Protective layer for lithium sulphur battery, preparation method thereof and lithium sulphur battery using protective layer

A lithium-sulfur battery and protective layer technology, applied in the field of electrochemistry, can solve the problems that the shuttle effect is still obvious and the improvement effect is limited, and achieve the effects of improving Coulombic efficiency, low cost, and improving ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

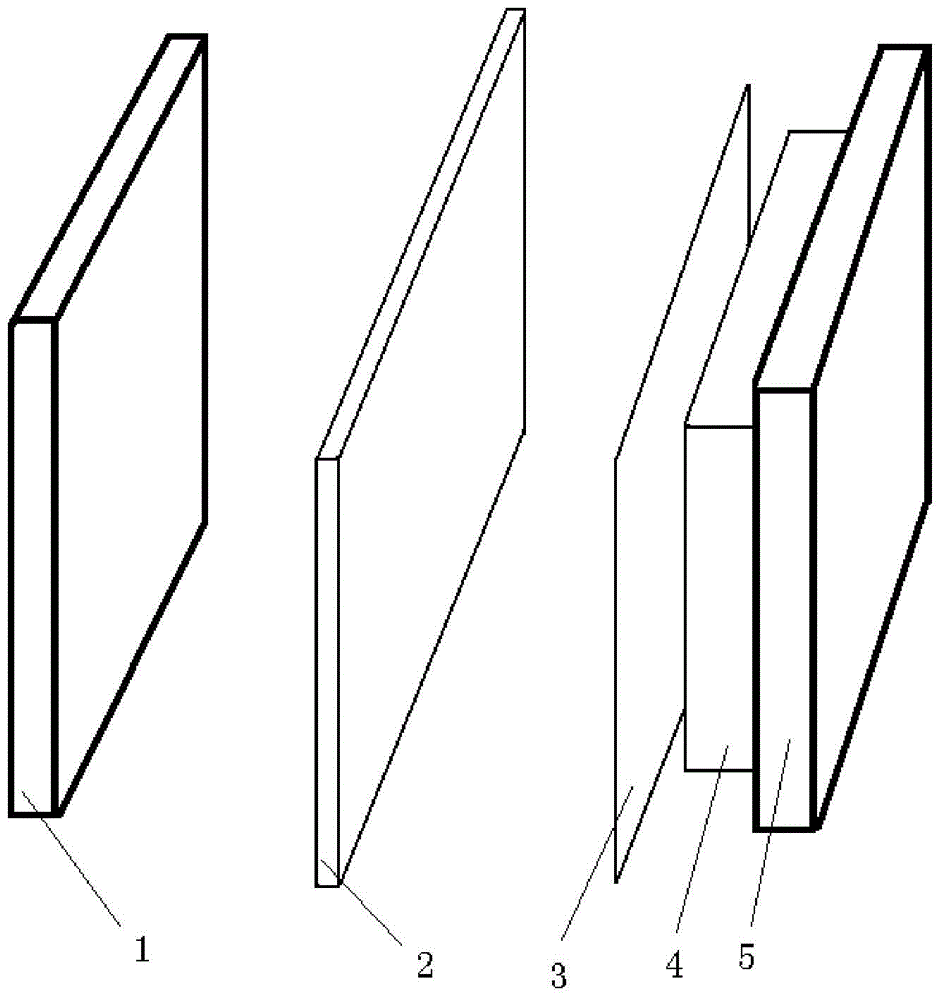

[0031] The protective layer preparation method of the present invention comprises the following steps:

[0032] 1) First take graphene oxide or graphene, and make it uniformly dispersed in a solvent or solution by means of stirring, ultrasonication and heating. The solvent is water, ethanol, propanol, N-methylpyrrolidone, acetone, dichloromethane, N , N-dimethylformamide or tetrahydrofuran; the solution is potassium hydroxide aqueous solution or sodium hydroxide aqueous solution;

[0033] Then add a modifier, the modifier is hydrofluoric acid, hydrochloric acid, sulfuric acid, nitric acid, polyethylene glycol, polyvinyl alcohol, ammonia water, hydrazine hydrate, hydrazine, ethylenediamine, triisopropanolamine, octadecylamine , N,N-dicyclohexylcarbodiimide, 3-aminopropyltriethoxysilane, acetic acid, chloroacetic acid, chlorosulfonic acid, thionyl chloride, propionic acid, potassium permanganate, sodium cyanide, Hydrogen cyanide, potassium cyanide, hydrogen thiocyanide, sodium ...

