Patents

Literature

40results about How to "Shiny metallic luster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-purity arsenic deoxidizing device and method

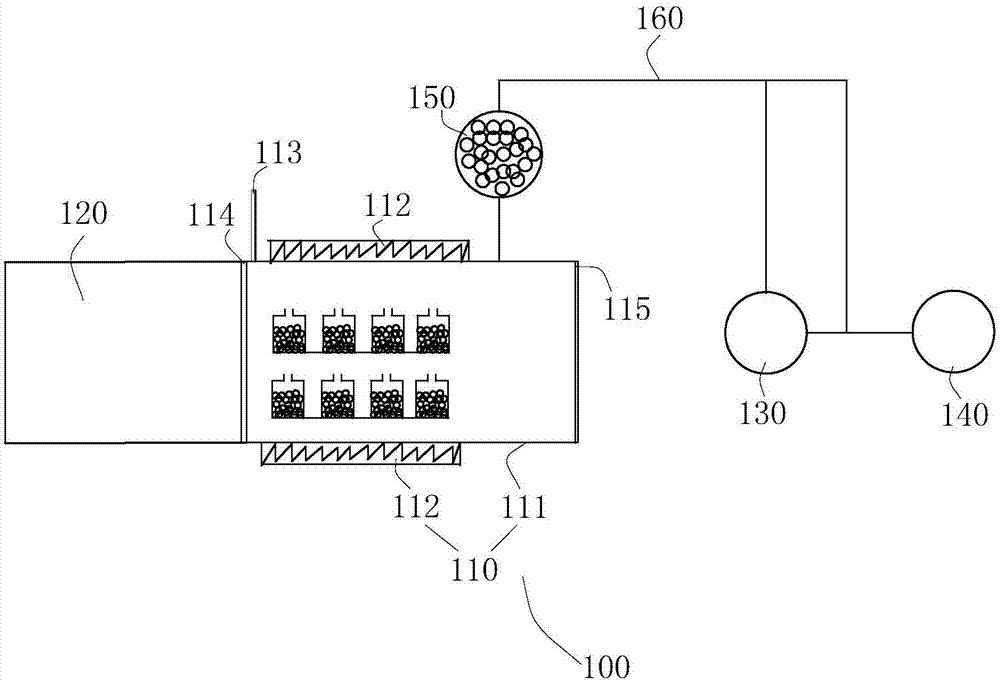

The invention provides a high-purity arsenic deoxidizing device which comprises a deoxidizing furnace and further comprises a glove box, a vacuum pump and a tail gas treatment device, wherein the glove box and the deoxidizing furnace share a bin door, the vacuum pump is connected with the deoxidizing furnace through an air flow pipeline, and the tail gas treatment device is connected with the vacuum pump through an air flow pipeline. A dust remover is arranged between the deoxidizing furnace and the vacuum pump. The deoxidizing furnace comprises a furnace body, a heating sleeve arranged outside the furnace body in a wrapping mode and an air inlet pipe. The two sides of the furnace body comprise the first bin door and a second bin door which can be opened and closed, and the first bin dooris shared by the deoxidizing furnace and the glove box. The dust remover is directly connected with the tail gas treatment device through another air flow pipeline. By adopting the high-purity arsenicdeoxidizing device and a high-purity arsenic deoxidizing method, the analysis result of prepared high-purity arsenic shows that after deoxidizing, the oxygen content of the high-purity arsenic is smaller than 1 ppm, the product requirement is met, and the prepared deoxidized high-purity arsenic is packed in the glove box and presents the bright metallic luster in color.

