Patents

Literature

38results about How to "Comfortable access" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

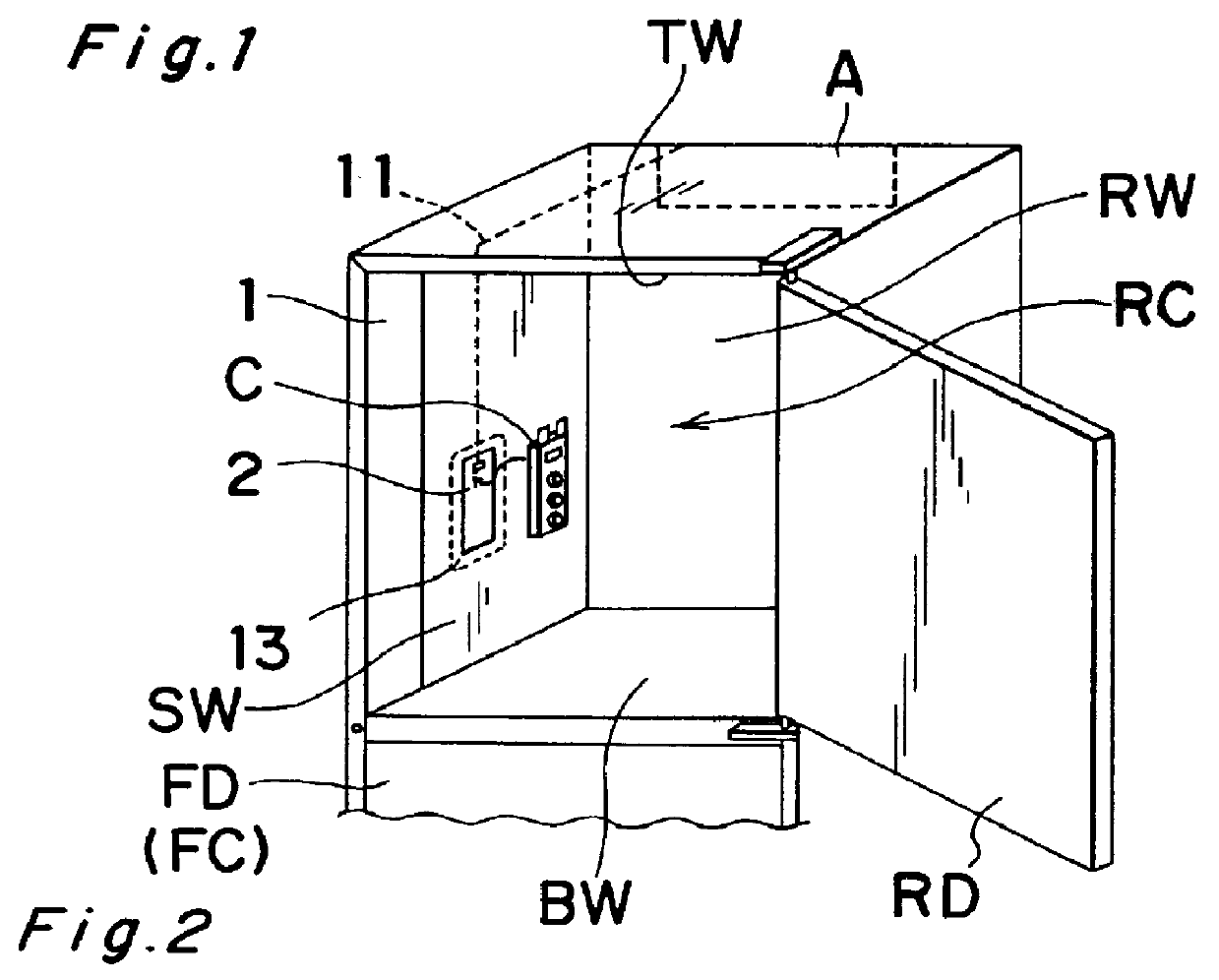

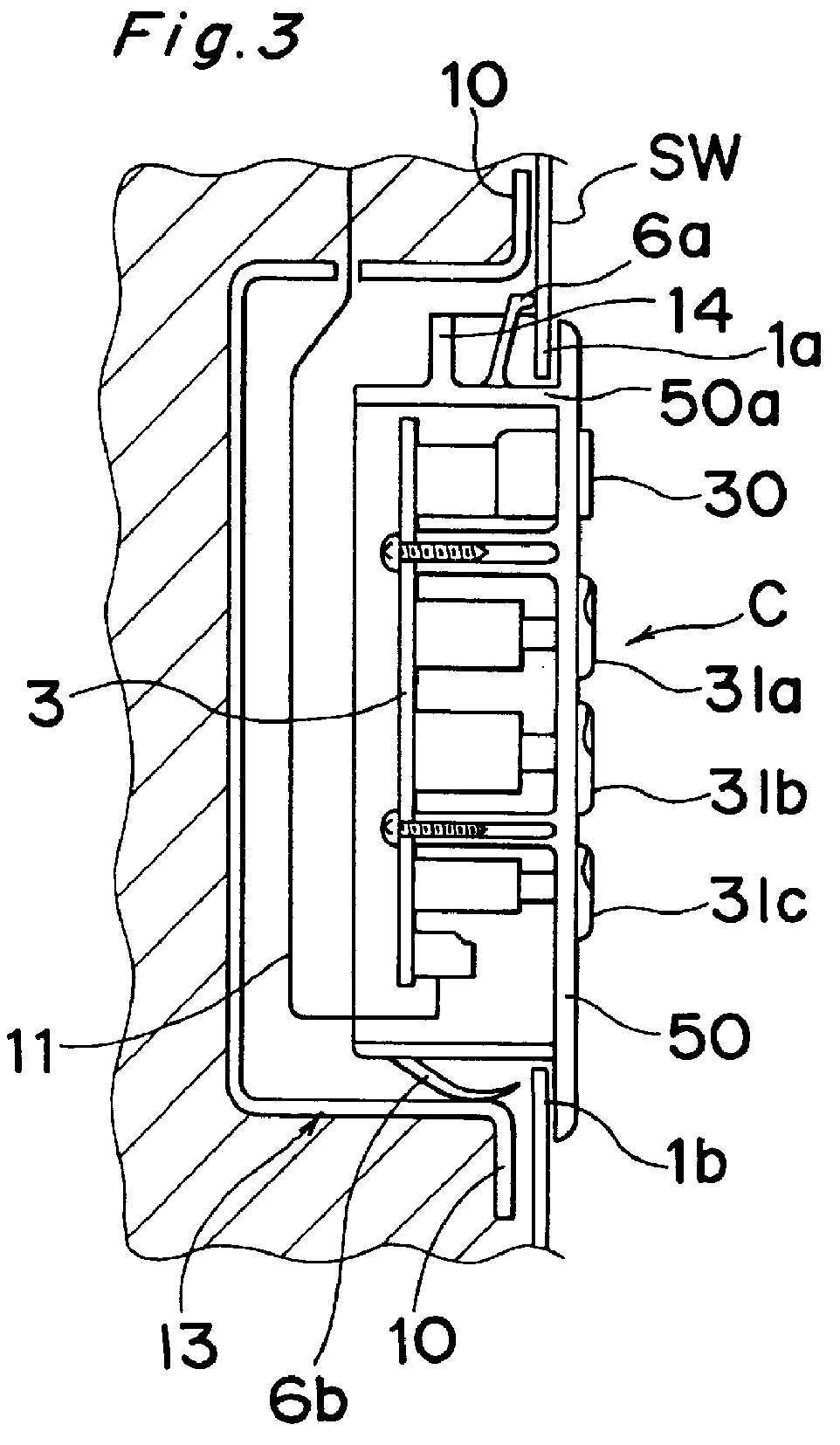

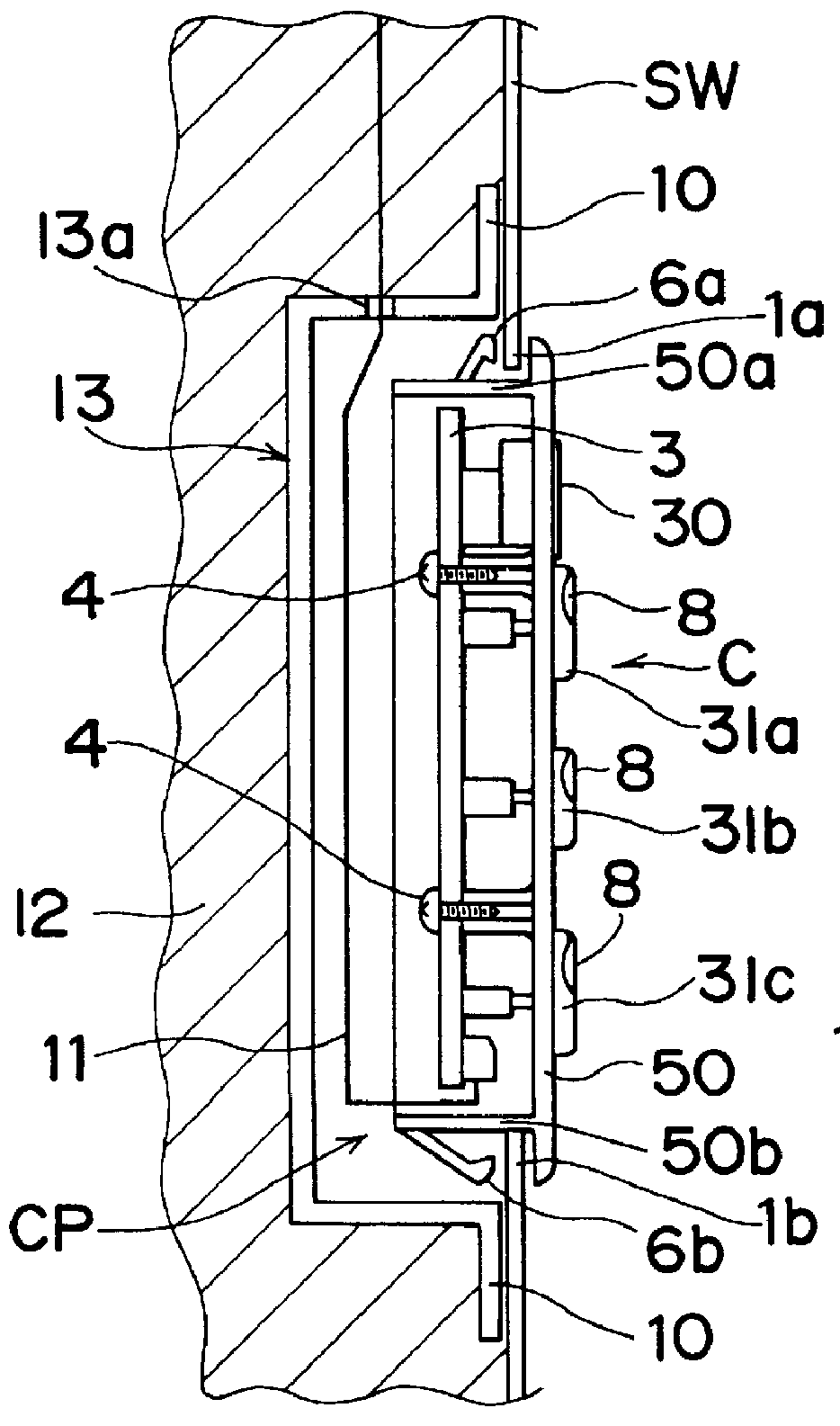

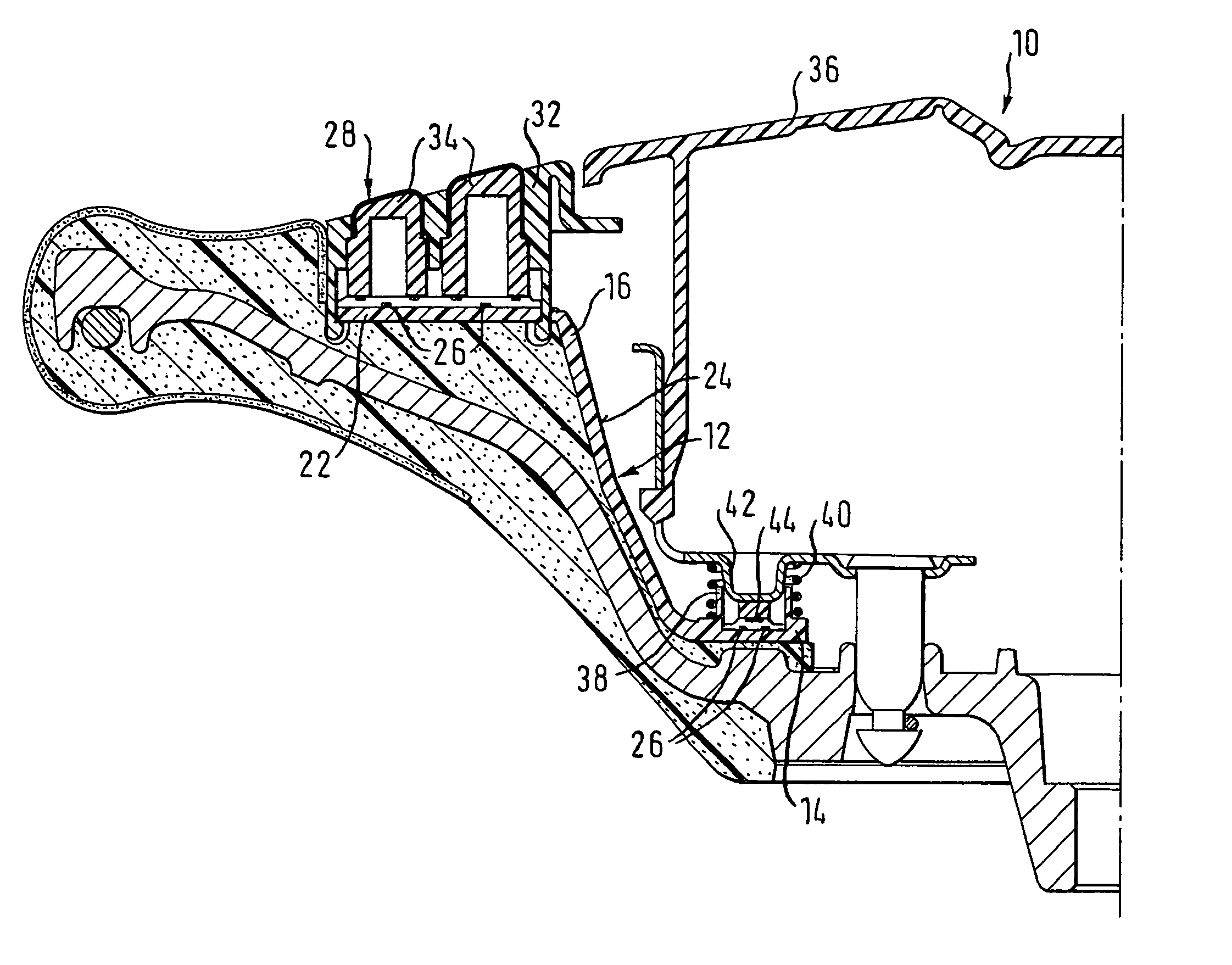

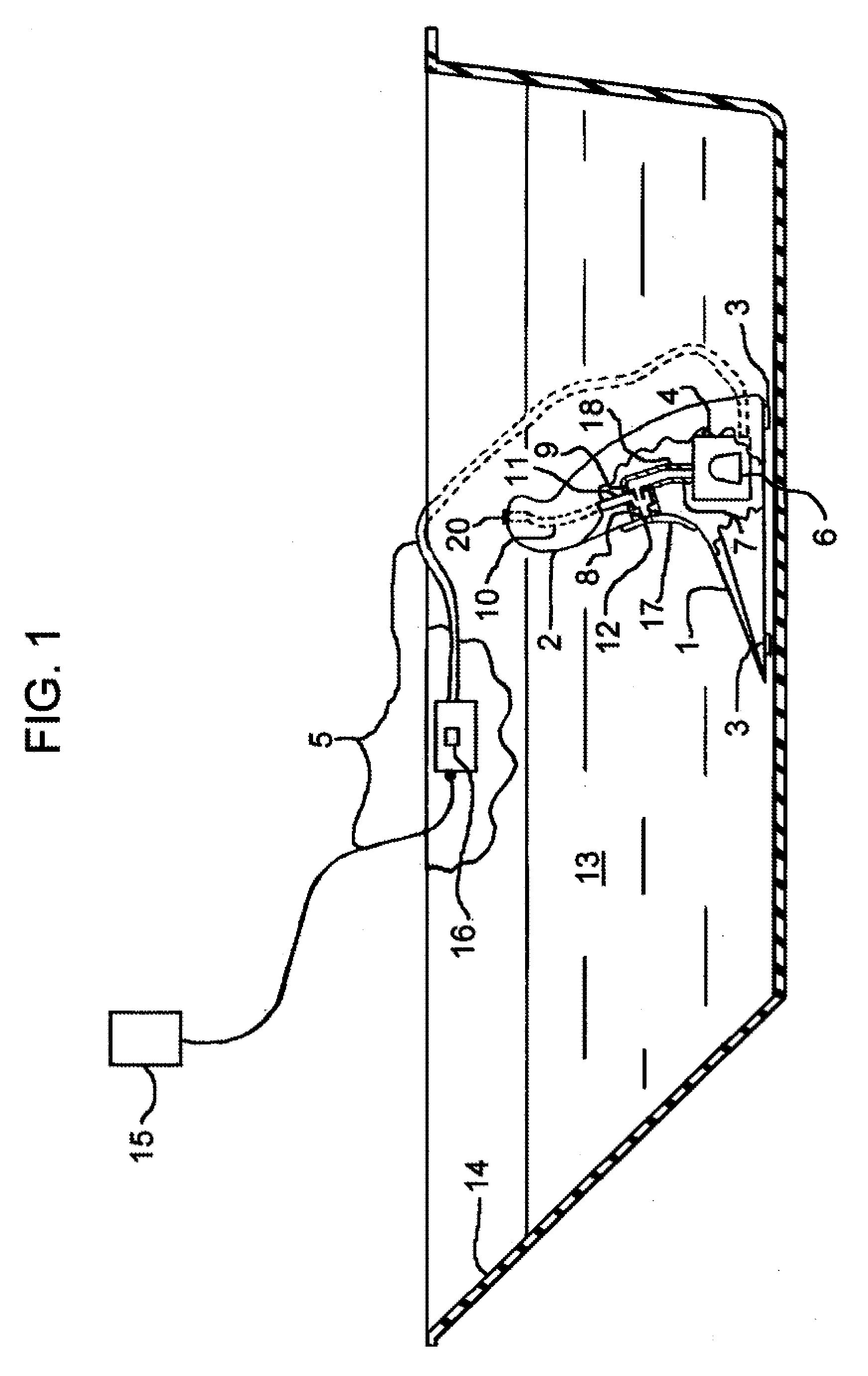

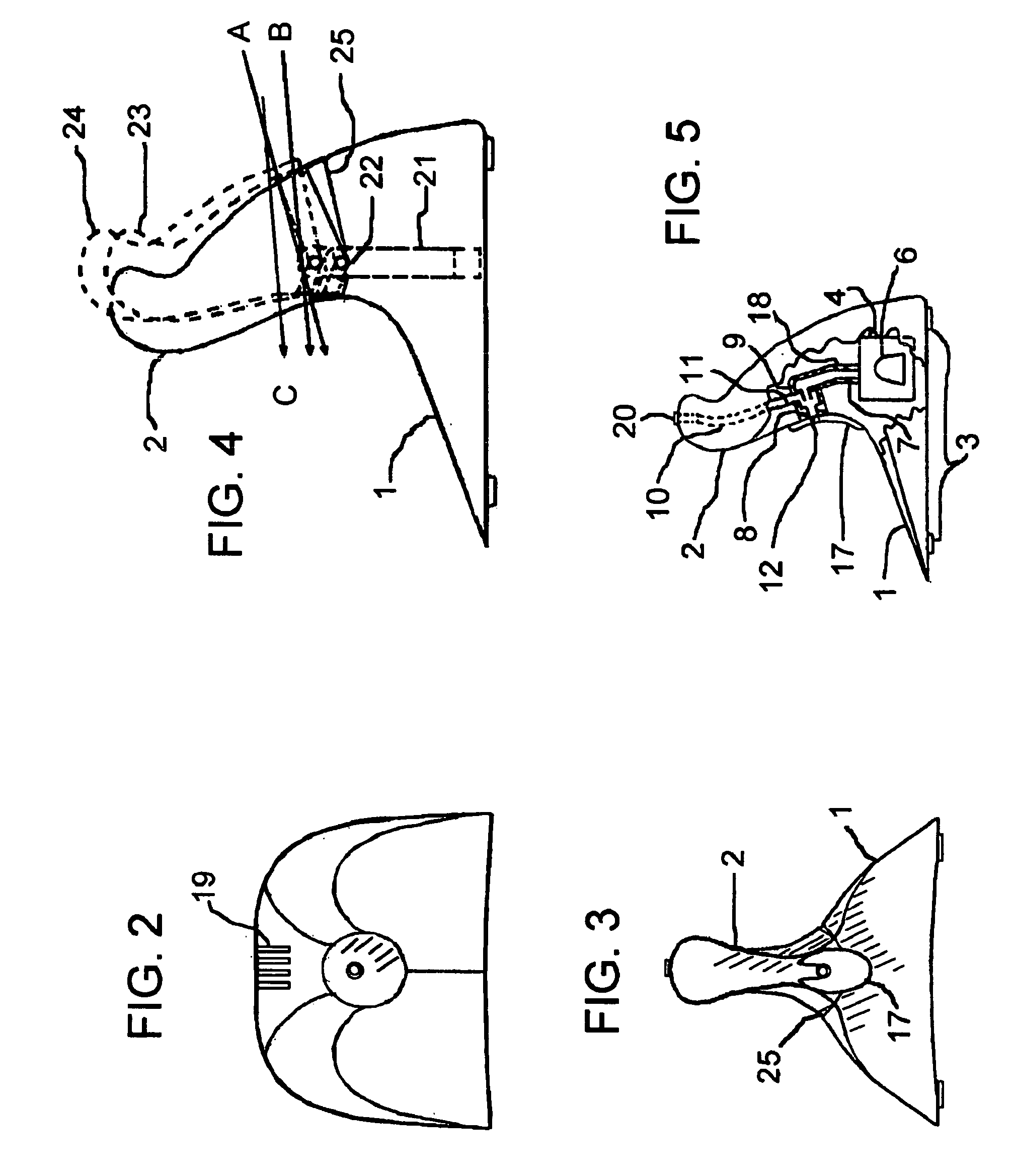

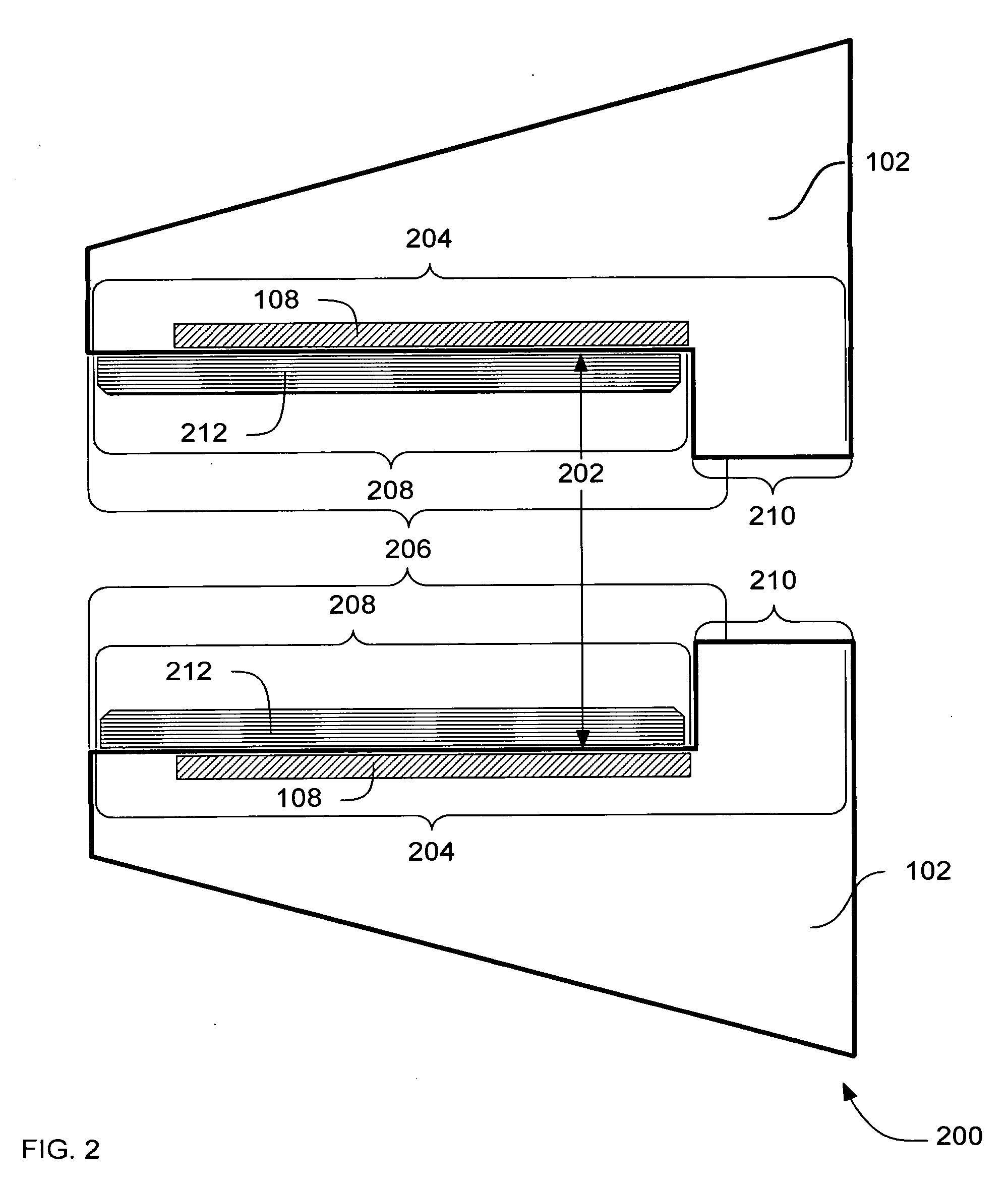

Temperature control device for refrigerators

