Vegetable oil-based concrete mold-release agent and preparation method thereof

A concrete release agent, vegetable oil-based technology, applied in the direction of additives, petroleum industry, manufacturing tools, etc., can solve the problems of high price of animal oil, waste of food resources, difficult to remove, etc., achieve good stability and lubricating effect, increase hydrophobicity Effect, effect of fermentation efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A kind of preparation method of vegetable oil-based concrete release agent of the present invention comprises the following steps:

[0047] Step 1: Preparation of Laccase

[0048] Insert the low-cost Aspergillus oryzae into the sugar-rich bagasse medium, cultivate it in a fermentation tank at 20±3°C for 20-30 days, then extract the culture solution, concentrate it to 25-30%, and obtain the varnish Enzyme concentrate; sugar-rich bagasse to increase fermentation efficiency.

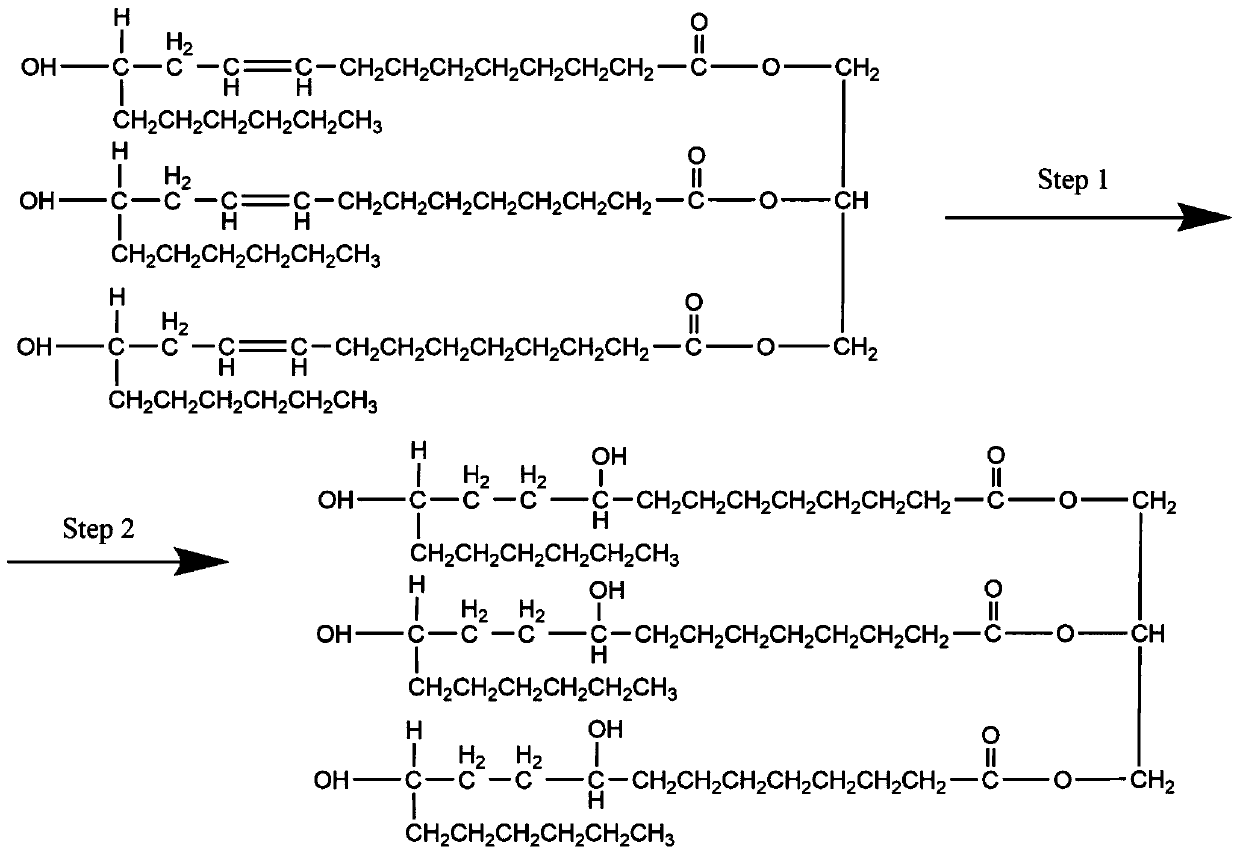

[0049] Step 2: Vegetable Oil Oxidation

[0050] Add the concentrated solution of laccase prepared in step 1 into the vegetable oil and put it into a reaction vessel to catalyze the oxidation of the vegetable oil. Use a blower to blow dust-free air into the vegetable oil and maintain the temperature at 40±5°C for 1.5 to 2.5 hours. And stir, then raise the temperature to 120±10°C, keep it warm for 30min, and then get the oxidized vegetable oil;

[0051] Step 3: Preparation of Modified Vegetable Oil ...

Embodiment 1

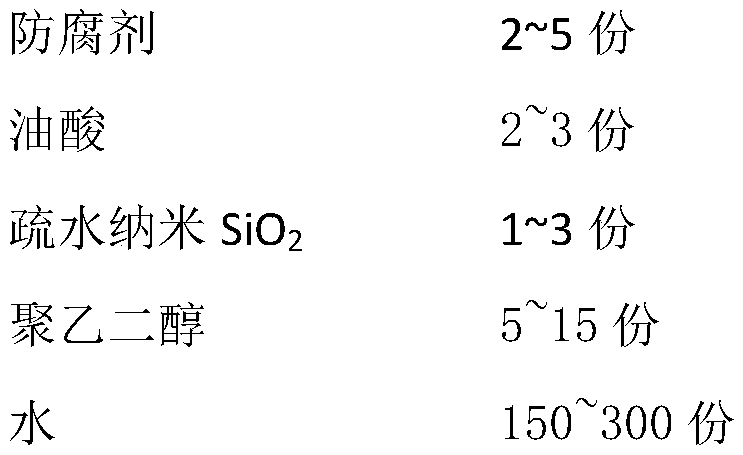

[0066] The raw materials contained in the vegetable oil-based concrete release agent are respectively by weight: 100 parts of castor oil, 200 parts of water, 4 parts of pH regulator, 2 parts of sodium benzoate, 6 parts of polyethylene glycol with a number average molecular weight of 10000, lacquer 3 parts of enzyme concentrate, hydrophobic nano-SiO 2 1 part, 50 parts of aluminum isopropoxide.

