Municipal waste harmless resourceful treatment system with sewage cyclic utilization function

A recycling technology for urban garbage and sewage, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as secondary pollution, limited service life, and large landfill volume , to achieve the effects of saving water resources, reducing effective control, and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

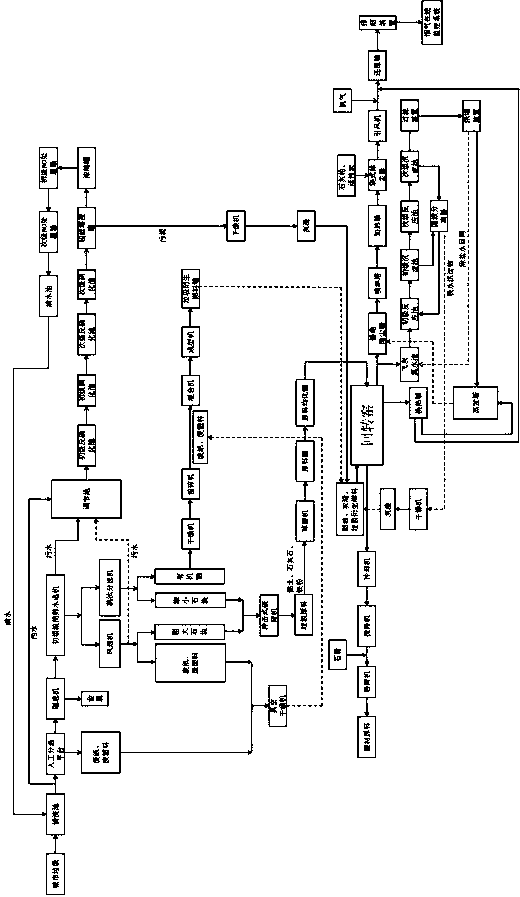

[0100] refer to figure 1 , a harmless and resourceful urban waste treatment system with sewage recycling, including:

[0101] Pre-treatment system, which sorts municipal waste through manual sorting platform, magnetic separator, trommel screen, air separator and jig separator to obtain waste raw materials and raw materials for preparation of waste-derived fuels;

[0102] Garbage rotary calcination system, which prepares garbage-derived fuel from the raw materials obtained in the pre-treatment process, and at the same time mixes the garbage raw materials with clay, limestone, and iron powder, and after crushing, they are calcined in a rotary kiln to prepare building material raw materials;

[0103] The post-processing system processes the fly ash produced by the calcination of the rotary kiln by means of dust removal and chemical reaction.

[0104] Among them, the pre-treatment system includes: a manual sorting platform for sorting directly recyclable items and some waste pap...

Embodiment 2

[0111] The post-treatment system also includes: a fly ash collection tank for collecting the fly ash of the rotary kiln; a primary reaction tank for preliminary removal of heavy metals in the slurry, and the chemical agent added in the primary reaction tank is sodium carbonate; a pool slag for collecting primary precipitation The primary sedimentation tank; the secondary reaction tank for final removal of heavy metals in the slurry, the chemical agent added in the secondary reaction tank is a heavy metal scavenger; the secondary sedimentation tank for collecting heavy metal slag for secondary precipitation; for Filter device for further removing granular impurities in wastewater; solid-liquid separator for dehydration and separation of heavy metal slag from primary sedimentation tank and secondary sedimentation tank; drying treatment of heavy metal slag obtained by dehydration and separation of solid-liquid separator Dryer; Concentration device for concentration and desalinatio...

Embodiment 3

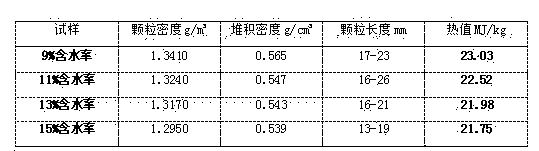

[0113] Control the mixed organic particles, waste paper and waste plastics to contain (according to mass percentage) 40% organic powder, 20% waste paper and 40% waste plastics, and control the moisture content of the garbage derived fuel (according to mass percentage Total) is 9% to 13%.

[0114] At the same time, the alkaline agent sprayed into the spray tower is selected to be specifically sodium hydroxide.

[0115] The amount of sodium carbonate is selected to be 40-70 kg per ton of slurry, and the heavy metal scavenger is sulfurized carbamate, and the amount of per ton of clear liquid is 1-5 kg.

[0116] The heat exchanger heats the evaporation tower by extracting a part of the high-temperature flue gas from the tail of the rotary kiln. The high-salt concentrated water in the evaporation tower quickly conducts heat transfer and evaporation, and the liquid part returns to the electrostatic precipitator in the gaseous state of water vapor for further processing. Purify agai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com