Patents

Literature

45results about How to "Save editing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

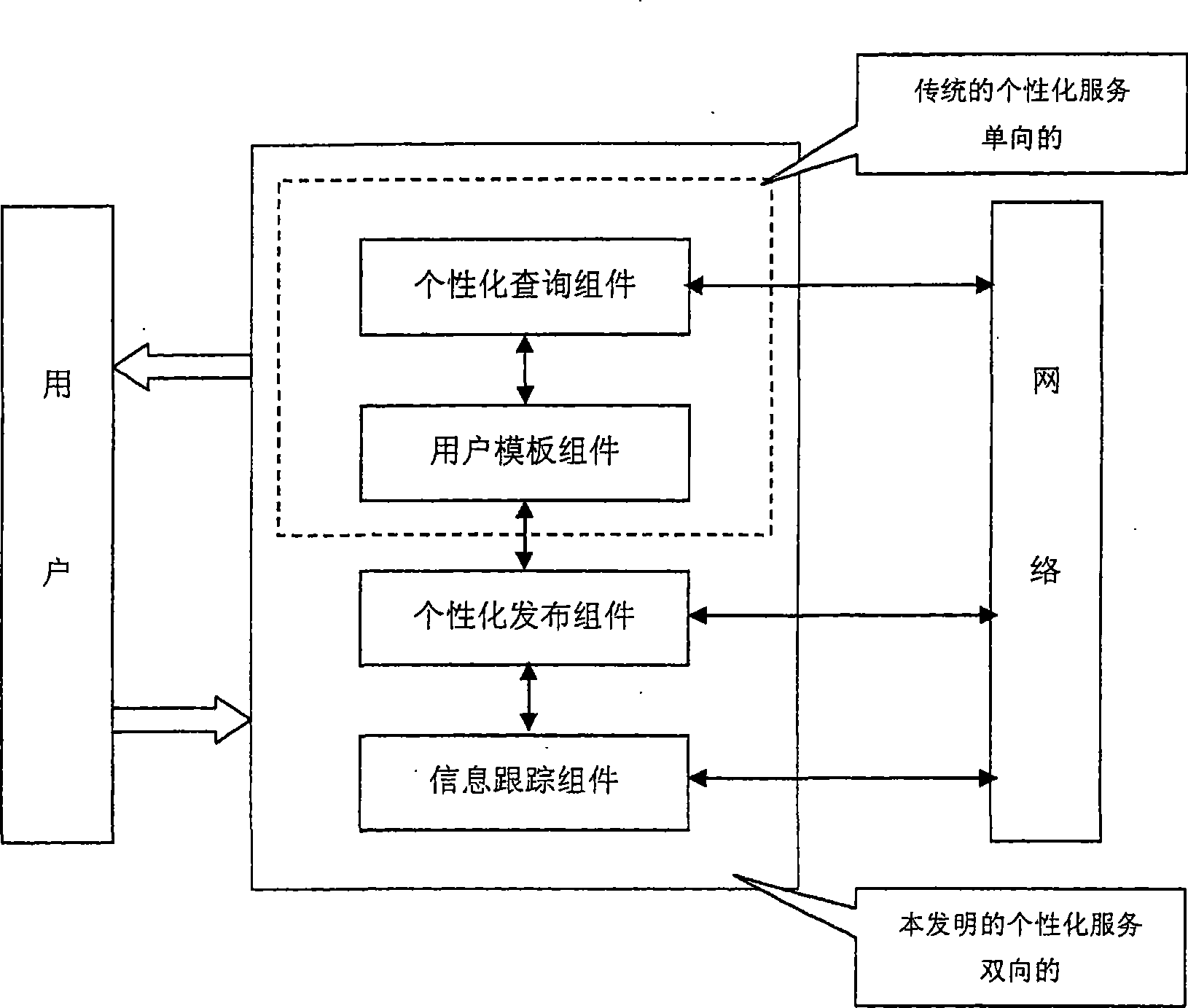

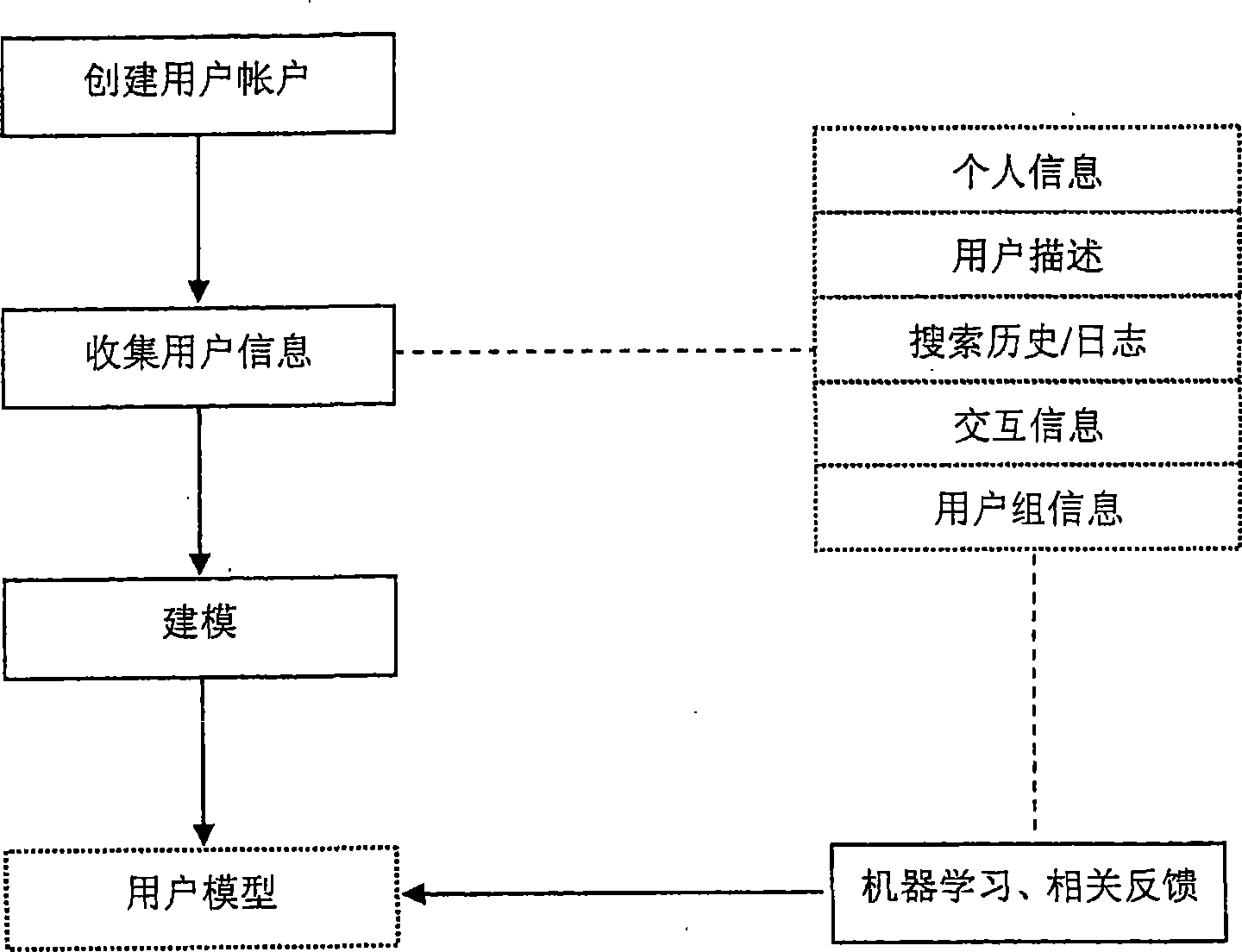

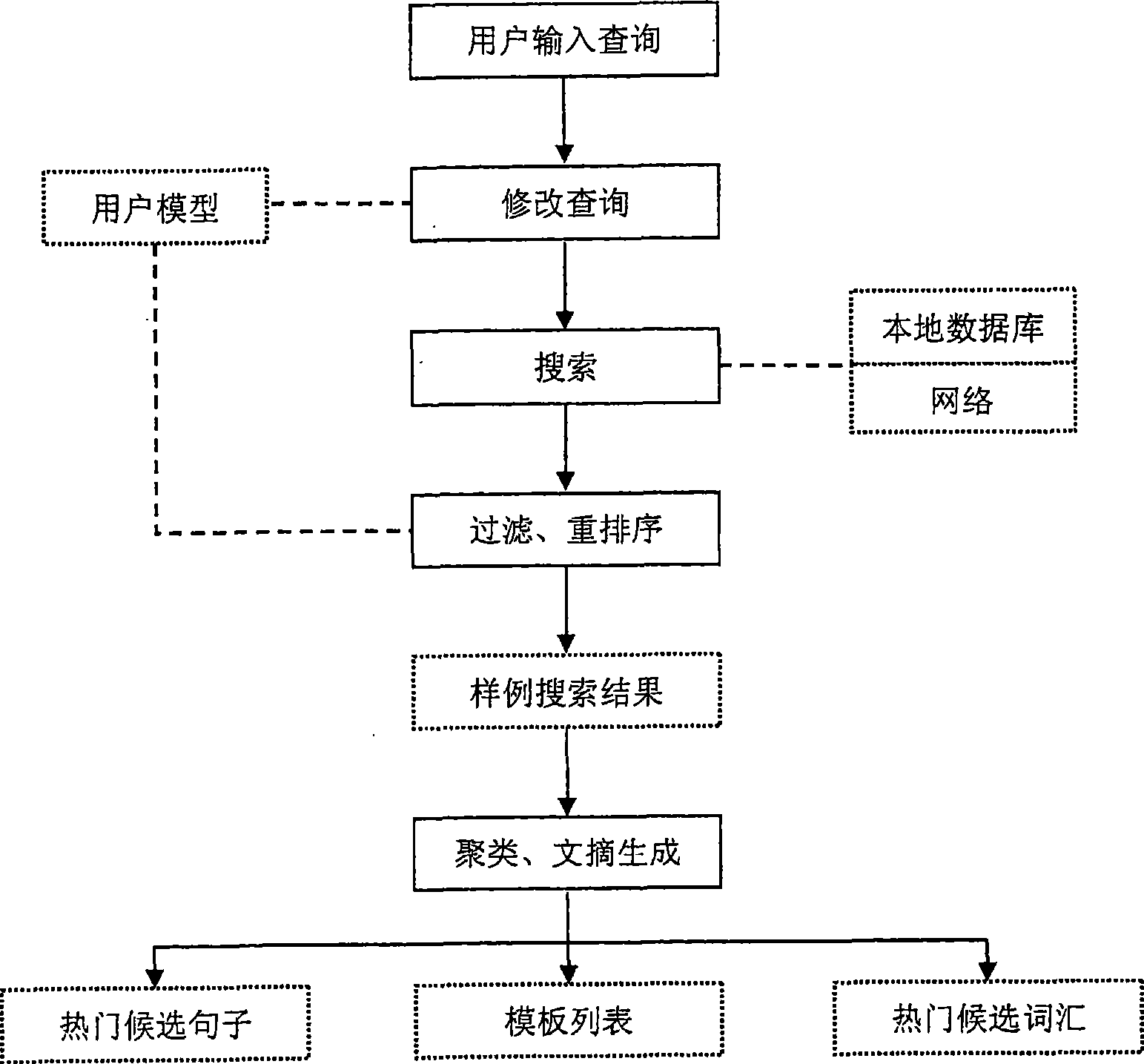

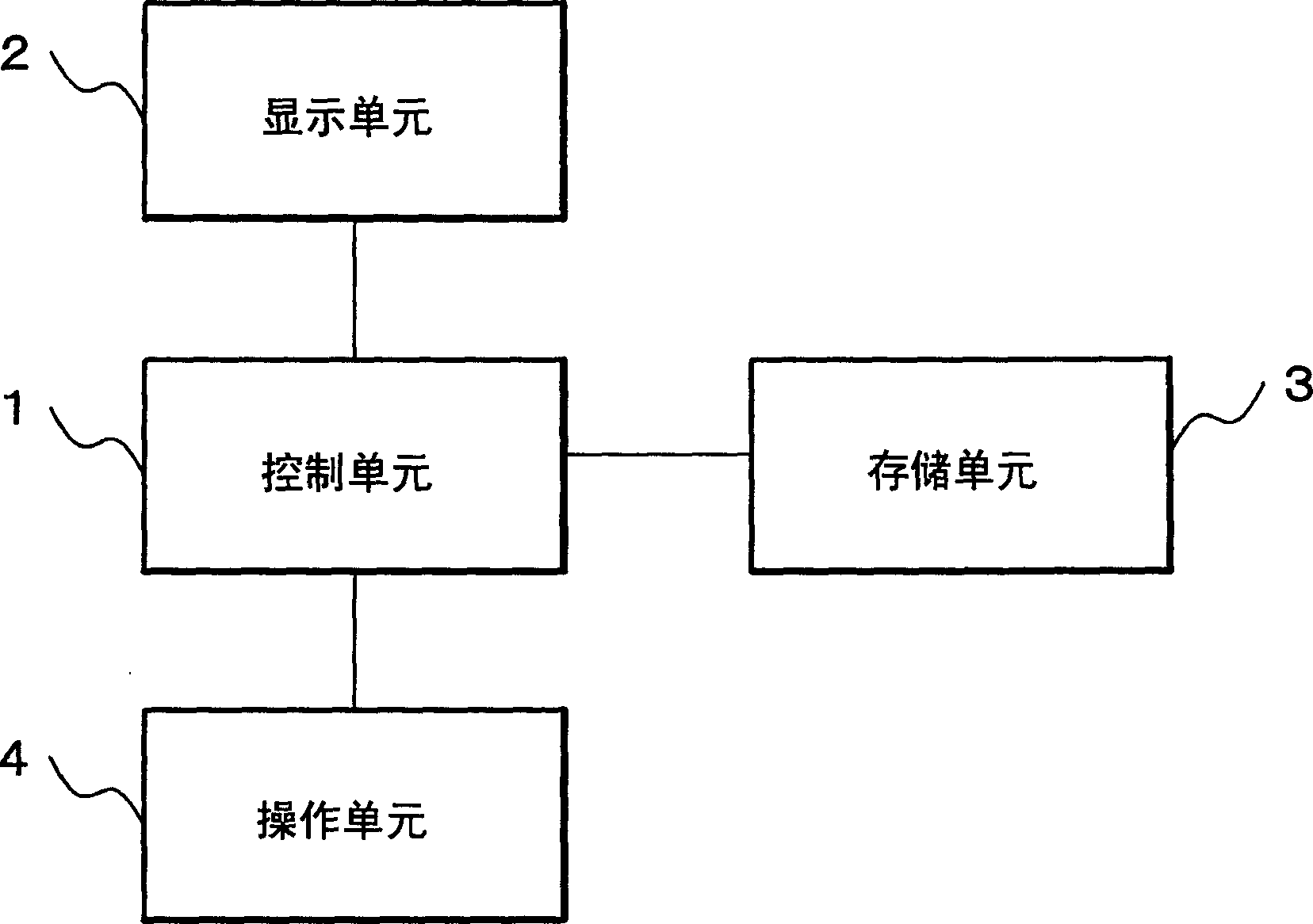

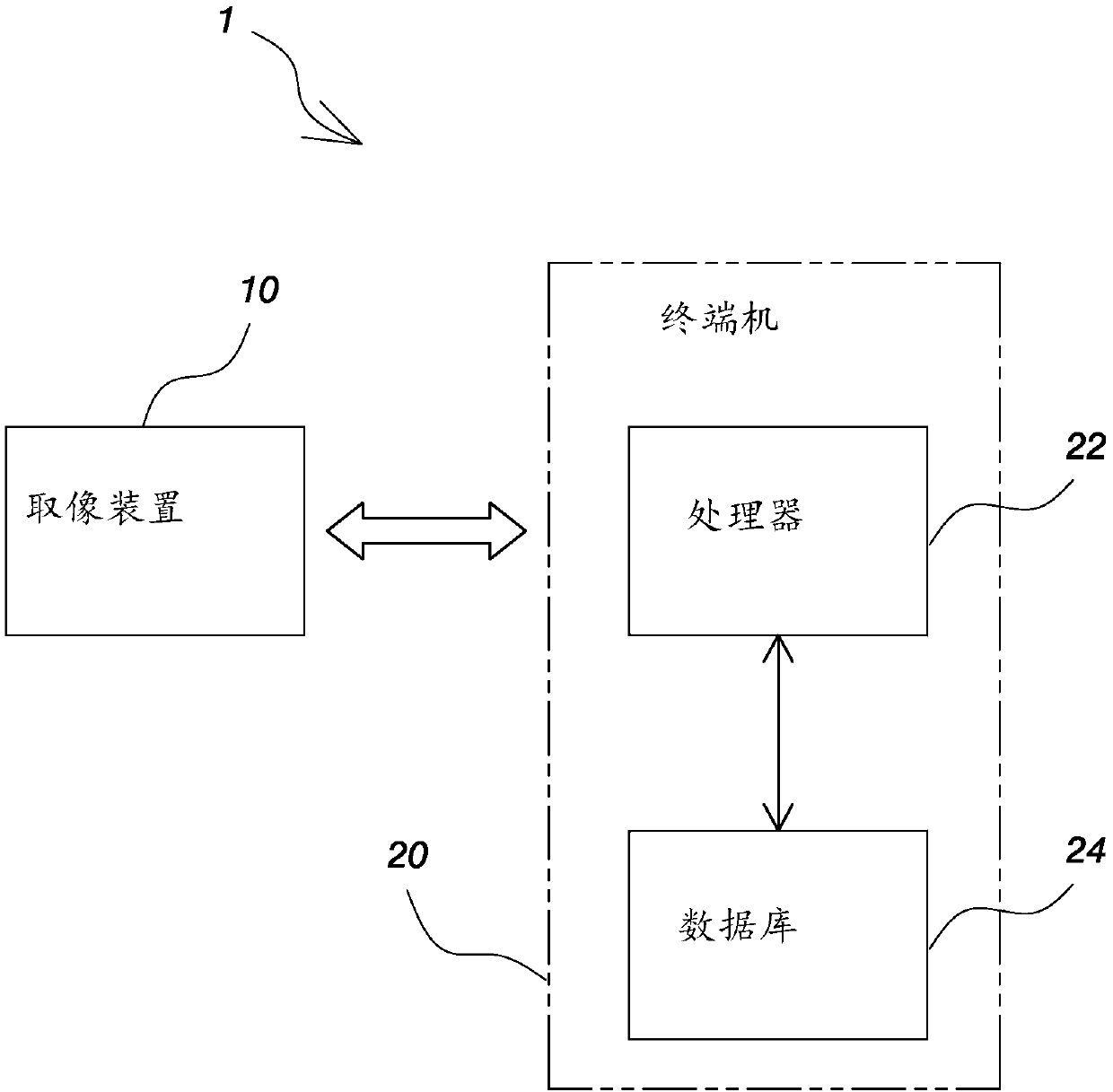

Information issuing system and information issuing method

InactiveCN101520784AReduce creationSave editing timeDigital data information retrievalSpecial data processing applicationsProcess moduleUser input

Owner:FUJITSU LTD

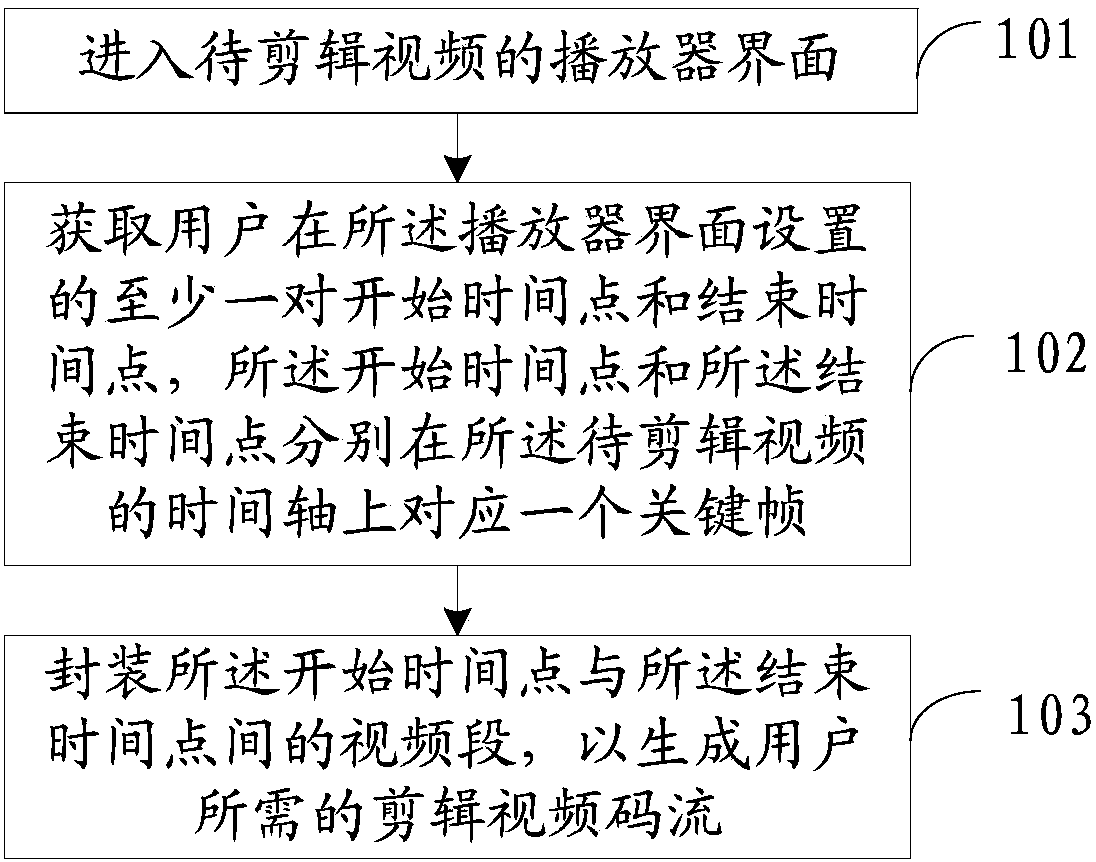

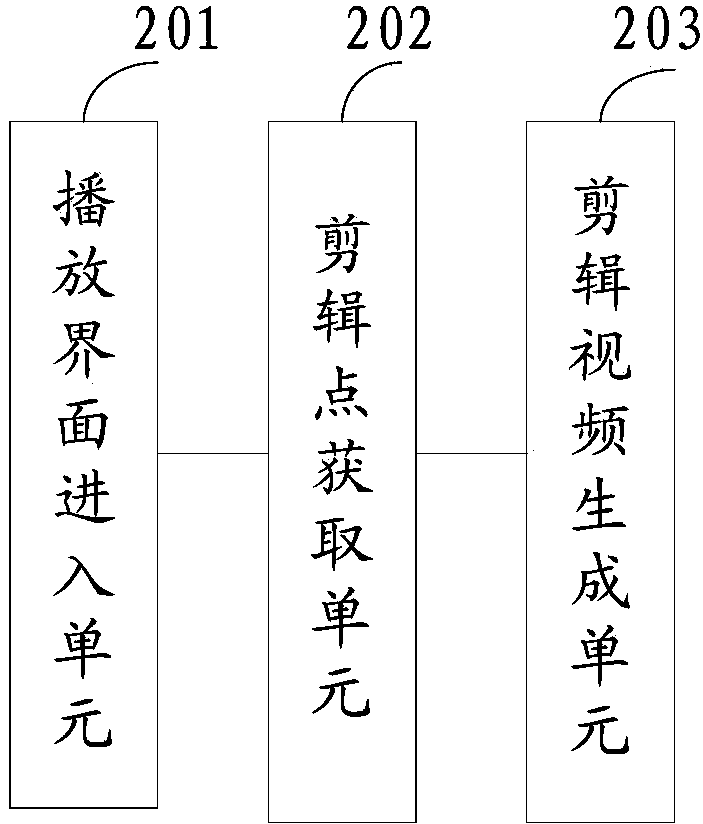

Video editing method and device

InactiveCN104185077ASave editing timeSelective content distributionSpecial data processing applicationsVideo bitstreamStart time

The invention discloses a video editing method. The video editing method comprises the steps of entering a player interface of a video to be edited; obtaining at least one pair of a start time point and an end time point set by a user on the player interface, wherein the start time point and the end time point respectively correspond to a key frame on a time line of the video to be edited; packaging a video segment between the start time point and the end time point to generate an edited video bitstream required by the user. The invention further discloses a video editing device.

