Patents

Literature

33results about How to "No ironing required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

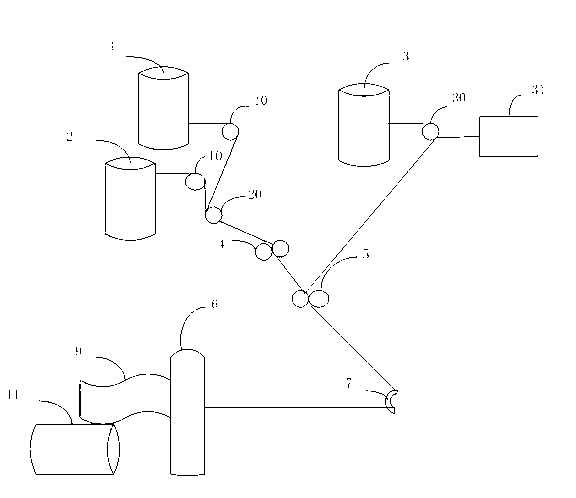

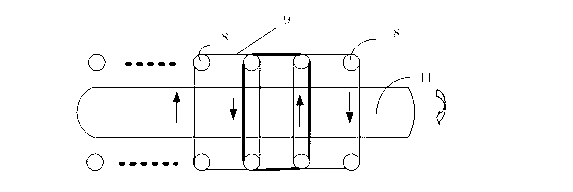

Flax wet-spun blended yarn and preparation method and spinning frame of flax wet-spun blended yarn

ActiveCN102704109AShinyColorfulBiochemical fibre treatmentDry-cleaning apparatus for textilesPolymer sciencePolymer chemistry

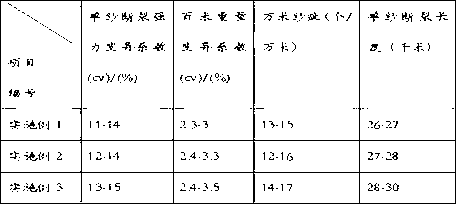

The invention discloses a flax wet-spun blended yarn comprising flax roves, wherein the flax roves comprise first flax roves and second flax roves, the number difference of the first flax roves and the second flax roves is not larger than 1.2, polyester filament yarns are added in the flax roves to form a flax wet-spun blended yarn main body, and the flax wet-spun blended yarn main body is in an S direction of twist. The invention also discloses a preparation method of flax wet-spun blended yarn. The invention also discloses a spinning frame for preparing the flax wet-spun blended yarn. The preparation method of the flax wet-spun blended yarn comprises the steps of: threading the polyester filaments with the first flax roves and the second flax roves to form the flax wet-spun blended yarn, wherein the flax wet-spun blended yarn is in the S direction of twist. The flax wet-spun blended yarn disclosed by the invention has the advantages of being gorgeous, glossy, stiff and smooth and durable, and needing no ironing.

Owner:JIANGSU HUAXIN LINEN TEXTILE

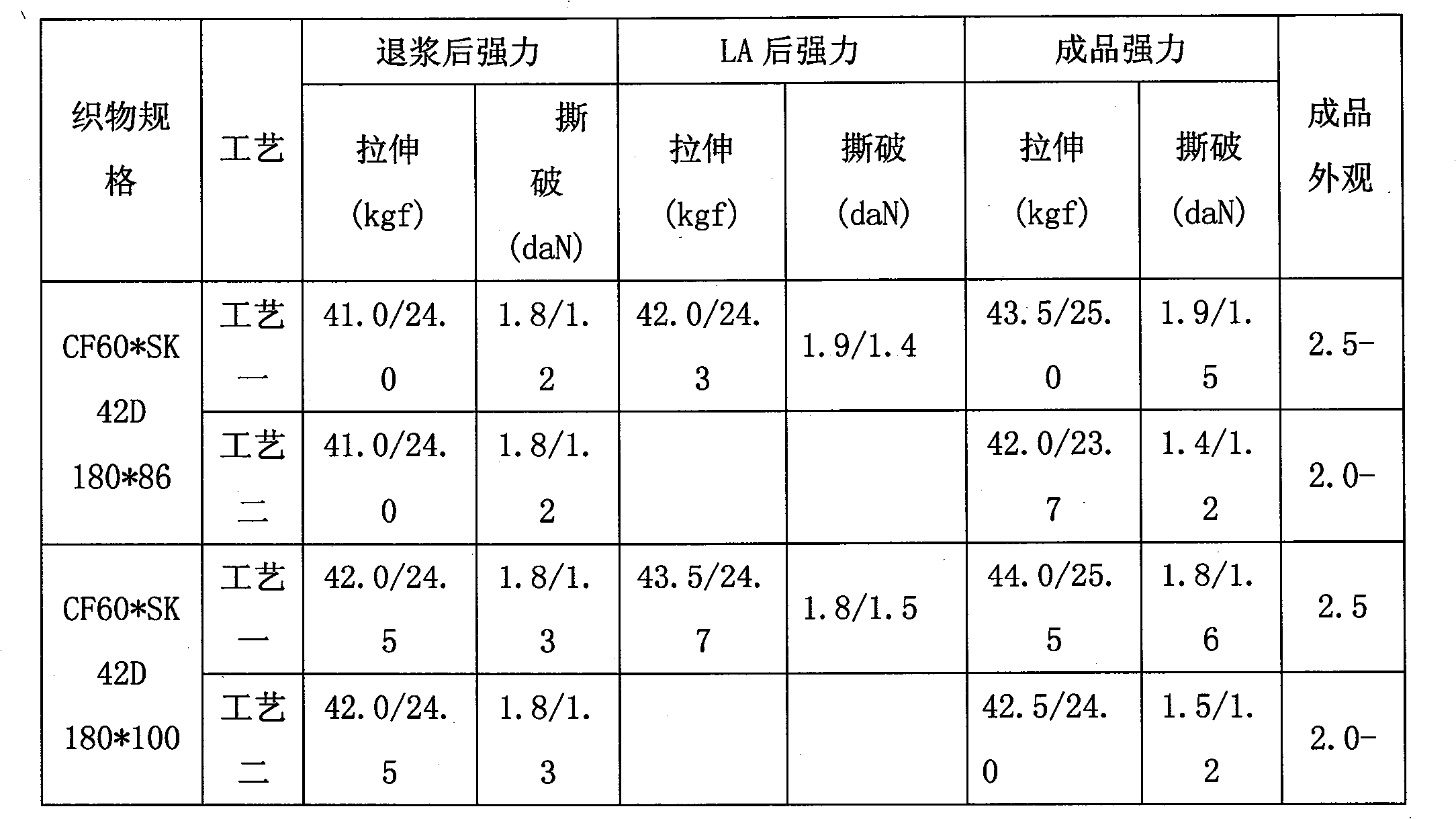

Method for processing liquid ammonia of cotton wire union cloth

InactiveCN101220555ASmall permeabilityImprove permeabilitySingeingVegetal fibresCotton fibreTherapeutic effect

A processing method of a cotton and silk interweaving fabrics comprises the following five steps: (1) singeing (2) desizing (3) liquid ammonia (4) sizing (5) preshrinking, and the step(3) comprises cloth inlet-prebaking-air cooling-padding the liquid ammonia-steaming - washing-roller drying-cropping, the cotton and silk fabrics which are processed by the liquid ammonia have the advantages of soft and smooth feeling, no mightiness damage, no ironing and little washing shrinkage. Although the expansion effect of caustic soda is three times higher than the liquid ammonia, the caustic soda is high in viscosity and uneven in permeability, and owing to the good impregnability of the liquid ammonia, the treatment effect of the liquid ammonia and the mercerization of the caustic soda is different; cotton fiber is swelling, the warp direction and the weft direction of which are both very even after the liquid ammonia treatment. Although the liquid ammonia finish has the sense of the mercerizing, the liquid ammonia finish is different from the traditional mercerizing which leads the mightiness, the elasticity, the feeling of the cotton and silk fabrics to increase and improves the steady of the size without any corrosion and non homogeneity to the fiber which are caused by the caustic soda mercerizing.

