Patents

Literature

43results about How to "Necessary stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

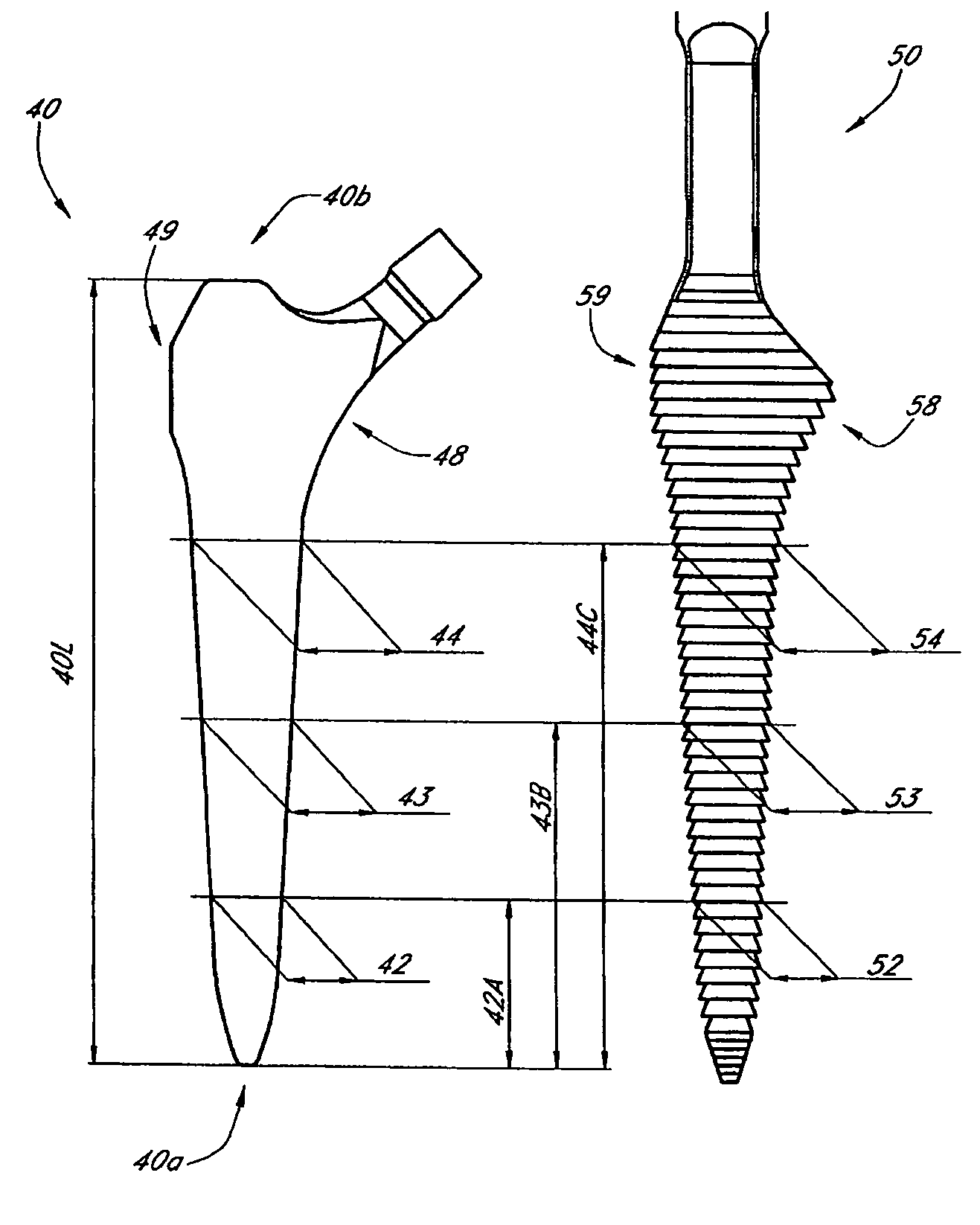

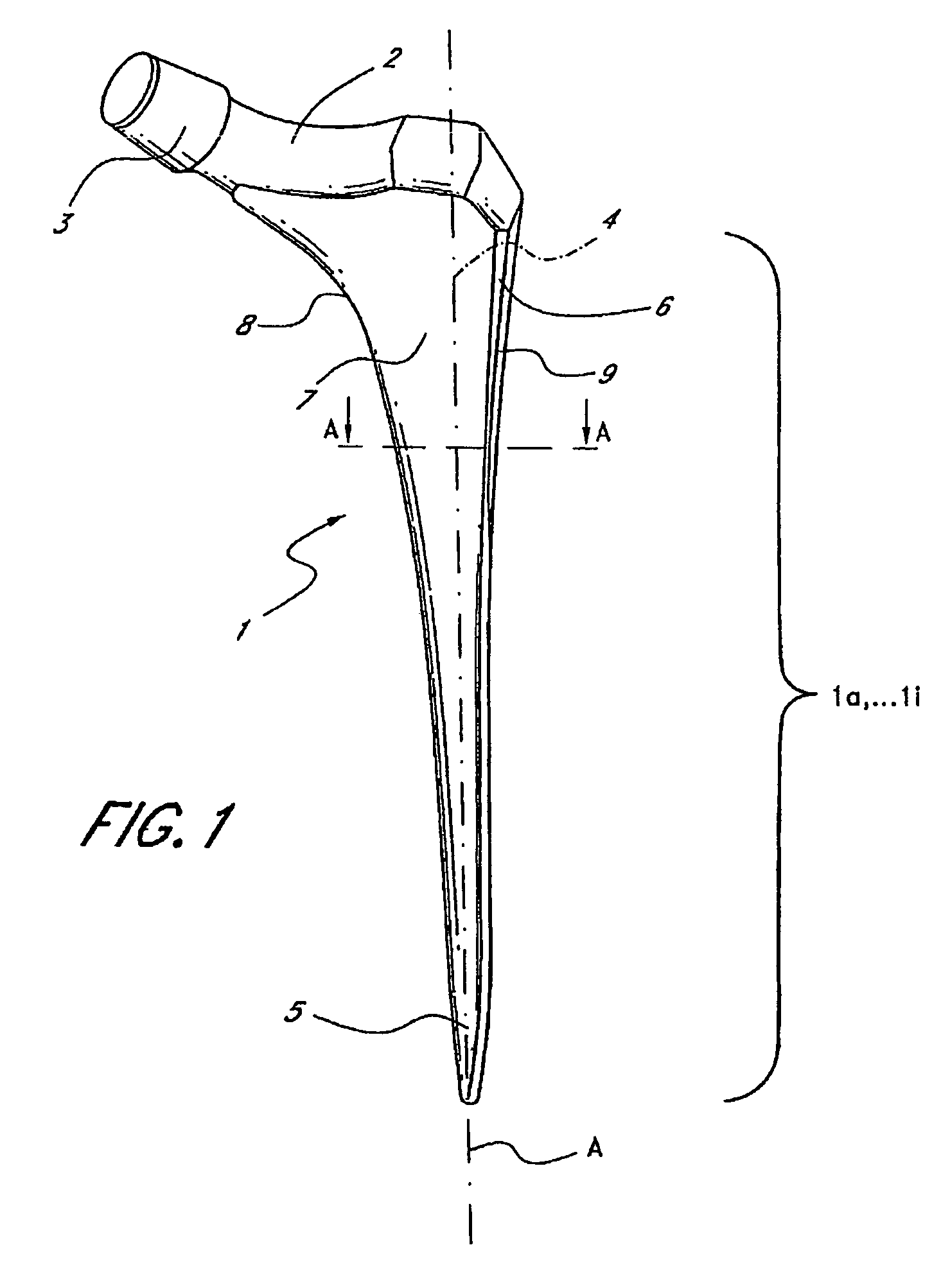

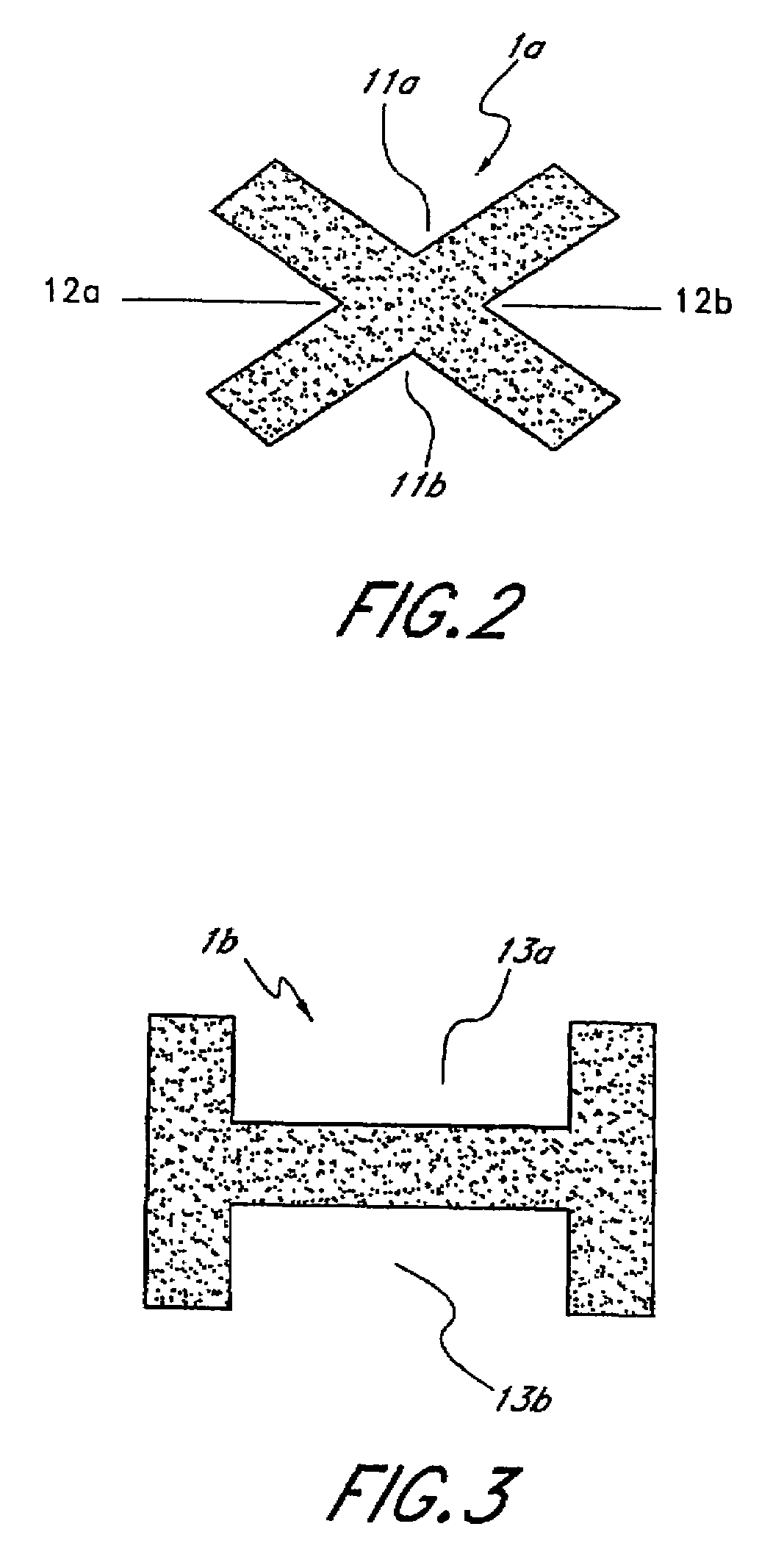

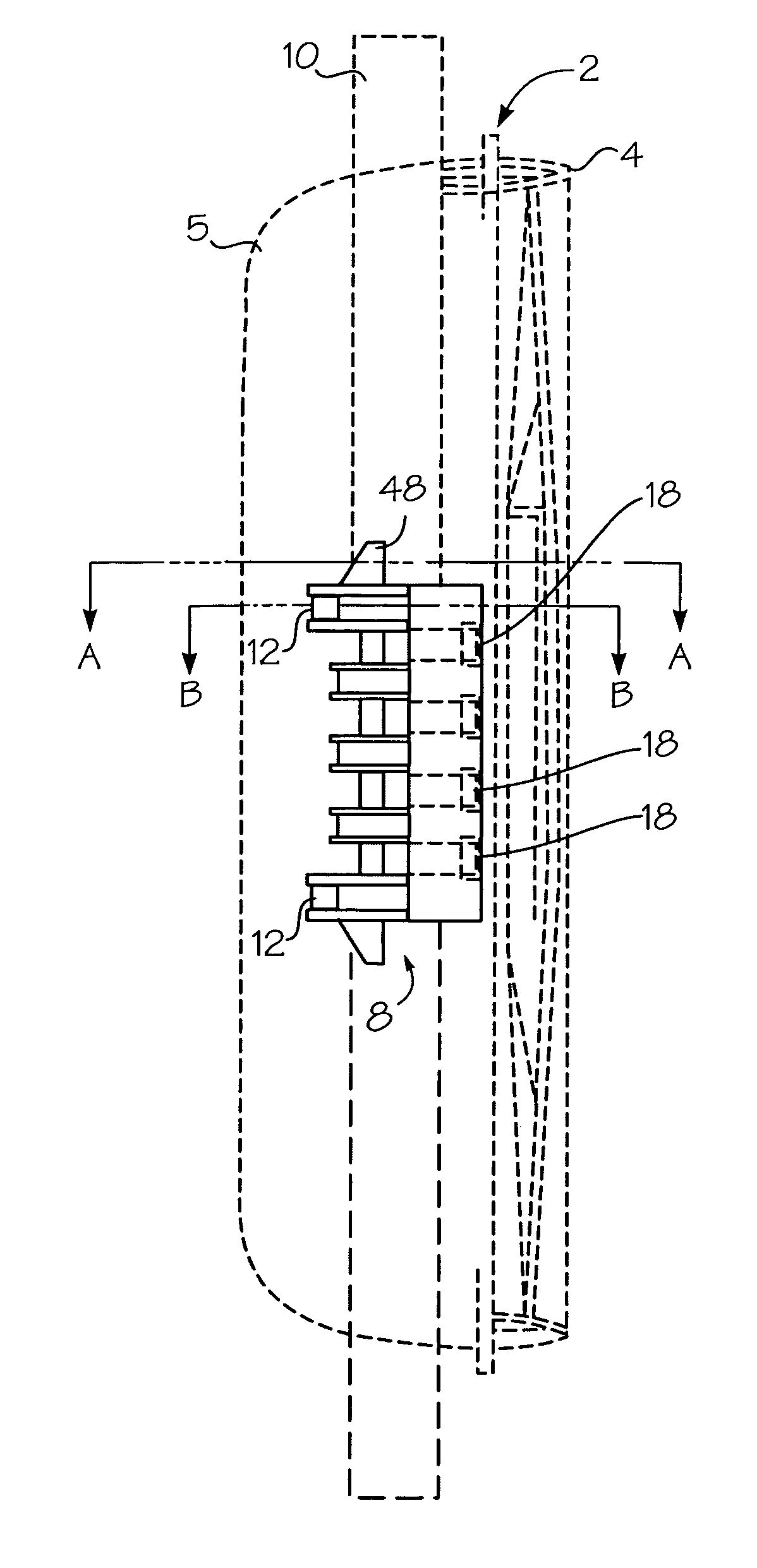

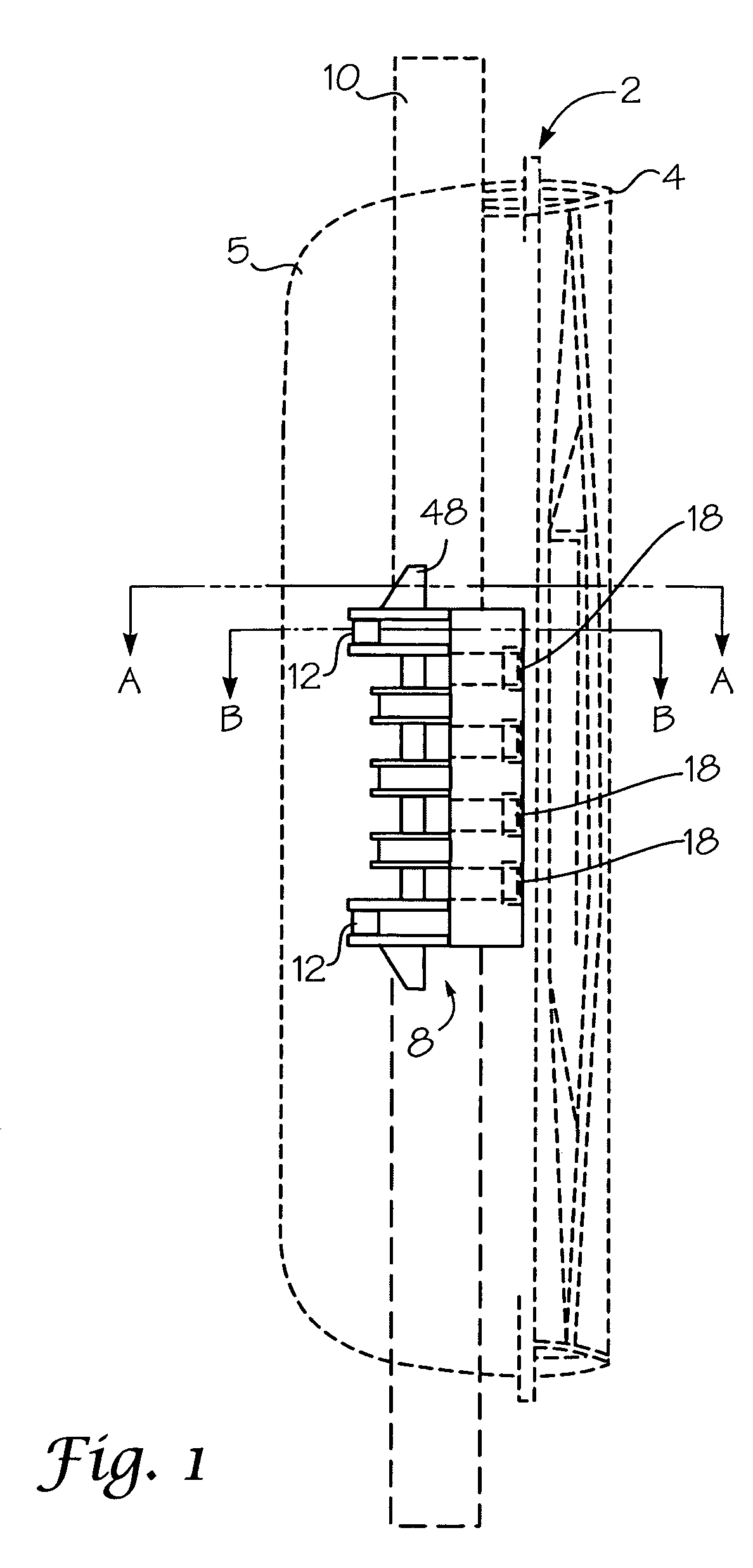

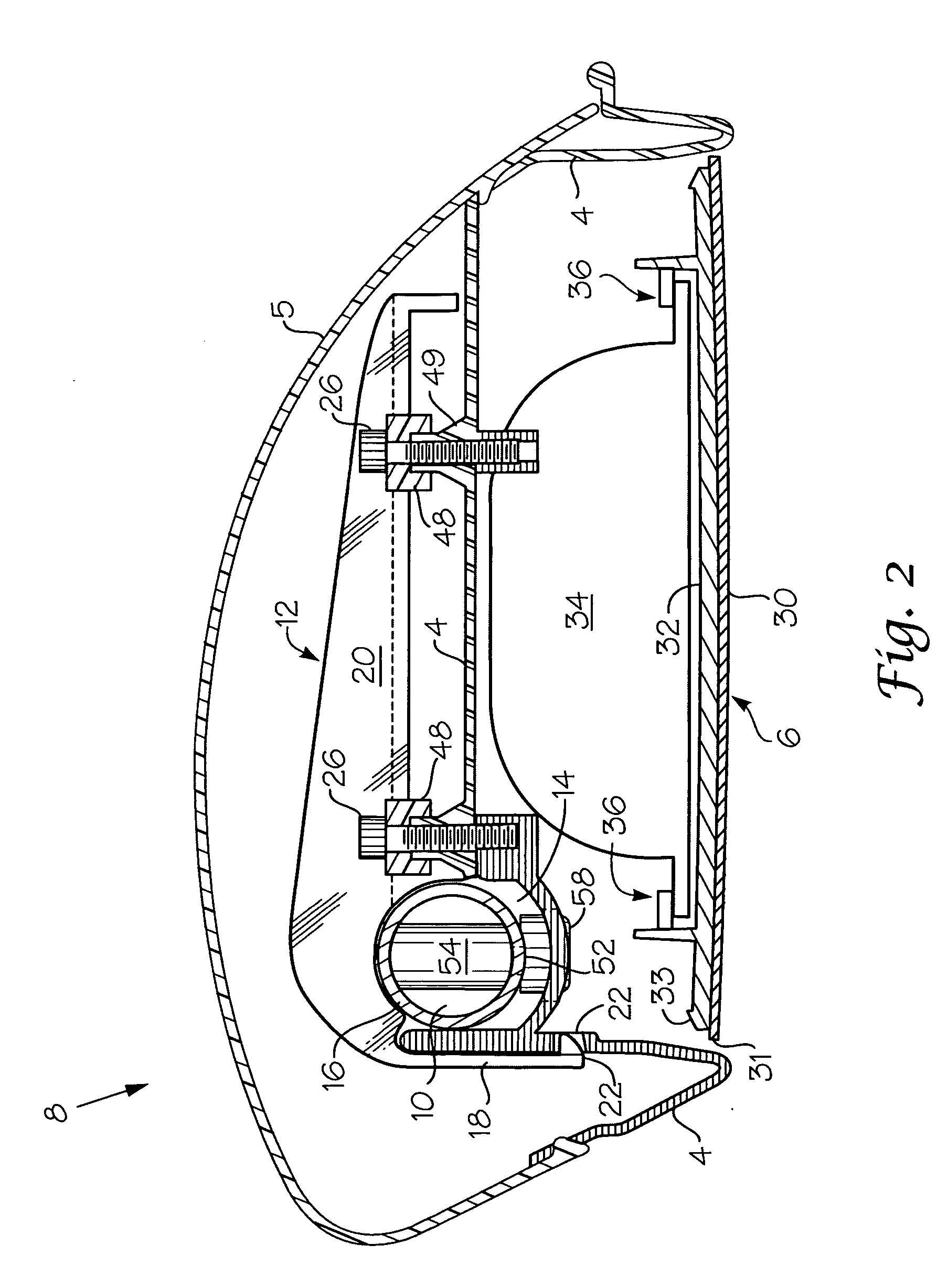

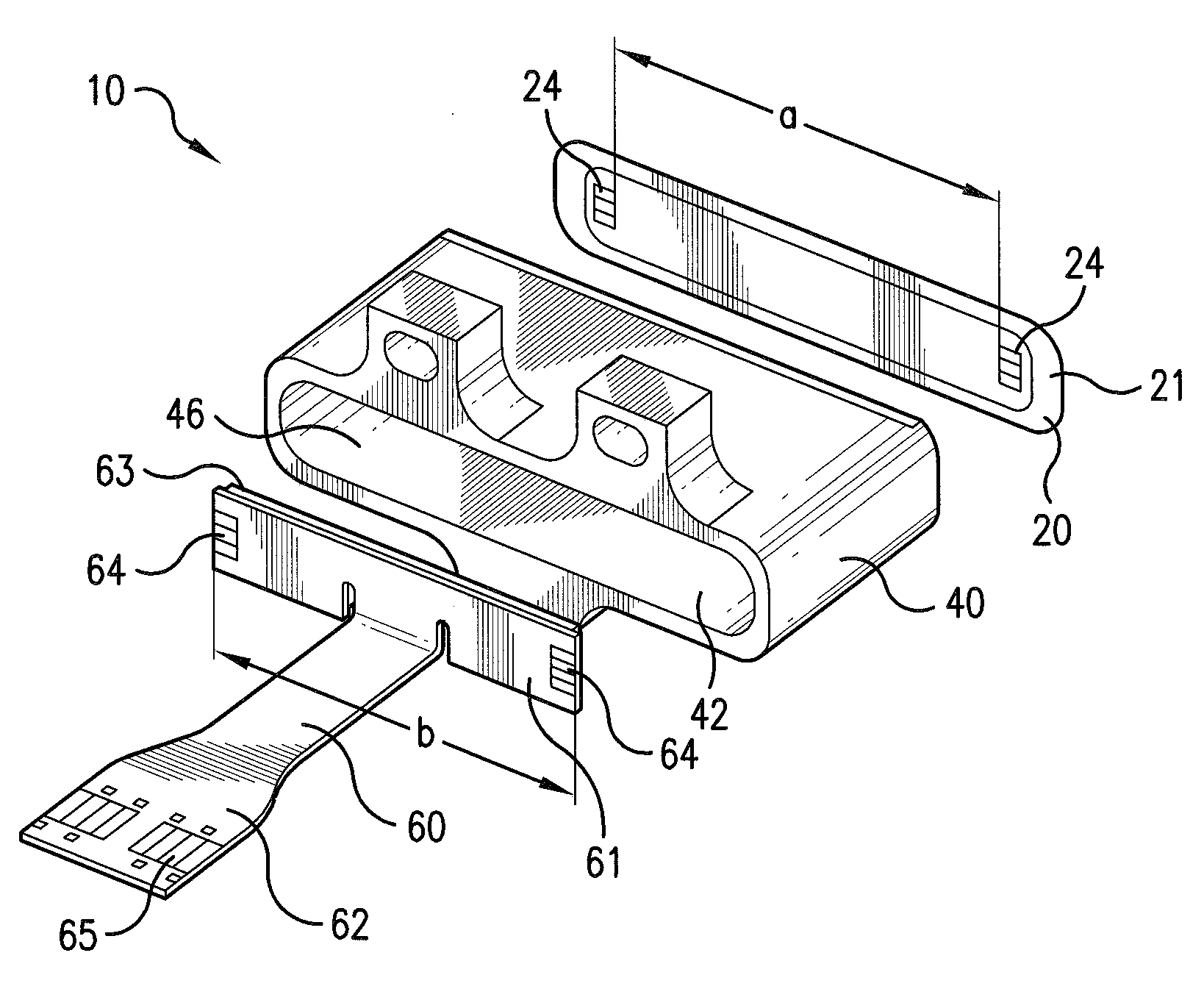

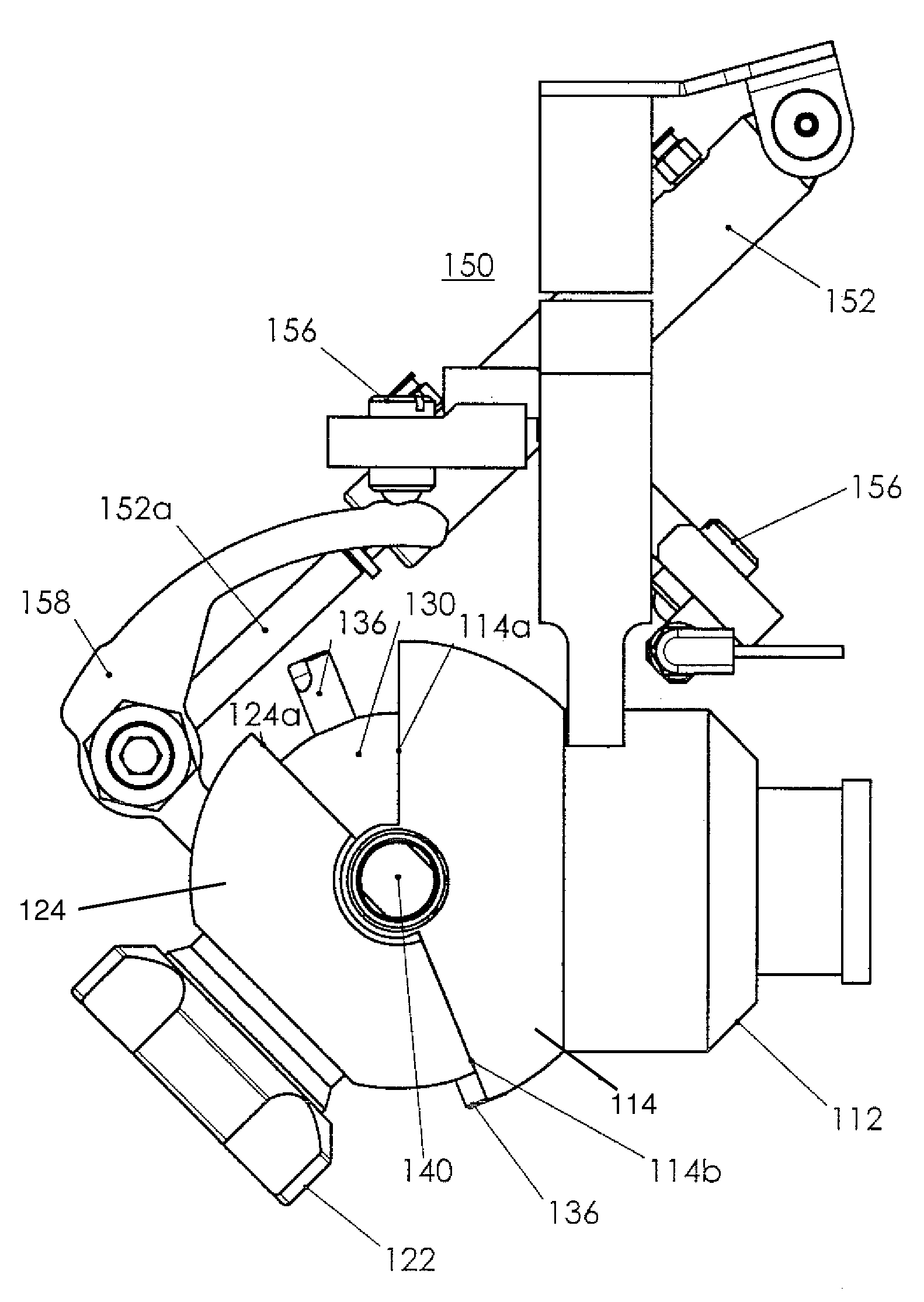

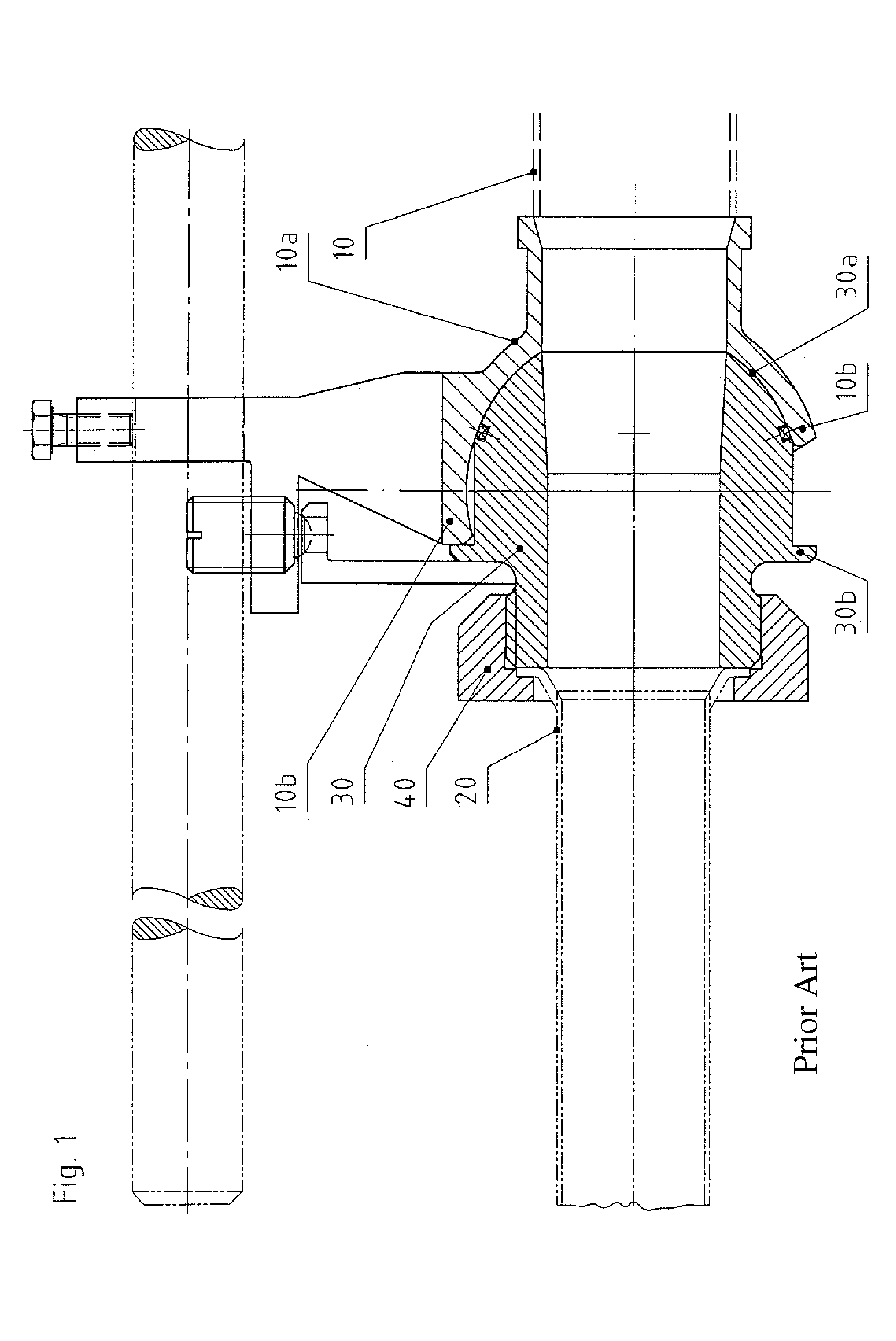

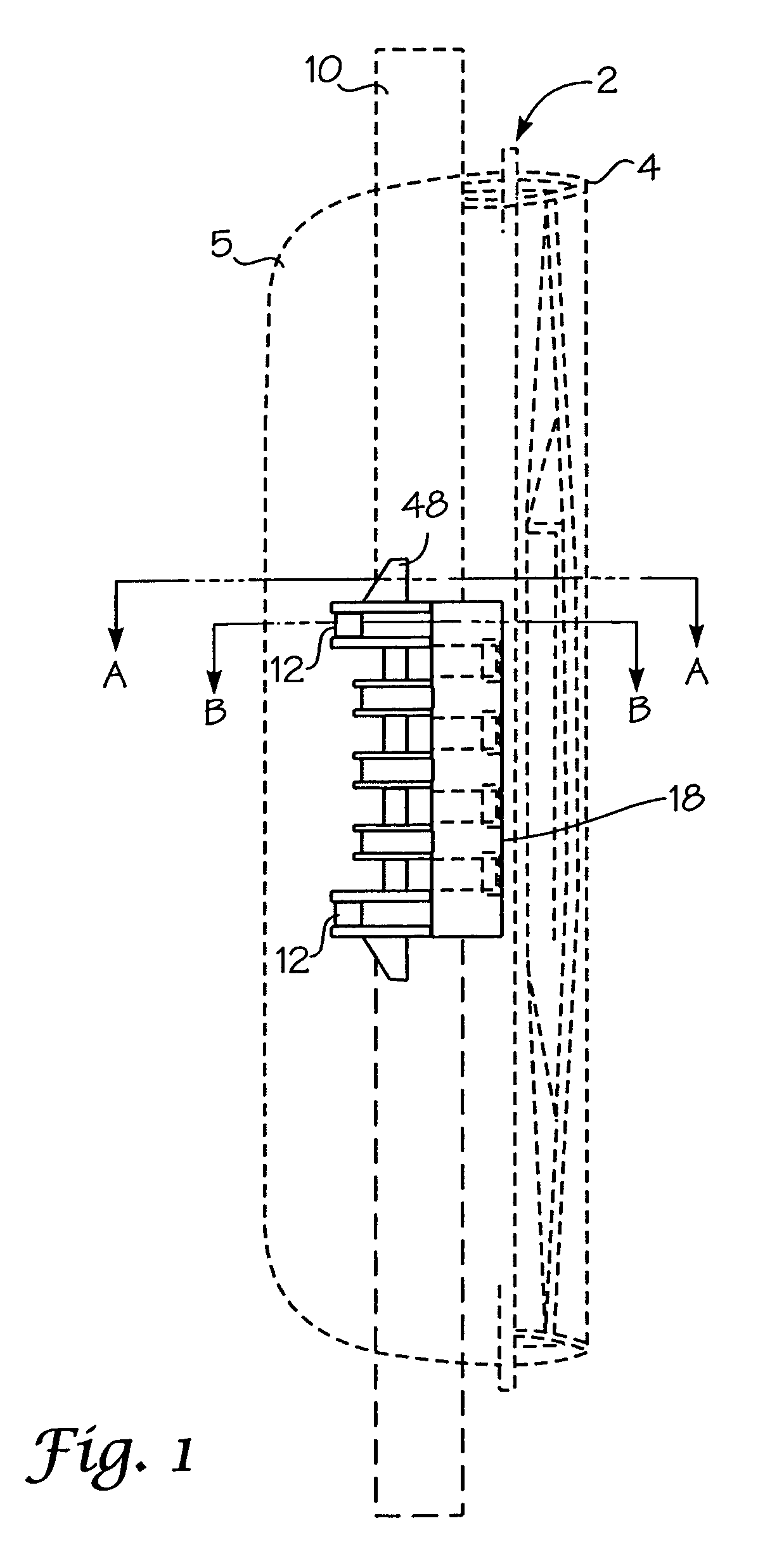

Leaflike shaft of a hip-joint prosthesis for anchoring in the femur

InactiveUS7494510B2Advantageous for revascularizationFacilitate revascularizationSurgeryJoint implantsRaspFemoral shaft

The present invention relates in certain embodiments to components of a hip-joint prosthesis. More particularly, embodiments of the invention relate to a leaf-like femoral shaft for use as part of a hip-joint prosthesis, and instruments (e.g., a rasp) and methods for implanting the shaft. The shaft includes an anchoring section extending between a proximal region and a distal end of the shaft. The shaft has a cross-sectional contour that defines a lateral side, a medial side, an anterior side and a posterior side. A corresponding rasp is preferably provided for each femoral shaft. The rasp is inserted into the femur to form a cavity having generally the same configuration as the rasp. The shaft is configured to be over-dimensioned in at least one of the anterior-posterior direction and medial-lateral direction relative to the rasped femur cavity. In one embodiment, the distance between diagonally opposite corner junctions of the shaft is substantially equal to the distance between corresponding diagonally opposite corner junctions of the femur cavity, so as to inhibit excess stress on the corticalis.

