Composite microbial inoculum for composting organic materials and preparation method thereof

A technology of composite microbial inoculants and organic materials, which is applied in the preparation of organic fertilizers, microorganism-based methods, biochemical equipment and methods, etc. Process and steps, easy industrial production, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0042] 1) Activate the strains stored at 4°C on a slope: Pichia pastoris, Lactobacillus acidophilus, Bacillus coagulans, Enterococcus faecium, Bacillus natto, and Bacillus subtilis were inoculated on the LB solid slope; Aspergillus nidulans, white rot Fungi, Aspergillus usa, Trichoderma harcii, Trichoderma reesei and Aspergillus niger were inoculated on the solid slope of PDA. All bacteria were activated at 35°C.

[0043] 2) Preparation of primary seed liquid: Inoculate the activated test tube slant bacteria into corresponding liquid medium (Pichia pastoris, Lactobacillus acidophilus, Bacillus coagulans, Enterococcus faecium, Bacillus natto, subtilis Bacillus was inoculated in LB liquid shake flasks; Aspergillus nidulans, white rot fungi, Aspergillus usa, Trichoderma harcii, Trichoderma reesei, and Aspergillus niger were inoculated in PDA liquid shake flasks), all strains were inoculated at 35°C and 200rpm Cultivate for 4 days to obtain liquid primary seeds.

[0044]3) Prepa...

Embodiment 2

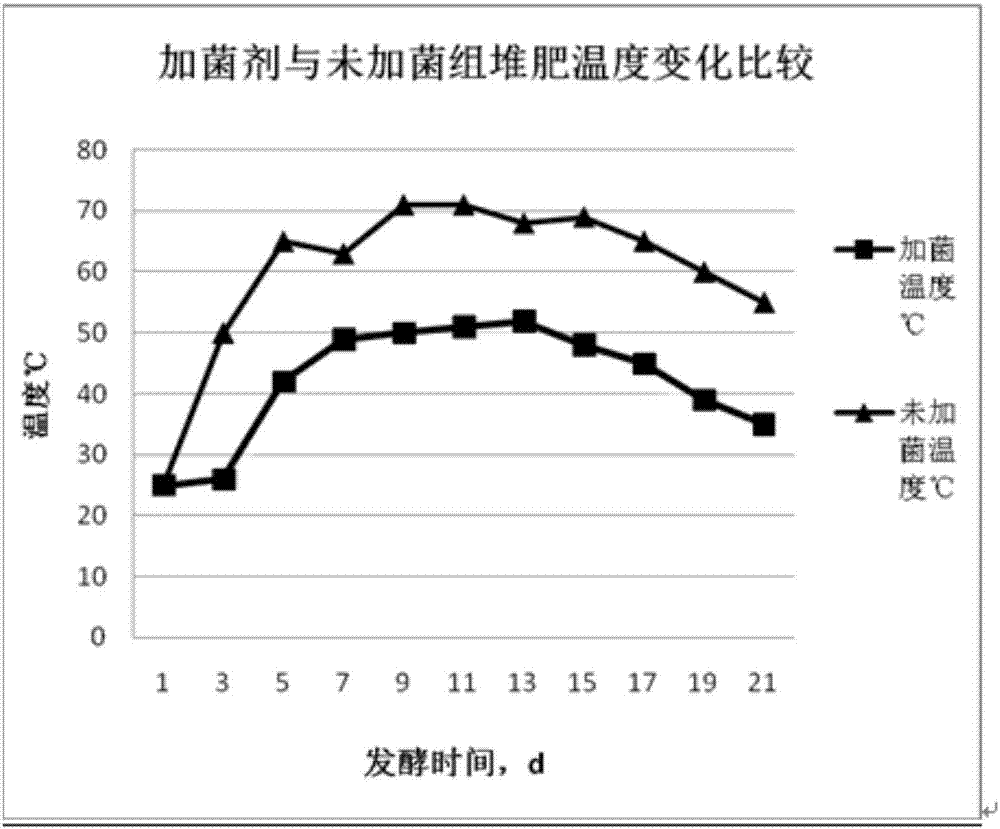

[0049] Application Effect Experiment of Composting Bacteria Agent

[0050] Raw material ratio of compost:

[0051] materials domestic sludge corn husk sugar residue Furfural residue Proportion 40% 20% 20% 20%

[0052] The moisture content of the fermentation material is controlled at 60%, and the raw materials for the production of 10 tons of finished organic fertilizers are divided into two equal parts: Group 1: add strains developed by our company; Group 2: control without strains

[0053] Adding method of bacteria agent: Activate the bacteria two days before composting, mix 1kg of bacteria with 5kg of rice bran, dissolve 300g of brown sugar in 1kg of water, mix the sugar water and bacteria of rice bran evenly, and then add appropriate amount of water to adjust the material Humidity at 60%, activation at 30°C for 2 days

[0054] Mix the material with the activated bacterial agent evenly (1 ton of material is mixed with 5kg of the activated bac...

Embodiment 3

[0062] Fertilizer effect experiment on corn:

[0063] The organic fertilizers produced by adding bacteria and not adding bacteria were used as the base fertilizer respectively, and the method of strip application was adopted, and the dosage was 2 tons per mu. The rest of the fertilization amount of corn is carried out in the following way:

[0064] a: Base fertilizer: N3.45g, P2O52.88g, zinc sulfate 0.72g (converted to urea 7.5g, common calcium 18g)

[0065] b: Topdressing: deep application of N8.06g and K2O3.36g (converted to urea, 17.5g, potassium chloride 5.6g) in combination with large potting soil during the big trumpet mouth period

[0066] Add bacteria compost group Compost without added bacteria No fertilization blank control Yield kg / mu 800 600 400

[0067] From the experimental results, it can be seen that the organic fertilizer with added bacteria has obvious fertilizer effect, which is 50% higher than that of the blank control group an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com