Method for preparing flat-plate type metal-support solid oxide fuel cell

A solid oxide, metal-supported technology, used in solid electrolyte fuel cells, fuel cell components, fuel cells, etc. Simplified structure and preparation process, good high temperature oxidation resistance, and the effect of avoiding electrolyte cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In the 50g 430 stainless steel powder, add solvent absolute ethanol 7g, butanone 5g, dispersant triethanolamine 4g, BYK1g, plasticizer dibutyl phthalate 1g, binder polyvinyl butyral 6g, Pore-forming agent ammonium oxalate 20g; add solvent xylene, butyl acetate 5g each, dispersant DM-55 1g, plasticizer B-50 1g, binder B-724g to 30g electrolyte YSZ powder; Add 4g of solvent xylene and butyl acetate, 1g of dispersant DM-55, 0.5g of plasticizer B-500.5g, 1g of binder B-72, and 10g of pore-forming agent ammonium oxalate to the cathode precursor layer YSZ powder;

[0055] Ball mill the above three kinds of slurries respectively, and sieve the mixed slurries through sieves and vacuum treatment to remove the air in the slurries;

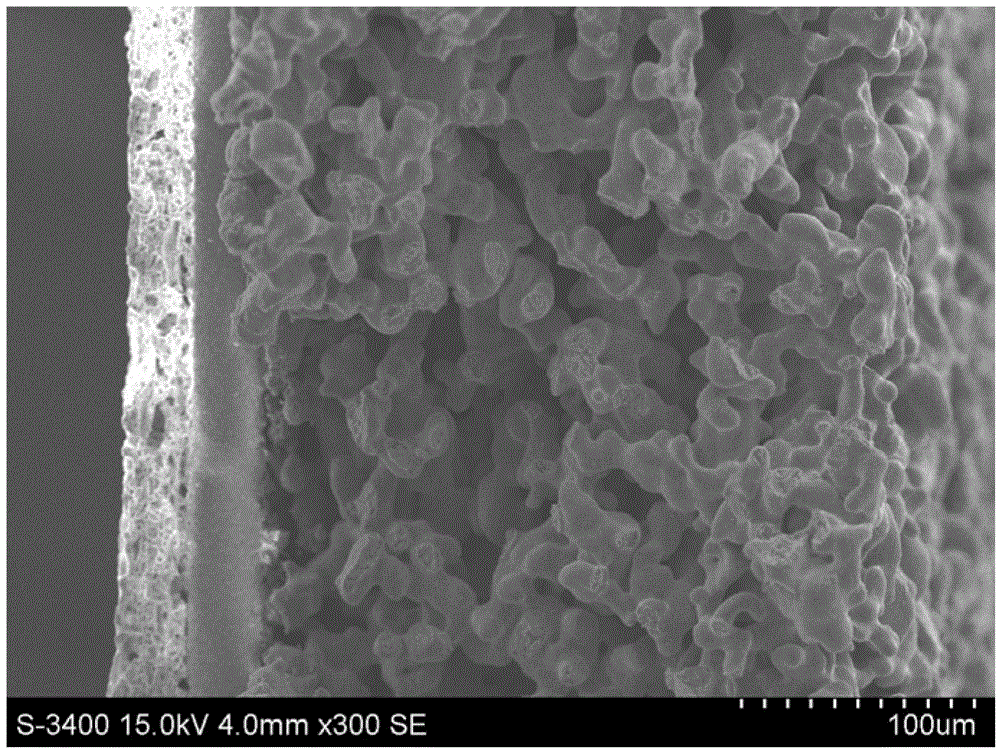

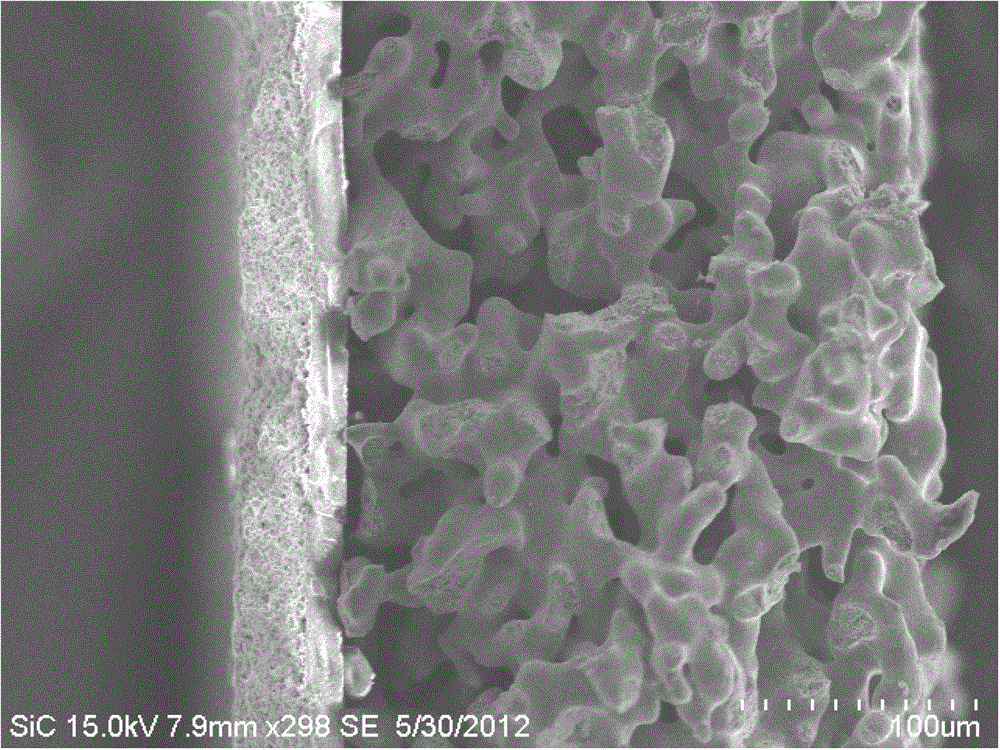

[0056] Carrying out tape casting and drying the above three kinds of slurries respectively to obtain green bodies of metal support layer, electrolyte layer and cathode precursor layer, and cutting each green body into green bodies meeting the size req...

Embodiment 2

[0063] Add 12g of solvent absolute ethanol, 6g of methyl ethyl ketone, 4g of dispersant triethanolamine, 2g of plasticizer dibutyl phthalate and 2g of polyethylene glycol to 50g of 430 stainless steel powder, and binder polyvinyl alcohol Butyraldehyde 3g, pore-forming agent ammonium