Treatment solution for preparing fluorozirconic acid composite conversion film, preparation method of treatment solution and preparation method of conversion film

A technology of treating liquid and fluorozirconic acid, which is applied in the direction of metal material coating process, etc., can solve the problems of surface treatment of iron and steel parts, the corrosion resistance needs to be improved, the preparation method is complicated, etc., and achieves short treatment time and good corrosion resistance. , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

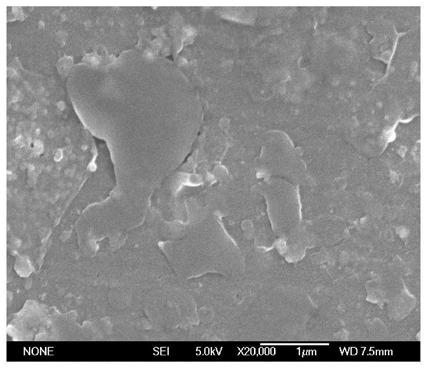

[0065] Example 1: Preparation of Fluorozirconate Composite Conversion Coating on Aluminum Alloy Surface

[0066] Take 8g of fluozirconic acid (mass concentration is 40%-45%), add 5g of fluoboric acid, 2g of boric acid, 3g of ammonia water (mass concentration of 25%-28%), and 12g of triethanolamine while stirring with a glass rod, add deionized Prepare 1L solution with water; take another 500g of deionized aqueous solution, 1g of calcium acetate, and 10g of sodium polyglutamate, and mix the above two components evenly to obtain a light yellow fluorozirconic acid conversion treatment solution, with a specific gravity of 1.04g / cm 3 .

[0067] Dilute the above treatment solution 20 times with water to be the working solution, adjust the pH value to 4.3; prepare the AA1070 series aluminum alloy test piece, immerse the aluminum alloy test piece in the commercially available RS-228 acid degreasing agent (60g / L) for 7 minutes, After washing with water, immerse in the treatment soluti...

Embodiment 2

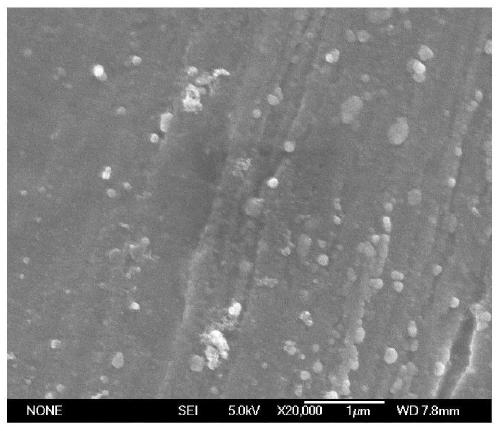

[0070] Example 2: Preparation of fluorozirconate composite conversion coating on the surface of cold-rolled steel

[0071] Take 10 g of sodium fluozirconate solution (mass concentration is 40% to 45%), add 20 g of fluoboric acid, 9 g of boric acid and 5 g of ammonia water (mass concentration of 25% to 28%), 14 g of triethanolamine, tungsten Sodium molybdate 7g, sodium molybdate 6g / L were added deionized water to prepare 1L solution; take another 500g deionized aqueous solution of magnesium acetate 1g, polyglycinate sodium 5g, and mix the above two components evenly to obtain a colorless fluorozirconate conversion treatment solution , the specific gravity is 1.073g / cm 3 .

[0072] Dilute the above treatment solution 10 times with water to get the working solution, adjust the pH value to 4.1, a lower pH value is conducive to the formation of a conversion film layer with better adhesion and better penetration. Prepare the cold-rolled steel test piece, immerse the cold-rolled st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current | aaaaa | aaaaa |

| Corrosion current | aaaaa | aaaaa |

| Self-corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com