Owner:SMITH & NEPHEW ORTHOPAEDICS

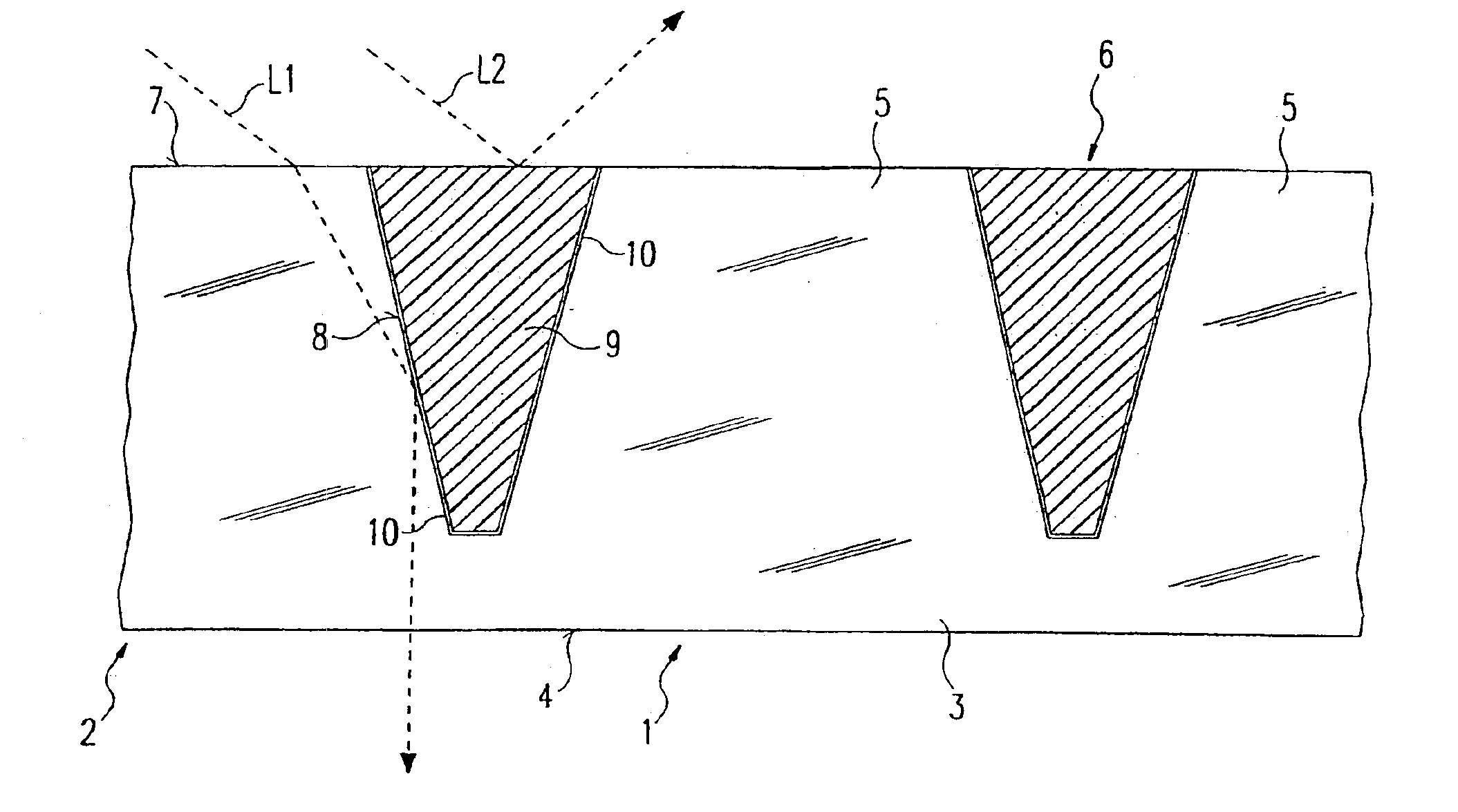

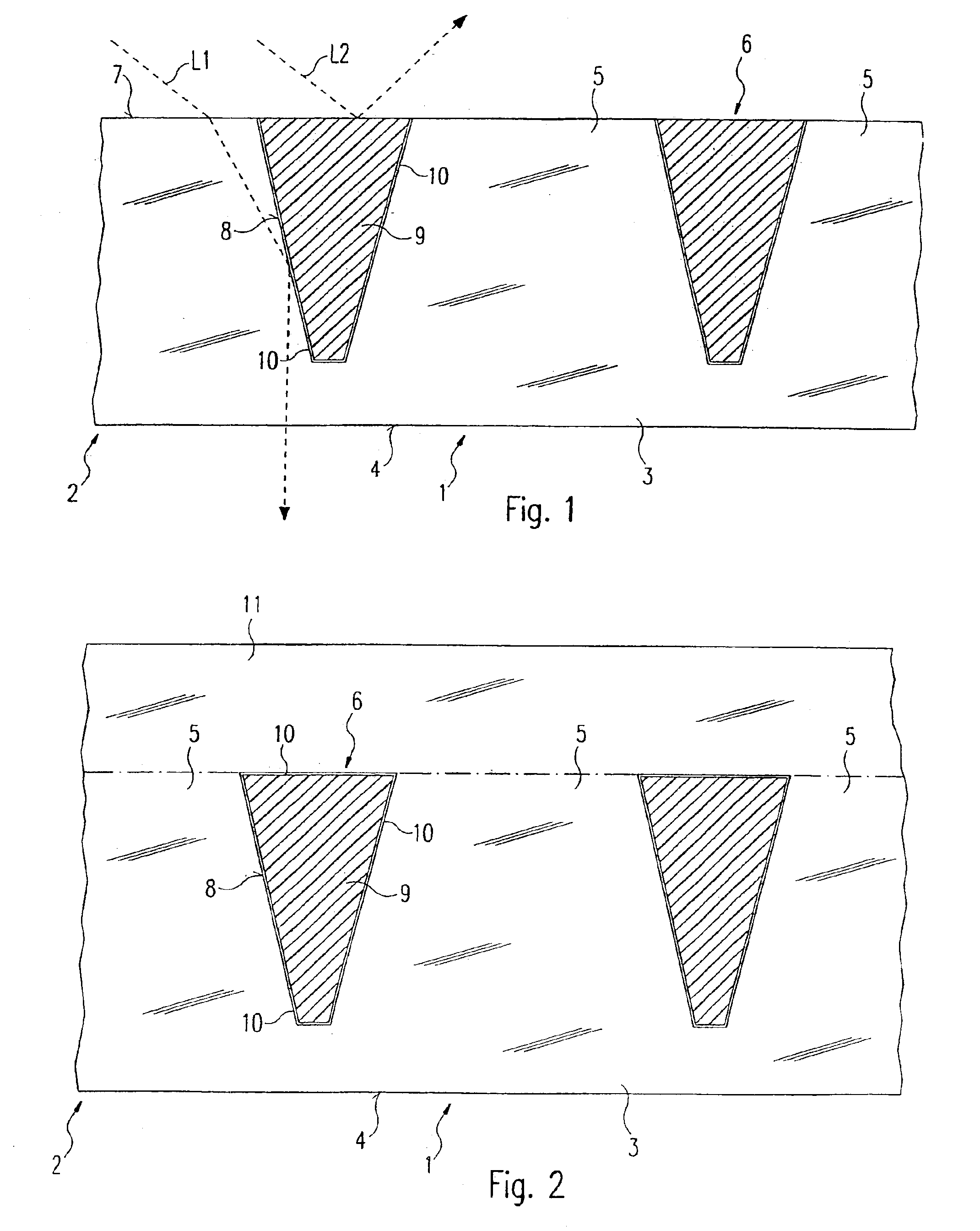

Optical element having total reflection

InactiveUS6980728B2Simpler and economical possibilityReliable maintenancePrismsMechanical apparatusEngineeringPoint contact