Owner:FIRST SEMICON MATERIALS

Mixed fabric with anti-bacterial function

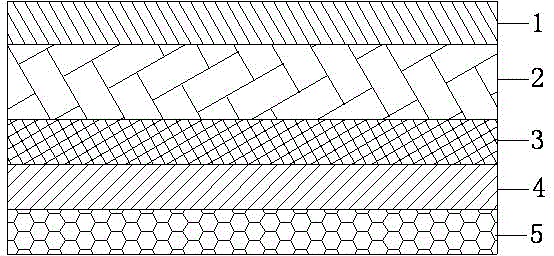

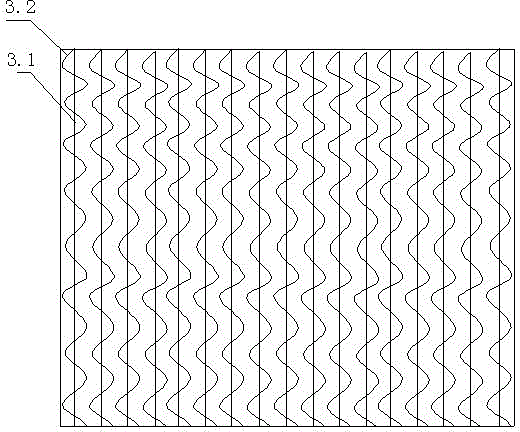

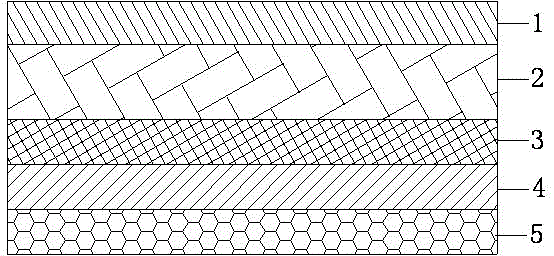

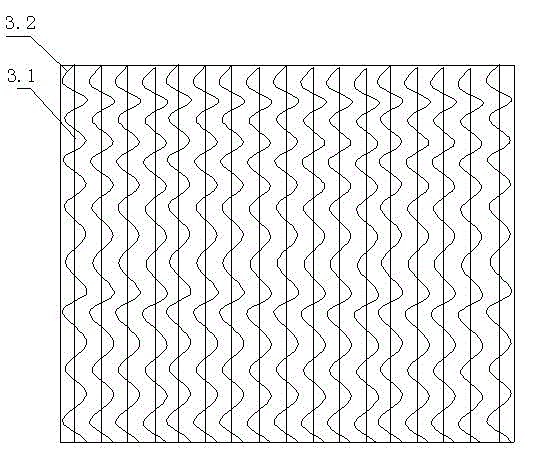

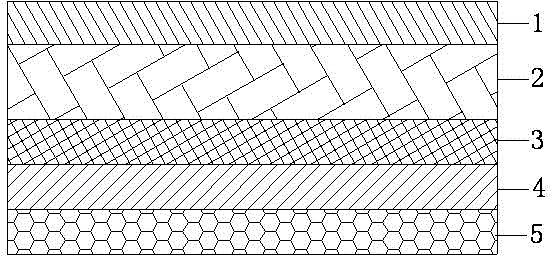

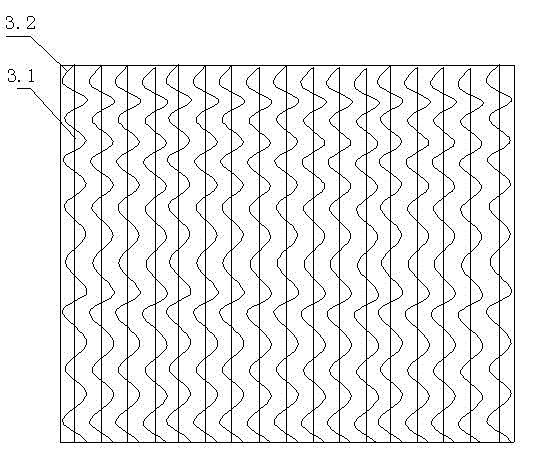

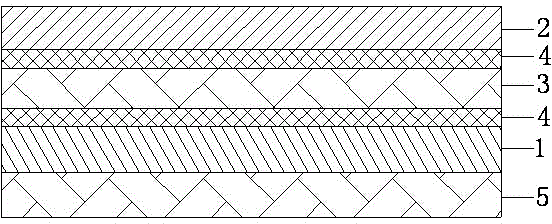

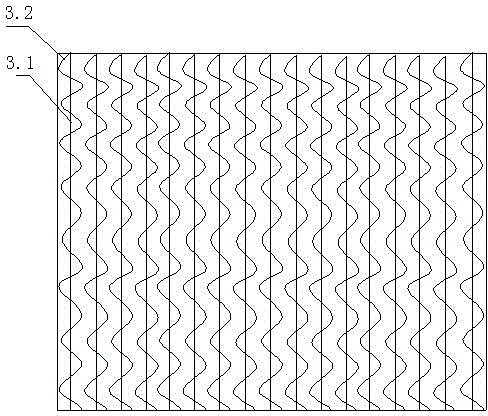

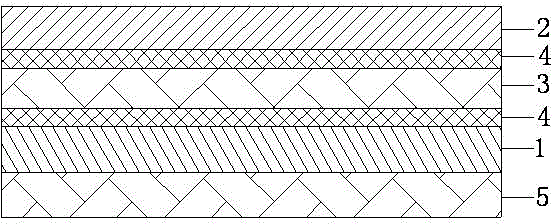

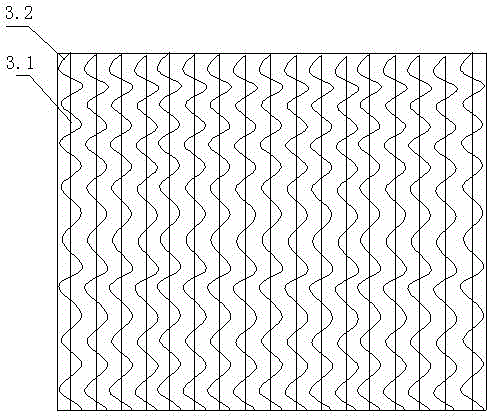

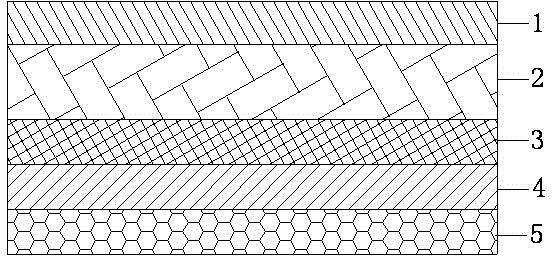

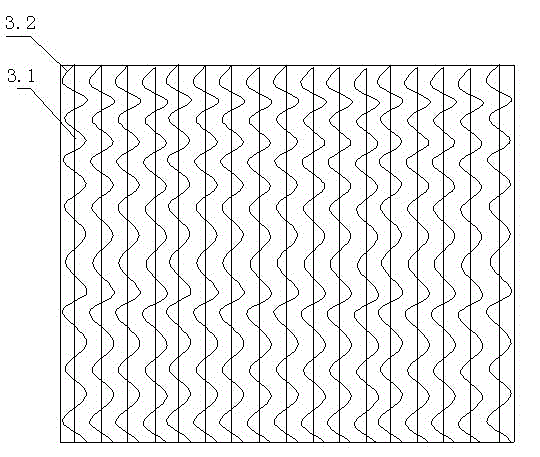

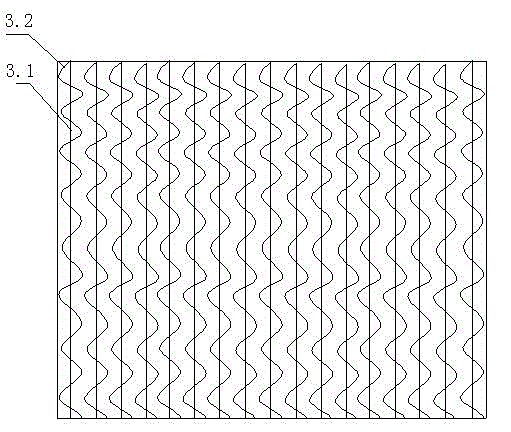

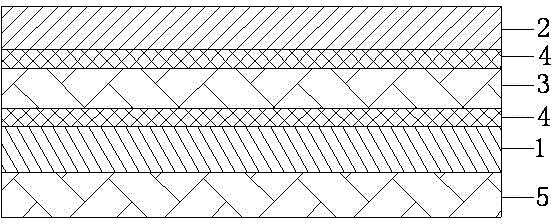

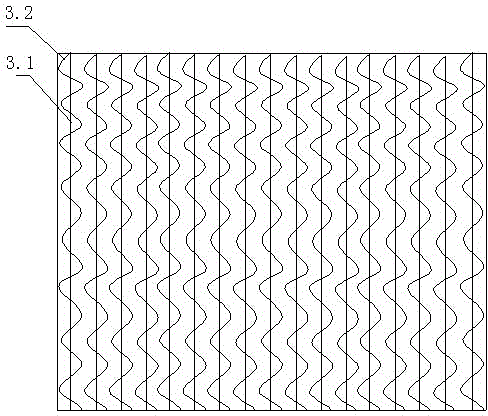

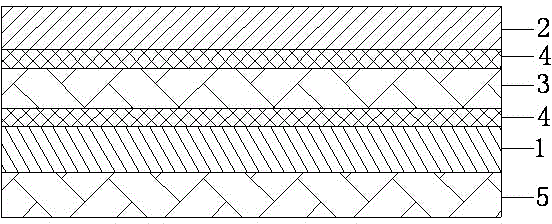

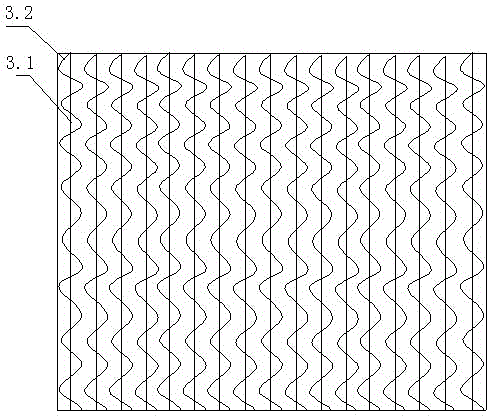

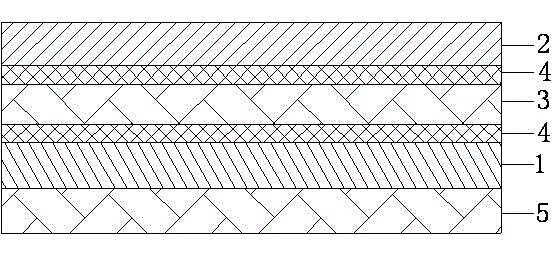

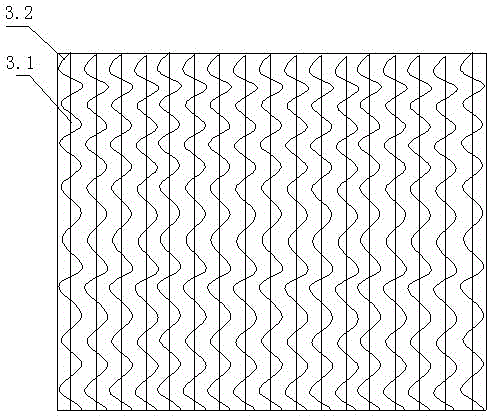

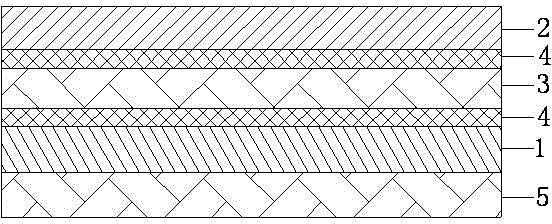

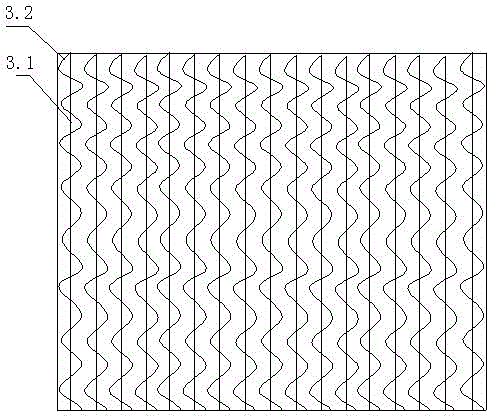

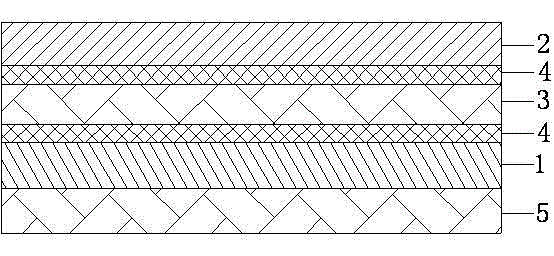

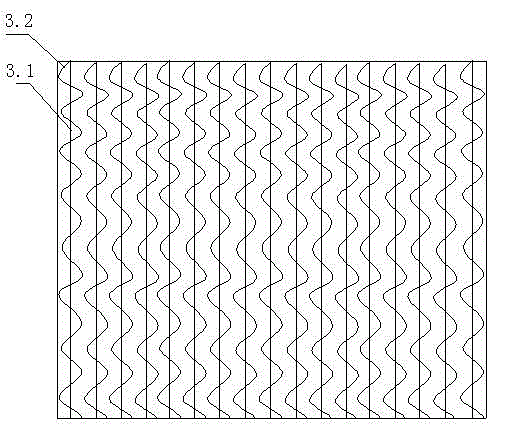

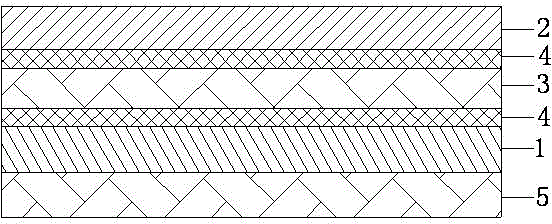

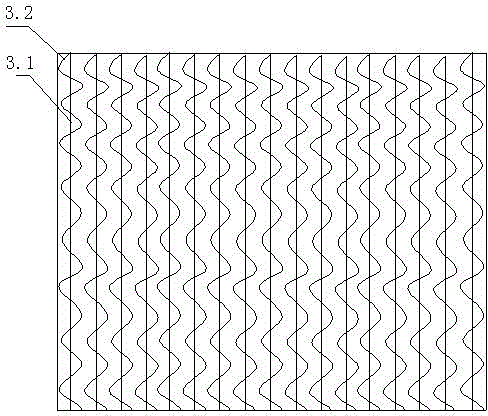

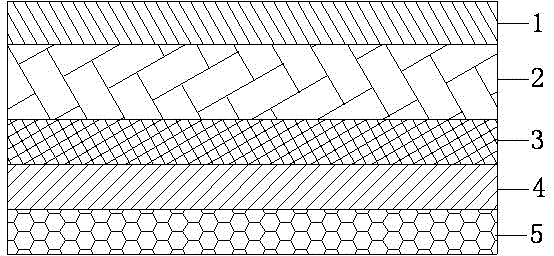

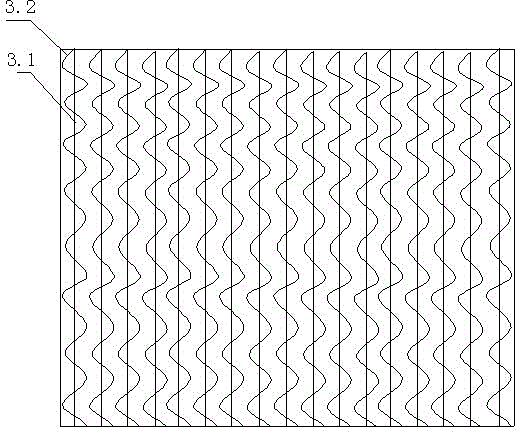

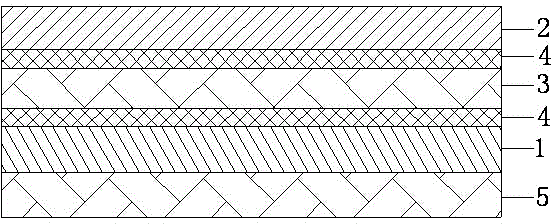

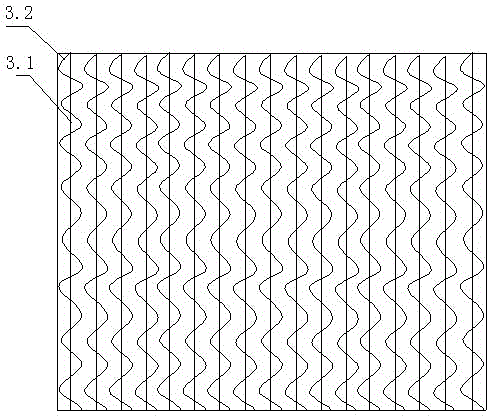

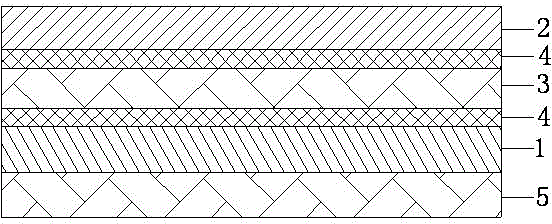

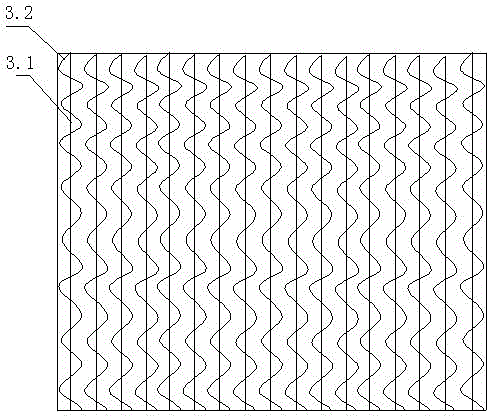

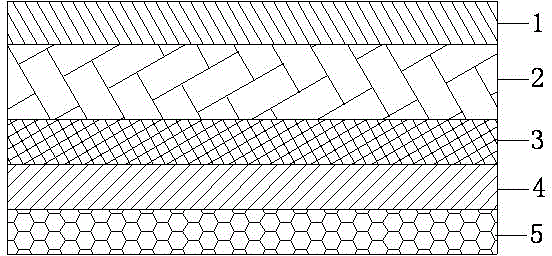

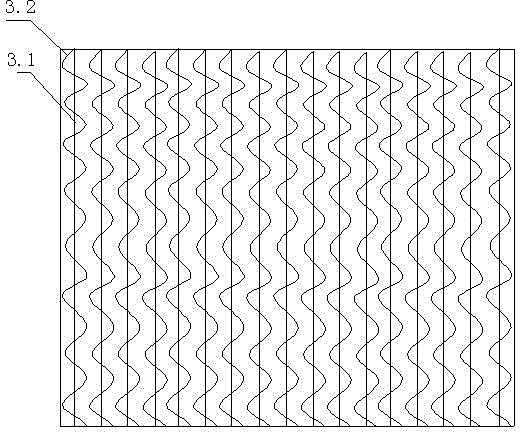

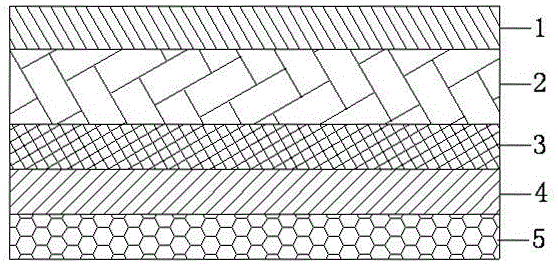

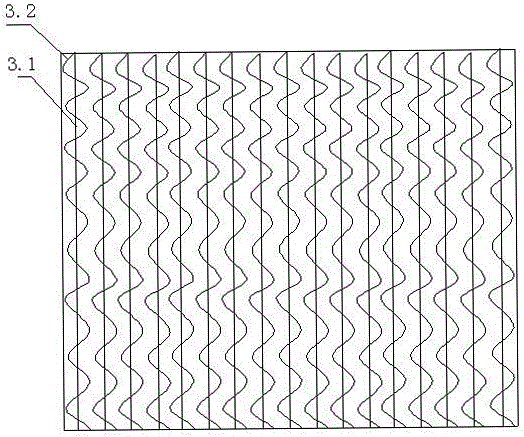

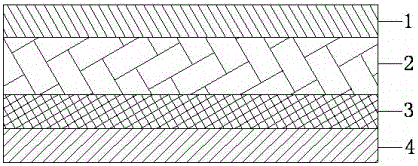

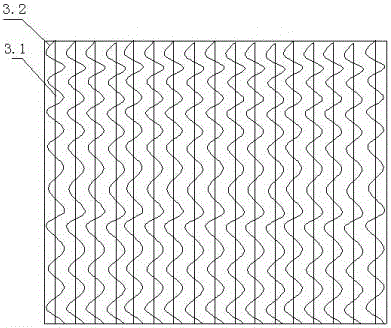

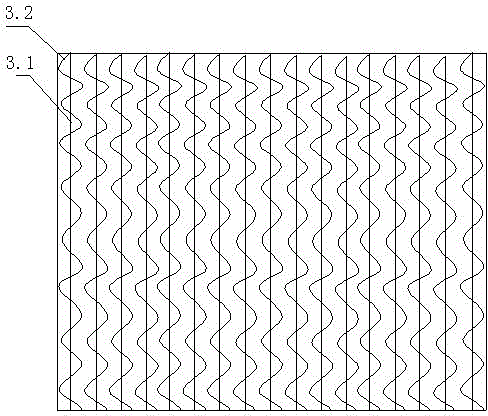

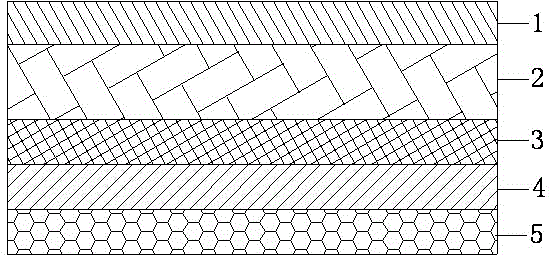

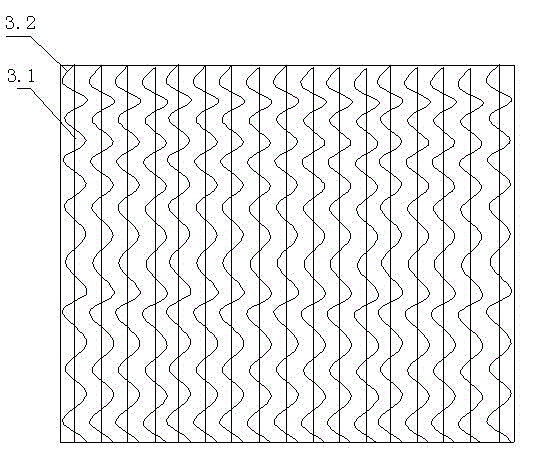

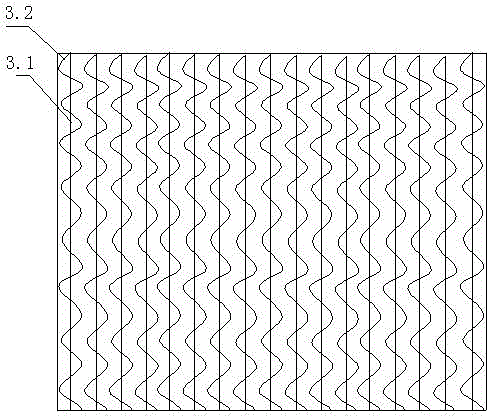

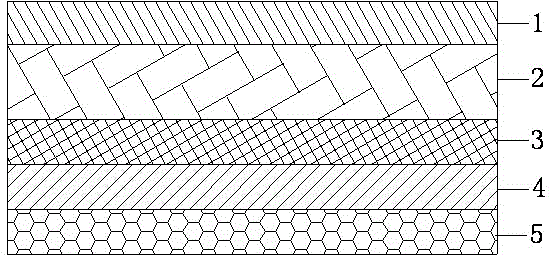

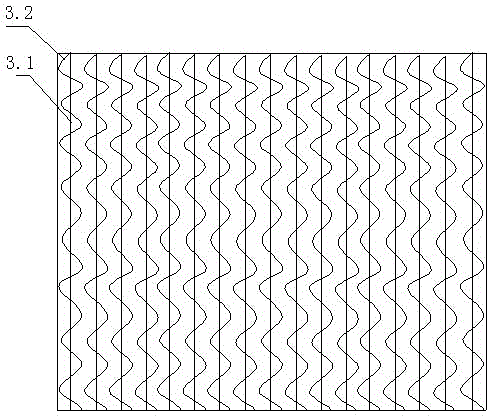

The invention relates to a mixed fabric with the anti-bacterial function. The mixed fabric with the anti-bacterial function comprises a pure cotton fabric (1). A bamboo charcoal fiber layer (2) is arranged under the pure cotton fabric (1). An anti-static layer (3) is arranged under the bamboo charcoal fiber layer (2) and made of core wrapping wire fiber. The core wrapping wire fiber comprises yarn (3.1) and metal wires (3.2) wound on the yarn (3.1). The bottom of the anti-static layer (3) is covered with a layer of blended fabric (4) formed by blending of soybean fiber and pure cotton fiber. A base layer (5) is combined to the lower surface of the blended fabric (4). The base layer is made of woven fabric, and the woven fabric comprises an outer layer, an inner layer and an anti-bacterial layer arranged between the outer layer and the inner layer, wherein the outer layer and the inner layer are ordinary fiber, and the anti-bacterial layer is formed by weaving anti-bacterial fiber. The mixed fabric is not prone to shrinking or wrinkling. By means of the mixed fabric, the anti-bacterial function is achieved.

