Rapid preparation method for MSi2O2N2:Eu<2+> phosphor

A technology of msi2o2n2 and phosphor, which is applied in the field of rapid preparation of MSi2O2N2:Eu2+ phosphor, can solve the problems of increased process difficulty, reduced fluorescence intensity of phosphor, and reduced energy utilization rate, so as to promote the dissolution-precipitation process and avoid crystal lattice Integrity, high synthetic conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

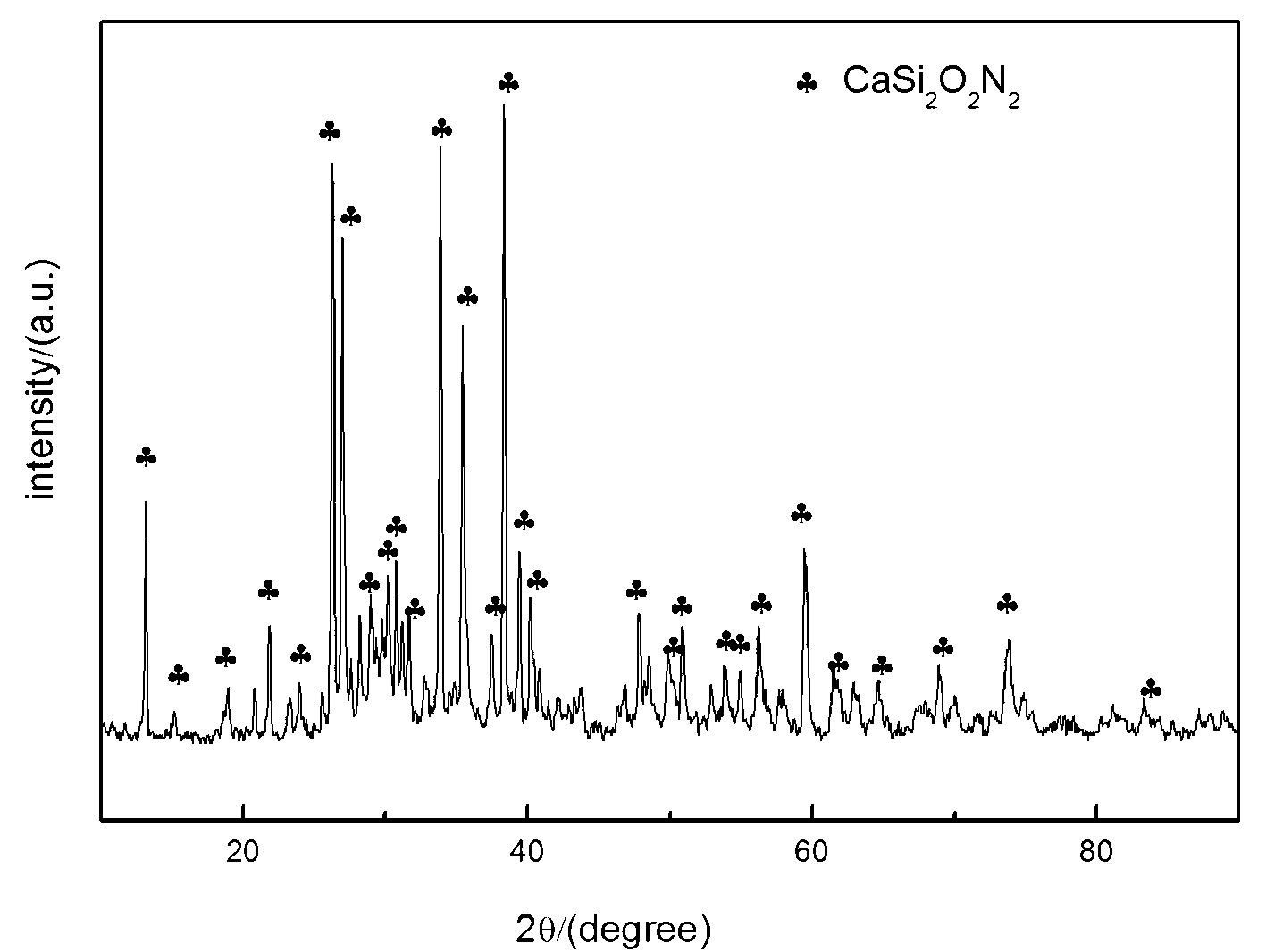

[0046] A kind of oxynitride fluorescent powder, its chemical formula is Ca 0.98 Si 2 o 2 N 2 :Eu 0.02 2+ .

[0047] The preparation method of the above-mentioned oxynitride phosphor comprises the following steps:

[0048] (1) According to the chemical formula Ca 0.98 Si 2 o 2 N 2 :Eu 0.02 2+ , Weigh the raw material SiO at a molar ratio of 1:1:1.96:0.02 2 7.443g, Si 3 N 4 17.368g, CaCO 3 24.316g, Eu 2 o 3 0.873g, a total of 50g of raw material mixture with 150ml of absolute ethanol and 200g of Si 3 N 4 After the balls are mixed, ball mill for 2 hours; the slurry obtained from ball milling is washed and recovered with absolute ethanol, and then placed in a rotary evaporating flask in a constant temperature water bath at 60°C to obtain a preliminary dry mixed powder; the obtained preliminary dried mixed powder is placed in a vacuum drying oven Continue to dry at a constant temperature at 60°C for 2 hours to obtain a uniformly mixed raw material mixed powde...

