Matrix material of baking-free bricks and preparation method of baking-free bricks

A base material and unburned brick technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of waste of natural mineral resources, insufficient curing strength, waste of resources, etc., to save clay Natural resources, good curing effect, no fuel consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

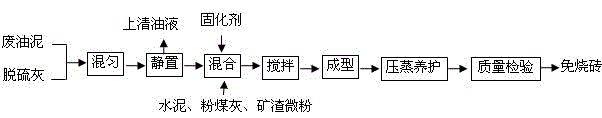

Method used

Image

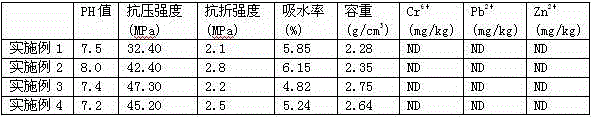

Examples

Embodiment 1

[0041] The matrix material composition of unburned bricks:

[0042] Waste oil sludge: Metal slab rolling often adopts lubricating oil filtration circulation system with automatic backwash function. During the reciprocating rolling, filtering, backwashing, and sedimentation process, lubricating oil is subjected to multiple effects such as temperature, pressure, air, dust, and metal contact, and gradually oxidizes and deteriorates until it forms rolling sludge that cannot be used any longer. After a period of natural settlement of the rolling sludge, a small part of the supernatant is recovered and blended for use, most of the bottom sludge (waste sludge) has high solid phase content (15%), carbon black, colloid, asphalt, metal and other impurities More, solid-liquid two-phase highly emulsified, poor settling, take out a suitable amount as the processing object of this embodiment.

[0043] Desulfurization ash: Desulfurization ash is obtained from the circulating fluidized bed d...

Embodiment 2

[0051] The matrix material composition of unburned bricks:

[0052] Waste sludge: The absorption tower of the wet flue gas desulfurization device needs to be equipped with an agitator system, and the gear box that drives the agitator generally uses high-grade synthetic lubricating oil. After half a year of use, lubricating oil gradually oxidizes and deteriorates to become waste oil. After the waste oil is taken out from the gearbox, it is flocculated and settled, and the supernatant can be mixed and reused. Most of the bottom sludge (waste sludge) is due to the high solid content ( 5%), there are many impurities such as carbon black, colloid, asphalt, metal, etc., the solid-liquid two-phase is highly emulsified, and the settling property is poor, so it cannot be effectively used. Now take out an appropriate amount as the processing object of this embodiment.

[0053] Desulfurization ash: Desulfurization ash is obtained from the rotary spray semi-dry desulfurization process, i...

Embodiment 3

[0061] The matrix material composition of unburned bricks:

[0062] Waste oil sludge: After one year of use, the lubricating oil for transformers gradually oxidizes and deteriorates, becoming waste oil. After the waste oil is taken out, it is centrifuged and the supernatant can be mixed and reused. The content is high (15%), there are many impurities such as carbon black, colloid, asphalt, metal, etc., the solid-liquid two-phase is highly emulsified, and the settling property is poor, so it cannot be effectively used. Now take out an appropriate amount as the processing object of this embodiment.

[0063] Desulfurization ash: Desulfurization ash is obtained from the new integrated (NID) semi-dry desulfurization process, in which CaSO 4 ·H 2 O mass fraction is 32.5%, CaSO 3 1 / 2H 2O mass fraction is 31.0%, f-CaO mass fraction is 14.3%, Ca(OH) 2 The mass fraction is 9.5%, SiO 2 The mass fraction is 8.2%, Al 2 o 3 Mass fraction is 1.5%, MgO mass fraction is 1.6%, Fe 2 o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com