Owner:JIANGYIN FANRONG YARN DYE FABRIC

Golden ball pen ink composition and preparation method thereof

The invention discloses a golden ball pen ink composition composed of metal pigment, resin, a solvent, a thickener and an assistant. The invention also discloses the preparation method of the pen ink composition. The preparation method comprises the following steps of: firstly, adding the solvent into a reaction kettle, stirring and heating; then, adding the resin and stirring at constant speed until the resin is completely dissolved; next, adding the metal pigment and stirring at constant speed until the metal pigment is uniformly dispersed in the mixing system of the resin and the solvent; and finally, adding the thickener and the assistant and stirring until all the components in the system are dispersed uniformly, and then, cooling to the room temperature to obtain the golden ball pen ink composition. Through adding modified bronze powder, the written stroke has bright and dazzled metal luster, smooth writing is realized, and the golden ball pen ink composition has the excellent performance such as weather resistance, heat resistance, water resistance and pollution resistance and can meet the requirement of people for artistic effects of artwork and souvenir decoration, invitation card writing, signature and the like.

Owner:XIAN UNIV OF TECH

Production process for positioning stamping film

PendingCN108608752AHigh technical contentStrong confidentialityDuplicating/marking methodsPattern printingVisual observationZinc sulfide

The invention relates to a production process for a positioning stamping film comprising a PET base film; the PET base film is successively provided with a release layer, a coloring layer, a vacuum aluminum plating layer and a back glue layer from inside to outside. The production process comprises the following steps successively: mixing of a release layer coating, coating of a release layer, mixing of a coloring layer coating, coating of a coloring layer, mold pressing, vacuum aluminizing, aluminum washing, zinc sulfide coating, mixing of a back glue layer coating, back glue layer coating, slitting, and quality inspection. The production process has the advantages that the positioning stamping film produced by the steps has the advantages of high technical content and strong secrecy, isnon-duplicated, and can give consumers direct visual observation discrimination of authenticity before purchasing in goods anti-counterfeiting aspect, the packaging is prevented from being reused by counterfeiters, and the anti-counterfeiting performance and commercial benefits are improved; the produced positioning stamping film eliminates the gradual accumulation of stamping accuracy error in astamping process, and an independent pattern stamping foil needs a positioning cursor to correct the error of holographic patterns at intervals in time.