Owner:FLYING FOX INFORMATION TECH TIANJIN CO LTD

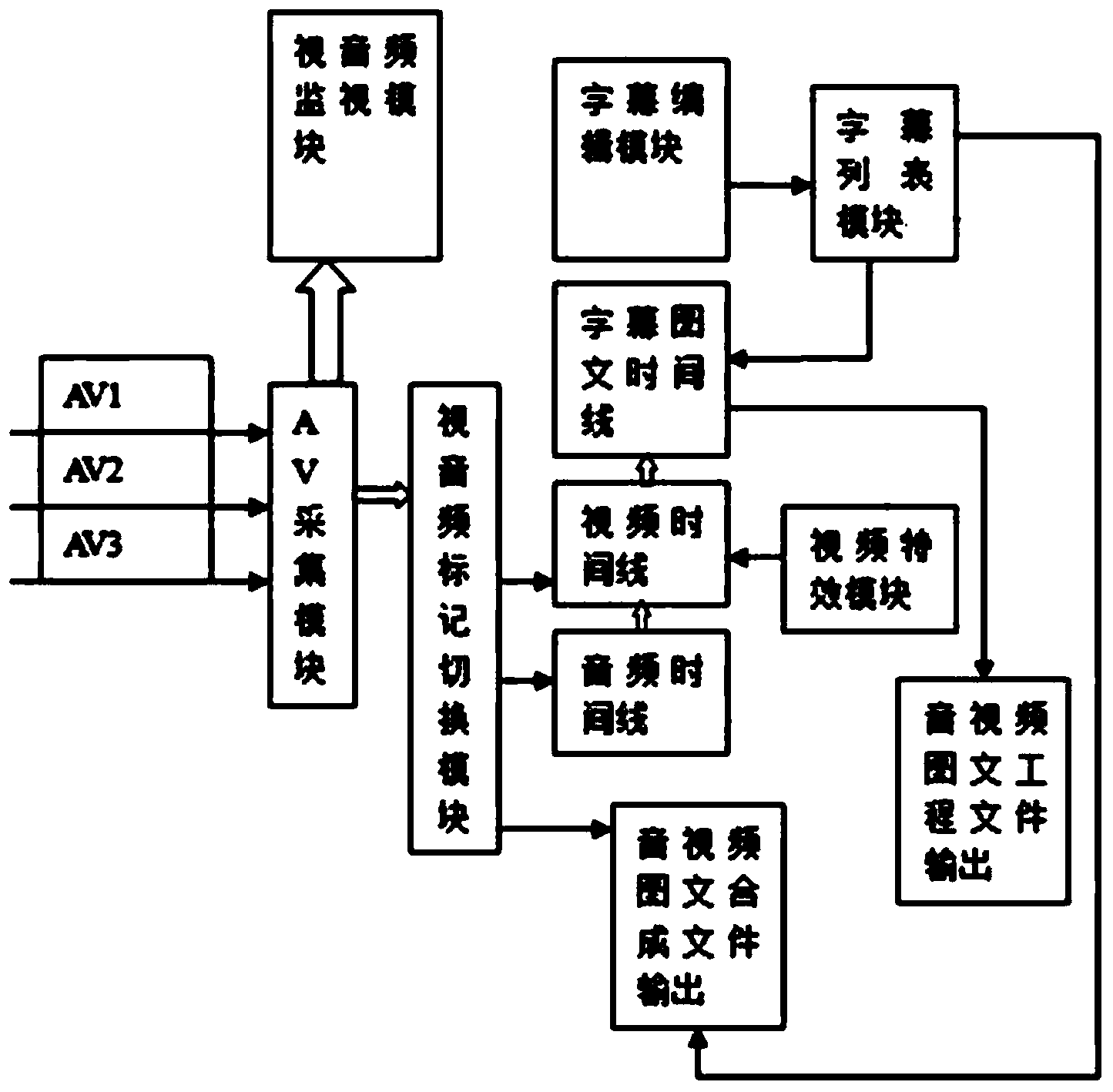

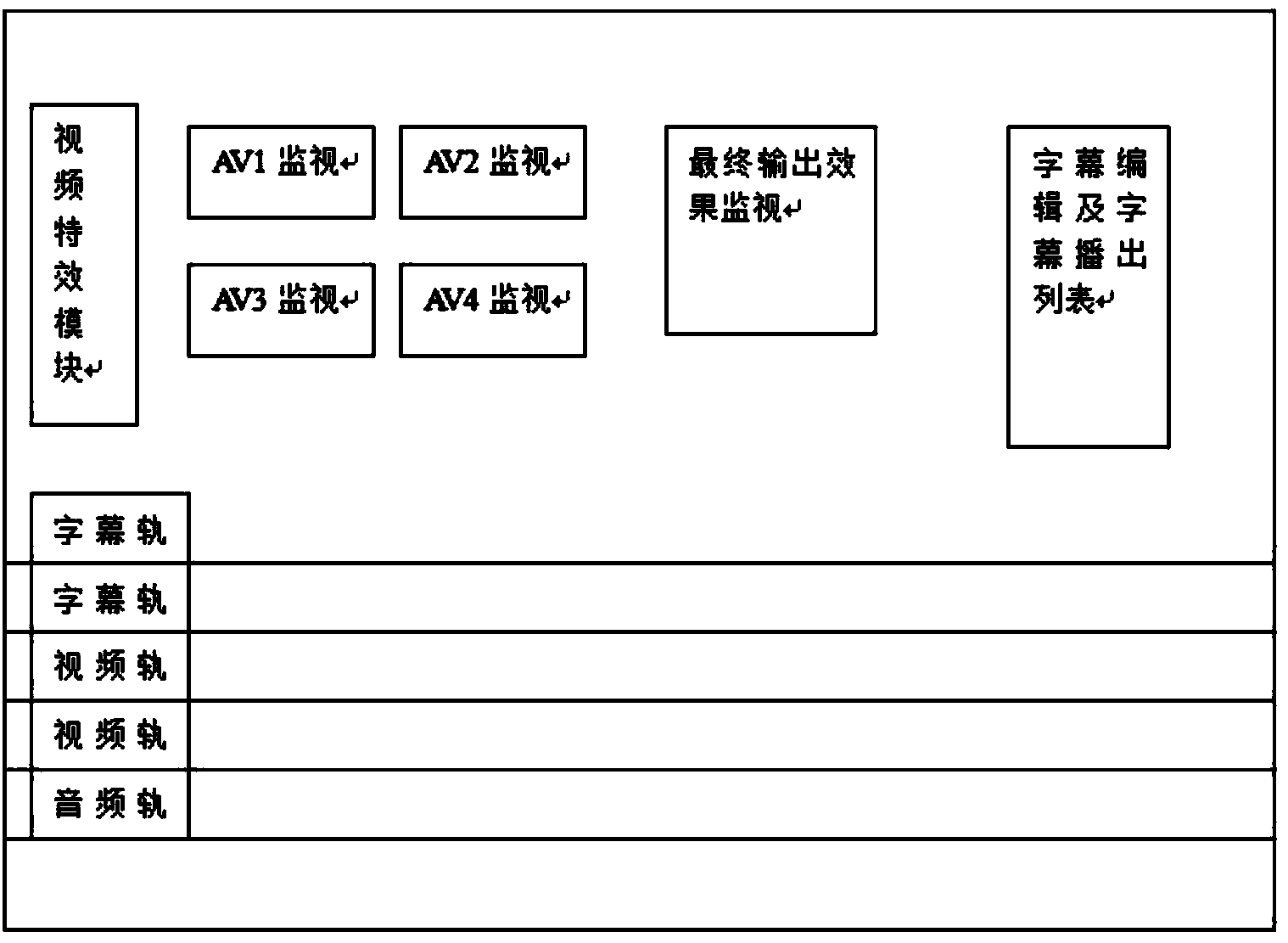

Multi-channel video and audio online-type playing and editing system

ActiveCN103761985ABacktracking implementation of director switchingToggle backtracking implementationTelevision system detailsElectronic editing digitised analogue information signalsSoftware systemTime line

The invention provides a multi-channel video and audio online-type playing and editing system which comprises a computer hardware system as an operation platform and a software system. The software system comprises a video and audio collecting module, a video and audio monitoring module, a video and audio marking and switching module, a video timeline module, an audio timeline module, a video and audio image-text composite file output module, a caption editing module, a caption listing module, a caption image-text timeline module and a video and audio image-text project file output module, wherein the video and audio collecting module is used for collecting signal sources, the video and audio monitoring module is used for monitoring the signal sources, the video and audio marking and the switching module is used for marking the collected signal sources, sending marked videos to the video timeline module to obtain editable video project files, sending marked audios to the audio timeline module to obtain editable audio project files and sending the videos and the audios to the video and audio image-text composite file output module to obtain composite finished video and audio files, the caption editing module, the caption listing module and the caption image-text timeline module are connected in sequence to form editable caption image-text project files, and the video and audio image-text project file output module is used for forming editable video and audio image-text project files. The multi-channel video and audio online-type playing and editing system can form finished files and editable project files and can achieve the functions of broadcasting director recall, simultaneous recording and editing, one-way recording and multi-way recording.

Owner:HUAKEFEIYANG

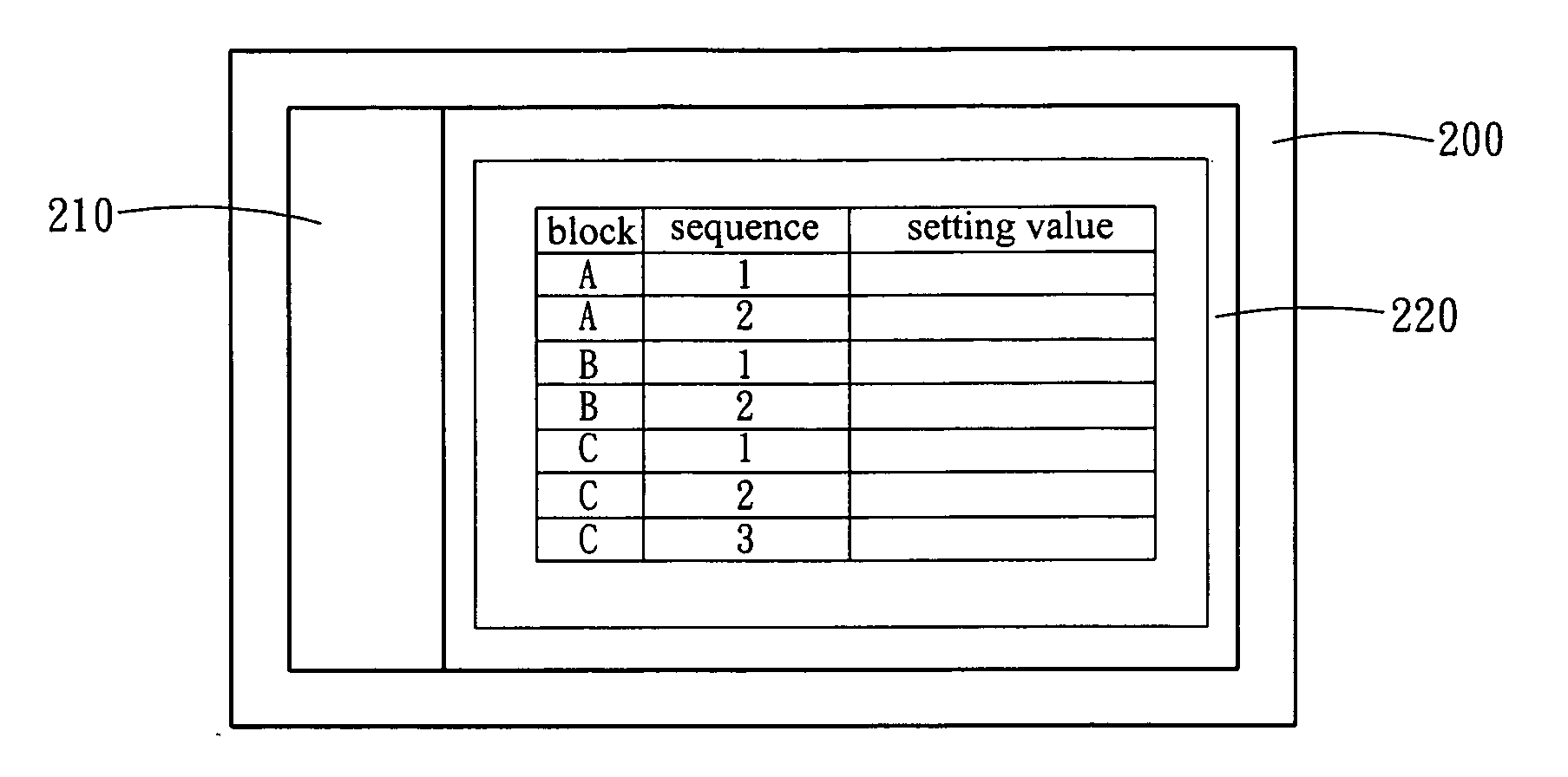

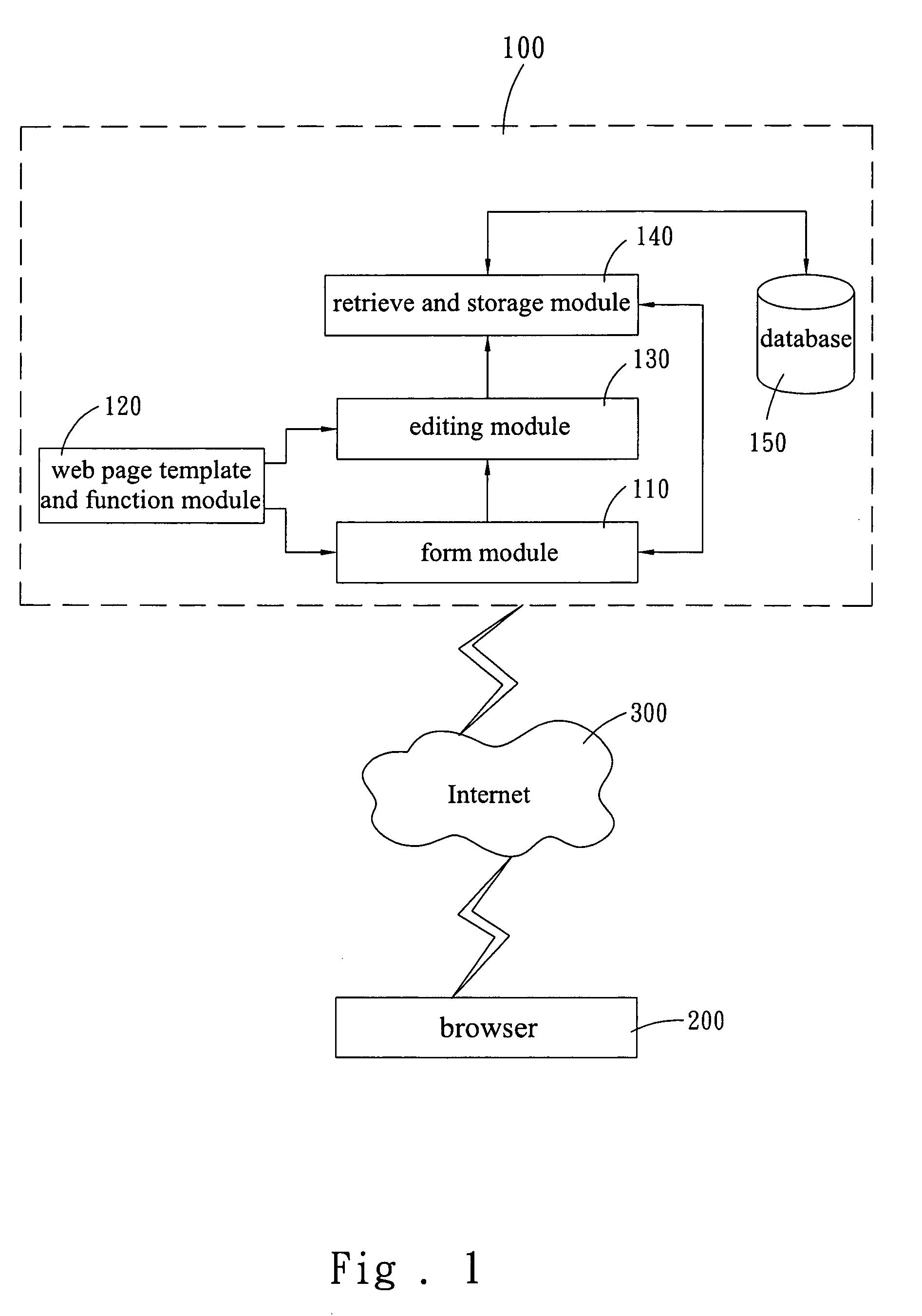

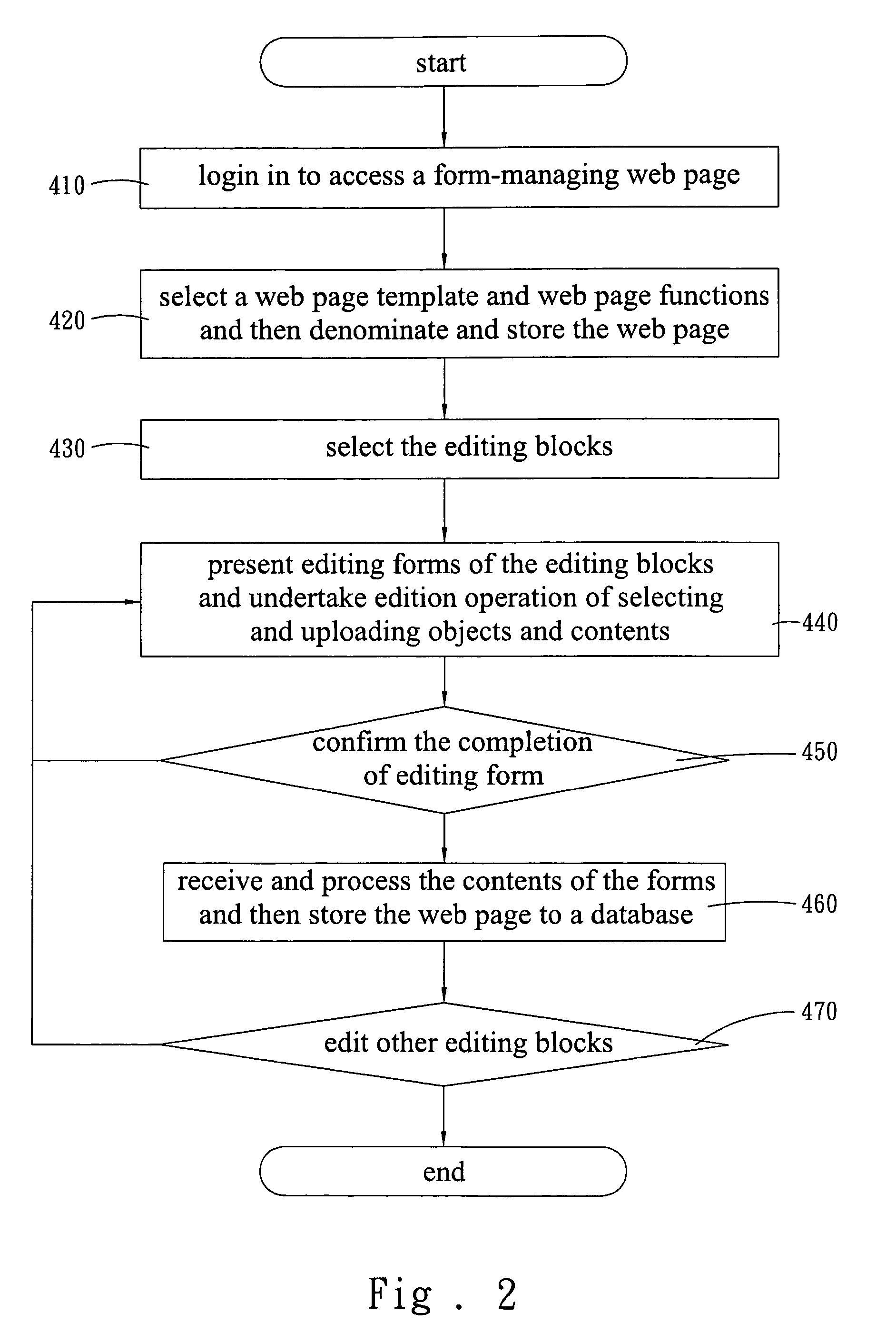

Modularized web page editing system and method thereof

InactiveUS20070067714A1Easy to editWeb page editing is simplifiedWebsite content managementSpecial data processing applicationsInternet usersModularity

The present invention discloses a modularized web page editing system and a method thereof, wherein via the Internet, the user utilizes solely a browser to link the system of the present invention; via a multi-template form module, the user can easily upload objects and contents needed by a web page to reassemble contents of the web page; the form module further comprises a date selection item for defining the self-triggered issue and close dates of a web page; and the system can directly update the database and can instantly retrieve contents of a web page so that the user can have a real-time monitoring for the web page.

Owner:LIN SHUI SHUN

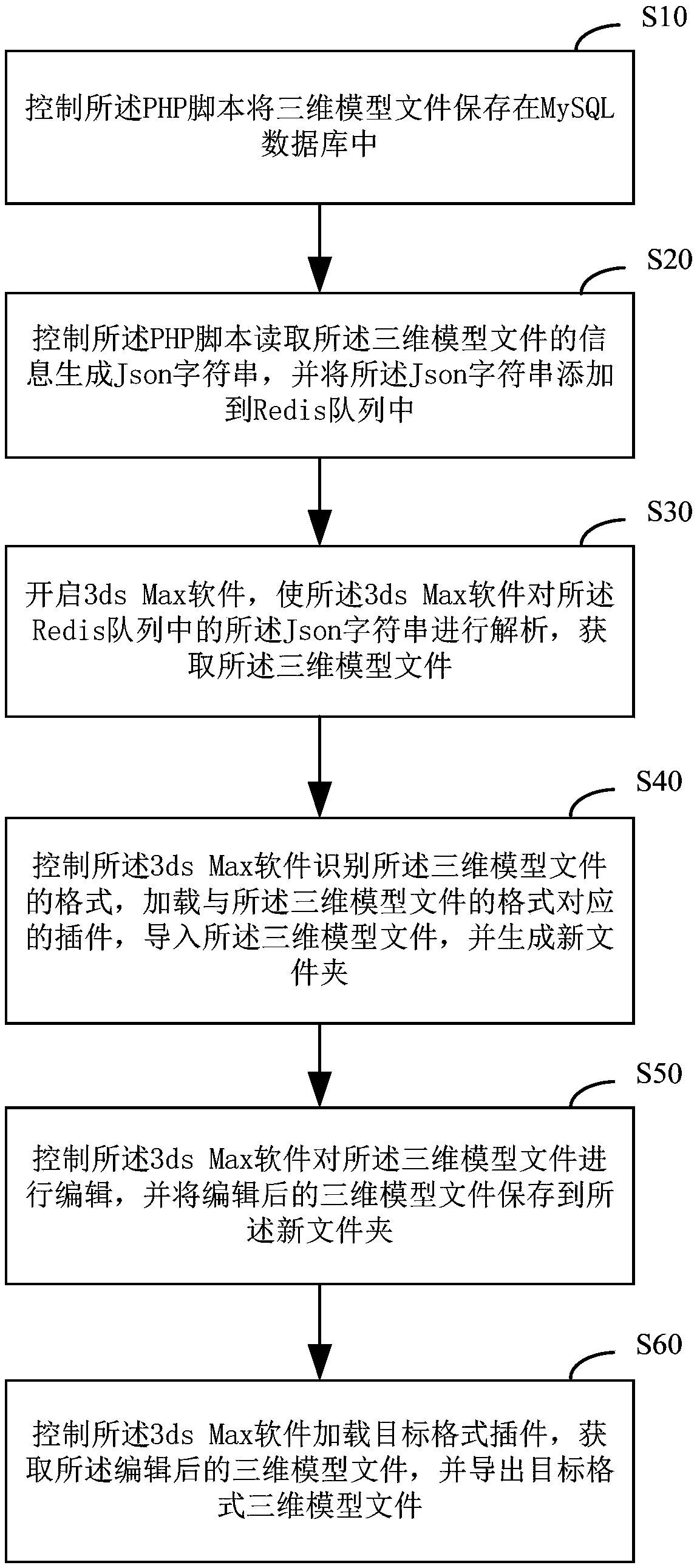

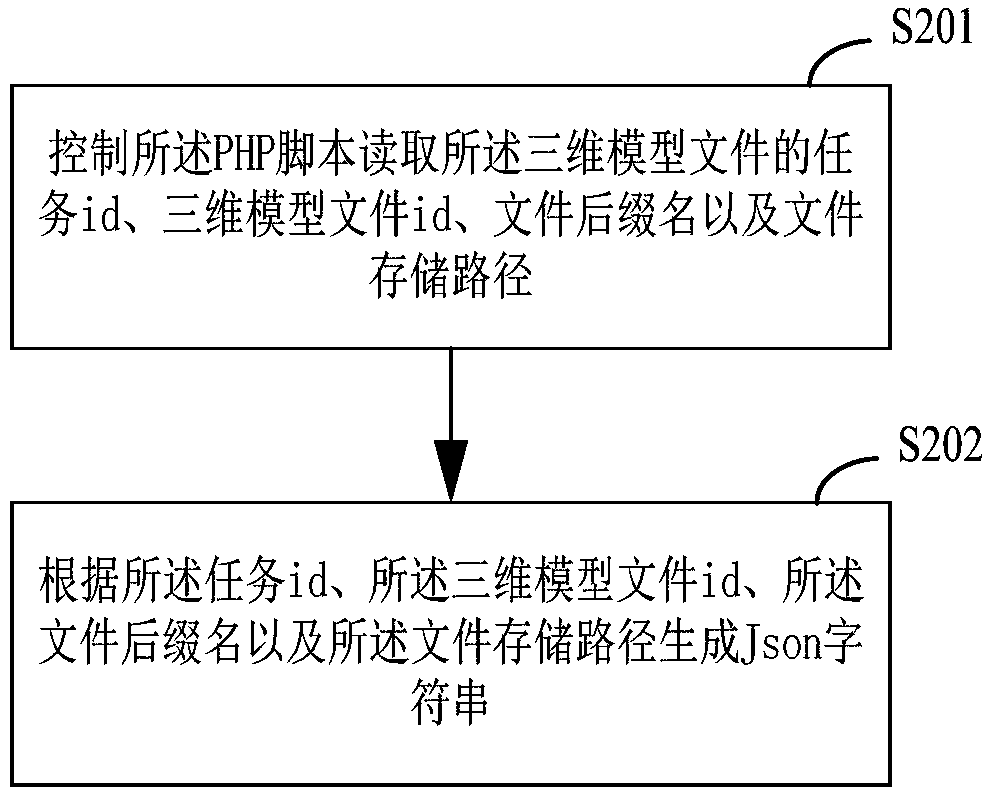

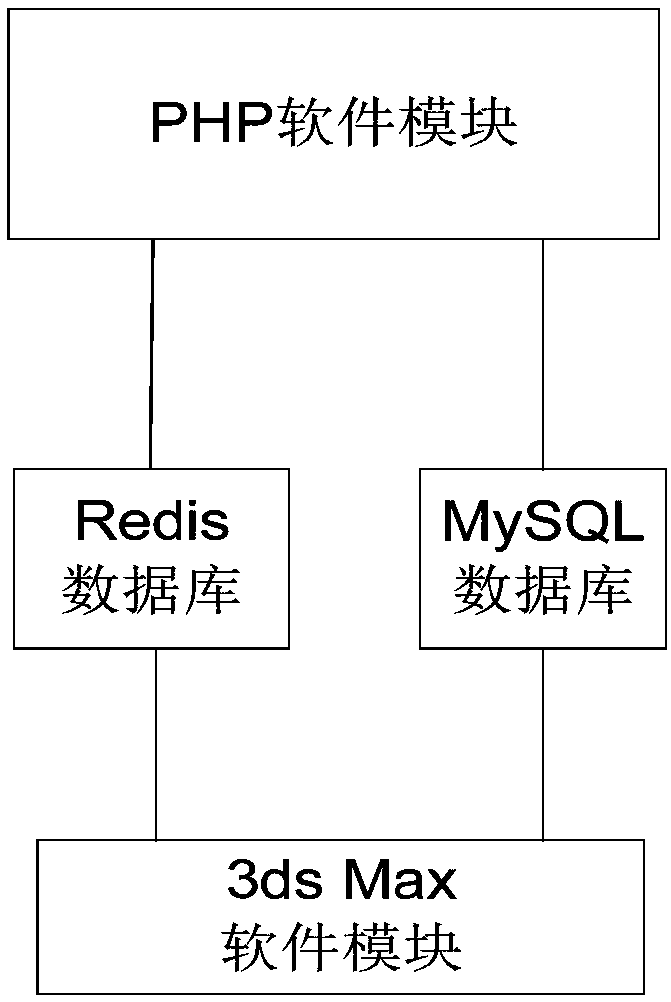

3D model format conversion method and system, compute device and storage medium

ActiveCN109448100AImprove compatibilityGuaranteed accuracyEnergy efficient computing3D modellingSoftware engineeringJSON

The invention discloses a three-dimensional model format conversion method, comprising controlling the PHP script to save the three-dimensional model file in a MySQL database; controlling the PHP script to read the information of the three-dimensional model file to generate a Json string, and adding the Json string to a Redis queue; controlling the 3ds Max software to recognize a format of the three-dimensional model file; controlling the 3ds Max software to edit the three-dimensional model file; controlling the 3ds Max software to load a target format plug-in, and exporting a target format three-dimensional model file; so that the method improves the compatibility of all kinds of 3D model file formats, adopts suitable software to edit 3D model file and data automatically, and adopts flexible file format export mode, reduces the edit time of batch model file and improves the edit efficiency of batch model file on the premise of ensuring the accuracy of model.