InactiveUS6101819ASimple structureEasy to installThermal switch detailsRefrigeration safety arrangementTemperature controlEngineering

PCT No. PCT / JP97 / 02737 Sec. 371 Date Sep. 15, 1998 Sec. 102(e) Date Sep. 15, 1998 PCT Filed Aug. 6, 1997 PCT Pub. No. WO98 / 05911 PCT Pub. Date Feb. 12, 1998A temperature control device is provided in a refrigerator having at least one compartment (RC or FC) defined by top, bottom and opposite side walls (TW; BW; and SW), and a heat insulating material (12) exteriorly encircling the compartment. One of the side walls (SW) has a mounting hole (2) defined therein and a front surface thereof confronts the compartment (RC or FC). The device includes a box-like console (C), and a circuit carrier board (3) fixedly connected to a rear surface of the console (C). Electric wiring (11) extends outwardly from the circuit carrier board, and a display panel (30) is disposed on a front surface of the console (C). At least one manipulatable temperature control element (31a, 31b, 31c: PB, LED) is mounted on the console (C), and a hat-like console casing (13) having a peripheral flange (10) is fixedly secured to the side wall (SW) in alignment with the mounting hole (2). The peripheral flange (10) is held in abutment with a rear surface of the side wall (SW) so as to define a console pocket (CP). Also, a plurality of mounting elements (6a, 6b; 55) are engaged with an outer surface of the side wall (SW) around the mounting hole (2) for securing the console (C) to the side wall (SW). The console (C) is received in the console pocket (CP) with the electric wiring (11) accommodated within the console pocket (CP) and with the display panel (30) and the temperature control element confronting the compartment.