Owner:ZHEJIANG YAXIN PACKAGE MATERIAL

Mixed fabric with good usability

InactiveCN104786566AReasonable structureEasy to useWoven fabricsMetal layered productsYarnBiochemical engineering

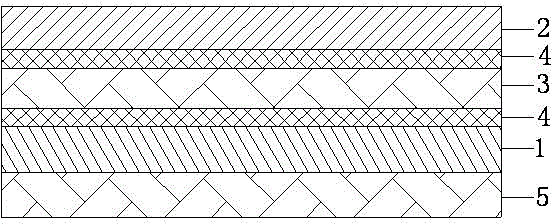

The invention relates to a mixed fabric with good usability. The mixed fabric comprises a pure cotton fabric (1); a bamboo charcoal fiber layer (2) is arranged on the lower surface of the pure cotton fabric (1); an anti-static layer (3) is arranged on the lower surface of the bamboo charcoal fiber layer (2), and is made of core spun silk fibers; the core spun silk fibers comprise yarns (3.1) and metal wires (3.2); the metal wire (3.2) are wound on the yarns (3.1); the bottom of the anti-static layer (3) is coated with a layer of blended fabric (4) which is formed by blending of soybean fibers and pure cotton fibers; a base layer (5) is compounded on the lower surface of the blended fabric (4), and is made of a textile; the warps and the wefts of the textile adopt wool fibers and coconut fibers respectively; the diameter of the wool fibers is 9 [mu]m; the diameter of the coconut fibers is 10 [mu]m; the warp density of the textile is 26.6 threads / cm; the weft density of the textile is 31.3 threads / cm. The mixed fabric has low probabilities of shrinkage and crinkle; the adopted fabric construction is reasonable; the service performance is good.

Owner:JIANGYIN HANXIN TEXTILE

Mixed fabric capable of effectively preventing electromagnetic wave

InactiveCN104786571AAvoid harmGood radiation protectionCellulosic plastic layered productsMetal layered productsYarnEngineering

The invention relates to a mixed fabric capable of effectively preventing an electromagnetic wave. The mixed fabric comprises a pure cotton fabric (1), wherein a bamboo charcoal fiber layer (2) is arranged below the pure cotton fabric (1); an anti-static layer (3) is arranged below the bamboo charcoal fiber layer (2); the anti-static layer (3) is prepared from core-spun yarn fiber; the core-spun yarn fiber comprises yarns (3.1) and metal wires (3.2); the yarns (3.1) are wound by the metal wires (3.2); a layer of blended fabric (4) covers the bottom of the anti-static layer (3); the blended fabric (4) is formed by blending soybean fiber with pure cotton fiber; a basic layer (5) is compounded below the blended fabric (4); the basic layer is prepared from a fabric; the fabric is formed by interweaving warps and wefts; the warps are prepared from nanometer metallic shield fiber yarns, and the wefts are prepared from tencel fiber yarns. The mixed fabric disclosed by the invention is low in possibility of shrinkage and ruffle, good in anti-radiation performance, and capable of effectively preventing a human body from being hurt by the electromagnetic wave.