Owner:浙江盛泰服装集团股份有限公司

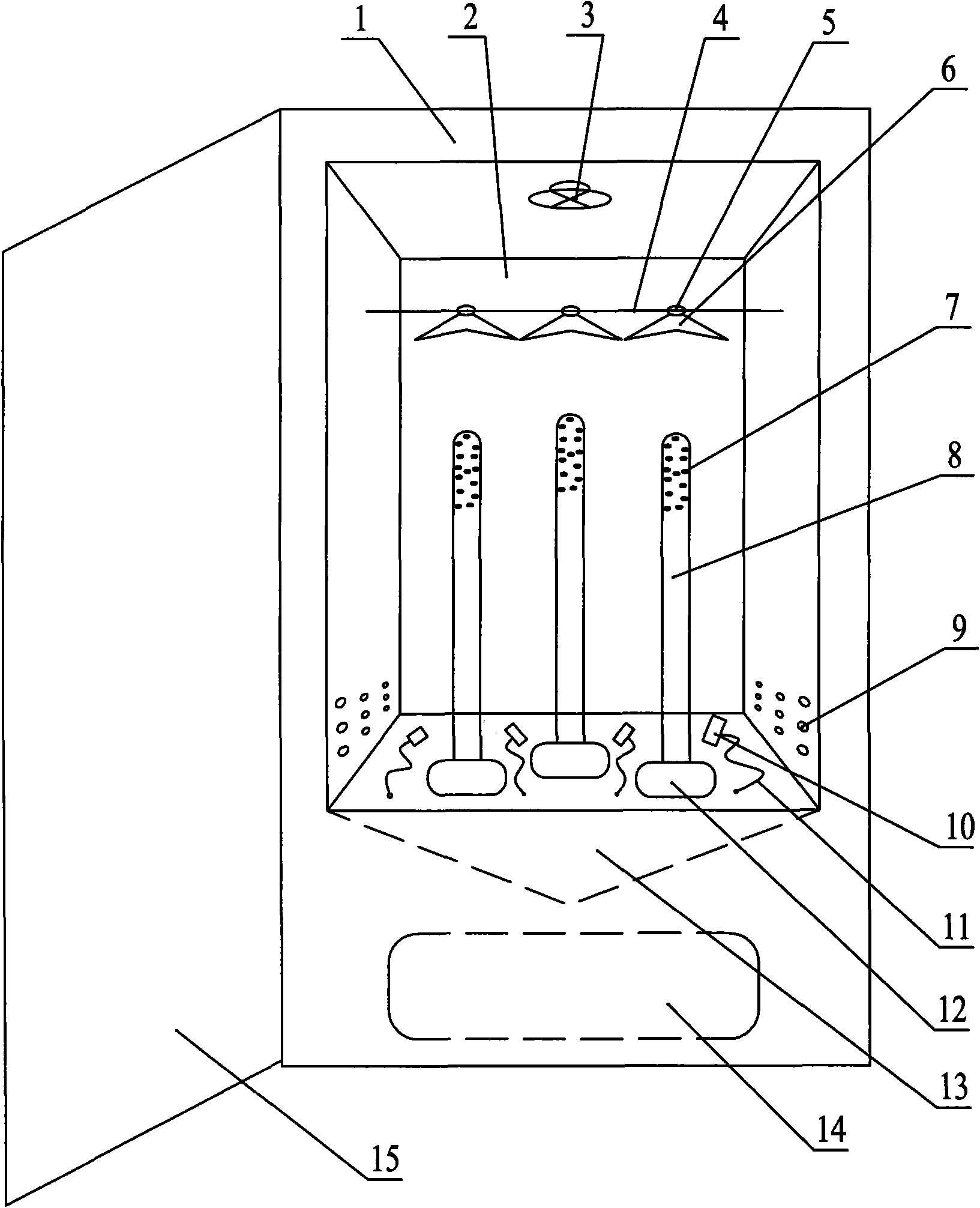

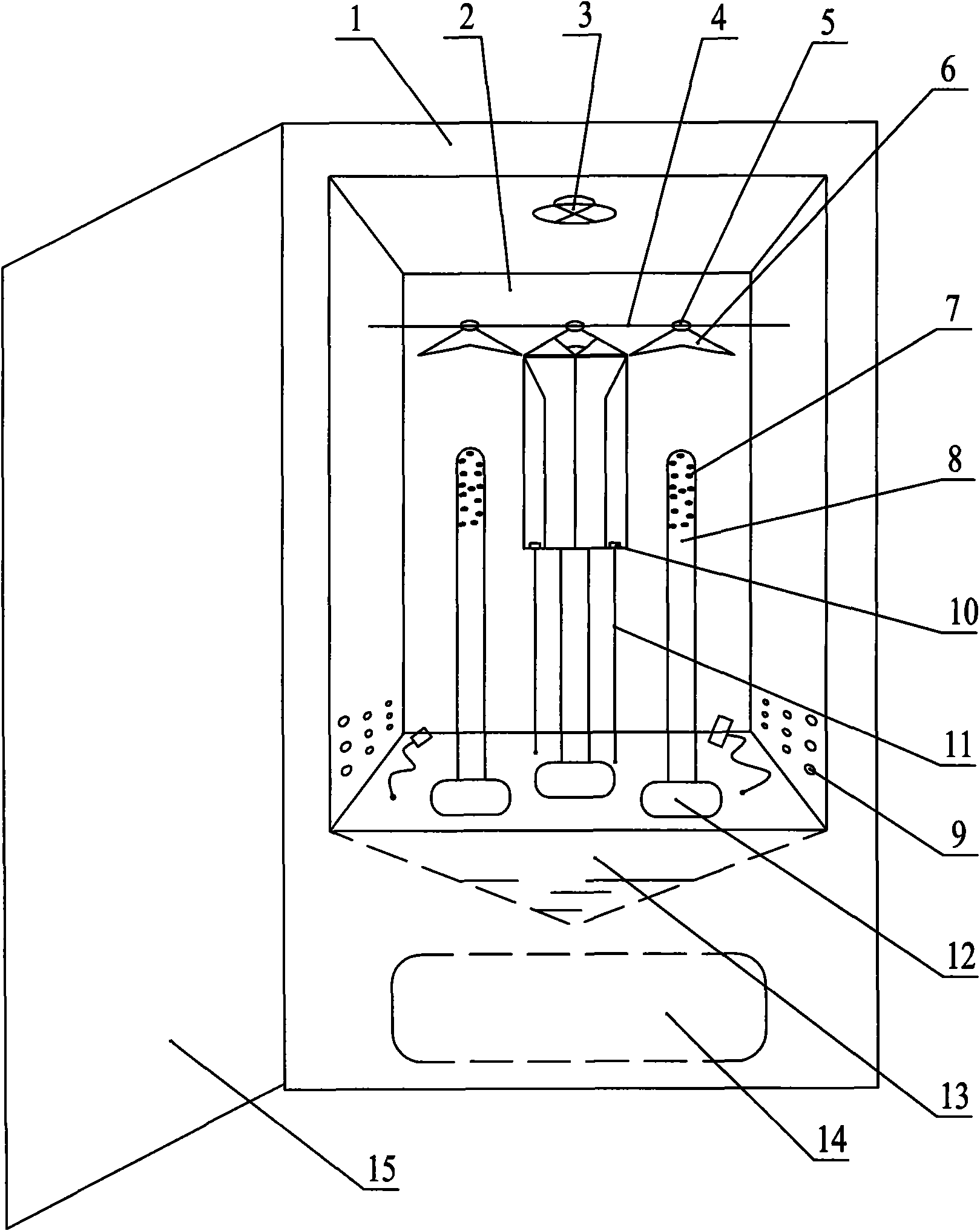

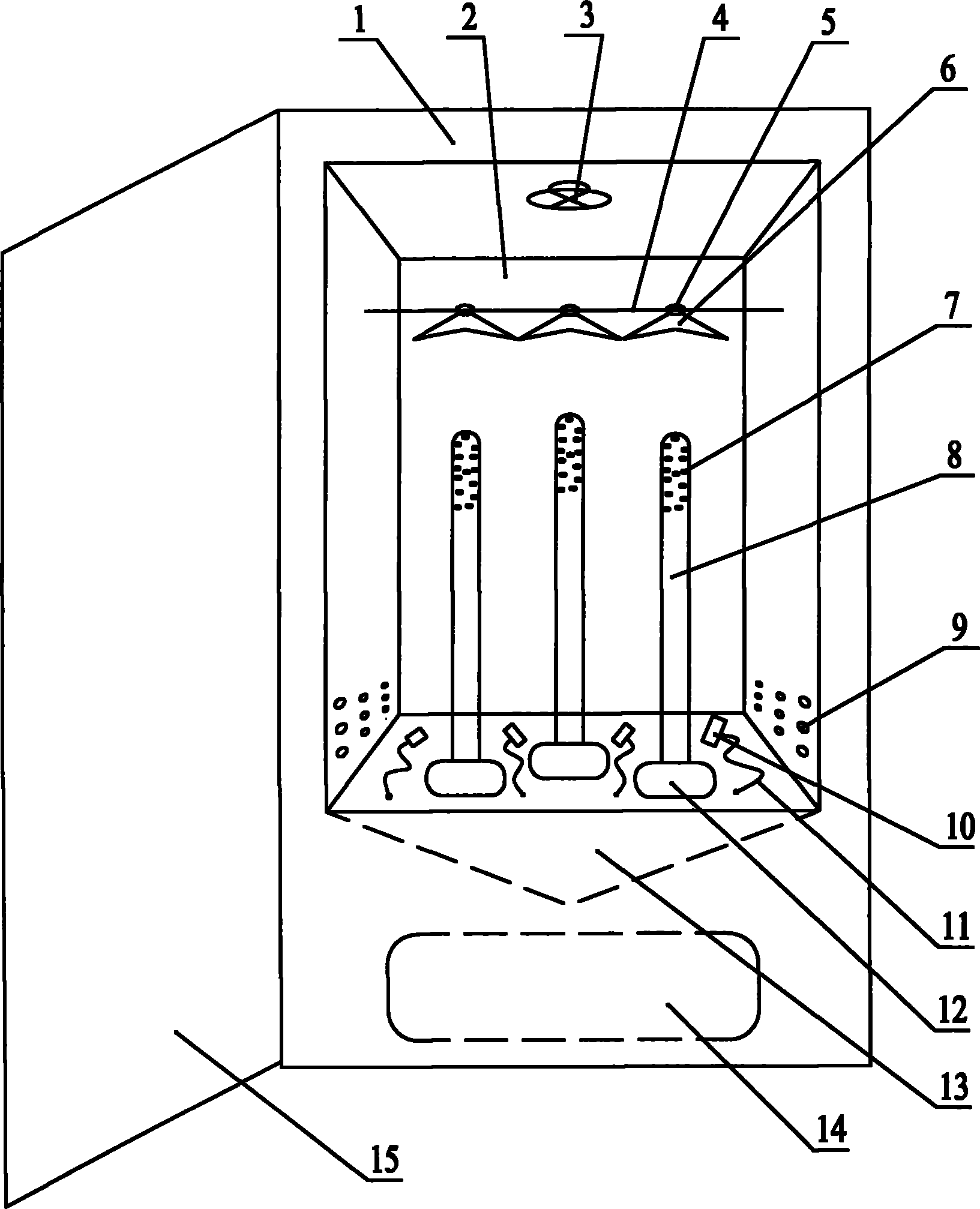

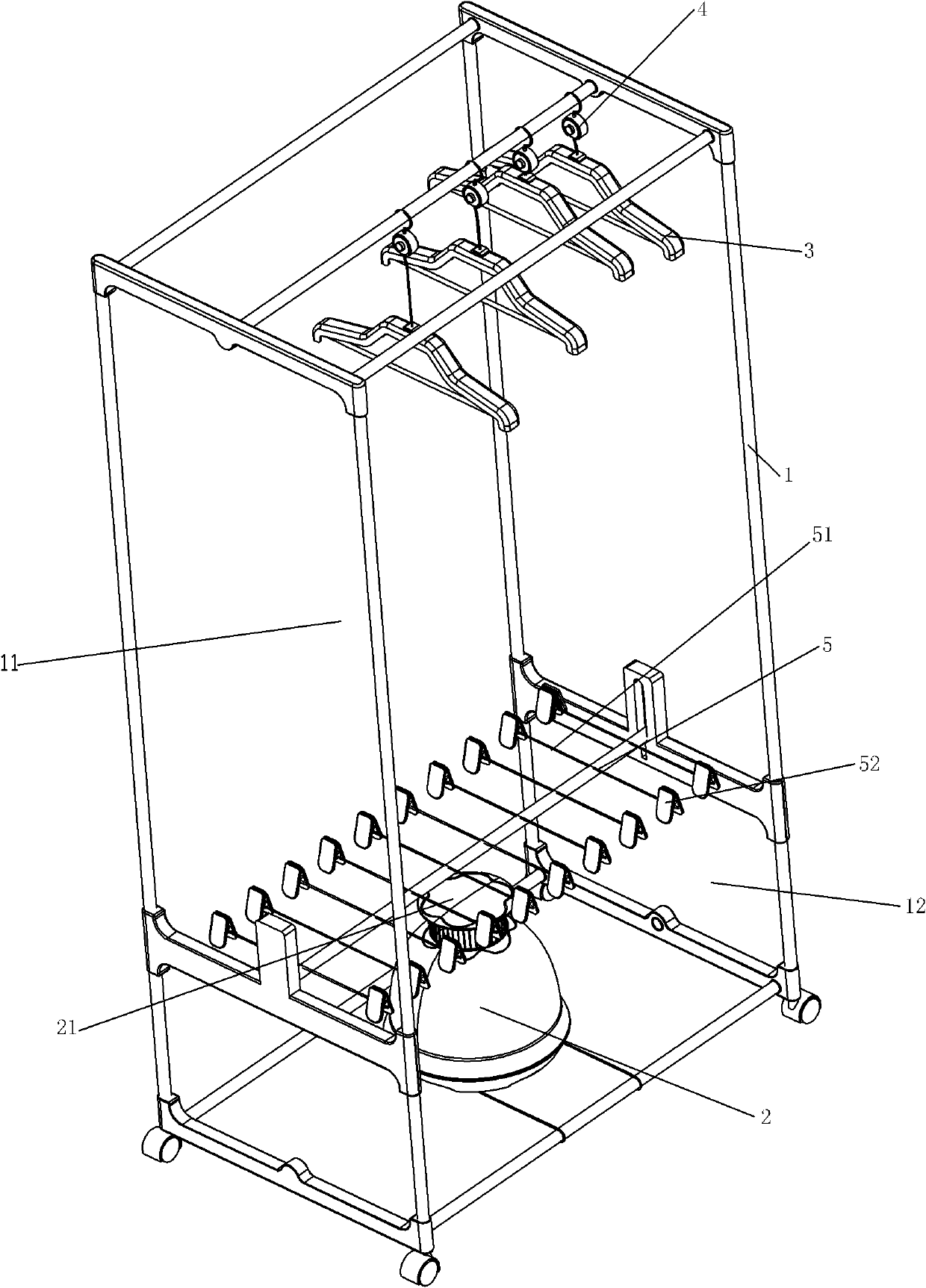

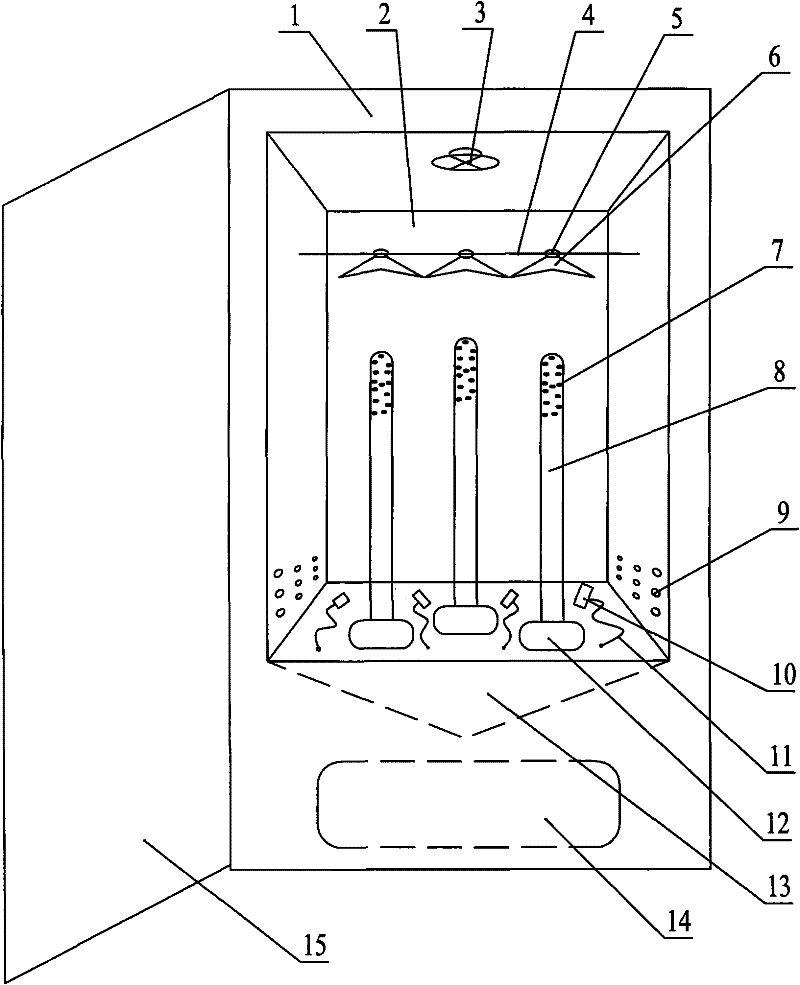

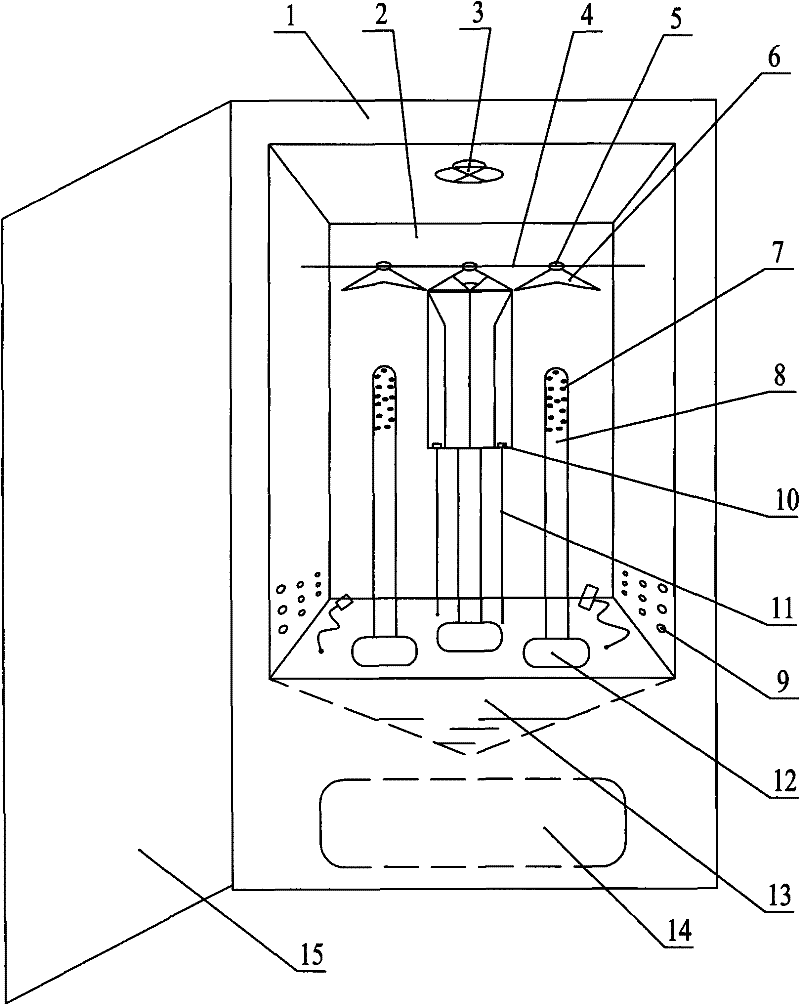

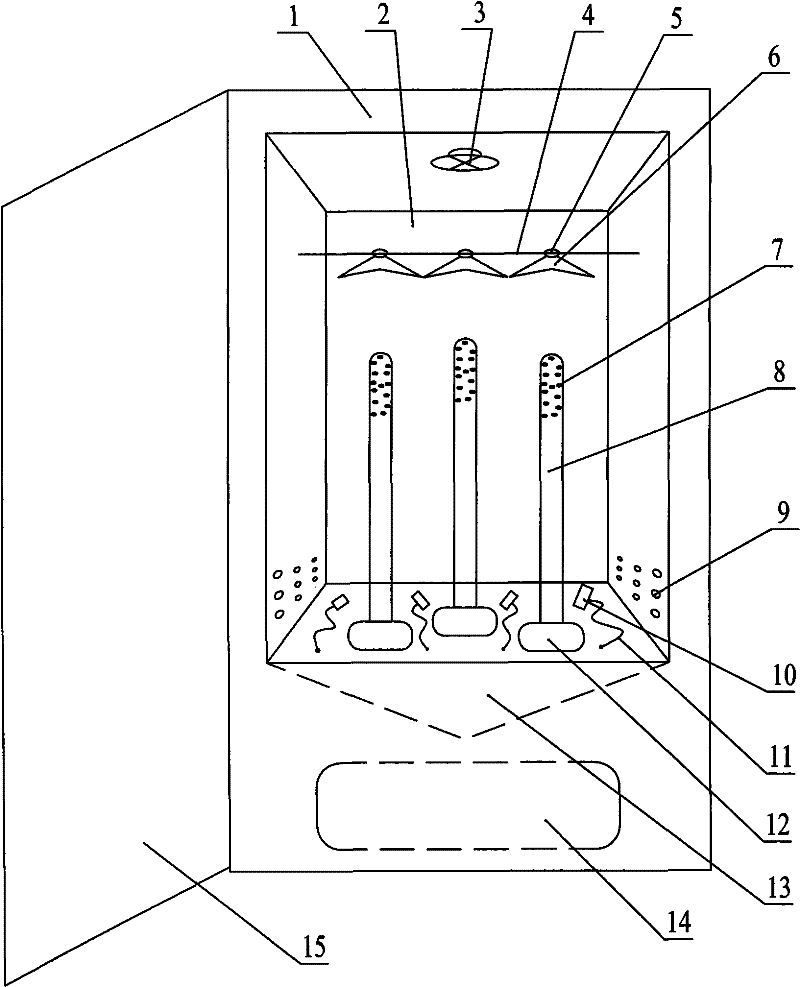

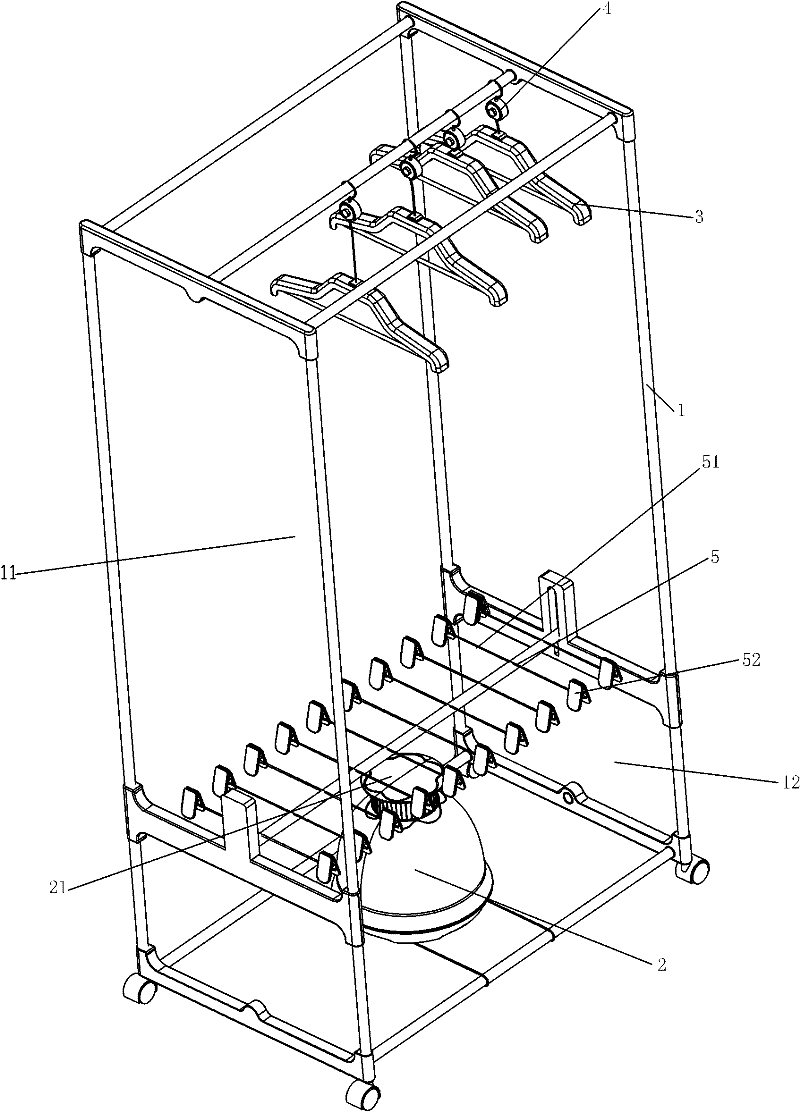

Steam washing machine with hanging-type clothes hanger

InactiveCN101838899AIngenious and reasonable structureImprove washabilityOther washing machinesWashing machine with receptaclesClothes hangerAutomation

The invention relates to a steam washing machine with a hanging-type clothes hanger. According to the technical scheme provided by the invention, the steam washing machine with the hanging-type clothes hanger comprises a box body, wherein a steam generator is arranged in the bottom of the box body, a washing room used for accommodating clothes is arranged in the box body, and outer jet holes are arranged on the wall of the washing room, communicated with the steam generator and used for spraying steam into the box body. The steam washing machine is characterized in that a hanging rod is arranged at the upper part of the washing room, and at least one clothes hanger is arranged on the hanging rod; at least one jet cylinder with hollow interior is vertically arranged at the bottom of the washing room, the jet cylinders are arranged under the clothes hangers and are in one-to-one correspondence with the clothes hangers, the lower ends of the jet cylinders are communicated with the steam generator, and inner jet holes are densely distributed all over the body of the upper part of the steam spray cylinder. The invention has smart and reasonable structure, high automation degree and favorable washing effect and can realize soft washing and reduce the wear damage to clothes by a large extent.