Owner:ZUMTOBEL STAFF

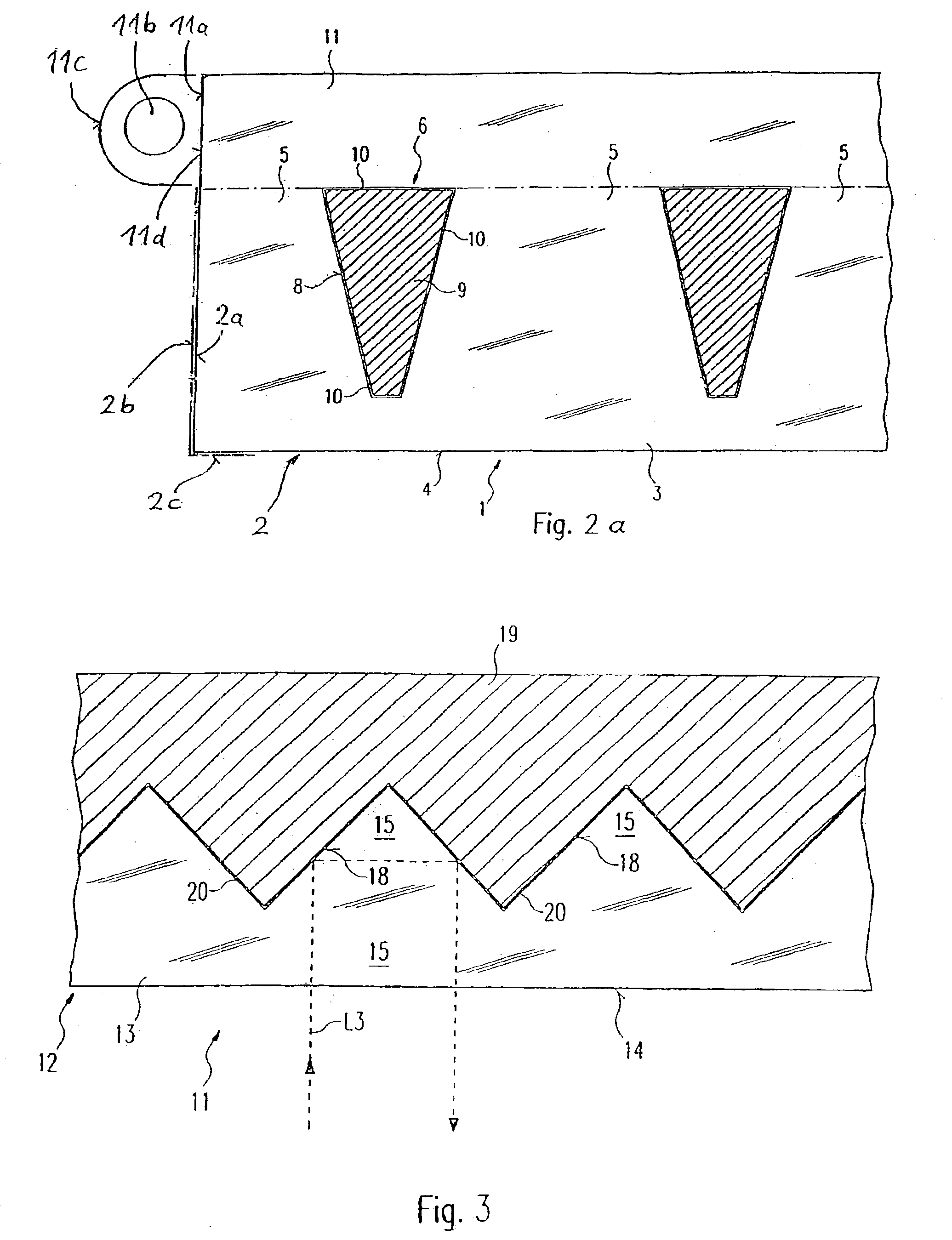

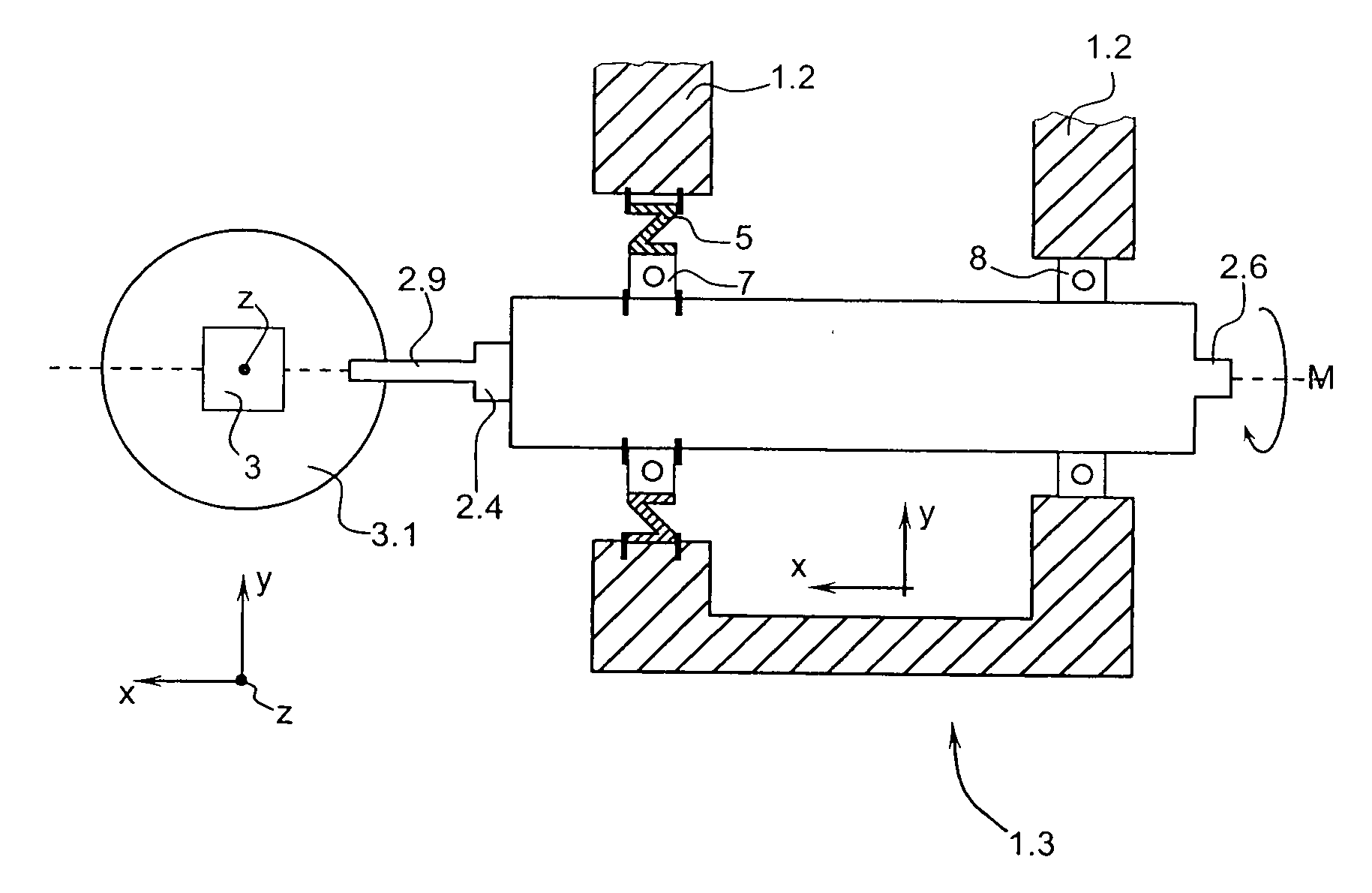

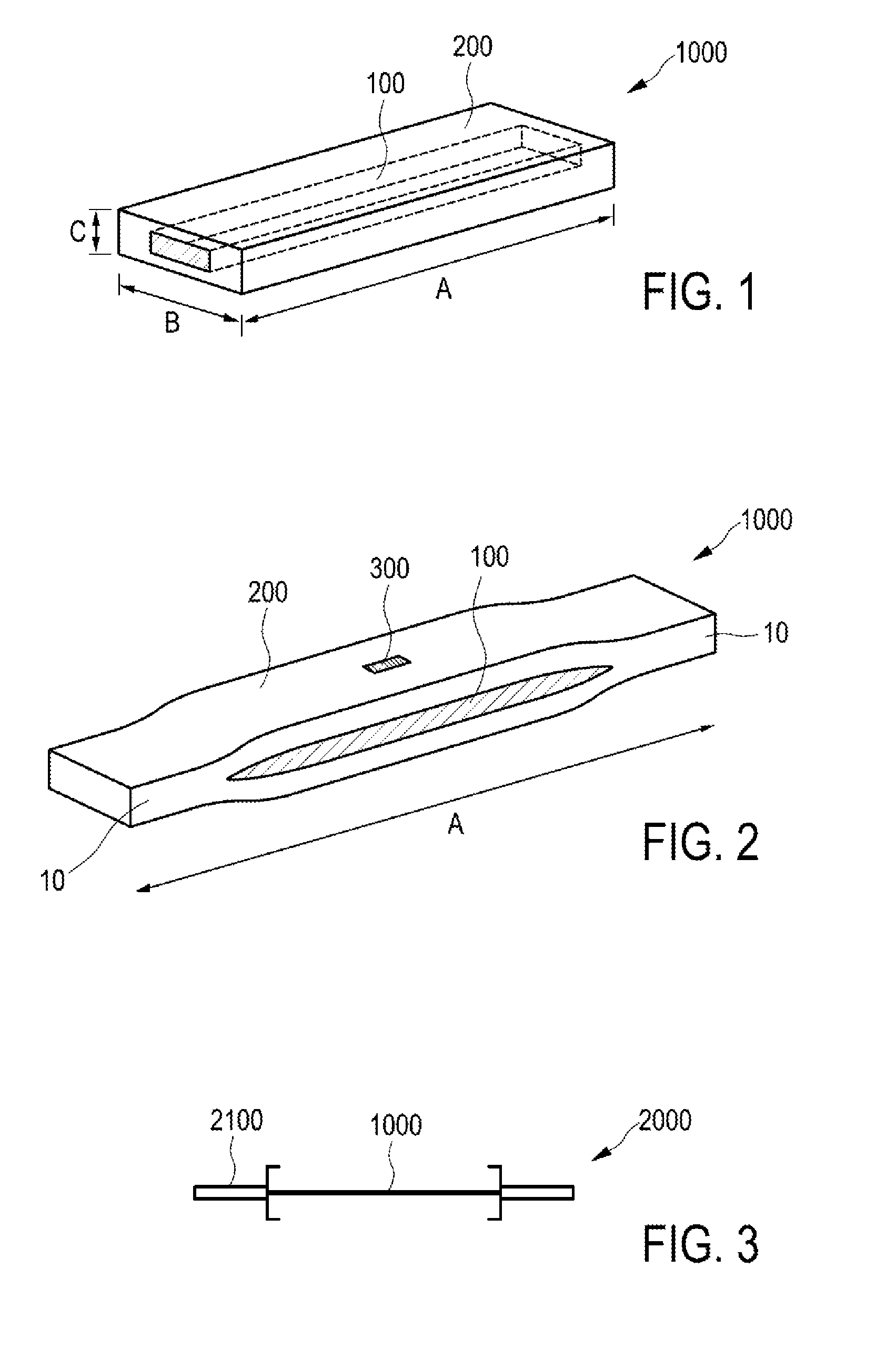

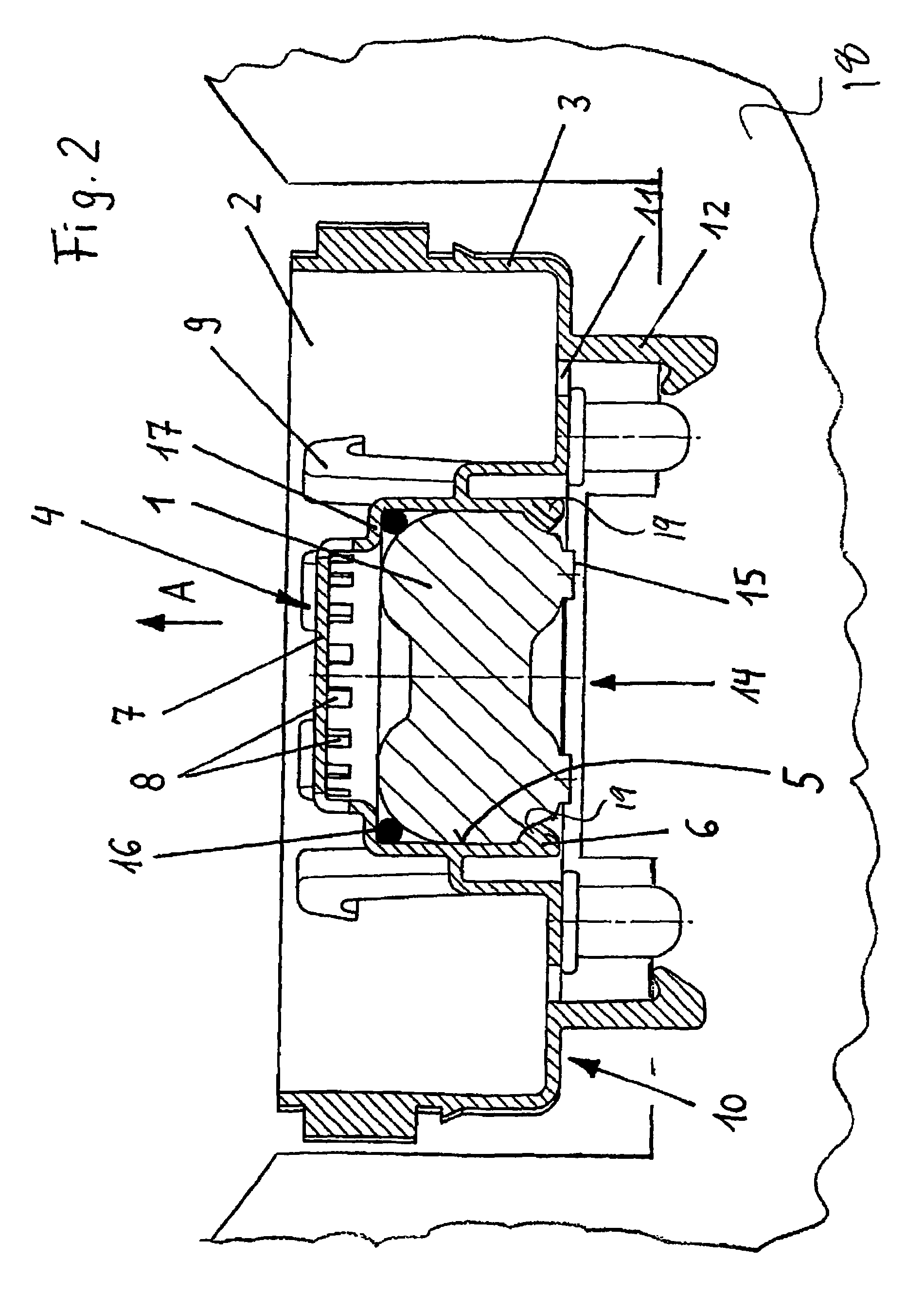

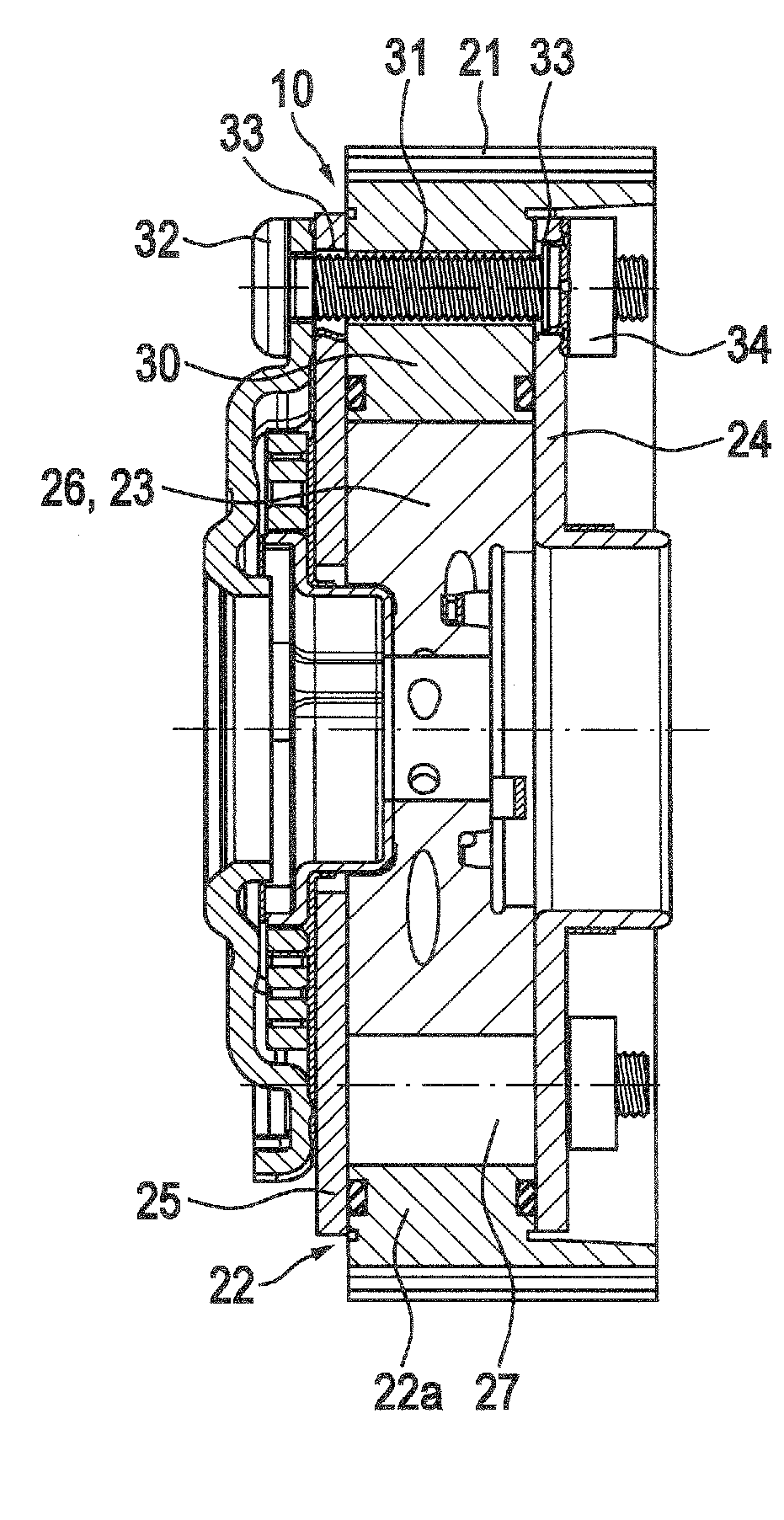

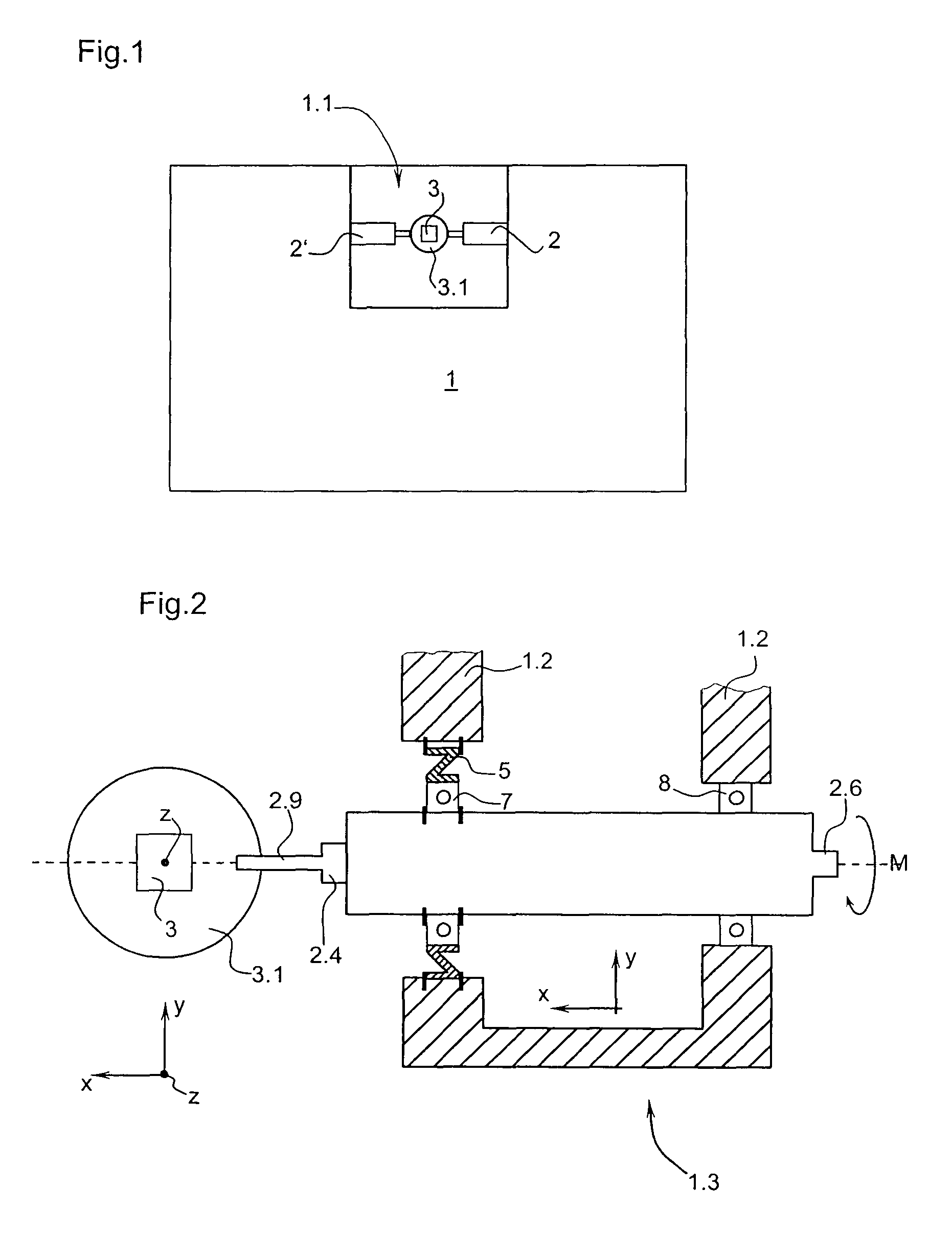

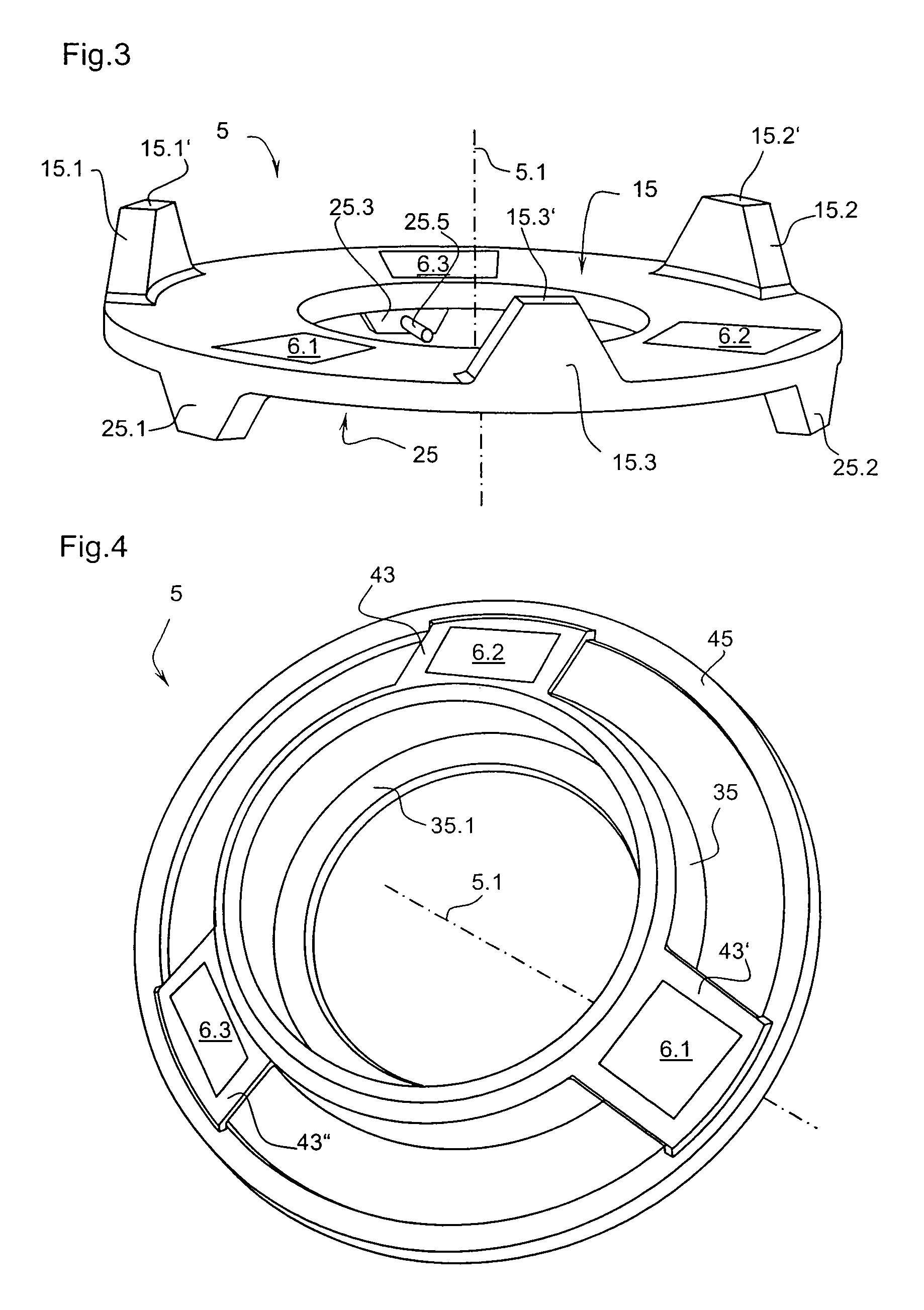

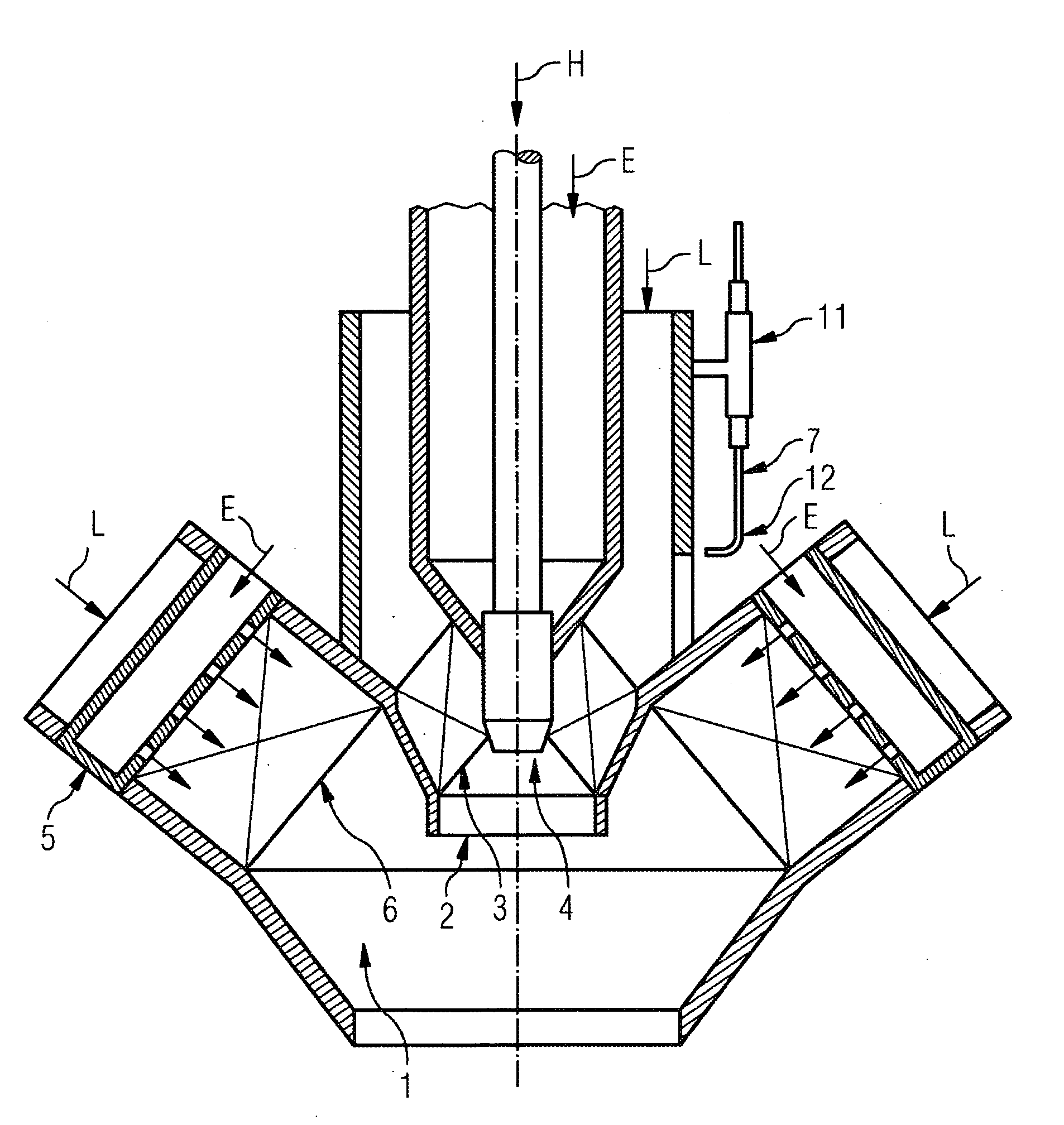

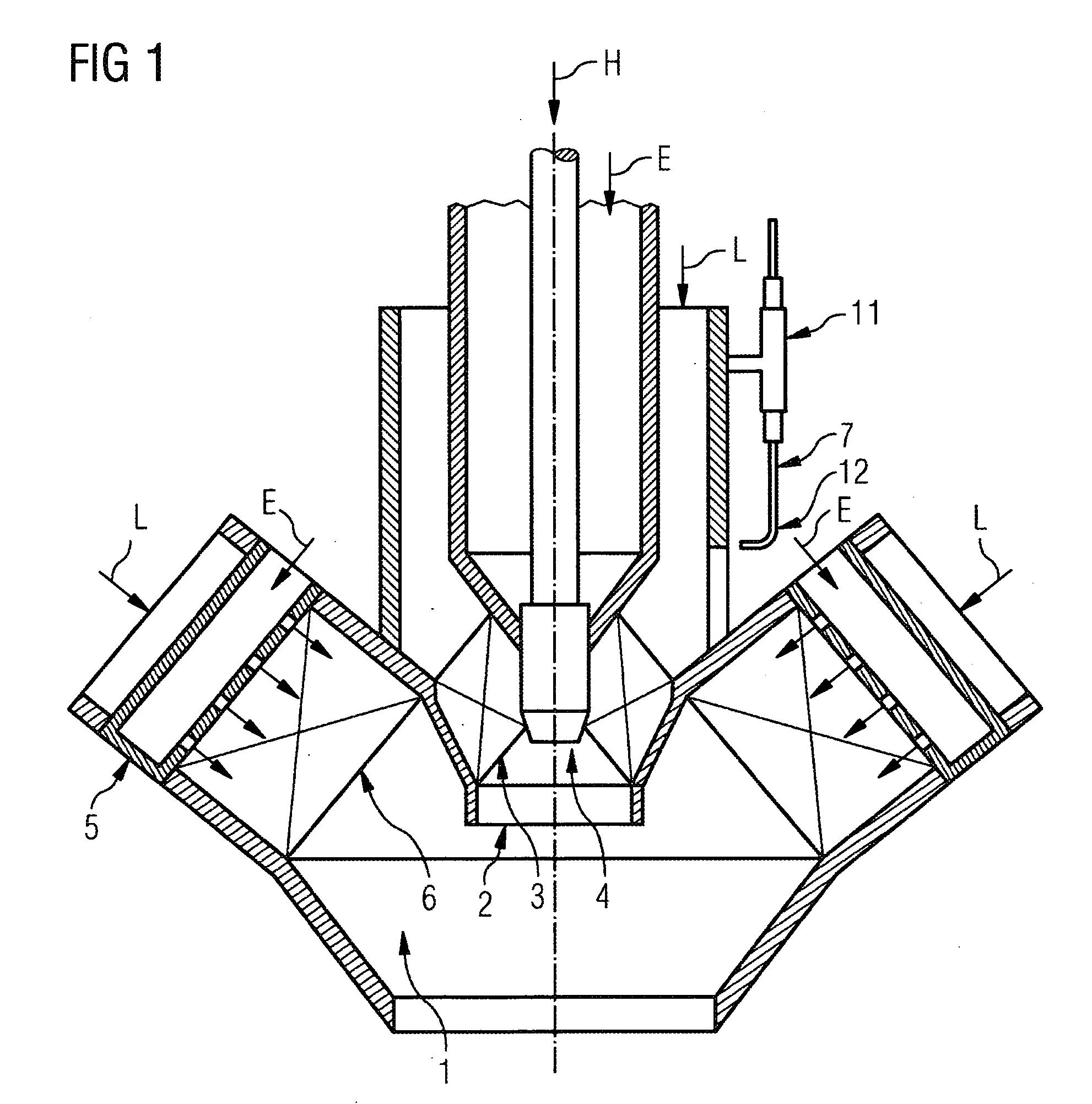

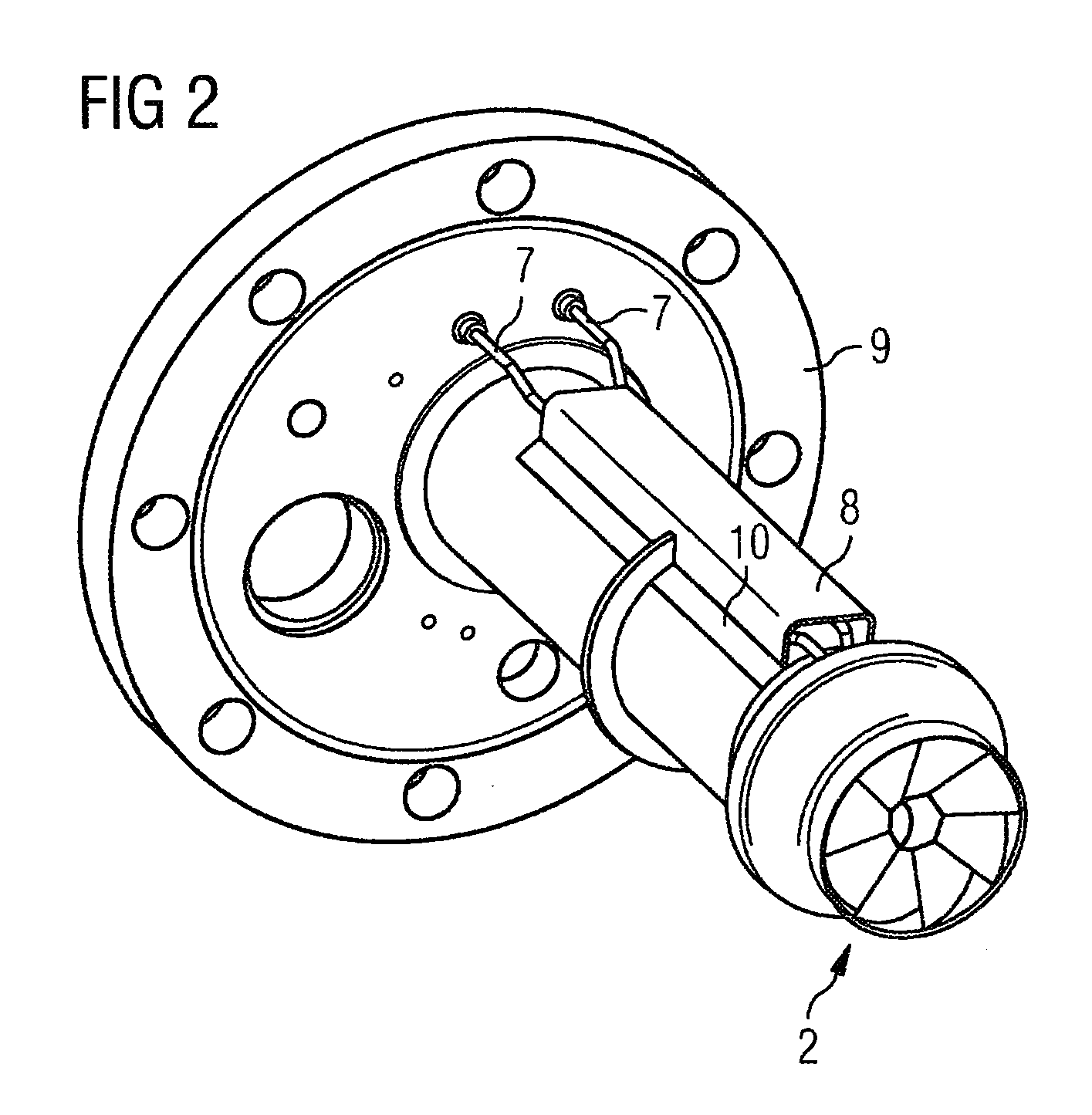

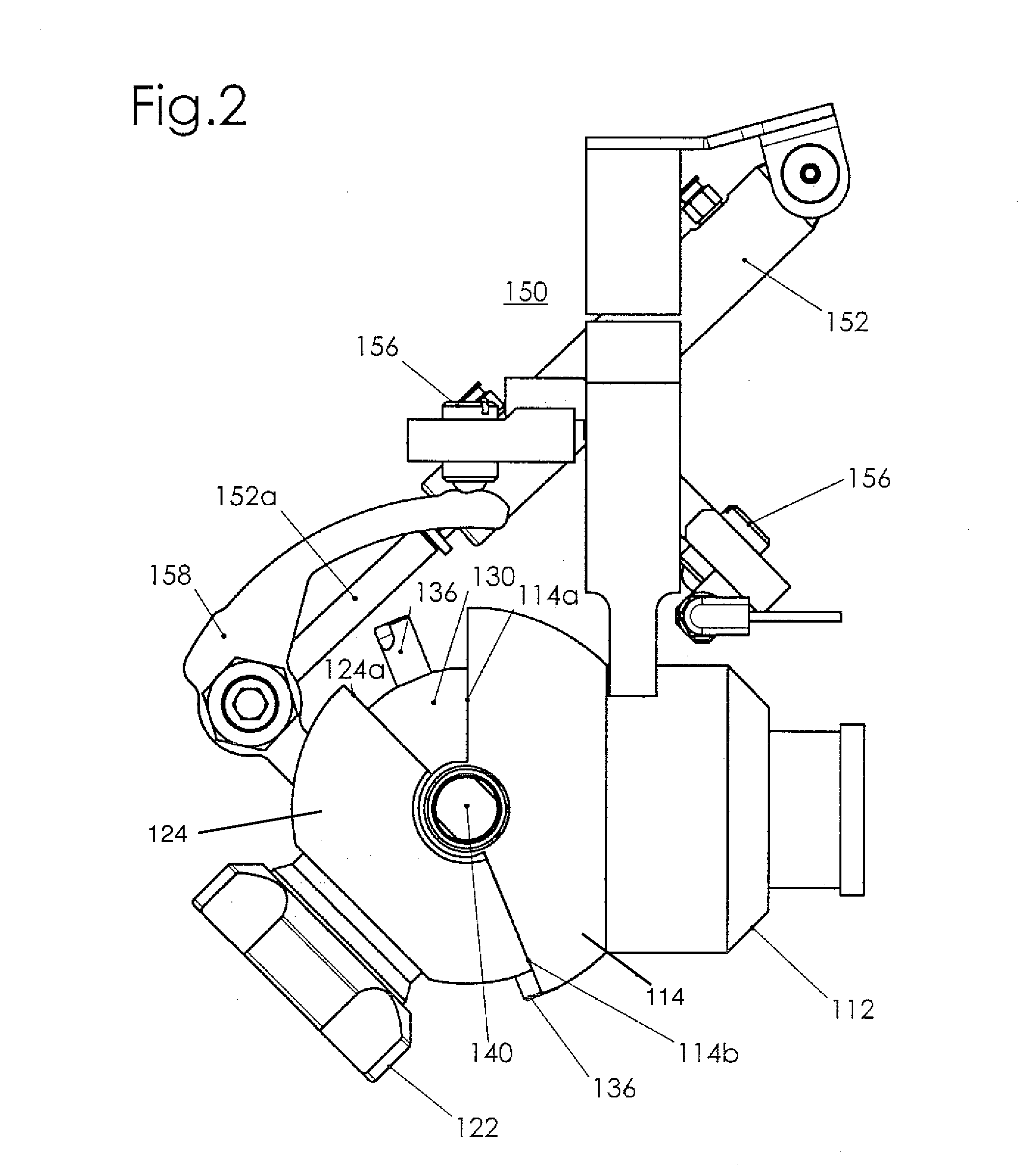

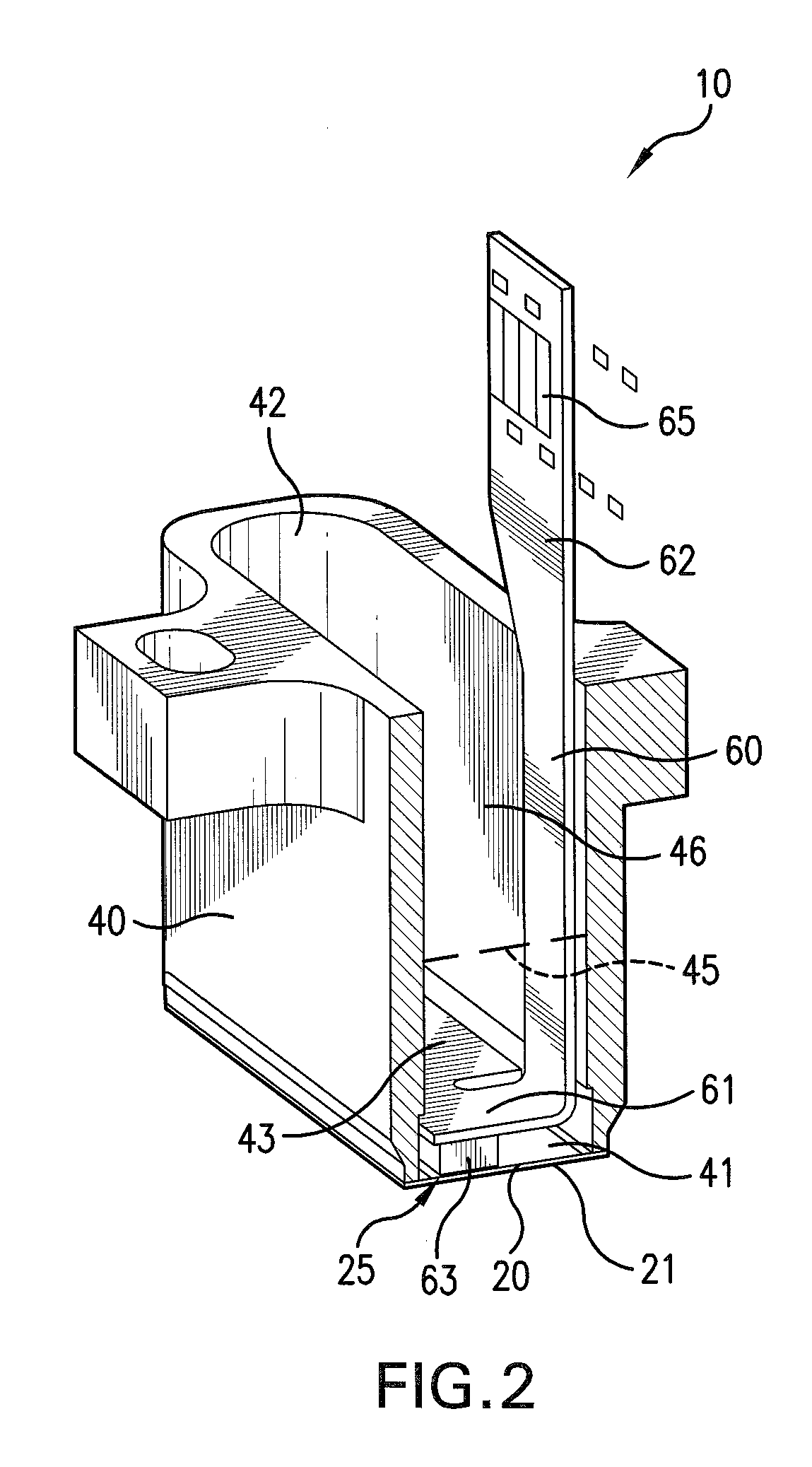

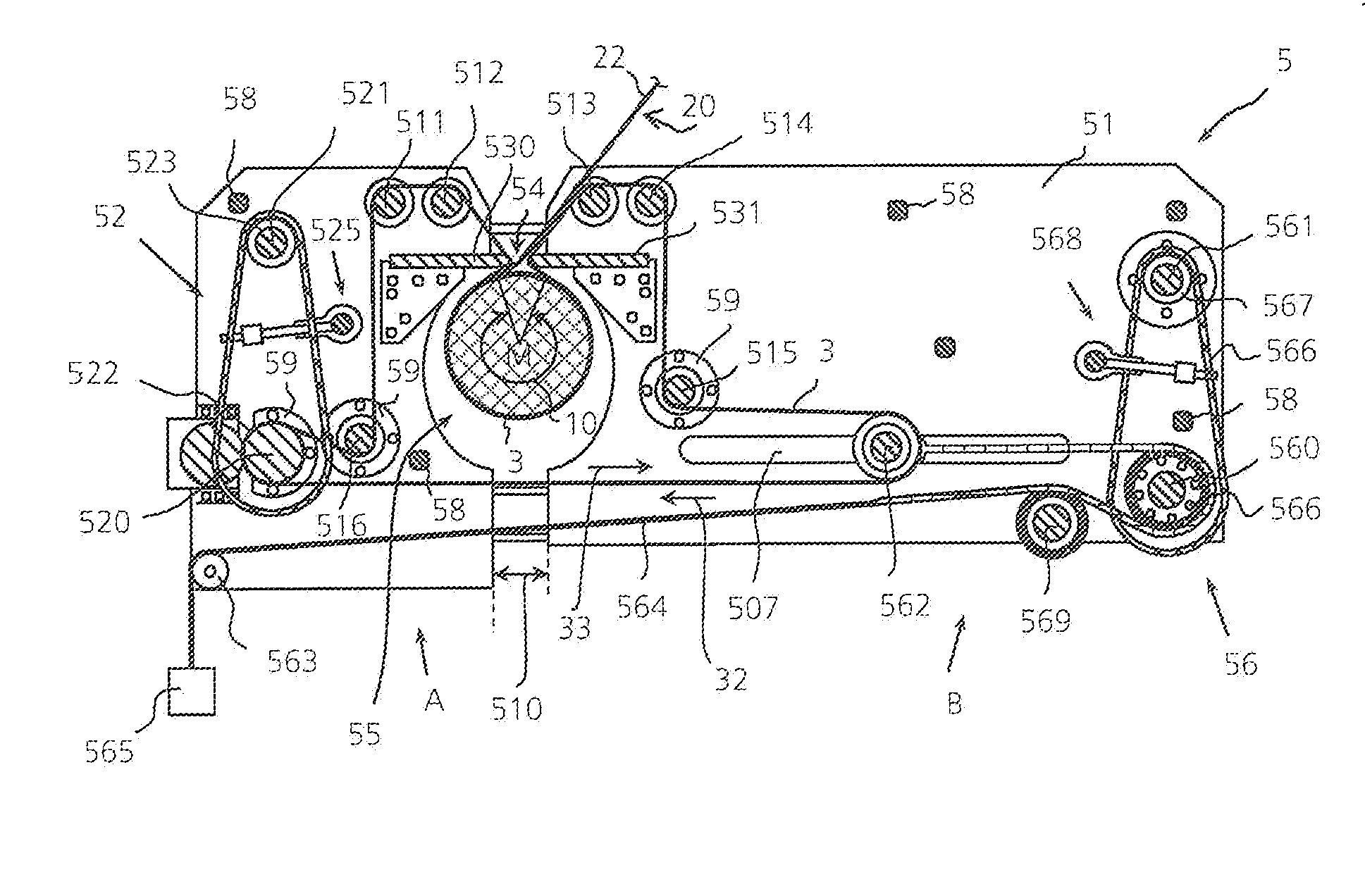

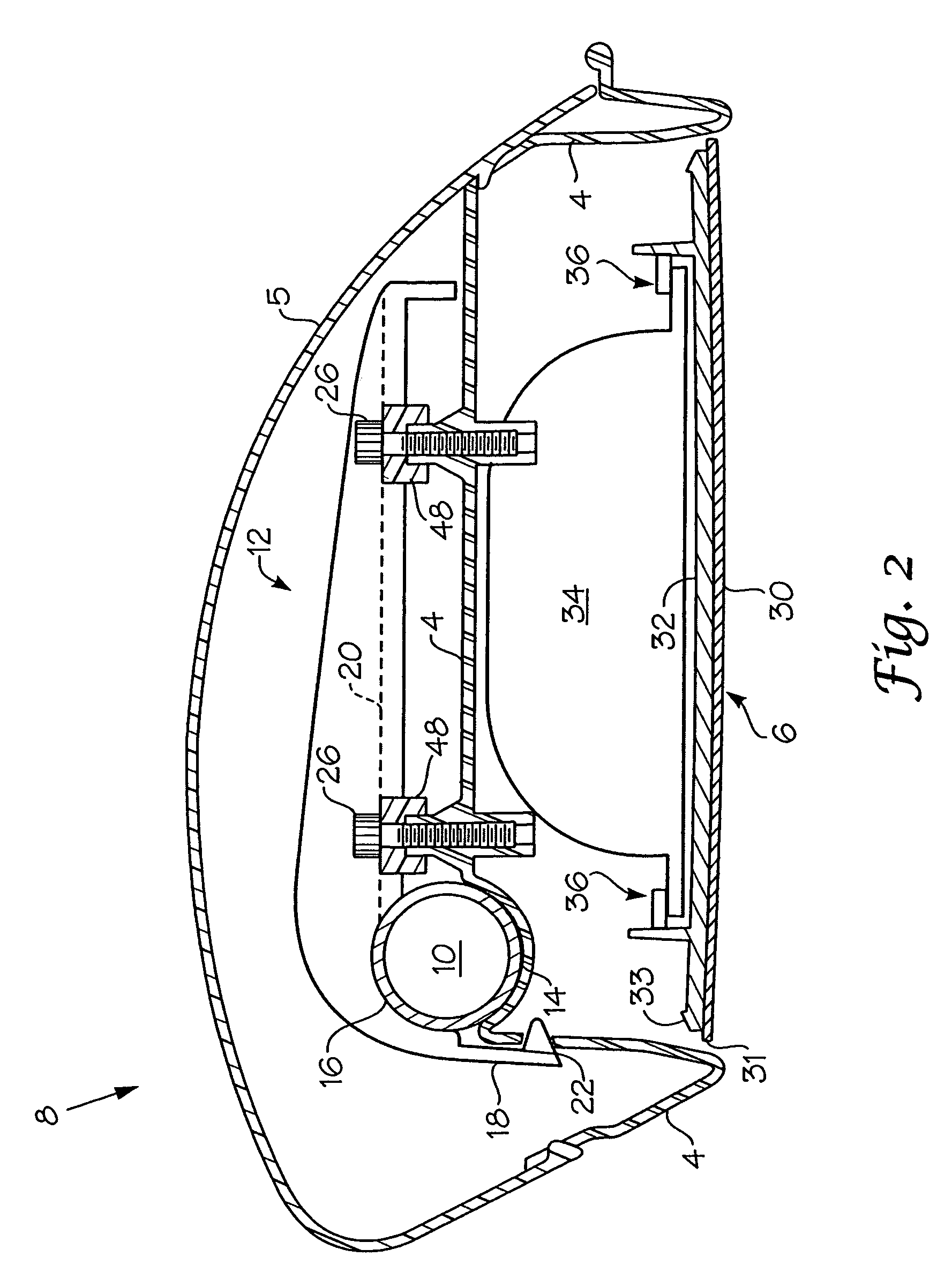

Dental machining unit with tool spindle

ActiveUS20080226409A1Evenly distributedAssures necessary stabilityRolling contact bearingsDiagnosticsEngineeringForce sensor

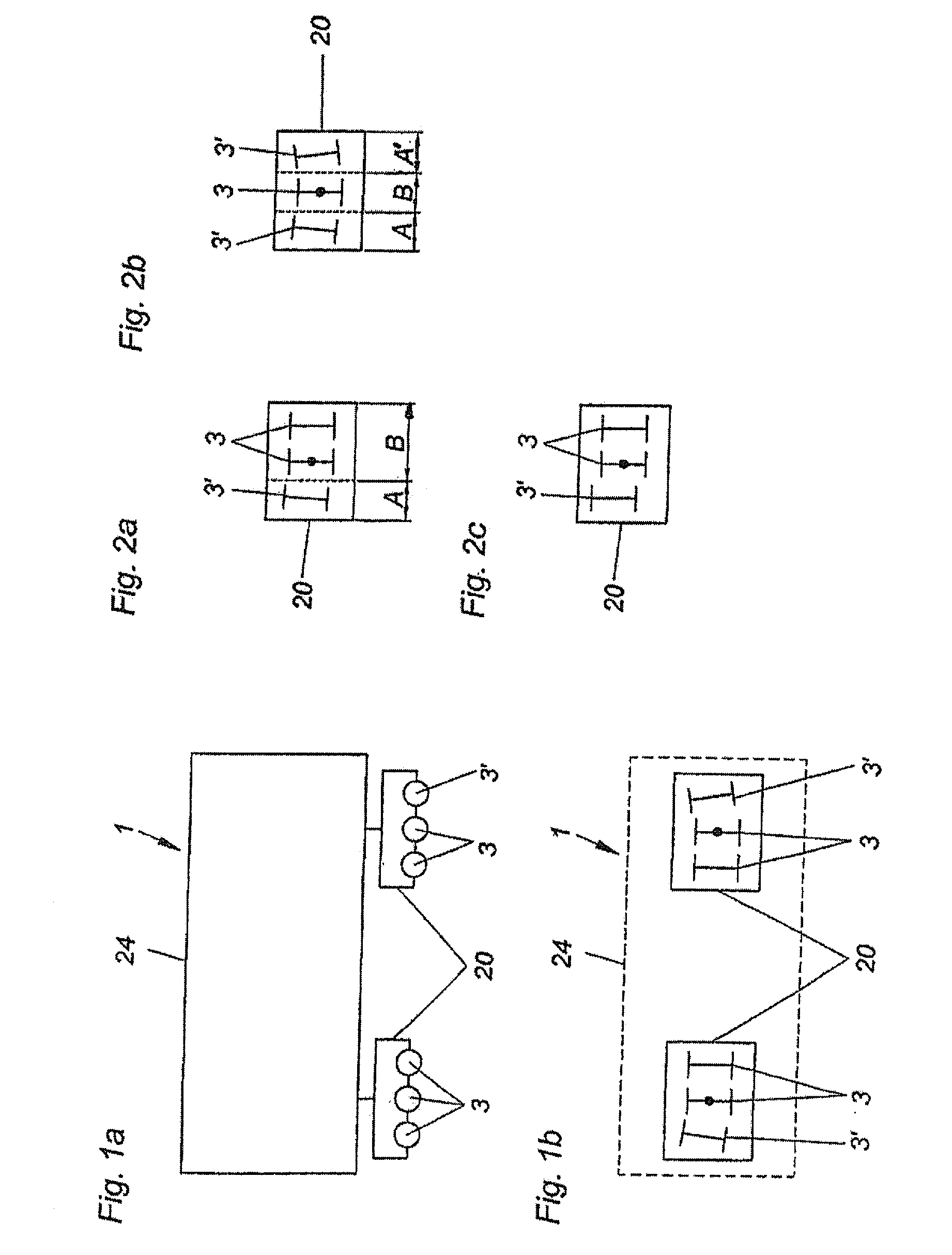

The present invention relates to dental machining apparatus (1) for blanks (3) comprising a tool spindle (2) having an axis of rotation (2.8) and mounted in a bearing housing (1.2) disposed on the machine housing side. A force sensor (5) is also provided, which is disposed between the tool spindle (2) and the bearing housing (1.2) for the purpose of detecting the machining force acting on the tool spindle (2), wherein the tool spindle (2) can be supported against the bearing housing (1.2) directly or indirectly via the force sensor (5).

Owner:SIRONA DENTAL SYSTEMS

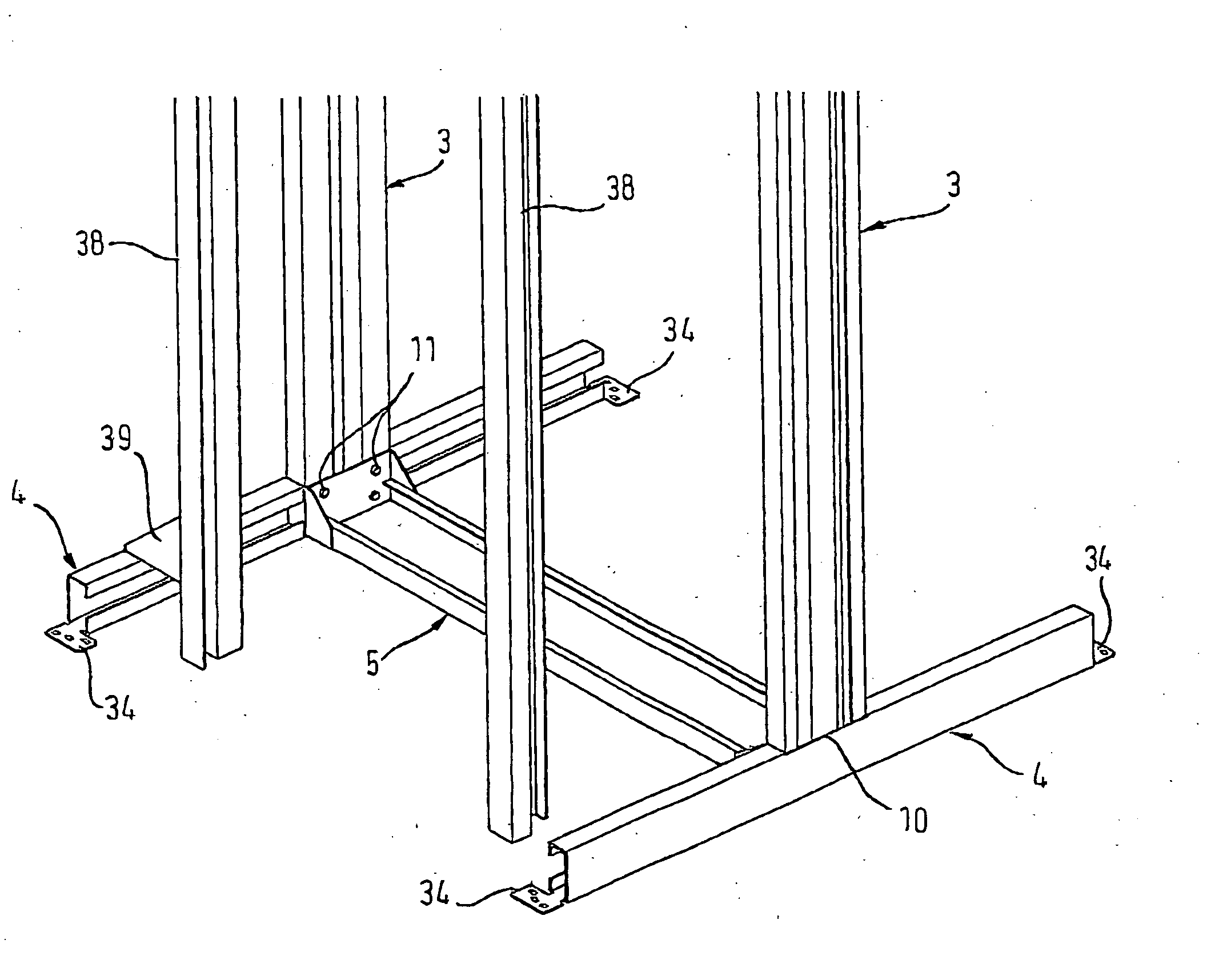

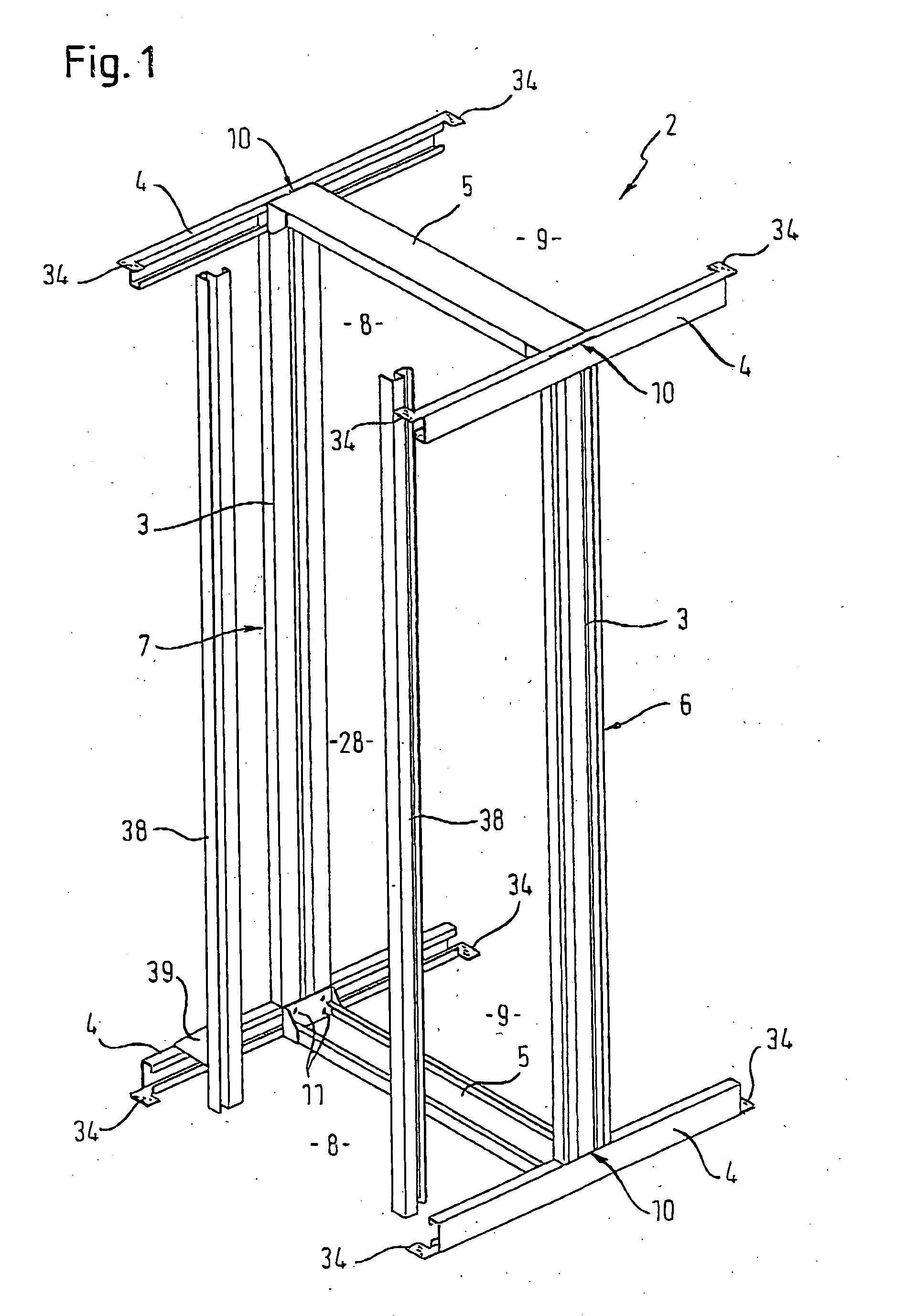

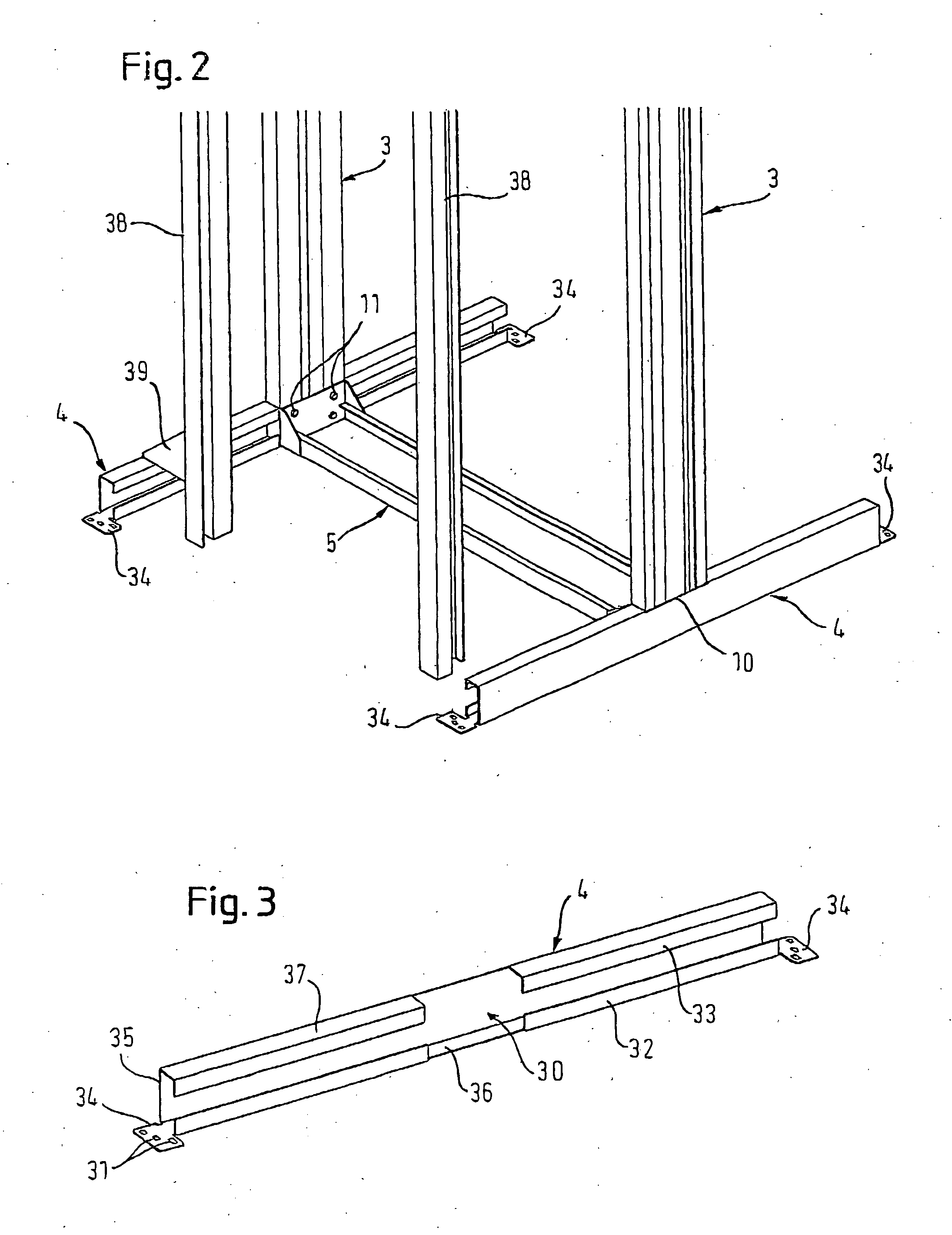

Frame structure

InactiveUS20070175836A1Differing bendabilityNecessary stabilityShow shelvesSelection arrangementsEngineeringLower upper