Owner:SHENZHEN BINCENT TECH

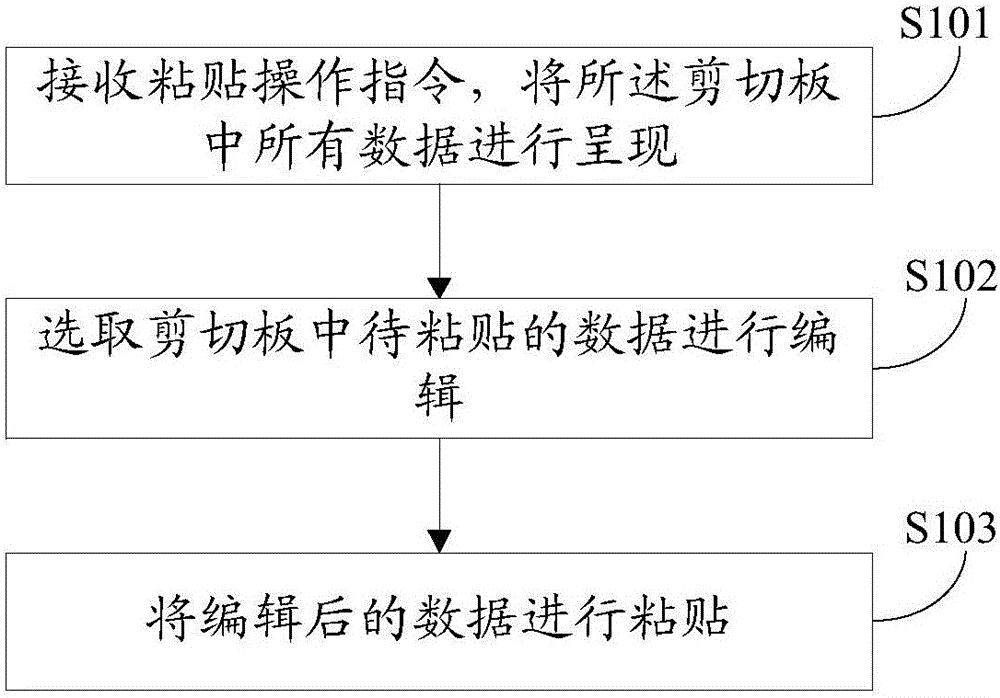

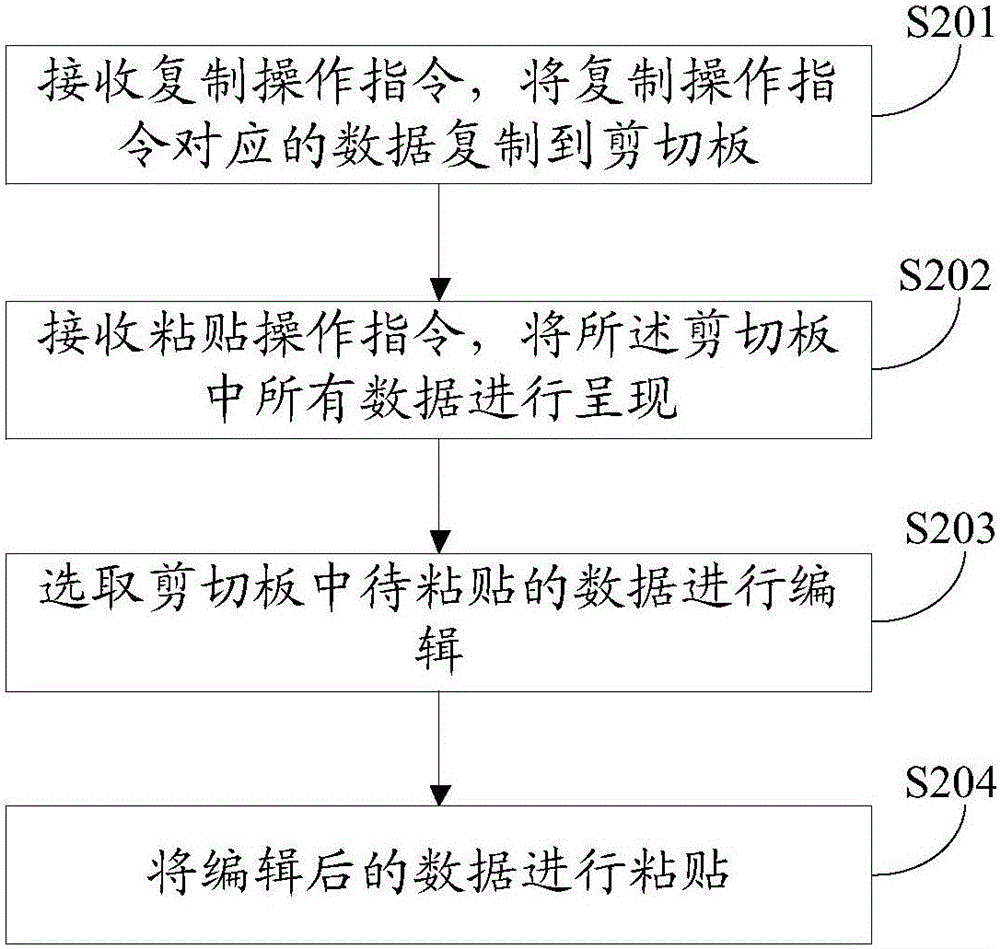

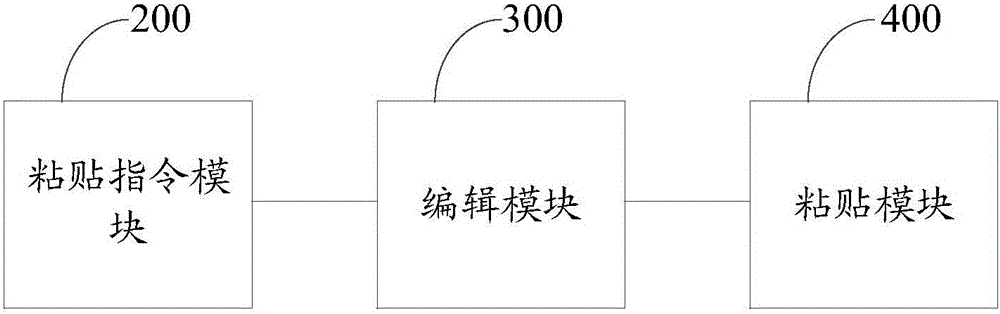

Data editing method and device based on clipboard

InactiveCN106201746ARealize editingOvercome flaws that cannot be replicatedInterprogram communicationNatural language data processingComputer scienceCopying

The invention provides a data editing method and device based on a clipboard. The method comprises the following steps: receiving a pasting operation instruction, and showing all data in the clipboard; selecting the to-be-pasted data in the clipboard and editing the to-be-pasted data; and pasting the edited data. In the data editing method and device based on a clipboard provided by the invention, the shortcoming in the prior art that the data cannot be copied between different applications is overcome, and the data in the clipboard is selected in a data copying process between different applications; and meanwhile, the data editing is realized in the copying process, the data copying efficiency between different applications is improved, the editing time in the data copying process is effectively shortened, and the user experience is enhanced.

Owner:DONGGUAN COOLPAD SOFTWARE TECH

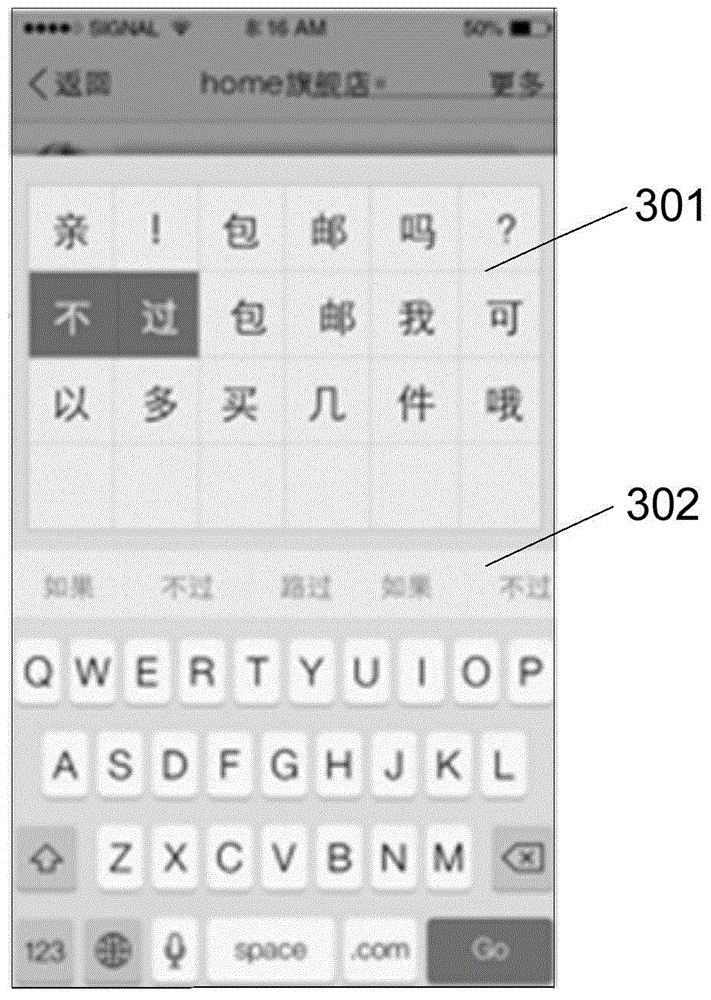

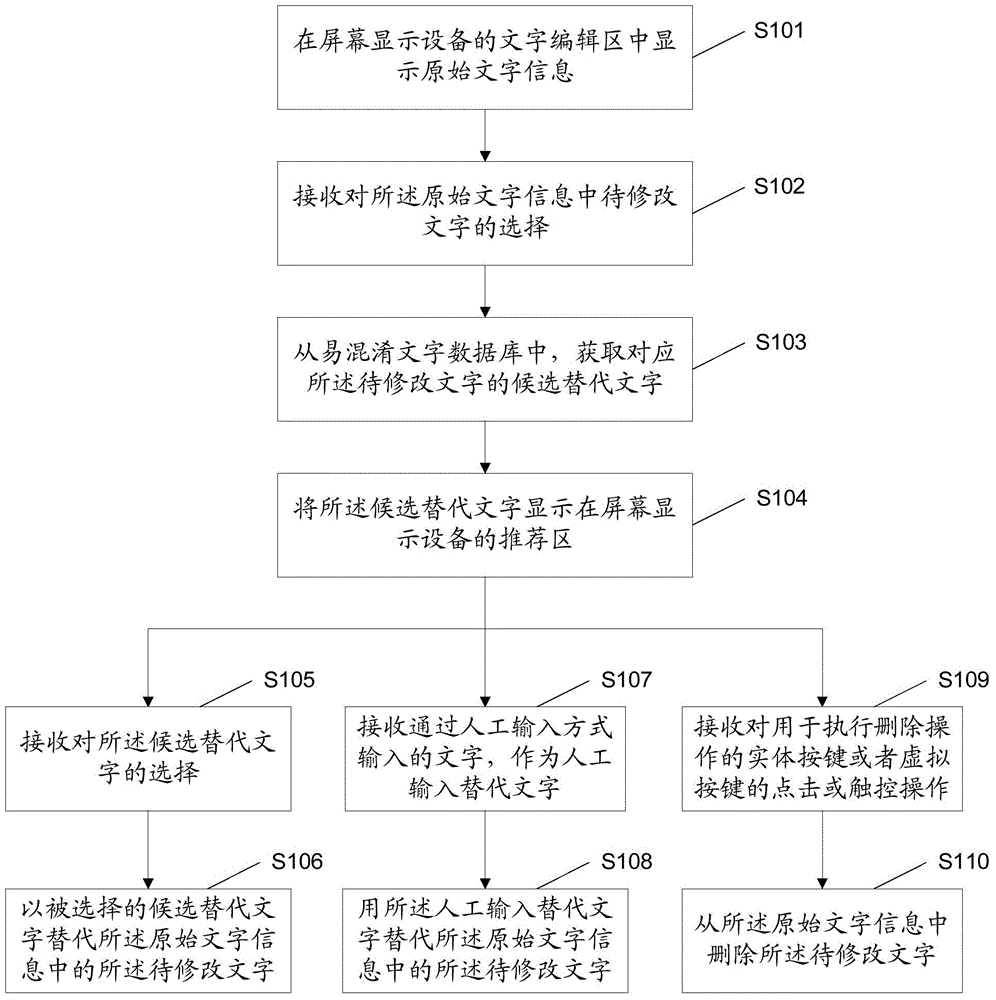

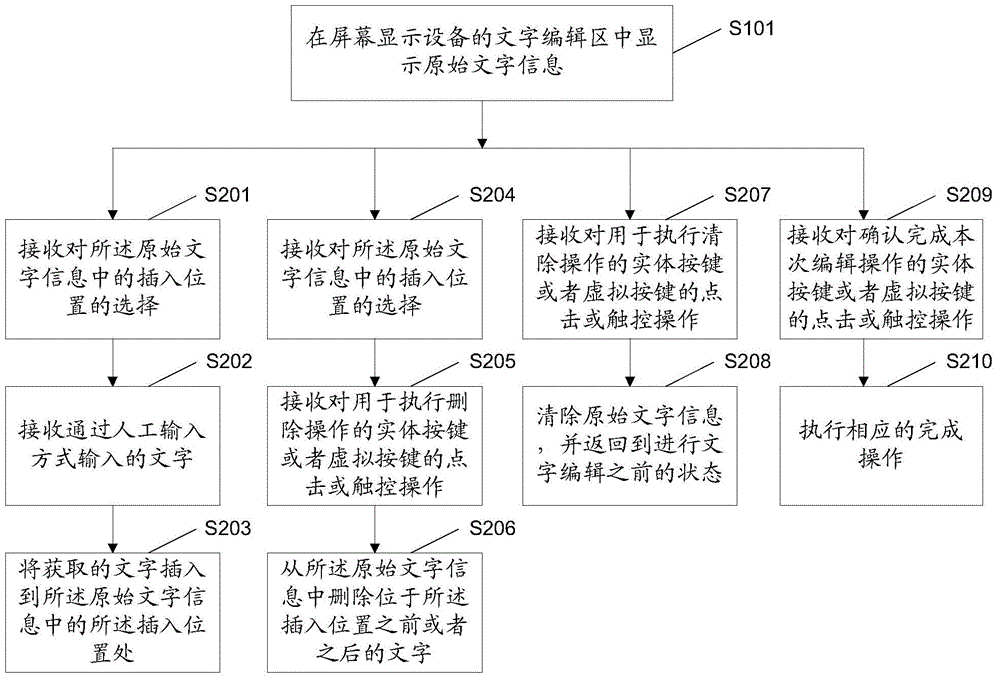

Text-editing method and device used for screen display device

InactiveCN105446572ASave editing timeImprove user experienceNatural language data processingVectoral format still image dataText editingDisplay device

The application discloses a text-editing method used for a screen display device. The method comprises following steps: displaying original text information in a test editing area of the screen display device; receiving selection to texts to be corrected in original text information; obtaining substitute texts corresponding to texts to be corrected from a database of confusable texts; displaying back-up substitute texts to a recommendation region of the screen display device; receiving selections of back-up substitute texts; and replacing texts to be corrected in the original text information with the back-up substitute texts. The application provides a text-editing device used for a screen display device.By adoption of the method, accuracy and operating efficiency in a text-editing process are increased and editing time of a user is reduced. Using experience of the user is effectively enhanced especially during editing operation of a mobile terminal converting speech input into texts.

Owner:ALIBABA GRP HLDG LTD

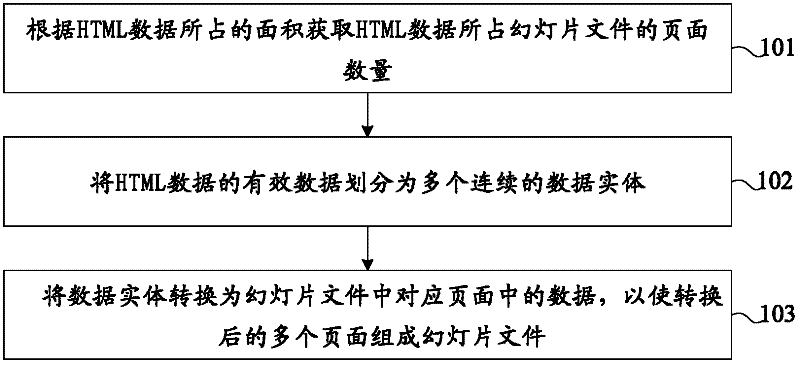

Data processing method and device

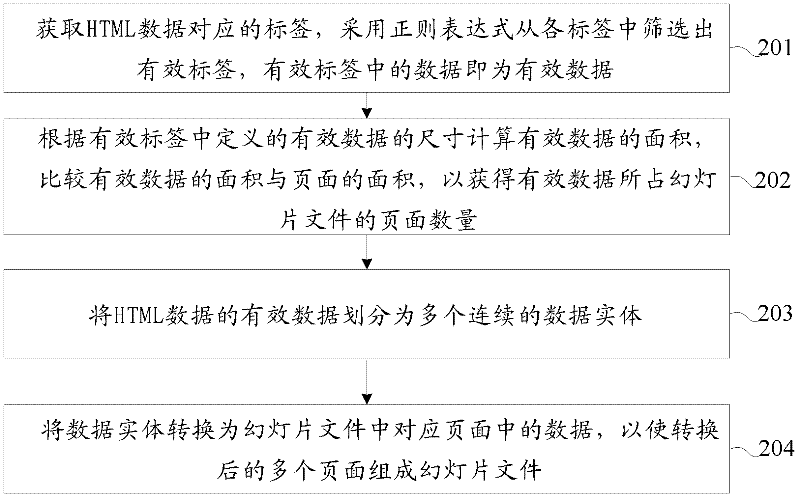

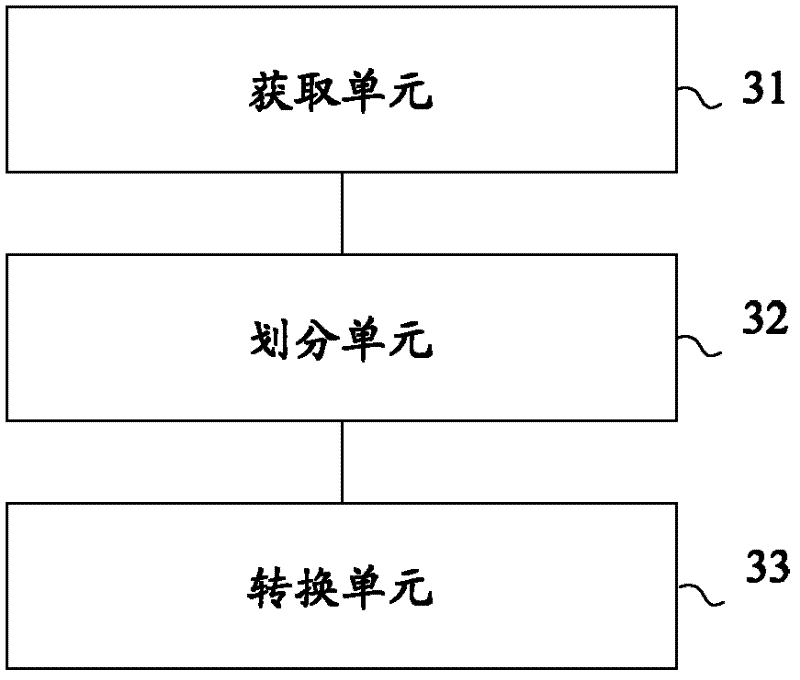

InactiveCN102339276ASave editing timeImprove conversion efficiencySpecial data processing applicationsText editingData entity

The invention discloses a data processing method and a data processing device. The data processing method comprises the following steps of: according to an area of a web page, occupied by an HTML (Hyperlink Text Markup Language) data, acquiring the number of pages of a slide file, which are occupied by the HTML data, wherein the areas of the pages in the slide file are the same; dividing effective data of the HTML data into a plurality of continuous data entities so that the areas of the data entities adapt to the areas of the pages, wherein the number of the data entities is the same as the number of the pages; and converting the data entities into data in the corresponding pages in the slide file, so that the slide file is formed by a plurality of pages. In the method, the HTML data is automatically converted into the page data of the slide file so as to further save the text editing time.

Owner:北京龙戴特信息技术有限公司

Method and system for realizing caption and speech synchronization in video-audio frequency processing

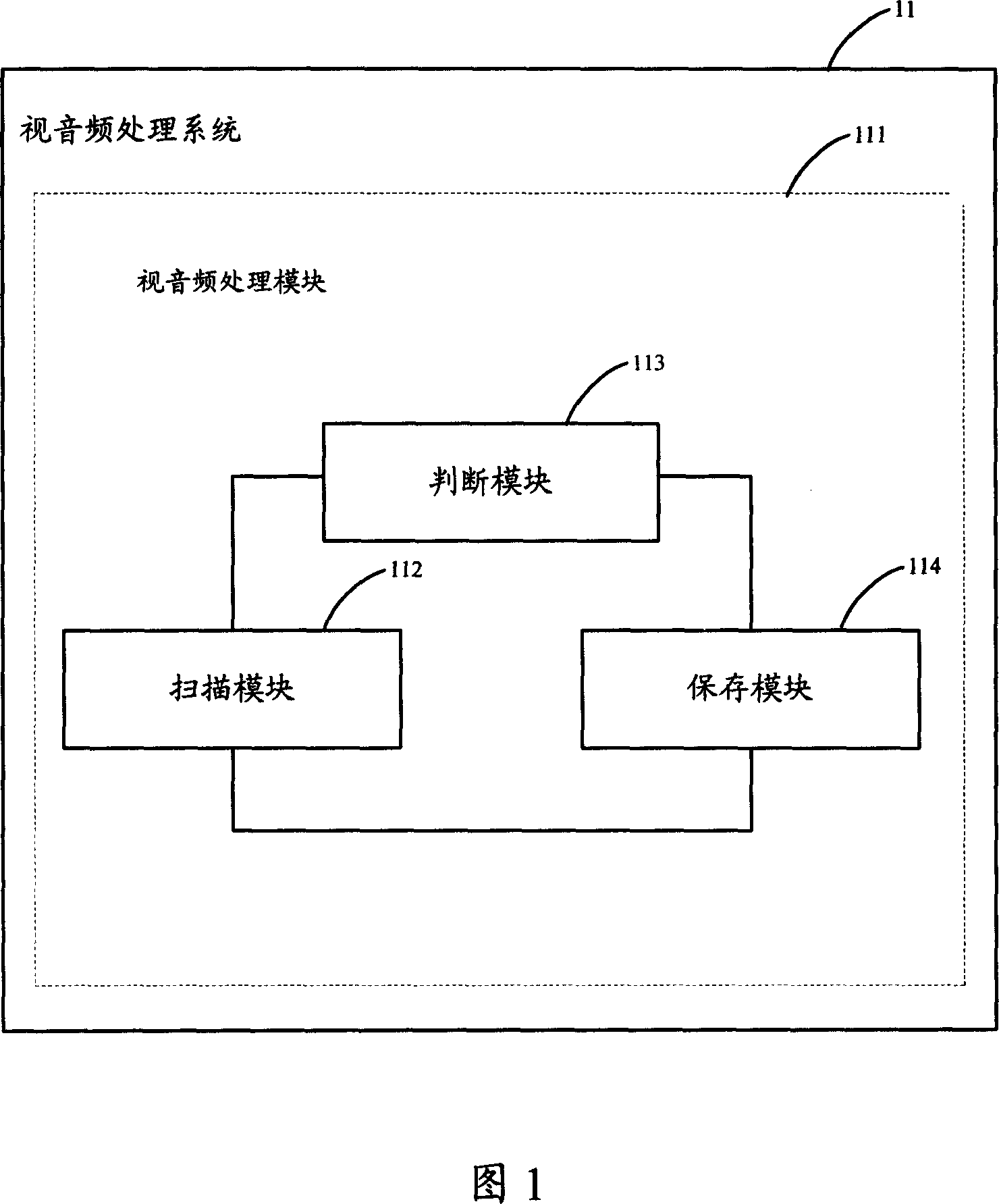

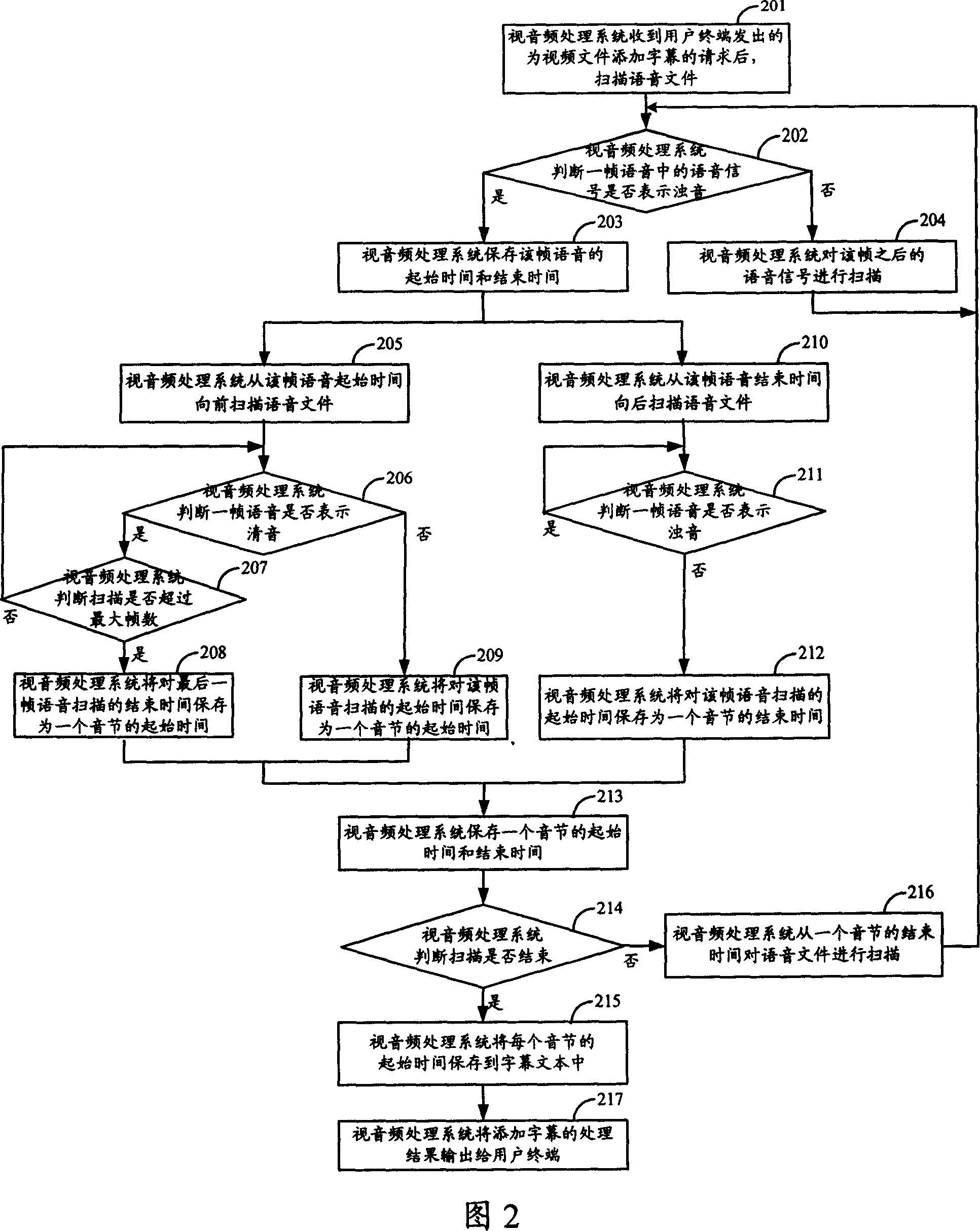

InactiveCN1932976AAvoid errorsSave editing timeTelevision system detailsColor television detailsAudio frequencySpeech sound

A method for synchronization of caption and sound during video and audio frequency dispose. The video and audio frequency dispose system scans sound document in audio frequency document. During the scanning process, confirm beginning time and close time of each syllable with sonant by characteristic parameter of sound signal to sonant. Keep the beginning time of each syllable into caption text as the appearance time for corresponding words in caption text and realize the synchronization to caption and sound. This also opens a system for synchronization of caption and sound during video and audio frequency dispose. The system relates to user end and incepting module, dispose module and sending module of video and audio frequency dispose system. It changes the handle operation about synchronization to caption and sound during video and audio frequency dispose into this system to reduce error taking by handle operation and greatly enhance the work efficiency of anaphase compilation.