Owner:PANASONIC CORP

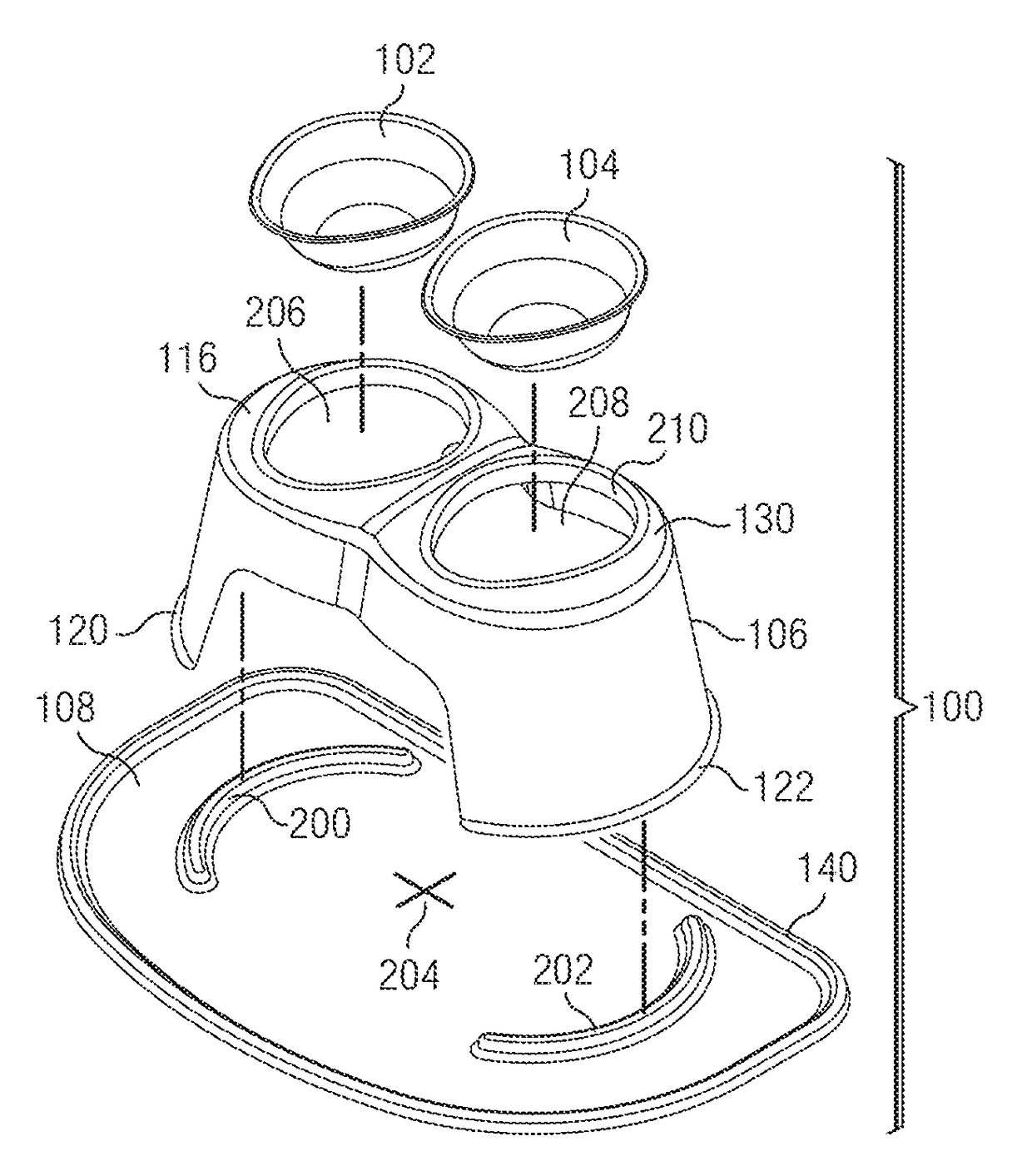