Owner:KNUERR AG

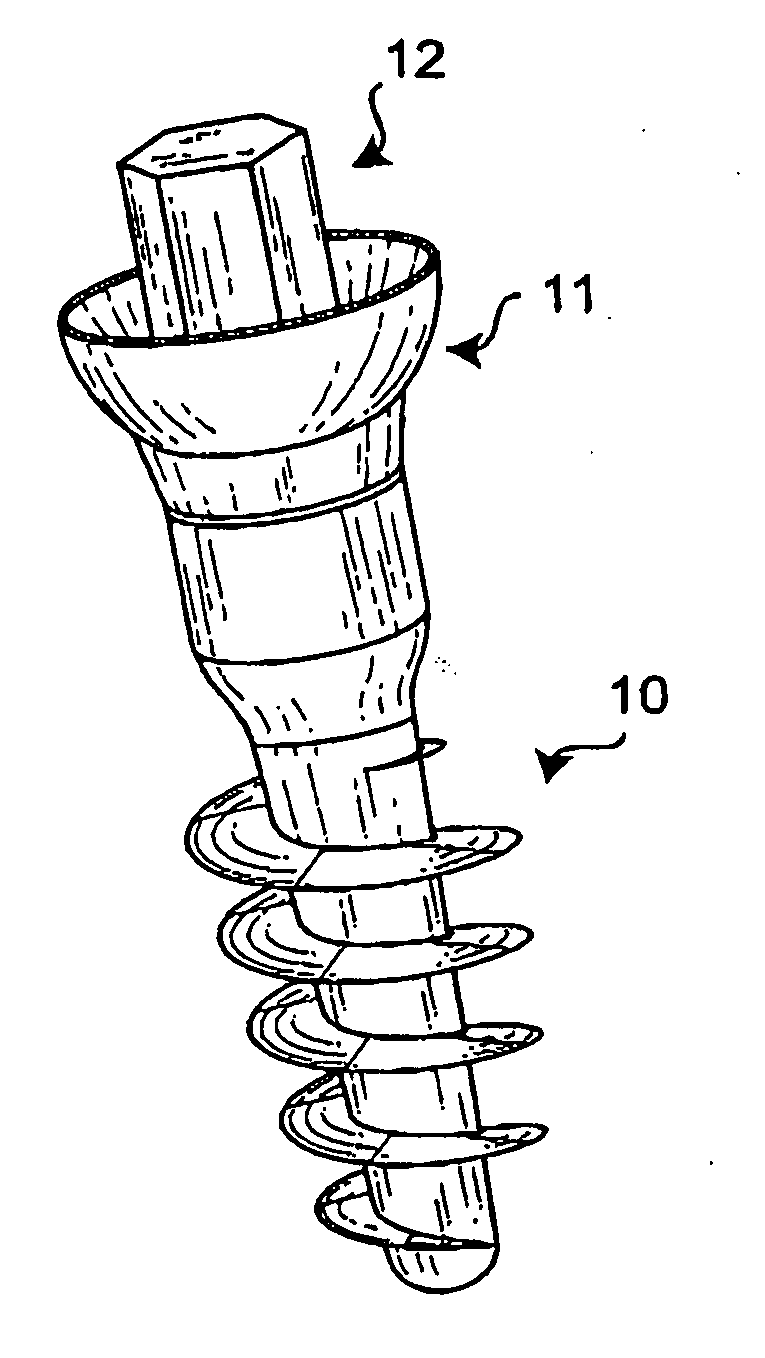

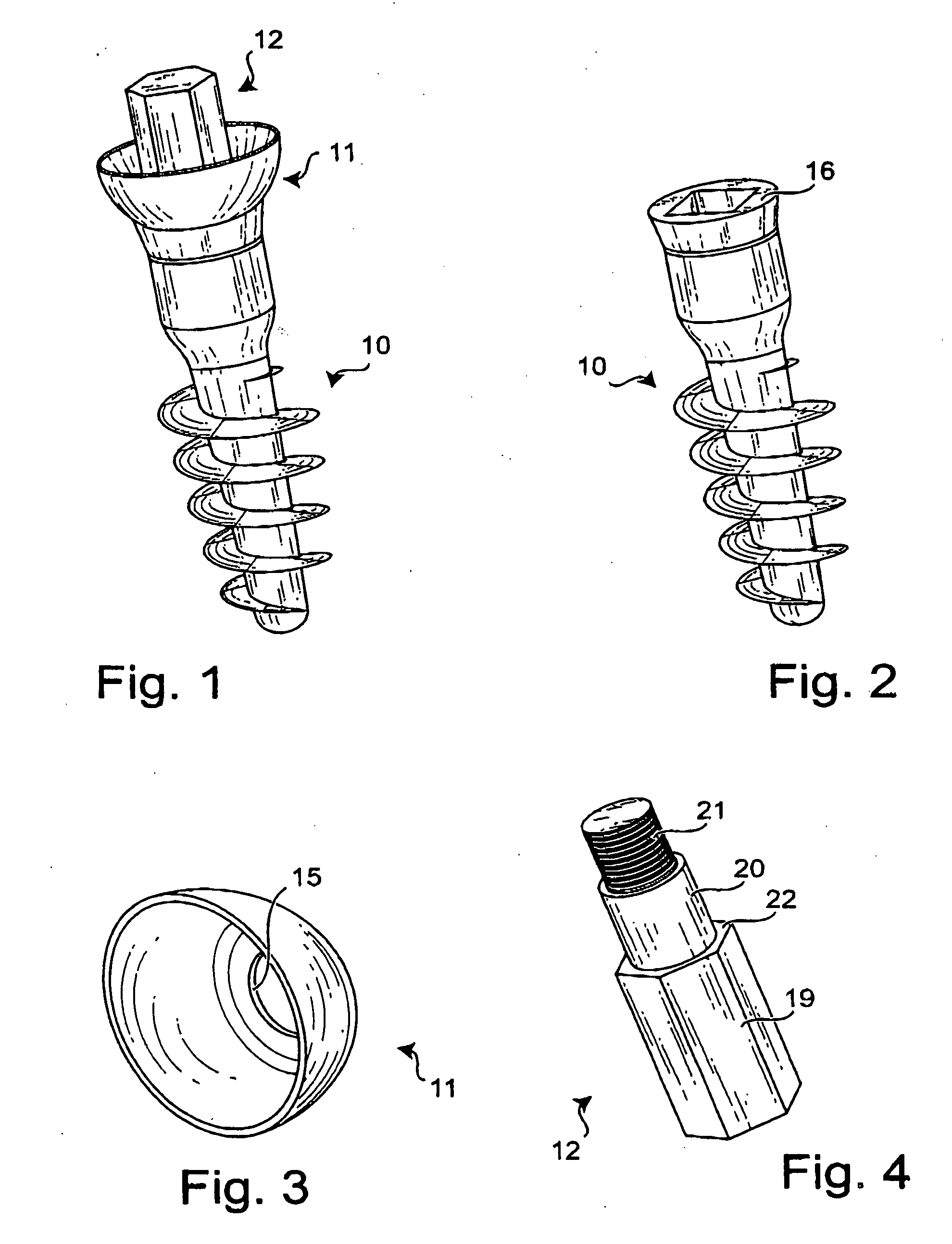

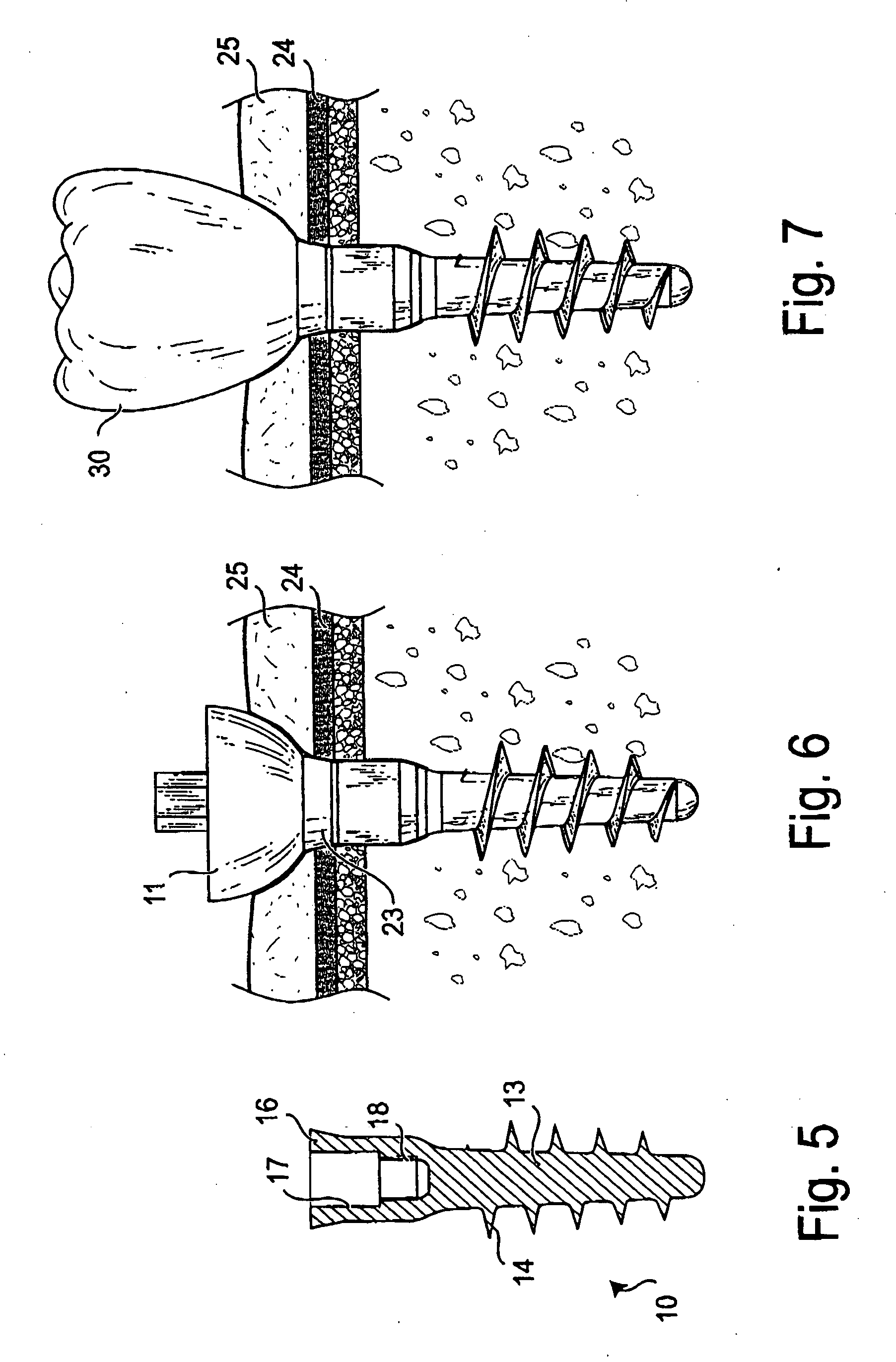

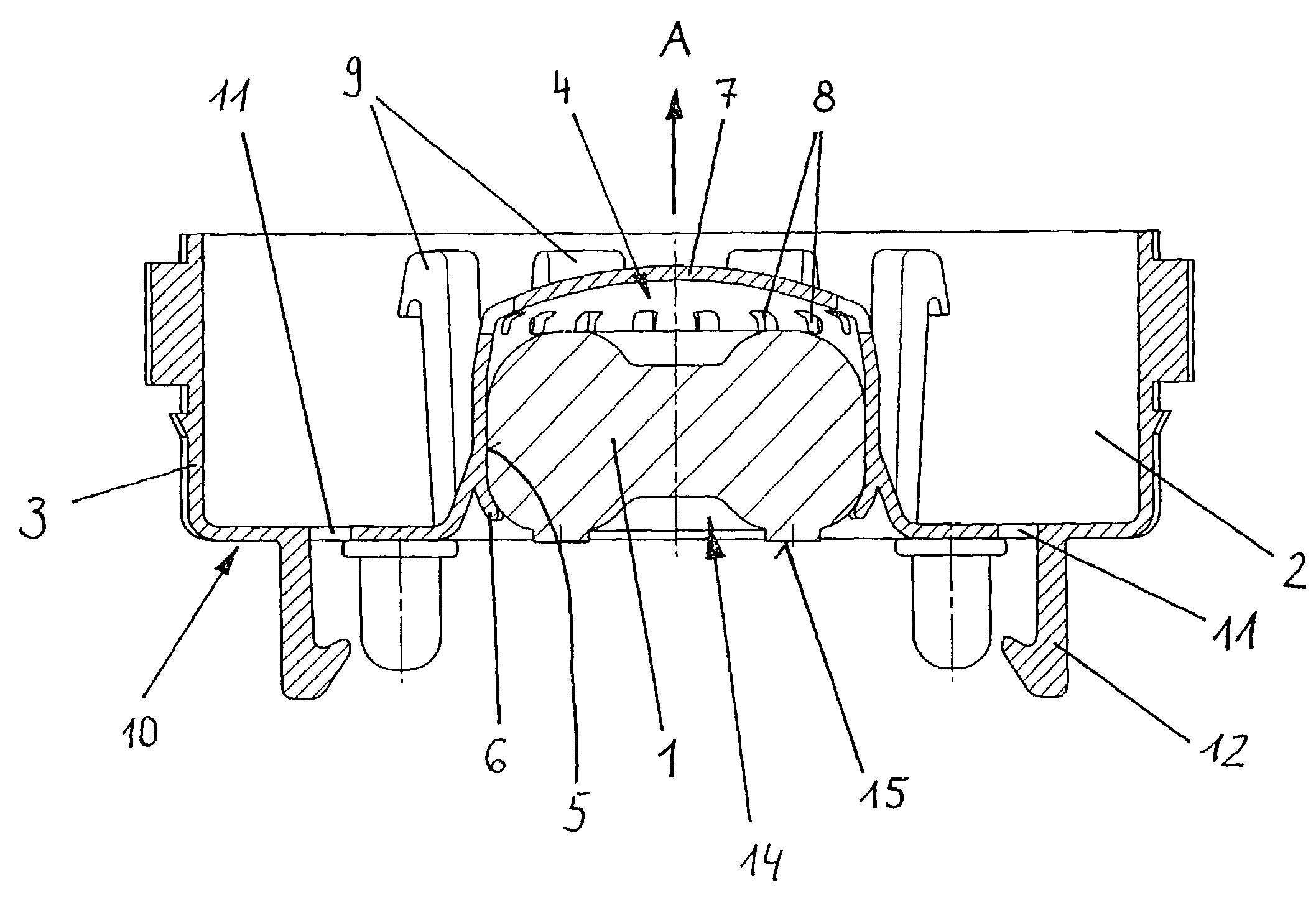

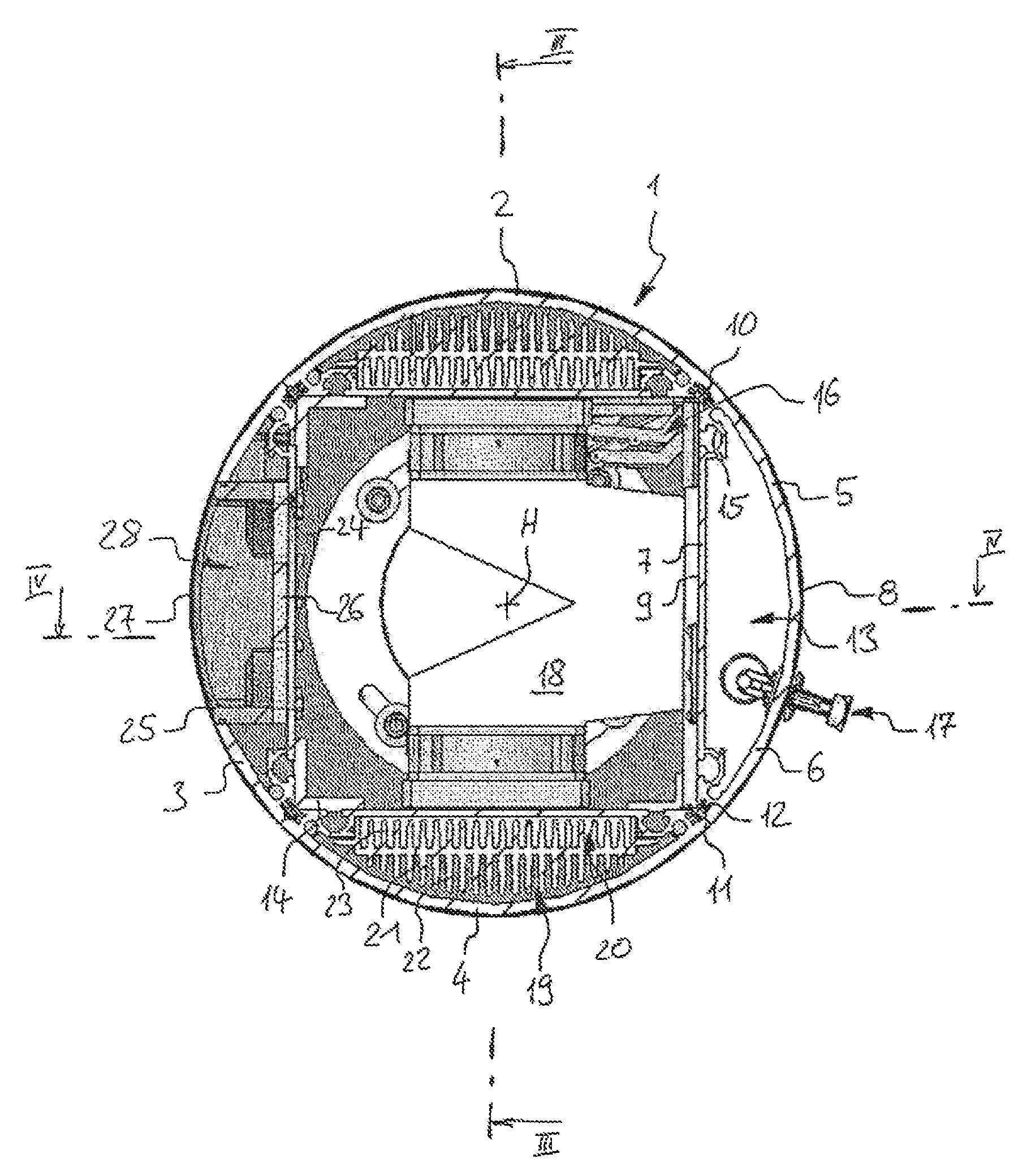

Intraosseous dental implant

InactiveUS20060240385A1Sufficient immediate stabilityNecessary stabilityDental implantsMedicineDentures

Endosseous dental implant of the type involving a threaded pin which is screwed into the bone cavity and is provided with a hole applied to the part of the implant emerging from the bone, housing a proper device protruding from the dental prosthesis in order to anchor the prosthesis to the threaded pin; onto the top part of the threaded pin exceeding the bone a removable hemispheric cup is applied so that when the threaded pin is in final position, the cup presses onto the surrounding gengiva; the cup being equipped with anchoring devices which firmly connect it to the pin, yet allowing it to be unscrewed from the pin in order to be replaced by the dental prosthesis that will fit the place occupied by the cup in the gengiva around the threaded pin.