Owner:BEIJING FOUNDER ELECTRONICS CO LTD +1

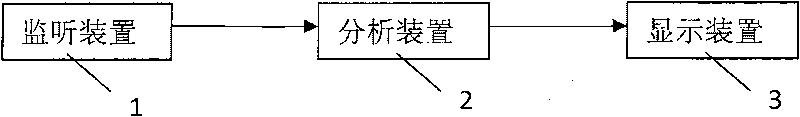

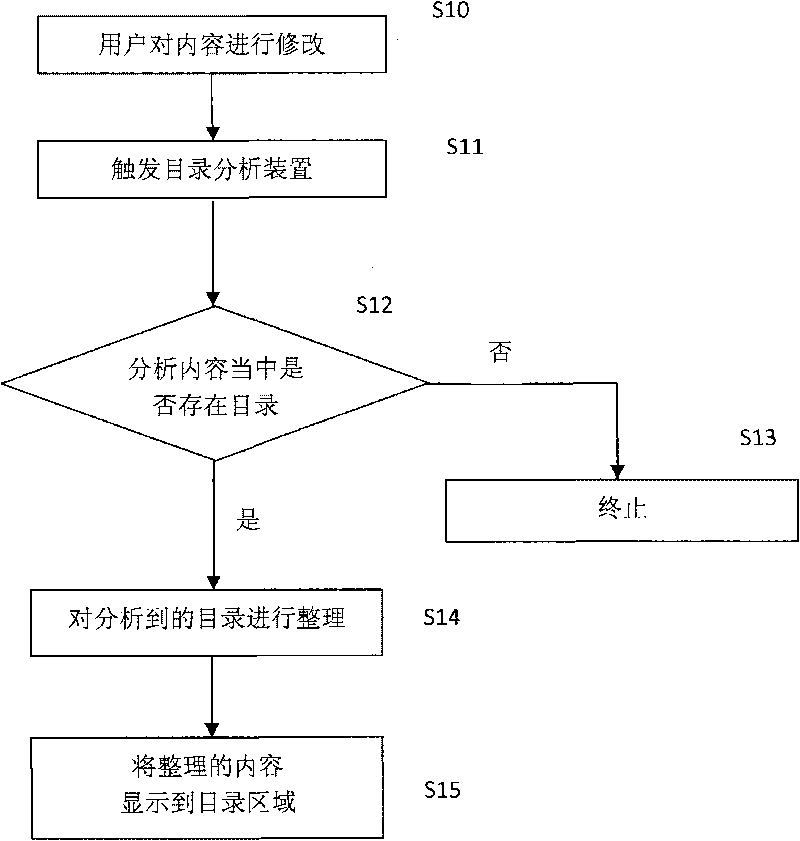

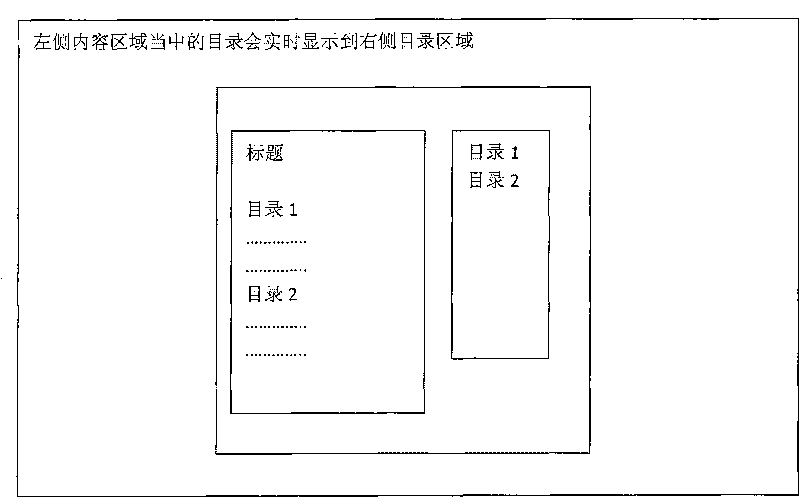

Device and method for displaying navigation catalogue and navigation catalogue content in real time

ActiveCN101739456AImprove editing efficiencyImprove user experienceSpecial data processing applicationsDisplay deviceWeb page

The invention relates to a device and a method for displaying a navigation catalogue and navigation catalogue content in real time. The device comprises a monitoring device, an analyzing device and a displaying device. The method comprises the following steps of: (1) setting a content area monitoring event when an editor is initialized and triggering a catalogue real-time displaying device when the monitoring event changes; (2) after the catalogue real-time displaying device is triggered, analyzing all catalogue marks in the monitoring event and sorting the catalogue marks into a displayable webpage content; and (3) displaying the analyzed and sorted catalogue list contents at the designated position. With the invention, users can see all navigation catalogue lists when editing the content without looking up one by one by dragging the webpage, thereby improving the editing efficiency of the user and the user experience and saving the editing time of the user.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

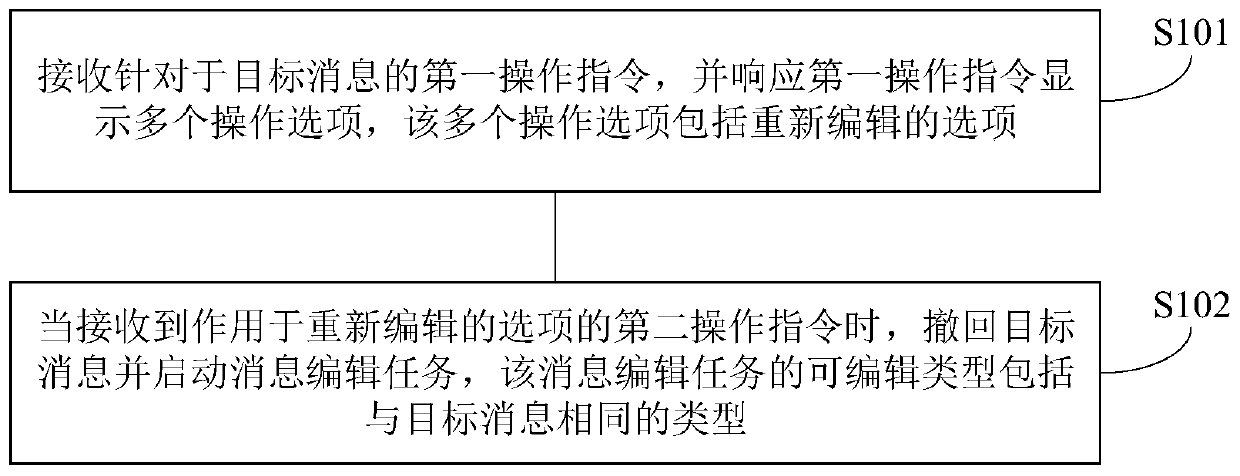

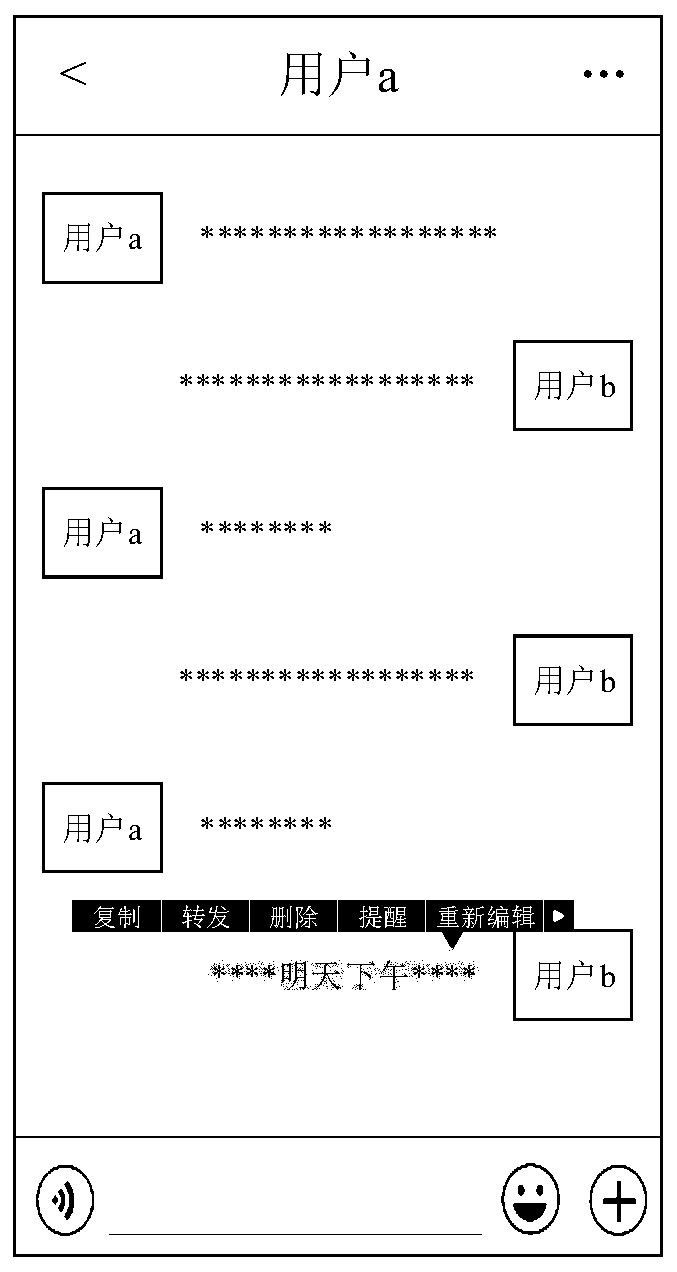

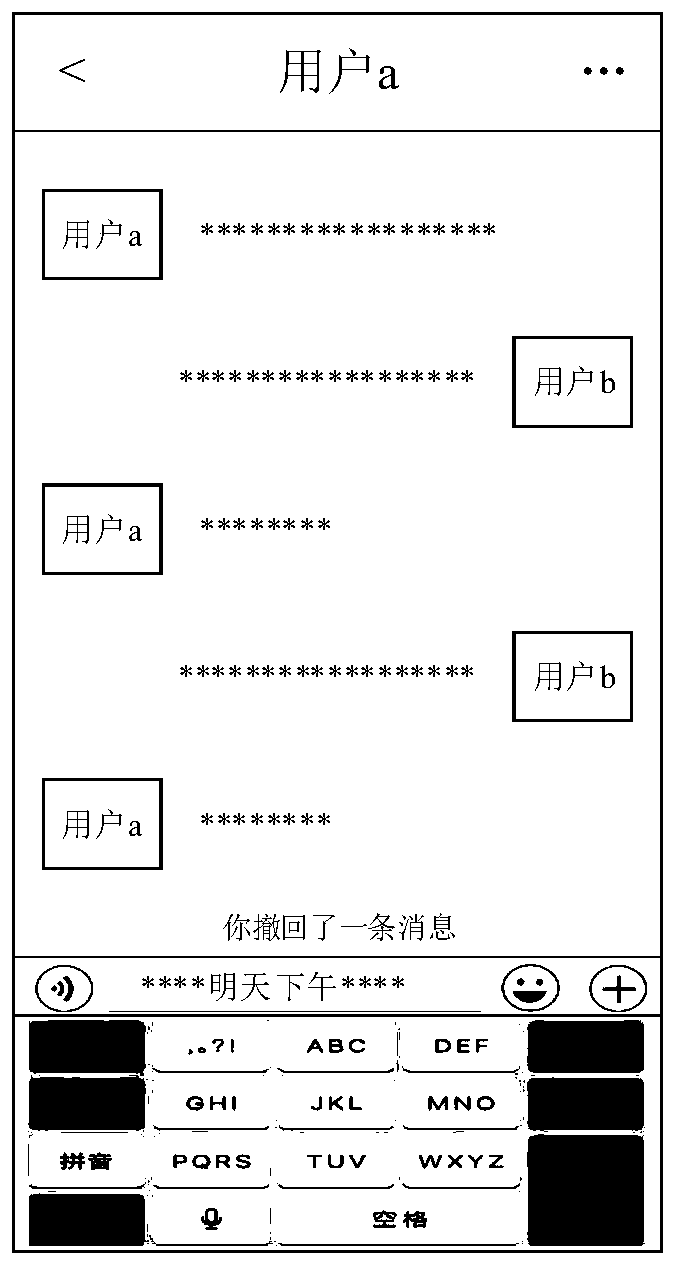

Message processing method and device

ActiveCN109951379ASave editing timeEasy to withdrawData switching networksMessage processingOperating system

The invention relates to a message processing method and device. The method comprises the following steps: receiving a first operation instruction for a target message and responding to the first operation instruction to display a plurality of operation options, wherein the plurality of operation options comprise reedited options; when a second operation instruction acting on the re-edited optionis received, the target message is withdrawn, a message editing task is started, and the editing type of the message editing task comprises the same type as the target message. According to the invention, the process of re-editing the message after the message is withdrawn can be simplified, so that the message editing time is saved and the user experience is improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

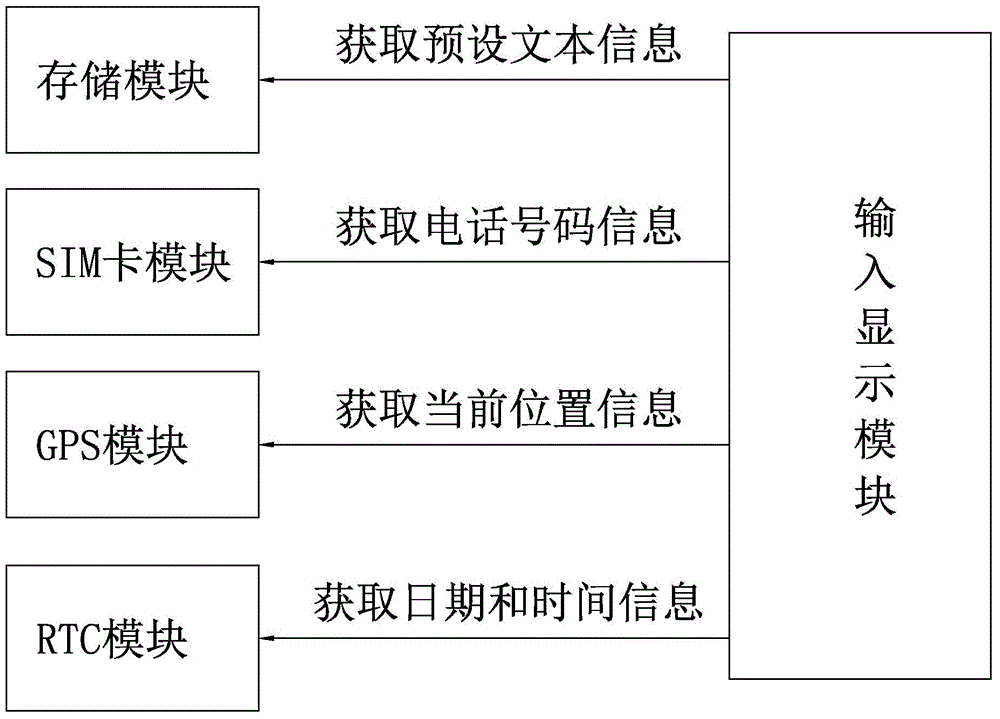

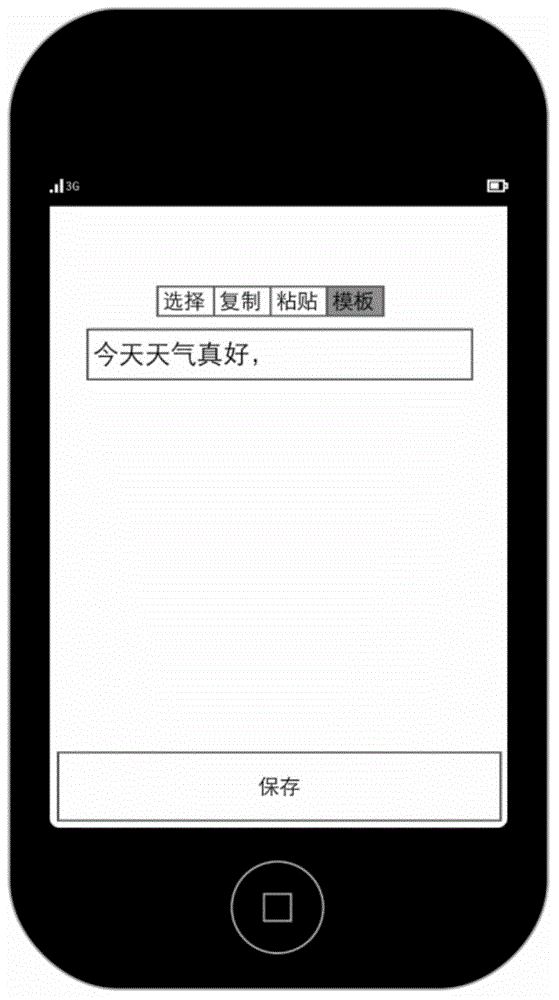

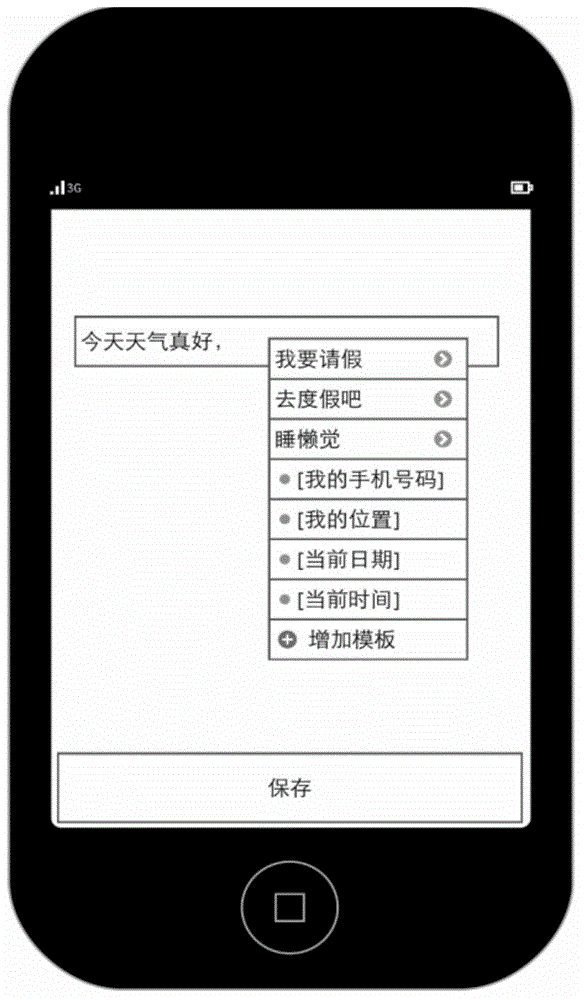

Method for quickly inputting on mobile equipment through template

InactiveCN104320539AFast inputSave editing timeSubstation equipmentInput/output processes for data processingMobile deviceSystem information

The invention discloses a method for quickly inputting on mobile equipment through a template. According to the method for quickly inputting on the mobile equipment through the template, the input interface of the mobile equipment is at least provided with a template option, the template option further comprises a text template and a link template, the text template refers to the text information created through user preset or system preset, the template content is stored in a storage module, and the template content can be directly called by an input display module and displayed on the input interface; the link template comprises a user information link template and a system information link template, the needed user information or system information is obtained through a corresponding information providing module on the mobile equipment when the template content is only called by the input display module, and the user information or system information is displayed on the input interface; through the template option, a user can directly call the template content and add the template content to the input frame of the input interface for realizing quick input, and accordingly a lot of editing time is greatly saved.

