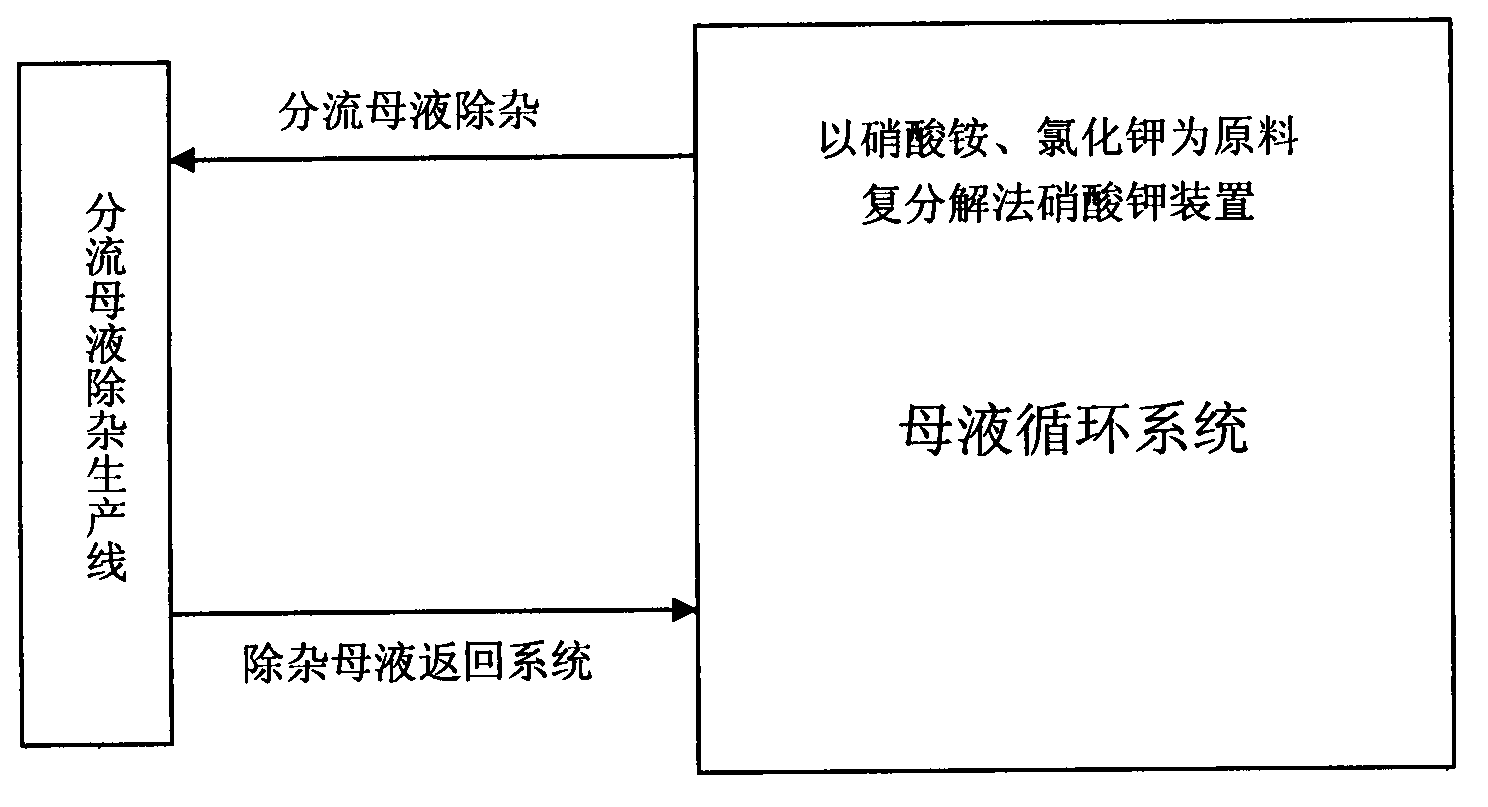

Double decomposition method for preparing potassium nitrate

A metathesis method and potassium nitrate technology are applied in the field of preparing potassium nitrate by metathesis method, and can solve problems such as affecting product quality, increasing product energy consumption, and having no known removal technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