Owner:C I R G

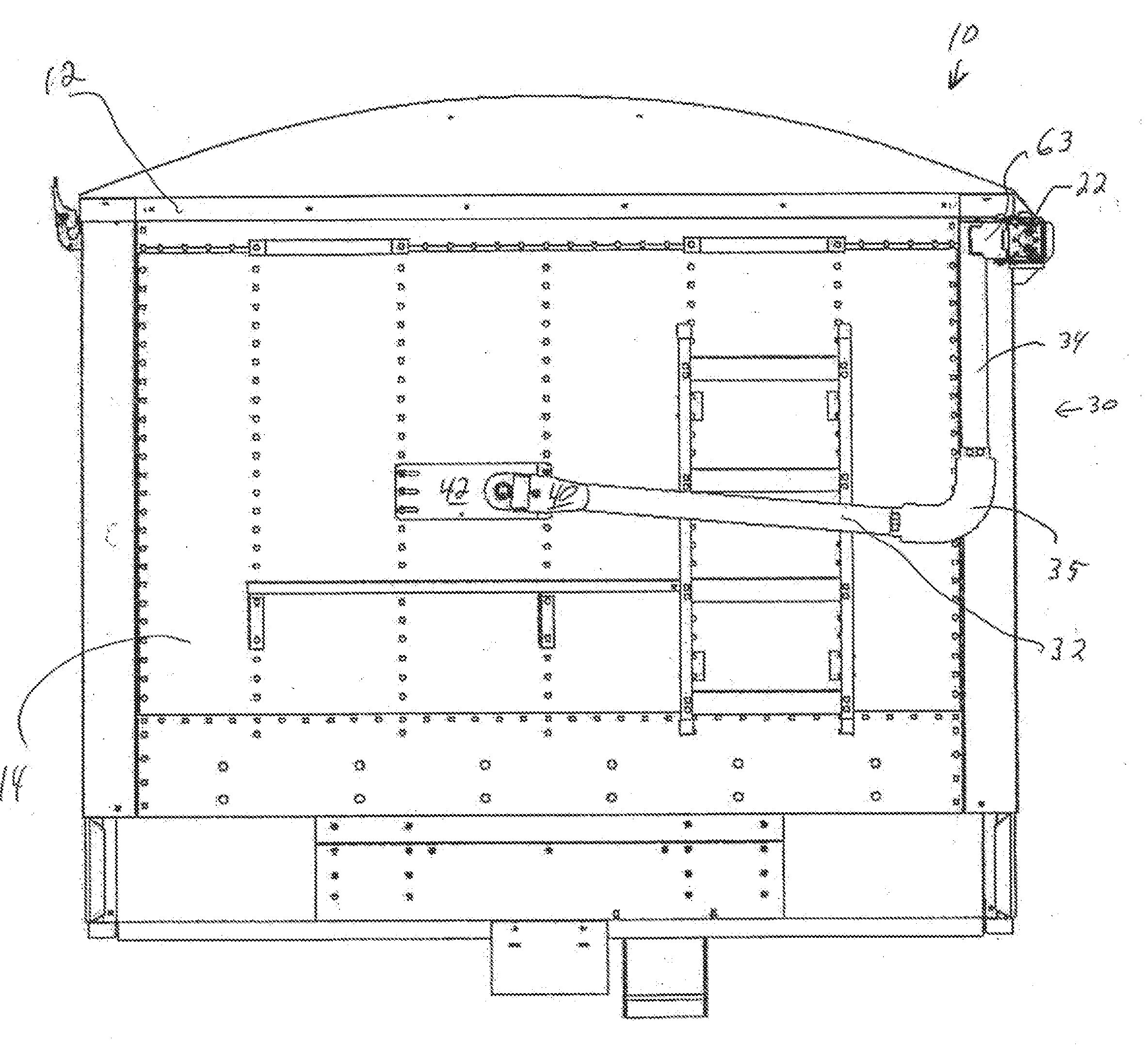

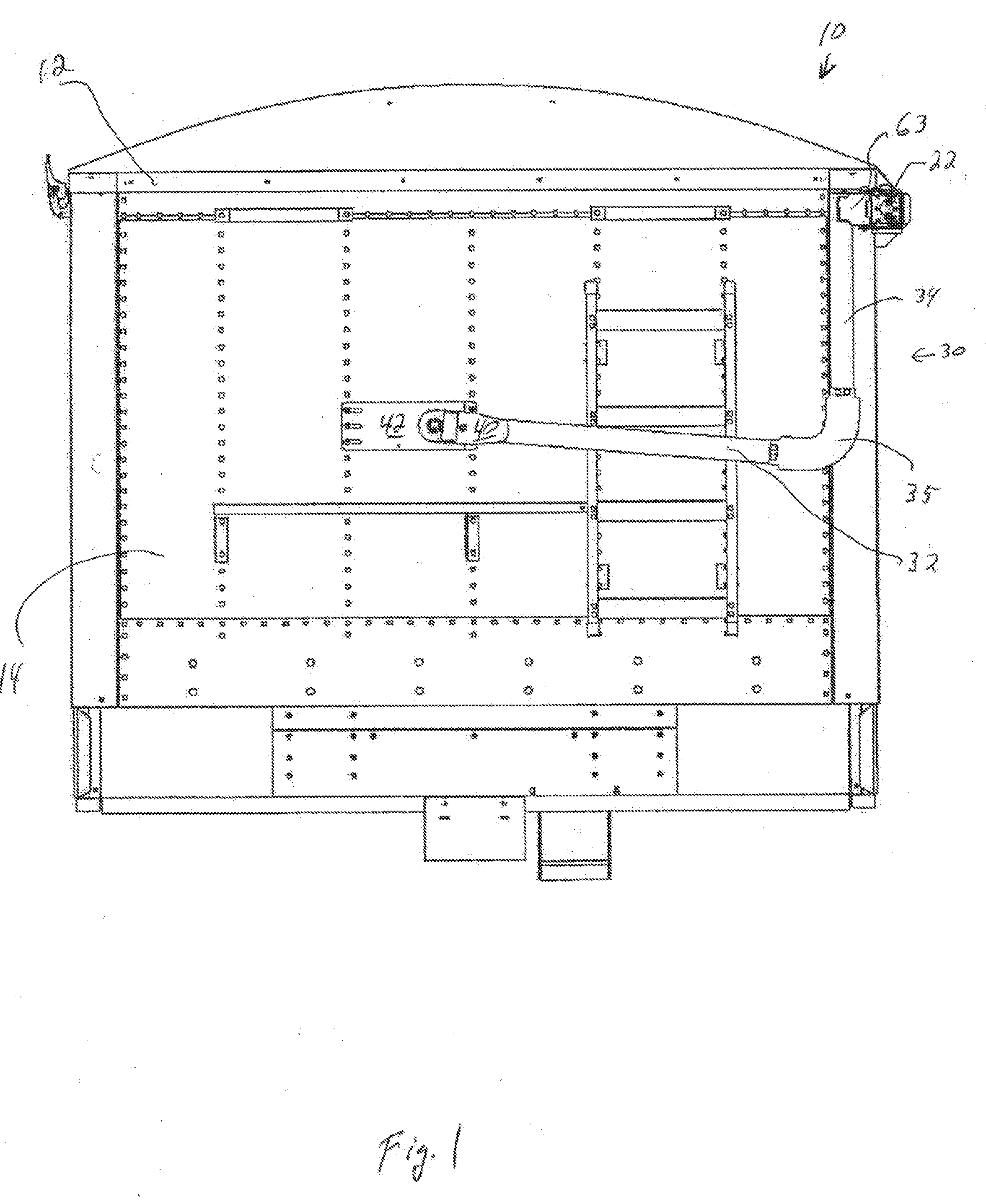

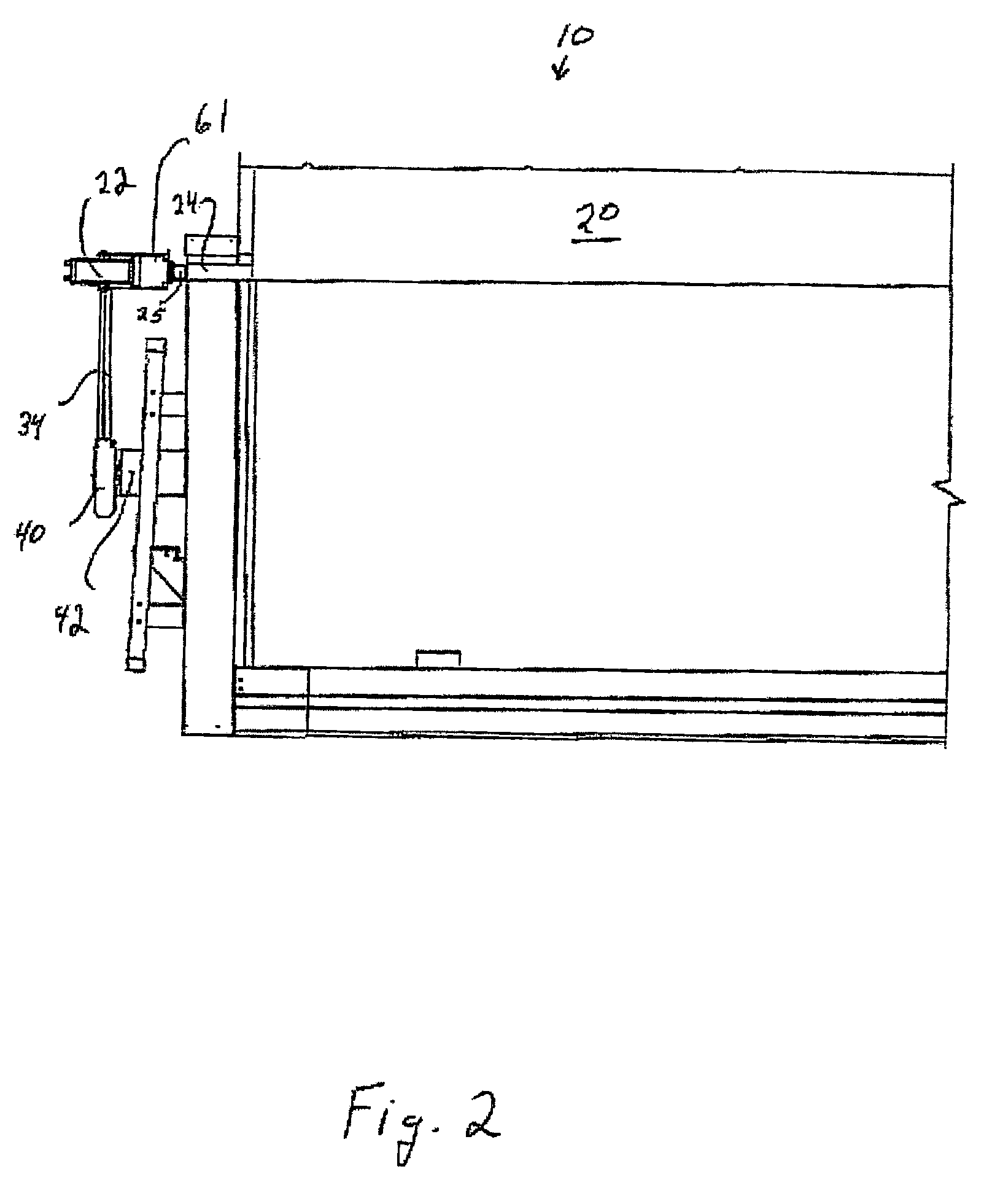

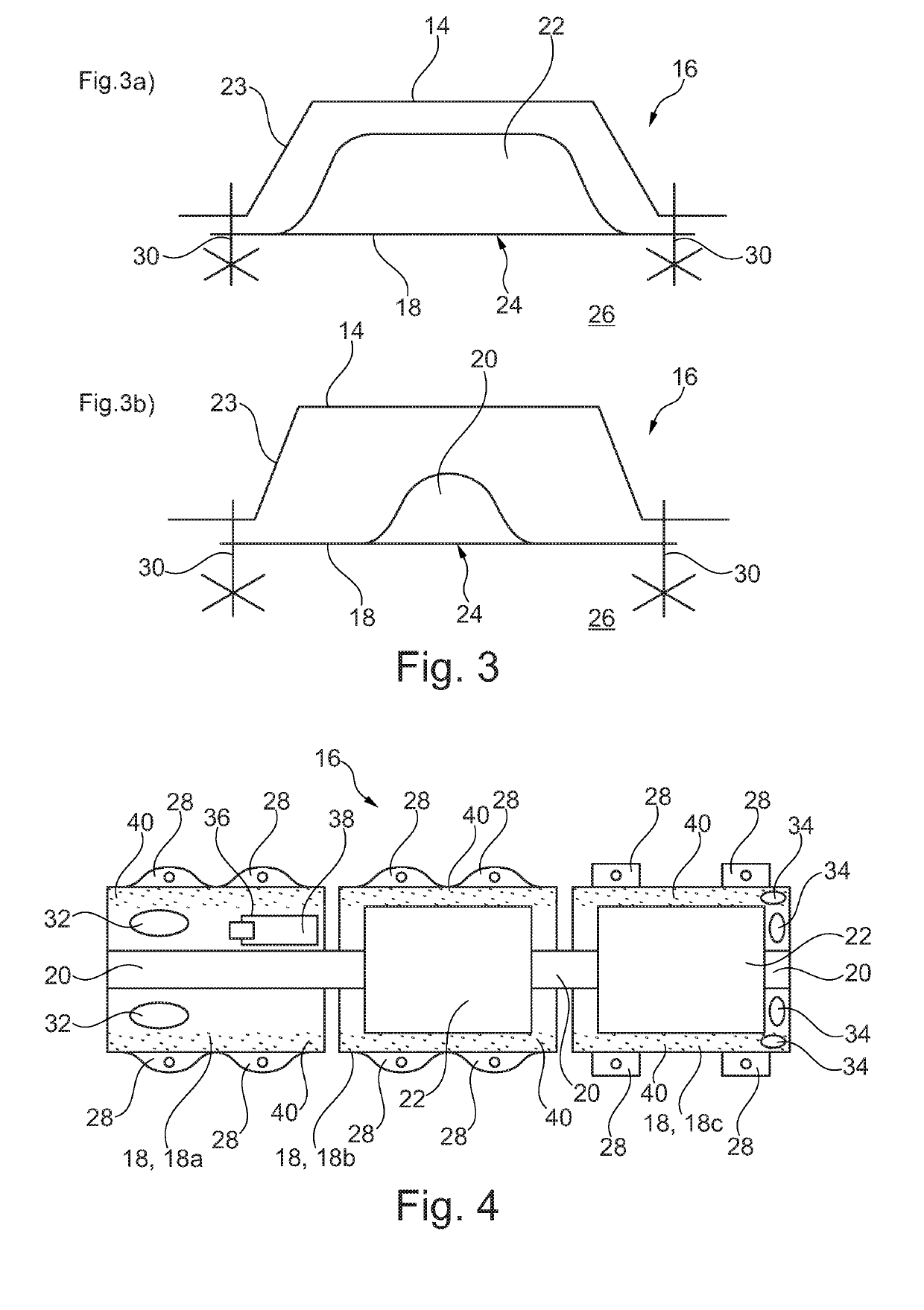

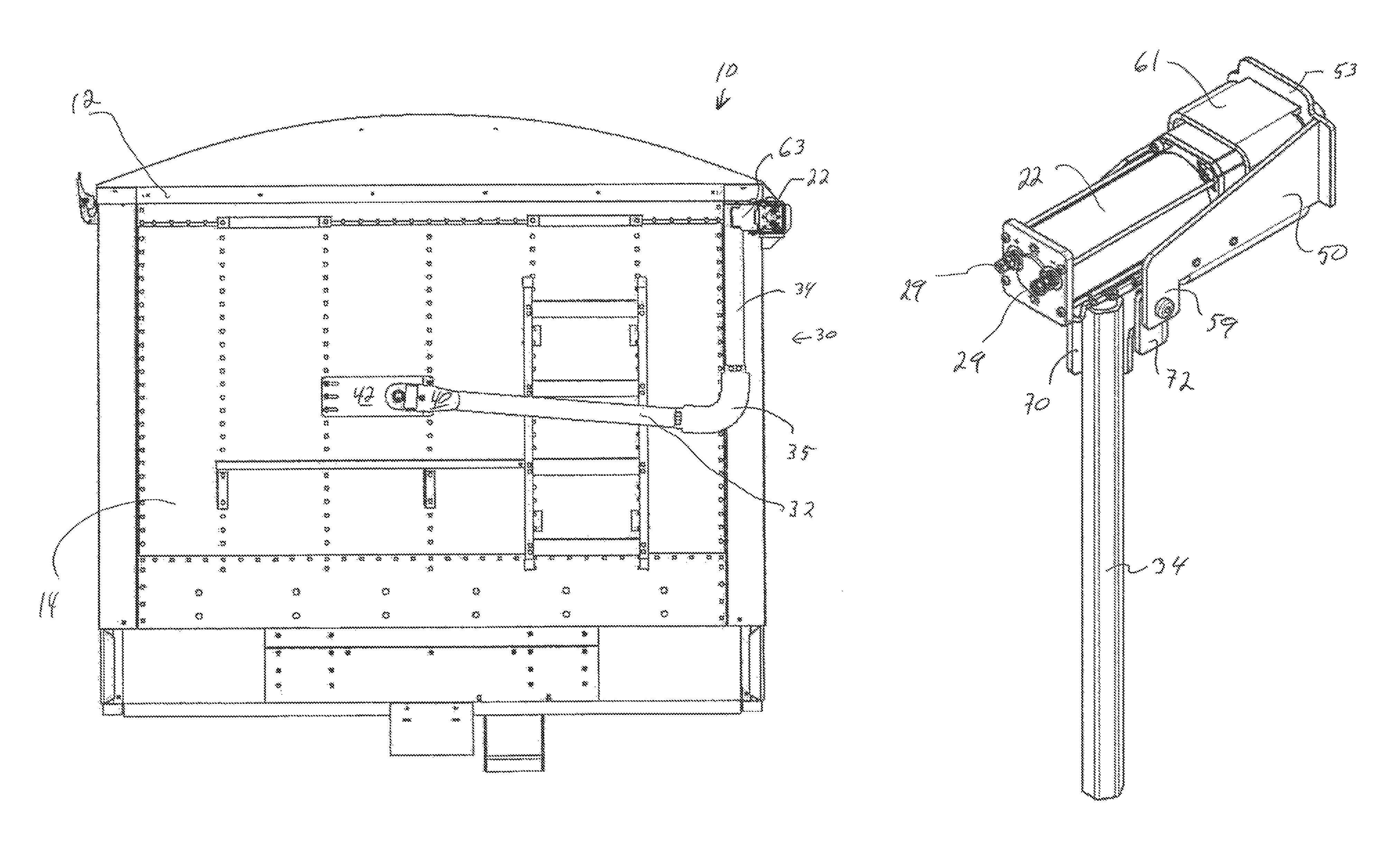

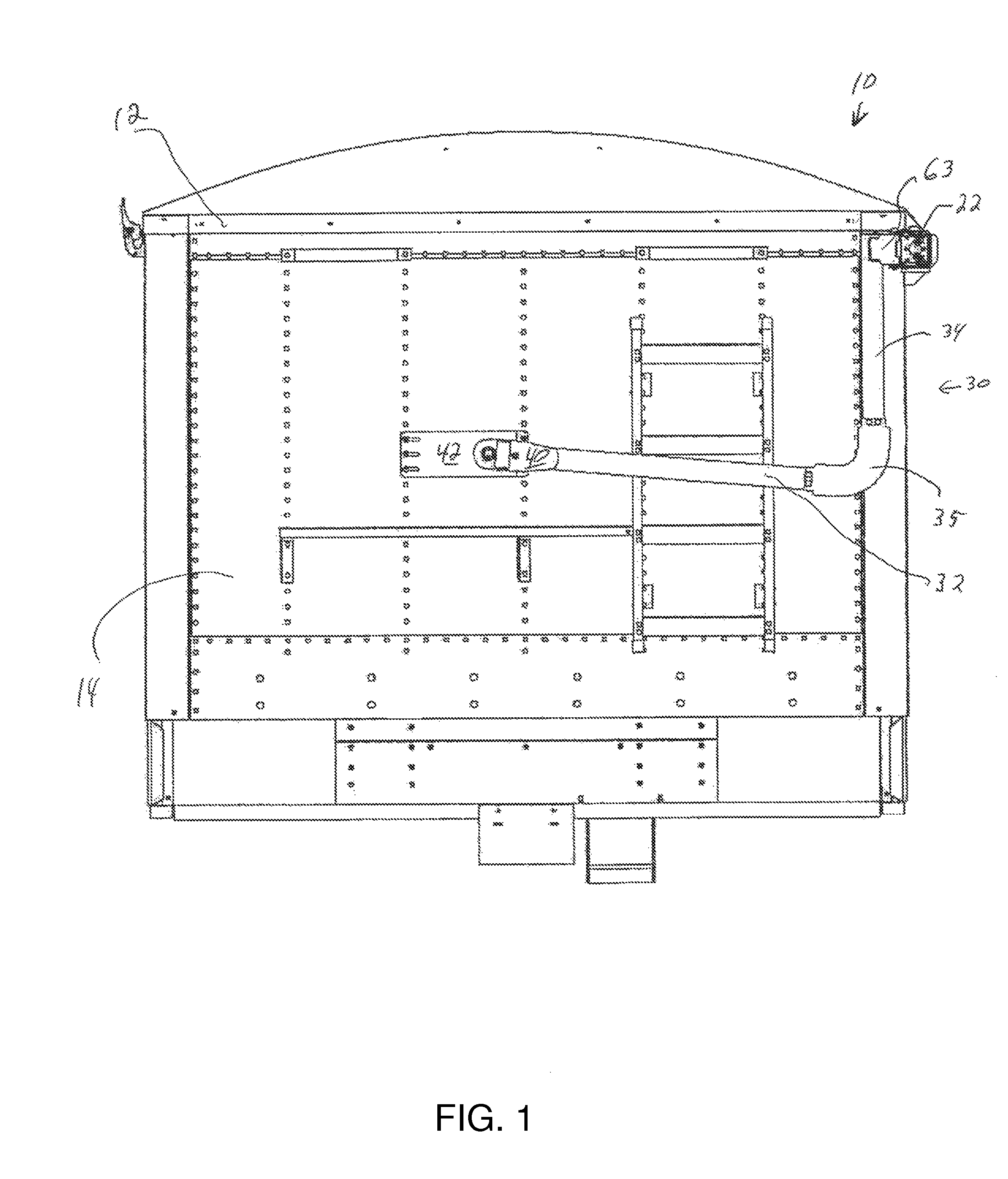

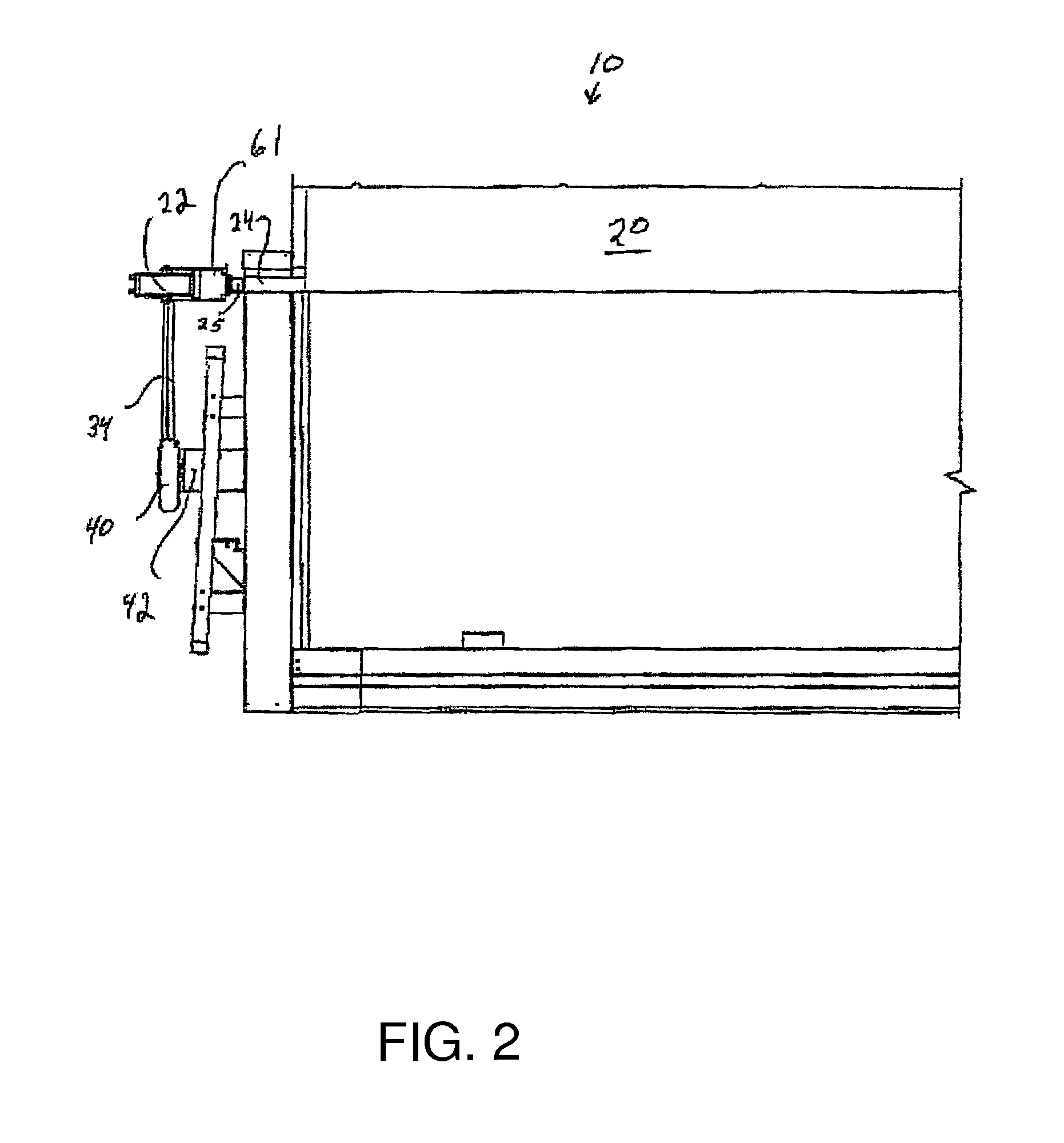

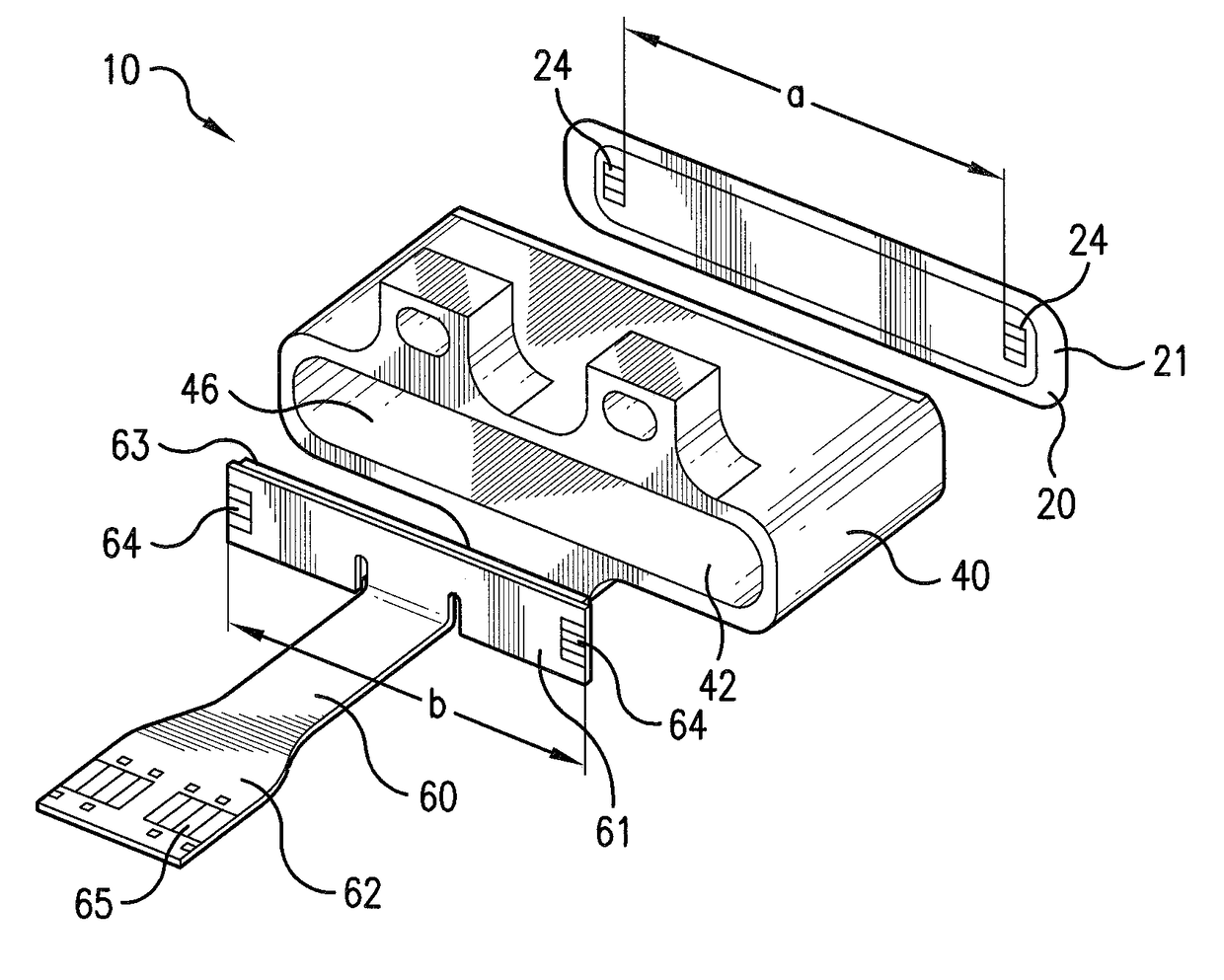

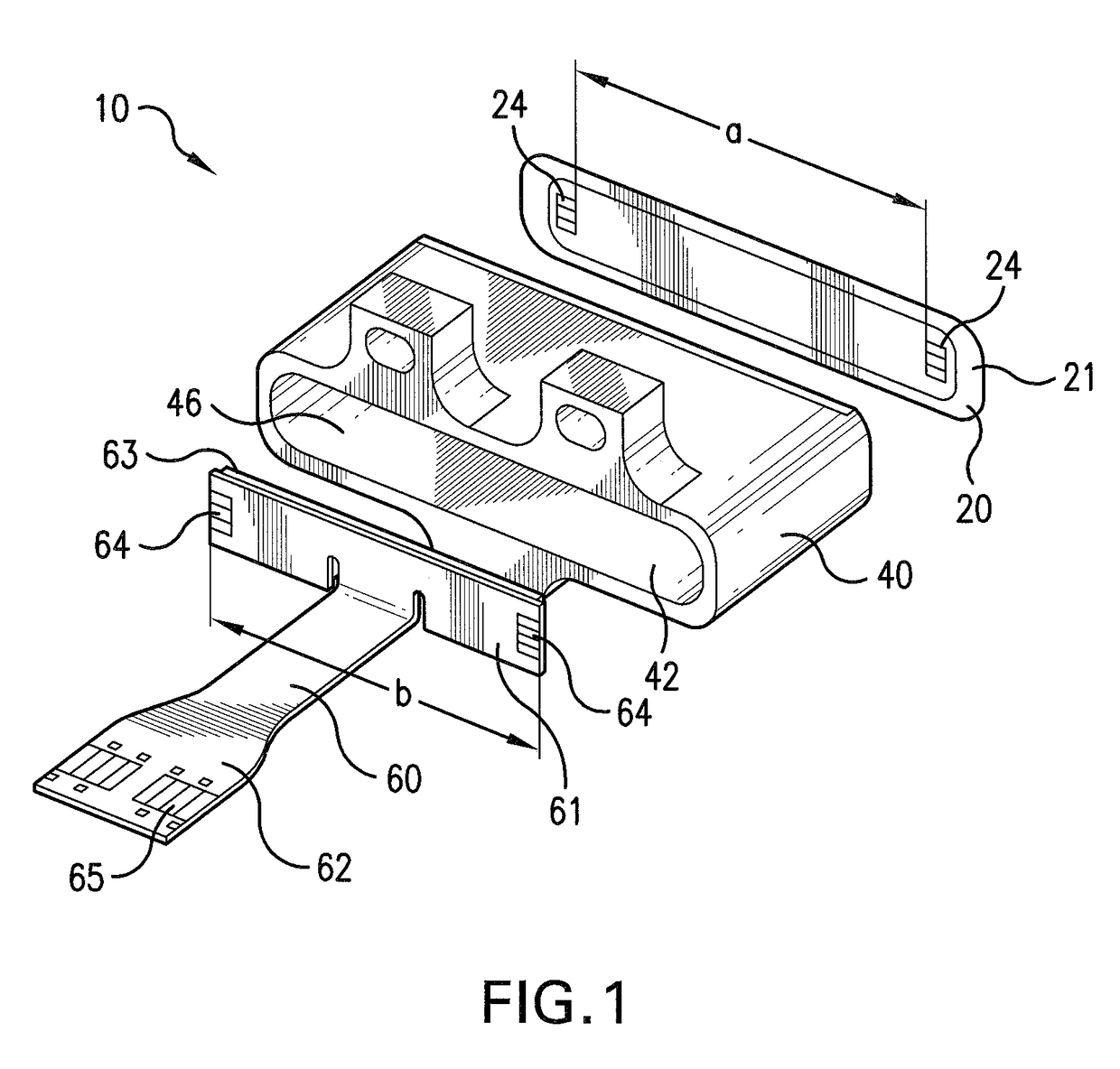

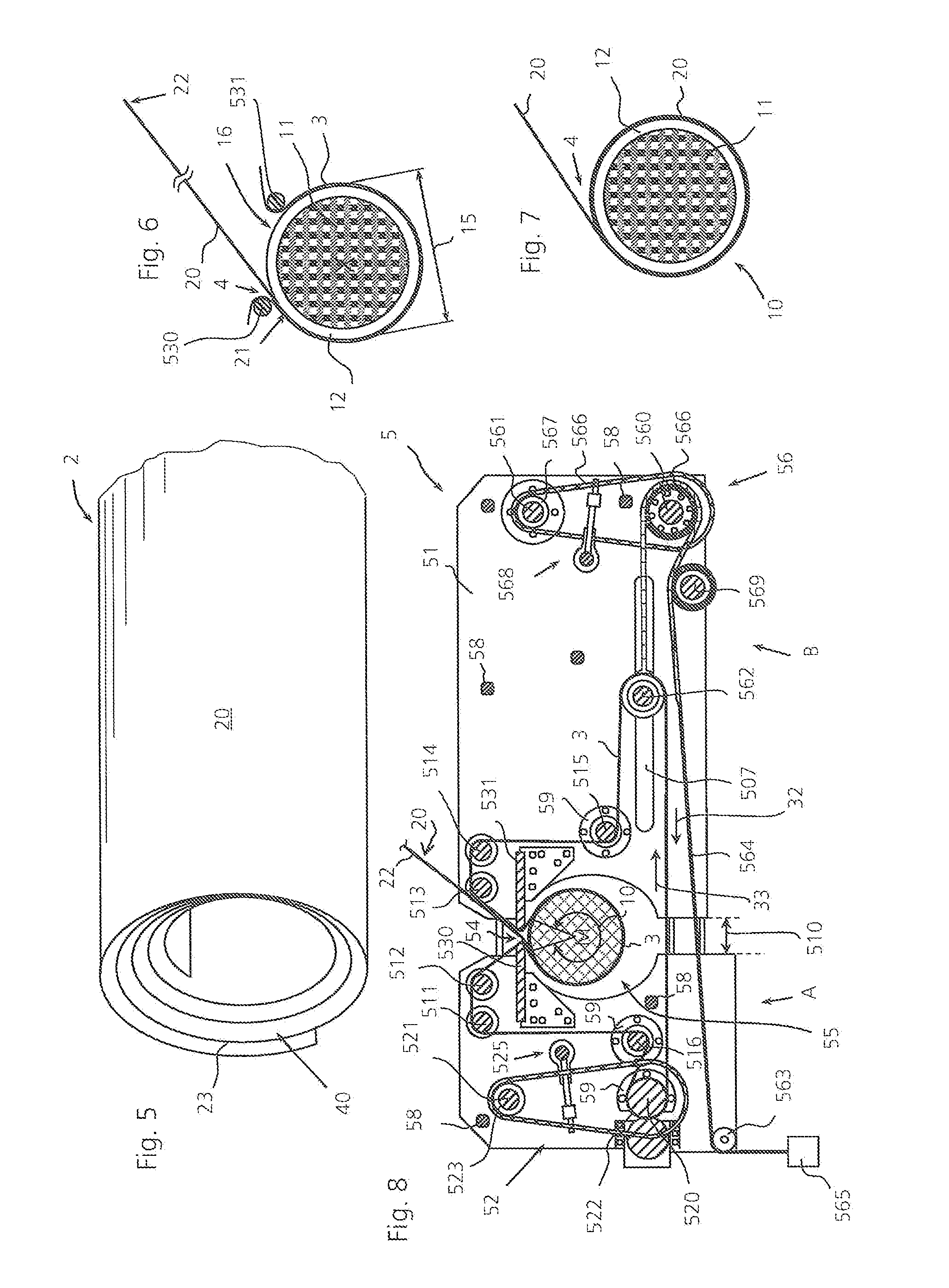

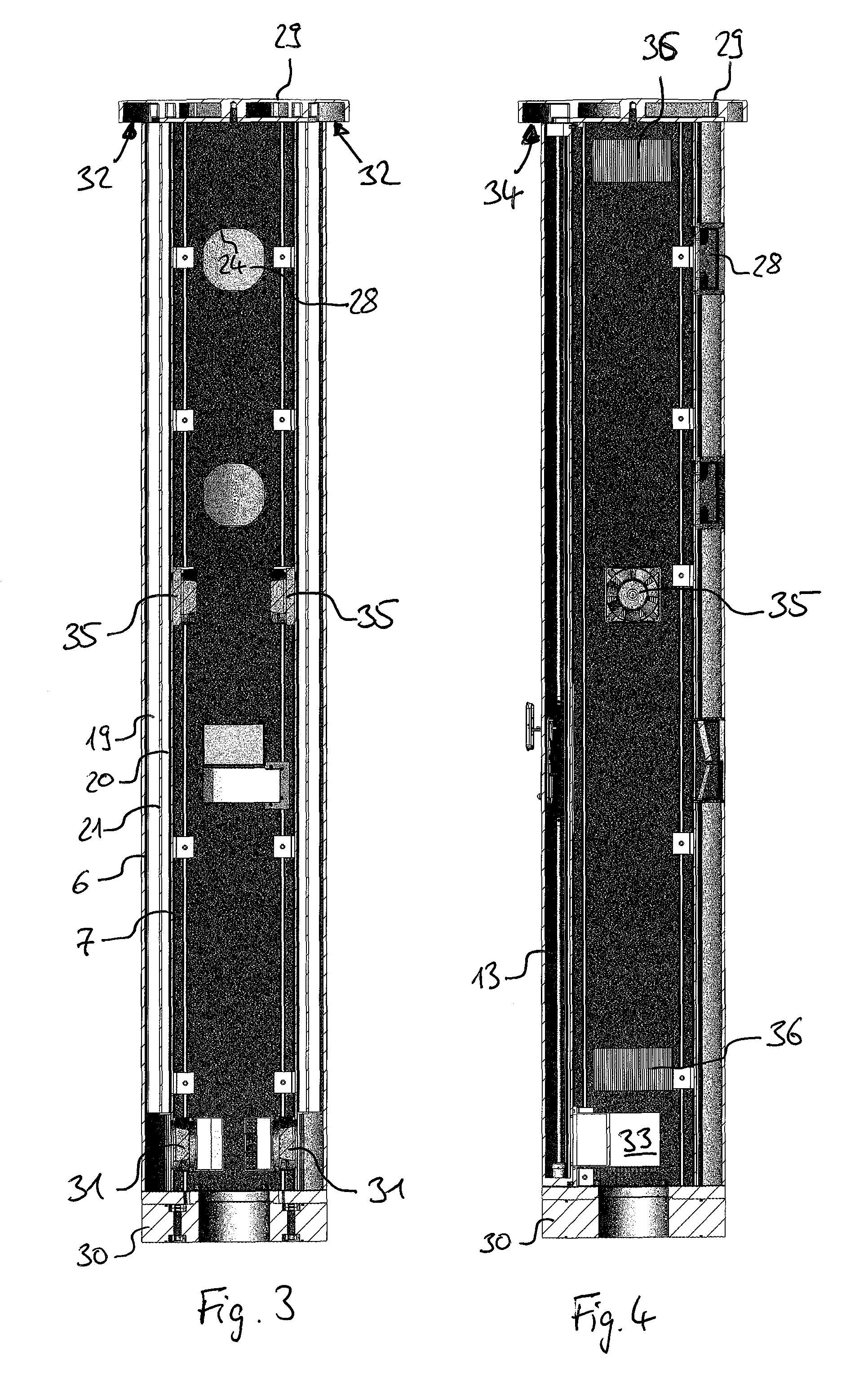

Rolling Cover System Motor Mount

ActiveUS20130241230A1Efficient transferRestrict movementRemovable external protective coveringsLoad coveringEngineering

A motorized rolling cover system for covering the top of an open-top vehicle. The system includes a cover, a shaft, a motor assembly, an arm assembly and a motor mount that supports the motor assembly on the arm assembly. The motor mount is pivotally attached to the end of the arm assembly to provide pivotal movement of the mount in a single plane. The plane of pivotal movement is either the same as (i.e., parallel to) the plane defined by the arm and the shaft, or is perpendicular to the arm-shaft plane.

Owner:SHUR

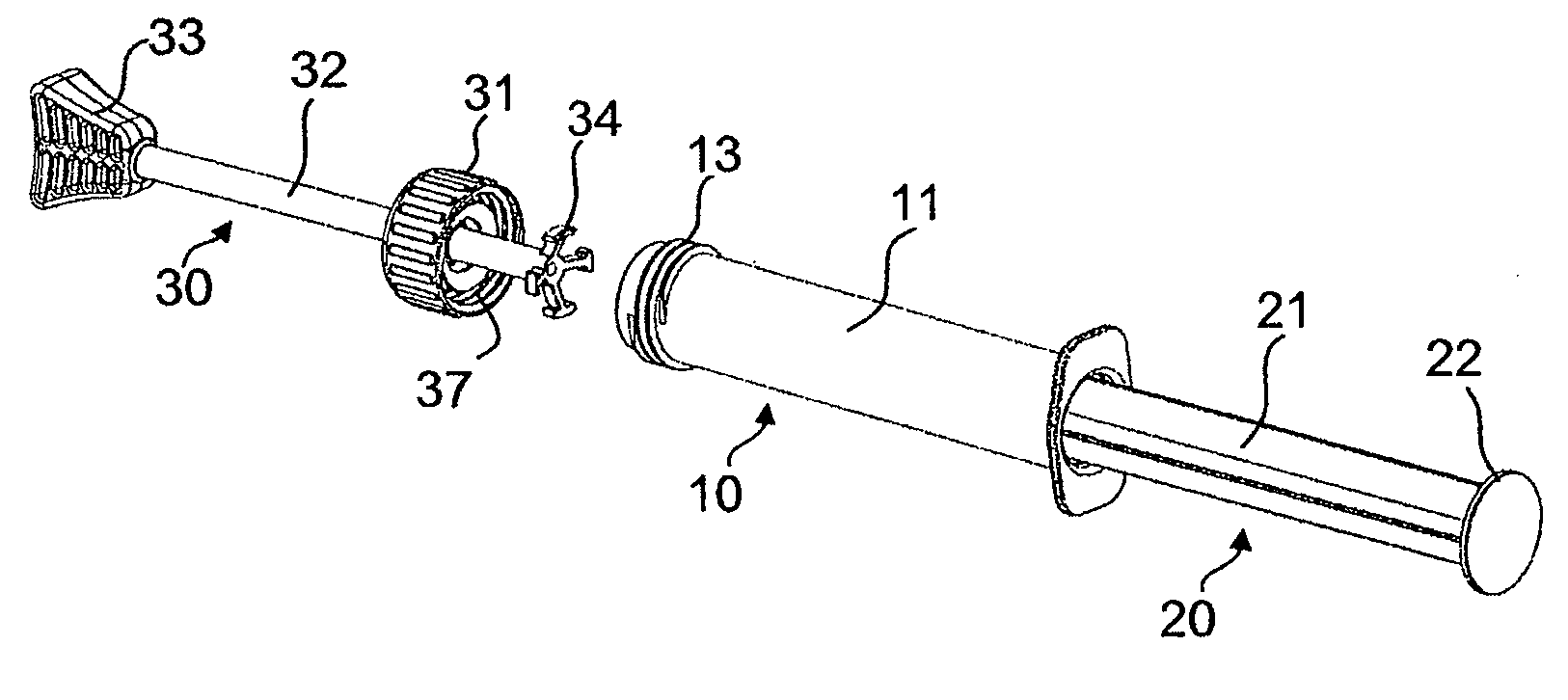

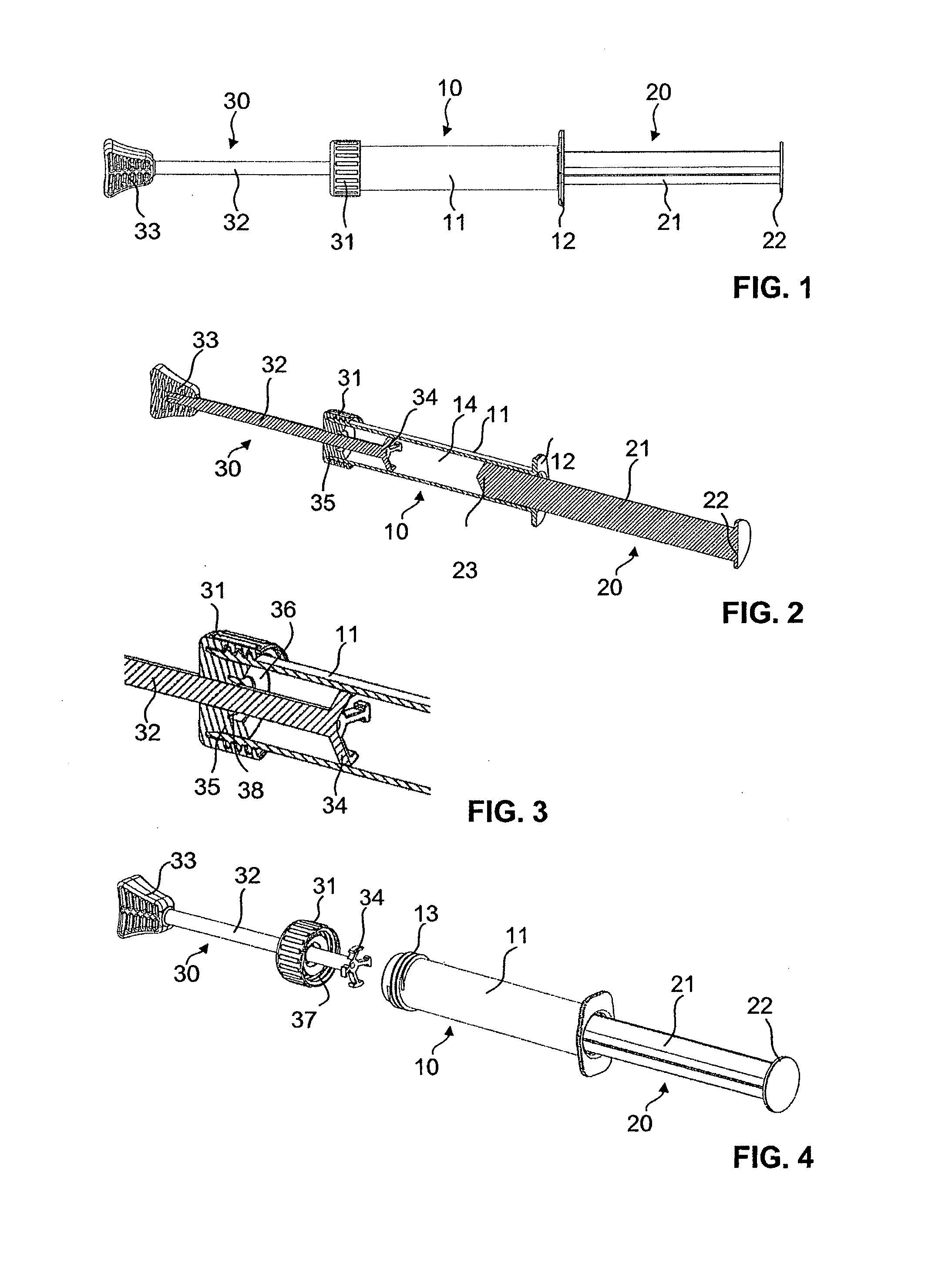

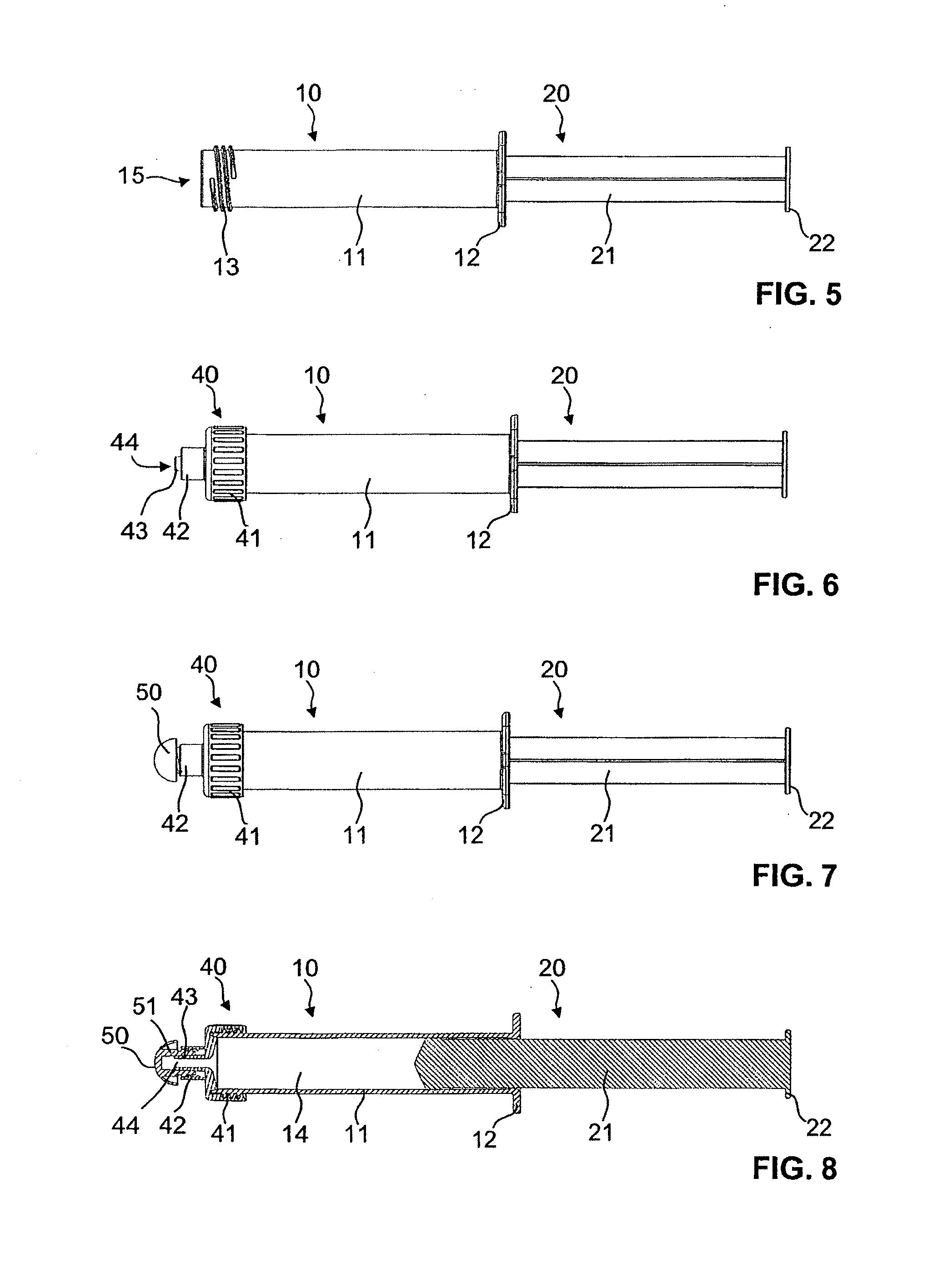

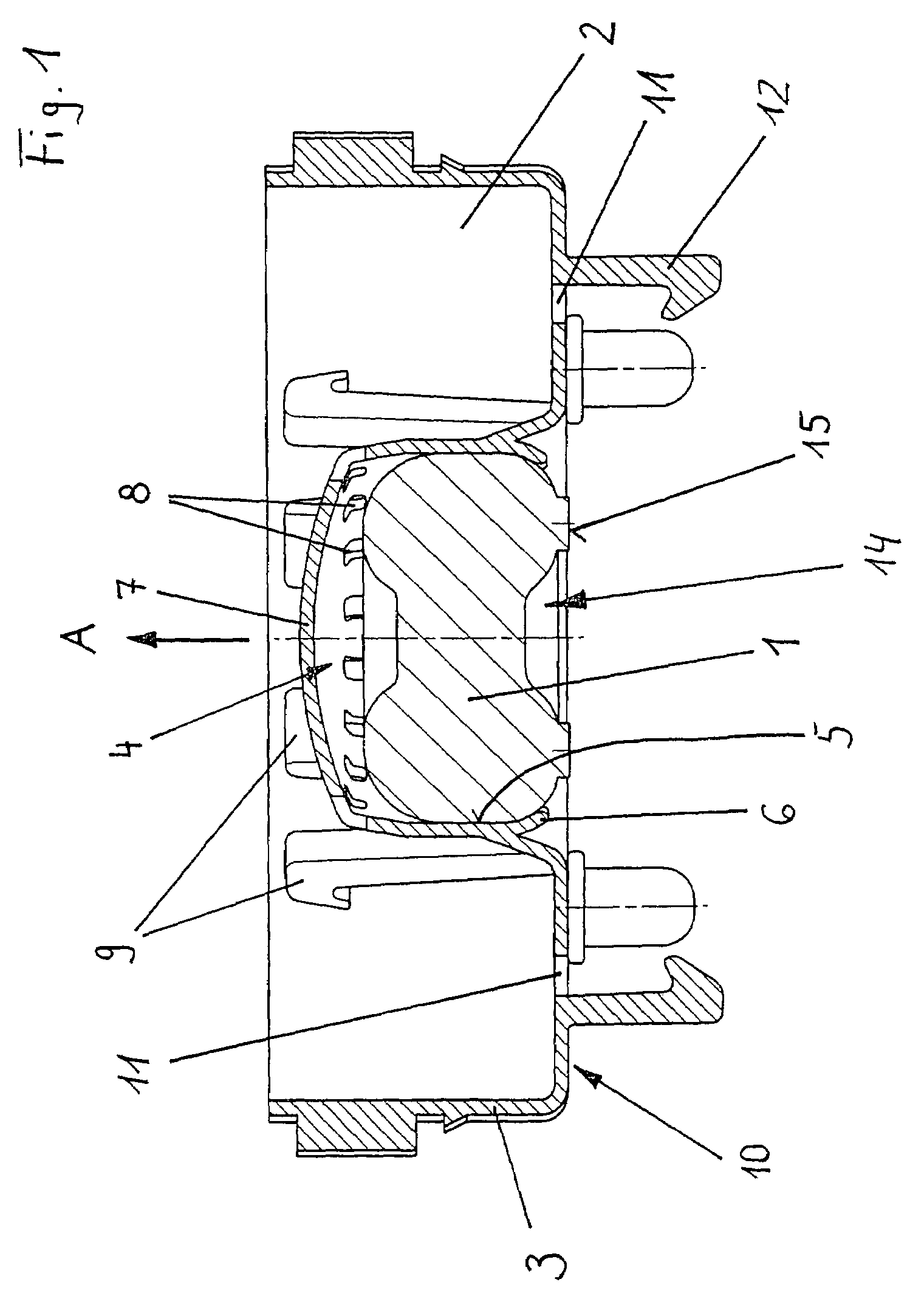

Syringe-like mixing device having a distally operable mixing element

InactiveUS20120330229A1Simple designSuitable for productionShaking/oscillating/vibrating mixersTransportation and packagingPistonMixing chamber

The invention relates to a syringe-like mixing device, comprising a housing, in which a mixing chamber is formed, a piston, which can be slid in the mixing chamber from the proximal side, and a mixing element, which can be operated from the distal side. In order to ensure simple operation, the mixing device has a sealing cap, which seals the distal open end of the mixing chamber and which has a passage opening, through which an operating rod for the mixing element is guided. The sealing cap can be completely removed from the housing together with the operating rod and the mixing element. In order to discharge the mixing product, a second sealing cap can be placed onto the housing. Accessory parts can be connected to said second sealing cap. The mixing product can then be discharged as with a conventional injection syringe.