Owner:XIAMEN MEITU MOBILE TECH CO LTD

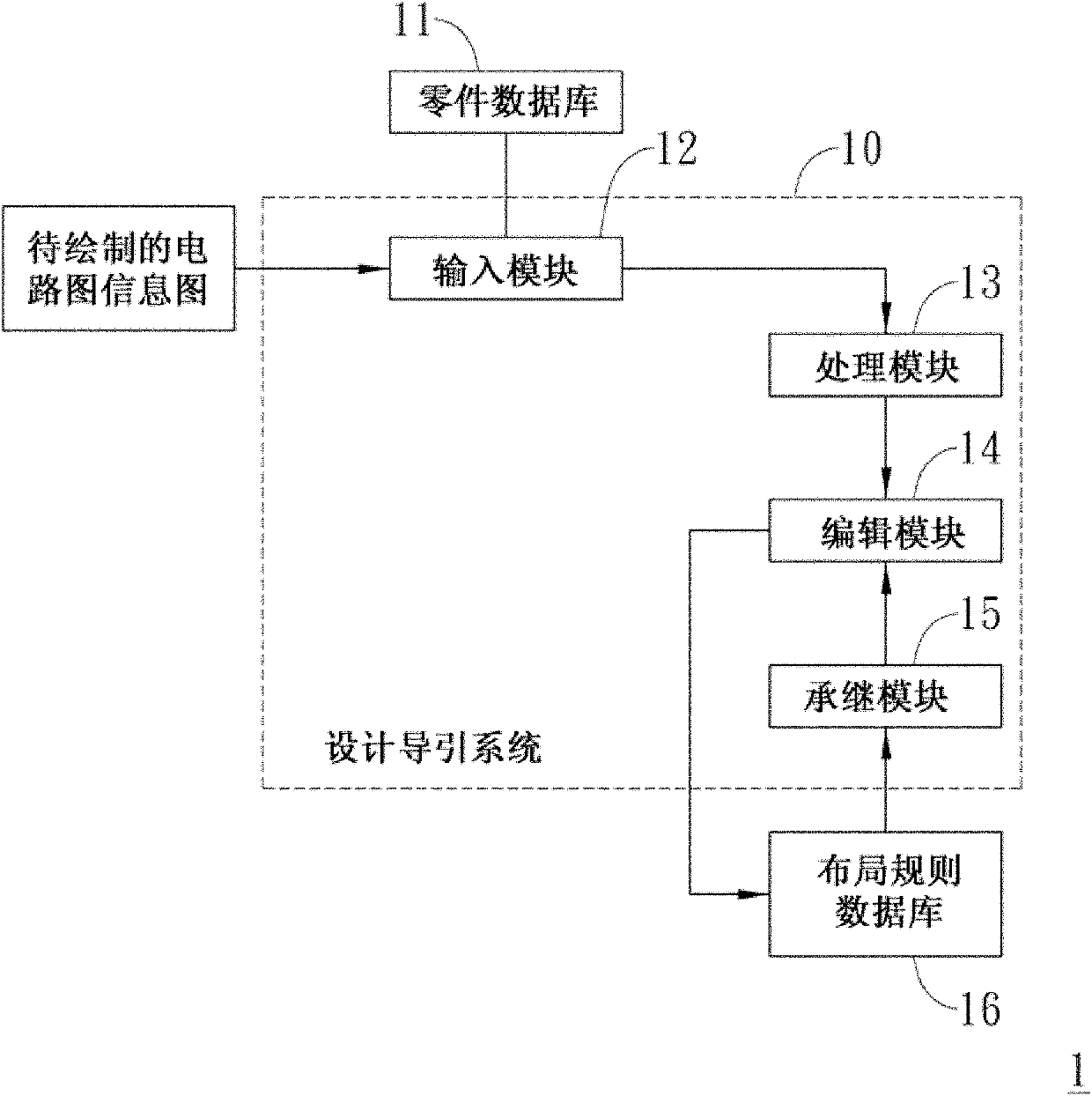

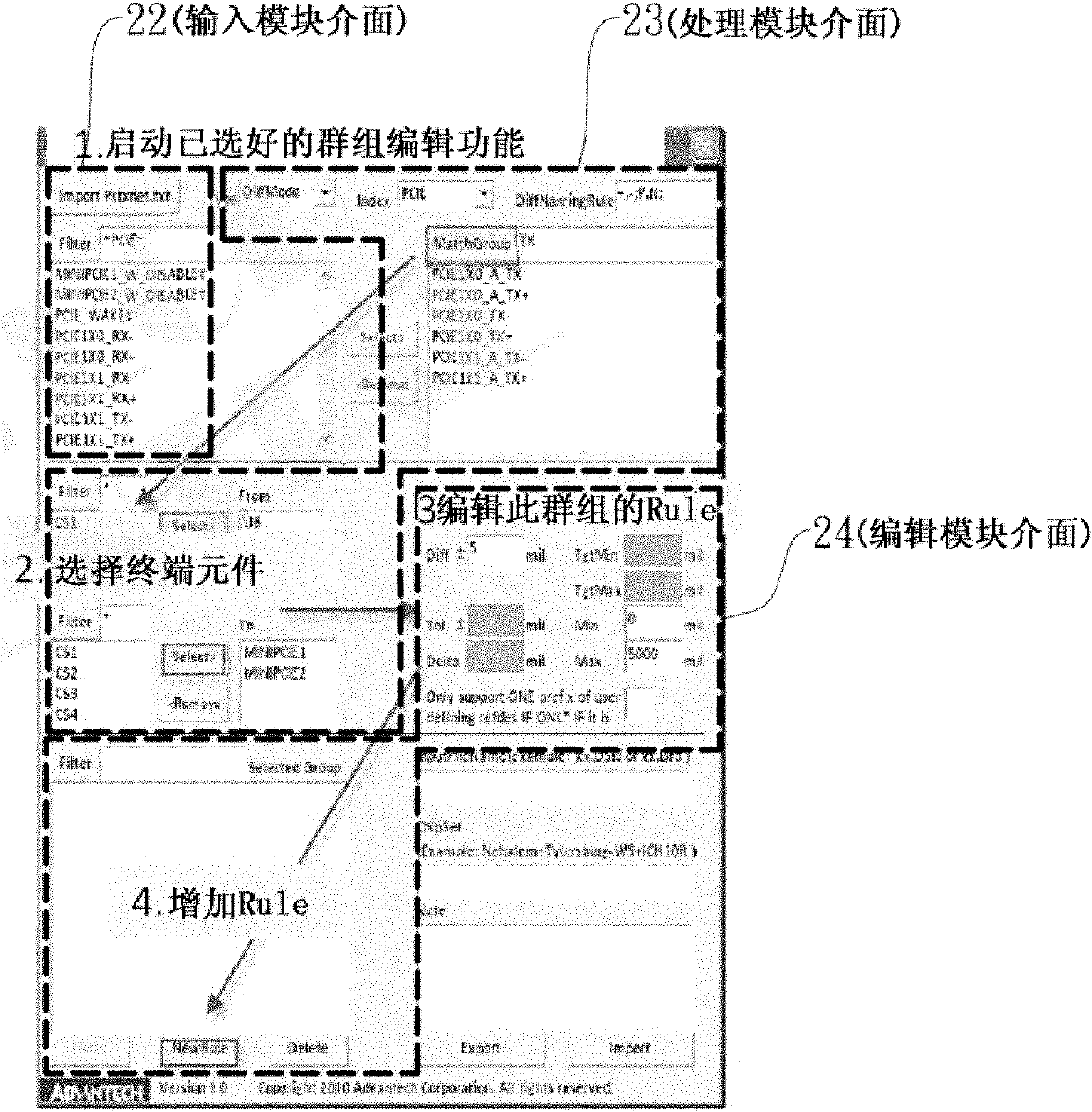

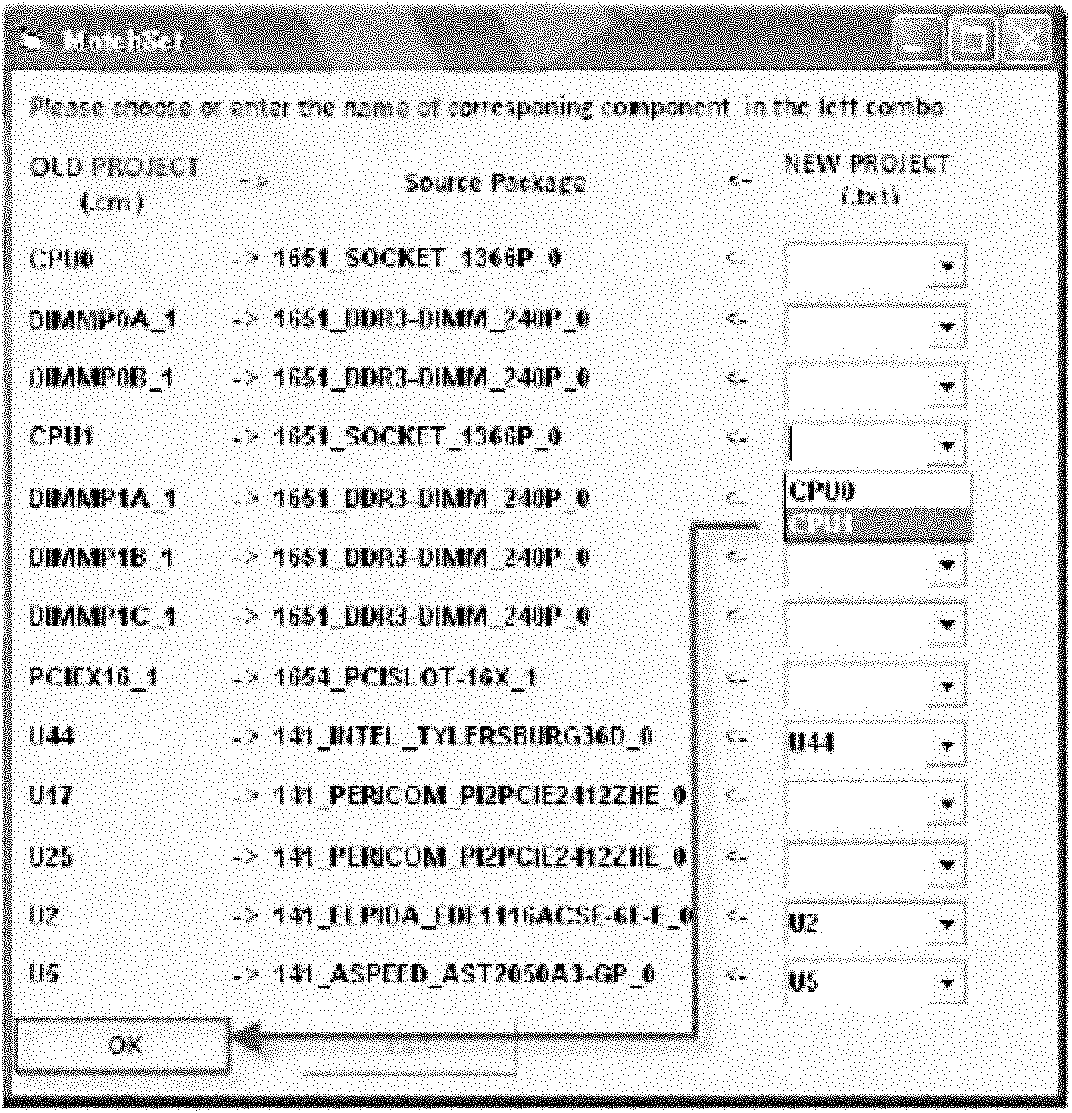

Design guiding system and method for circuit board layout rule

InactiveCN102567553ASave editing timeReduce drawing timeSpecial data processing applicationsComputer architectureComputer module

The invention discloses a design guiding system and method for a circuit board layout rule. The system comprises a part database, an input module, a processing module, an editing module, a succession module and a layout rule database, wherein the part database is used for storing packaging specification information data and name naming rule of a circuit board element; the input module is used for inputting network name of a circuit board to be drawn and the packaging specification information data of the related circuit board element and is connected with the part database; the processing module is used for selecting a specific network name as well as related element and terminal element names from the network name and the packaging specification information data, wherein layout rules are to be set for the specific network name as well as the related element and terminal element names; the editing module is used for finding out a connection relation and defining the layout rule of a matching group according to the analyzed circuit board terminal element; by using the succession module, the user can succeed the edited layout rule document to other circuit boards with the same circuit architectures; and the layout rule database is used for storing and arranging the edited documents so as to fast and conveniently search and obtain the desired layout rule document so that the resources are convenient to be shared and fast succeeded.

Owner:ADVANTECH CO LTD

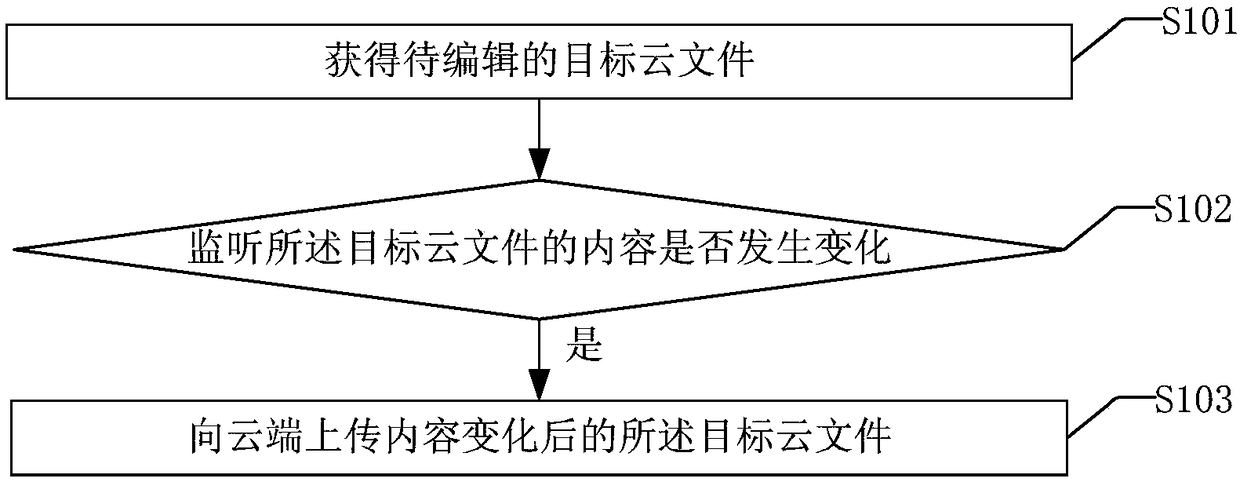

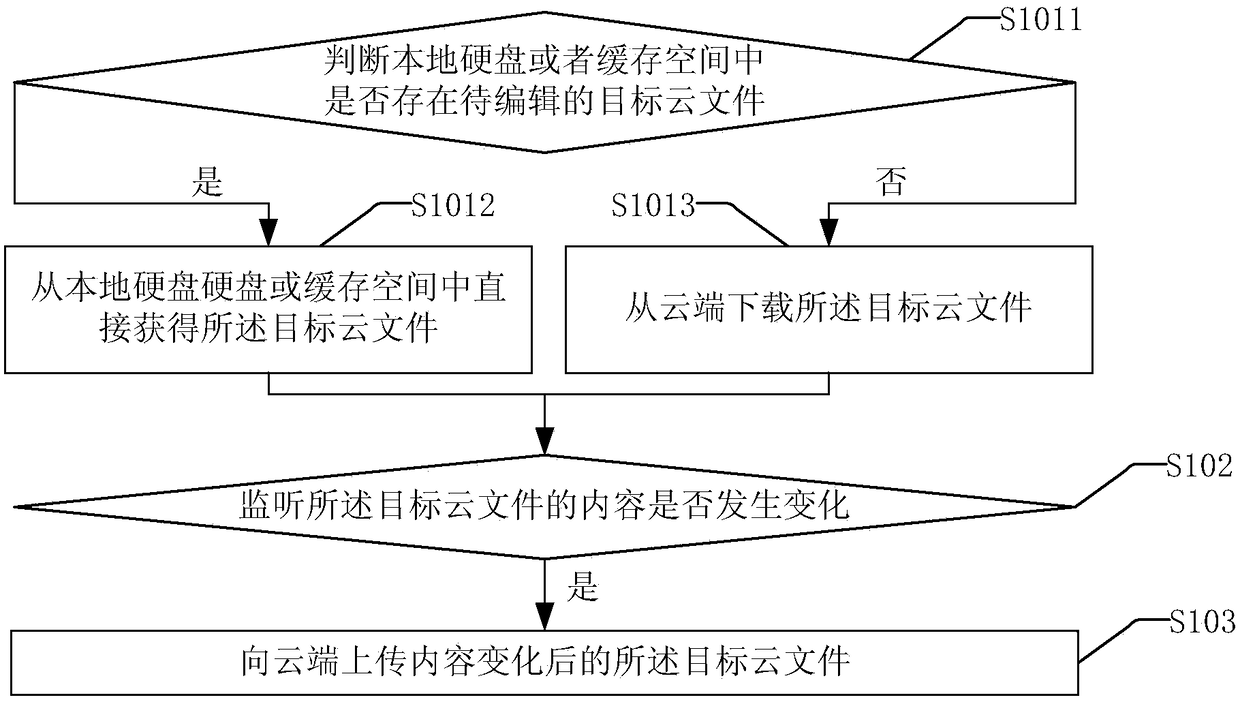

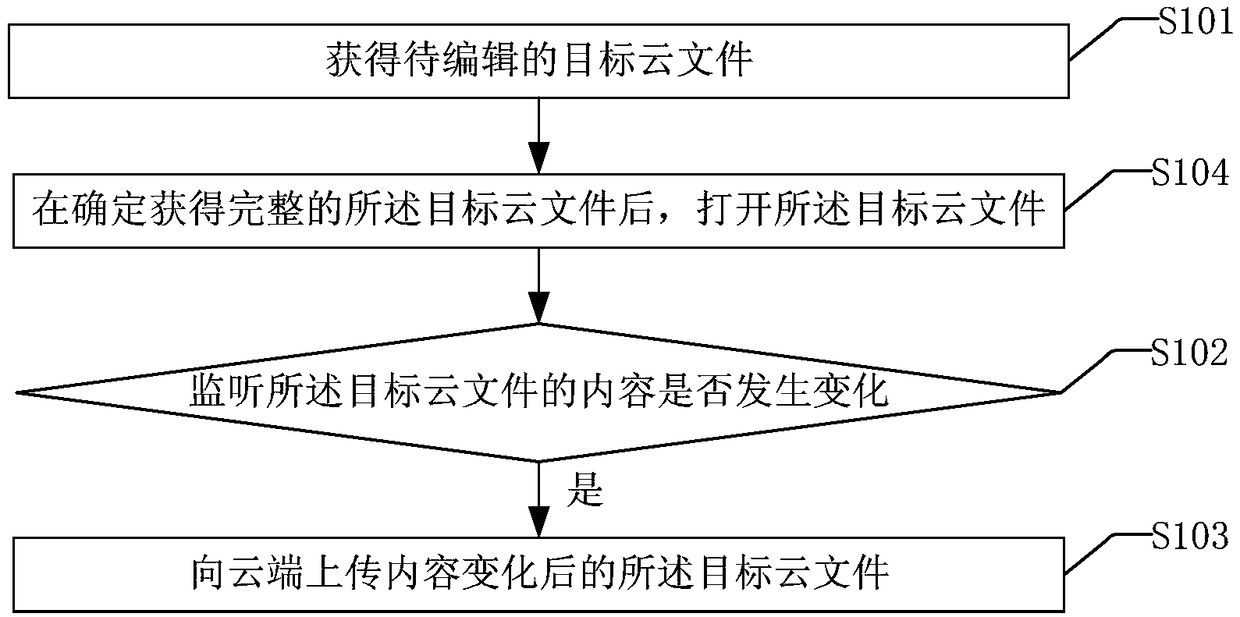

Cloud file editing method and apparatus

ActiveCN108234554ASimplify the editing processSave editing timeInput/output to record carriersTransmissionOperating systemComputer science

Owner:BEIJING KINGSOFT CLOUD NETWORK TECH CO LTD +1

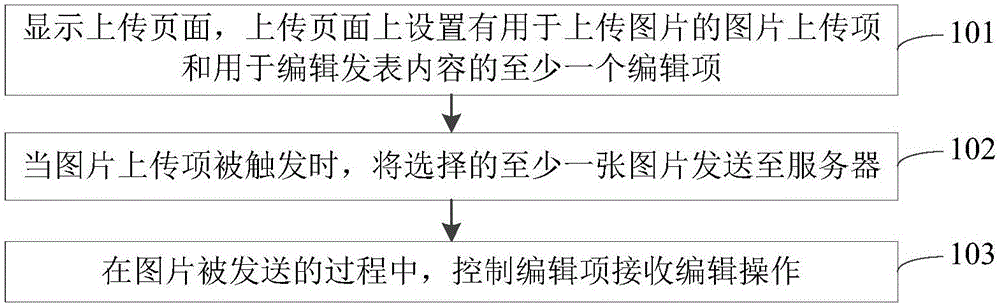

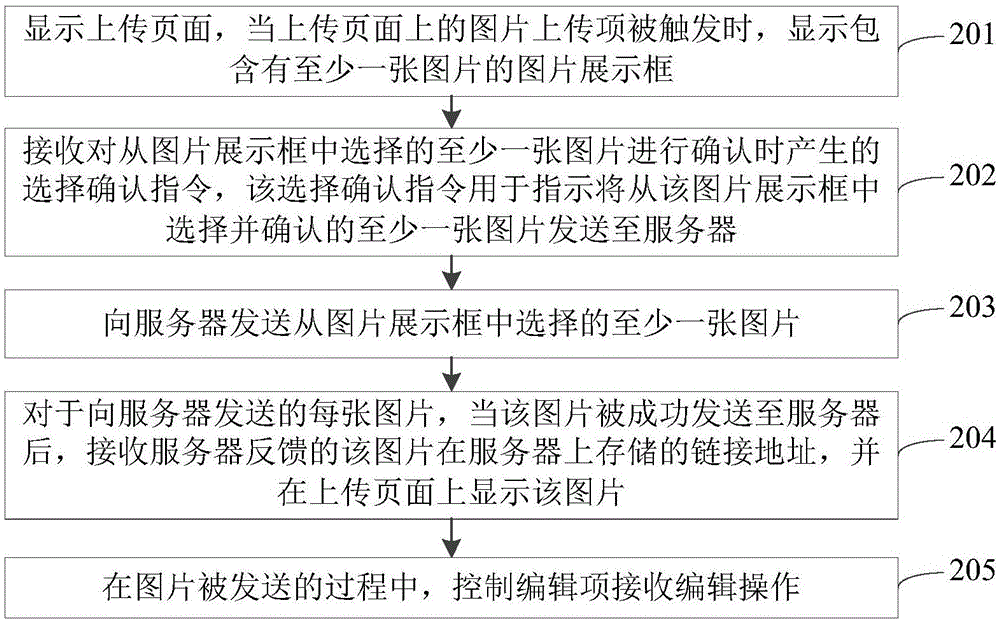

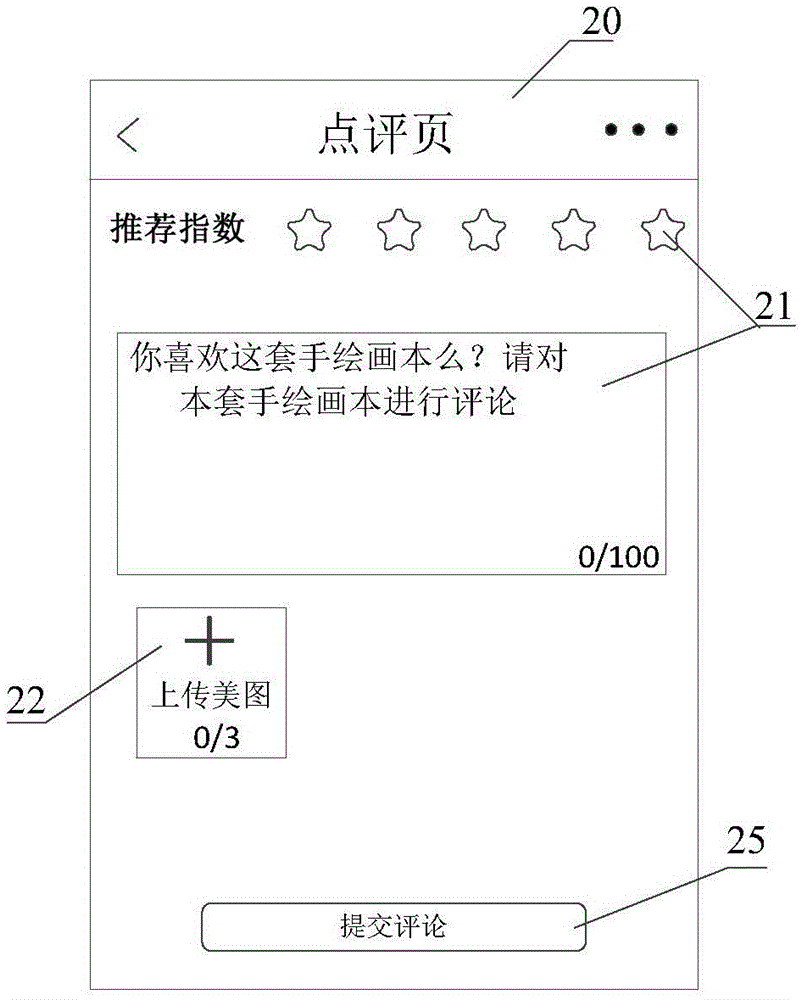

Method and apparatus for image upload

InactiveCN105162817ASave editing timeImprove comment efficiencyTransmissionComputer graphics (images)Multiple image

The invention discloses a method and apparatus for image upload, and belongs to the technical field of a computer. The method comprises the steps of displaying an upload page and setting up an image upload item for uploading an image and at least one editing item for editing content to be posted; when the image upload item is triggered, transmitting the selected at least one image to a server; and controlling the editing item to receive the editing operation while the image is being transmitted. The invention solves the problems in the prior art that too many editing items are on an upload page, a lot of time can be taken in editing the editing items and transmitting a plurality of images and the efficiency for a user to post a comment is relatively low; and achieves the effects of improving commenting efficiency when a comment with images is posted.

Owner:TENCENT TECH (BEIJING) CO LTD

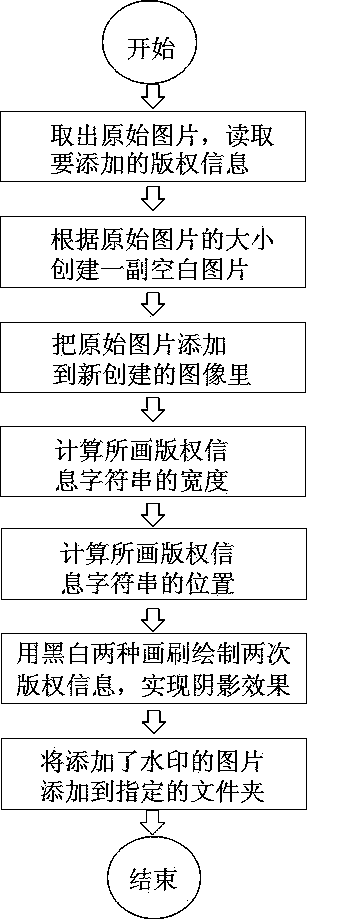

Watermark image realization method

InactiveCN103839217AThe method is simple and applicableSave editing timeImage data processing detailsThird partySoftware

The invention discloses a watermark image realization method which is simple and applicable. Without using image editing software to modify an image, a user can directly carry out image batch modifying through a website, and the watermark adding positions of all images are consistent. A lot of editing time is saved. The method does not need to use the third-party software, can complete production simply through GDI, and has the advantage of low production cost.

Owner:JURONG ZHONGXIN SOFTWARE SCI & TECH CO LTD

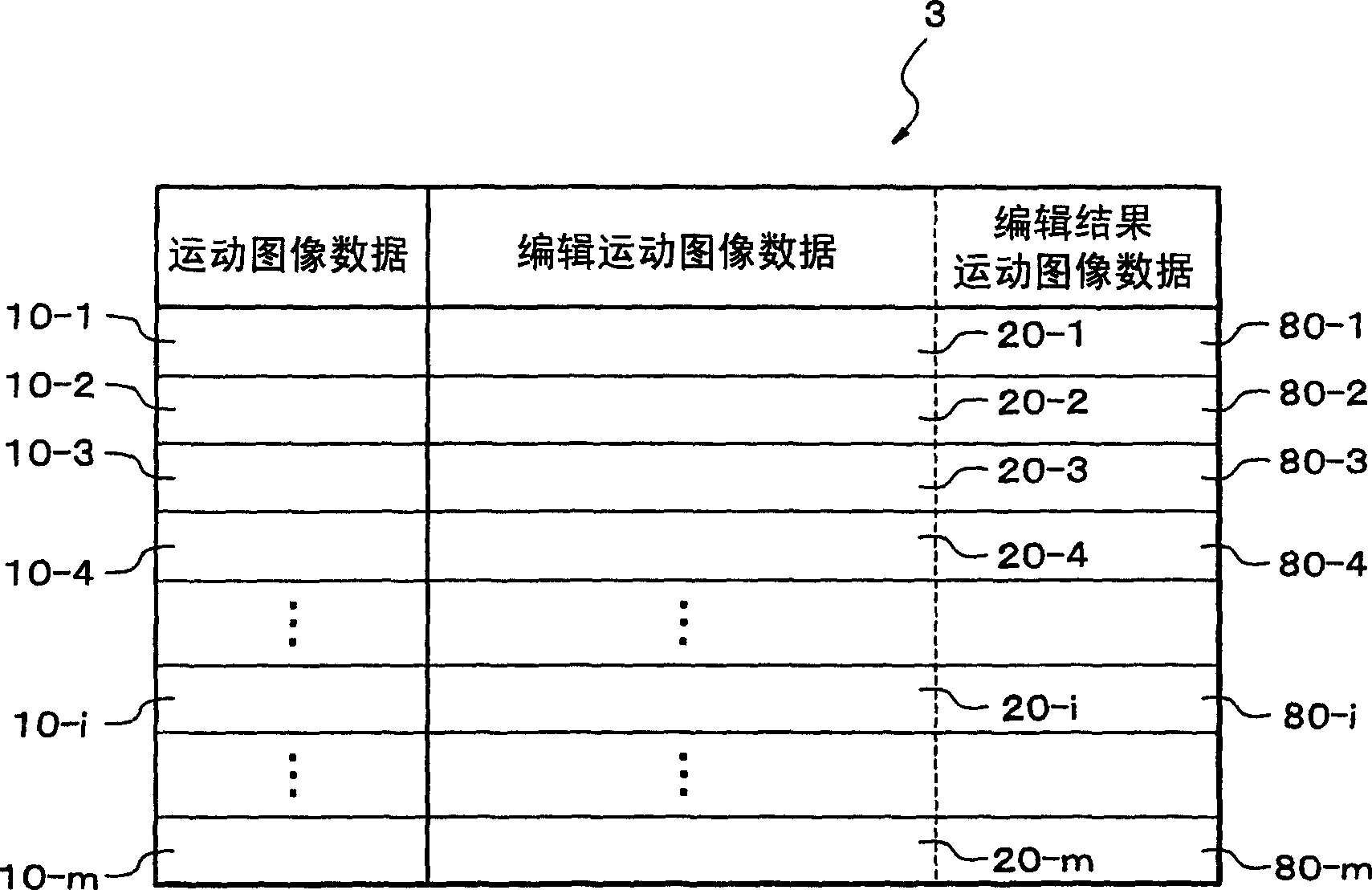

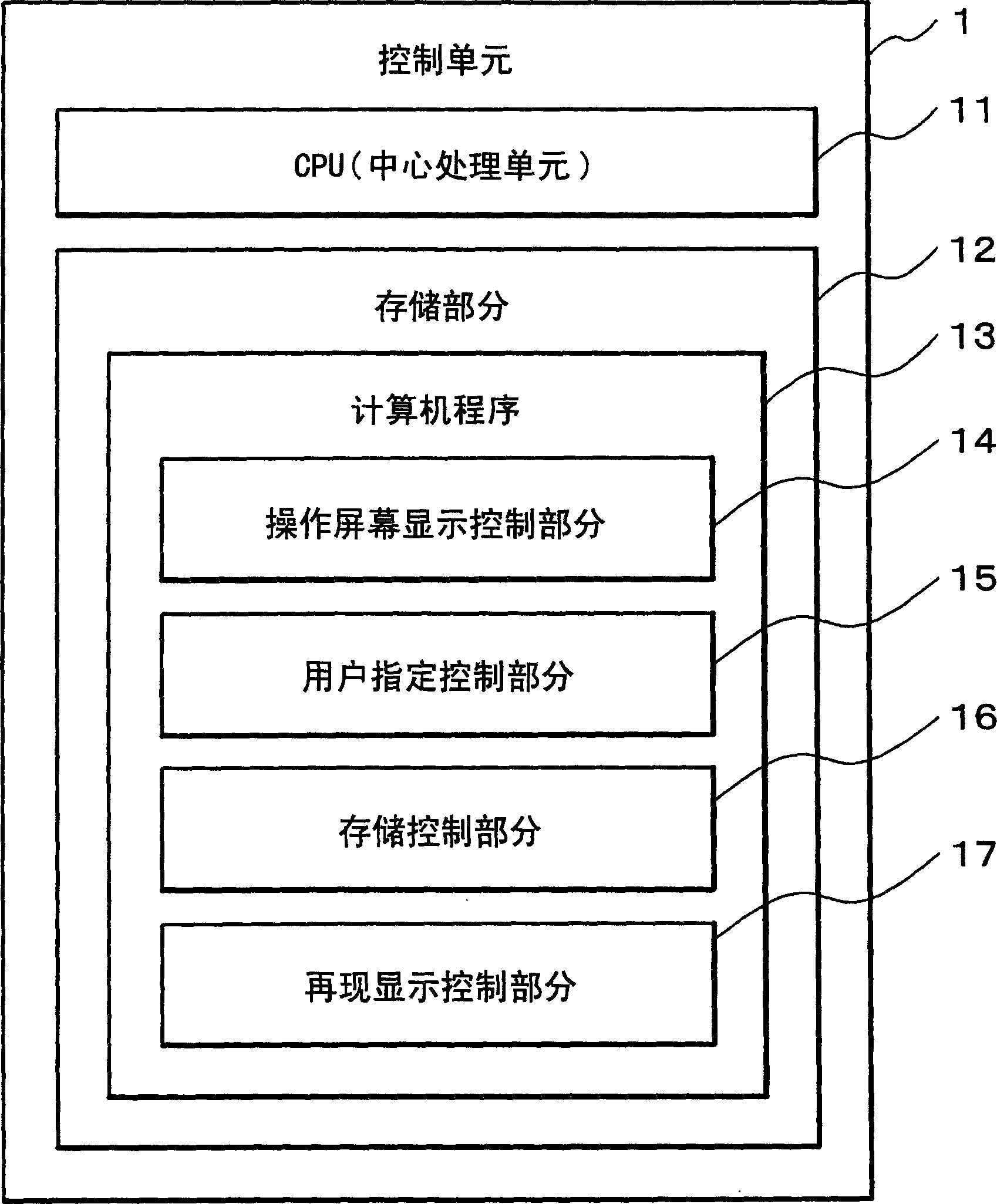

Apparatus and method for editing moving image data

InactiveCN1750630AReduced reproduction timeSave editing timeTelevision system detailsCarrier editingComputer graphics (images)Computer science

A apparatus and method for editing moving image data. A control unit displays an operation screen representing a plurality of moving image data on a display unit. The control unit specifies the first moving image data for each of the plurality of moving image data displayed on the operation screen. Editing time taken to edit a plurality of the moving image data is shortened, and the reproduction time in reproducing and displaying the moving image data is shortened.

