Methyl alcohol diesel additive based on yeast grease and methyl alcohol diesel prepared by using same

A technology of additives and oils, which is applied in the field of alcohol substitute fuels, can solve the problems of accelerating the electrochemical corrosion of the oil circuit system, increasing the conductivity of oil products, and the low flash point of methanol and diesel, achieving a transparent and clear appearance, solving the problem of emission pollution, The effect of high cetane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

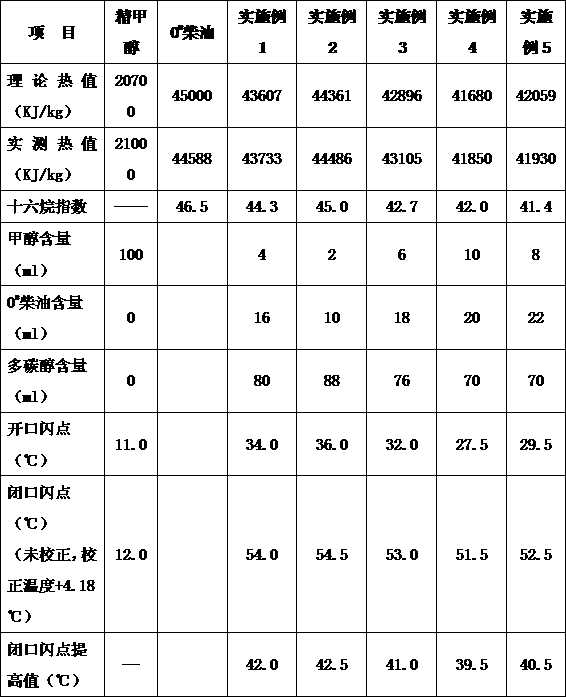

Embodiment 1

[0034] 1. Methanol diesel additives, calculated by volume unit percentage, are composed of the following functional components: 20% anti-delamination and solubility-promoting components, 9% anti-corrosion and anti-swelling components, 6% carbon-removing and colloid-removing components 30% of the flash point depressant component, 35% of the power-promoting combustion component; each component is added to the container, and stirred evenly at room temperature to obtain a transparent and clear methanol diesel additive product.

[0035] Among them, anti-delamination and solubilization components include 11% yeast oil, 4% mixture of n-octanol and n-dodecyl alcohol 1:2, 5% epoxy fatty acid methyl ester; anti-corrosion and anti-swelling components include yeast oil 2%, α-methyl naphthalene 4%, 1:1 mixture of cyclohexanone and alkyl salicylic acid 3%; remove carbon deposits and clear gum components, including yeast oil 1%, ethylene glycol and polyethylene glycol Alcohol 1:2 mixture 3%,...

Embodiment 2

[0038] 1. Methanol diesel additive, calculated by volume unit percentage, is composed of the following functional components: 25% anti-delamination and solubilizing components, 6% anti-corrosion and anti-swelling components, 9% carbon-removing and colloid-removing components Points, 28% of the flash point depressant component, 32% of the power-promoting combustion component, each component is added to the container, and stirred evenly at room temperature to obtain a transparent and clear methanol diesel additive product.

[0039] Among them, the anti-layering and solubilizing components include 12% of yeast oil, 7% of a 1:2 mixture of n-octanol and n-dodecyl alcohol, and 6% of a 1:1 mixture of fatty acid methyl ester and epoxy fatty acid methyl ester; Corrosion and anti-swelling components, including 1% of yeast oil, 2% of a 1:1 mixture of tributyl phthalate and trioctyl phthalate, and 3% of a 1:1 mixture of cyclohexanone and alkyl salicylic acid; Colloid removal components, i...

Embodiment 3

[0042] 1. Methanol diesel additives, calculated by volume unit percentage, are composed of the following functional components: 30% anti-delamination and solubility-promoting components, 6% anti-corrosion and anti-swelling components, 6% carbon-removing and colloid-removing components Points, 22% of the flash point depressant component, 36% of the power-promoting combustion component; each component is added to the container, and stirred evenly at room temperature to obtain a transparent and clear methanol diesel additive product.

[0043] Among them, anti-delamination and solubilizing components include 15% yeast oil, 9% mixture of n-octanol and n-dodecyl alcohol 1:2, 6% epoxy fatty acid methyl ester; anti-corrosion and anti-swelling components include yeast oil 1%, a 1:1 mixture of tributyl phthalate and trioctyl phthalate 3%, a 1:1 mixture of cyclohexanone and alkyl salicylic acid 2%; remove carbon deposits and clear gum components, Including 1% yeast fat, 2% mixture of eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com