Vinyl sulfone-substituted cysteine-N-carboxyanhydride, polymer thereof and application of polymer

A technology of cysteine hydrochloride and cysteine, applied in the field of polymer materials, can solve problems such as weak physical and mechanical properties, complicated preparation process, and strict conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

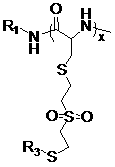

[0073] Example 1 Synthesis of vinylsulfone substituted cysteine N-carboxyl internal anhydride (VSCys-NCA).

[0074] (1) Dissolve 4.45 g (25 mmol) of cysteine hydrochloride in 80 ml of methanol, drop by drop into the methanol solution of divinyl sulfone (12.55 ml, 125 mmol); stir in an oil bath at 50°C and react for 100 hours The resulting solution was concentrated under reduced pressure and precipitated with ethyl acetate, filtered, and dried to obtain 6.58 g of white solid powder (vinylsulfone substituted L-cysteine, VSCys), with a yield of 94.4%.

[0075] (2) Weigh VSCys (3.75 g, 13.6 mmol) in a dry three-necked round bottom flask, add anhydrous THF (100 ml), then add pinene (α-pinene) (5.0 ml, 31.5 mmol), The reaction system was placed in an oil bath at 50°C for 30 minutes, and then solid triphosgene (2.02 g, 6.8 mmol) was added; the reaction temperature was increased to 70°C, and after 1 hour of reaction, the crude product of VSCys-NCA was obtained by precipitation with pet...

Embodiment 2

[0077] Example 2: Synthesis of vinylsulfone substituted cysteine N-carboxyl internal anhydride (VSCys-NCA)

[0078] (1) Dissolve 4.45 g (25 mmol) of cysteine hydrochloride in 80 ml of methanol, drop by drop into the methanol solution of divinyl sulfone (50.2 ml, 500 mmol); stir and react in an oil bath at 40°C for 60 hours The resulting solution was concentrated under reduced pressure and precipitated with ethyl acetate, filtered, and dried to obtain 6.97 g of white solid powder (vinylsulfone substituted L-cysteine, VSCys) with a yield of 95.7%.

[0079] (2) Weigh VSCys (3.75 g, 13.6 mmol) in a dry three-necked round bottom flask, add anhydrous THF (100 ml), then add pinene (α-pinene) (6.5 ml, 40.8 mmol), The reaction system was placed in an oil bath at 50°C for 30 minutes, and then solid triphosgene (2.02 g, 13.6 mmol) was added; the reaction temperature was increased to 70°C, and after 1 hour of reaction, the crude product of VSCys-NCA was obtained by precipitation with petro...

Embodiment 3

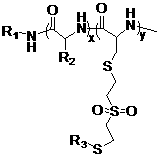

[0080] Example 3 Preparation of polyamino acid random copolymer by copolymerization of VSCys-NCA and other α-amino acid-N-carboxyl internal acid anhydride

[0081] According to the ratio of each component in Table 1, dissolve other α-amino acid-N-carboxyl internal acid anhydride and VSCys-NCA solid in anhydrous DMF in a glove box; add the small molecule initiator propylene trimethylsilazane The reaction of alkane in DMF solution was placed in an oil bath at 40°C for 48 h under anhydrous conditions, and the reaction was terminated with two drops of acetic acid; the polymer solution was precipitated in glacial ether, filtered and vacuum dried at room temperature to obtain the product polyamino acid.

[0082] Attached figure 2 Schematic diagram of the above random copolymerization reaction. The reaction was monitored by infrared: After the reaction was carried out for 48 h, the carbonyl absorption peak of the two monomer anhydrides in the infrared spectrum was 1869 cm -1 (VS-Cys NCA)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com