Owner:NEC PERSONAL PRODUCTS LTD

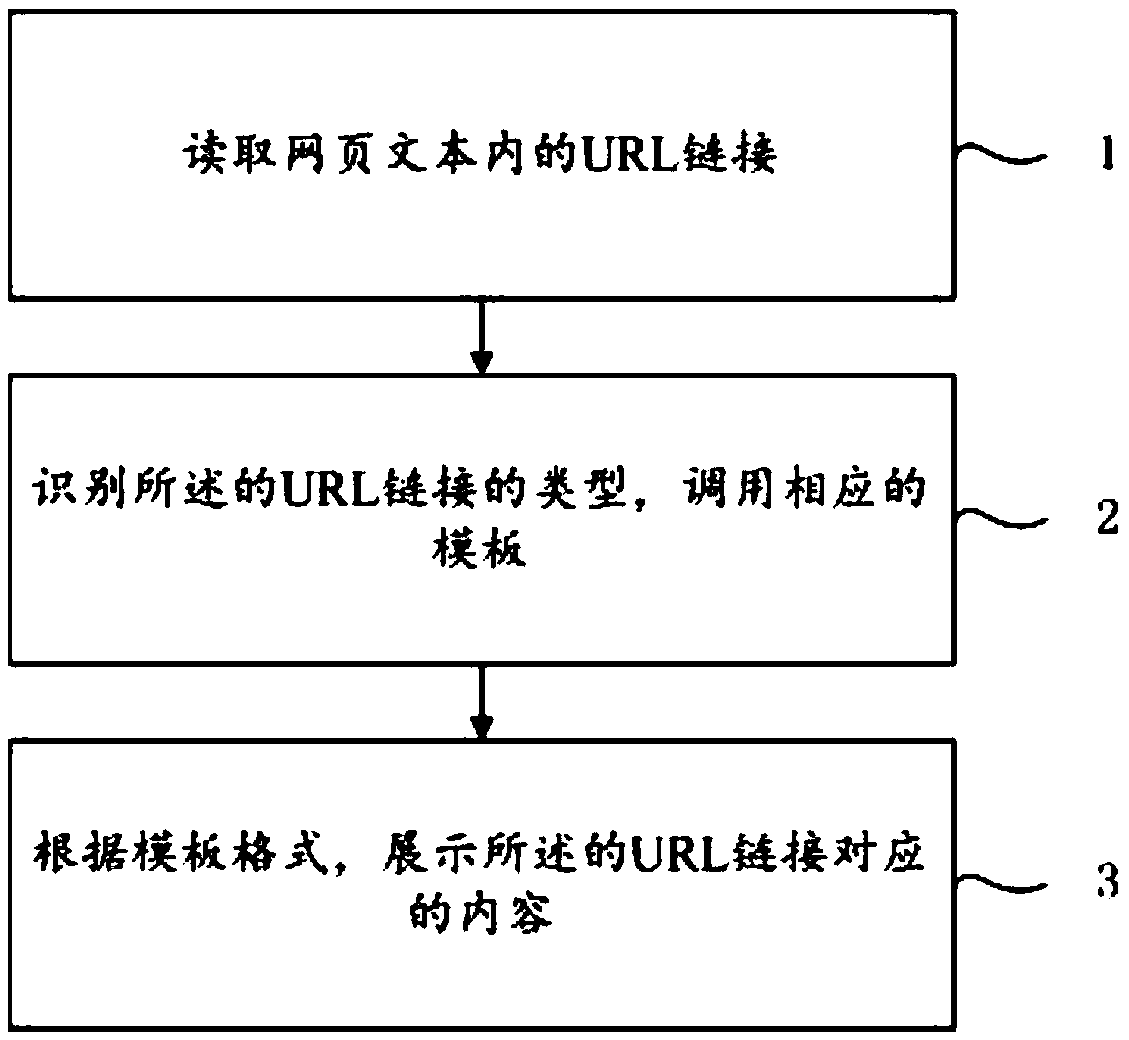

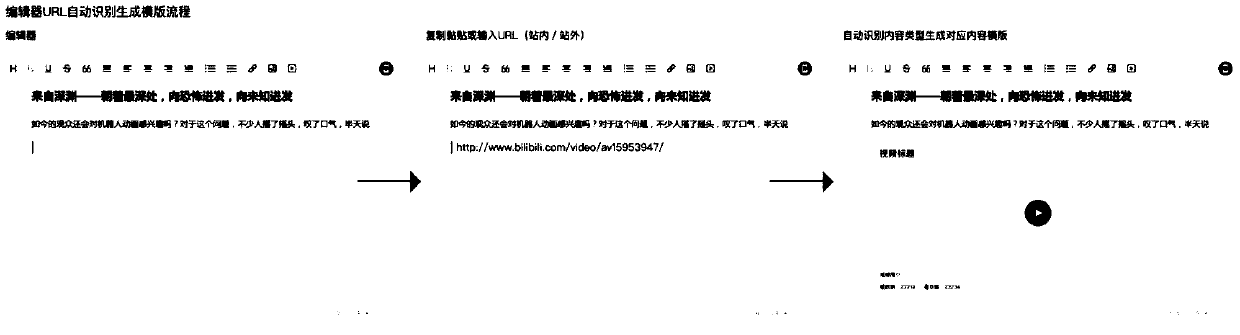

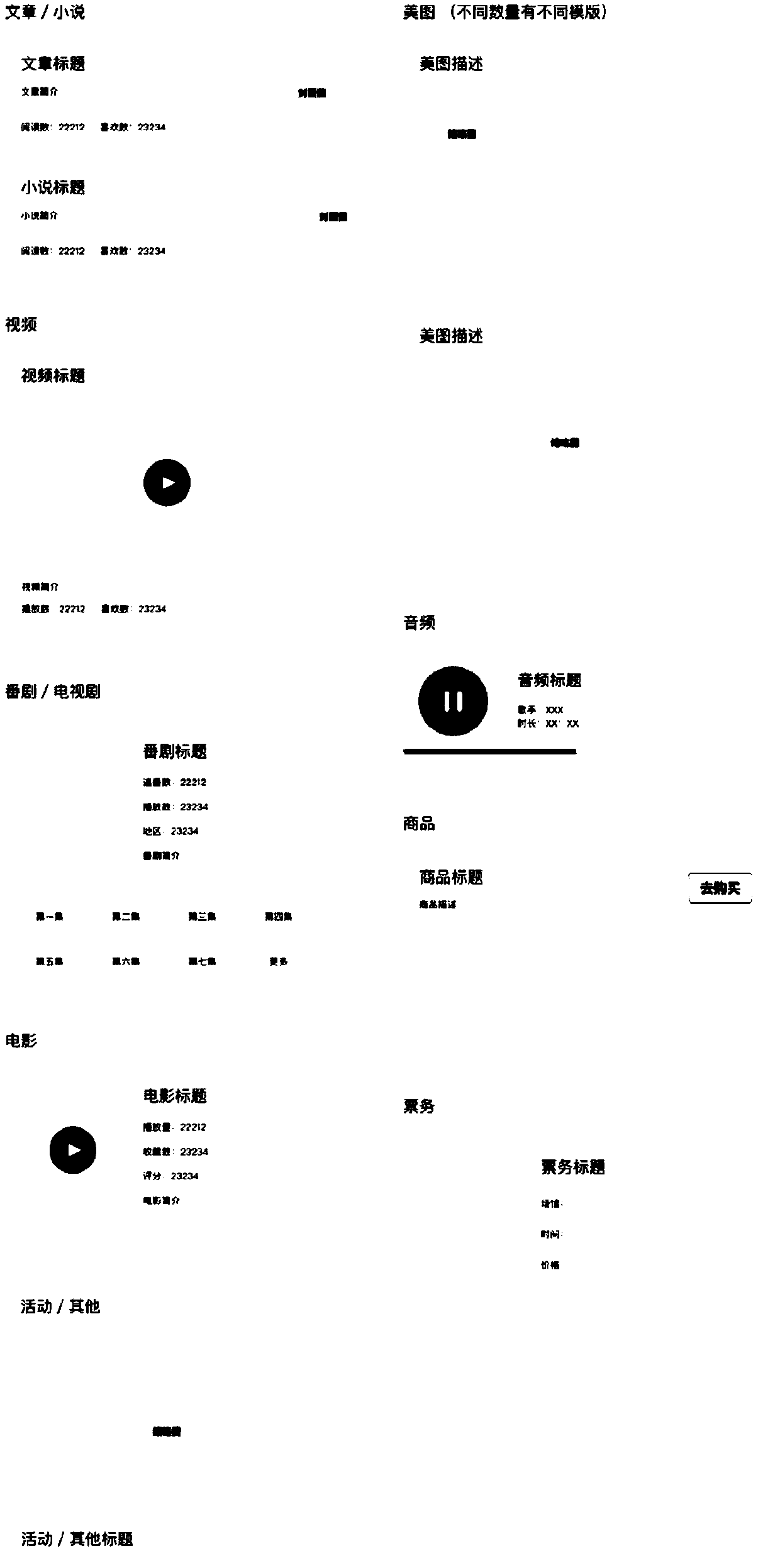

Webpage text editing method and device based on URL recognition and storage medium

PendingCN110781418AImprove convenienceImprove automation performanceNatural language data processingWebsite content managementText editingThe Internet

The invention relates to a webpage text editing method and device based on URL recognition and a storage medium, and belongs to the technical field of the Internet. The webpage text editing method comprises the following steps: reading a URL link in a webpage text; identifying the type of the URL link, and calling a corresponding template; and displaying the content corresponding to the URL link according to a template format. The webpage text editing device comprises a processor and a memorizer, wherein a computer program is stored in the memorizer, and when the computer program is executed by the processor, the webpage text editing method based on URL recognition is achieved. A computer program is stored on the medium, and when the computer program is executed by the processor, the webpage text editing method based on URL recognition is achieved. Compared with the prior art, the webpage text editing method has the advantages of being convenient to edit, high in automation performance, wide in application range and the like.

Owner:SHANGHAI BILIBILI TECH CO LTD

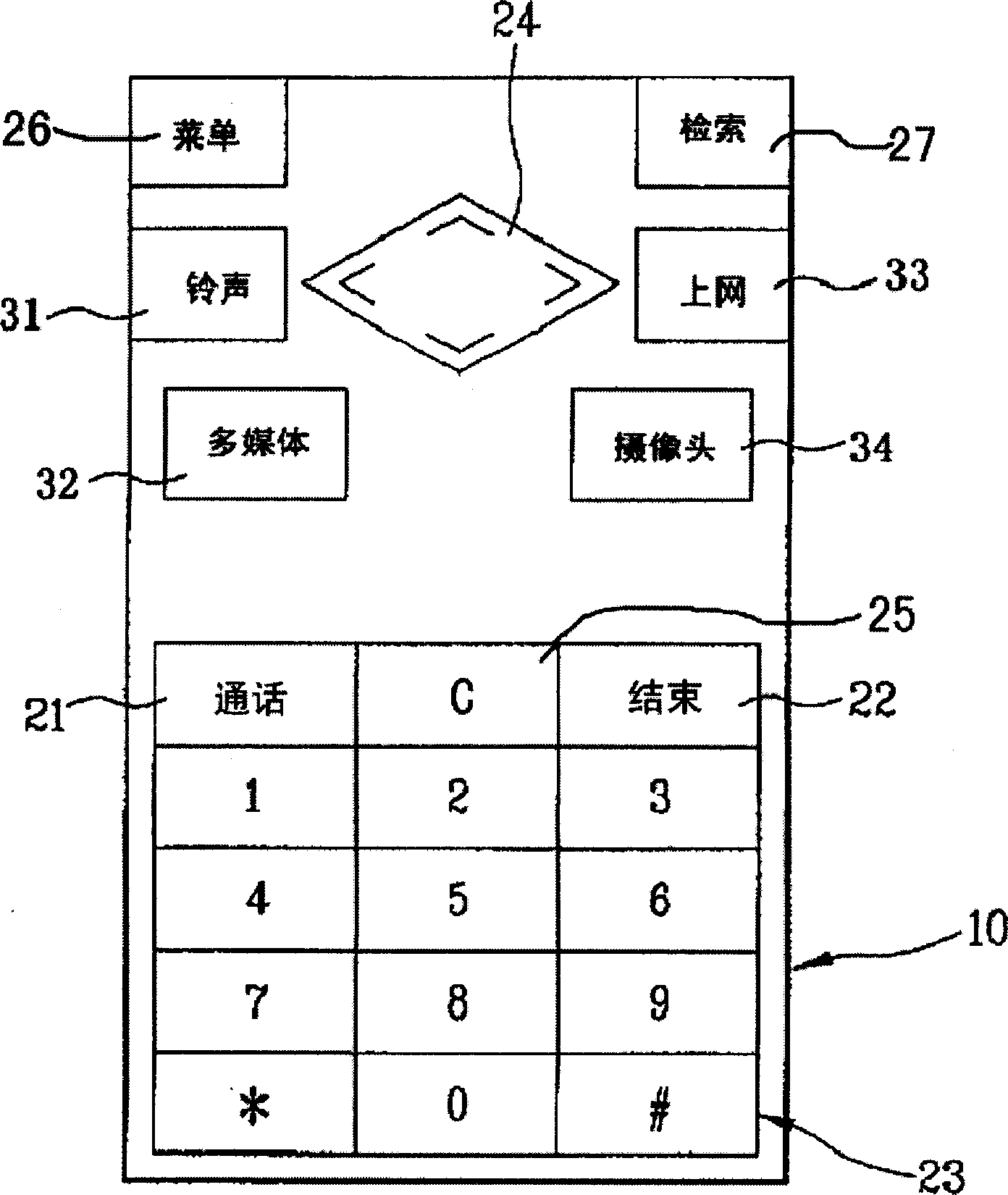

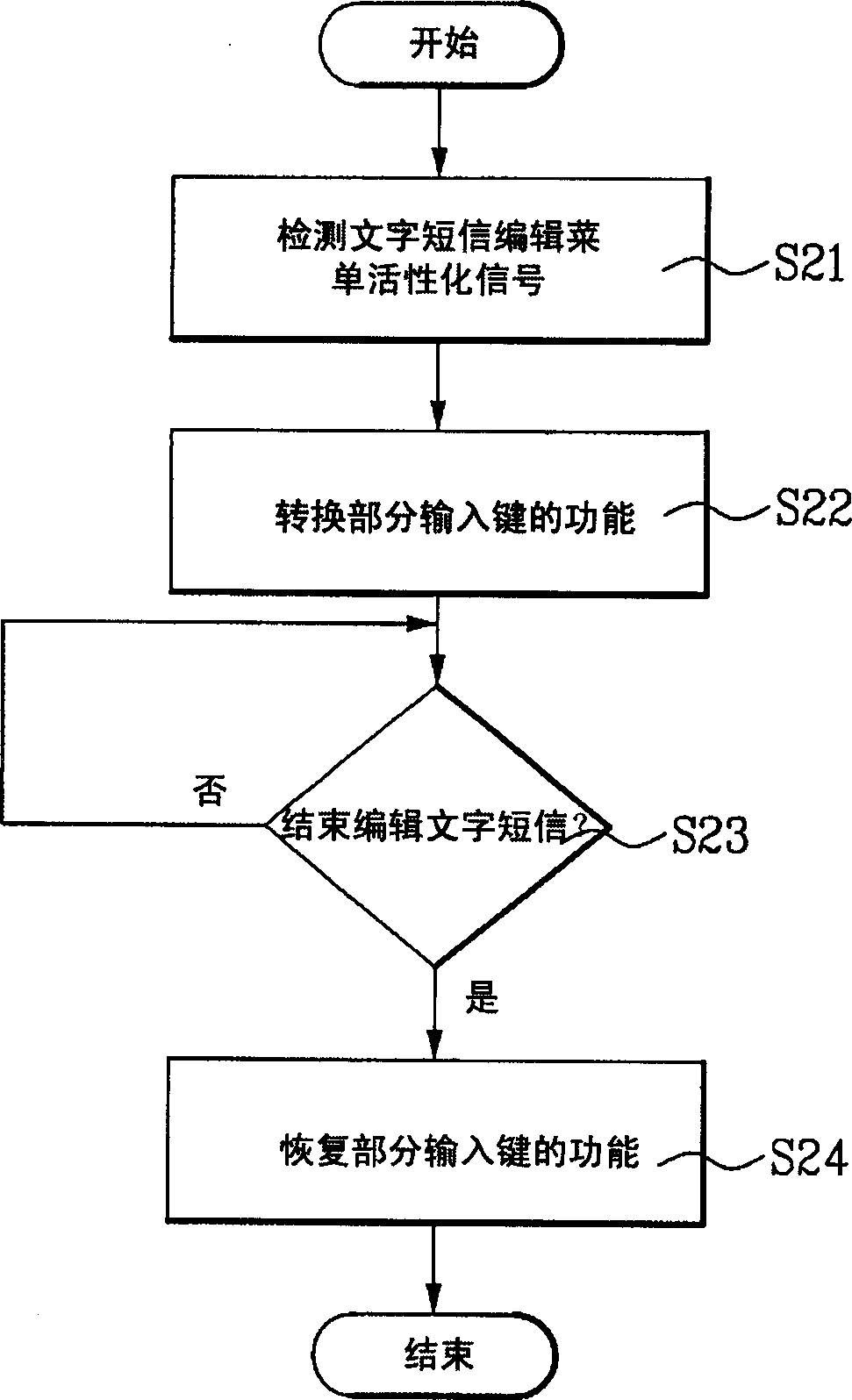

Mobile telephone with functional key for moving cursor quickly to edit short message and its method

InactiveCN1780303AImprove efficiencySave editing timeSpecial data processing applicationsTelephone set constructionsMobile phoneNon functional

The invention discloses a mobile phone with a function key for quickly moving a cursor when editing text messages and a method belonging to the range of mobile communication tools. The mobile phone includes a call key for making a call, a text or number or symbol input key, an end key for turning off / on and ending a call, a menu key, a search key, a delete key, and when selecting a menu or editing a text message, one grid up and down, left and right An arrow key for moving the cursor. It also includes multiple function setting keys such as mobile phone Internet access key, multimedia key or camera start key, and ringtone setting key; when editing a text message, the setting key has the function of activating and moving the cursor to the position required by the user, while the original There are functions that get deactivated. Therefore, when editing a text message, the user can quickly move the cursor to the beginning or end of the message, and to the front or back of the line where the cursor is located, thereby improving the efficiency of editing the text message and shortening the editing time.

Owner:LG ELECTRONICS (CHINA) R&D CENT CO LTD

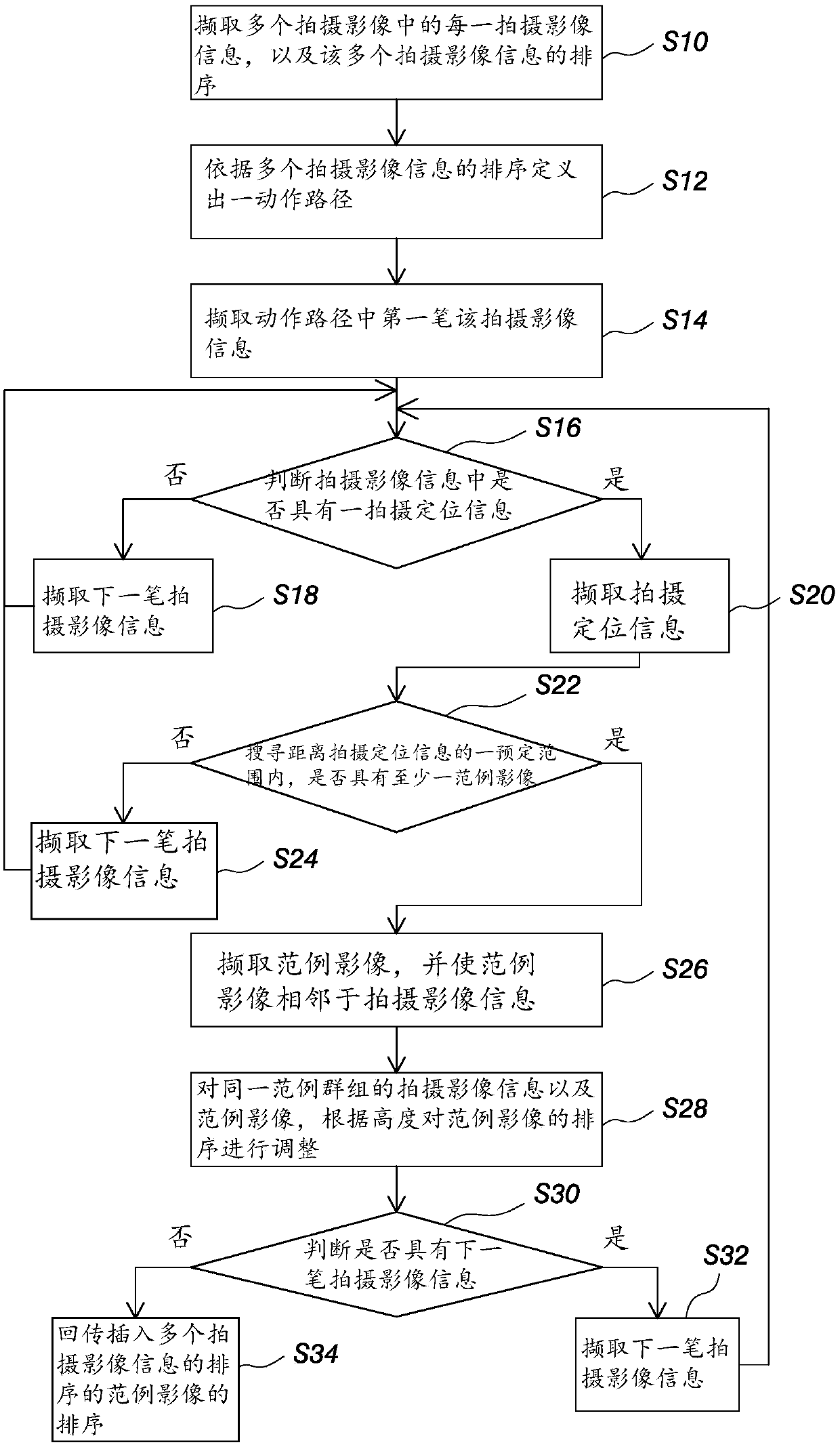

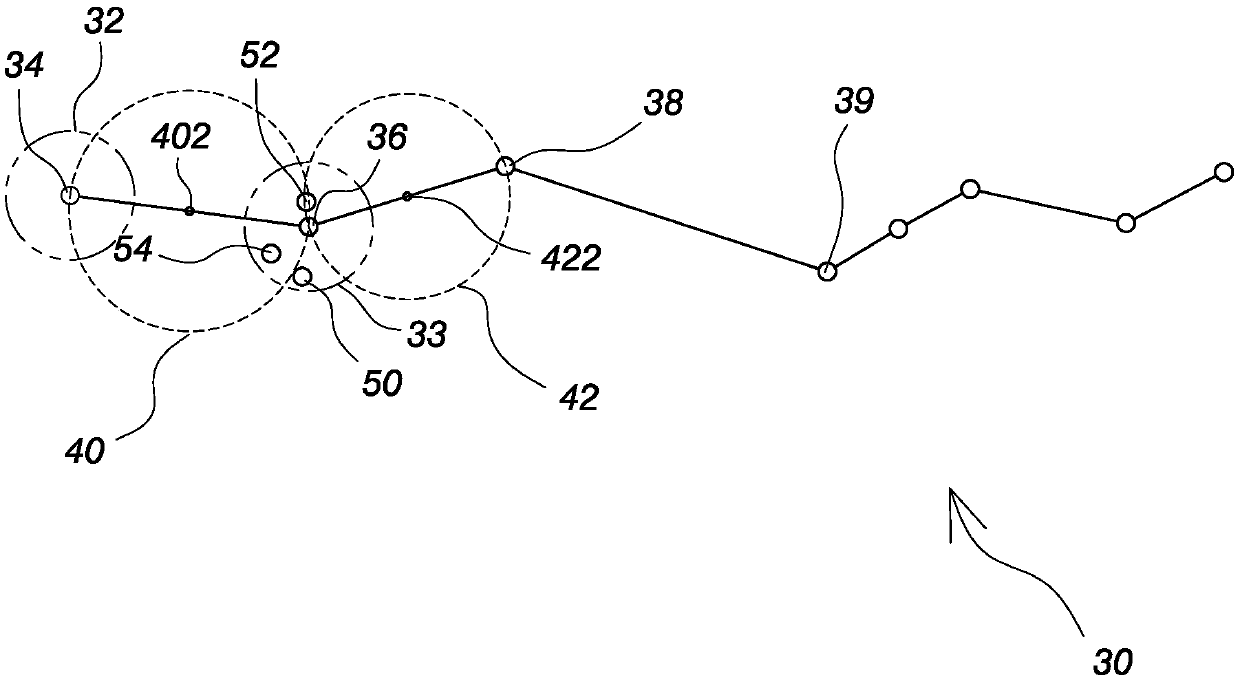

Rapid image sorting method

InactiveCN110377791ASave editing timeSmall footprintTelevision system detailsMetadata video data retrievalImage contentComputer graphics (images)

The invention discloses a rapid image sorting method. Only a plurality of pieces of shot image information and a plurality of pieces of shot image information in the device need to be selected and sorted; therefore, an action path can be defined. A distance action path is searched in a database; the first pen shoots an example image in a preset range of the positioning information; the next shooting positioning information is captured to repeatedly search the example image until no next shooting image information exists, and then the example image of the search result is returned to the periphery of the matching image of the sequence of the original plurality of shooting images of the device, so as to facilitate the user to visually see the image content and select and insert the image content into the sequence of the original plurality of shooting images. The image content of the image does not need to be output to the outside, the image can be searched and returned for arrangement only according to the shot image information of the device and the sequence of the shot image information, the image arrangement speed and the image content richness can be improved, and meanwhile, theimage picture content is prevented from being leaked.