Owner:丁晔

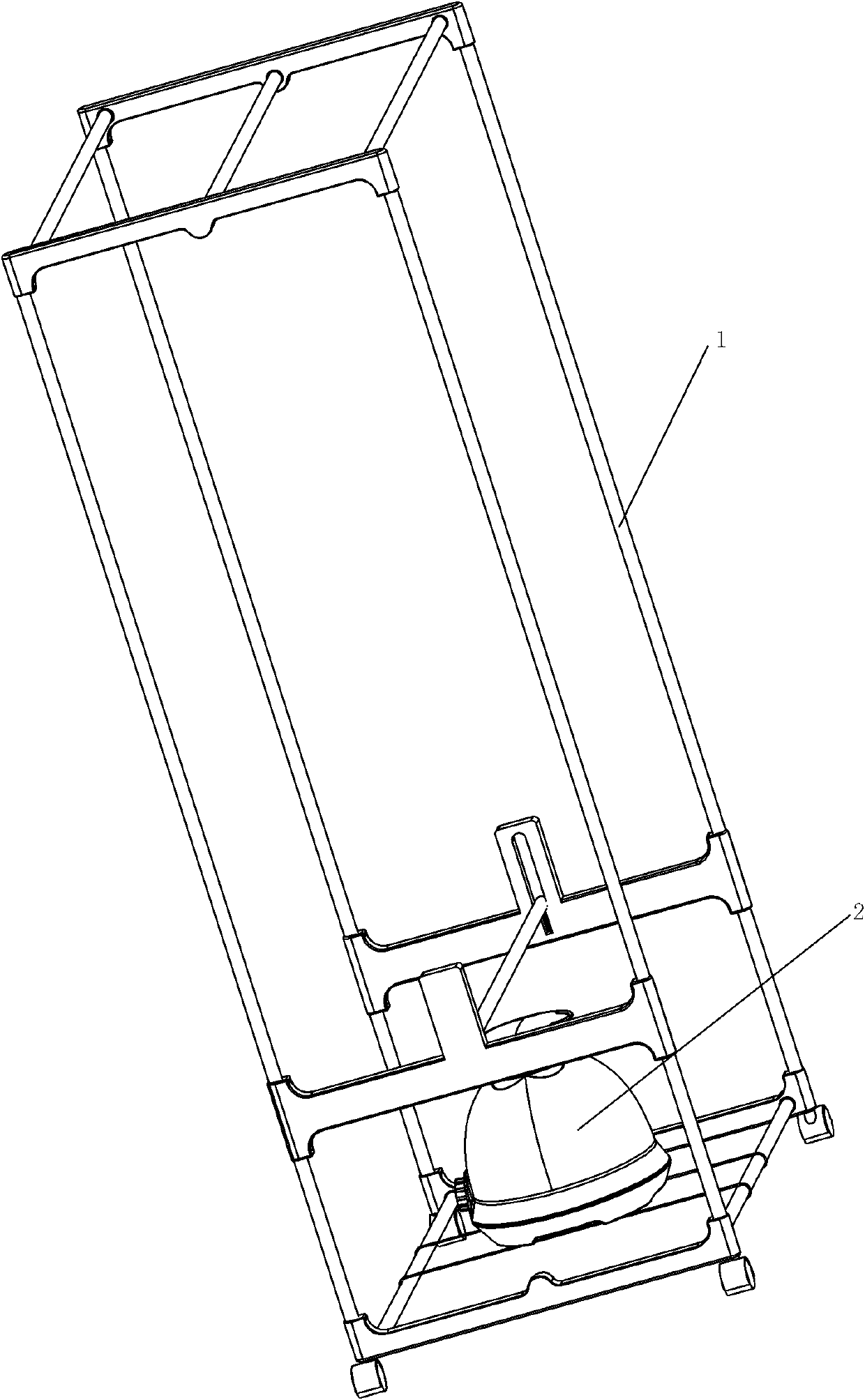

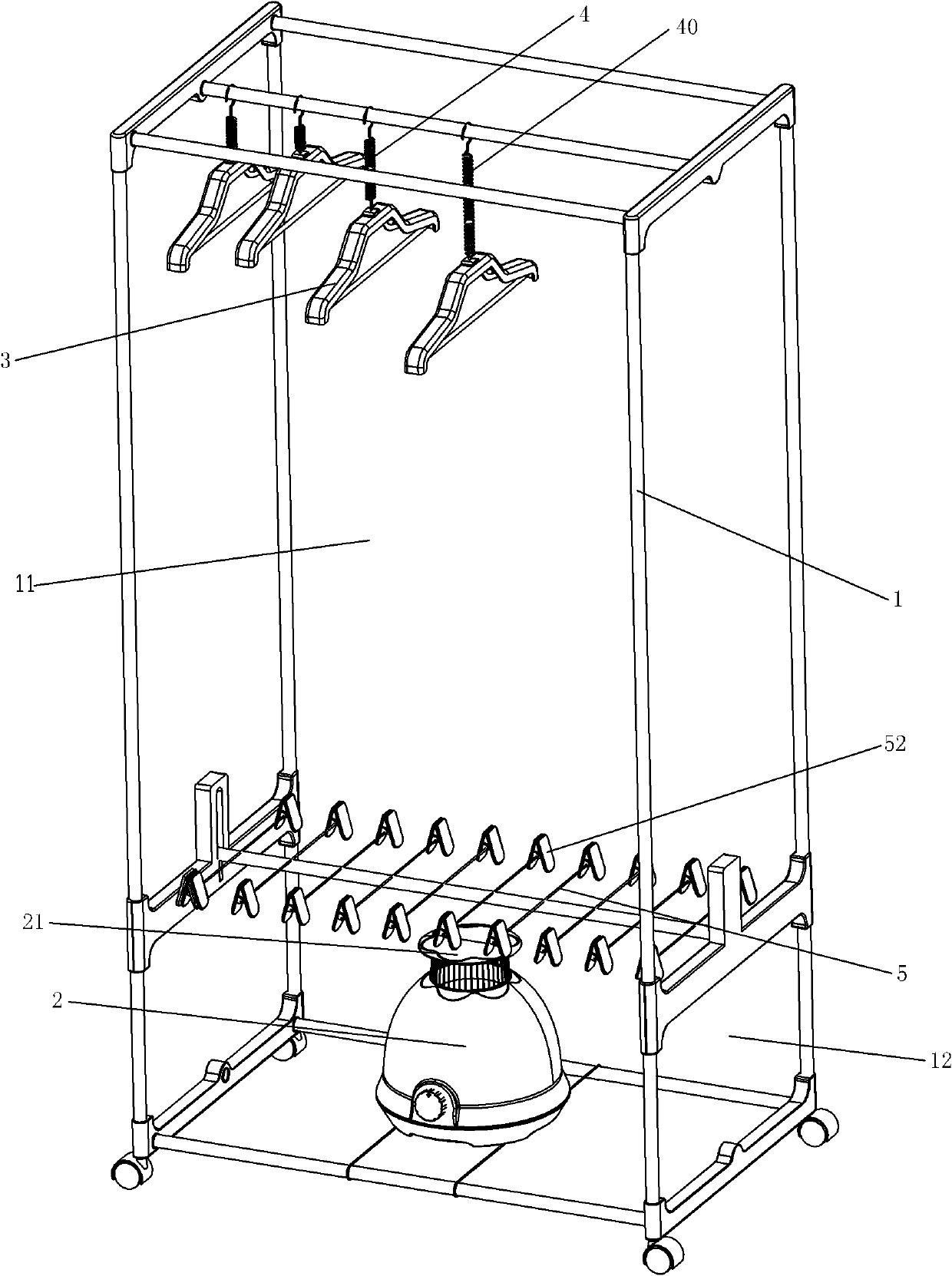

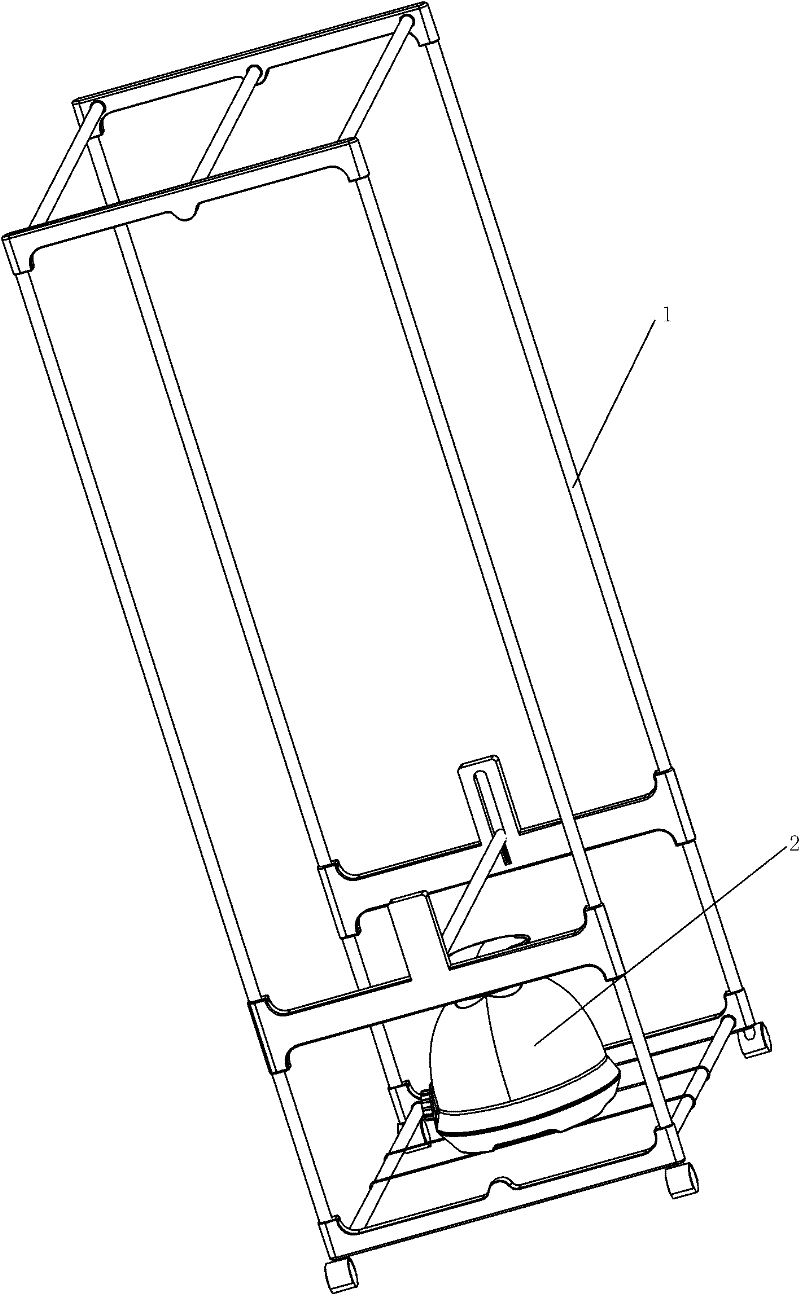

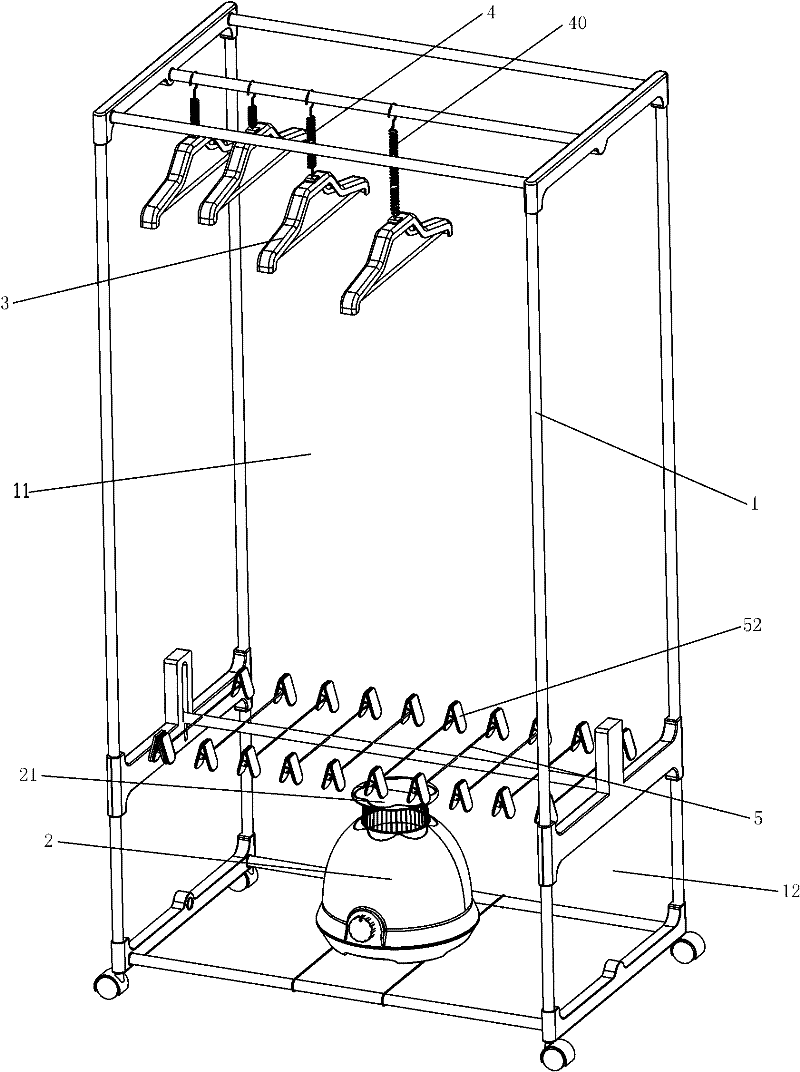

Non-ironing clothes dryer

InactiveCN102168360AWrinkle freeShorten drying timeOther drying apparatusTextiles and paperWrinkle skinBiochemical engineering

The invention relates to a non-ironing clothes dryer comprising a machine body, wherein the lower part of the machine body is provided with a warm wind device, and the upper part of the machine body is provided with a hanger. The non-ironing clothes dryer is characterized in that the hanger is provided with a retractor device which can drive the hanger to move up and down, and a fixing device used for fixing the lower part of the clothes and straightening the clothes is arranged between the hanger and the warm wind device. Because the upper part of the hanger of the machine body of the clothes dryer is provided with the retractor device and the lower part of the machine body of the clothes dryer is provided with the fixing device, the retractor device can adjust the height of the hanger according to the height of the clothes, and the lower fixing device clamps the lower part of the clothes and straightens the clothes, thus the clothes hung on the hanger can be pulled open and straightened; and the clothes can not move when being dried by the warm wind device, the clothes are very straight and flat without wrinkles after being dried, the drying time is short, and the clothes do not need to be ironed.

Owner:ZHONGSHAN MESTER IND

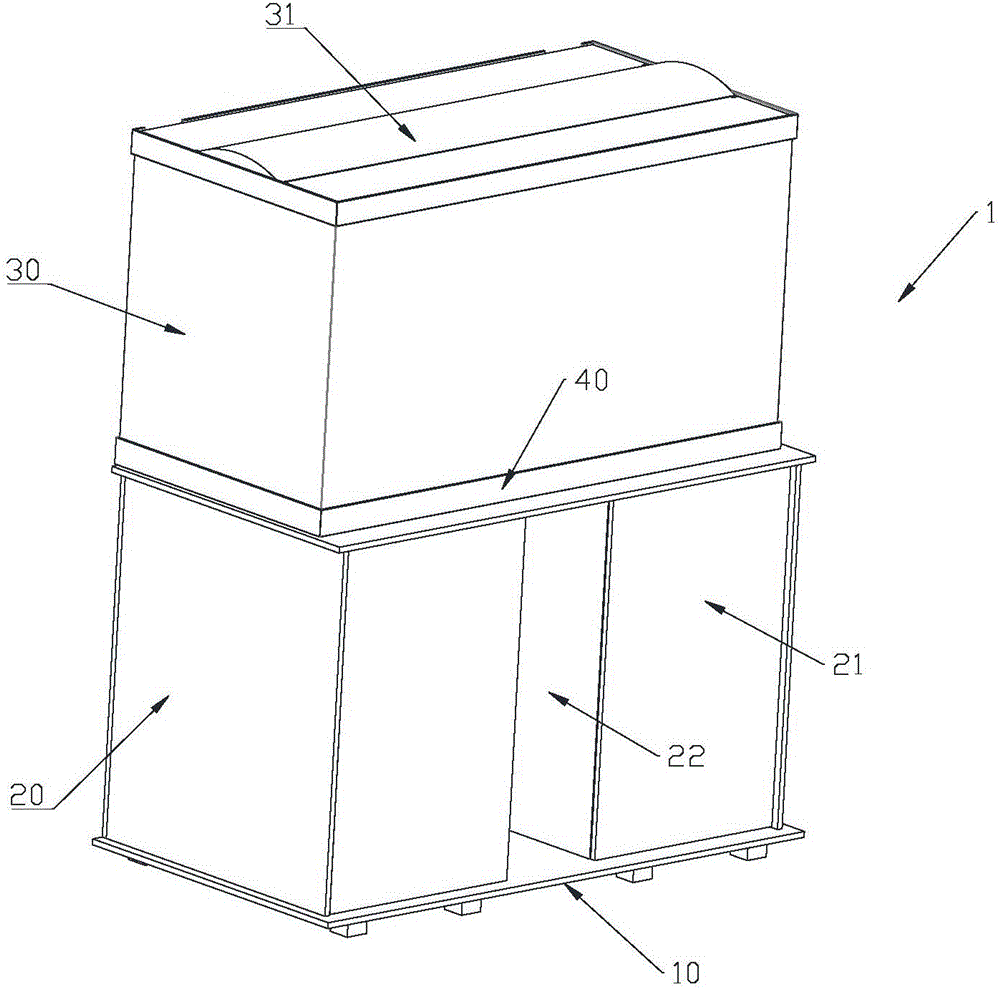

Drying machine

The invention discloses a drying machine which comprises a fixing base. An electric heating fan and an exhaust fan are arranged on the fixing base, a ventilation opening is formed between the electric heating fan and the exhaust fan, a clothes drying box is arranged at the top of the electric heating fan and