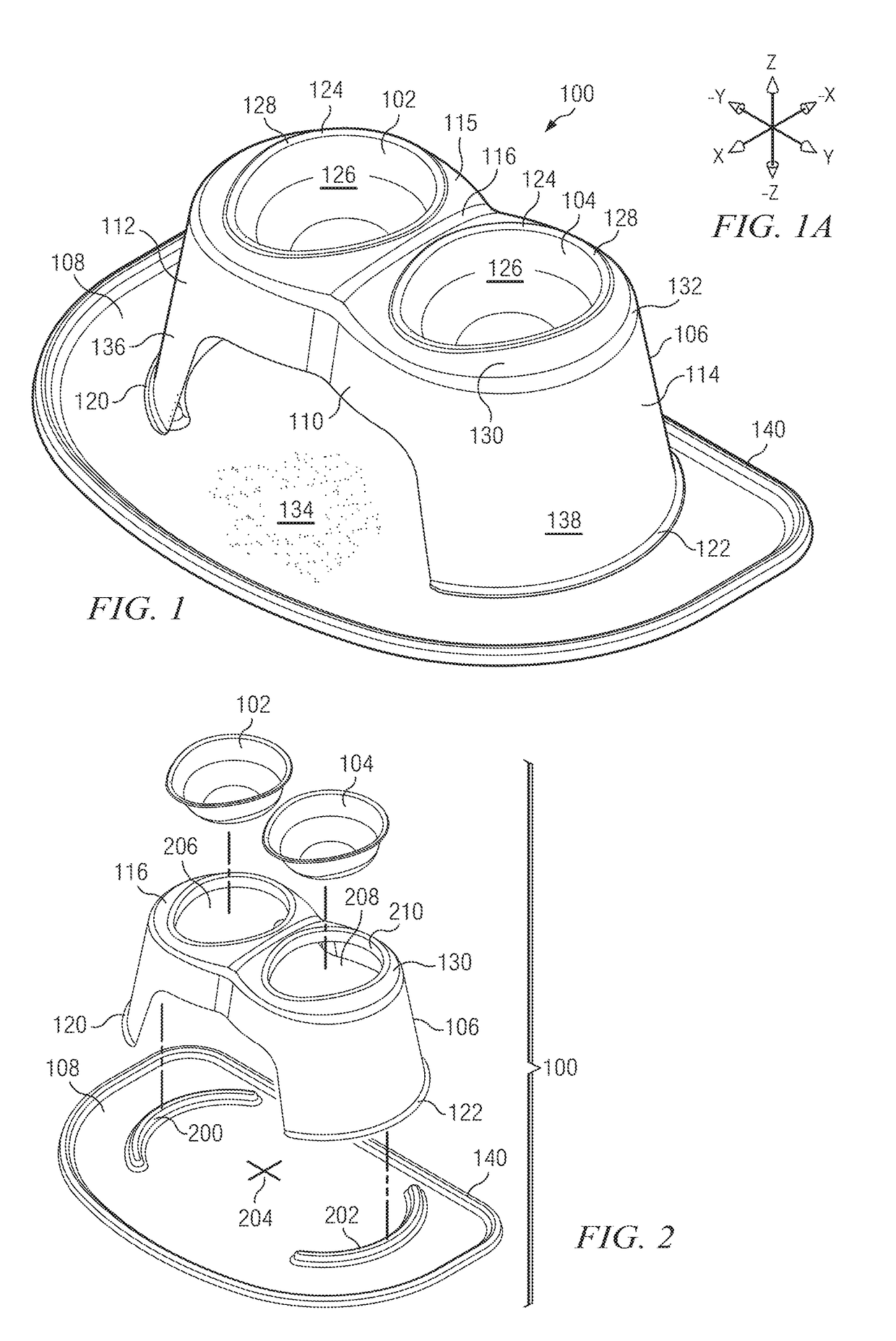

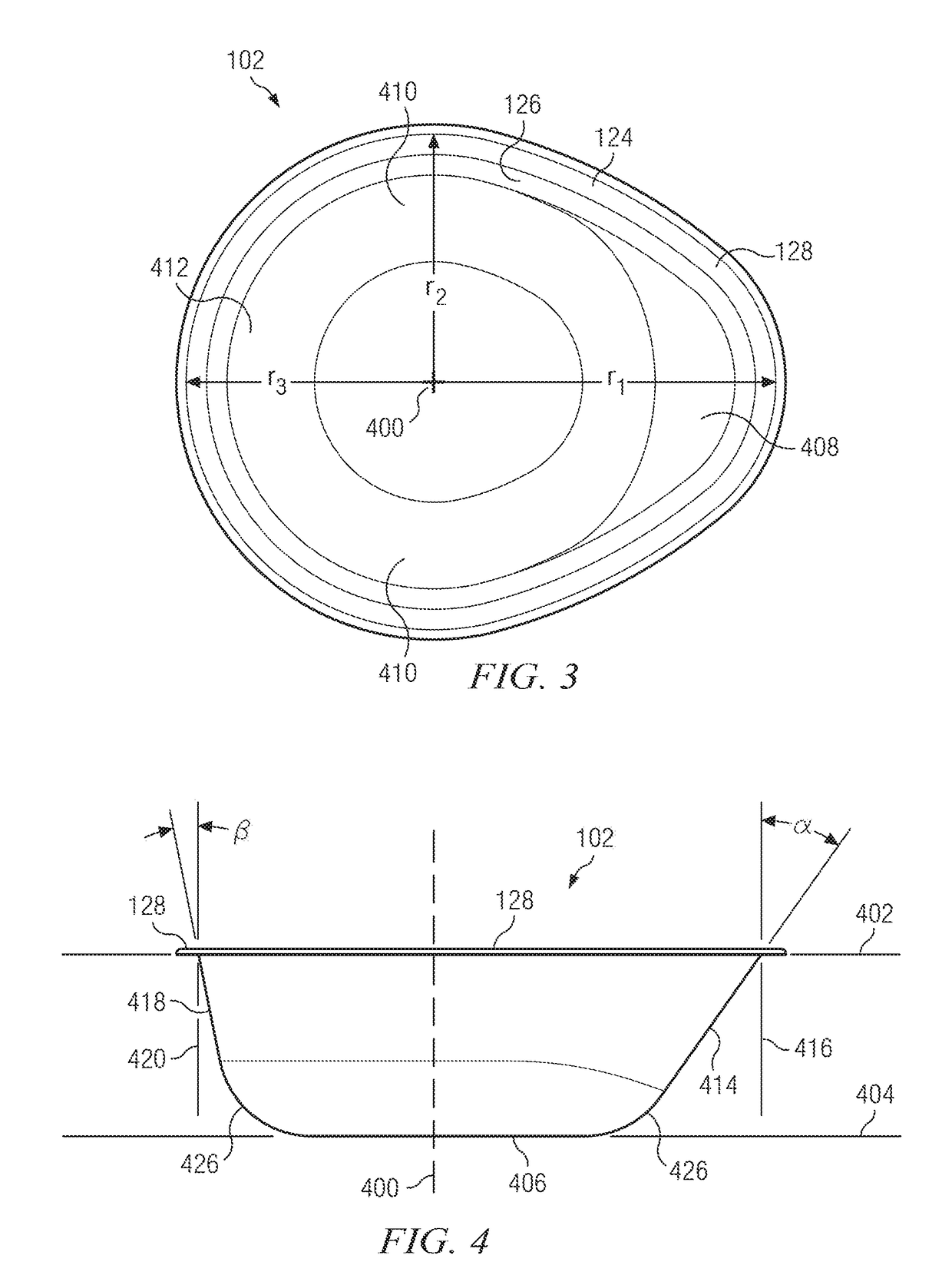