Owner:刘谨铭

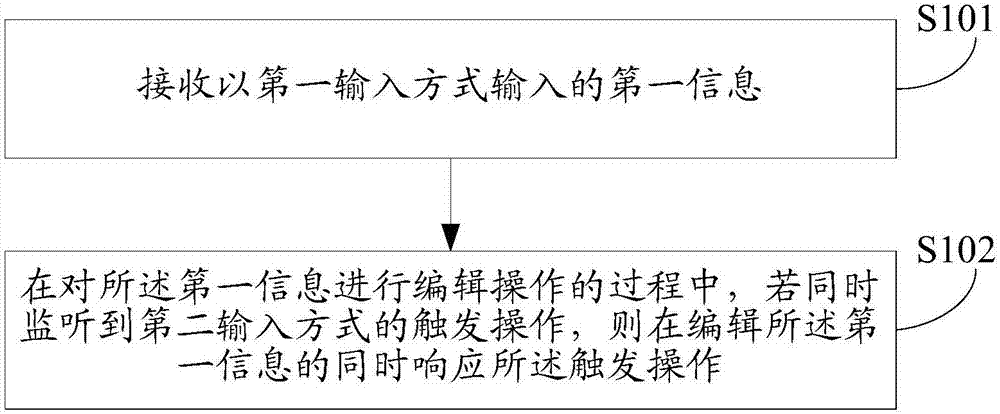

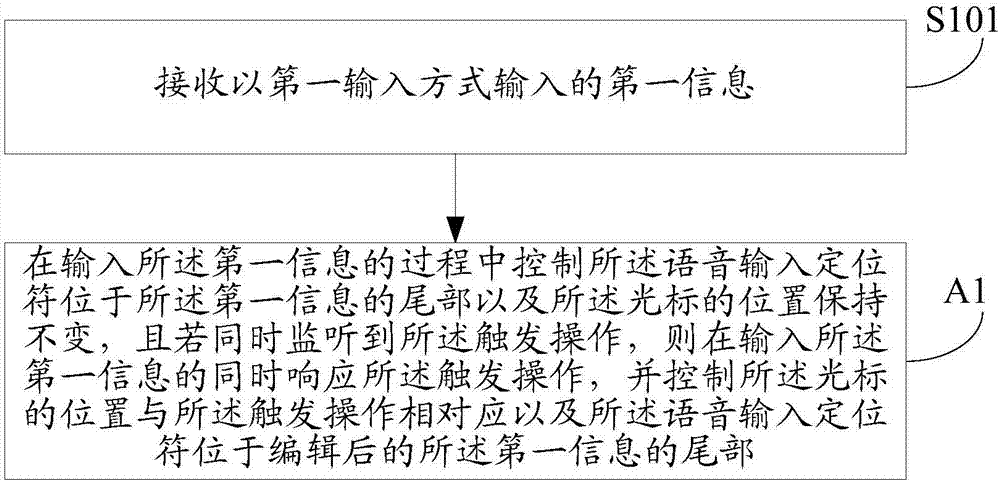

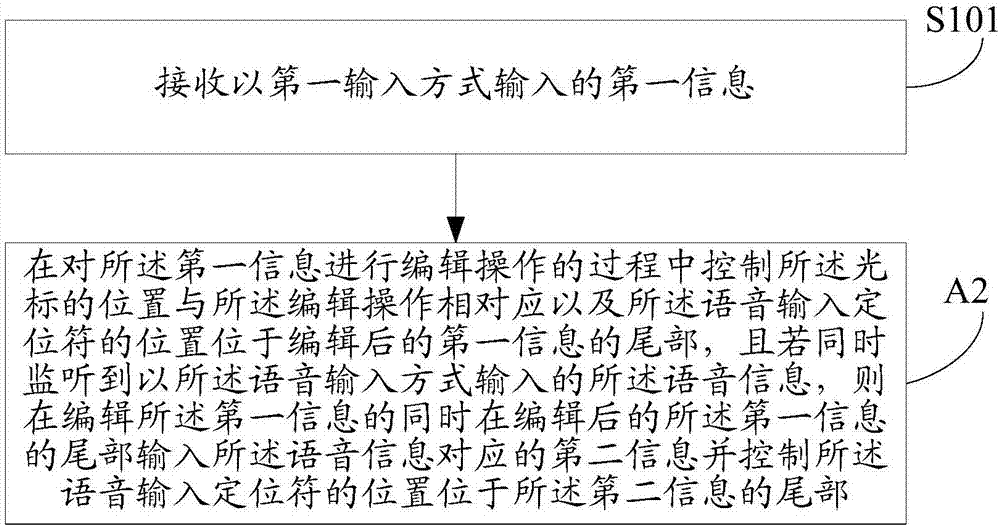

Information editing method and device

ActiveCN106940595AImprove editingSave editing timeInput/output for user-computer interactionGraph readingComputer science

Owner:BEIJING UNISOUND INFORMATION TECH

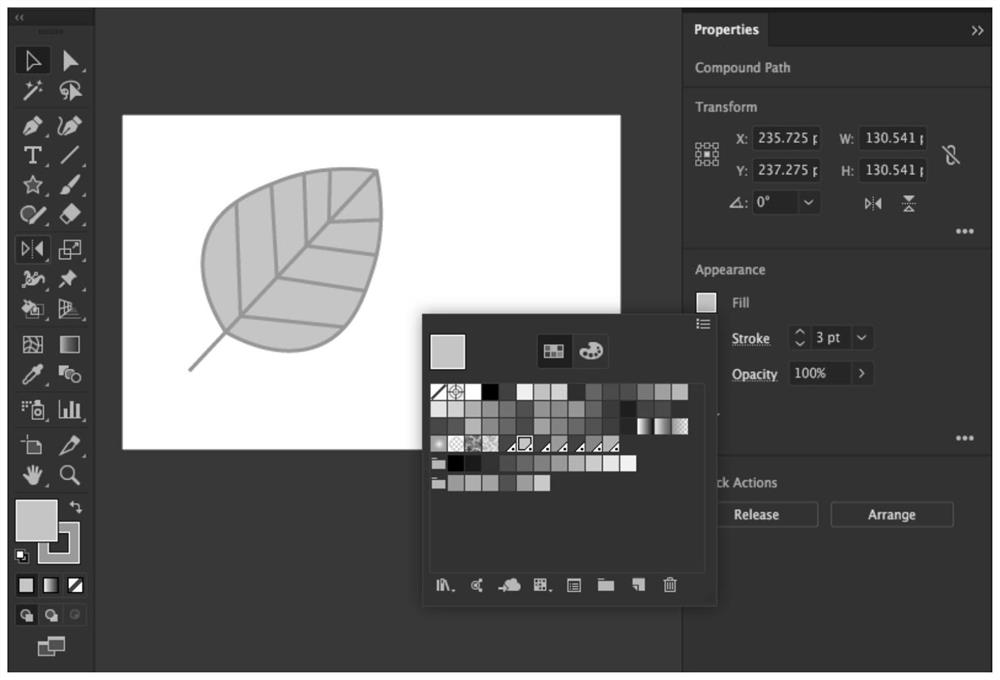

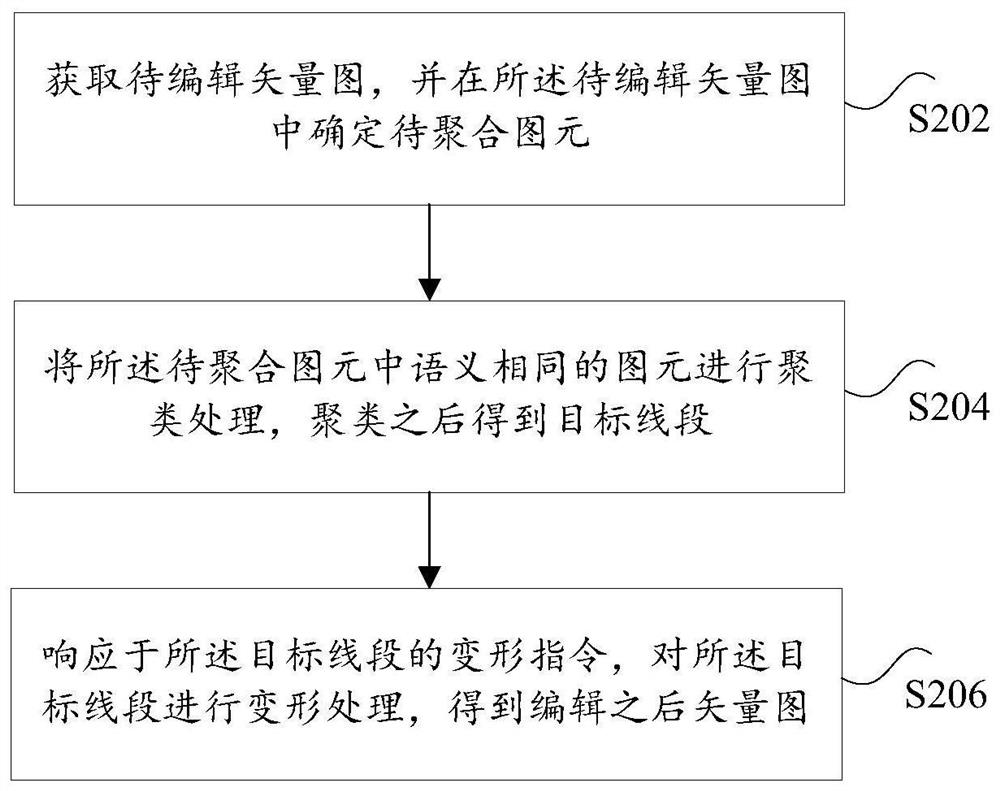

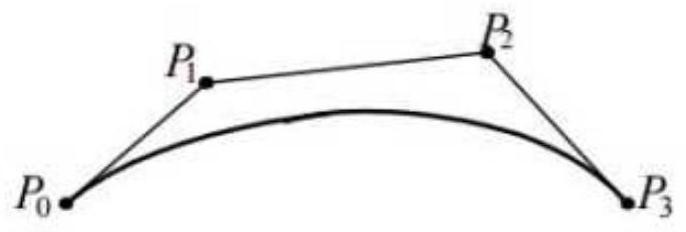

Vector diagram processing method and device, electronic equipment and computer readable medium

PendingCN112132928AQuick editImprove editing efficiencyDrawing from basic elementsCharacter and pattern recognitionAlgorithmTheoretical computer science

The invention provides a vector diagram processing method and device, electronic equipment and a computer readable medium, and relates to the technical field of graphic processing. The method comprises the steps: obtaining a to-be-edited vector diagram, determining to-be-aggregated primitives in the to-be-edited vector diagram, and enabling each to-be-aggregated primitive to comprise a line segment and / or a curve; clustering the primitives with the same semantics in the to-be-aggregated primitives , and obtaining a target line segment after clustering, wherein the primitives with the same semantics represent the primitives capable of being clustered to the same line segment; and in response to a deformation instruction of the target line segment, performing deformation processing on the target line segment to obtain an edited vector diagram. Technical problems of complex operation and low processing efficiency of an existing vector diagram editing method are alleviated.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

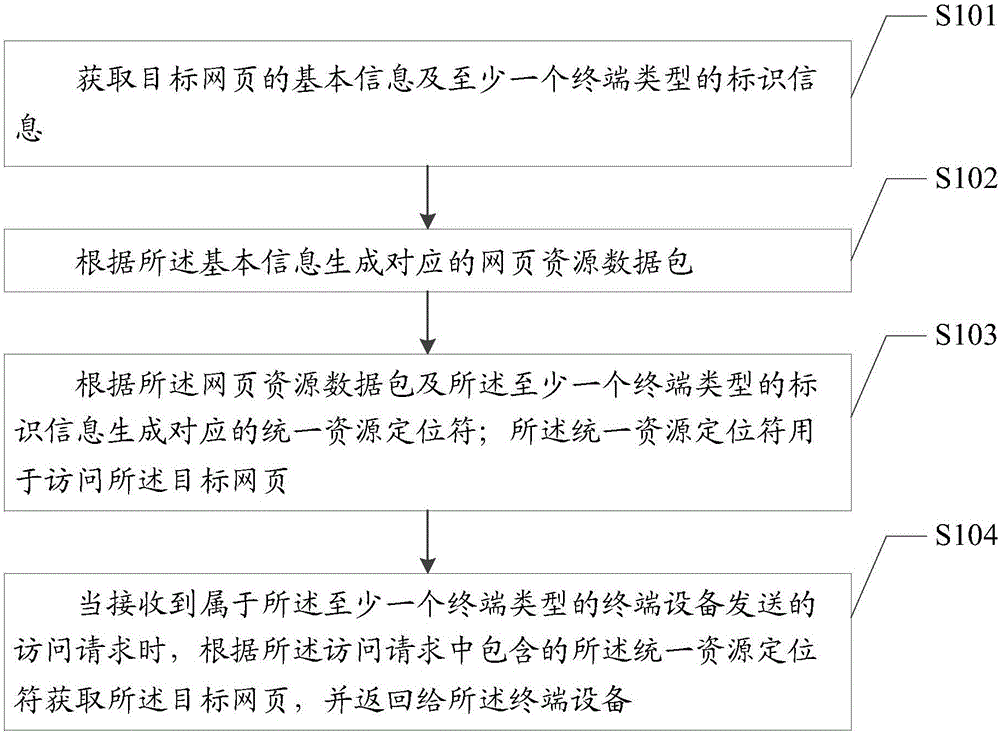

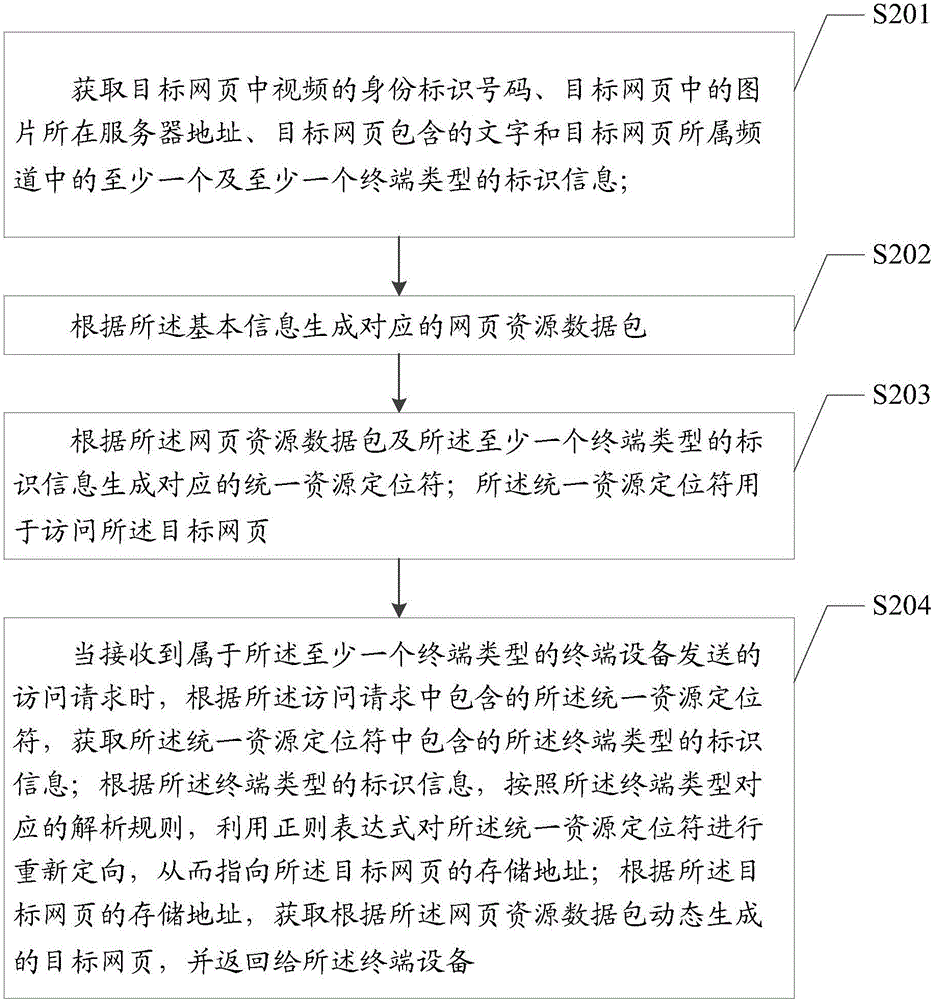

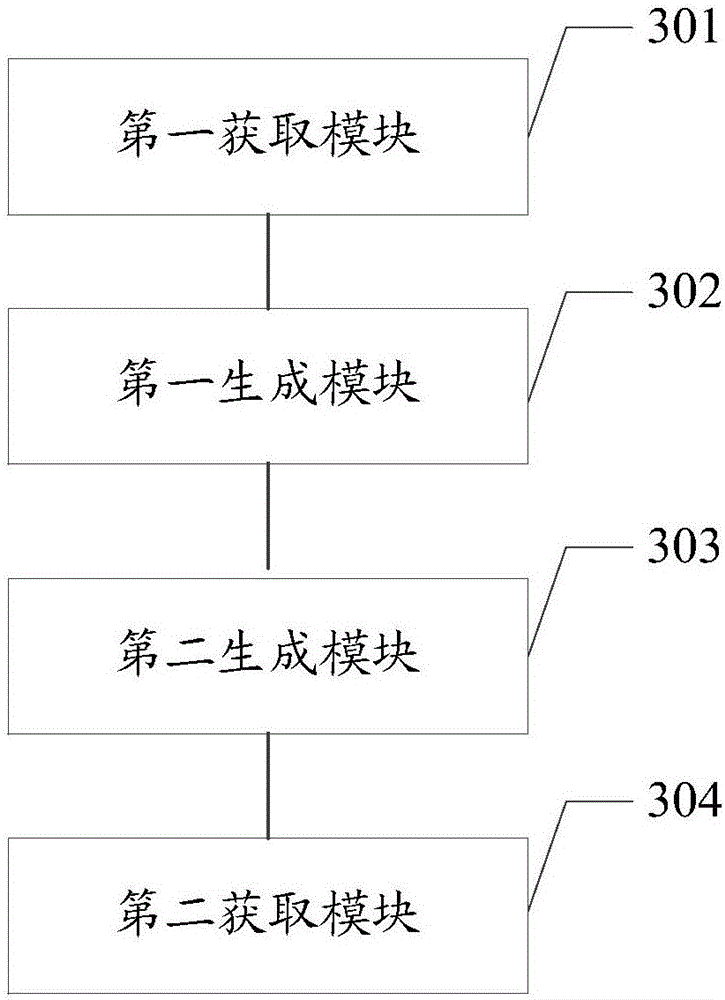

Web page generating method and device

InactiveCN106326403ASave editing timeWebsite content managementSpecial data processing applicationsStatic web pageWeb page

The invention is applicable to the technical field of web page making, and provides a webpage generating method and device. The method comprises the following steps: basic information of a target web page and identification information of at least one terminal type are obtained, a corresponding web page resource data package is generated according to the basic information, and a corresponding uniform resource locator is generated according to the web page resource data package and the identification information of the at least one terminal type, wherein the uniform resource locator is used for visiting the target web page; when an access request sent by terminal equipment belonging to the at least one terminal type is received, the target web page is obtained according to the uniform resource locator contained in the access request, and is returned to the terminal equipment. The web page generating method and device provided by the invention solve the problem that for different terminals, when a web page with identical displayed practical contents needs to be generated, repeated edition is needed for obtaining a uniform resource locator and further obtaining the web page.