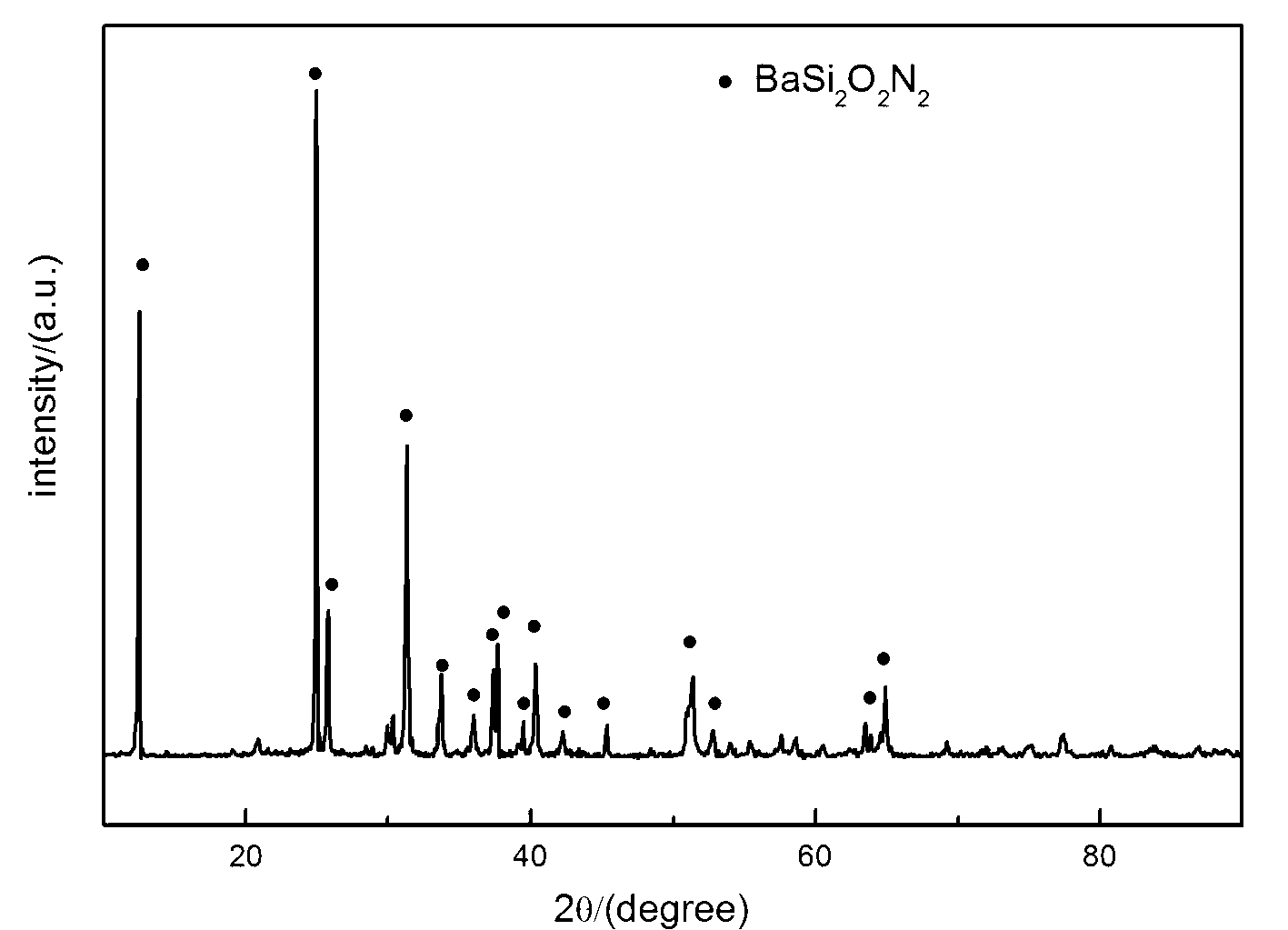

Embodiment 2

[0052] A kind of oxynitride fluorescent powder, its chemical formula is Ca 0.99 Si 2 o 2 N 2 :Eu 0.01 2+ .

[0053] The preparation method of the above-mentioned oxynitride phosphor comprises the following steps:

[0054] (1) According to the chemical formula Ca 0.99 Si 2 o 2 N 2 :Eu 0.01 2+ , Weigh the raw material SiO at a molar ratio of 1:1:1.98:0.01 2 9.542g, Si 3 N 4 22.264g, CaO 17.633g, Eu 2 o 3 0.560g, a total of 50g of raw material mixture with 150ml of absolute ethanol and 200g of Si 3 N 4 After the balls are mixed, ball mill for 2 hours; the slurry obtained from the ball mill is washed and recovered completely with absolute ethanol, and then placed in a rotary evaporating flask in a constant temperature water bath at 60°C to obtain a preliminary dry mixed powder; the obtained preliminary dried mixed powder is placed in vacuum drying Continue drying at a constant temperature in the box at 60°C for 2 hours to obtain a homogeneously mixed powder of...