the top of the exhaust fan, the clothes drying box is communicated with the electric heating fan and the exhaust fan, hot air produced by the electric heating fan dries clothes through the clothes drying box and is discharged out by the exhaust fan, the top of the clothes drying box is provided with an opening, the opening is covered with a cover body, and an air filter screen is arranged at the bottom of the clothes drying box. When the drying machine performs clothes drying, clothes are stacked or hung in the clothes drying box, the hot air produced by the electric heating fan enters the clothes drying box and carries away water vapor on the clothes, and wet and hot air is extracted by the exhaust fan and discharged out of the machine. The surfaces of the clothes dried by the drying machine are flat without ironing and pressing, and the drying machine is convenient and quick.

Owner:航星洗涤机械(泰州)有限公司

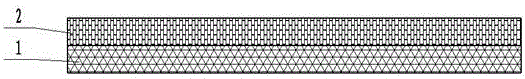

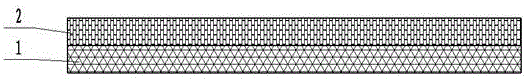

Easy-dry and non-ironing fabric having water-proof, oil-proof and anti-fouling functions

InactiveCN106273845AGood waterproofDehydration fastSynthetic resin layered productsWoven fabricsPolyesterEngineering

The invention relates to an easy-dry and non-ironing fabric having water-proof, oil-proof and anti-fouling functions. The fabric comprises a base layer (1), and a quick-dry layer (2) is arranged at the outer side of the base layer. A lining fabric layer is arranged on the back of the base layer, the lining fabric layer comprises three layers, wherein the outer layer is a Teflon coating, the interlayer is a textile fabric, the inner layer is a Teflon coating, the textile fabric is a nylon water-proof fabric or a polyester fabric, and the thickness of the Teflon coating is 10-13 microns. The fabric can be quickly dried, is naturally straight after washing, does not need ironing and is stiff and smooth, and the inner layer is comfortable.