Owner:LETV HLDG BEIJING CO LTD +1

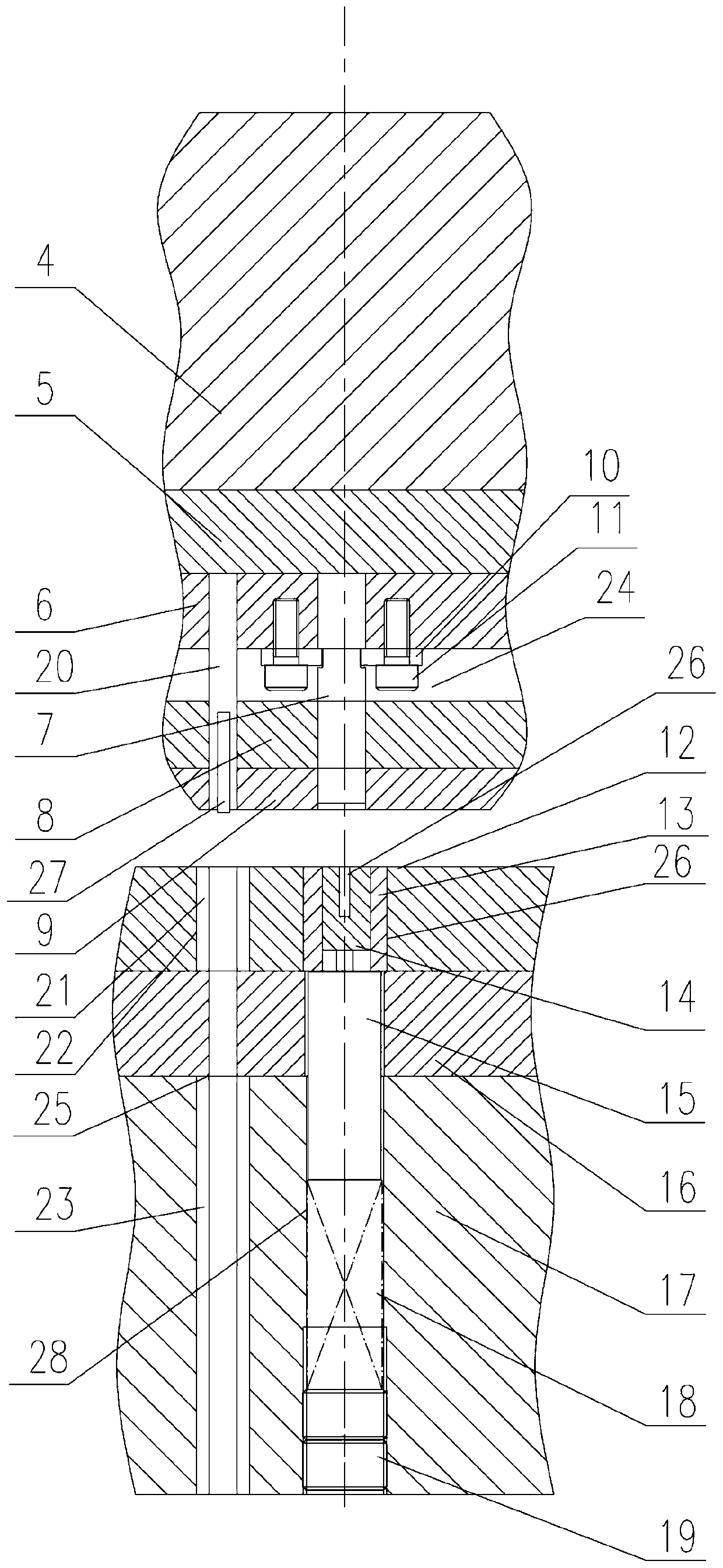

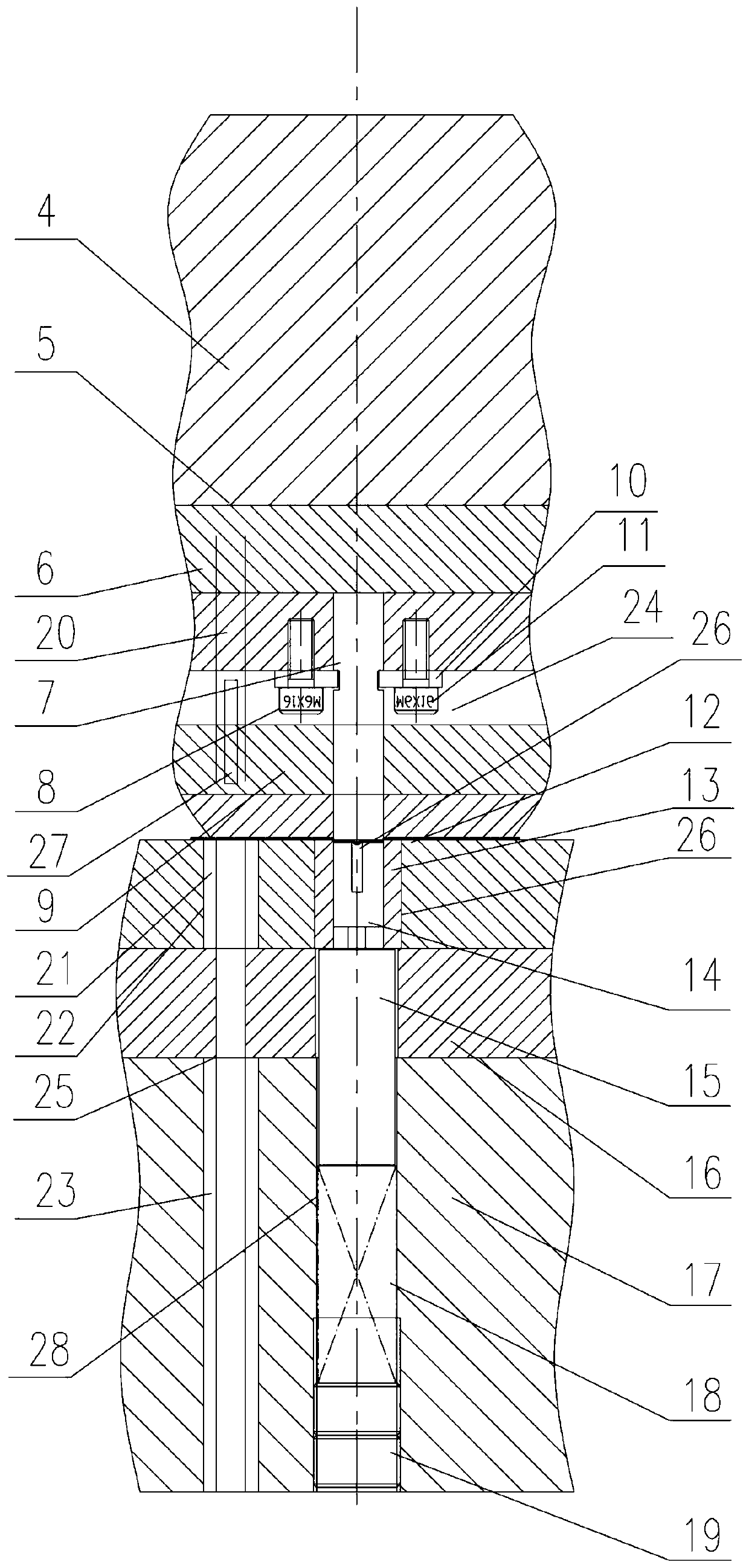

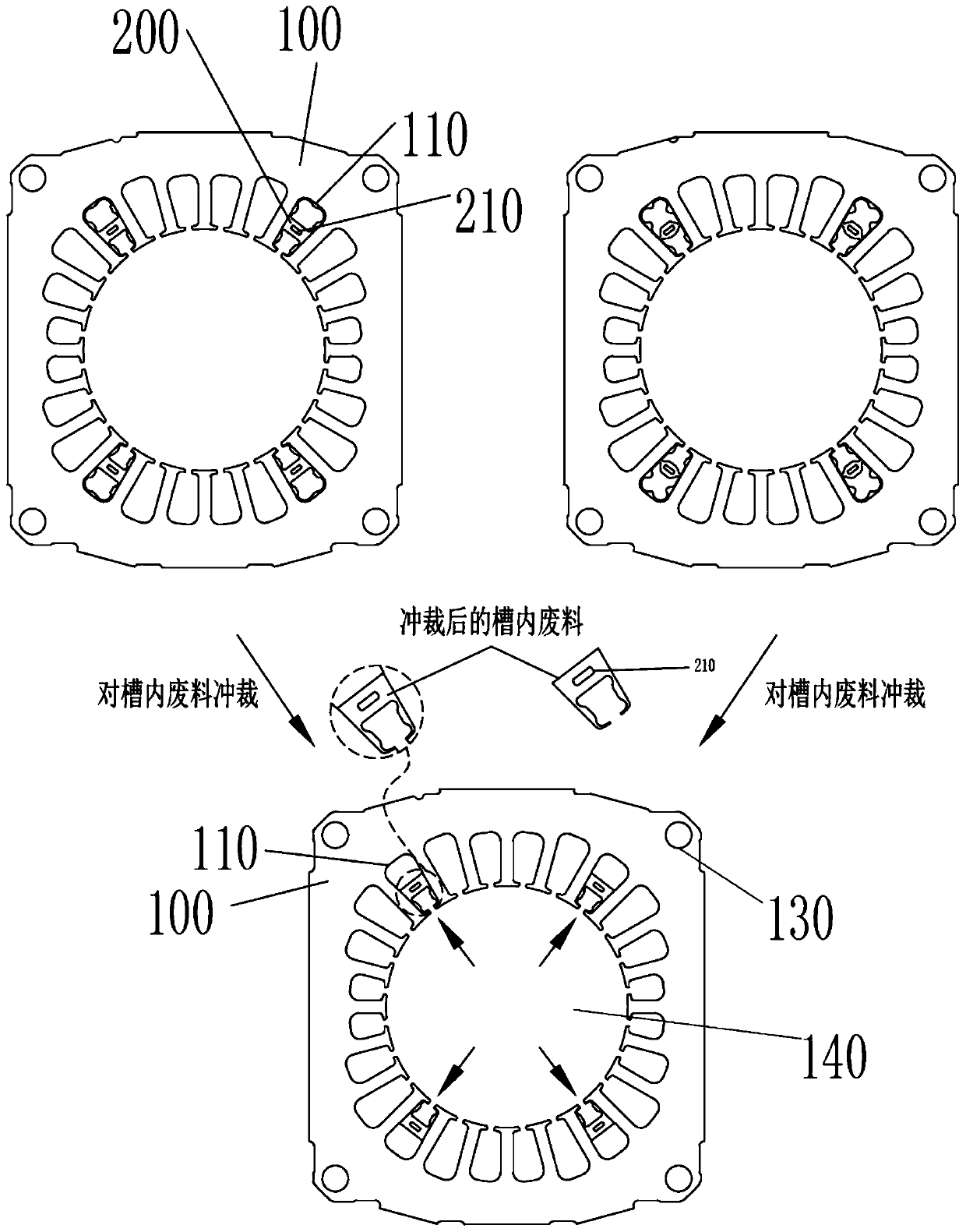

Manufacturing method for stacked iron core

ActiveCN110918777ASave editing timeImprove manufacturing efficiencyShaping toolsPerforating toolsManufacturing engineeringWaste material

The invention discloses a manufacturing method for a stacked iron core. The manufacturing method for the stacked iron core comprises the steps that multiple iron core pieces are punched in a machiningpiece one by one through a male die of a punching die, central holes, circular holes and / or through grooves, waste materials fixed in the circular holes or the through grooves in an interference fitmode and buckling points on the waste materials are formed in the iron core pieces while the iron core pieces are punched, and the through grooves are located in the inner side walls of the central holes or the outer circumferential sides of the iron core pieces; the multiple iron core pieces with the waste materials are stacked and then riveted through the buckling points, and the stacked iron core is formed; the waste materials in the through grooves are radially pushed to be radially separated from the through grooves; and a plurality of pits are formed in the inner side walls of the circular holes through punching in the step 1, a plurality of grooves and a plurality of convex blocks are formed in the outer circumferential walls of the waste materials in the circular holes, the end side faces of the convex blocks are closely attached to the inner side walls of the circular holes, and after the waste materials in the punched circular holes are rotated or radially pushed, the waste materials in the circular holes are in a suspended state and automatically fall to be separated from the circular holes. According to the method, the using performance is better, and the stacked iron core is perfect after being formed.

Owner:NINGBO ZHENYU TECH

Processing program post-processing method and light guide strip die processing method

ActiveCN110209121ASave editing timeAvoid elongation errorsProgramme controlComputer controlNumerical controlLight guide

The invention discloses a processing program post-processing method and a light guide strip die processing method and belongs to the field of die manufacturing. The device comprises the following steps: reading information of a CAM program list; performing automatic tool changer matching on tool information in the CAM program list; performing program selective merging on the same tools of different workpieces; automatically connecting programs in series and printing a series program list, thereby improving the automation process and reducing the error rate. The invention further provides a dieprocessing method. The die processing method comprises the following steps: calculating numerical control data according to a die processing procedure; selecting a machining tool with the diameter tolerance within 0.002 mm; performing processing program processing to obtain processed numerical control data; controlling the room temperature to be 20-21 DEG C, and maintaining the constant temperature; adjusting the radial runout of a main shaft in the installation state of the machining tool to be within 0. 001 mm; preheating the main shaft to 25-26 DEG C; and processing according to the processed numerical control data, so that the processing quality can be effectively improved.

Owner:慈溪市悦宇精密模具有限公司

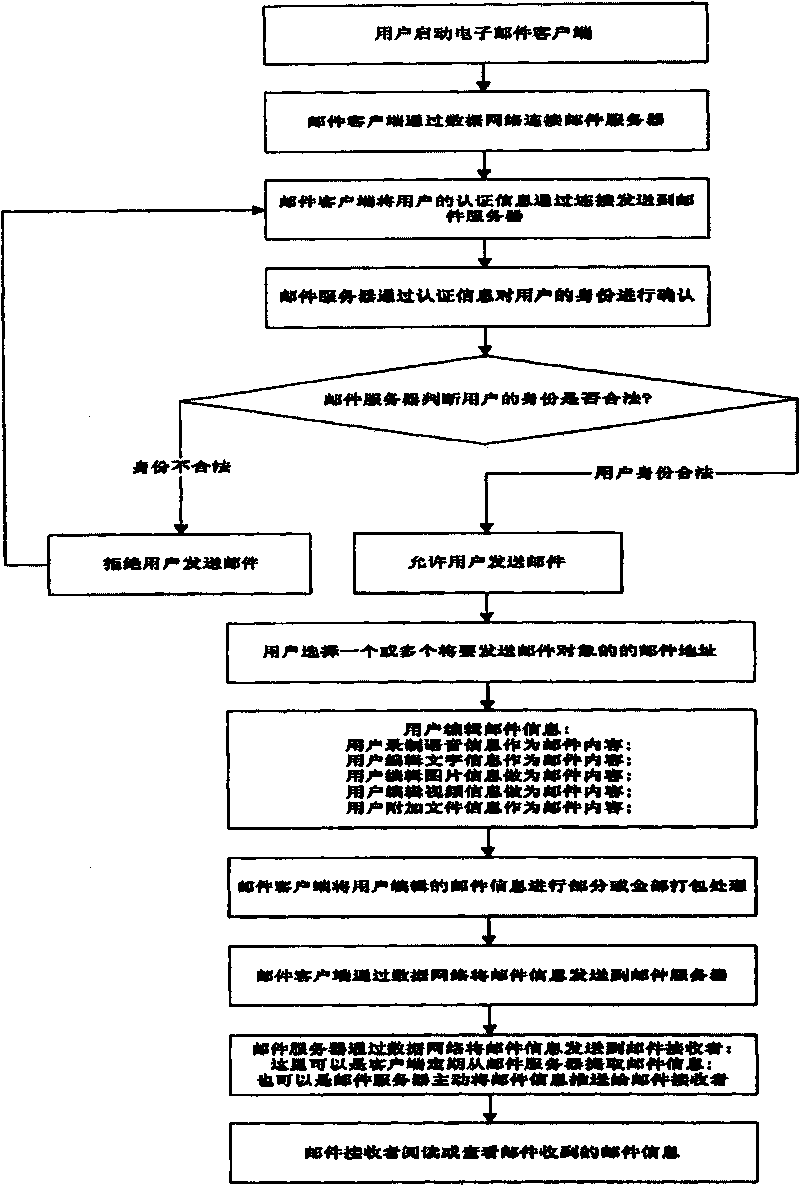

Computer connection transmitting and transceiving method

InactiveCN101699804ASolve input difficultiesResolution timeData switching networksSecuring communicationClient-sideSpeech sound

The invention provides a computer connection transmitting and transceiving method which is characterized by comprising the steps: step 1, the user starts and operates an email client in a terminal; step 2, the user transfers voice recording equipment of the terminal and directly records the words of the user into voice mail; steps 3, the voice mail is sent to a mail server by a data network, and then is provided for the mail receiver by the mail server according to the mail address; and step 4, after receiving the voice mail, the mail receiver transfers a voice play device of the terminal to directly listen in to the voice mail. The method can lead the mail sender to conveniently edit the mail information, and provides a simple way for reading the mail for the mail receiver at the same time.

Owner:卢苇

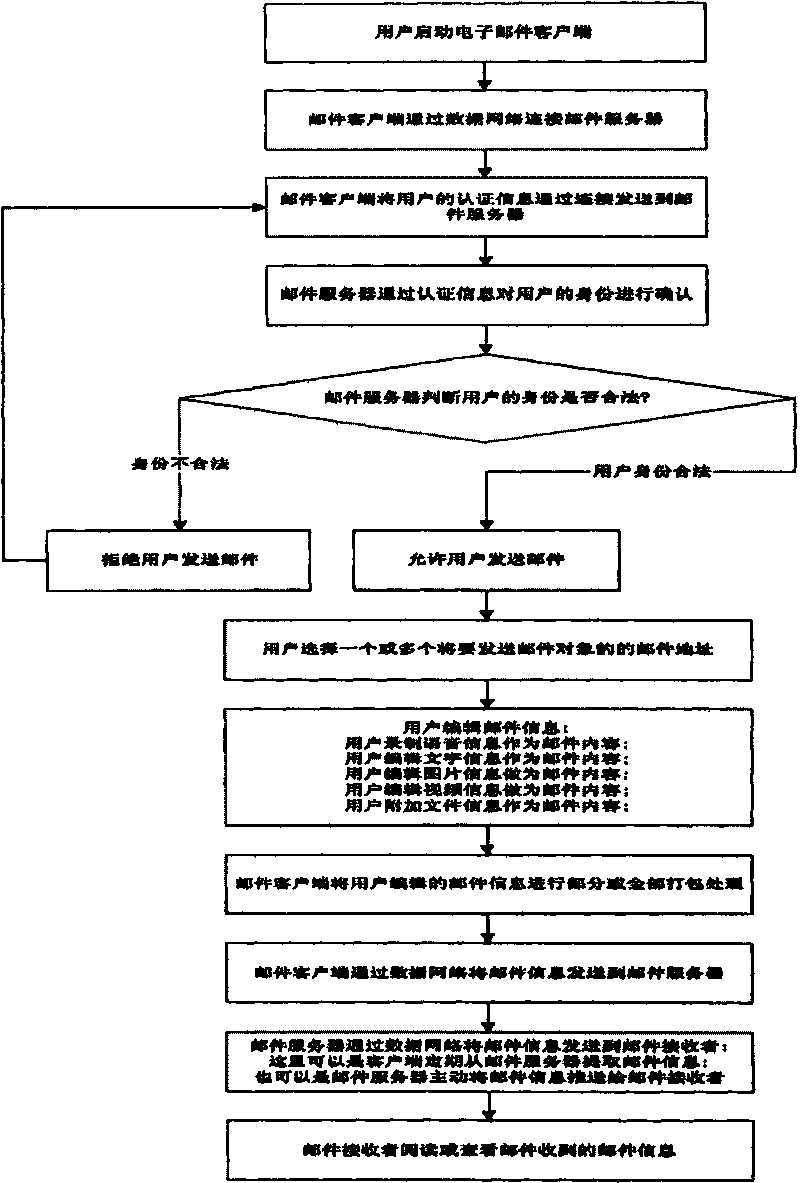

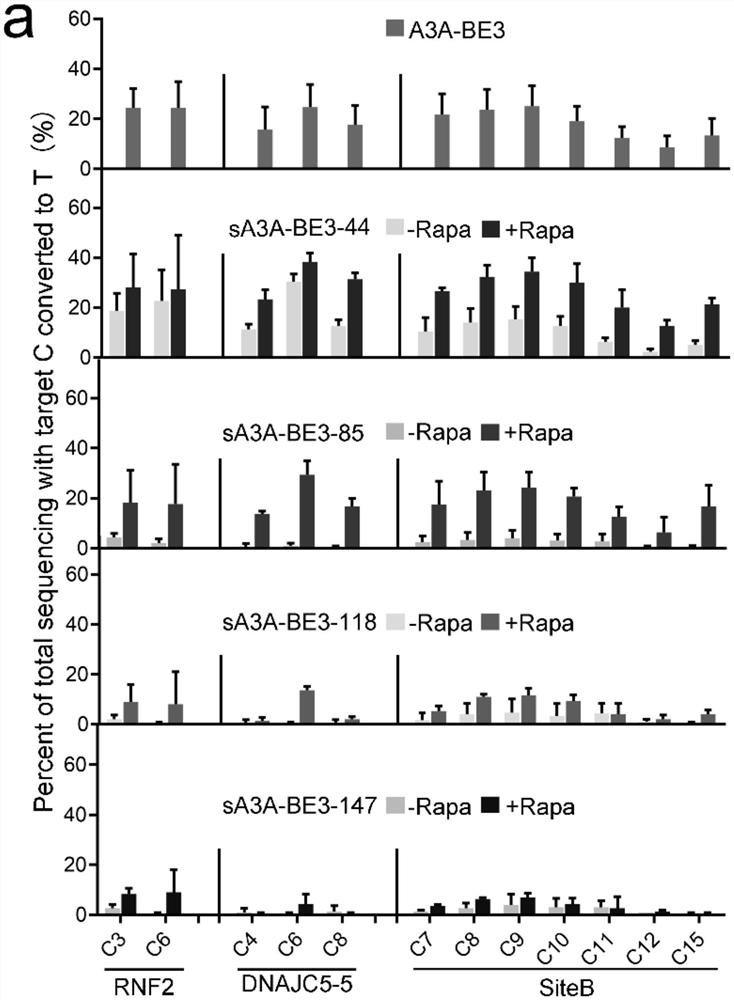

Inductive base editing system and application thereof

ActiveCN112877314ASave editing timeReduce off-target editingHydrolasesDNA/RNA fragmentationCytosine deaminaseBase J

The invention discloses an inducible base editing system and an application thereof. The base editing system is composed of inducible human source cytosine deaminase (A3A) and SpCas9 with single nick activity; the deaminase can be split on the basis of potential amino acid sites; rapamycin interacts with the N end and the C end of the amino acid resolution site through FRB / FKBP to recombine split deaminase, and basic group editing is completed through induction. According to the method, the base editing activity is controlled by constructing the inducible base editing system, so that off-target editing is reduced; meanwhile, the splitting design in the application does not reduce target editing, so that the splitting design can be used as a compensation strategy of protein mutation, and can be used in combination with the mutated deaminase to further reduce off-target editing.

Owner:SICHUAN UNIV

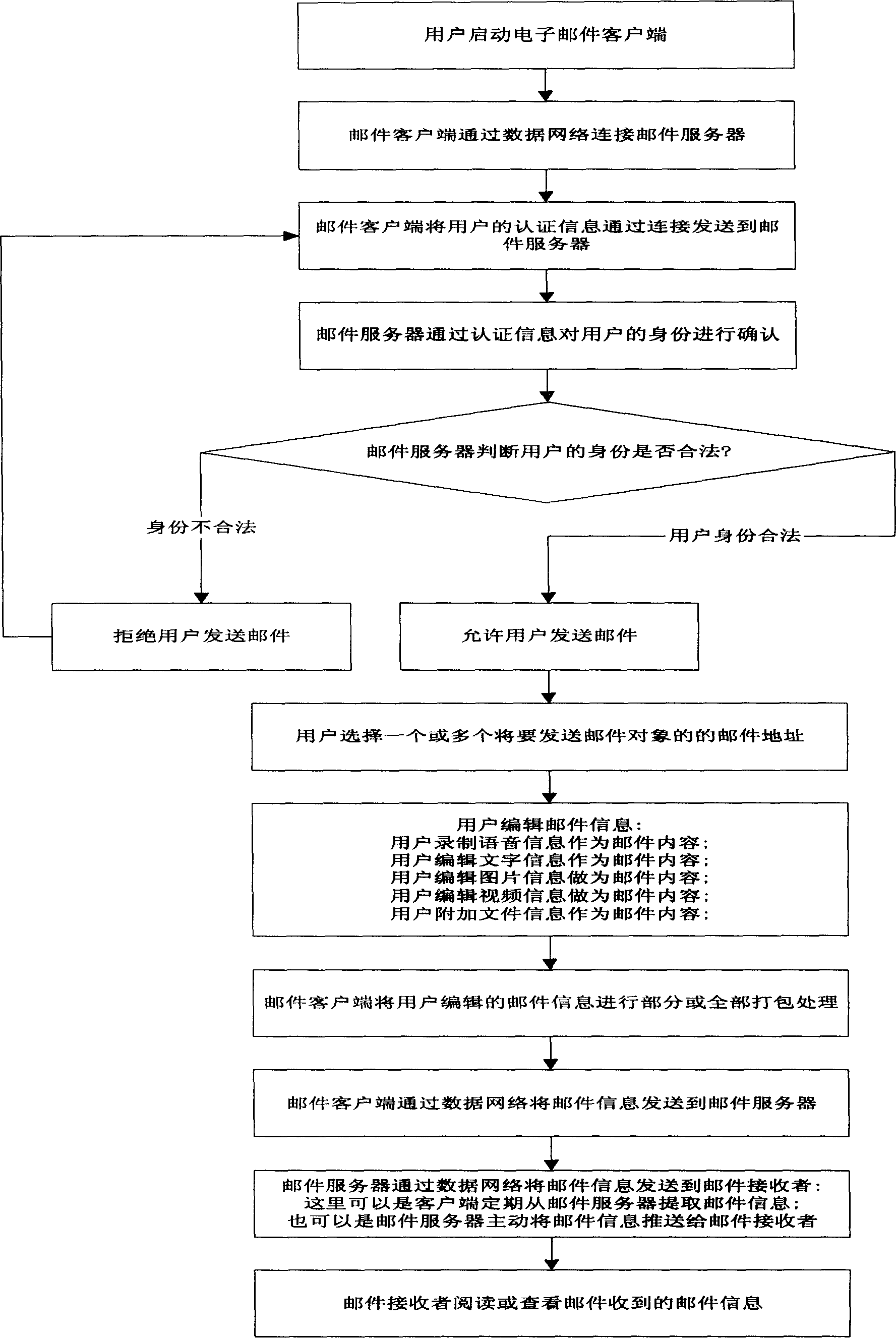

Method for transmitting and receiving E-mail

The invention is an E-mail transmitting-receiving method, characterized in that in includes the below steps of: 1. a user starts up and operates Email client end in a terminal; 2. the user calls sound recording equipment in the terminal to directly record what he said into a voice E-mail; 3. He transmits the voice E-mail through data network to an E-mail server and the E-mail server provides it for an E-mail receiver according to the E-mail address; 4. the E-mail receiver obtains the voice E-mail and then calls voice broadcasting equipment in the terminal to directly listen in to the voice E-mail. The invention can be convenient for an E-mail transmitter to edit E-mail information and simultaneously provides a simple E-mail reading mode for an E-mail receiver.

Owner:蒋晓海

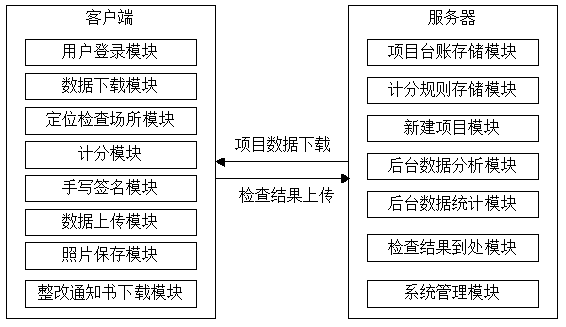

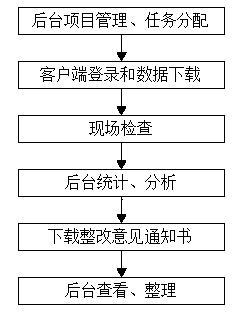

A system and method for fire protection inspection

InactiveCN109460967AImprove analytics utilizationReduce error rateNatural language data processingOffice automationFire protectionEngineering

A system and method for fire protection inspection is provide, comprises a fire inspection system composed of a client and a server, the client end provides an inspection interface for assisting a fire inspector to carry out on-site inspection, At that same time, it also provide the function of taking photograph corresponding to specific inspection problems, At the end of the inspection, the owneris required to sign and confirm the function, as well as the on-site function of giving the notice of rectification opinions to rectify the major problems found in the inspection, and the server provides the unified specifications of the inspection and the calculation support to the inspection results, which effectively improves the efficiency, scientificity and interactivity of the fire controlinspection.

Owner:中联科锐消防科技有限公司

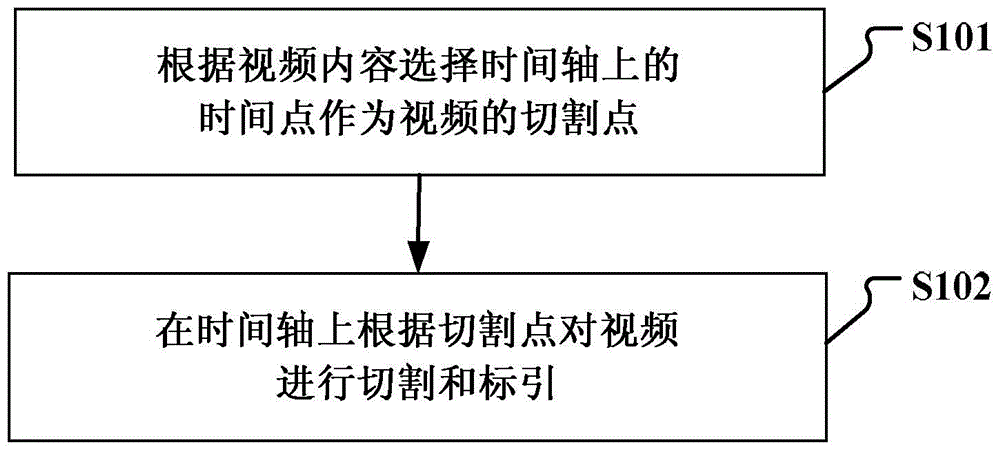

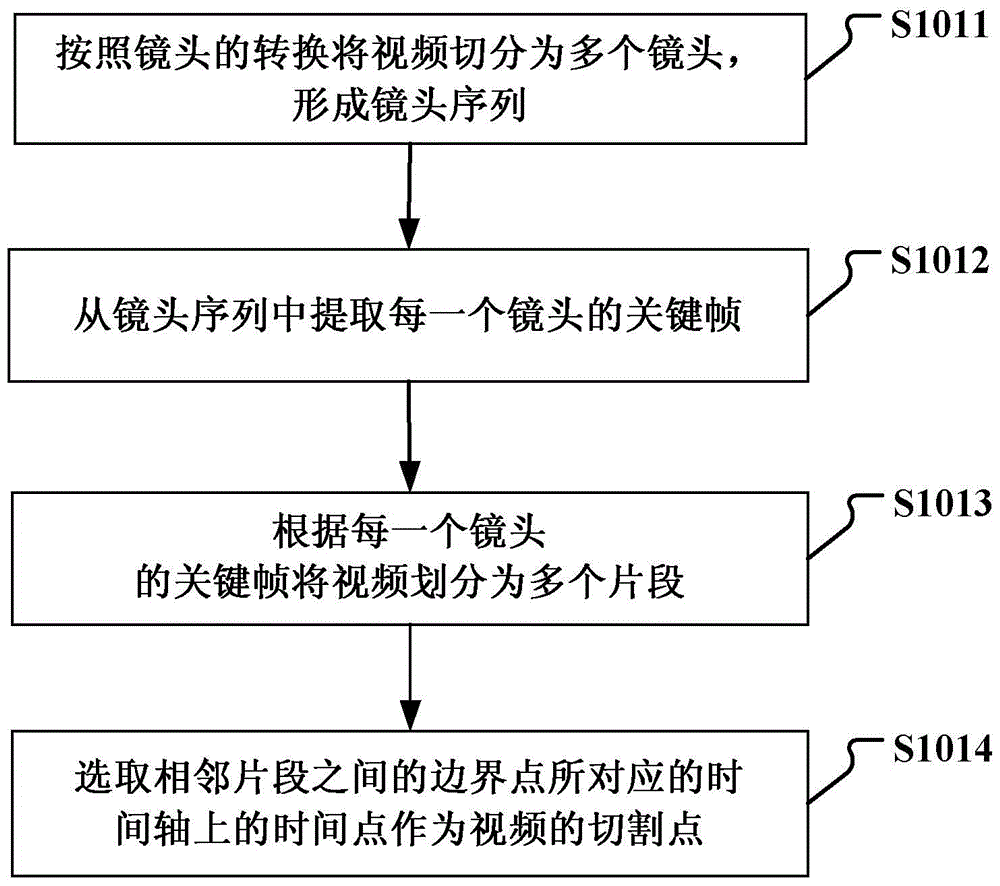

A video processing method and device

InactiveCN104185088BImprove editing efficiencySave editing timeSelective content distributionComputer graphics (images)Video processing

The invention discloses a video processing method and device which are used for realizing rapid indexing of a video. The method comprises selecting time points on a time axis as cut points of the video according to the contents of the video, and carrying out cutting and indexing on the video on the time axis according to the cut points. Through cutting and indexing the video on the time axis, the function of carrying out quick positioning on the video is realized, thereby helping to give auxiliary instructions to the video and enhancing the information bearing capability of video data.

Owner:WUXI TVMINING MEDIA SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com