Gas diffusion layer, preparation method thereof and fuel cell

A gas diffusion layer and fuel cell technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of high processing cost, complex process, and low conductivity of products, and achieve precise controllable pore size and pore spacing. The effect of simple process and wide industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

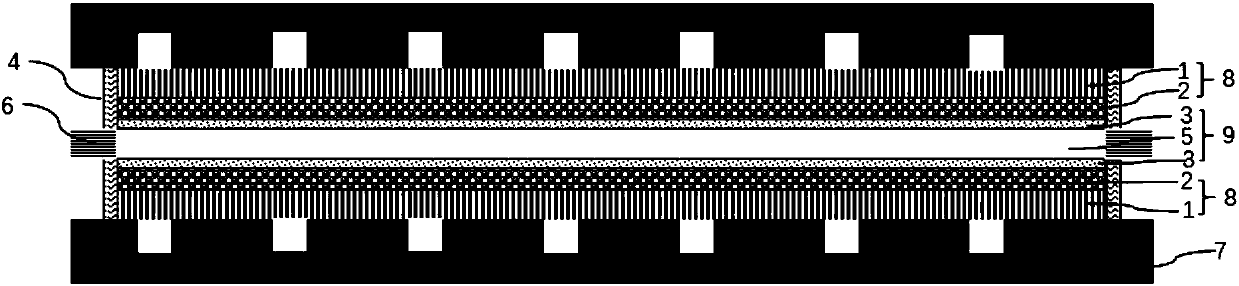

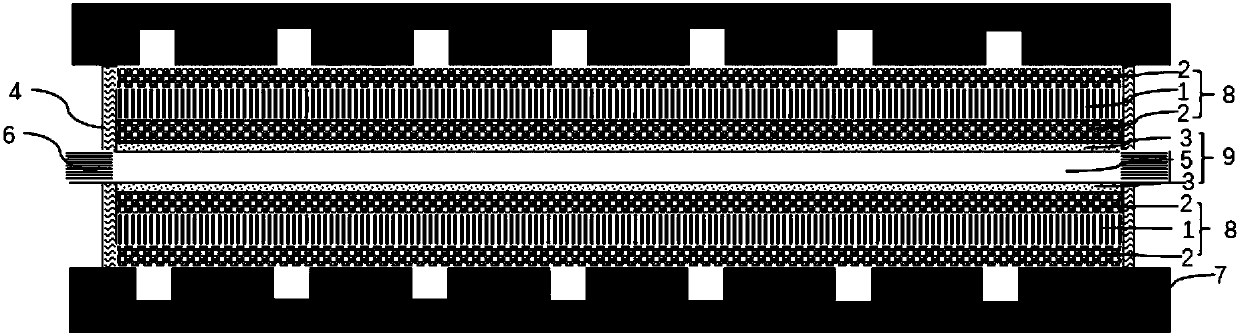

[0048] The present invention also provides a method for preparing a gas diffusion layer 8, the gas diffusion layer 8 is the above gas diffusion layer 8, and the preparation method includes the following steps:

[0049] Coating the conductive paint on at least one side of the substrate 1 , forming a conductive microporous layer 2 by sintering, and combining the substrate 1 and the conductive microporous layer 2 into one.

[0050] Based on the total weight of solid matter in the conductive paint as 100%, the conductive paint comprises the following raw materials in weight percentages:

[0051] Conductive particles 50-80wt%, such as 50wt%, 55wt%, 60wt%, 65wt%, 70wt%, 75wt% or 80wt%, etc.;

[0052] Adhesive 10-30wt%, such as 10wt%, 15wt%, 20wt%, 25wt% or 30wt%, etc.;

[0053] Surfactant 1-5wt%, such as 1wt%, 2wt%, 3wt%, 4wt% or 5wt%, etc.;

[0054] Carbon fiber 0-10wt%, such as 0, 2wt%, 5wt%, 8wt% or 10wt%, etc.;

[0055] Pore forming agent 1-5wt%, such as 1wt%, 2wt%, 3wt%, 4...

Embodiment 1

[0075] A method for preparing a gas diffusion layer 8, comprising the following steps:

[0076] (1) A porous graphite paper substrate with a thickness of 100 μm, a pore diameter of 200 μm, and a pore spacing of 100 μm was obtained by laser drilling.

[0077] (2) Dissolve 0.6g of polyethylene glycol octylphenyl ether in 40g of water, stir well, then slowly add 10g of flake graphite powder with a particle size of 2μm, 2g of acetylene black, 0.4g of carbon fiber powder and 0.5g of ammonium bicarbonate ; Then take 10g mass fraction of 60% polytetrafluoroethylene solution and 1g mass fraction of 0.6% carboxymethyl cellulose solution and add dropwise to the above slurry, and disperse evenly to obtain conductive coating.

[0078] (3) Scrape-coat the conductive paint onto the porous graphite paper substrate obtained in step (1) by spraying, with a spraying thickness of 150 μm.

[0079] (4) Sintering at a temperature of 250° C. for 2 hours in a nitrogen atmosphere to obtain a gas diffus...

Embodiment 2

[0081] A method for preparing a gas diffusion layer 8, comprising the following steps:

[0082] (1) A porous graphite paper substrate with a thickness of 200 μm, a pore diameter of 500 μm, and a pore spacing of 160 μm was obtained by laser drilling.

[0083] (2) Dissolve 1g of alkylphenol polyoxyethylene ether in 30g of water and stir evenly; then slowly add 15g of flexible worm graphite, 5g of carbon fiber powder and 1g of ammonium oxalate with a particle diameter of 80 objects; The polytetrafluoroethylene solution and 1 g of carboxymethyl cellulose solution with a mass fraction of 0.6% were added dropwise to the slurry, and dispersed evenly to obtain a conductive coating.

[0084] (3) Scrape-coat the conductive paint onto the porous graphite paper substrate obtained in step (1) by a scrape-coating method, with a scrape-coating thickness of 100 μm.

[0085] (4) Sintering at a temperature of 330° C. for 1 h in a nitrogen atmosphere to obtain the gas diffusion layer 8 with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com