Long-life anode electrode material and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

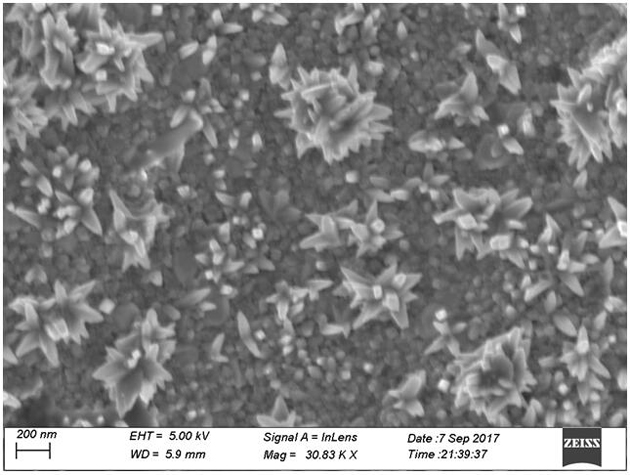

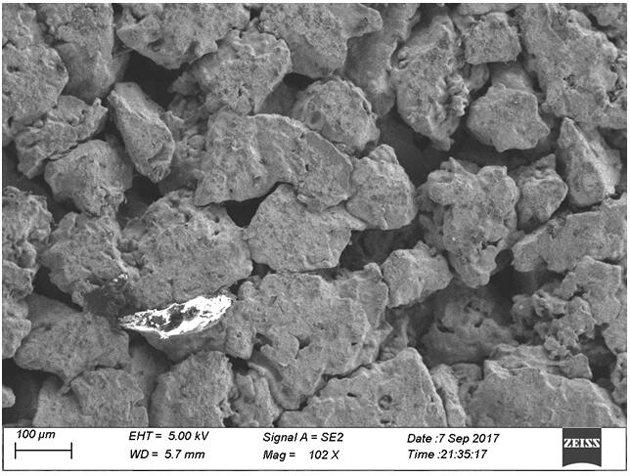

Image

Examples

Embodiment 1

[0046] Prepare a hydrochloric acid solution with a mass fraction of 15%, put it into a water bath and heat it to 80°C, weigh the cut porous titanium, and then etch it for 120min. After taking it out, clean it ultrasonically and dry it. The porous titanium was transferred to an atmosphere furnace, a mixture of hydrogen and argon was introduced (the volume fraction of hydrogen was 5%), the temperature was programmed to 600°C, and after thermal reduction for 1 h, it was naturally cooled to room temperature.

[0047] Transition layer: Weigh tin tetrachloride to make 200mM ethylene glycol, oxalic acid, acetone solution (volume fraction, 80% ethylene glycol, 15% acetone, 5% oxalic acid), and stir for more than 24 hours. Lay the etched titanium sheet flat, dip the tin salt solution with a wool brush and brush it on the surface of the titanium sheet. After the solvent evaporates, transfer the loaded titanium sheet to a muffle furnace, control the temperature at 400°C, and heat After ...

Embodiment 2

[0050] Prepare a solution of oxalic acid with a mass fraction of 15%, put it into a water bath and heat it to 80°C, weigh the cut porous titanium, and perform etching for 120 minutes. After taking it out, clean it ultrasonically and dry it. The porous titanium was transferred to an atmosphere furnace, a mixture of hydrogen and nitrogen was introduced (the volume fraction of hydrogen was 7%), the temperature was programmed to rise to 600 °C, and after thermal reduction for 1 h, it was naturally cooled to room temperature.

[0051] Transition layer: Weigh manganese dichloride to make 200mM ethylene glycol, oxalic acid, acetone solution (volume fraction, 80% ethylene glycol, 15% propanol, 5% acetic acid), and stir for more than 24 hours. Lay the etched titanium sheet flat, dip the tin salt solution with a wool brush and brush it on the surface of the titanium sheet. After the solvent evaporates, transfer the loaded titanium sheet to a muffle furnace, control the temperature at 40...

Embodiment 3

[0054] Prepare a nitric acid solution with a mass fraction of 15%, put it into a water bath and heat it to 80°C, weigh the cut porous titanium, and then etch it for 120min. After taking it out, clean it ultrasonically and dry it. The porous titanium was transferred to an atmosphere furnace, and a mixture of carbon monoxide and argon (the volume fraction of carbon monoxide was 3%) was introduced, and the temperature was programmed to rise to 600°C. After thermal reduction for 1 h, it was naturally cooled to room temperature.

[0055] Transition layer: Weigh cobalt dichloride to make 200mM ethylene glycol, acetone, oxalic acid solution (volume fraction, 80% ethylene glycol, 15% acetone, 5% oxalic acid), and stir for more than 24 hours. Lay the etched titanium sheet flat, dip the tin salt solution with a wool brush and brush it on the surface of the titanium sheet. After the solvent evaporates, transfer the loaded titanium sheet to a muffle furnace, control the temperature at 400...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com