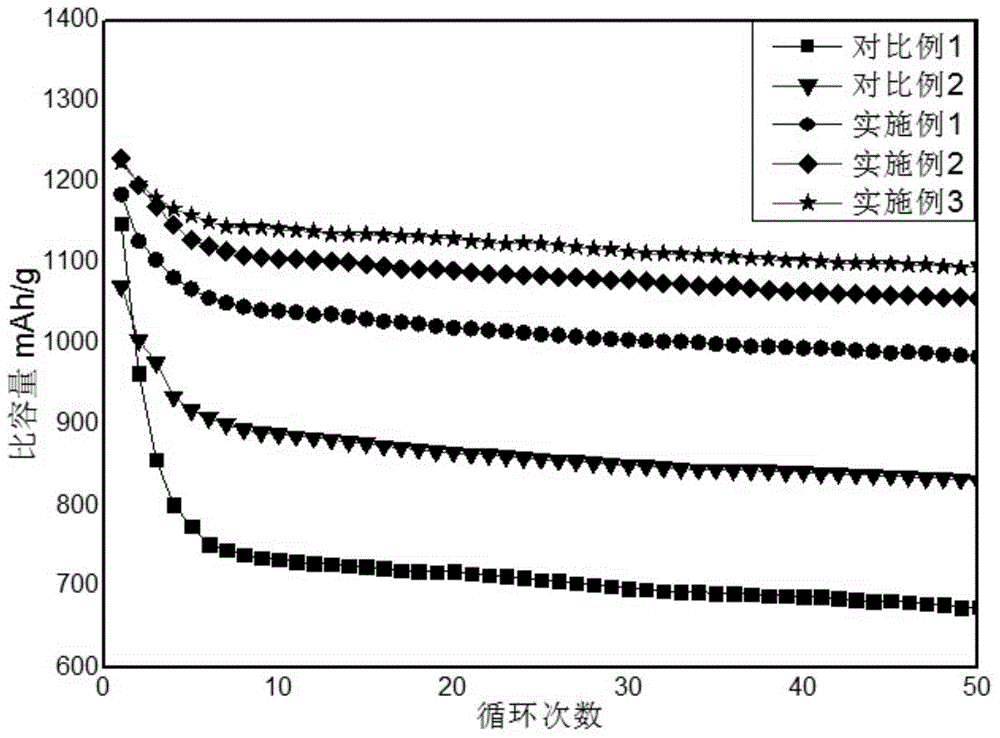

Embodiment 1

[0058] (1) Preparation of cathode composite material:

[0059] Weigh 10g of superconducting black (Super P) and place it in a flask, add 240mL of concentrated nitric acid dropwise into the flask, mix well, heat in a water bath to 80°C, keep the temperature for 3 hours, cool to room temperature, wash and filter to obtain modified superconducting black (m -Super P). Take 1g m-Super P, 0.1g polyethylene glycol (PEG) and 200mL deionized water and heat to 50°C, then add 20mL concentrated sulfuric acid and mix well, and keep the temperature at 60°C for 10h; then add 40mL concentrated sulfuric acid, dropwise A certain amount of Na 2 S and Na 2 SO 3 After the dropwise addition, continue to stir for 30 minutes, filter with suction, dry for subsequent use, and obtain the modified superconducting black / sulfur composite material (m-Super PS);

[0060] (2) Preparation of positive pole piece:

[0061] Mix m-Super PS, acetylene black, and LA132 uniformly in an aqueous solution at a mass...

Embodiment 2

[0072] (1) The preparation of positive electrode composite material, the preparation of positive pole sheet and the preparation method of graphene oxide are the same as in Example 1;

[0073] (2) Preparation of hydroxy-modified graphene:

[0074]Take 0.5g of graphene oxide and disperse it in 125mL of deionized water, after ultrasonic stirring for 1h, slowly add 2.5mL of 50% hydrazine hydrate dropwise, then reflux at 100°C for 24h; after the reflux, add 4g of 2-( 4-amino-phenyl)ethanol and 3mL isoamyl nitrite, continue to stir at 80 ° C, fully react, after the reaction is completed, cool to room temperature, the suspension is filtered with a microporous membrane, and excess deionized water and Washing with DMF, finally washing 3 times with acetone, and drying to obtain hydroxyl-modified graphene;

[0075] (3) Preparation of protective layer:

[0076] Hydroxyl-modified graphene is selected as the adsorption material of the protective layer, gelatin is used as the adhesive, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com