Owner:JIANGYIN YASHUN GARMENT

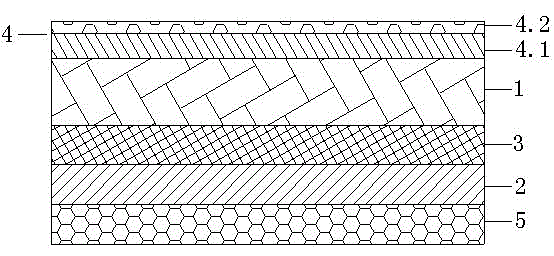

Flame-retardant multi-color fabric

InactiveCN104783379AMeet different needsAnti-static hasFibre treatmentWoven fabricsEngineeringCotton cloth

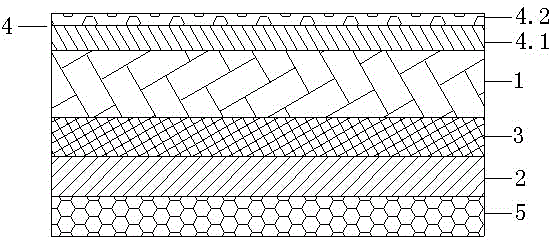

The invention relates to a flame-retardant multi-color fabric. The flame-retardant multi-color fabric comprises an upper cotton cloth layer (1) and a lower cotton cloth layer (2). A base player (5) is combined to the lower face of the lower cotton cloth layer (2). An anti-static layer (3) is further arranged between the upper cotton cloth layer (1) and the lower cotton cloth layer (2) and is made of core spun silk fibers. The fibers comprise yarns (3.1) and metal wires (3.2). The metal wires (3.2) are wound around the yarns (3.1). The surface of the upper cotton cloth layer (1) is covered with a flame-retardant coating (4). The flame-retardant coating (4) comprises a flame-retardant polyurethane layer (4.1) at the bottom and an organic silicon oil layer (4.2) at the top. The base layer (5) is made of a fabric. The fabric comprises first weft yarns, second weft yarns and warp yarns. The first weft yarns are wound around the warp yarns from the left side, the second weft yarns are wound around the warp yarns from the right side with the same latitude, and the first weft yarns and the second weft yarns share one of the warp yarns and are different. The flame-retardant multi-color fabric is low in cost, bendable and deformable, and has multiple colors.

Owner:JIANGYIN HONGWEI QINGSHAN SPINNING

Bamboo charcoal fiber fabric with antibacterial function

InactiveCN105644044ASpecial rigidityVariable bendingMetal layered productsYarnBiochemical engineering

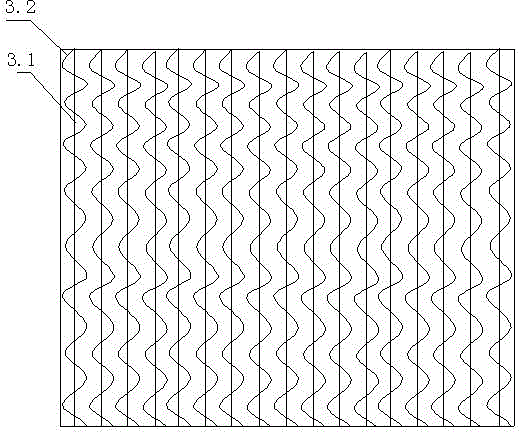

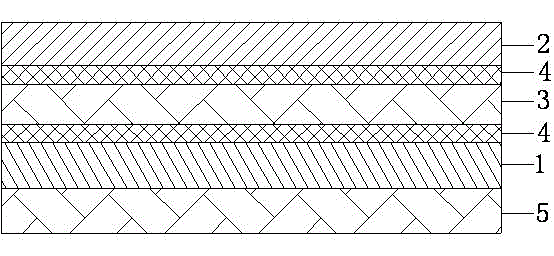

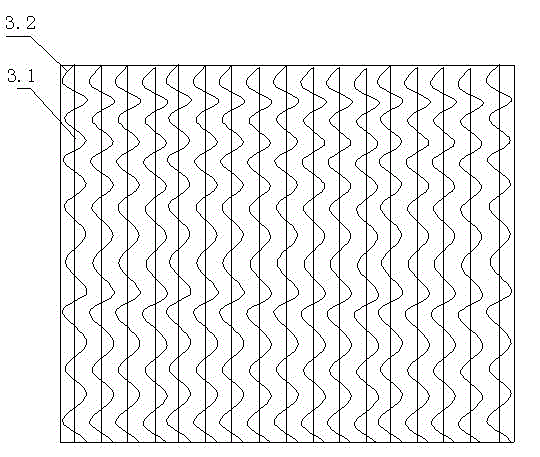

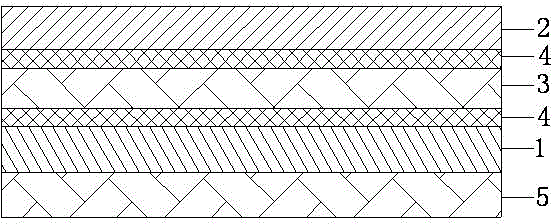

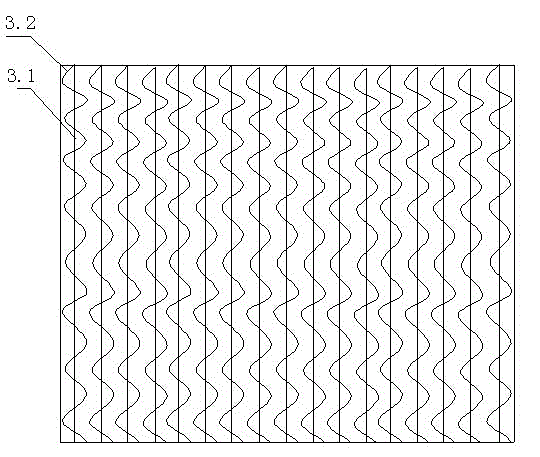

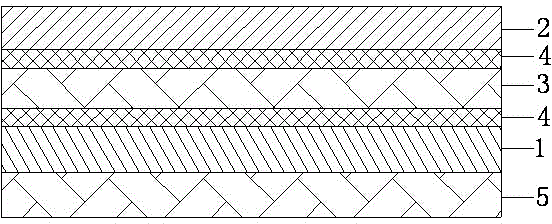

The present invention relates to a bamboo charcoal fiber fabric with antibacterial function, the bamboo charcoal fiber fabric includes bamboo charcoal fiber (1), the upper surface of the bamboo charcoal fiber (1) is covered with a layer of a non-woven fabric (2), the lower surface of the bamboo charcoal fiber (1) is covered with a base layer (5), an anti-static layer (3) is arranged between the non-woven fabric (2) and the bamboo charcoal fiber (1), the anti-static layer (3) is made from core-spun yarn fiber, the core-spun yarn fiber comprises a yarn (3.1) and a metal wire (3.2), and the metal wire (3.2) winds the yarn (3.1). The base layer is made of a fabric, the fabric comprises an outer layer, an inner layer and an antimicrobial layer disposed between the outer and inner layers, the outer and inner layers are ordinary fiber, and the antibacterial layer is woven by antibacterial fiber. The bamboo charcoal fiber fabric is breathable, anti-static and anti-radiation, and has antibacterial function.

Owner:吴建平

Bamboo carbon fiber fabric with good air permeability and comfort

InactiveCN104783380AStrong three-dimensional senseDelicate feelCellulosic plastic layered productsWoven fabricsWoven fabricYarn

The invention relates to a bamboo carbon fiber fabric with good air permeability and comfort. The bamboo carbon fiber fabric comprises bamboo carbon fiber (1), the upper surface of the bamboo carbon fiber (1) is covered with a non-woven fabric (2), the lower surface of the bamboo carbon fiber (1) is covered with a base layer (5), and an anti-static layer (3) is arranged between the non-woven fabric (2) and the bamboo carbon fiber (1). The anti-static layer (3) is made of spun-core yarn fiber which comprises a yarn (3.1) and a metal yarn (3.2), wherein the yarn (3.1) is wound by the metal yarn (3.2). The base layer is made of a fabric which is formed by tatting viscose filaments and silk in a 1 / 1 tabby mode, wherein the monofilament diameter of the viscose filaments ranges from 0.8 microns to 1.5 microns. The bamboo carbon fiber fabric has the advantages of air permeability, anti-static performance and anti-radiation performance. The bamboo carbon fiber fabric is good in air permeability and comfort.