[0067] The specific process of making the release agent includes the following six steps:

[0068] Step 1: Preparation of Laccase

[0069] Insert low-cost Aspergillus oryzae into sugar-rich bagasse medium, culture in a fermentation tank at 20°C for 20 days, then extract the culture solution, and concentrate it to a laccase concentrate containing 28% laccase; Sugar-rich bagasse can improve fermentation efficiency.

[0070] Step 2: Vegetable Oil Oxidation

[0071] Add the concentrated solution of laccase prepared in step 1 into castor oil, put it into a reaction kettle, catalyze the o...

Embodiment 2

[0085] The raw materials contained in the vegetable oil-based concrete release agent are respectively by weight: 120 parts of castor oil, 180 parts of water, 6 parts of pH regulator, 3 parts of sodium benzoate, 7 parts of polyethylene glycol with a number average molecular weight of 10000, lacquer 4 parts of enzyme concentrate, hydrophobic nano-SiO 2 1.5 parts, 60 parts of aluminum isopropoxide.

[0086] The specific process of making the release agent includes the following six steps:

[0087] Step 1: Preparation of Laccase

[0088] Insert low-cost Aspergillus oryzae into sugar-rich bagasse medium, culture in a fermentation tank at 20°C for 25 days, then extract the culture medium, and concentrate it to a laccase concentrate containing 30% laccase; Sugar-rich bagasse can improve fermentation efficiency.

[0089] Step 2: Vegetable Oil Oxidation

[0090] Add the concentrated solution of laccase prepared in step 1 into castor oil, put it into a reaction kettle, catalyze the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com