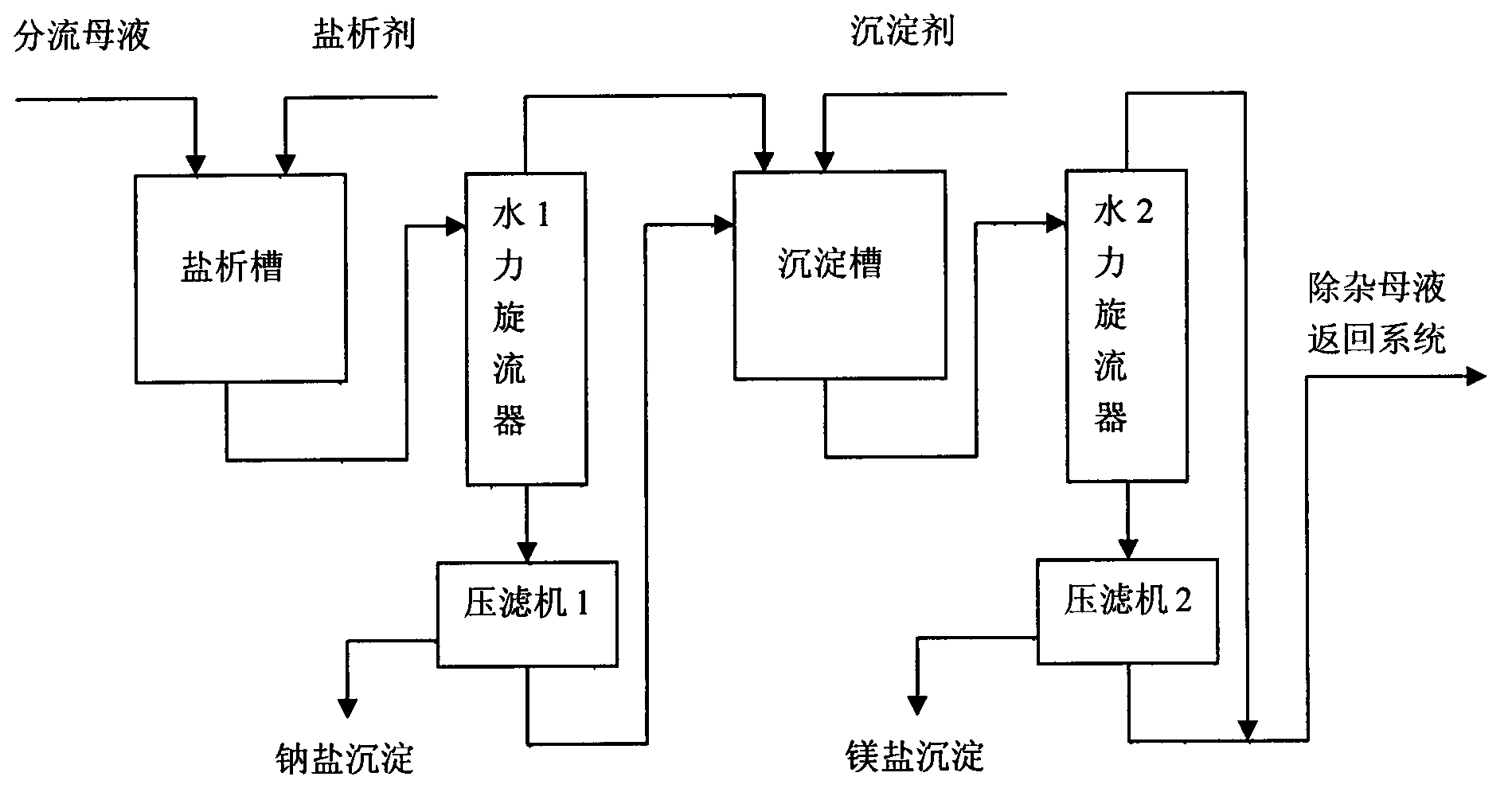

[0027] Example 1: In such as figure 2 In the split mother liquor production line, the split mother liquor temperature is 40°C, pumped into the salting out tank, adding the salting out agent magnesium chloride hexahydrate crystallization, the addition amount is 10kmol as magnesium ion, fully stirred, the solution temperature is 70°C, and the residence time is 30 minutes to form Impurity sodium chloride crystal slurry is passed through hydrocyclone 1 and filter press 1 to obtain impurity sodium salt precipitation filter residue, the amount of filter residue is about 10kmol in terms of sodium ions, and the purity of sodium salt precipitation is about 98%.

Embodiment 2

[0028] Embodiment 2: In embodiment 1, salting out tank solution temperature is 60 ℃, and filter residue amount is about 10kmol by sodium ion, and the sodium salt precipitation purity is about 95%.

Embodiment 3

[0029] Embodiment 3: in embodiment 1, salting out tank solution temperature 50 ℃, filter residue amount is about 10kmol by sodium ion, and sodium salt precipitation purity is about 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com