Owner:JIANGYIN CHUNZHILAN SPECIAL YARN

Method for processing liquid ammonia of cotton wire union cloth

InactiveCN101220555BSmall permeabilityImprove permeabilitySingeingVegetal fibresCotton fibreTherapeutic effect

A processing method of a cotton and silk interweaving fabrics comprises the following five steps: (1) singeing (2) desizing (3) liquid ammonia (4) sizing (5) preshrinking, and the step(3) comprises cloth inlet-prebaking-air cooling-padding the liquid ammonia-steaming - washing-roller drying-cropping, the cotton and silk fabrics which are processed by the liquid ammonia have the advantages of softand smooth feeling, no mightiness damage, no ironing and little washing shrinkage. Although the expansion effect of caustic soda is three times higher than the liquid ammonia, the caustic soda is high in viscosity and uneven in permeability, and owing to the good impregnability of the liquid ammonia, the treatment effect of the liquid ammonia and the mercerization of the caustic soda is different; cotton fiber is swelling, the warp direction and the weft direction of which are both very even after the liquid ammonia treatment. Although the liquid ammonia finish has the sense of the mercerizing, the liquid ammonia finish is different from the traditional mercerizing which leads the mightiness, the elasticity, the feeling of the cotton and silk fabrics to increase and improves the steady ofthe size without any corrosion and non homogeneity to the fiber which are caused by the caustic soda mercerizing.

Owner:浙江盛泰服装集团股份有限公司

Transfer-printed ironing-free fabric easy to dry

InactiveCN106240063ADehydration fastNo ironing requiredSynthetic resin layered productsClothingsBoPETEngineering

The invention relates to a transfer-printed ironing-free fabric easy to dry. The transfer-printed ironing-free fabric easy to dry comprises a basic layer (1), and a quick-drying layer (2) is arranged on the outer side of the basic layer. A lining fabric layer is arranged on the back side of the basic layer, is a fabric transfer film and comprises a two-way stretching polyester BOPET film, and a release layer, a coloring layer, an aluminum-plated layer and a bottom glue layer are arranged on the surface of the BOPET film in sequence. The transfer-printed ironing-free fabric easy to dry can be dewatered quickly, is naturally stiff and straight after being soaked in water and is free of ironing, stiff and smooth, and the inner layer is comfortable and cool.

Owner:JIANGYIN JIAYI GIFT

Easy-drying non-iron fabric capable of reducing outward dissipation of heat

InactiveCN106142740ADehydration fastNo ironing requiredSynthetic resin layered productsClothingsTemperature controlEngineering

The invention relates to an easy-drying non-iron fabric capable of reducing outward dissipation of heat, comprising a base layer (1); a quick-drying layer (2) is provided outside the base layer; a lining fabric layer is arranged on the back of the base layer and at least has a temperature-control fabric layer and a heat-resisting layer, material of the temperature-control fabric layer has moisture-absorbing and heat-producing characteristics, the temperature-control fabric layer has moisture regain difference of 1% to 8% under relative humidities of 90% and 40%, and the heat-resisting layer is adjacent to the outer surface of the temperature-control fabric layer. The fabric of the invention can dry fast, is naturally stiff after being watered, is free of ironing and is stiff and smooth, and an inner layer of the fabric is comfortable and cool.

Owner:JIANGYIN YUEDA DYEING & PRINTING

Rapid drying processing device for clothes processing

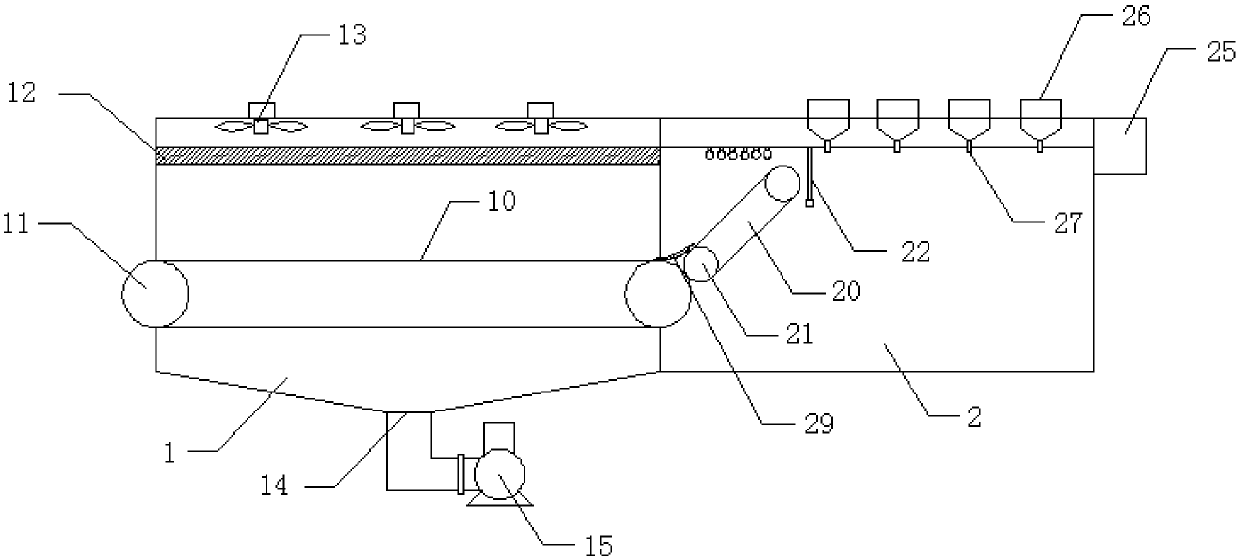

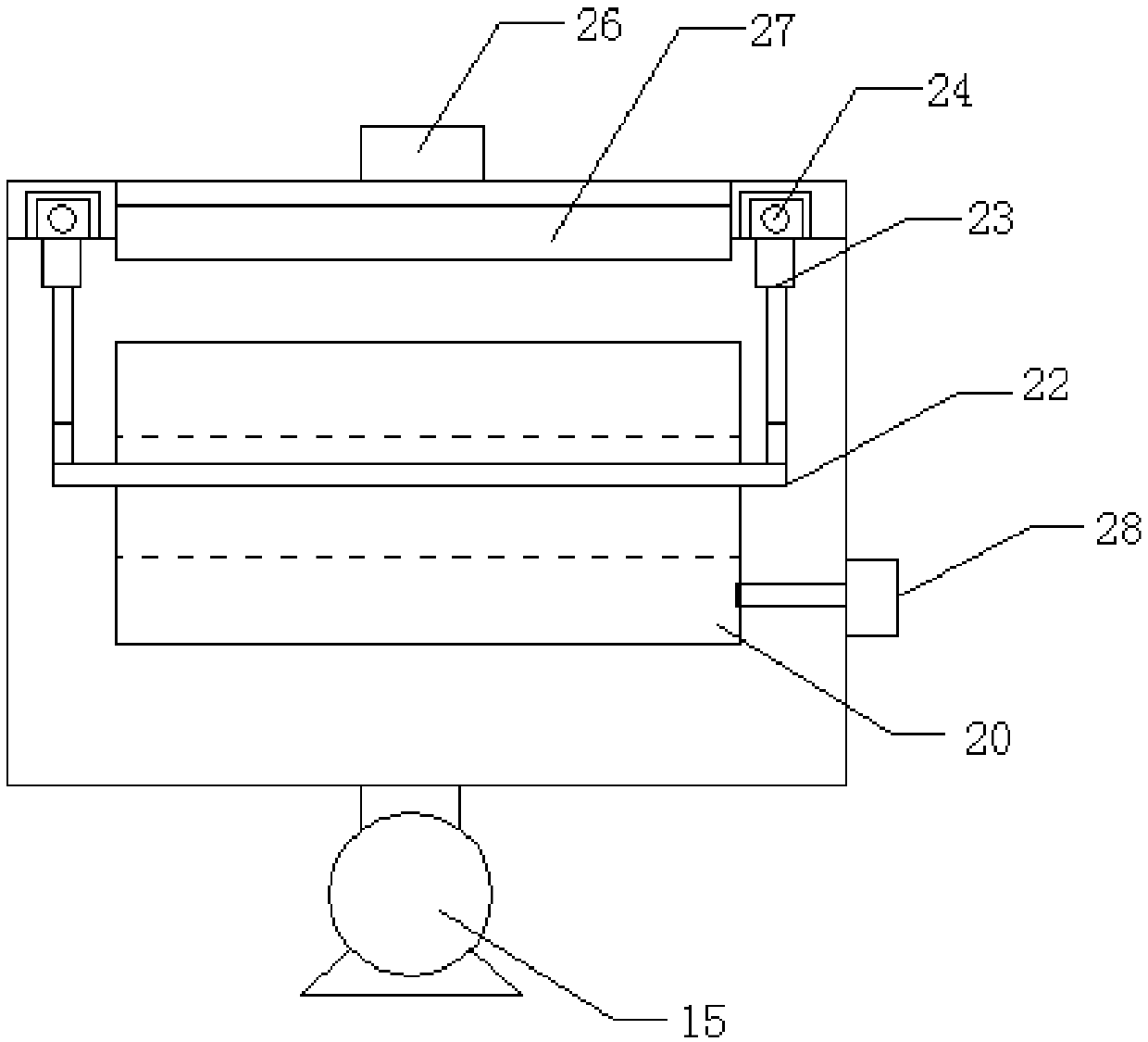

ActiveCN108018663AWrinkle freeImprove drying efficiencyLiquid/gas/vapor removalTextile treatment carriersWire meshElectric heating

The invention provides a rapid drying processing device for clothes processing. The device comprises a primary drying box and a secondary drying box which are arranged on left and right sides and communicated with each other, a horizontal conveyer belt is horizontally arranged in the first drying box, the horizontal conveyer belt is driven by a first conveying roller, and the upper portion of theprimary drying box is provided with an electric heating wire mesh; the secondary drying box is provided with an inclined conveyer belt for receiving fabrics on the horizontal conveyer belt, the inclined conveyer belt is arranged obliquely upwards, the inclined conveyer belt is driven by a second conveying roller, and the upper portion of the secondary drying box is provided with a plurality of hangers. According to the rapid drying processing device for clothes processing, drying is conducted twice, dyed fabrics are put in the primary drying box and the secondary drying box successively, drying efficiency is greatly improved, and meanwhile the fabrics are flat and wrinkle-free with no need to iron after the fabrics pass through the secondary drying box, thereby simplifying process steps and further improving working efficiency.

Owner:池州市金能供热有限公司

Easy-care fabric capable of meeting special needs and easy to dry

InactiveCN106245189AReasonable structureEasy to useLayered productsClothingsSpecial needsBiochemical engineering

The invention relates to easy-care fabric capable of meeting special needs and easy to dry. The easy-care fabric comprises a base layer (1), wherein a quick drying layer (2) is arranged on the outer side of the base layer. A lining fabric layer is arranged on the back of the base layer, warp yarn and weft yarn of the lining fabric layer adopt cotton fibers and tussah silk fibers respectively, wherein the diameter of the cotton fibers is 16.3 mu m, the fineness of the cotton fibers is 278 dtex, the diameter of the tussah silk fibers is 13.9 mu m, the fineness of the tussah silk fibers is 263 dtex, the warp density is 35.1 pieces / cm, and the weft density is 18.3 pieces / cm. The fabric can be rapidly dewatered, is naturally straight after being wetted with water, is not required to be ironed and is stiff and smooth, and the inner layer is comfortable and dry.

