Nanometer composite material, preparing method and application

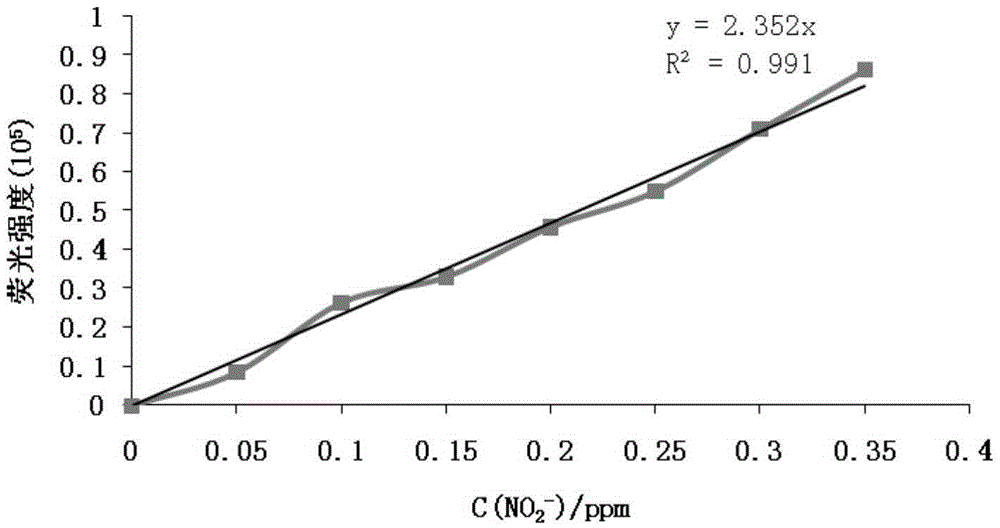

A technology of nanocomposite materials and core-shell nanomaterials, which is applied in the direction of material analysis, material excitation analysis, and material analysis through optical means, and can solve problems such as narrow application range, sensitivity, and extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

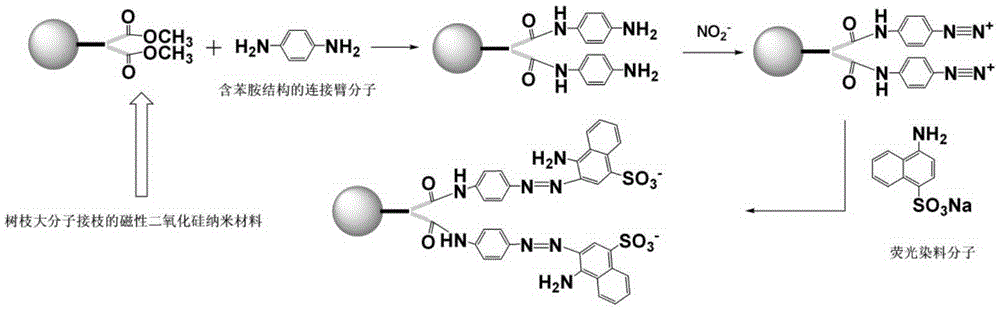

[0042] The present invention also provides a preparation method of the above-mentioned nanocomposite material, comprising: mixing the inner core of the upper half-generation dendrimer grafted by a silane compound with an aniline compound in an organic solvent, and after the reaction, the nanocomposite material is obtained ; the inner core is a magnetic core-shell nanomaterial; the half-generation dendrimer is a half-generation dendrimer terminal with an ester group; the amino number of the aniline compound is greater than or equal to 2.

[0043] Wherein, the magnetic core-shell nanomaterials, silane compounds, half-generation dendrimers and aniline compounds are the same as those described above, and will not be repeated here.

[0044] The preparation method of the magnetic core-shell nanomaterial is a preparation method well known to those skilled in the art, and there is no special limitation. In the present invention, the chemical precipitation method is preferably used, tha...