Embodiment 3

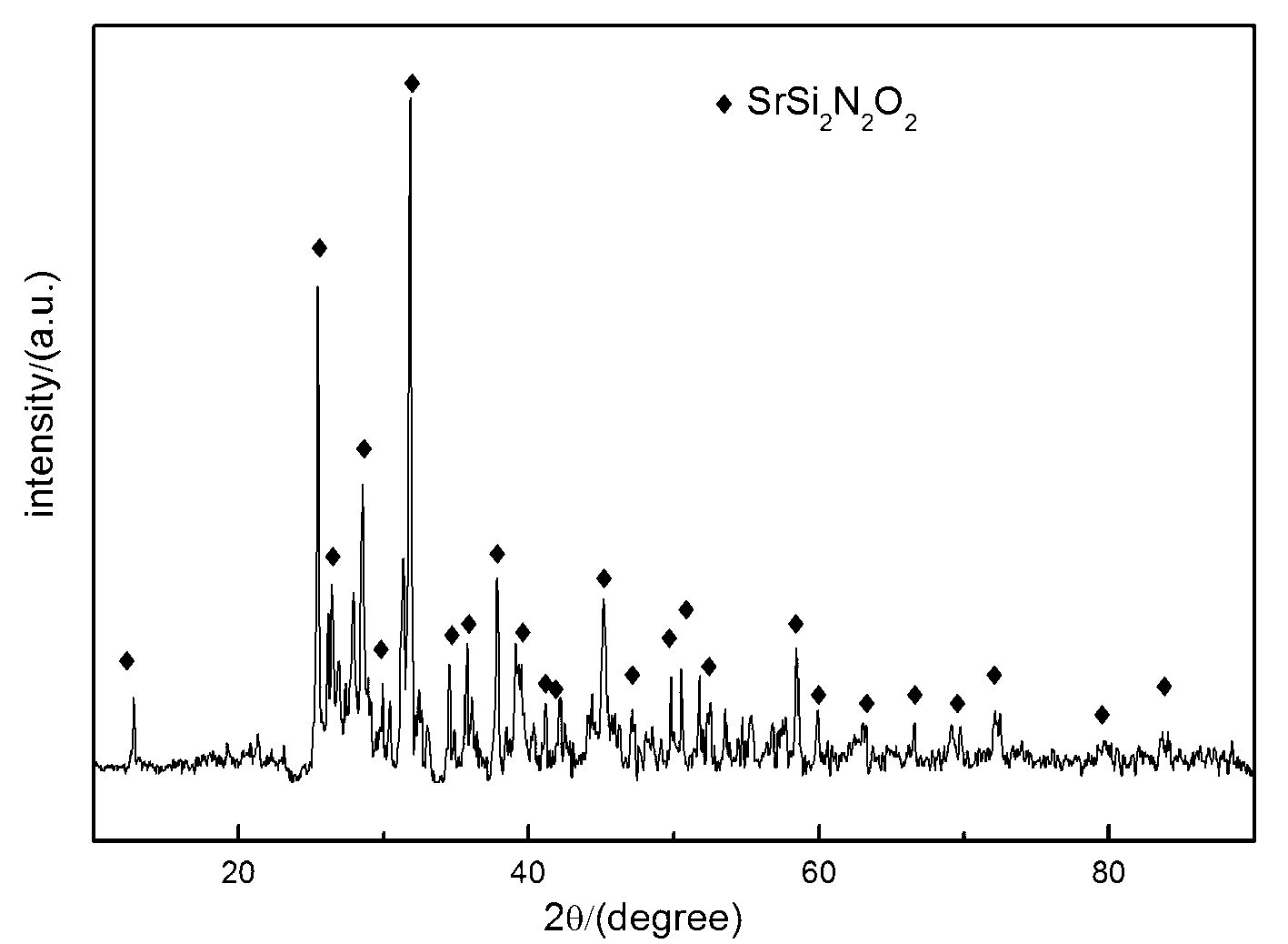

[0058] A kind of oxynitride fluorescent powder, its chemical formula is Sr 0.98 Si 2 o 2 N 2 :Eu 0.02 2+ .

[0059] The preparation method of the above-mentioned oxynitride phosphor comprises the following steps:

[0060] (1) According to the chemical formula Sr 0.98 Si 2 o 2 N 2 :Eu 0.02 2+ , Weigh the raw material SiO at a molar ratio of 1:1:1.96:0.02 2 6.045g, Si 3 N 4 14.103g, SrCO 3 29.143g, Eu 2 o 3 0.709g, a total of 50g of raw material mixture with 150ml of absolute ethanol and 200g of Si 3 N 4 After the balls are mixed, ball mill for 2 hours; the slurry obtained from ball milling is washed and recovered with absolute ethanol, and then placed in a rotary evaporating flask in a constant temperature water bath at 60°C to obtain a preliminary dry mixed powder; the obtained preliminary dried mixed powder is placed in a vacuum drying oven Continue to dry at a constant temperature at 60°C for 2 hours to obtain a uniformly mixed raw material mixed powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com