Owner:JIANGYIN YASHUN GARMENT

Blended fabric with better dimensional stability

InactiveCN105615081ABig spaceIncrease elasticitySynthetic resin layered productsWoven fabricsPolyesterMetal filament

The invention relates to blended fabric with better dimensional stability. The blended fabric comprises pure cotton fabric (1), wherein a bamboo charcoal fiber layer (2) is arranged under the pure cotton fabric (1); an anti-static layer (3) is arranged under the bamboo charcoal fiber layer (2) and is made of core spun silk fibers, the core spun silk fibers comprise yarn (3.1) and metal filaments (3.2), and the yarn (3.1) is wound with the metal filaments (3.2); the bottom of the anti-static layer (3) is covered with a blended cloth layer (4) which is prepared from soybean fibers and pure cotton fibers through blending, and a base layer (5) is compounded under the blended cloth layer (4). The base layer is made of fabric, the fabric is formed through interweaving of warp yarn and weft yarn, the warp yarn and the weft yarn are arranged in a two-up and two-down mode, and the warp yarn adopts 50D / 72F polyester drawn textured yarn; the blended yarn is not prone to shrinking and creasing and has the better dimensional stability.

Owner:JIANGYIN FANGLONG FINERY HANDICRAFT

Reasonable-structure bamboo charcoal fiber fabric

InactiveCN104786578AReasonable structureEasy to useSynthetic resin layered productsMetal layered productsRadiation resistantMetal

The invention relates to reasonable-structure bamboo charcoal fiber fabric which comprises bamboo charcoal fiber (1), wherein the upper surface of the bamboo charcoal fiber (1) is coated with a non-woven fabric layer (2); the lower surface of the bamboo charcoal fiber (1) is coated with a base course (5); an anti-static layer (3) is arranged between the non-woven fabric layer (2) and the bamboo charcoal fiber (1) and is made of core-spun silk fiber; the core-spun silk fiber comprises yarns (3.1) and metal wires (3.2); the metal wires (3.2) are wound on the yarns (3.1). The base course comprises a textile; the textile warp yarns and weft yarns adopt chinlon 6 fiber and tussah silk fiber respectively; the diameter of the chinlon 6 fiber is 9 [Mu] m, and the dtex of the chinlon 6 fiber is 398 dtex; the diameter of the tussah silk fiber is 4 [Mu] m, and the dtex of the tussah silk fiber is 356 dtex; the warp density of the textile is 22.3 pieces / cm, and the weft density of the textile is 20.2 pieces / cm. The reasonable-structure bamboo charcoal fiber fabric has the air permeable, anti-static and radiation-resistant effects. The adopted textile is reasonable in structure and excellent in usability.

Owner:江阴市华凯针织制衣有限公司

Bamboo charcoal fiber fabric with strong breathability and strong sweat-releasing property

InactiveCN105686178AStrong three-dimensional senseSpecial rigidityWoven fabricsProtective garmentRadiation resistanceViscose fiber

The invention relates to a bamboo charcoal fiber fabric with strong breathability and strong sweat-releasing property. The bamboo charcoal fiber fabric comprises bamboo charcoal fibers (1), wherein a layer of non-woven fabric (2) covers the bamboo charcoal fibers (1), a base layer (5) is covered by the bamboo charcoal fibers (1), an anti-static layer (3) is arranged between the non-woven fabric (2) and the bamboo charcoal fibers (1), and is prepared by core-spun yarn fibers, the core-spun yarn fibers comprise yarns (3.1) and metal wires (3.2), and the metal wires (3.2) wind the yarns (3.1). The base layer is prepared by a textile, the textile is formed by interweaving warp yarns and weft yarns in a plain structure with the arrangement manner of one warp yarn on the upper part and one weft yarn on the lower part, the weft yarns comprise first weft yarns and second weft yarns which are arranged according to the ratio of 1 to 1, the warp yarns adopt PET fibers, and the first weft yarns adopt viscose fibers. The bamboo charcoal fiber fabric has the effects of breathability, static electricity resistance and radiation resistance. The bamboo charcoal fiber fabric has strong breathability and strong sweat-releasing property.

Owner:江苏迈克王科技有限公司

Layered bamboo carbon fiber fabric

The invention relates to a layered bamboo carbon fiber fabric. The layered bamboo carbon fiber fabric comprises bamboo carbon fibers (1), a non-woven fabric (2) covers upper surfaces of the bamboo carbon fibers (1), a base layer (5) covers lower surfaces of the bamboo carbon fibers (1), an antistatic layer (3) is arranged between the non-woven fabric (2) and the bamboo carbon fibers (1), the antistatic layer (3) is prepared from core-spun yarn fibers, the core-spun yarn fiber comprises yarn (3.1) and metal wires (3.2) and the metal wires (3.2) enwind the yarn (3.1). The base layer is prepared from a fabric, the surface of the fabric is provided with several three-dimensional stripes, the several three-dimensional stripes are horizontally arranged at the equal intervals, the three-dimensional stripe has a L-shaped cross section, the previous three-dimensional stripe is connected to the adjacent next three-dimensional stripe and the joint is located at the bottom of the previous three-dimensional stripe and is fixed to the fabric through a wire. The layered bamboo carbon fiber fabric has permeability, static resistance and radiation resistance. The three-dimensional stripes with the joints improve fabric layering.

Owner:WUXI HUALIAN PLASTIC PROD CO LTD

Bamboo carbon fiber fabric with high comfort level

InactiveCN105619927AReasonable structural designImprove breathabilityYarnMetal layered productsYarnIrradiation

The invention relates to a bamboo carbon fiber fabric with high comfort level. The bamboo carbon fiber fabric comprises bamboo carbon fiber (1); the upper surface of the bamboo carbon fiber (1) is coated with a layer of non-woven fabric (2), and the lower surface is coated with a layer of base layer (5); an anti-static layer (3) is arranged between the non-woven fabric (2) and the bamboo carbon fiber (1); the anti-static layer (3) is prepared from core-spun yarn fiber; the core-spun yarn fiber comprises yarn (3.1) and metal wires (3.2); the yarn (3.1) is winded by the metal wires (3.2); the base layer is prepared from a fabric, and the fabric is composed of first yarn and second yarn; the first yarn and the second yarn circles in sequence along the parallel direction of the fabric, and interlaces sequentially and alternately in the longitudinal direction so as to obtain the fabric with a weft knitted structure; the front surface of the fabric is provided with convex strips; and the convex strips are obtained via knitting of the first yarn and the second yarn. The bamboo carbon fiber fabric possesses gas permeability, antistatic properties, and irradiation resistance. Comfort level of the bamboo carbon fiber fabric is high.

Owner:苏光明

Bamboo charcoal fiber fabric with persistent elasticity

InactiveCN104802468ASpecial rigidityVariable bendingWoven fabricsMetal layered productsMetal filamentBiochemical engineering

The invention relates to bamboo charcoal fiber fabric with persistent elasticity. The bamboo charcoal fiber fabric comprises bamboo charcoal fiber (1), wherein a non-woven fabric layer (2) is arranged above the bamboo charcoal fiber (1) in a covered manner; a base layer (5) is arranged below the bamboo charcoal fiber (1) in a covered manner; an anti-static layer (3) is further arranged between the non-woven fabric layer (2) and the bamboo charcoal fiber (1) and is prepared from core-spun fiber which comprises yarn (3.1) and metal filaments (3.2) wound around the yarn (3.1); the base layer is prepared from textile fabric which is woven by warp yarn and weft yarn in an up and down manner, the warp yarn adopts non-elastic yarn, the weft yarn adopts elastic yarn and comprises first weft yarn and second weft yarn which are double weft, and the warp yarn, the first weft yarn and the second weft yarn are woven in an up and down manner to form a five-heddle backed weave structure. The bamboo charcoal fiber fabric has the effects of breathability, anti-static performance and radiation resistance; the fabric has persistent elasticity and a very high anti-crease effect.

Owner:JIANGYIN GUORUN TEXTILE RAW MATERIALS SALES

Bamboo charcoal fiber fabric capable of preventing electromagnetic waves effectively

InactiveCN104859216AAvoid harmGood radiation protectionCellulosic plastic layered productsMetal layered productsYarnEngineering

The invention relates to a bamboo charcoal fiber fabric capable of preventing electromagnetic waves effectively. The fabric comprises bamboo charcoal fibers (1), the top of the bamboo charcoal fibers (1) is covered with a layer of non-woven cloth (2), and the bottom of the bamboo charcoal fibers (1) is covered with a base layer (5). An anti-static layer (3) is further arranged between the non-woven cloth (2) and the bamboo charcoal fibers (1) and is made of core spun silk fibers which comprise yarns (3.1) and metal wires (3.2). The metal wires (3.2) are wound on the yarns (3.1), and a base layer (4) is arranged under the anti-static layer (3) and is made of a textile. The textile is formed by interweaving of warps and wefts. The warps are composed of nano metal shielding fiber yarns, and the wefts are composed of tencel fiber yarns. The fabric has the advantages of being breathable, anti-static and anti-radiation, good in radiation resistance and capable of preventing hurt to human bodies from electromagnetic waves effectively.