Owner:MEDMIX SYST

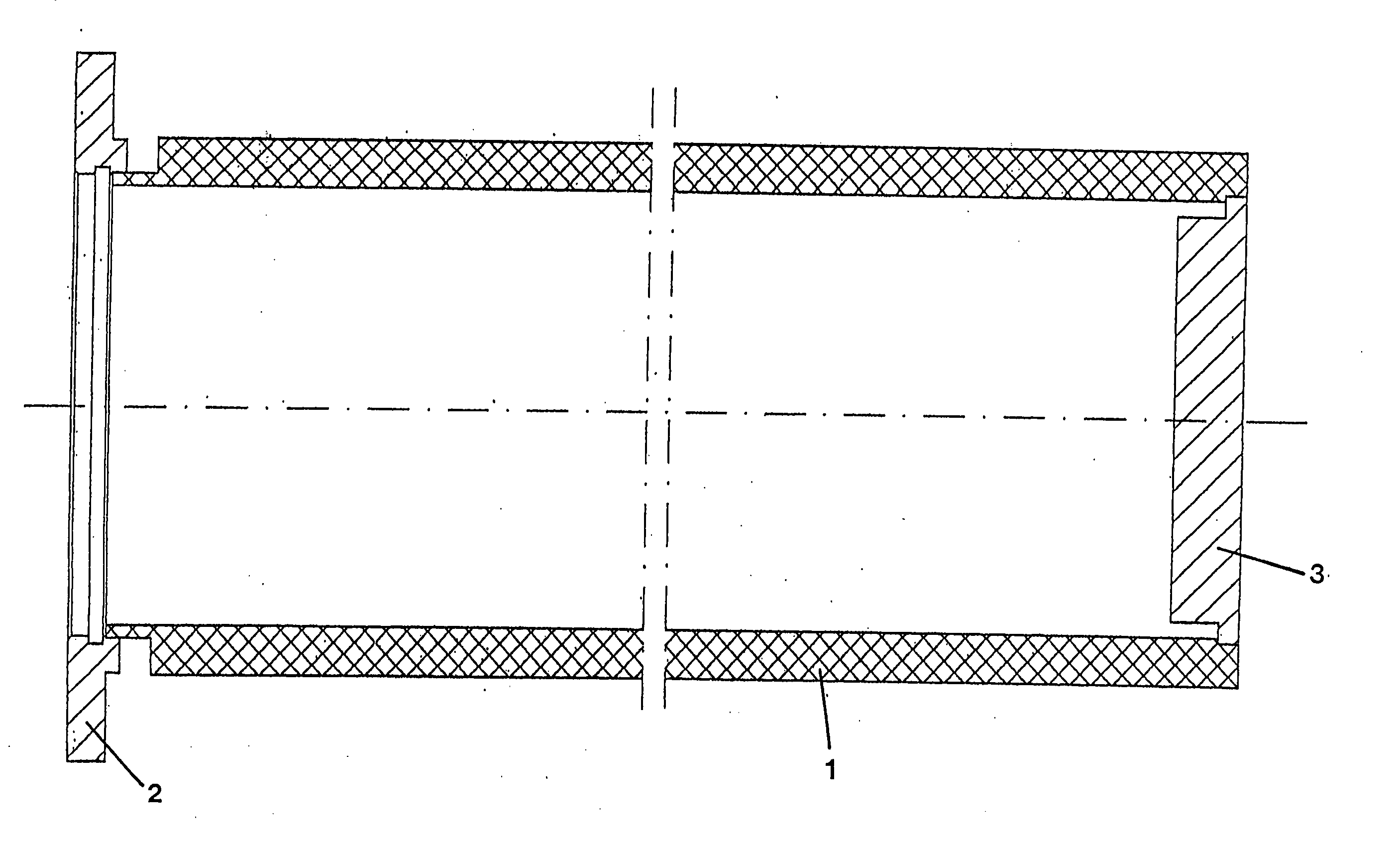

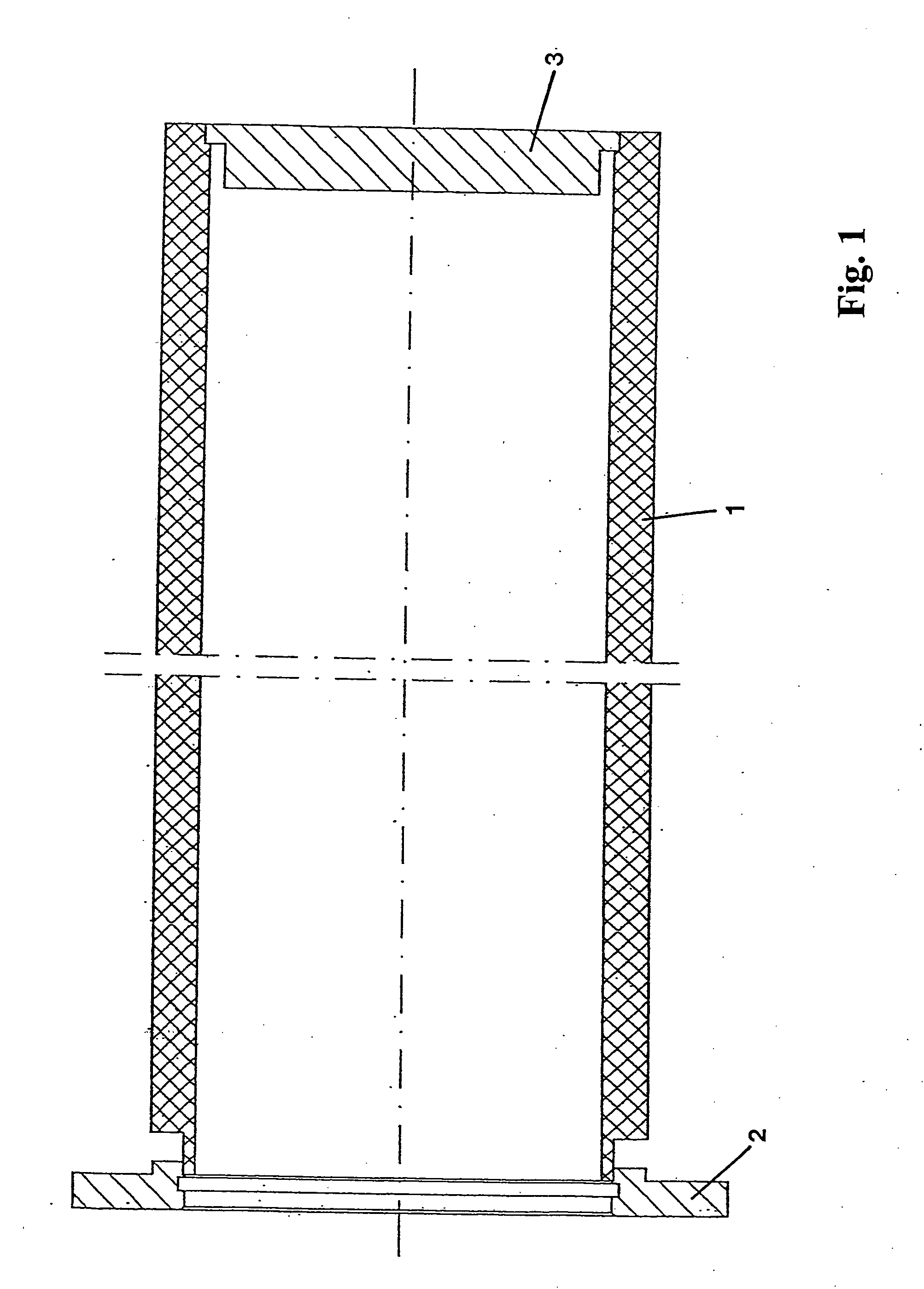

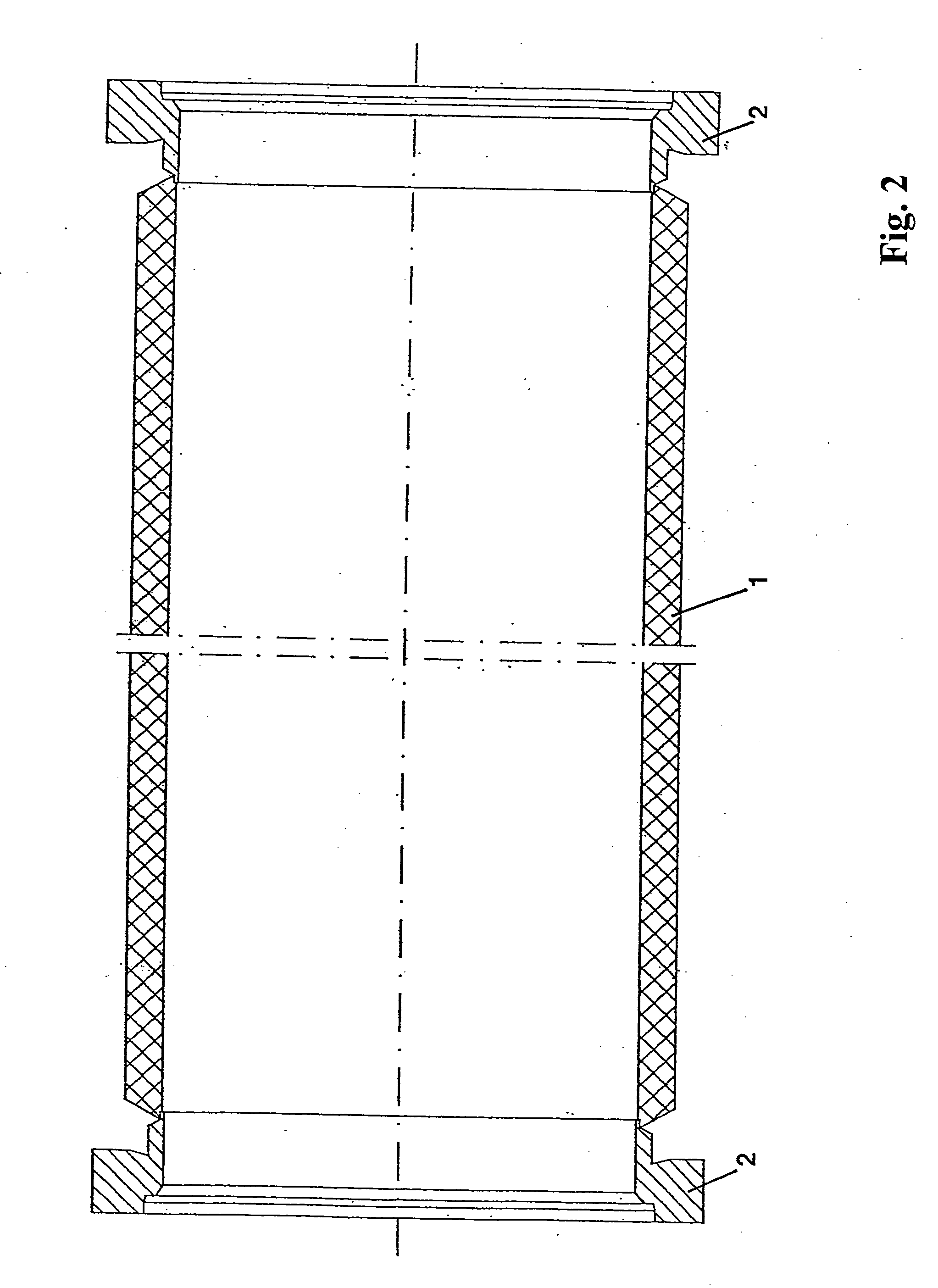

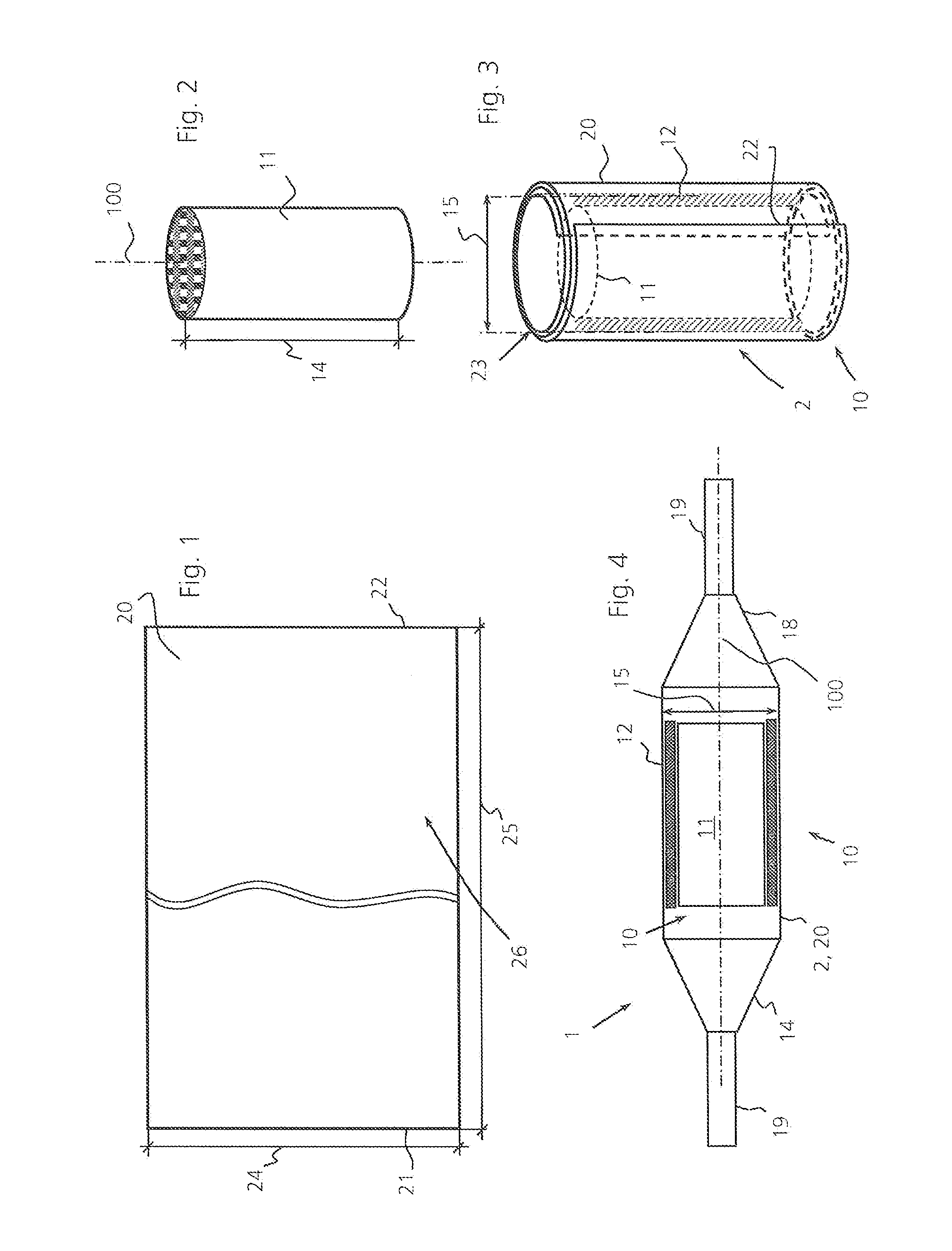

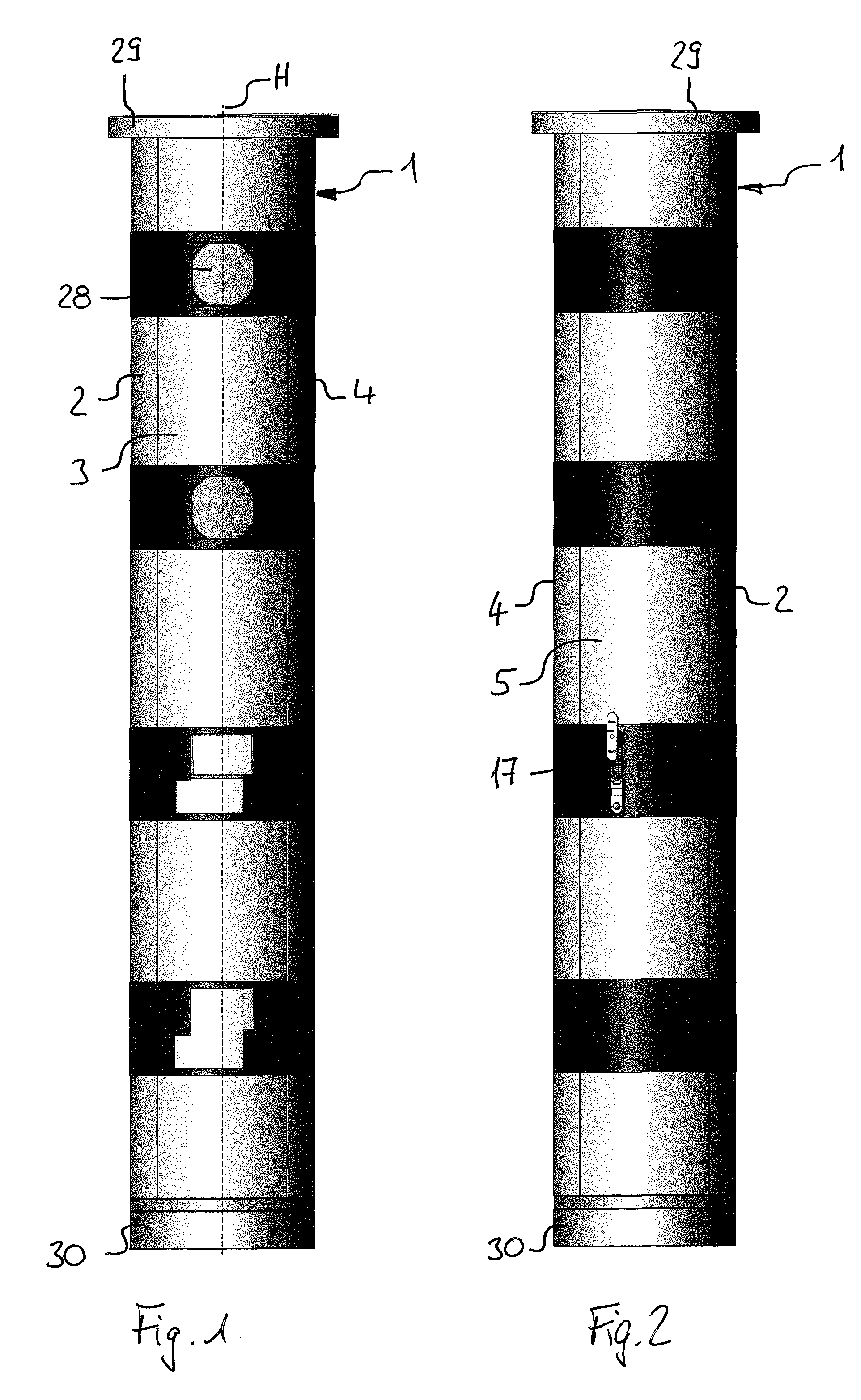

Tubular sputtering target

InactiveUS20060151320A1Avoid problemsGuarantee necessary stabilityCellsElectric discharge tubesEngineering

A tubular sputtering target with a target body and with an attachment device arranged at at least one end of the target body. The attachment device and / or an end cover are joined with the target body by material joining or positive locking.

Owner:W C HERAEUS GMBH

Emulsion comprising a nut paste

ActiveUS20050281939A1Necessary stabilitySimpler and cheapEdible oils/fats ingredientsMilk preservationEmulsionSugar

A process for the preparation of a bake stable nut butter emulsion which comprises the following steps (a) selecting a sugar syrup solution and diluting it with water until it contains an amount of sugar solids which is in the range 55-80 wt. %, (b) heating the solution to a temperature in the range 40-100° C., (c) dispersing a starch into the heated solution until it contains 1-5 wt. % of dissolved starch, (d) dispersing an emulsifier into the heated solution until it contains 0.5-3 wt. % of dissolved emulsifier, (e) dispersing a gelling agent into the heated solution until it contains 0.2-1 wt. % of dissolved gelling agent, (f) cooling the heated solution into which the starch, emulsifier and gelling agent have been dispersed to a temperature which is in the range of 20-50° C., (g) dispersing under vigorous stirring conditions a nut butter into the cooled solution, while controlling the rate of addition such that the resulting emulsion remains water continuous, (h) allowing the emulsion to cool and to obtain a plastic consistency. The process delivers an edible nut butter containing emulsion which comprises 10-25 wt. % of a dispersed fat phase and 75-90 wt. % of a continuous aqueous phase which comprises sugar solids, starch, gelling agent and emulsifier, which emulsion has a plastic consistency and which emulsion possesses bake stability. The invention also relates to a bake stable nut butter emulsion.

Owner:UNILEVER BESTFOODS NORTH AMERICA DIV OF CONOPCO

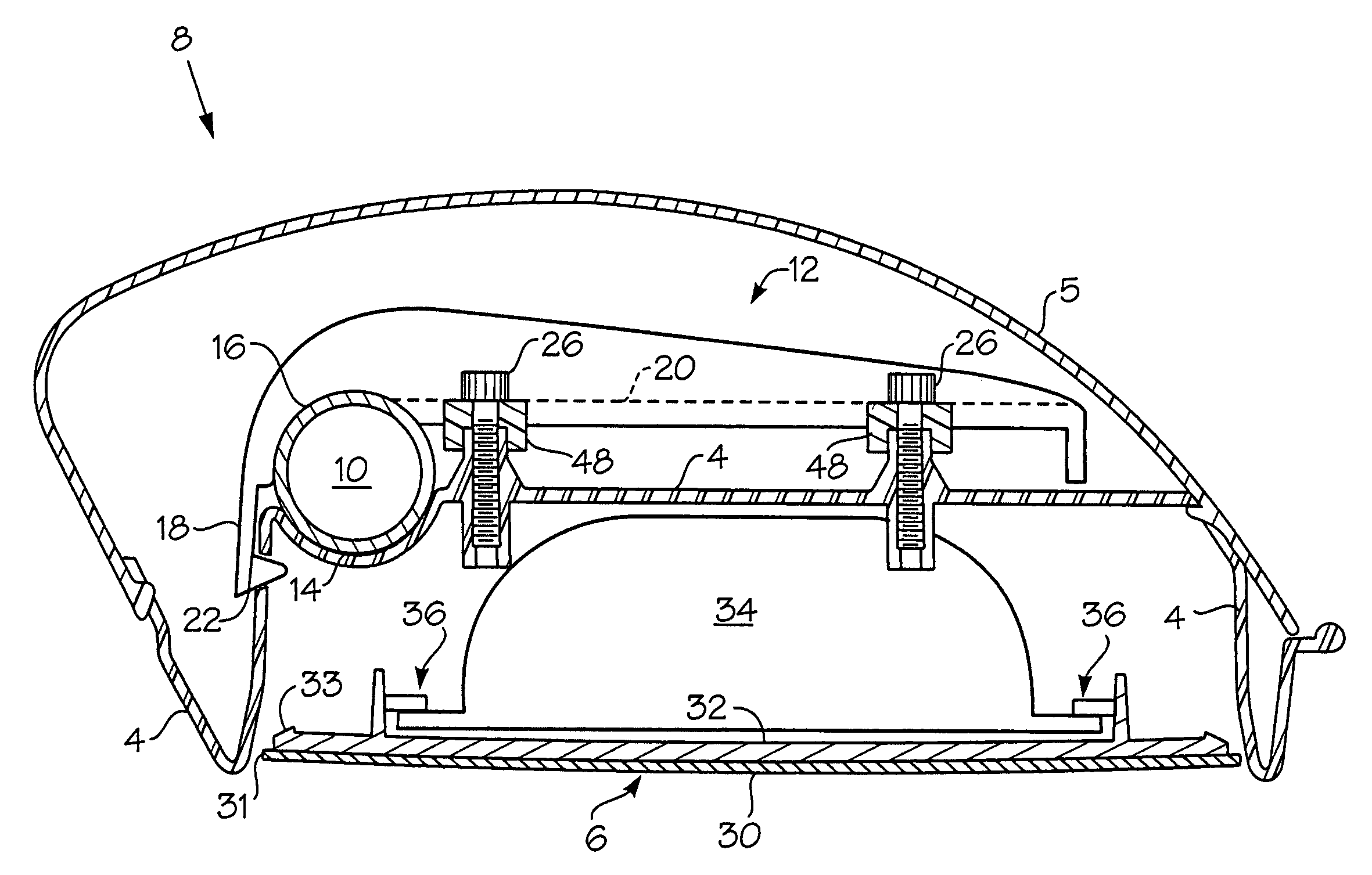

Rearview mirror assembly for motor vehicles

InactiveUS20070053087A1Convenient lightingNecessary stabilityPicture framesDomestic mirrorsEngineeringMotorized vehicle

A rearview mirror assembly for attachment to a holding tube carried by a vehicle. The assembly includes a housing framing configured to encase a portion of the holding tube and to attach with a mirror element. A clamping bracket is also configured to encase a portion of the holding tube and to attach with the housing frame. A projection formed with one of the housing framing and the clamping bracket is positioned to extend into the holding tube when encased by the clamping bracket and housing framing. Connectors are engaged with the housing framing, clamping bracket and the extension locking them in position relative to each other and the holding tube.

Owner:LANG MEKRA NORTH AMERICA LLC

Emulsion comprising a nut paste

ActiveUS7163710B2Necessary stabilitySimpler and cheapEdible oils/fats ingredientsMilk preservationEmulsionSugar

A process for the preparation of a bake stable nut butter emulsion which comprises the following steps (a) selecting a sugar syrup solution and diluting it with water until it contains an amount of sugar solids which is in the range 55–80 wt. %, (b) heating the solution to a temperature in the range 40–100° C., (c) dispersing a starch into the heated solution until it contains 1–5 wt. % of dissolved starch, (d) dispersing an emulsifier into the heated solution until it contains 0.5–3 wt. % of dissolved emulsifier, (e) dispersing a gelling agent into the heated solution until it contains 0.2–1 wt. % of dissolved gelling agent, (f) cooling the heated solution into which the starch, emulsifier and gelling agent have been dispersed to a temperature which is in the range of 20–50° C., (g) dispersing under vigorous stirring conditions a nut butter into the cooled solution, while controlling the rate of addition such that the resulting emulsion remains water continuous, (h) allowing the emulsion to cool and to obtain a plastic consistency. The process delivers an edible nut butter containing emulsion which comprises 10–25 wt. % of a dispersed fat phase and 75–90 wt. % of a continuous aqueous phase which comprises sugar solids, starch, gelling agent and emulsifier, which emulsion has a plastic consistency and which emulsion possesses bake stability. The invention also relates to a bake stable nut butter emulsion.

Owner:UNILEVER BESTFOODS NORTH AMERICA DIV OF CONOPCO

Inductive sensor

ActiveUS20080211489A1Easy to manufactureSmall distanceLinear bearingsUsing electrical meansEngineeringMetal

An inductive sensor has an electrically nonconductive substrate, at least one electrically conducting coil that is integrally joined to the substrate, with the mechanical rigidity of the substrate significantly greater than that of the conducting coil, a metal plate covering the conducting coil, with the substrate comprised by the metal plate, and with the surface of the metal plate on the side oriented toward the conducting coil provided with an electrically insulating layer.

Owner:ROBERT BOSCH GMBH

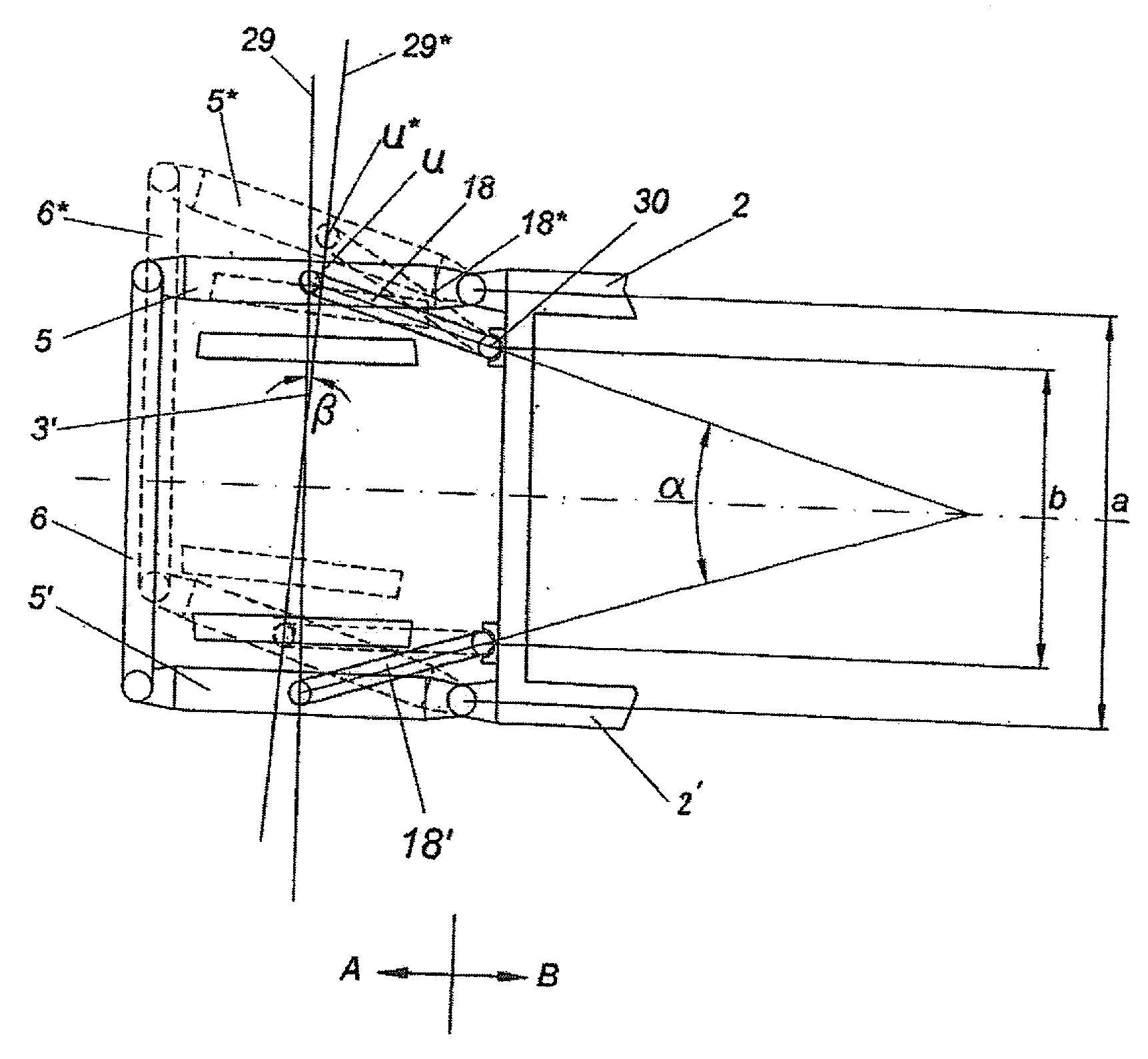

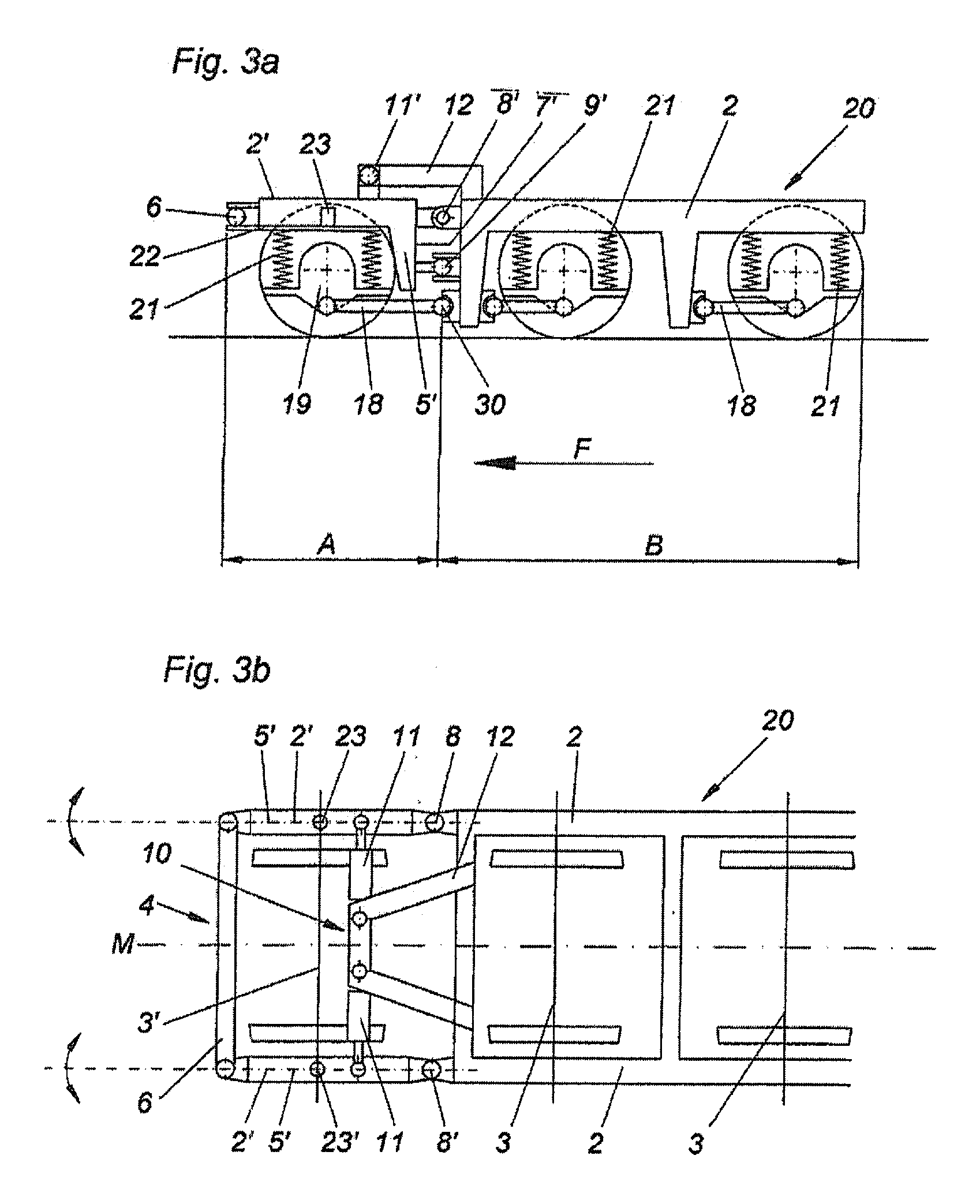

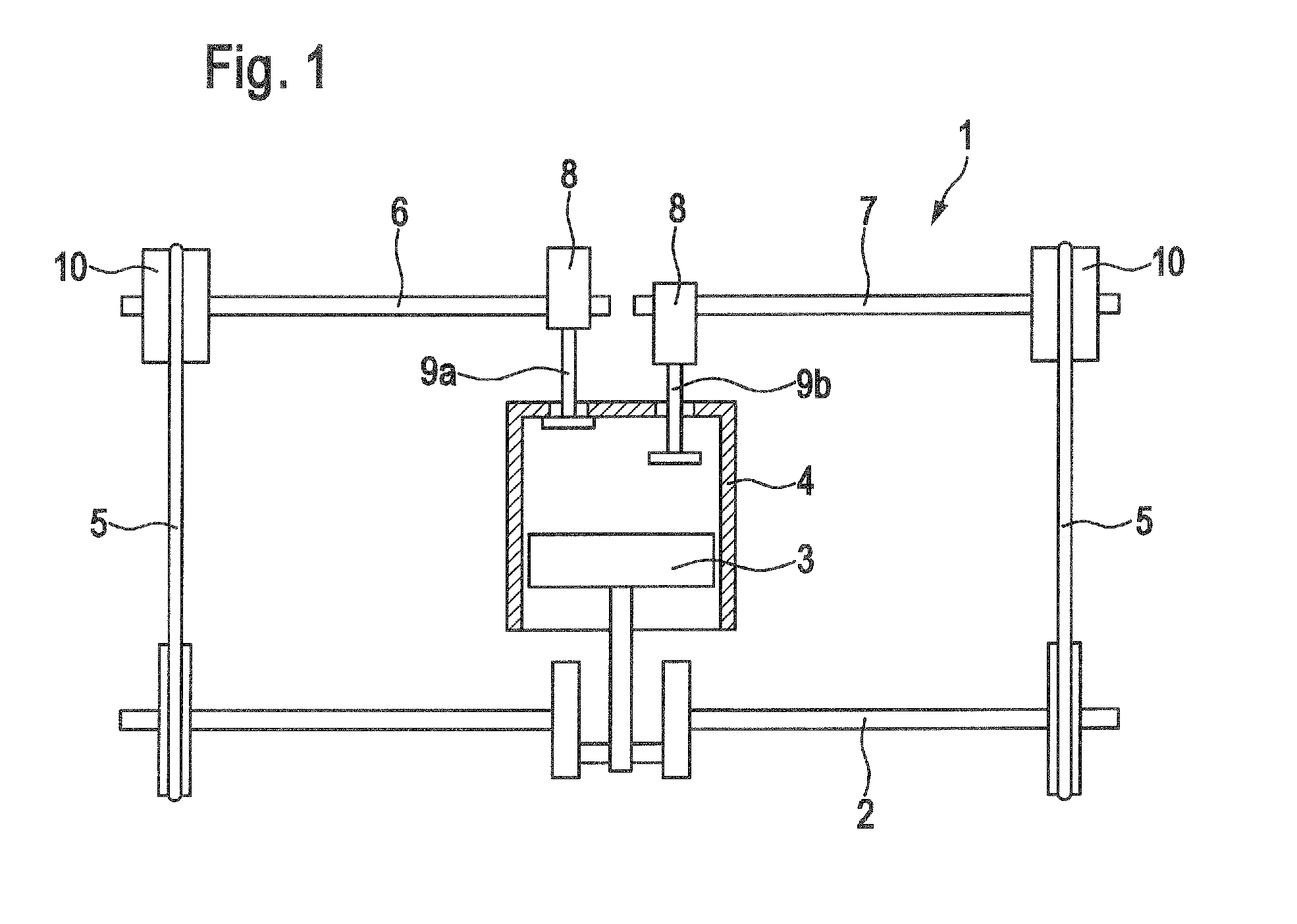

Running gear for rail vehicles

ActiveUS20080196618A1Robust designNecessary stabilityUnderframesPassenger carriagesEngineeringMechanical engineering

This invention comprises a running gear for rail vehicles with at least three wheel sets housed in a bogey frame and at least one steering device that makes possible a transverse displacement of an end wheel set, wherein the bogey frame, seen in longitudinal direction, has several sections, wherein at least the frontmost section, seen in the direction of travel, in which the leading wheel set is arranged, is connected horizontally pivotable to a second, rigid section, characterized in that at least the frontmost section, seen in the direction of travel, of the bogey frame in which the leading wheel set is arranged is formed as a parallelogram that can be displaced transversely to the longitudinal axis of the bogey frame.

