A stainless steel electrode that resists redness and cracking of the drug skin

A technology of stainless steel and coating, which is applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc. It can solve the problems of vertical welding and overhead welding operation difficulties, unreachable, and decreased mechanical properties of welds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

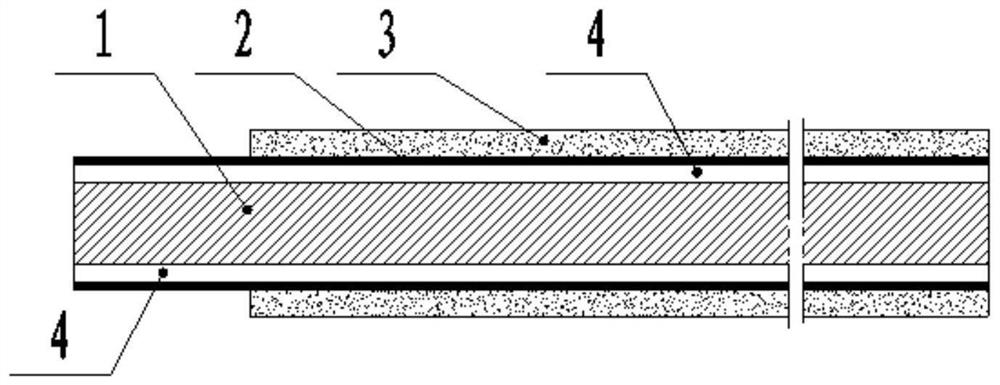

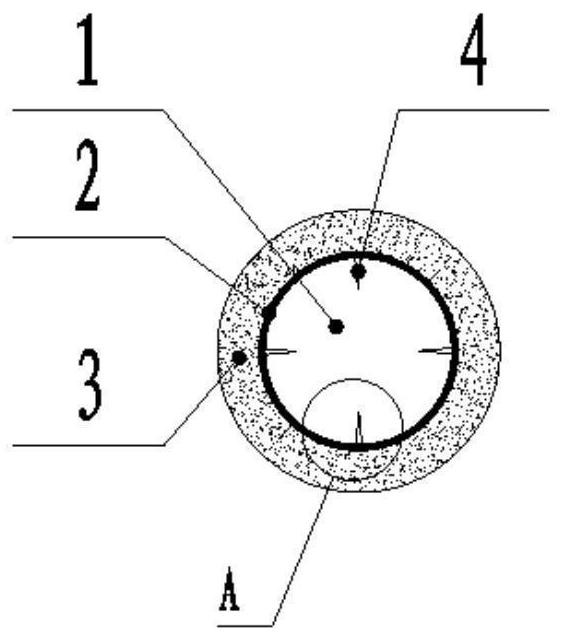

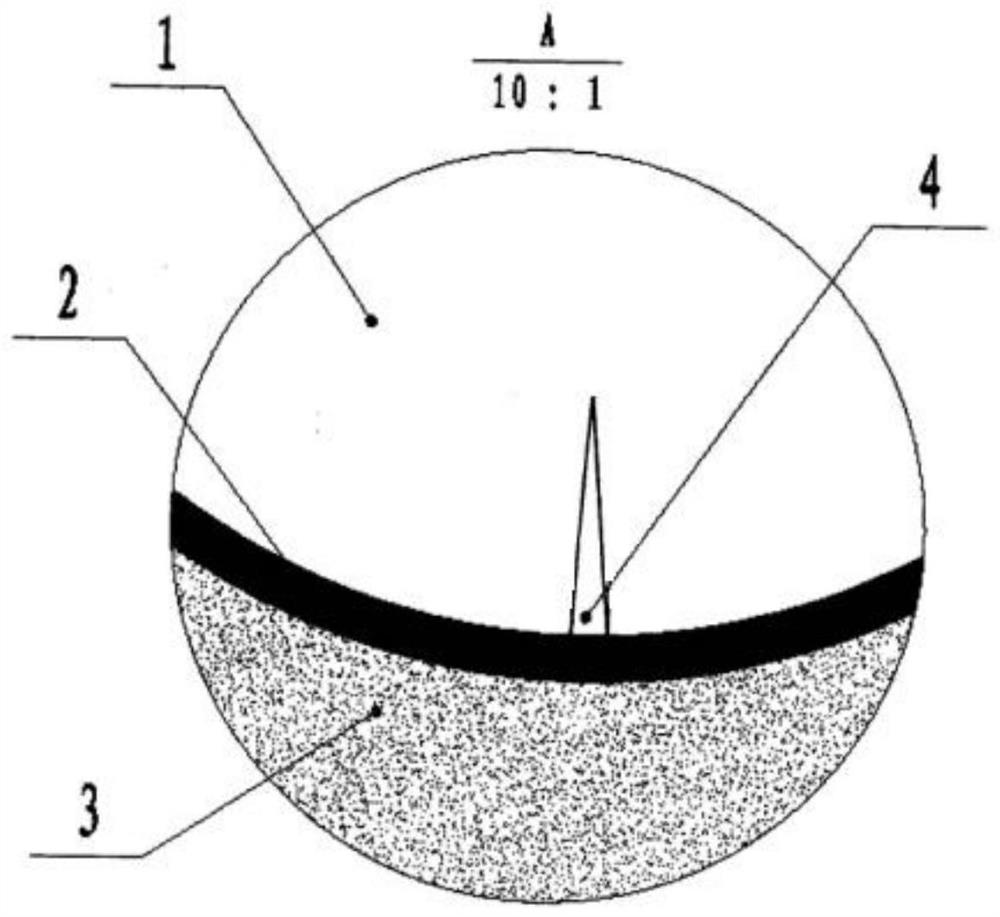

[0058]Preparation of the anti-drug-free red and cracking stainless steel welding rods according to the present invention, the ingredients of dry powder are: 20% of rutones, 8% mica, 8% calcium carbonate, 10% carbonate, nickel carbonate 5%, white Mud 3%, zirconia 2%, fluorite 8%, lithium glow stone 1%, manganese iron 5%, titanium iron 3%, silicon iron 6%, sodium alginate, 0.15% carboxymethylcellulose, nano Cerium oxide and / or nanocium oxide and / or nano oxide 1.5%, the rest is potassium waith; the binder is a potassium water glass, wherein the molar ratio of potassium ions and sodium ions is 1: 2, potassium water glass. The modulus is 2.95, the potassium water glass is 48.5 ° Bé; the mass of the binder is 29% of the total mass of the dry powder in the medicine, the width of the V-shaped groove is 0.2mm, and the depth of the groove is 0.8 mm; the number of V-shaped grooves is 3, and the copper-plated layer thickness of the surface of the stainless steel welding core is 0.2 μm.

Embodiment 2