Owner:JIANGYIN CHENGXIN SPECIAL PRINTING

Cold-resistant bamboo charcoal fiber fabric

The invention relates to cold-resistant bamboo charcoal fiber fabric which comprises bamboo charcoal fiber (1), wherein the upper surface of the bamboo charcoal fiber (1) is coated with a non-woven fabric layer (2); the lower surface of the bamboo charcoal fiber (1) is coated with a base course (5); an anti-static layer (3) is arranged between the non-woven fabric layer (2) and the bamboo charcoal fiber (1) and is made of core-spun silk fiber; the core-spun silk fiber comprises yarns (3.1) and metal wires (3.2); the metal wires (3.2) are wound on the yarns (3.1). The base course comprises a textile; the textile is formed by tightly compounding a textile layer, warm-keeping layer, a cavity layer and a surface layer in sequence from the inside out, the surface layer is formed by interweaving yarns containing conductive fiber, and common fiber yarns; the common fibers comprise cotton, hemp, fur, silk or chemical fiber; the warm-keeping layer is made of sponge. The cold-resistant bamboo charcoal fiber fabric has the air permeable, anti-static and radiation-resistant effects and is cold-resistant.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

Mixed fabric of textile fabric with decorative pattern

InactiveCN104856312ANo need to dyeSpecial rigiditySynthetic resin layered productsWoven fabricsEngineeringBrightness perception

The invention relates to a mixed fabric of a textile fabric with a decorative pattern, which comprises a pure cotton fabric (1), wherein a bamboo charcoal fiber layer (2) is set below the pure cotton fabric (1); an anti-static electricity layer (3) is set below the bamboo charcoal fiber layer (2); the anti-static electricity layer (3) is made of coated core silk fiber; the coated core silk fiber comprises yarn (3.1) and a metal wire (3.2); the metal wire (3.2) is wound on the yarn (3.1); the bottom of the anti-static electricity layer (3) is covered with a piece of blended cloth (4); the piece of the blended cloth (4) is blended by soybean fiber and pure cotton fiber; and a basic layer (5) is composited below the piece of the blended cloth (4). The basic layer is made of fabric; the fabric is interwoven by warp yarn and weft yarn; the texture structure is third one interwoven twill texture structure; the warp yarn is 800 D dacron FDY with super brightness; the weft yarn is 800 D dacron FDY with super brightness; the density of the warp yarn is 25 per centimeter and the density of the weft yarn is 16 per centimeter; and the warp yarn is twisted 180 per meter. The mixed fabric is not easily contracted and crumpled; and the mixed fabric provided herein is relatively harder.

Owner:JIANGYIN CHENGXIN SPECIAL PRINTING

Flame-retardant cold-resistant fabric

InactiveCN105619918ASimple structureAgainst the coldSynthetic resin layered productsProtective garmentFiberYarn

The invention relates to a flame-retardant cold-resistant fabric. The fabric comprises an upper cotton fabric layer (1) and a lower cotton fabric layer (2). A base layer (5) is compounded under the lower cotton fabric layer. An antistatic layer (3) is arranged between the upper cotton fabric layer and the lower cotton fabric layer. The antistatic layer is prepared from core-spun yarn fiber. The fiber comprises yarn (3.1) and metal filament (3.2); the metal filament is wound on the yarn; a flame-retardant coating layer (4) coats the surface of the upper cotton fabric layer. The flame-retardant coating layer (4) comprises a flame-retardant polyurethane layer (4.1) on the bottom and an organosilicone oil layer (4.2) on the top. The base layer is prepared from textile. The textile is prepared by closely compounding the four layers of a textile layer, a thermal insulation layer, a hollow cavity layer and a surface layer from inside to outside. The surface layer is prepared by interweaving yarn containing conductive fiber and common fiber yarn. The common fiber is cotton, linen, wool, silk or chemical fiber. The thermal insulation layer adopts sponge. The fabric provided by the invention has a low cost, and is flexible. The fabric is cold resistant.

Owner:卞平芳

Golden ball pen ink composition and preparation method thereof

The invention discloses a golden ballpoint pen pen and ink composition, which consists of metal pigments, resins, solvents, thickeners and auxiliary agents. The invention also discloses a preparation method of the above pen and ink composition. Firstly, the solvent is added into the reaction kettle, stirred and heated, then the resin is added and stirred at a constant speed until the resin is completely dissolved, and then the metal pigment is added and stirred at a constant speed to make the metal pigment Disperse evenly in the mixed system of resin and solvent; finally add thickener and other additives and stir until the components in the system are evenly dispersed, and finally cool to room temperature to prepare. By adding modified copper and gold powder, the writing strokes have a dazzling metallic luster, smooth writing, and have excellent properties such as weather resistance, heat resistance, water resistance, and pollution resistance, which can meet people's needs for artworks, souvenirs, decorations and Requirements for artistic effects such as writing and signature on invitations.

Owner:XIAN UNIV OF TECH

Bamboo charcoal fiber fabric with good dimension stability

InactiveCN105639792ABig spaceIncrease elasticitySynthetic resin layered productsWoven fabricsYarnMetal filament

The invention relates to a bamboo charcoal fiber fabric with good dimension stability; the bamboo charcoal fiber fabric comprises bamboo charcoal fibers (1); the bamboo charcoal fibers (1) is covered by a non-woven fabric (2); a base layer (5) is arranged under the bamboo charcoal fibers (1); an antistatic layer (3) is arranged between the non-woven fabric (2) and the bamboo charcoal fibers (1), and formed by core-spun silk fibers; the core-spun silk fibers comprise yarns (3.1) and metal filaments (3.2) wrapping the yarns (3.1); the base layer is formed by cloth, and the cloth is formed by mutually interlacing warp yarns with filling yarns, wherein the warp yarns and the filling yarns are two-up two-down arranged; the warp yarn refers to 50D / 72F terylene low elasticity filament; the filling yarn is 50D / 36F terylene low elasticity filament; the warp yarn and the filling yarn are twill structures. The bamboo charcoal fiber fabric is good in permeability, antistatic and radiation hardening effect, and good in dimension stability.

Owner:JIANGYIN YONGLONG PLASTICS

Bamboo charcoal fiber shell fabric with fabric provided with patterns

InactiveCN104790095ANo need to dyeSpecial rigidityLayered productsWoven fabricsRadiation resistantEngineering

The invention relates to a bamboo charcoal fiber shell fabric with fabric provided with patterns. The bamboo charcoal fiber shell fabric with the fabric provided with the patterns comprises bamboo charcoal fiber (1), the upper side of the bamboo charcoal fiber (1) is covered with a layer of non-woven fabric (2), the lower side of the bamboo charcoal fiber (1) is covered with a base layer (5), an anti-static layer (3) is further arranged between the non-woven fabric (2) and the bamboo charcoal fiber (1), the anti-static layer (3) is made of core-spun yarn fibers, the core-spun yarn fibers comprise yarns (3.1) and metal wires (3.2), and the metal wires (3.2) is wound by the yarns (3.1). The base layer is made of fabric, the fabric is formed by interweaving warp yarns and weft yarns, the organization structure is of a 3 / 1 interweaving twill-weave structure, the warp yarns adopt 800D dacron super bright FDY, the weft yarns adopt 800D dacron super bright FDY, the warp density is 25 yarns / cm, the weft density is 16 yarns / cm, and Z twist yarns are added into the warp yarns at the frequency of 180 yarns / m. The bamboo charcoal fiber shell fabric with the fabric provided with the patterns has the air permeability effect, the anti-static effect and the radiation-resistant effect. The bamboo charcoal fiber shell fabric with the fabric provided with the patterns forms the patterns through changes of the interweaving twill-weave structure of the fabric, no dyeing is needed after the interweaving is finished, meanwhile, the warp yarns are the yarns added with the twist yarns, and therefore the fabric is stiff.