Owner:JIANGSU HAIPENG SPECIAL VEHICLES

Easy-to-dry non-ironing fabric having good tear resistance strength

InactiveCN106142718ADehydration fastNo ironing requiredSynthetic resin layered productsClothingsTear resistanceEngineering

The invention relates to an easy-drying and non-ironing fabric with better tear strength, which comprises a base layer (1), and a quick-drying layer (2) is arranged outside the base layer. The back of the base layer is provided with a lining fabric layer, the lining fabric layer is a composite fabric, which includes: a first fabric layer and a first film layer, the first fabric layer has a first surface 1. A second surface and a plurality of pores, the pores are distributed in the first fabric layer and communicate with the first surface and the second surface; the first film layer has a third surface and a fourth surface, The fourth surface of the first film layer is against the first surface of the first fabric layer and partially penetrates into the pores of the first fabric layer. The present invention can dehydrate quickly, straighten naturally after passing through the water without ironing, the fabric is crisp, and the inner layer is comfortable.

Owner:JIANGYIN CHENGXIN SPECIAL PRINTING

Easy-drying non-iron fabric allowing wider applicable range of nanosilver health fiber

InactiveCN106142736ADehydration fastNo ironing requiredWarp knittingSynthetic resin layered productsEngineeringWool

The invention relates to easy-drying non-iron fabric allowing wider applicable range of nanosilver health fiber, comprising a base layer (1) and a quick-drying layer (2) arranged outside the base layer (1). The back of the base layer is provided with a lining fabric layer, the lining fabric layer is warp-knitted fabric, the warp-knitted fabric is composed of yarns and filaments wrapping the yarns in a spiral form, the yarns include a core yarn, the core yarn is a blended yarn of nanosilver health fiber or nanosilver health fiber and other fibers, and the other fibers are cotton, linen, wool, polyester, nylon or spandex, and the filaments are of polyester or nylon. The easy-drying non-iron fabric dries fast, is naturally stiff after being wetted, is free of ironing and stiff and smooth, and has a comfortable lining.

Owner:JIANGYIN DUJUAN BEADED

Easy-dry wash-and-wear fabric for packaging and decoration

InactiveCN106273725ADehydration fastNo ironing requiredSynthetic resin layered productsClothingsEngineeringHot-melt adhesive

The invention relates to an easy-dry wash-and-wear fabric for packaging and decoration. The fabric comprises a base layer (1), wherein a quick-dry layer (2) is arranged outside the base layer; a lining fabric layer is arranged on the back of the base layer and comprises a plastic base, a separation layer and an adhesive layer, which are superposed in sequence; a fabric layer and an aluminium foil layer are arranged between the separation layer and the adhesive layer in sequence; the adhesive layer is formed by a hot melt adhesive; the fabric layer is formed by a textile fabric. The fabric can be quickly dehydrated, becomes straight naturally and dispenses with ironing after being washed with water, is stiff and smooth and has a comfortable inner layer.

Owner:JIANGYIN DONGFA GARMENT MAKING

Permanent-press fabric easy to dry with reasonable structure and high usability

InactiveCN106167936AReasonable structureEasy to useLayered productsWoven fabricsFiberPolymer science

The invention relates to a permanent-press fabric easy to dry with a reasonable structure and high usability. The fabric comprises a base layer (1), wherein a quick-dry layer (2) is arranged on the outer side of the base layer, a lining fabric layer is arranged on the back side of the base layer, casein fiber with a diameter of 18.62 microns and fineness of 252 dtex serve as warps of the lining fabric layer, viscose with a diameter of 8.29 microns and fineness of 198 dtex serves as wefts of the lining fabric layer, warp density is 25.9 pieces per centime, weft density is 16.3 pieces per centimeter, and a reinforced twill weave structure is adopted. The fabric can be dewatered quickly and becomes flat naturally after being rinsed in water, ironing is not needed, the fabric is stiff and smooth, and an inner layer feels comfortable.

Owner:JIANGYIN NEW QUANSHENG TEXTILE PRINTING & DYEING

Passive luminescent easy-care shell fabric easy to dry

InactiveCN107685488ADehydration fastNo ironing requiredLayered productsWoven fabricsLight guideEngineering

The invention relates to a passive luminescent easy-care shell fabric easy to dry which comprises a base layer (1), wherein a quick-dry layer (2) is arranged on the outer side of the base layer, and alining fabric layer is arranged on the back side of the base layer. The lining fabric layer comprises a plurality of first light reflecting units, a plurality of light guiding units and a plurality of light storing units, wherein the first light reflecting units are arranged at intervals in the first direction, and the light guiding units are arranged at intervals in the second direction different from the first direction. The passive luminescent easy-care shell fabric disclosed by the invention can be quickly dewatered, can be natural, straight and upright after being rinsed, is free of ironing, is stiff and smooth and has a comfortable and cool inner layer.

Owner:黄磊

Easily-dried non-ironing shell fabric capable of multiplying siphon effect of sweat in inner layer

InactiveCN106183062AIncreased total surface areaImprove water absorptionSynthetic resin layered productsClothingsYarnEngineering

The invention relates to an easily-dried non-ironing shell fabric capable of multiplying a siphon effect of sweat in an inner layer. The shell fabric comprises a base layer (1), wherein a quick-drying layer (2) is arranged on the outer side of the base layer; a lining fabric is arranged on the back of the base layer and is a double-layer fabric formed by interweaving an inner layer and an outer layer, and the inner layer is woven from polypropylene fiber with a hydrophobic property; and the outer layer is woven from abnormal-shaped fracture surface yarns with a hydrophilic property. The shell fabric can be rapidly dehydrated, is naturally straight and upright after rinsing, does not need to be ironed and is stiff and smooth, and the inner layer is comfortable.

Owner:JIANGYIN GUORUN TEXTILE RAW MATERIALS SALES

Fast-drying non-ironing plus material with low washing deformation rate

InactiveCN106142738AReduce processLow yarn lossSynthetic resin layered productsClothingsYarnEngineering

The invention relates to a fast-drying non-ironing plus material with a low washing deformation rate. The fast-drying non-ironing plus material comprises a basic layer (1), wherein a fast-drying layer (2) is arranged at the outer side of the basic layer; the back surface of the basic layer is provided with a liner fabric layer, the liner fabric layer is a color cross-striped fabric and comprises at least two cross-striped patterns, each cross-striped pattern is identical in color but different in brightness, each cross-striped pattern is respectively formed by weaving different materials, and the cross-striped patterns are arranged at intervals along respective width direction and connected together by virtue of crocheting. The natural-color yarns of different materials are woven to form the cross-striped patterns, and the cross-striped patterns are crotched. The fast-drying non-ironing plus material can be rapidly dewatered, is naturally straight and upright after being washed and free from ironing, the surface material is smooth and stiff, and the inner layer is comfortable.

Owner:JIANGYIN HONGWEI QINGSHAN SPINNING

Quick-dry and non-ironing fabric for preventing displacement of fabric threads and carbon fiber threads

InactiveCN106240075AAvoid displacementImprove securitySynthetic resin layered productsClothingsFiberEngineering

The invention relates to quick-dry and non-ironing fabric for preventing the displacement of fabric threads and carbon fiber threads. The fabric comprises a base layer (1), and a quick-dry layer (2) is arranged on the outer side of the base layer. A lining fabric layer is arranged on the back of the base layer; the lining fabric layer comprises fabric threads, a plurality of carbon fiber threads and conductors; the fabric threads, the carbon fiber threads and the conductors form a fabric layer through weaving; the carbon fiber threads are electrically connected with the conductors; the fabric further comprises insulating layers at least arranged on the two sides of the fabric layer, and edge sealing components for clamping the insulating layers. The fabric can rapidly remove water, is natural and straight after being rinsed, does not need ironing, and is stiff and smooth, and is comfortable in an inner layer.

Owner:JIANGYIN HONGWU TEXTILE CO LTD

Easy-care shell fabric easy to dry and with mutually intermeshed unit coils

InactiveCN107685505ADense metal networkGood flexibilityWeft knittingMetal layered productsEngineeringStainless steel fiber

The invention relates to an easy-drying and non-ironing fabric with interlocking unit coils, which comprises a base layer (1), and a quick-drying layer (2) is arranged outside the base layer. A lining fabric layer is arranged on the back of the base layer, and the lining fabric layer is a kind of knitted fabric formed by interlacing continuous unit coils, and the continuous unit coils are made of stainless steel fibers. The present invention can dehydrate quickly, straighten naturally after passing through the water without ironing, the fabric is crisp, and the inner layer is comfortable.

Owner:JIANGYIN HAOZHOU TEXTILE CO LTD

Evaporation heat loss prevention easy-drying easy-care fabric

InactiveCN106218112AReduce discharge efficiencyImprove insulation effectSynthetic resin layered productsWoven fabricsPolyesterEvaporation

The invention relates to an evaporation heat loss prevention easy-drying easy-care fabric which comprises a base layer (1), and a quick-drying layer (2) is arranged on the outer side of the base layer. A lining fabric layer is disposed on the back side of the base layer, is a compound fabric and is composed of a lining, a barrier layer and a fabric layer which cannot be wetted by water easily. The barrier layer is made from one of polyethylene, nylon, polyester, ethyl carbamate and polytetrafluoroethylene. The fabric can be quickly dewatered, is natural and straight after being washed with water and does not need to be ironed, the fabric is stiff and smooth, and the inner layer is comfortable and cool.

Owner:JIANGYIN HULIAN DYEING & FINISHING

Fluffy conductive easy-care fabric easy to dry

InactiveCN106273844ASuitable for meeting conductivity needsMeet conductivity needsSynthetic resin layered productsClothingsCompound (substance)Engineering

The invention relates to fluffy conductive easy-care fabric easy to dry. The fluffy conductive easy-care fabric comprises a base layer (1). A quick-dry layer (2) is arranged on the outer side of the base layer. A lining fabric layer is arranged at the back of the base layer. The lining fabric layer is fluffy conductive fabric and contains conductive polyaniline polymer provided by the in-situ chemical polymerization of aniline and oxidant ammonium peroxydisulfate in an acid medium. The fluffy conductive easy-care fabric has the advantages that fast dewatering can be achieved, the fabric is naturally stiff and smooth after washing, ironing is not needed, stiffness and smoothness are achieved, and the inner layer of the fabric is comfortable.