Owner:EVOINVENT

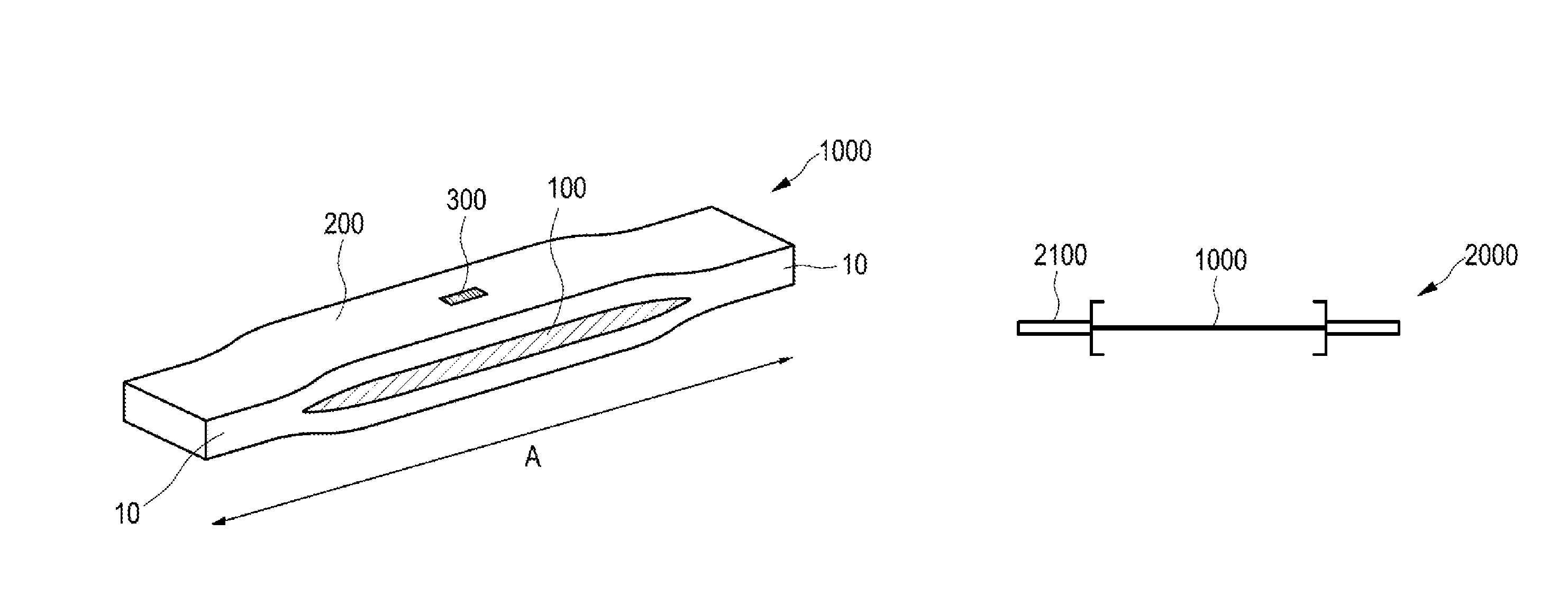

Test piece, test method, wind turbine generator system

ActiveUS9581529B2Small measurement errorNecessary stabilityFlow propertiesMaterial strength using tensile/compressive forcesTransverse axisTurbine

Owner:WOBBEN PROPERTIES GMBH

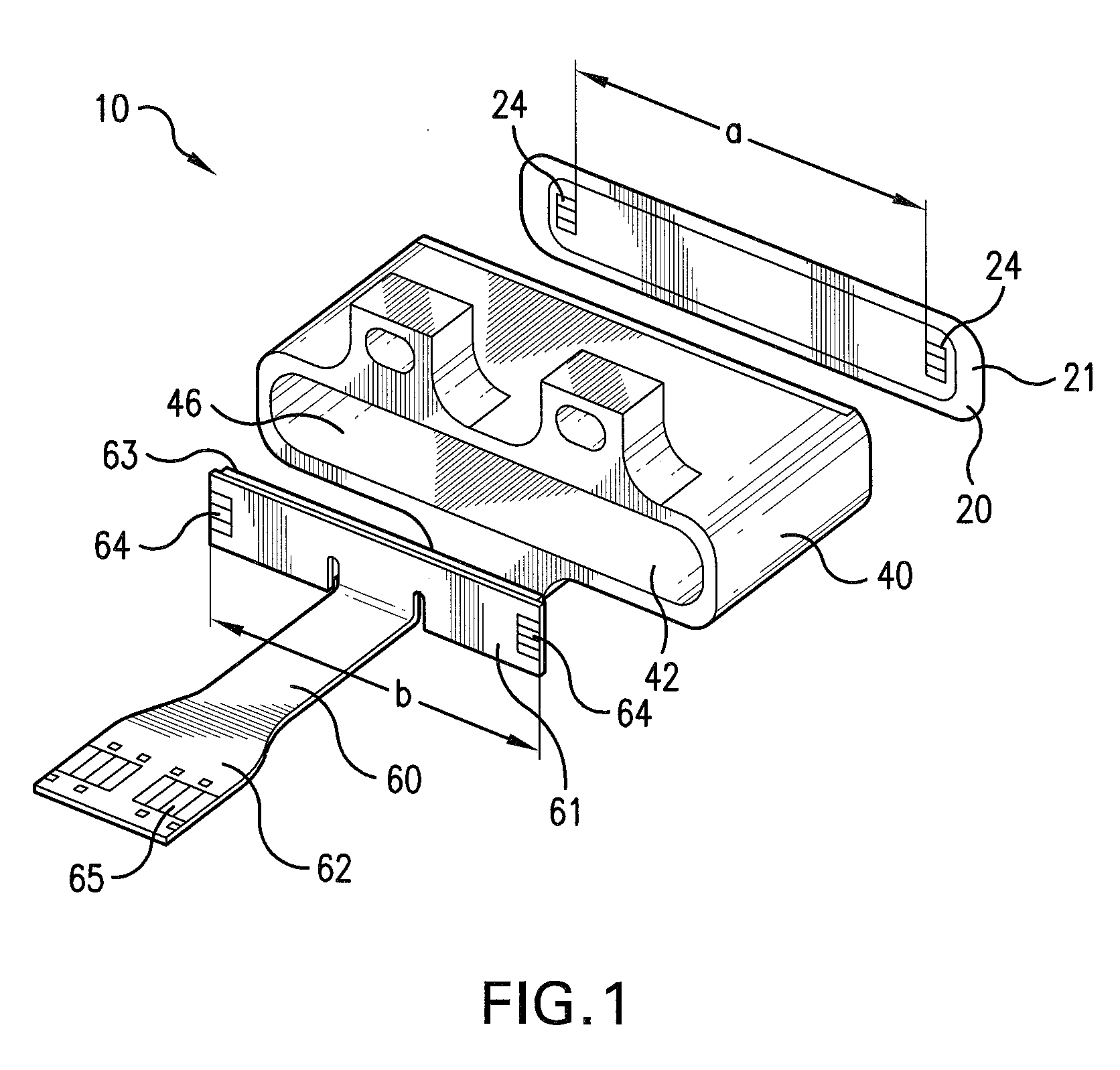

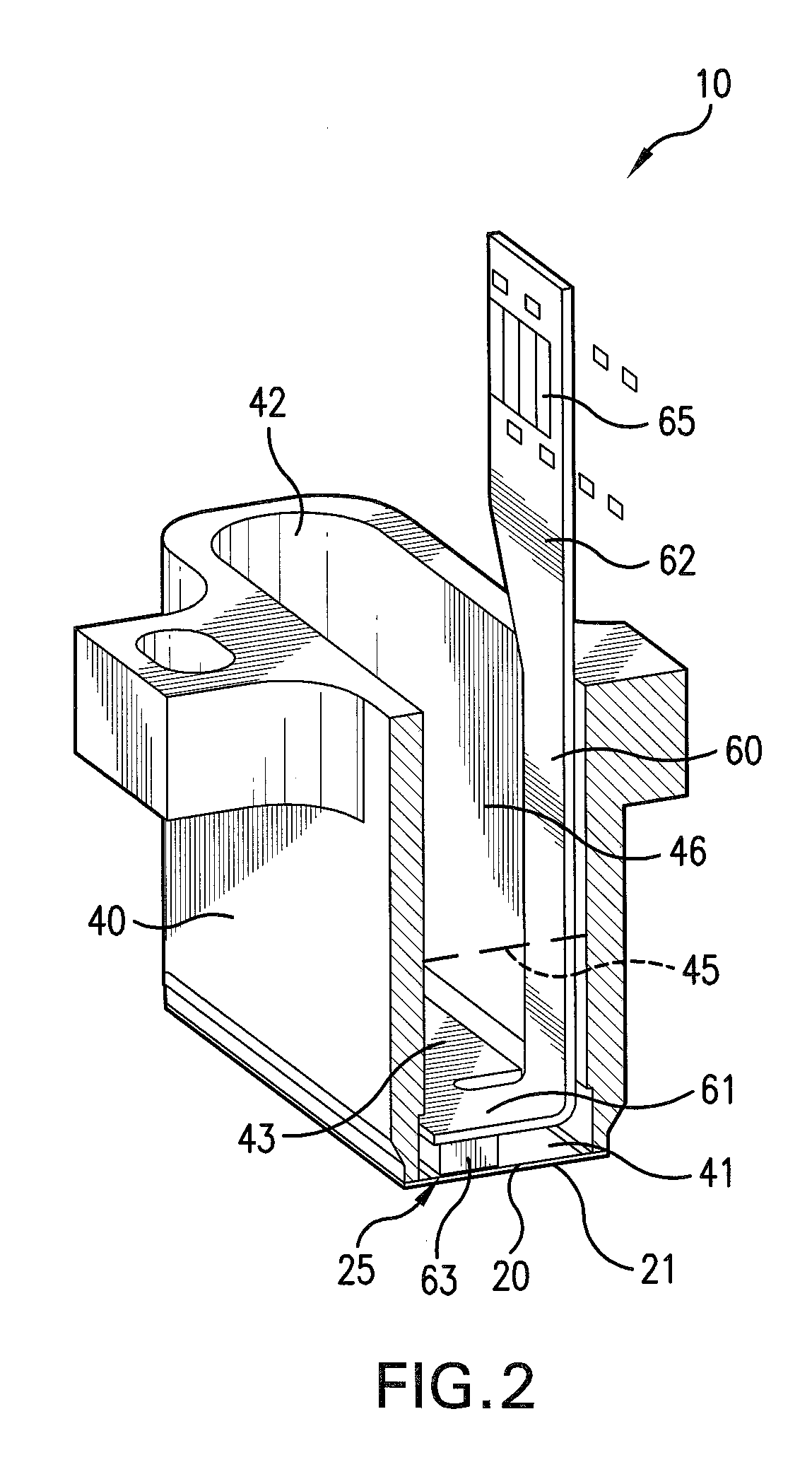

Housing for motor vehicle airbag

InactiveUS7083185B2Economically manufacturedEasy to assemblePedestrian/occupant safety arrangementMobile vehicleMotor vehicle part

A housing for an inflatable air bag of a motor vehicle is presented, which has a gas generator, a mounting space for inserting the folded air bag as well as a diffusor made integrally with the housing for the uniform distribution of the gas released by the fired gas generator. The gas generator is inserted into the diffusor and has a positive-locking connection with the diffusor chamber inner wall for its fixation in the diffusor.

Owner:ZF LEMFOERDER METALLWAREN AG

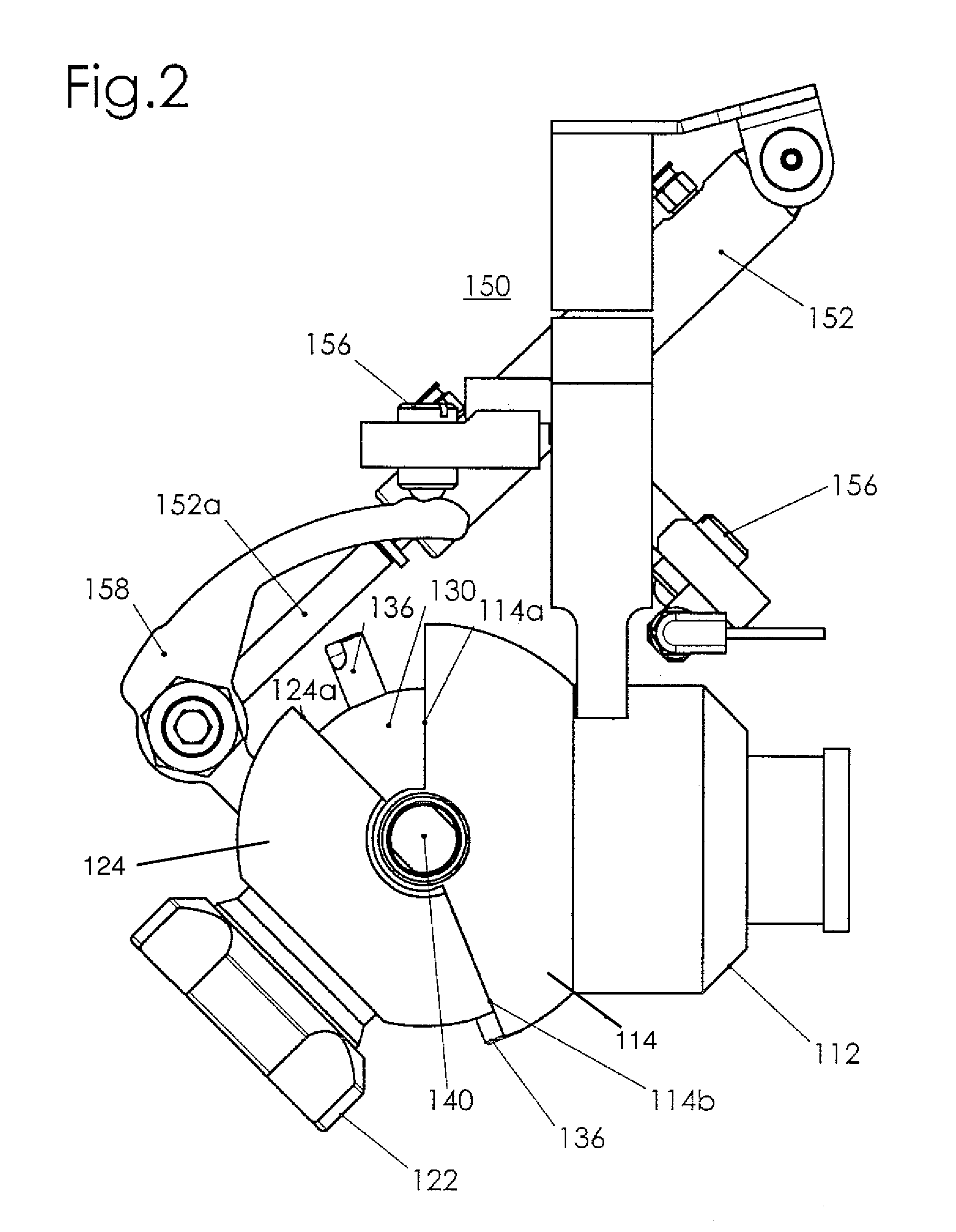

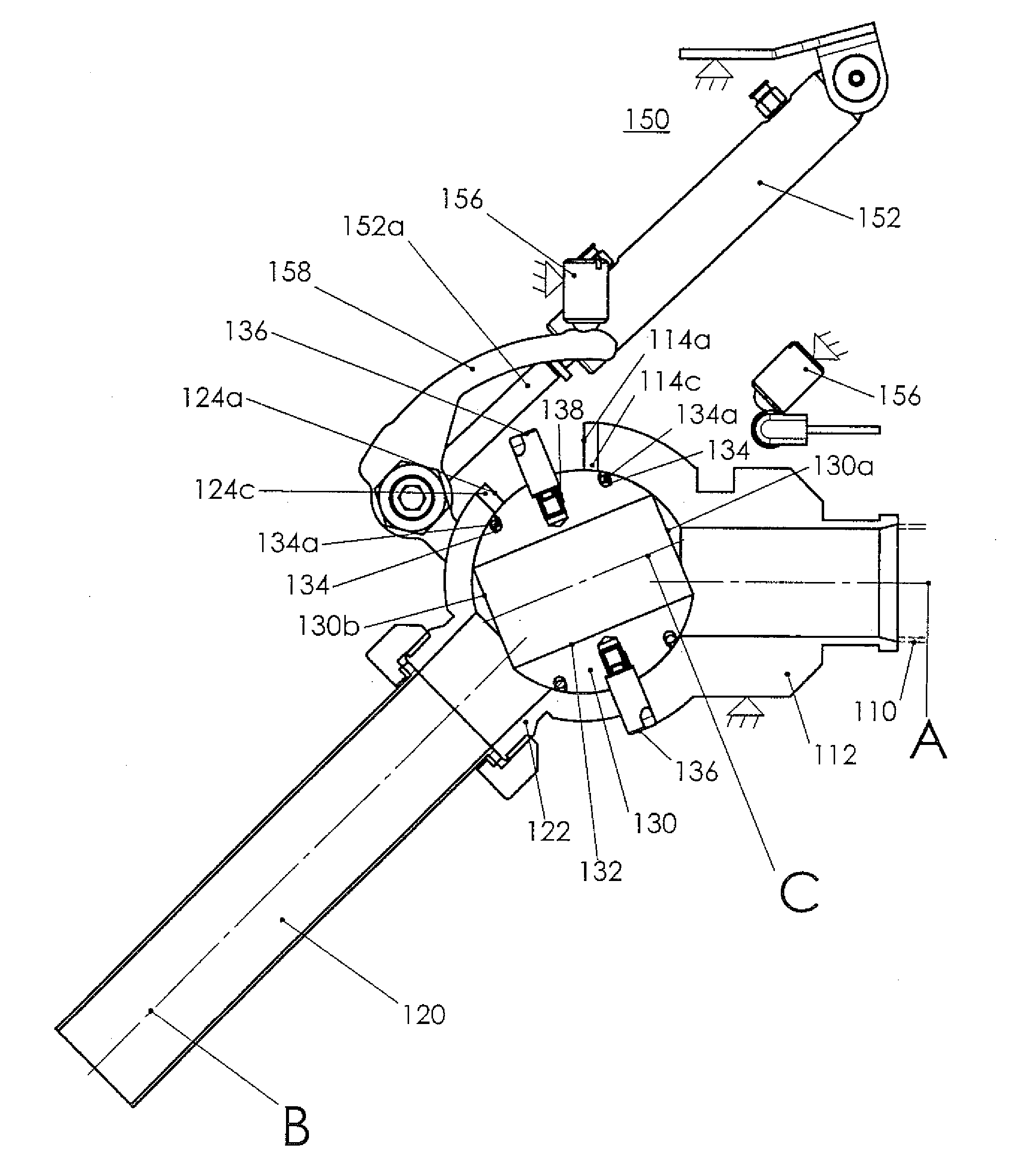

Filling joint arrangement for a flowable filling medium

InactiveUS7513821B2Improve accessibilityNecessary stabilitySausage filling/stuffing machinesFirst FillEngineering

A filling joint arrangement for a filling medium which is capable of flow, in particular for a sausage meat, including a first filling pipe portion with a first filling pipe axis and a second filling pipe portion with a second filling pipe axis, wherein the second filling pipe portion is reversibly pivotable from a filling position in which the second filling pipe axis is aligned with the first filling pipe axis into a tilted position in which the second filling pipe axis is out of alignment with the first filling pipe axis, and further including a joint device which is disposed in filling medium-tight relationship between the first and the second filling pipe portions and which has a first joint receiving portion connected in filling medium-tight relationship to the first filling pipe portion and which includes a joint intermediate portion which has a third filling pipe portion with a third filling pipe axis and which is held pivotably by the first joint receiving portion in such a way that it is reversibly pivotable from the filling position into a tilted position in which the third filling pipe axis is out of alignment with the first filling pipe axis. It is further provided that there is a second joint receiving portion which is connected in filling medium-tight relationship to the second filling pipe portion and which together with the second filling pipe portion is reversibly pivotable with respect to the joint intermediate portion out of the filling position by way of a tilted intermediate position in which at least the third filling pipe axis is out of alignment with the first filling pipe axis into a tilted end position in which the second filling pipe axis is out of alignment with the third filling pipe axis.

Owner:POLY CLIP SYST

Sulfur-Resistant Exhaust Gas Aftertreatment System For The Reduction Of Nitrogen Oxides

ActiveUS20090255240A1Avoid deactivationInhibition formationCombination devicesGas treatmentChemistryMolecular sieve

Owner:MAN NUTZFAHRZEUGE AG

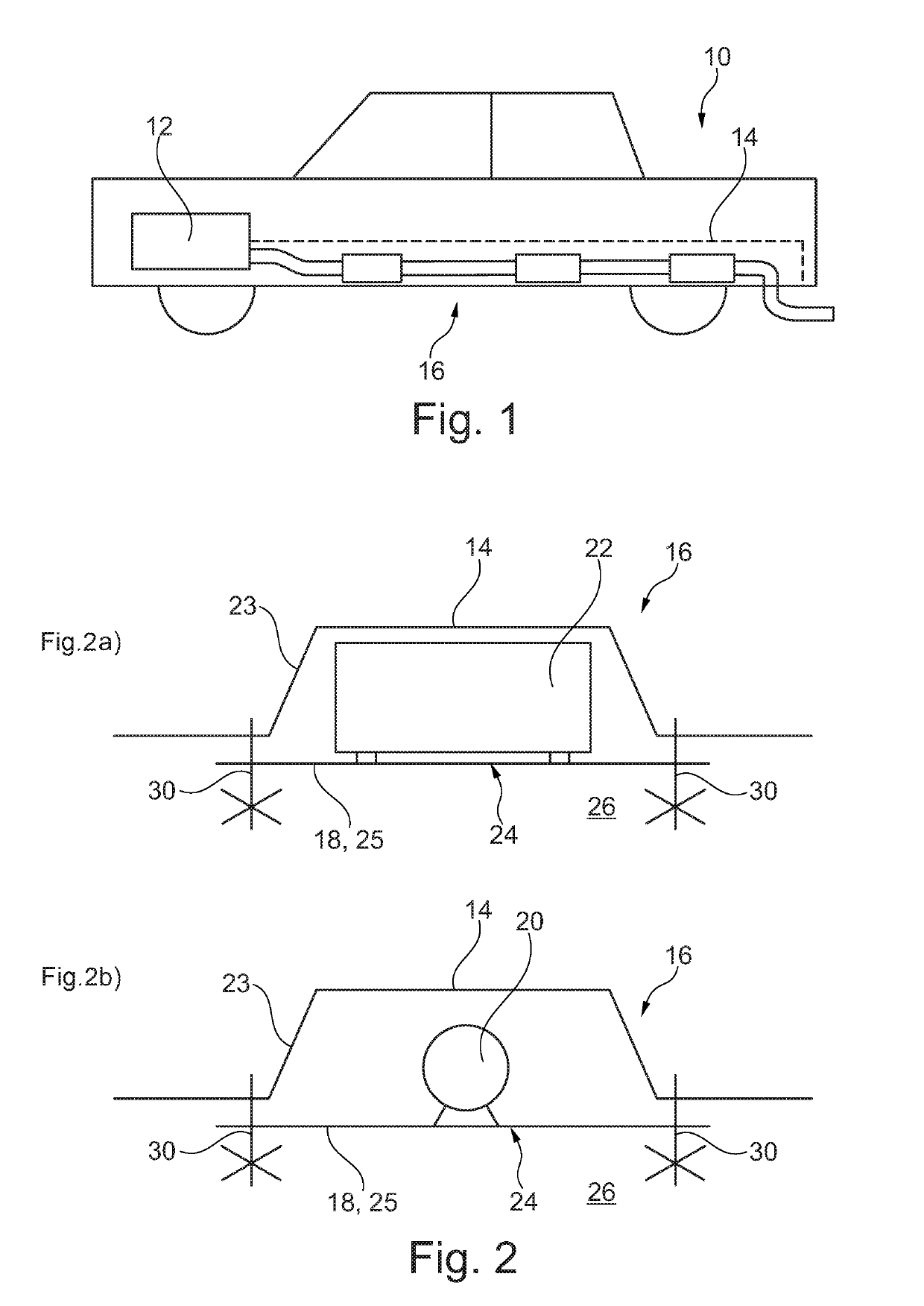

Exhaust system for a combustion engine of a motor vehicle and motor vehicle

ActiveUS20190195116A1Reduce wall thicknessReduce weightExhaust apparatusSilencing apparatusCombustionPlastic materials

An exhaust system for a combustion engine of a motor vehicle comprises a support plate on which at least one exhaust line or at least one exhaust silencer is provided. The support plate is made of a plastic material. A motor vehicle comprises a combustion engine and an exhaust system which is arranged in an underfloor tunnel of the motor vehicle.

Owner:FAURECIA EMISSIONS CONTROL TECH GERMANY

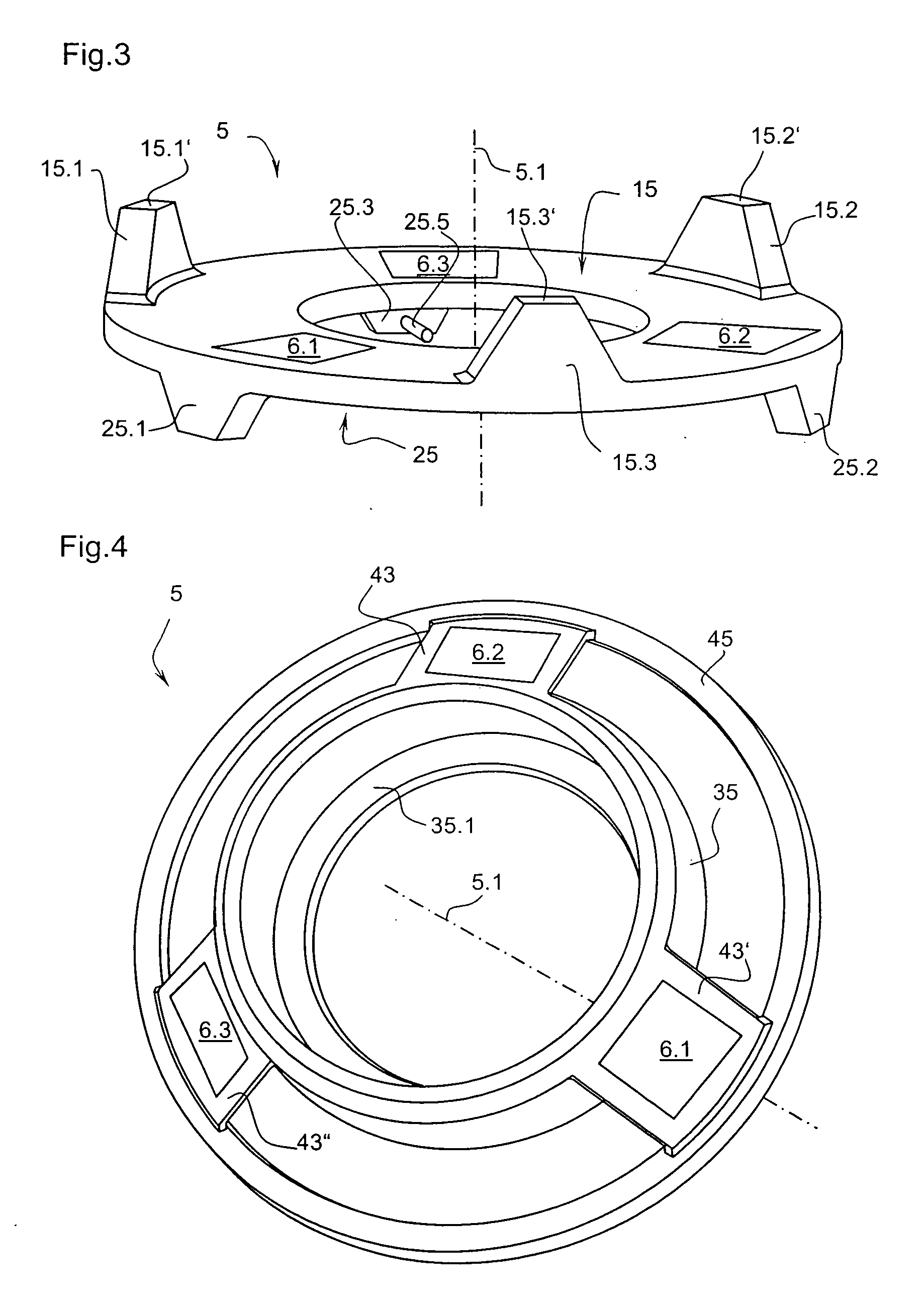

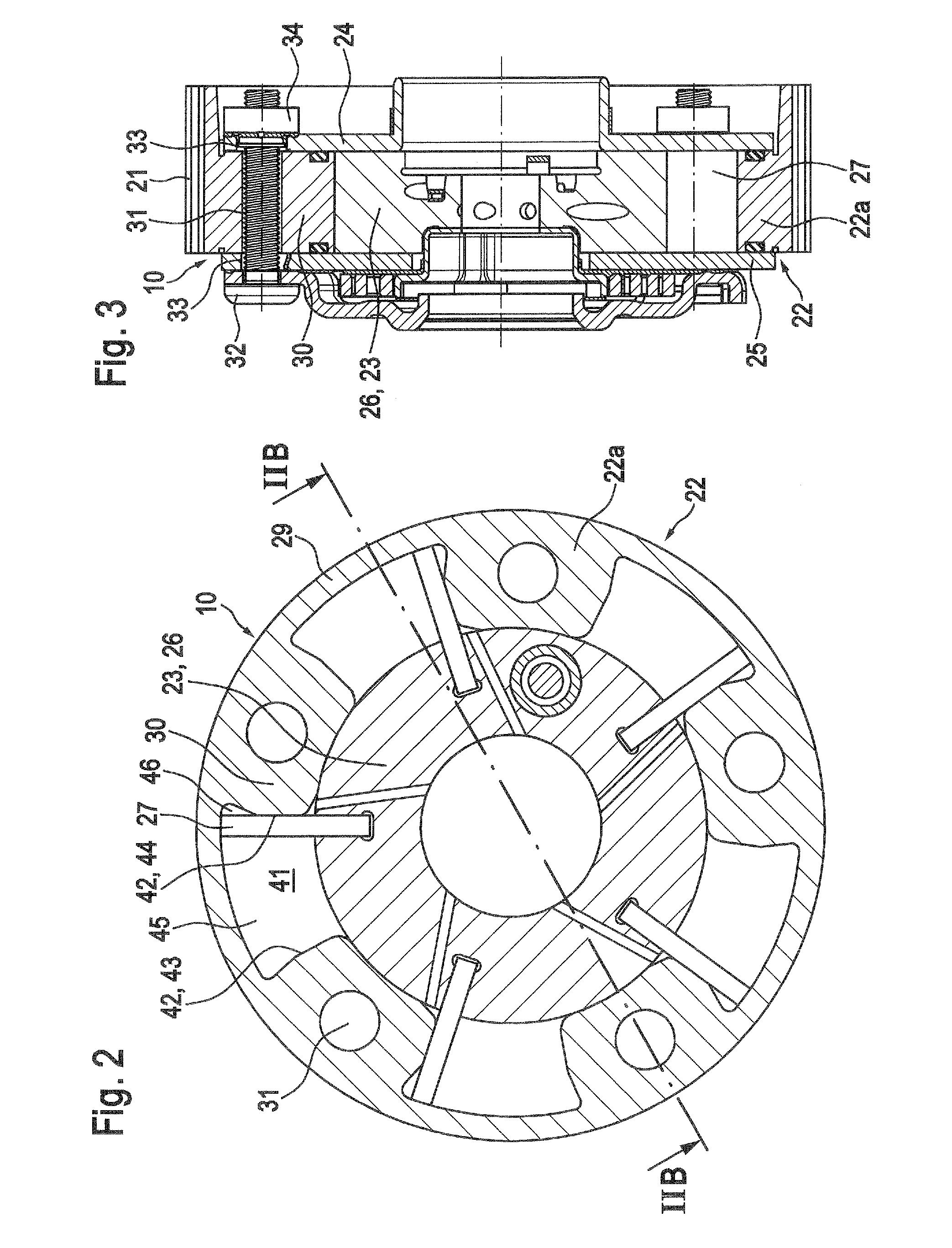

Apparatus for the variable setting of the control times of gas exchange valves of an internal combustion engine

ActiveUS20110314656A1Low costReduce weightValve arrangementsMachines/enginesExternal combustion engineEngineering

Owner:SCHAEFFLER TECH AG & CO KG

Dental machining unit with tool spindle

ActiveUS8845197B2Reduced effectNecessary stabilityRolling contact bearingsBearing assemblyEngineeringForce sensor

Owner:SIRONA DENTAL SYSTEMS

Burner having a protective element for ignition electrodes

ActiveUS20110120077A1Avoid deformationInhibit currentIncandescent ignitionElectric spark ignitersCombustorEngineering

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Filling joint arrangement for a flowable filling medium

InactiveUS20080064314A1Improve accessibilityNecessary stabilitySausage filling/stuffing machinesFirst FillEngineering

A filling joint arrangement for a filling medium which is capable of flow, in particular for a sausage meat, including a first filling pipe portion with a first filling pipe axis and a second filling pipe portion with a second filling pipe axis, wherein the second filling pipe portion is reversibly pivotable from a filling position in which the second filling pipe axis is aligned with the first filling pipe axis into a tilted position in which the second filling pipe axis is out of alignment with the first filling pipe axis, and further including a joint device which is disposed in filling medium-tight relationship between the first and the second filling pipe portions and which has a first joint receiving portion connected in filling medium-tight relationship to the first filling pipe portion and which includes a joint intermediate portion which has a third filling pipe portion with a third filling pipe axis and which is held pivotably by the first joint receiving portion in such a way that it is reversibly pivotable from the filling position into a tilted position in which the third filling pipe axis is out of alignment with the first filling pipe axis. It is further provided that there is a second joint receiving portion which is connected in filling medium-tight relationship to the second filling pipe portion and which together with the second filling pipe portion is reversibly pivotable with respect to the joint intermediate portion out of the filling position by way of a tilted intermediate position in which at least the third filling pipe axis is out of alignment with the first filling pipe axis into a tilted end position in which the second filling pipe axis is out of alignment with the third filling pipe axis.

Owner:POLY CLIP SYST

Rolling cover system motor mount

ActiveUS9346343B1Restrict movementNecessary stabilityRemovable external protective coveringsLoad coveringCovering systemEngineering

A motorized rolling cover system for covering the top of an open-top vehicle. The system includes a cover, a shaft, a motor assembly, an arm assembly and a motor mount that supports the motor assembly on the arm assembly. The motor mount is pivotally attached to the end of the arm assembly to provide pivotal movement of the mount in a single plane. The plane of pivotal movement is either the same as (i.e., parallel to) the plane defined by the arm and the shaft, or is perpendicular to the arm-shaft plane.

Owner:SHUR

Inductive sensor for a position measuring system, method of manufacturing inductive sensor, and position measuring system provided with inductive sensor

ActiveUS9605980B2Easy to manufactureSmall distanceLinear bearingsUsing electrical meansElectricityEngineering

An inductive sensor has an electrically nonconductive substrate, at least one electrically conducting coil that is integrally joined to the substrate, with the mechanical rigidity of the substrate significantly greater than that of the conducting coil, a metal plate covering the conducting coil, with the substrate comprised by the metal plate, and with the surface of the metal plate on the side oriented toward the conducting coil provided with an electrically insulating layer.