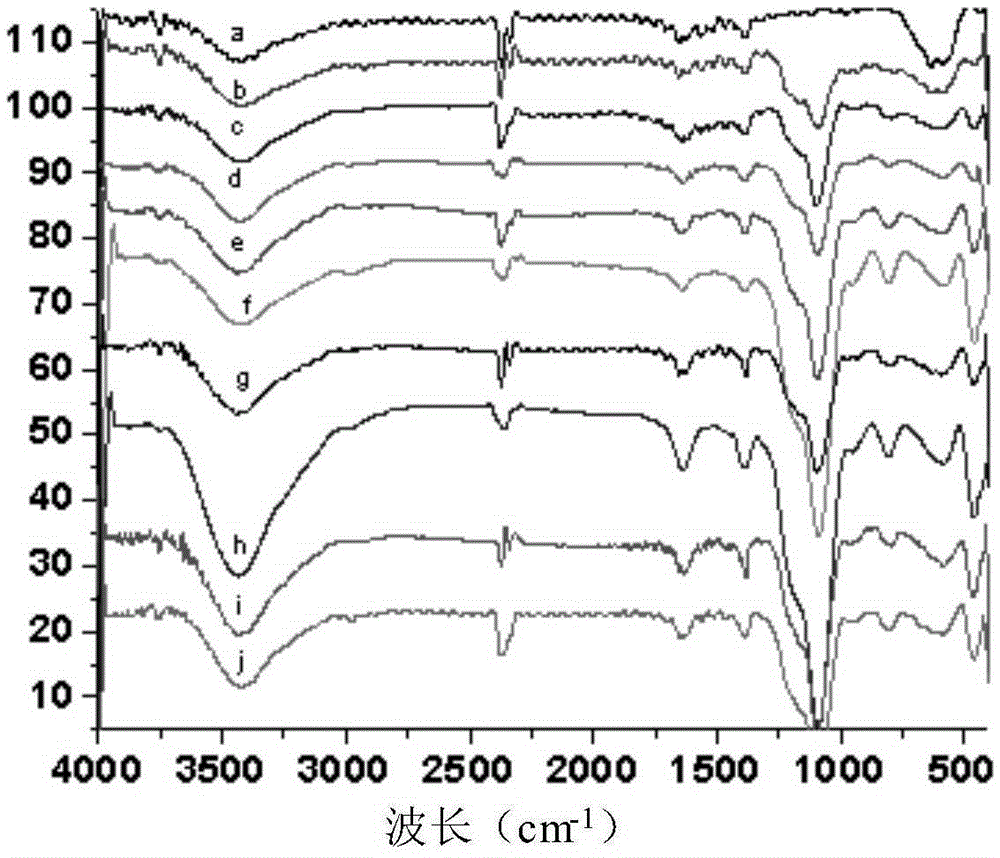

Embodiment 1

[0064] 1.1 At room temperature, first mix 12.98g of anhydrous FeCl 3 and 7.95gFeCl 2 4H 2 O (molar ratio: Fe(III) / Fe(II)=2:1) was dissolved in 400mL of high-purity nitrogen deoxygenated water, heated to 80°C in a water bath, and 48mL of concentrated ammonia water was added with a constant pressure funnel under rapid stirring, and then, Stir and heat at this temperature for 6 hours, contact the outer wall of the round bottom flask with a magnet to collect magnetic nanomaterials, wash the obtained black powder three times with deionized water, add citric acid to 0.1mol / L ultrasonic 30min under the protection of nitrogen, magnetic Separated, washed with ethanol for 3 times, and then stored at 4°C to obtain ferric oxide nanomaterials. (Reaction principle: Fe 2+ +2Fe 3+ +8OH - →4H 2 O+Fe 3 o 4 )

[0065] 1.2 The Fe obtained in 4.63g1.1 3 o 4 Ultrasonic dispersion in 50mL of deionized water, followed by adding 25mL of 25% ammonia and 700mL of ethanol. At room temperatu...

Embodiment 2

[0084] Under the protection of nitrogen, the nanomaterial (Fe 3 o 4 SiO 2 G0.5, Fe 3 o 4 SiO 2 G1.5, Fe 3 o 4 SiO 2 G2.5 or Fe 3 o 4 SiO 2 G3.5) Disperse in 50mL of methyl isobutyl ketone and transfer to a round-bottomed flask, then add a certain amount of linker reagent into the flask, reflux and stir at 30°C for 48-96h to obtain a nanocomposite material , respectively denoted as Fe 3 o 4 SiO 2 G0.5-ARM, Fe 3 o 4 SiO 2 G1.5-ARM, Fe 3 o 4 SiO 2 G2.5-ARM and Fe 3 o 4 SiO 2 G3.5-ARM.

[0085] The dosages of linker reagents under the above reaction conditions are: p-diphenylamine 3-5g; m-diphenylamine 3-5g; 3,3'-diaminobenzidine 6-8.8g; 4,4'-diaminobenzidine 6 ~8.8g; 1,5-naphthalene diamine 6~8.8g; 2,6-naphthalene diamine 6~8g.

[0086] Potentiometric titration is used to measure the amino group on the surface of magnetic nanomaterials: Potentiometric titration utilizes the change in potential in the titration process to determine the titration end point. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence | aaaaa | aaaaa |

| fluorescence | aaaaa | aaaaa |

| fluorescence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com