carbonate 20g; add solvent xylene, butyl acetate 5g each, dispersant DM-55 1g, plasticizer B-50 2g, binder B- 72 4g; Add 4g of solvent xylene and butyl acetate, 1.5g of dispersant DM-55, 1g of plasticizer B-50, and 2g of binder B-72 to 15g of cathode precursor layer YSZ powder, and make holes Agent ammonium carbonate 15g;

[0064] Ball mill the above three kinds of slurries respectively, and sieve the mixed slurries through sieves and vacuum treatment to remove the air in the slurries;

[0065] Carrying out tape casting and drying the above three kinds of slurries respectively to obtain green bodies of metal support layer, electrolyte layer and cathode precursor layer, and cutting each green body ...

Embodiment 3

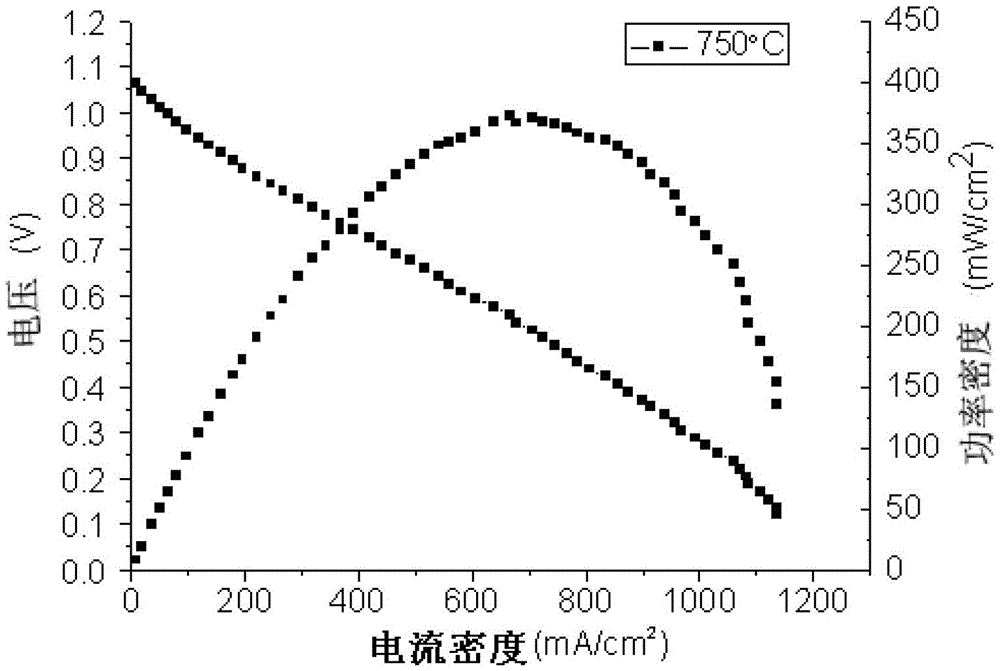

[0072] The preparation process of the SOFC of three-layer structure is consistent with embodiment 2; The nitrate water-ethanol solution of active cathode material LSCF-GDC is impregnated in cathode precursor layer, and wherein the addition of ethanol is 50% of solvent total volume used; Then in inert The battery cathode is obtained after heat treatment at 850°C in the atmosphere; the active anode material Ni-CeO is impregnated in the metal support layer 2 The nitrate water-ethanol solution, wherein the amount of ethanol added is 40% of the total volume of the solvent used; and then the anode of the battery is obtained after heat treatment in the air at 500 ° C; the flat metal-supported SOFC is obtained.

[0073] After testing, the cathode side is ambient air and the anode side is 97%H 2 +3%H 2 0. The maximum power density of the battery prepared in this example is 350mW / cm at 700°C 2 , still has good electrical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com