Owner:ROBERT BOSCH GMBH

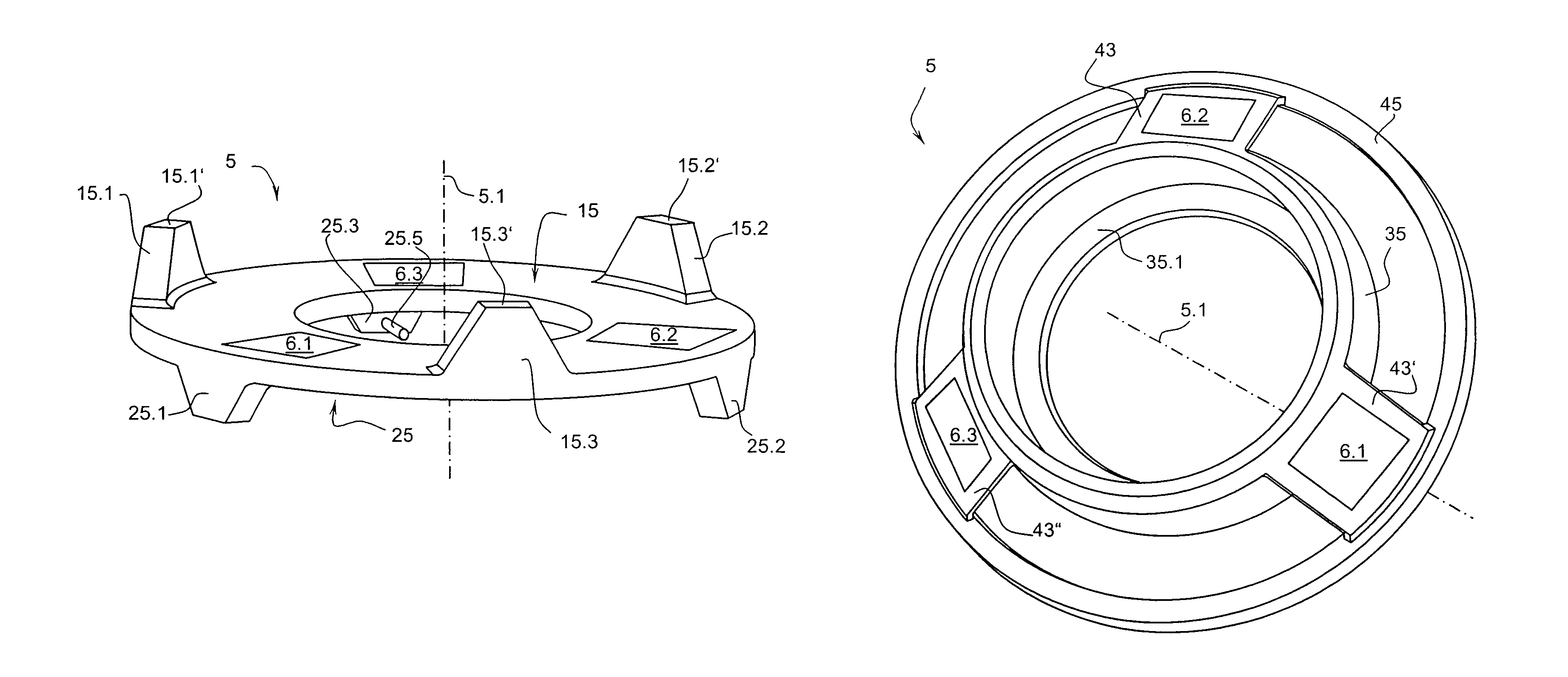

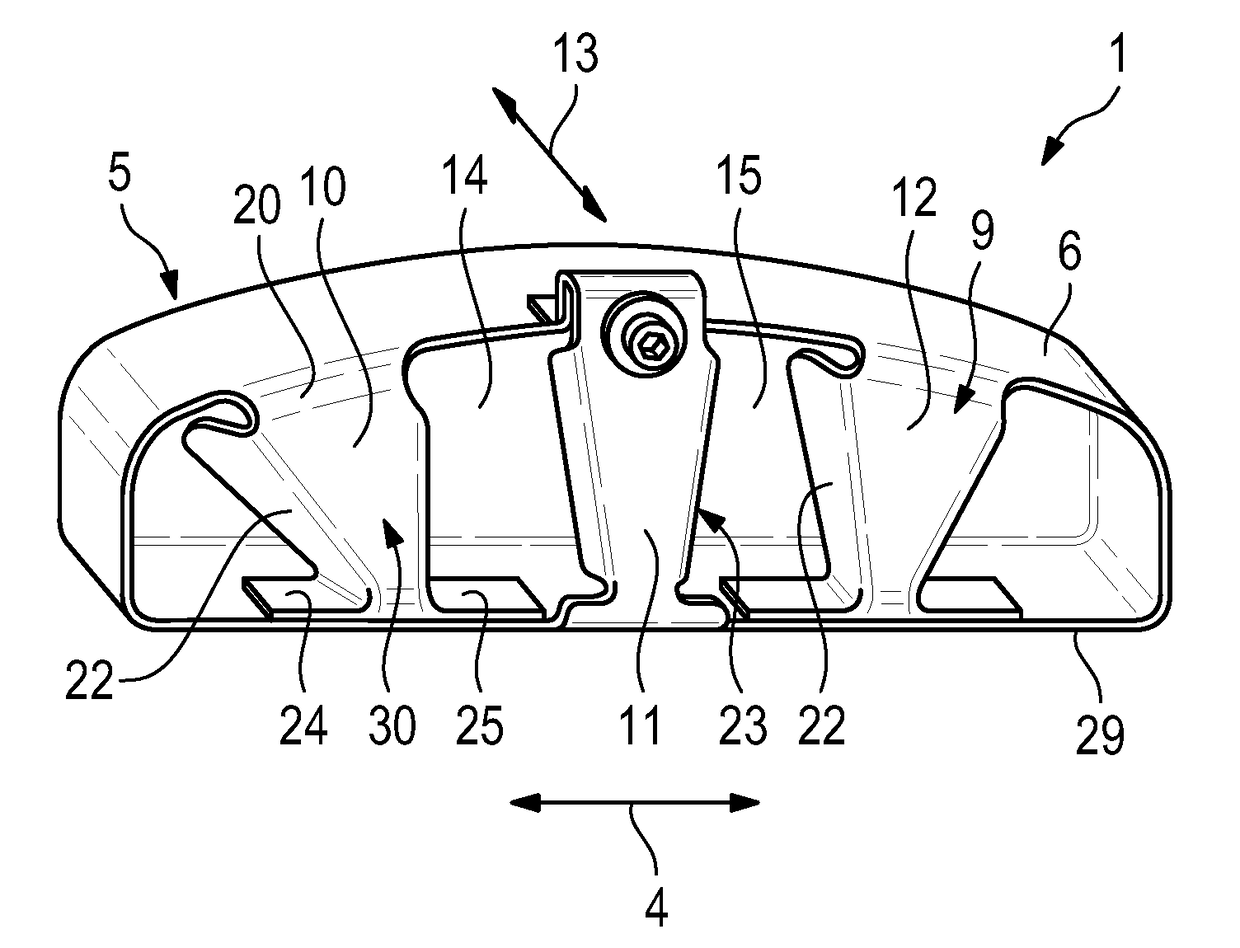

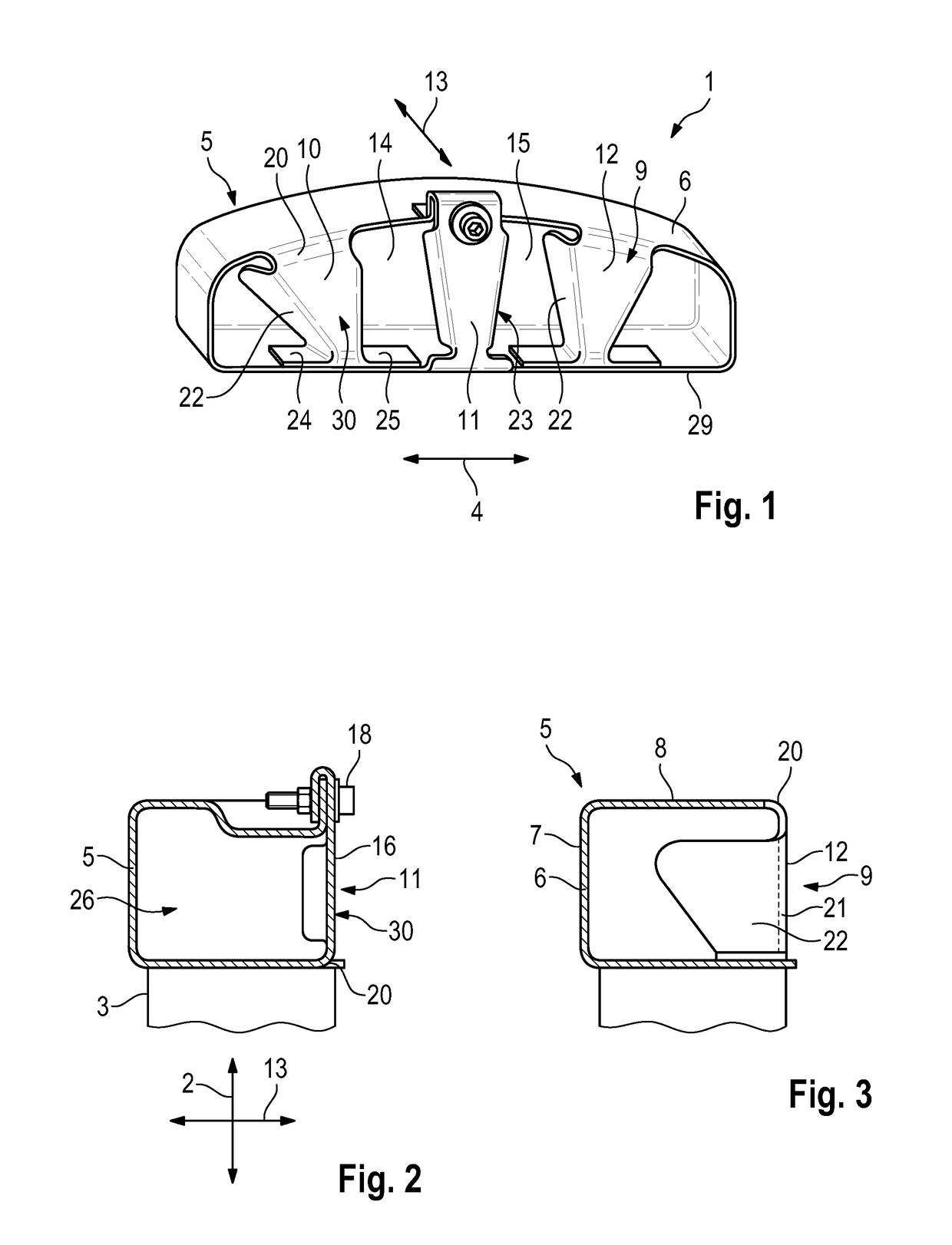

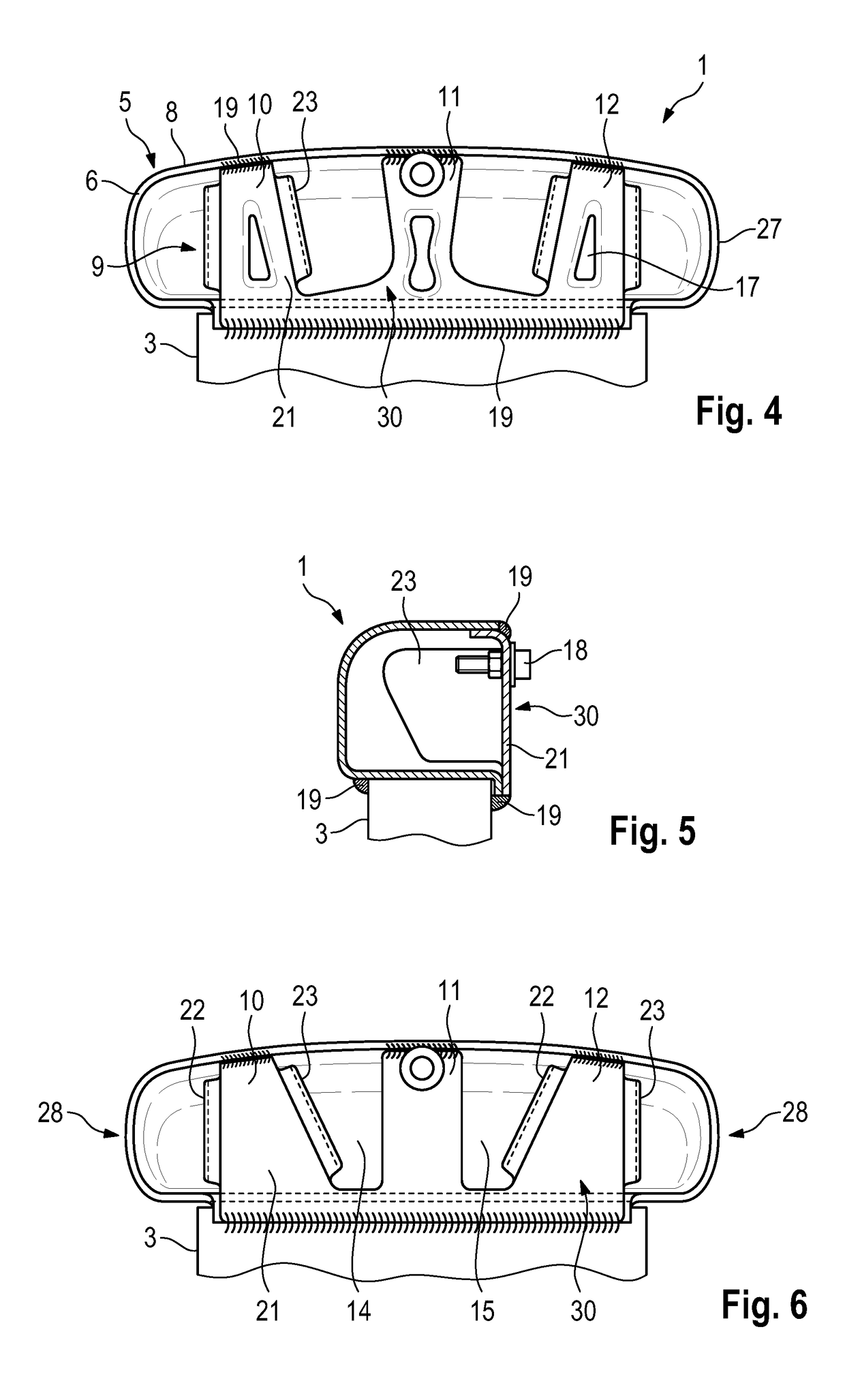

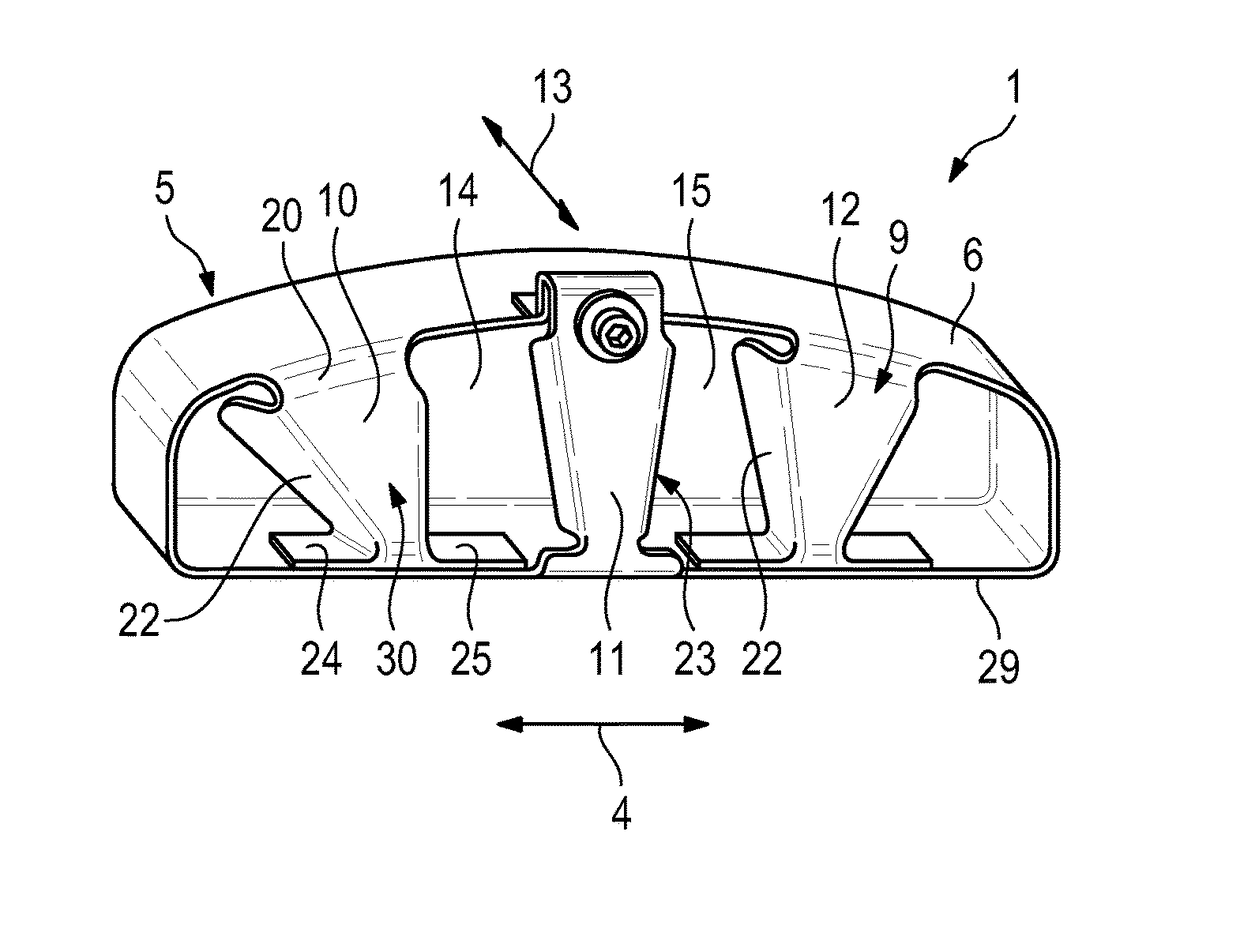

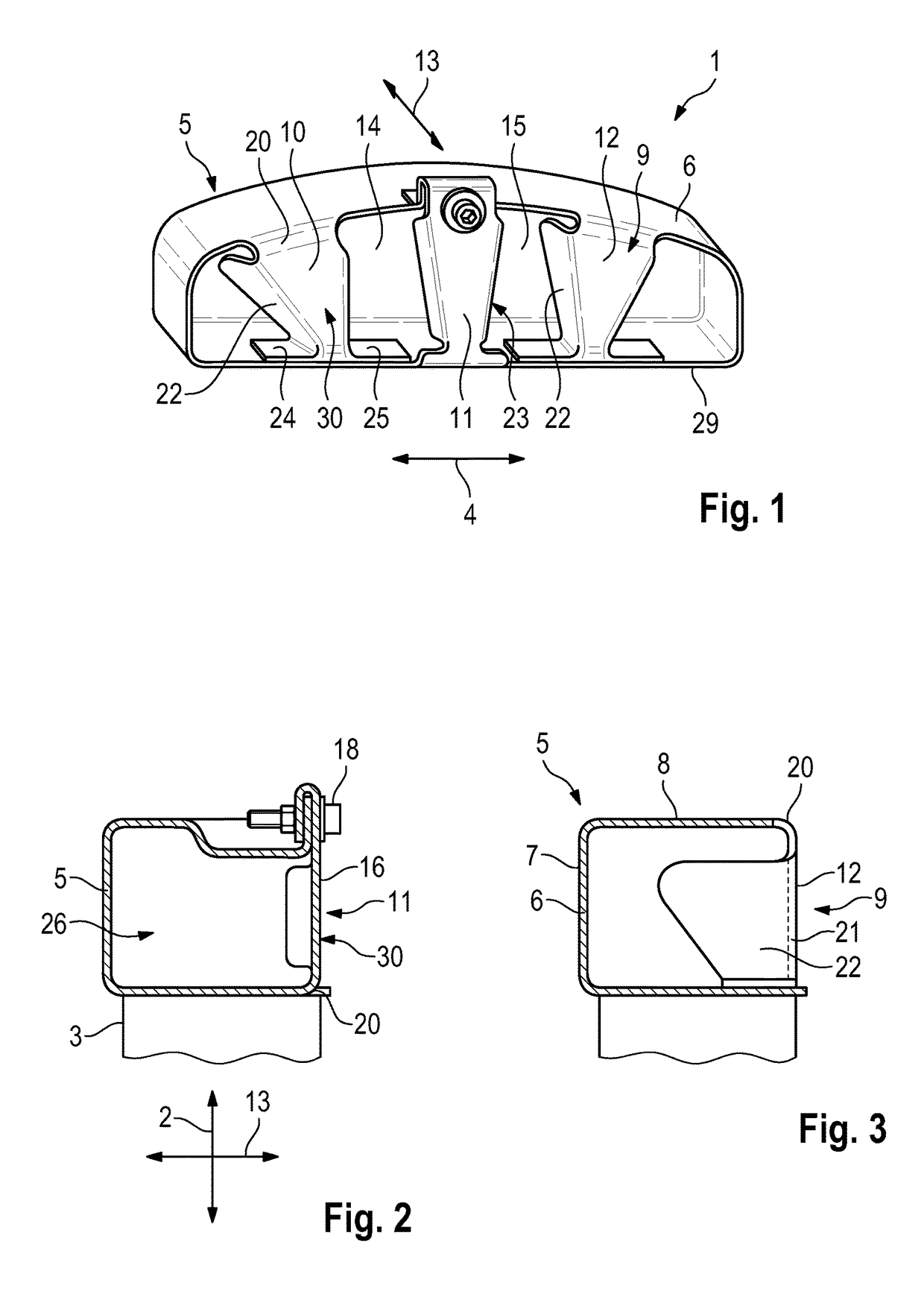

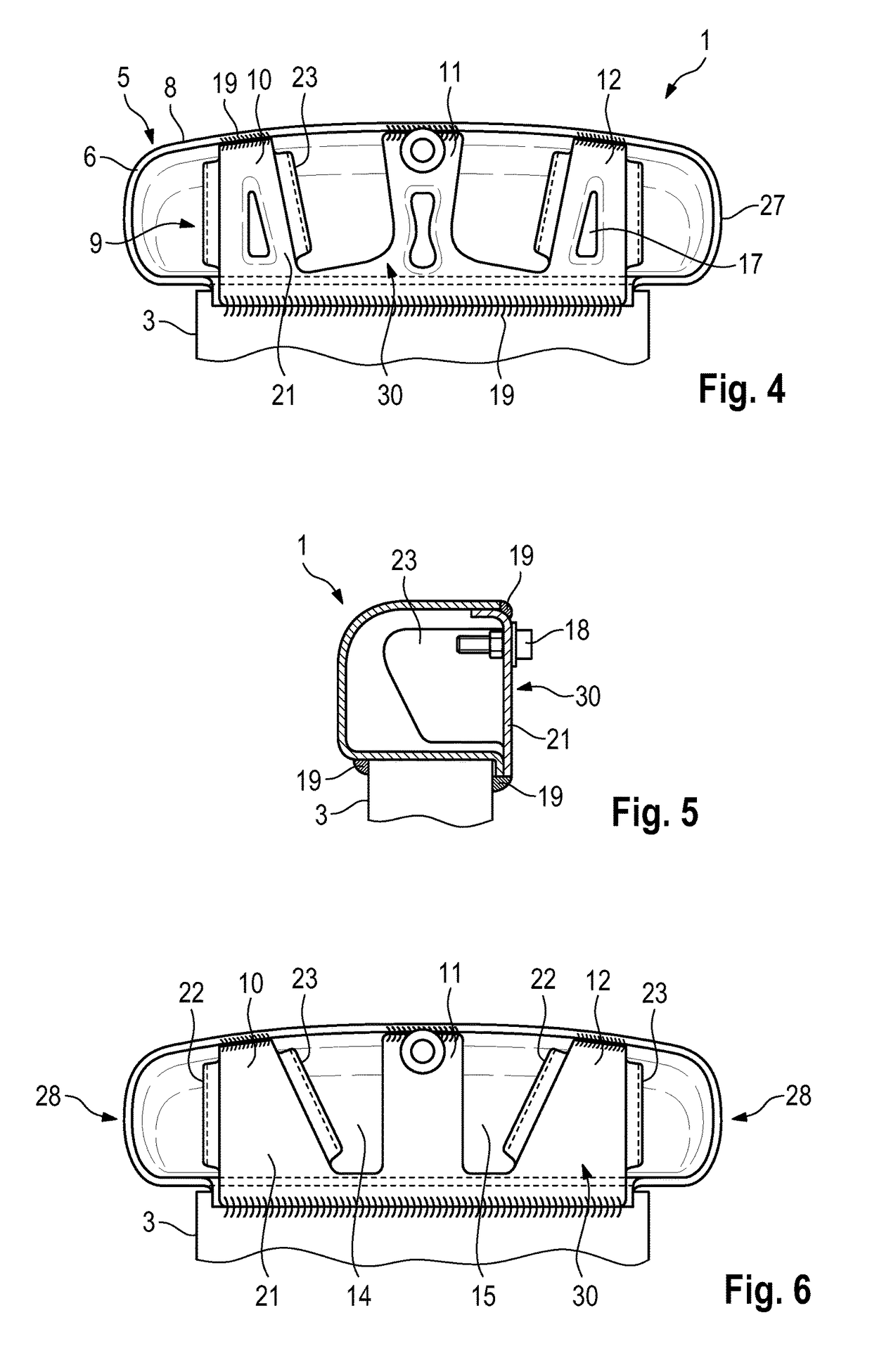

Rollover protective device

ActiveUS20170361799A1Improve overall utilizationImprove bending performancePedestrian/occupant safety arrangementVehicle sub-unit featuresRolloverMechanical engineering

A rollover protective device (1) for a passenger vehicle has a supporting device (3) extending in the vertical elevation (2) when installed correctly. A crossbar (5) is fastened to the supporting device (3) and extends in a lateral direction (4) when installed correctly. The crossbar (5) is of beam-shaped design and is formed by a sheet metal construction (6) with a deformed front side and / or upper side (7, 8) and an inner supporting structure (9).

Owner:DR ING H C F PORSCHE AG

Method for encasing a body of an exhaust gas system

ActiveUS20130202887A1Possible to moveAvoid corrosionExhaust apparatusSilencing apparatusConductor CoilMechanical engineering

A method for encasing a body of an exhaust gas system with a housing which is wound around the body. Using a winding method, the body is placed in a loop formed by a belt-shaped conveyor element that can be driven in a conveyor device, wherein the conveyor element is seated against the outer casing face at a wrapping angle u of at least 270 degrees. Starting with a first edge, the metal strip is then introduced in a conveyor device between the body and the conveyor element, is drawn into the gap between the body and the conveyor element and is bent around the body until the body is encased at least twice by the metal strip.

Owner:TENNECO

Rearview mirror assembly for motor vehicles

InactiveUS7370984B2Convenient lightingNecessary stabilityPicture framesDomestic mirrorsRear-view mirrorMechanical engineering

Owner:LANG MEKRA NORTH AMERICA LLC

Traffic monitoring apparatus

ActiveUS9297126B2Easy to assembleImprove stabilityDetection of traffic movementEmbedding padsEngineeringVertical axis

Owner:VITRONIC DR ING STEIN BILDVERARBEITUNGSSYST

Rollover protective device

ActiveUS9956934B2Considerable forceNecessary stabilityPedestrian/occupant safety arrangementVehicle sub-unit featuresRolloverEngineering

A rollover protective device (1) for a passenger vehicle has a supporting device (3) extending in the vertical elevation (2) when installed correctly. A crossbar (5) is fastened to the supporting device (3) and extends in a lateral direction (4) when installed correctly. The crossbar (5) is of beam-shaped design and is formed by a sheet metal construction (6) with a deformed front side and / or upper side (7, 8) and an inner supporting structure (9).

Owner:DR ING H C F PORSCHE AG

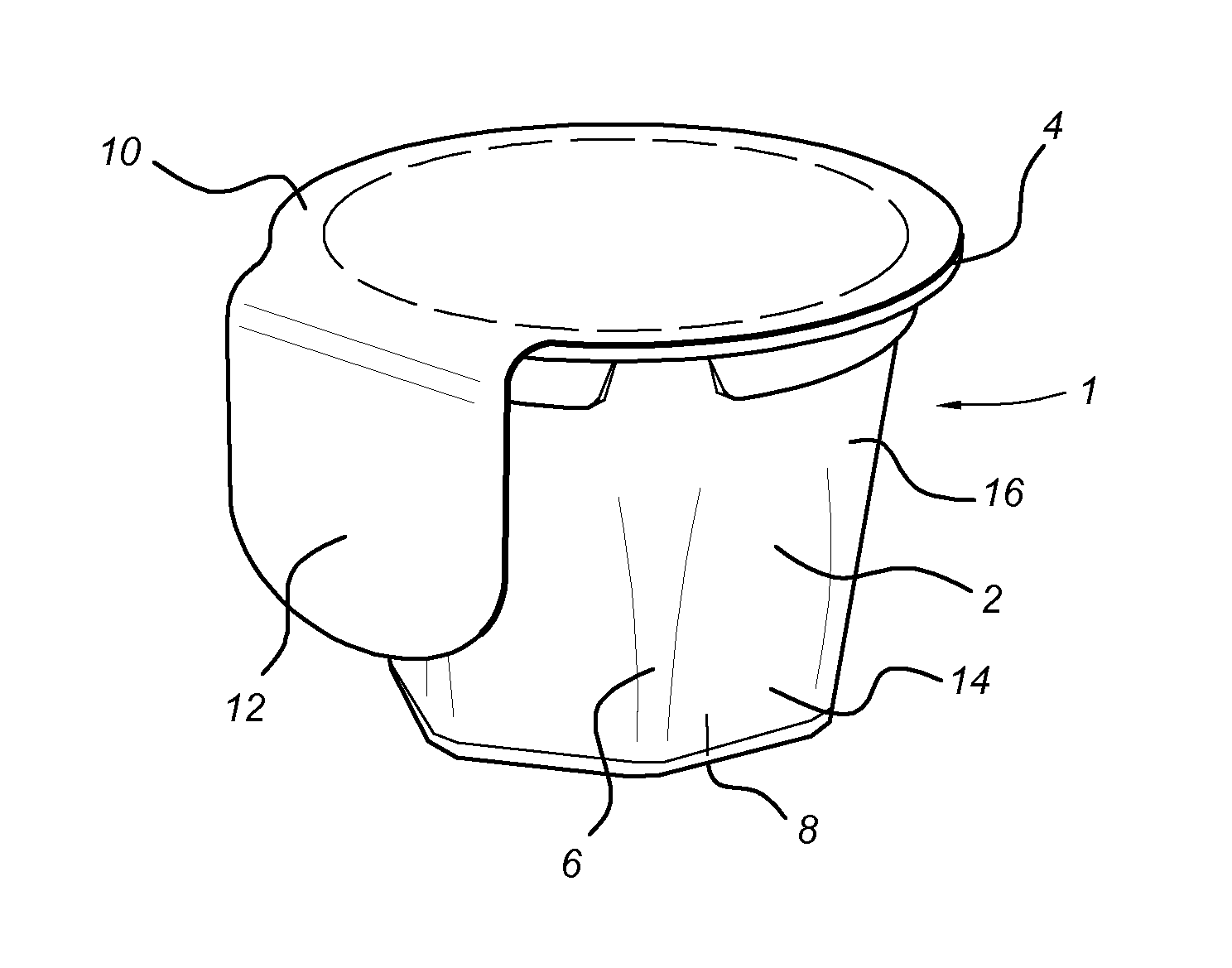

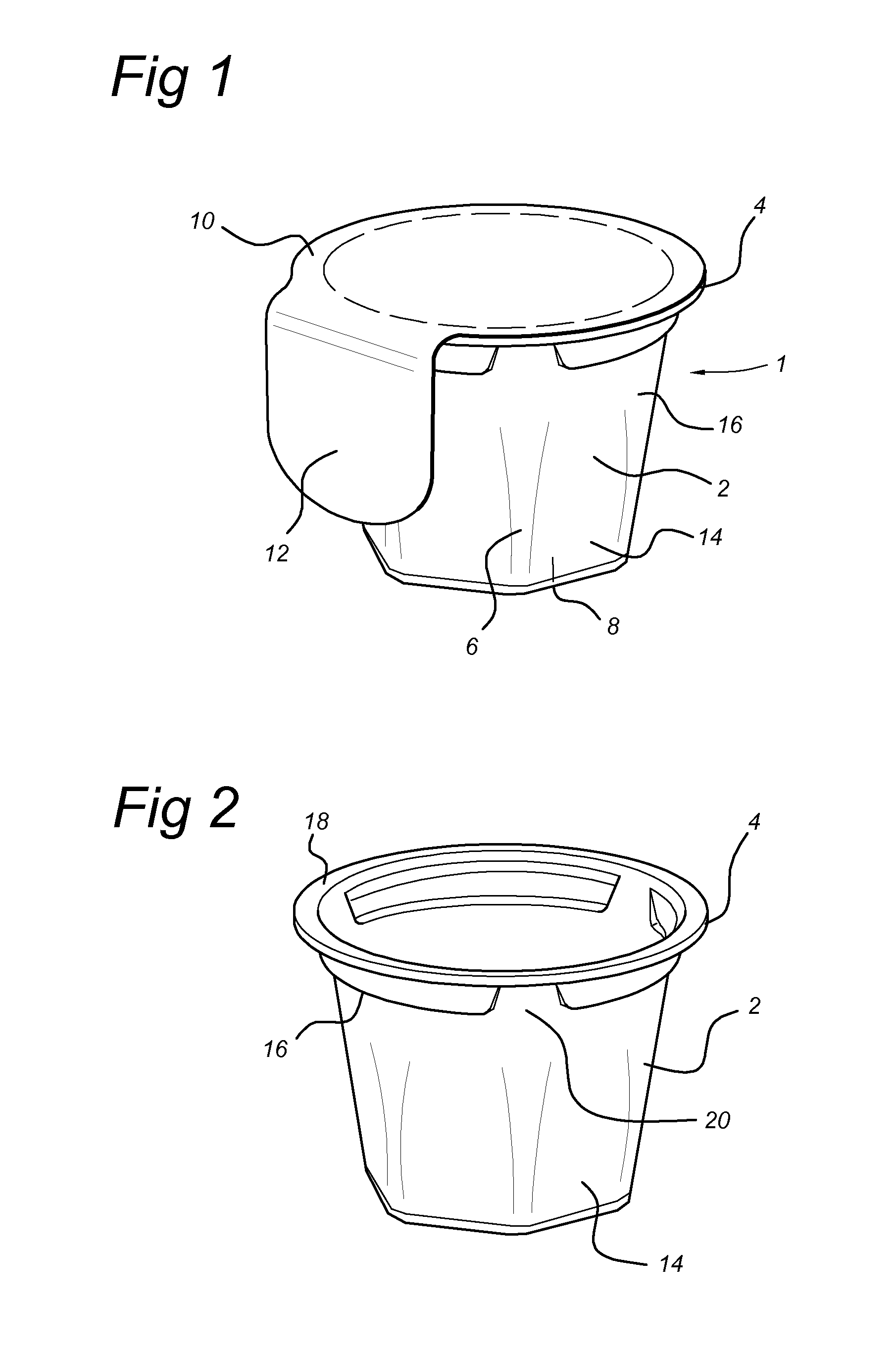

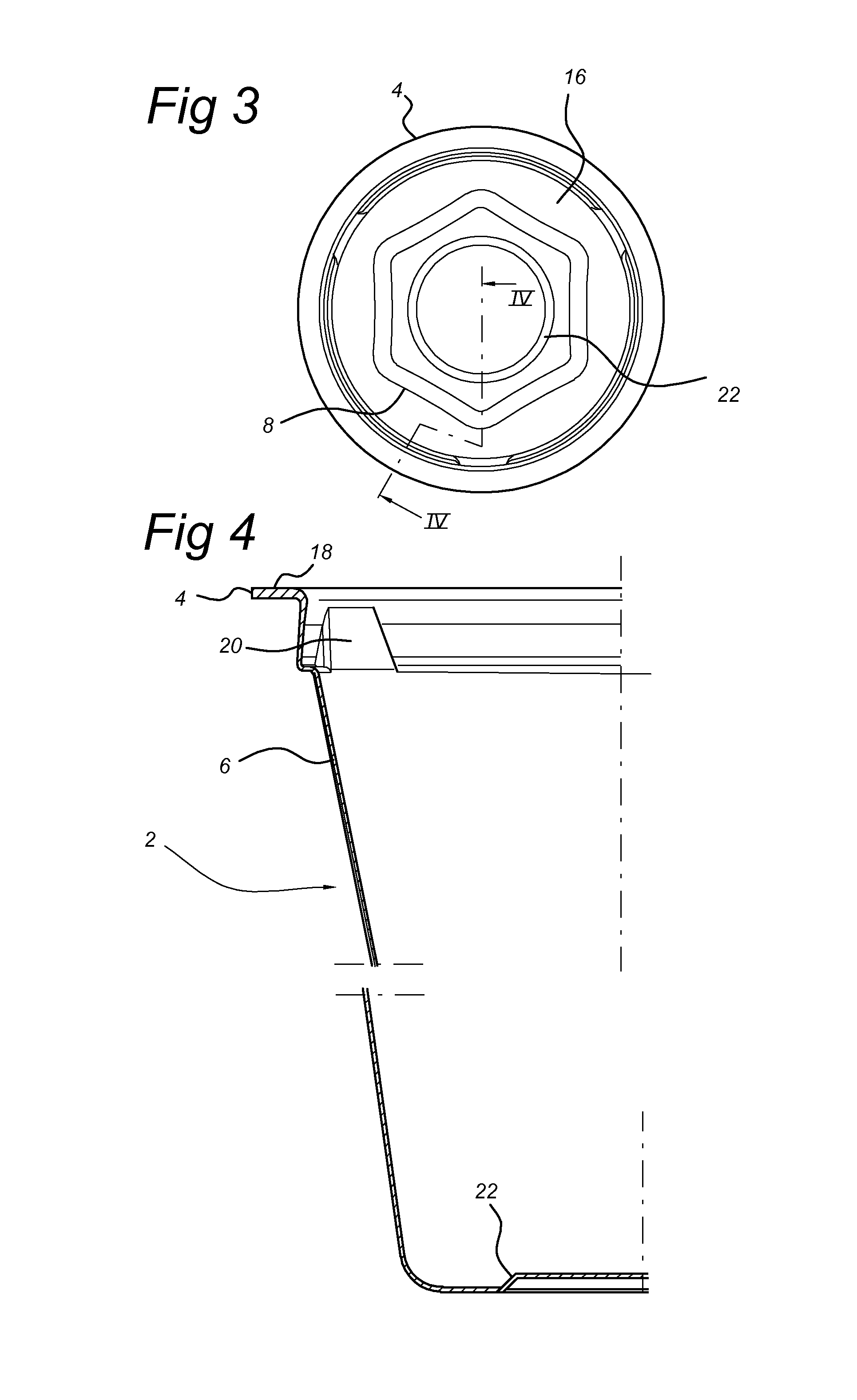

Unit dose package for nutritional product

InactiveUS20140328979A1Increase the area ratioImprove barrier propertiesReady-for-oven doughsSynthetic resin layered productsOxygen transmission rateNutritional products

A unit dose package of a liquid nutritional product comprises a form-stable, cup shaped container with a capacity of less than 70 ml having a rim, a frustoconical sidewall and a base. A quantity of the nutritional product is enclosed within the container and a foil closure is sealed to the rim. The container is formed of a laminate comprising a barrier layer of highly 5 orientable EVOH having an ethylene content of less than 31 mol %, preferably around 27 mol %, and an oxygen transmission of less than 0.0068 ml / ml / year, between an inner carrier layer and an outer carrier layer. The package is especially adapted for long term storage of oxygen sensitive products.

Owner:NUTRICIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com