Method for treating stone coal acid leaching solution

A technology of coal acid and leaching liquid, applied in chemical instruments and methods, aluminum sulfate, inorganic chemistry, etc., can solve the problems of unsystematic treatment process, poor removal or recovery effect, etc., and achieve the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

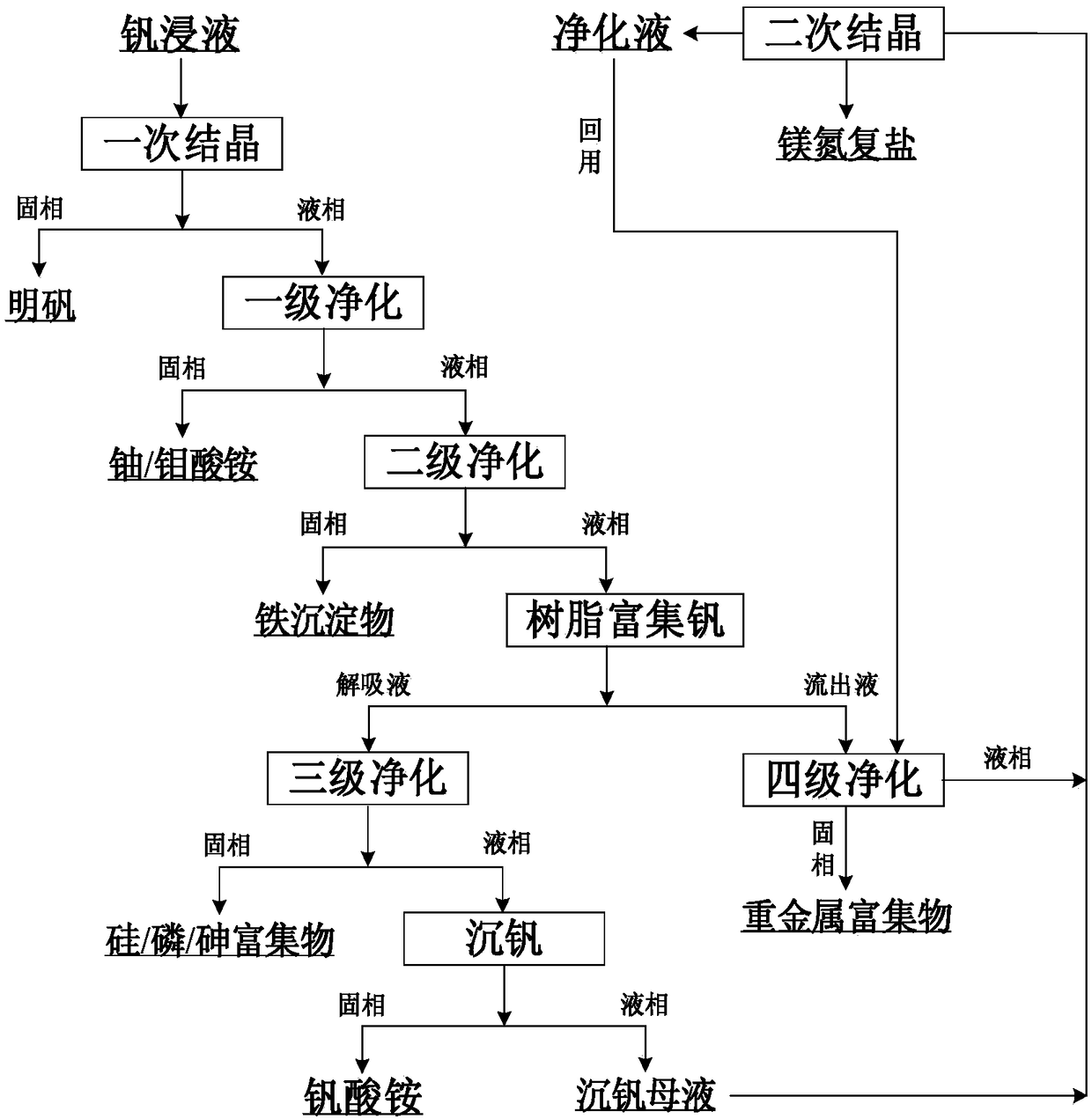

[0167] Such as figure 1 As shown, the stone coal acid leaching solution is processed according to the following steps:

[0168] (1) Primary crystallization: cooling and crystallizing the stone coal pickling solution at 40° C., separating solid and liquid to obtain alum and filtrate.

[0169] (2) Primary purification: the filtrate obtained in step (1) is first adjusted to pH 2, and then sodium persulfate, potassium thiosulfate, potassium sulfide, potassium pyrosulfite, sodium hydrosulfide, ammonium sulfide and ammonium bisulfite are added Adjust the redox potential of the solution to 550mV, and finally add sodium bisulfate to adjust the sulfate concentration in the solution to 0.1mol / L. Uranium-rich resin and molybdenum-enriched resin and effluent are obtained by adsorption with amine extraction and leaching resin, and the concentration of uranium and molybdenum in the effluent is less than 0.4ppm. The uranium-rich and molybdenum resins are respectively desorbed twice through...

Embodiment 2

[0178] (1) Primary crystallization: Add sodium sulfate, ammonium bisulfate, ammonium bicarbonate and potassium bicarbonate to the stone coal acid leaching solution, so that the aluminum in the acid leaching solution forms alum (MAl(SO 4 ) 2 12H 2 O, M is K + , NH 4 + 、Na + ) and iron to form jarosite NFe 3 (SO 4 ) 2 (OH) 6 (N is Na + , NH 4 + 、K + ) to meet 5 times of the theoretical amount, cooling and crystallization at room temperature (20° C.), solid-liquid separation, and obtaining alum and filtrate.

[0179] (2) One-level purification: the pH of step (1) gained filtrate is first adjusted to be 1.8, then add sodium persulfate, potassium persulfate, sodium thiosulfate, sodium sulfide, potassium sulfite, potassium hydrosulfide, ammonium hydrosulfide and Potassium bisulfite adjusted the redox potential of the solution to 710mV, and finally added ammonium sulfate and sodium sulfate to adjust the sulfate concentration in the solution to 0.3mol / L. Uranium-rich res...

Embodiment 3

[0188] (1) Primary crystallization: ammonium sulfate, ammonium carbonate and ammonium bicarbonate are added to the acid leaching solution of stone coal, so that the aluminum in the acid leaching solution forms alum (MAl(SO 4 ) 2 12H 2 O, M is K + , NH 4 + 、Na + ) and iron to form jarosite NFe 3 (SO 4 ) 2 (OH) 6 (N is Na + , NH 4 + 、K + ) satisfying 0.1 times of the theoretical amount, cooling and crystallization at 0°C, solid-liquid separation, and obtaining alum by-products and filtrate.

[0189] (2) Primary purification: firstly adjust the pH of the filtrate obtained in step (1) to be 1, then feed sulfur dioxide, add hydrogen peroxide to adjust the redox potential of the solution to be 750mV, and finally add potassium sulfate to adjust the sulfate concentration in the solution to be 0.5mol / L . The uranium-rich and molybdenum-rich resin and the effluent are obtained by adsorption with a neutral extraction resin, and the concentrations of uranium and molybdenum i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com