Multi-walled carbon nanotube loaded ruthenium catalyst, and preparation and application thereof

A technology of multi-walled carbon nanotubes and ruthenium catalyst, which is applied in catalyst activation/preparation, hydroxyl compound preparation, organic compound preparation and other directions, can solve the problems of large amount of catalyst, complex preparation method, poor mechanical properties, etc., and achieve comprehensive utilization The effect of cost reduction, improved catalytic efficiency, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the preparation of Ru / MWCNTs catalyst

[0026] (1) Preparation of functionalized carbon nanotube carrier: Weigh 5.0 grams of multi-walled carbon nanotubes (average inner diameter 5-10nm, outer diameter 20-40nm, length 10-30μm) in a 250mL round bottom flask, add Concentrated nitric acid (65-68%) 100mL, install a reflux condenser, heat to 120°C with an oil bath, reflux at a constant temperature for 12h under stirring conditions, filter after cooling, wash with distilled water until the pH value of the filtrate is neutral, and then place in a vacuum oven Dry at 60° C. for 12 hours to obtain a functionalized multi-walled carbon nanotube carrier.

[0027] (2) Preparation of ruthenium particles by liquid phase reduction method: Weigh 0.10g of ruthenium trichloride, 6mL of lauryl polyoxyethylene ether and 25mL of ethanol in a 100mL single-necked flask, stir magnetically for 0.5h, add 1mL of ruthenium at a concentration of 1mol / L of sodium borohydride solution, ...

Embodiment 2

[0029] Embodiment 2: the conversion rate of sugar and the selective detection method of sugar alcohol

[0030] Take 20 μL of the reactant before the sealed reactor and the product after the hydrogenation reaction, dilute to 1 mL with ultrapure water, and detect the sugar concentration in the reactant, the residual sugar concentration and the sugar alcohol concentration in the product by high performance liquid chromatography .

[0031] The high-performance liquid chromatographic instrument used for detection is a waters system 2414 differential detector, and the chromatographic column is an AminexHPX-87H column (300 × 7.8mm), and the mobile phase is 5mM H 2 SO 4 , flow rate 0.6mL / min, column temperature: 60.0°C, injection volume: 20μL.

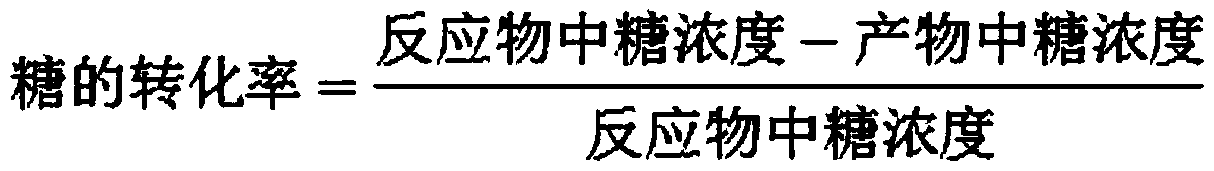

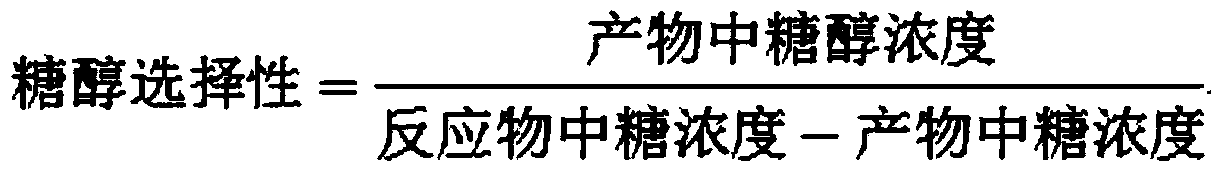

[0032] The conversion rate of sugar and the selectivity calculation formula of sugar alcohol are as follows:

[0033]

[0034]

Embodiment 3

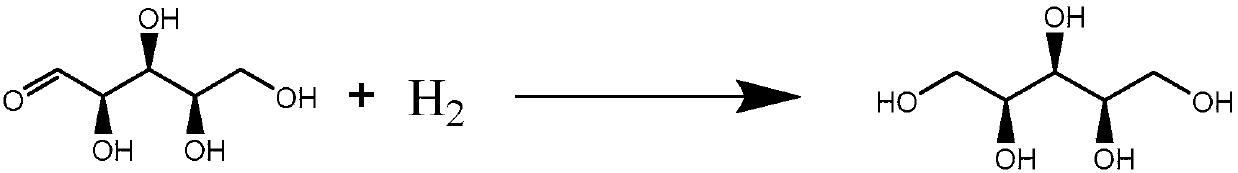

[0035] Embodiment 3: Preparation of xylitol by hydrogenation of xylose

[0036]

[0037]Weigh 7.5g of anhydrous xylose, add it to 42.5mL ultrapure water, prepare a xylose solution with a mass fraction of 15%, transfer the xylose solution to a 100mL reactor, add 0.5g of Ru / MWCNTs catalyst, and seal the reactor . The reactor was replaced three times with nitrogen, and the air in the reactor was removed. Adjust the temperature of the reactor to 110° C., and the stirring speed to 500 rpm. After the temperature is stabilized, hydrogen gas is charged to 4.0 MPa to start the reaction. After reacting for 120 minutes, the reactor was rapidly cooled, and when the temperature dropped to room temperature, the hydrogen gas was vented to end the hydrogenation reaction.

[0038] Using the method of Example 2 to detect, the conversion rate of xylose is 100%, and the selectivity of xylitol is 99.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com