacuum package, piezoelectric vibrator, oscillator, electronic device, and radio-controlled timepiece

InactiveUS20110228643A1Improve air tightnessImprove installation strengthPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksEngineeringUltimate tensile strength

Provided are a vacuum package and a method for manufacturing the vacuum package having excellent airtightness and capable of improving mounting strength, and a piezoelectric vibrator, an oscillator, an electronic device, and a radio-controlled timepiece. The package includes a base substrate and a lid substrate bonded to each other, a cavity formed between the base substrate and the lid substrate and configured to be capable of sealing a piezoelectric vibrating reed, and penetration electrodes penetrating through the base substrate in the thickness direction so as to make the inner side of the cavity and the outer side conductive. Portions of the base substrate and the lid substrate in the vicinity of the cavity form bonding regions in which the two substrates are bonded. A notch portion through which the bonding surface of the lid substrate is exposed as seen from the thickness direction of the base substrate is formed on the corner portions of the base substrate.

Owner:SII CRYSTAL TECH

Haptic driving apparatus and electronic device having haptic function

ActiveUS10303286B2Input/output for user-computer interactionGraph readingEngineeringElectrical current

A haptic driving apparatus provides a user with electrovibration of certain strength regardless of a variance of a surrounding environment, and an electronic device has a haptic function. The haptic driving apparatus comprises a haptic electrode driver generating a haptic driving signal to supply the generated haptic driving signal to a haptic electrode through a current monitor and varying the haptic driving signal in accordance with voltages at both ends of the current monitor.

Owner:LG DISPLAY CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com