[0060]Preparation of the resistant steel welding rods and cracking stainless steel welding of the present invention, the ingredients of dry powder are: 20% of rutiles, 10% mica, 10% calcium carbonate, 12% carbonate, 8% carbonate, white Mud 5%, zirconia 4%, fluorite 10%, lithium glow stone, 7% manganese iron, 6% titanium iron, 8% silicon, 0.3% sodium alginate, carboxymethylcellulose 0.25%, nanometer Cerium oxide and / or nano oxide and / or nano oxide 2%, the rest is potassium waith; the binder is a potassium water glass, wherein the molar ratio of potassium ions and sodium ions is 1: 2, potassium water glass. The modulus is 3.05, the potassium water glass is 50.5 ° Bé; the mass of the binder is 32% of the total mass of the dry powder in the pharmaceutical skin, and the width of the V-shaped groove is 0.4mm, the groove The depth is 1.2 mm; the number of V-shaped grooves is 8, and the copper plating layer thickness of the stainless steel welding core surface is 0.2 μm.

Embodiment 3

[0062]Preparation of the anti-drug skin red and cracking stainless steel welding rods described in the present invention, the ingredients of the dry powder are: 20% of rutiles, 9% mica, 9% calcium carbonate, 11% magnesium carbonate, nickel carbonate 6.5%, white Mud 4%, zirconia 3%, fluorite 9%, lithium glow stone 2%, manganese iron, 4.5% titanium iron, silicon, 0.25% sodium alginate, carboxymethylcellulose 0.2%, nano Cerium oxide and / or nano oxide and / or nano oxide 1.75%, the rest is potassium longite; the binder is potassium water glass, wherein the molar ratio of potassium ions and sodium ions is 1: 2, potassium water glass. The modulus is 3, the potassium water glass is 49.5 ° Bé; the mass of the binder is 30.5% of the total mass of dry powder in the pharmacodynamic. The V-shaped groove has a width of 0.3 mm, the depth of the groove is 1.0 mm; the number of V-shaped grooves is 4, and the copper plating layer thickness of the stainless steel core surface is 0.2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com