Porous sodium vanadium fluorophosphate composite material regulated and controlled by carbon quantum dots as well as preparation method and application of composite material

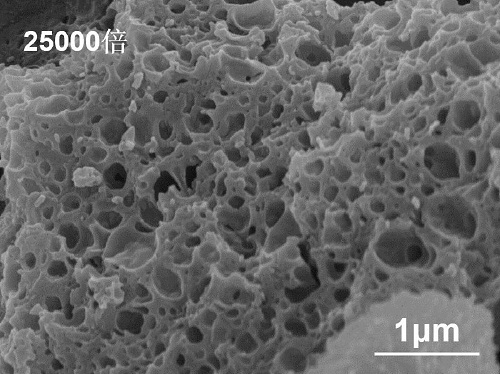

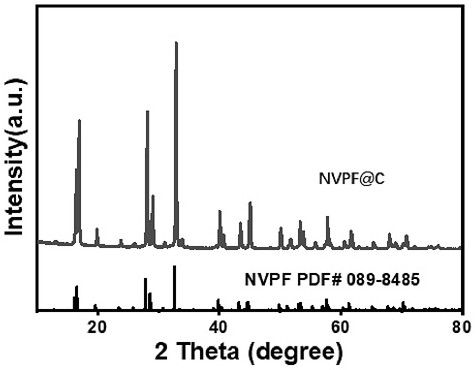

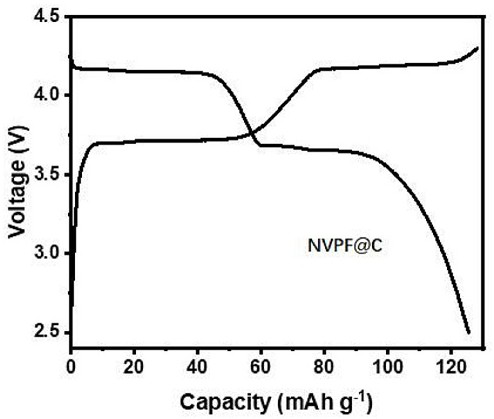

A technology of sodium vanadium fluorophosphate and carbon quantum dots, which is applied in the field of porous sodium vanadium phosphate composite materials and its preparation, and can solve the problems of full contact between unfavorable electrode materials and electrolyte solutions, low electronic conductivity of sodium vanadium fluorophosphate materials, and carbon layer Uneven distribution and other problems, to achieve the effect of inhibiting the dissolution of metal ions, inhibiting side reactions at the interface, and solving uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of porous sodium vanadium phosphate composite material, comprising the following steps:

[0048] S1. Dissolve 0.5 mmol of vanadium pentoxide and 2 mmol of oxalic acid in 20 ml of deionized water, add dilute HCl solution or ammonia water to adjust the pH=3 to obtain a mixed solution; heat the mixed solution to 80°C at a speed of 400 rpm Stir at low temperature for 2 h, then add 1.5 mmol sodium fluoride and 1.0 mmol phosphoric acid to the mixed solution successively, continue stirring for 2 h to obtain a transparent blue solution, and cool to room temperature naturally;

[0049] S2. Add the polymer solution to the obtained blue solution, stir at a rate of 400 rpm for 2 h, place the obtained solution in a petri dish, and transfer it to an oven for aging at 100°C for 24 h to obtain a green uniform sodium vanadium phosphate precursor ; Wherein, the polymer solution is prepared by dissolving 20 mg of carbon quantum dots in 20 mL of solvent, and the solven...

Embodiment 2

[0060] A preparation method of porous sodium vanadium phosphate composite material, comprising the following steps:

[0061] S1. Dissolve 0.5 mmol of vanadium trioxide and 2 mmol of citric acid in 20 ml of deionized water, add dilute HCl solution or ammonia water to adjust pH=6 to obtain a mixed solution; heat the mixed solution to 70°C, and Stir at high speed for 2 h; then add 1.5 mmol sodium fluoride and 1.0 mmol phosphoric acid to the mixed solution in turn, continue stirring for 2 h, and cool the transparent blue solution to room temperature naturally;

[0062] S2. Add the polymer solution to the obtained blue solution, stir at a rate of 400 rpm for 2 h, place the obtained solution in a petri dish, and transfer it to an oven for aging at 100° C. for 24 h to obtain a uniform green green sodium vanadium phosphate precursor; Among them, the polymer solution is prepared by dissolving 20 mg of sulfur-doped carbon quantum dots in 20 mL of solvent, and the solvent is mixed with t...

Embodiment 3

[0065] A preparation method of porous sodium vanadium phosphate composite material, comprising the following steps:

[0066] S1. Dissolve 1.0 mmol ammonium metavanadate and 2 mmol malic acid in 20 ml deionized water, add dilute HCl solution or ammonia water to adjust pH=4 to obtain a mixed solution; raise the temperature of the mixed solution to 60°C at a rate of 300 rpm Stir for 2 h, then add 1.5 mmol of sodium carbonate, 1.0 mmol of ammonium dihydrogen phosphate and 1.0 mmol of ammonium fluoride to the solution in sequence, and continue stirring for 2 h to obtain a transparent blue solution, which is naturally cooled to room temperature;

[0067] S2. Add the polymer solution to the obtained blue solution, stir at a rate of 500 rpm for 2 h, place the obtained solution in a petri dish, and transfer it to an oven for aging at 100° C. for 36 h to obtain a uniform green green sodium vanadium phosphate precursor; Among them, the polymer solution is prepared by dissolving 20 mg of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com