Owner:JIANGYIN BEIYE TEXTILE

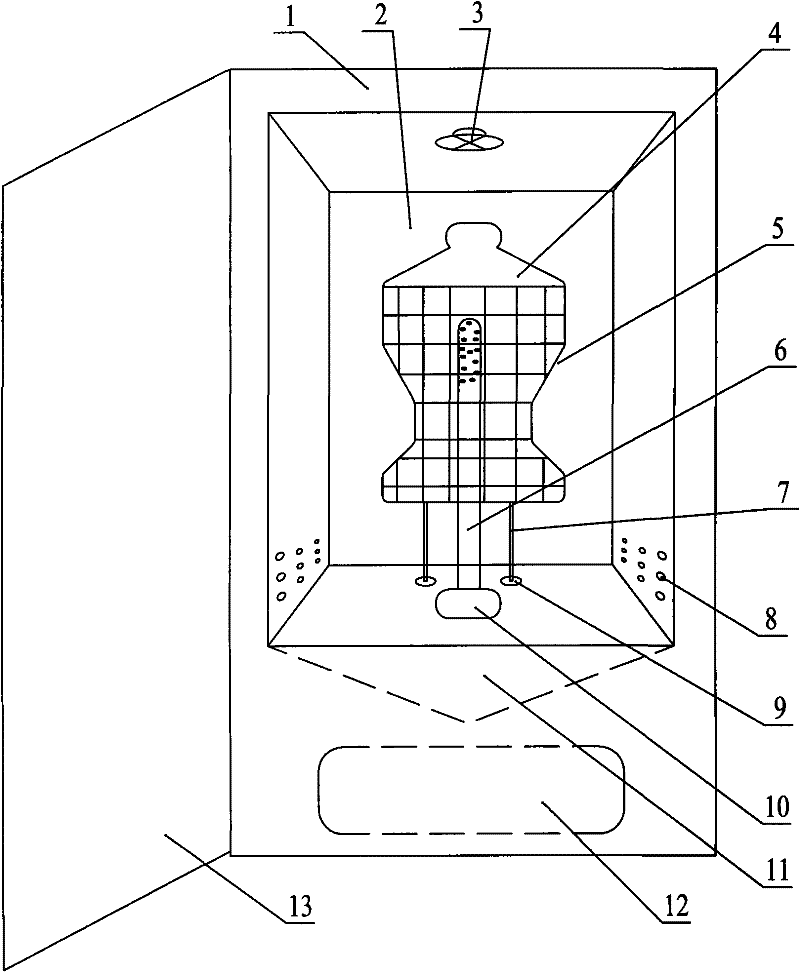

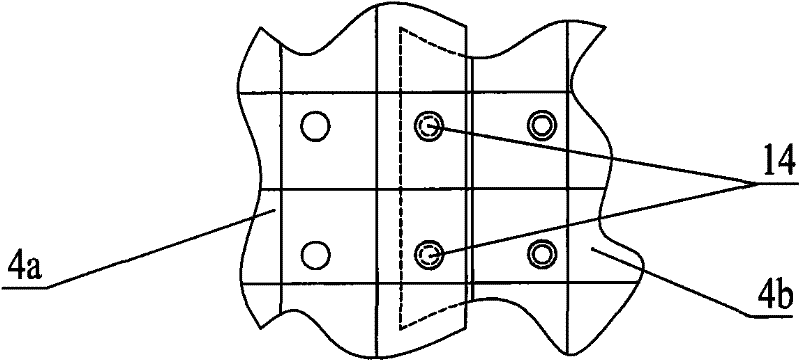

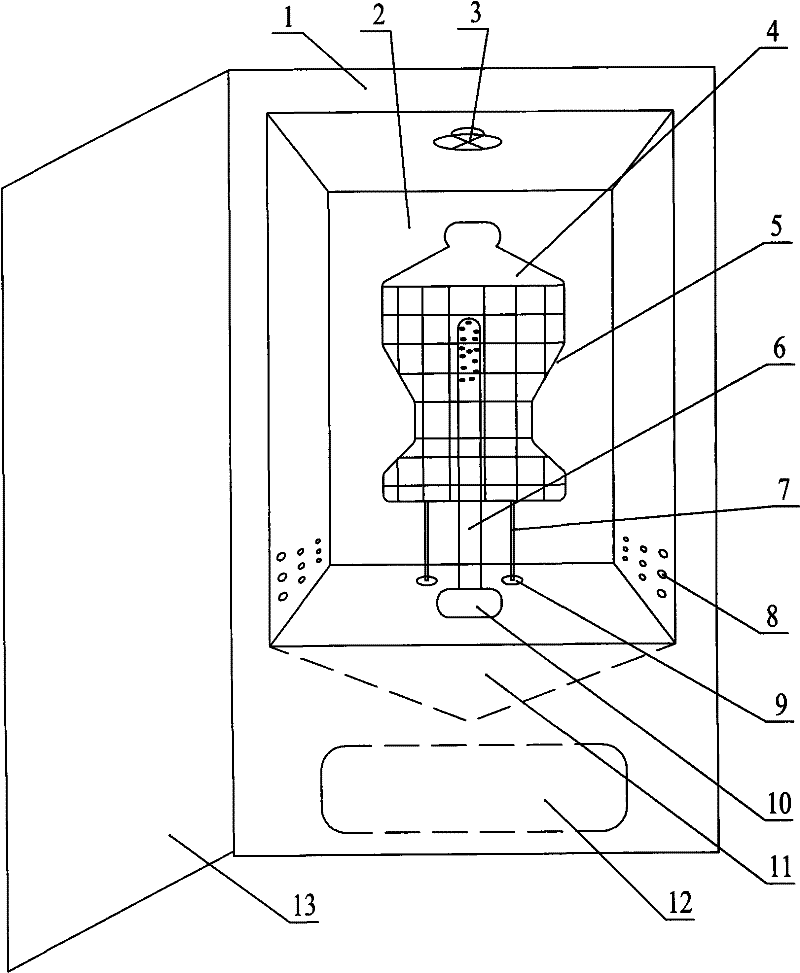

Steam washing machine with three-dimensional gridding clothing die

InactiveCN101838918BIngenious and reasonable structureImprove washabilityOther washing machinesTextiles and paperEngineeringAutomation

Owner:丁晔

Steam washing machine with hanging-type clothes hanger

InactiveCN101838899BIngenious and reasonable structureImprove washabilityOther washing machinesWashing machine with receptaclesEngineeringClothes hanger

The invention relates to a steam washing machine with a hanging-type clothes hanger. According to the technical scheme provided by the invention, the steam washing machine with the hanging-type clothes hanger comprises a box body, wherein a steam generator is arranged in the bottom of the box body, a washing room used for accommodating clothes is arranged in the box body, and outer jet holes are arranged on the wall of the washing room, communicated with the steam generator and used for spraying steam into the box body. The steam washing machine is characterized in that a hanging rod is arranged at the upper part of the washing room, and at least one clothes hanger is arranged on the hanging rod; at least one jet cylinder with hollow interior is vertically arranged at the bottom of the washing room, the jet cylinders are arranged under the clothes hangers and are in one-to-one correspondence with the clothes hangers, the lower ends of the jet cylinders are communicated with the steam generator, and inner jet holes are densely distributed all over the body of the upper part of the steam spray cylinder. The invention has smart and reasonable structure, high automation degree and favorable washing effect and can realize soft washing and reduce the wear damage to clothes by a large extent.

Owner:丁晔

Non-ironing clothes dryer

InactiveCN102168360BWrinkle freeShorten drying timeOther drying apparatusTextiles and paperWrinkle skinBiochemical engineering

Owner:ZHONGSHAN MESTER IND

Shell fabric capable of permanently emitting plenty of negative ions, easy to dry and free from ironing

The invention relates to an easy-drying and non-ironing fabric that permanently emits a large amount of negative ions, comprising a base layer (1), and a quick-drying layer (2) is arranged outside the base layer. The back side of the base layer is provided with a lining fabric layer, and the lining fabric layer is a kind of negative ion fabric, which includes general yarns, elastic yarns and negative ion yarns interwoven through double-sided weaving; the general yarn weaving 2% of the elastic yarn replaces part of the common yarn in the weaving arrangement, and the negative ion yarn is woven on the inner surface and the component content is less than 48%. The present invention can dehydrate quickly, straighten naturally after passing through the water without ironing, the fabric is crisp, and the inner layer is comfortable.

Owner:JIANGYIN HANXIN TEXTILE

Non-ironingspotjacquard fabric easy to dry

InactiveCN106273940AEnhance the sense of widthSuitable for different needsSynthetic resin layered productsSwivel-woven fabricsYarnEngineering

The invention relates to a non-ironingspotjacquard fabric easy to dry. The non-ironingspotjacquard fabric comprises a basic layer (1), wherein a rapid drying layer (2) is arranged on the outer side of the basic layer. A lining fabric layer is arranged on the back side of the basic layer and is a spotjacquard fabric with jacquards on the front side and back side, convex points are uniformly distributed on the front side of the spotjacquard fabric and are formed on a base fabric by adopting first yarns, the back side of the spotjacquard fabric is provided with vertical stripes formed on the back side of the base fabric through second yarns, and adjacent stripes are parallel. The non-ironingspotjacquard fabric can be rapidly dehydrated, is natural, straight and upright after being washed, is not needed to be ironed, is stiff and smooth and has a comfortable inner layer.

Owner:JIANGYIN SHANGFENG TEXTILE

Entire-easy-to-dry ironing-free fabric with marker units printed

InactiveCN106240064ADehydration fastNo ironing requiredSynthetic resin layered productsClothingsInformation layerHigh stiffness

The invention relates to an entire-easy-to-dry ironing-free fabric with marker units printed. The fabric includes a basic layer (1), and a quick-dry layer (2) arranged on the outer side thereof. A lining fabric layer is formed on the back of the basic layer and is a porous fabric which includes a basic material made of the porous fabric. The porous fabric also includes a bottom layer and an information layer, wherein the bottom layer is directly formed on the basic material and the information layer is arranged on the bottom layer and comprises machine-recognizable patterns. The machine-recognizable patterns are formed by arranging a plurality of marker units. The bottom layer is a compact film, wherein the pore diameter of the bottom layer is less than the size of the marker units. The fabric can be quickly dried, and has a naturally stiff sense after being wetted without necessity of ironing. The fabric has high stiffness and has a comfortable inner layer.

Owner:江苏红柳床单有限公司

Easy-dry and easy-care fabric with excellent memorability

The invention relates to easy-dry and easy-care fabric with excellent memorability. The fabric comprises a basic layer (1), and a quick-dry layer (2) is arranged at the outer side of the basic layer (1). A lining fabric layer is arranged on the back face of the basic layer and comprises two mesh surface layers distributed in parallel and an elastic material layer arranged between the two mesh surface layers, multiple through holes are distributed in each mesh surface layer, the elastic material layer is formed by any one or more of multiple sets of vertical linear filiform elastic material distributed in a dispersed mode, multiple sets of vertical elastic X-type cross structures and multiple sets of vertical U-shaped elastic rings, wherein each annular elastic ring is formed by curling a filiform elastic material. The easy-dry and easy-care fabric can drain water fast, naturally straightens after rinsing, does not need to be ironed and is stiff and smooth, and the inner layer is comfortable and cool.

Owner:JIANGYIN FANRONG YARN DYE FABRIC

Decorative and practical easy-to-dry easy-care fabric

The invention relates to a decorative and practical easy-to-dry easy-care fabric. The fabric comprises a basic layer (1), and a quick-dry layer (2) is arranged on the outer side of the basic layer. The back surface of the basic layer is provided with a lining fabric layer which is a Kesi fabric, the Kesi fabric comprises a plurality of warps in parallel and a plurality of continuous and / or non-continuous wefts, and a plurality of locally naturally hollowed-out patterns formed by interweaving of the warps and the warps are distributed on the surface of the fabric. The decorative and practical easy-to-dry easy-care fabric has advantages of quickness in dewatering, natural straightness after rinsing, freeness of ironing, stiffness and smoothness of the fabric and coziness of the inner layer.

Owner:JIANGYIN BETTER TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com