Owner:JIANGYIN CHUNLAN TEXTILE

Mixed fabric with good heat preservation effect

InactiveCN104786573ASufficient air contentStop the spreadCellulosic plastic layered productsMetal layered productsEngineeringMetal

The invention relates to a mixed fabric with a good heat preservation effect. The mixed fabric comprises a pure cotton fabric (1), wherein a bamboo carbon fiber layer (2) is arranged under the pure cotton fabric (1); an anti-static layer (3) is further arranged under the bamboo carbon fiber layer (2) and made from core-spun silk fiber; the core-spun silk fiber comprises yarns (3.1) and metal wires (3.2); the metal wires (3.2) wind the yarns (3.1); the bottom of the anti-static layer (3) is coated with a layer of blended cloth (4); the blended cloth (4) is formed by blending soybean fiber and pure cotton fiber; a base layer (5) is compounded under the blended cloth (4); the base layer is made from a textile fabric, the textile fabric is formed by interweaving warp yarns and weft yarns, the warp yarns and the weft yarns adopt hollow structures, and a through hole is formed in the center of each of the warp yarns and the weft yarns along an axis. The mixed fabric is unlikely to shrink and wrinkle and good in heat preservation effect.

Owner:JIANGYIN CHUNLAN TEXTILE

Mixed fabric with uniform textile thickness

The invention relates to a mixed fabric with uniform textile thickness. The mixed fabric comprises a pure cotton fabric (1), wherein a bamboo carbon fiber layer (2) is arranged below the pure cotton fabric (1); an antistatic layer (3) is further arranged below the bamboo carbon fiber layer (2), and is made from core-spun yarn fibers; each core-spun yarn fiber comprises a yarn (3.1) and a metal wire (3.2); the metal wires (3.2) are wound on the yarns (3.1); the bottom of the antistatic layer (3) is covered with a layer of blended fabric (4) which is formed by blending soybean fibers and pure cotton fibers; a layer of substrate (5) is compounded below the blended fabric (4), and is formed by a textile; the textile is a felt textile, and the felt textile comprises a cloth layer and a wool layer, which are fixedly connected; the wool layer is a reticular textile consisting of crisscross wool filaments. The mixed fabric is unlikely to shrink and crease, and is uniform in textile thickness.

Owner:江阴市华凯针织制衣有限公司

Blended fabric

The invention relates to a mixed fabric. It is characterized in that: it includes pure cotton fabric, a layer of bamboo charcoal fiber layer is arranged under the pure cotton fabric, and an antistatic layer is arranged under the bamboo charcoal fiber layer, the antistatic layer is made of core-spun silk fiber, the Fibers include yarns and wires wound around the yarns. Compared with the prior art, the beneficial effect of the present invention is that the yarn and the metal wire in the mixed fabric form the cored wire to form an antistatic layer, so that the fabric has special rigidity, variable bending, and strong three-dimensional effect , can form various wrinkle effects, not easy to shrink, not easy to wrinkle, shiny metallic luster, delicate hand feeling, anti-static, anti-radiation effect.

Owner:XINCHANG COUNTY ZHUOYUAN TEXTILE CO LTD

Fluorescence radiation bamboo charcoal fiber fabric

InactiveCN104856311AEasy to manufactureLight structureProtective garmentMetal layered productsYarnTriboluminescence

The invention relates to a fluorescence radiation bamboo charcoal fiber fabric, which comprises bamboo charcoal fiber (1), wherein the upper surface of the bamboo charcoal fiber (1) is covered with a layer of non-woven fabric (2) and the lower surface thereof is covered with a basic layer (5); an anti-static electricity layer (3) is also set between the non-woven fabric (2) and bamboo charcoal fiber (1); the anti-static electricity layer (3) is made of coated core silk fiber; the coated core silk fiber comprises yarn (3) and a metal wire (3.2); the metal wire (3.2) is wound on the yarn (3.1); the basic layer is made of fabric; the fabric comprises a fabric body, an interlayer and a fluorescence body sequentially set on the fabric body; and the back side of the fluorescence body is provided with an adhesive layer and the front side thereof is provided with a fluorescence face layer. The fluorescence radiation bamboo charcoal fiber fabric has the effects of air permeability, static electricity resistance and radiation resistance; the fabric provided herein can light; not only the structure is simple and light, but also the use is convenient and flexible; the fabric can be set at will according to needs; the manufacturing is simple; and the service life is long.

Owner:JIANGYIN BETTER TEXTILE

Blended fabric with stereoscopic sensation

InactiveCN105615086AStrong three-dimensional senseSpecial rigidityProtective garmentMetal layered productsYarnMetal filament

The invention relates to blended fabric with stereoscopic sensation. The blended fabric comprises pure cotton fabric (1), wherein a bamboo charcoal fiber layer (2) is arranged under the pure cotton fabric (1); an anti-static layer (3) is arranged under the bamboo charcoal fiber layer (2) and is prepared from core spun silk fibers, the core spun silk fibers comprise yarn (3.1) and metal filaments (3.2), and the yarn (3.1) is wound with the metal filaments (3.2); the bottom of the anti-static layer (3) is covered with a layer of blended fabric (4), the blended fabric (4) is prepared from soybean fibers and pure cotton fibers through blending, and a base layer (5) is composited under the blended fabric (4). The base layer is made of textile fabric, the textile fabric comprises a braided layer comprising a front side and a reverse side, a plurality of round sequins are arranged on the front side of the braided layer, a hole is formed in the center of each sequin, and the sequins are flatly arranged on the braided layer and constitute criss-cross grid matrixes. The blended fabric is not prone to shrinkage and creasing and has the stereoscopic sensation.

Owner:江苏迈克王科技有限公司

Bamboo charcoal fiber fabric with good usability

The invention discloses a bamboo charcoal fiber fabric with good usability. The bamboo charcoal fiber fabric comprises bamboo charcoal fibers (1); the upper surface of the bamboo charcoal fibers (1) is coated with a layer of non-woven fabric (2); the lower surface of the bamboo charcoal fibers (1) is coated with a base layer (5); an anti-static layer (3) is arranged between the non-woven fabric (2) and the bamboo charcoal fiber (1), and is made of core spun silk fibers; the core spun silk fibers comprise yarns (3.1) and metal wires (3.2); the metal wire (3.2) are wound on the yarns (3.1); a base layer is made of a textile; the warps and the wefts of the textile adopt wool fibers and coconut fibers respectively; the diameter of the wool fibers is 9 [mu]m; the diameter of the coconut fibers is 10 [mu]m; the warp density of the textile is 26.6 threads / cm; the weft density of the textile is 31.3 threads / cm. The bamboo charcoal fiber fabric has the effects that the bamboo charcoal fiber fabric is air-permeable, anti-static and radiation-resistant; the adopted fabric construction is reasonable; the service performance is good.

Owner:JIANGYIN DONGFA GARMENT MAKING

Multi-color mixed fabric

InactiveCN105644042ASpecial rigidityVariable bendingWoven fabricsMetal layered productsYarnWrinkle skin

The present invention relates to a multi-color mixed fabric, which comprises a pure cotton fabric (1), wherein a layer of a bamboo charcoal fiber layer (2) is arranged under the pure cotton fabric (1), an antistatic layer (3) is arranged under the bamboo charcoal fiber layer (2), and is made from core-packed wire fibers, the core-packed wire fibers comprise a yarn (3.1) and a metal wire (3.2), the metal wire (3.2) is wound on the yarn (3.1), a layer of a blended cloth (4) covers on the bottom portion of the antistatic layer (3), the blended cloth (4) is formed by blending soybean fibers and pure cotton fibers, a base layer (5) is compounded under the blended cloth (4) and is made from a fabric, the fabric contains first weft, second weft and warp, the first weft is wound on the weft from the left side, the second weft is wound on the warp from the right side in the same latitude, and the first weft and the second weft share the one warp, and are different. According to the present invention, the multi-color mixed fabric has characteristics of shrinkage resistance, wrinkle resistance, and multiple colors.

Owner:JIANGYIN YONGTAI PLASTICS CO LTD

Soft and drapey bamboo charcoal fiber fabric

InactiveCN105619926ASpecial rigidityVariable bendingLayered productsWoven fabricsPolyesterMetal filament

The invention relates to a soft and drapey bamboo charcoal fiber fabric. The fabric comprises bamboo charcoal fiber (1). The bamboo charcoal fiber (1) is covered by a non-woven fabric layer (2). A base layer (5) is below the bamboo charcoal fiber (1). An antistatic layer (3) is between the non-woven fabric (2) and the bamboo charcoal fiber (1). The antistatic layer (3) is prepared with core-spun fiber. The fiber comprises yarn (3.1) and metal filament (3.2). The metal filament (3.2) is wound on the yarn (3.1). The base layer is prepared with textile. The textile is prepared by cross-weaving warp yarn 1, warp yarn 2 and weft yarn. The warp yarn 1 is 75D polyester-cotton composite yarn. The warp yarn 2 is jute fiber. The weft yarn is 32S cotton. The warp yarn 1 and warp yarn 2 are arranged alternately. The fabric provided by the invention is breathable, antistatic and radiation-resisting. The fabric is delicate, soft and drapey. With the existence of jute fiber, the fabric is not closely fitted.

Owner:李士清

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com