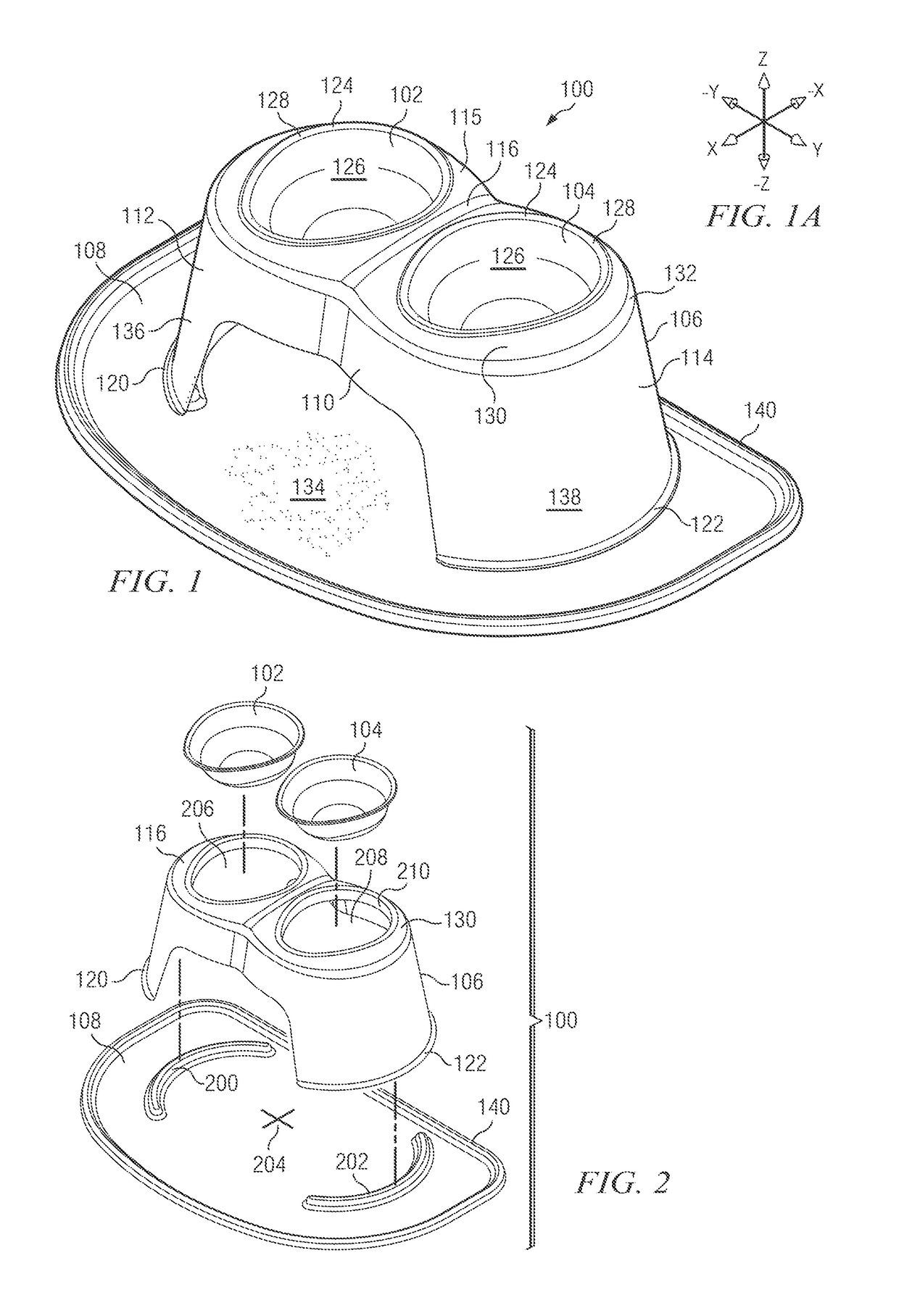

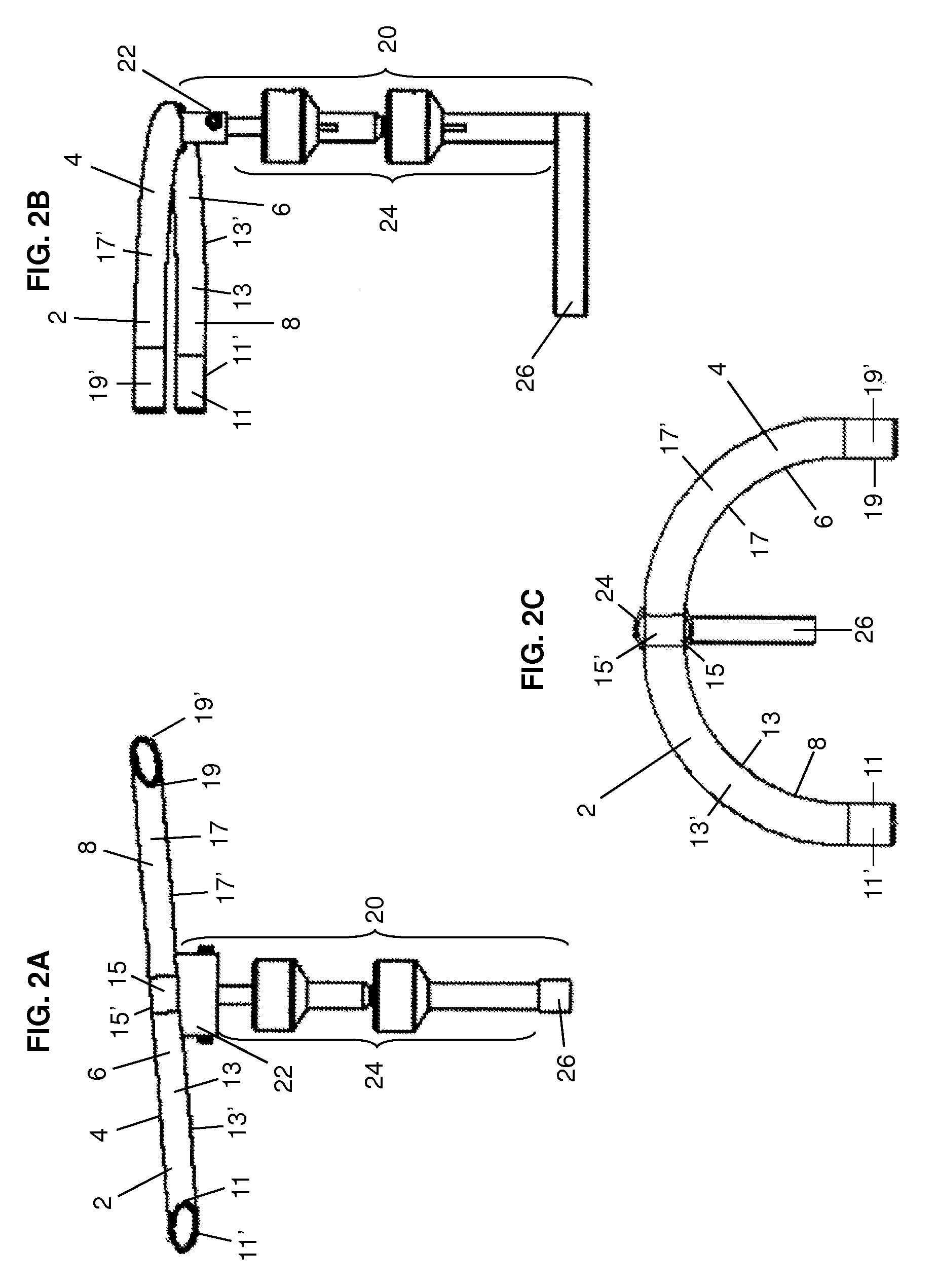

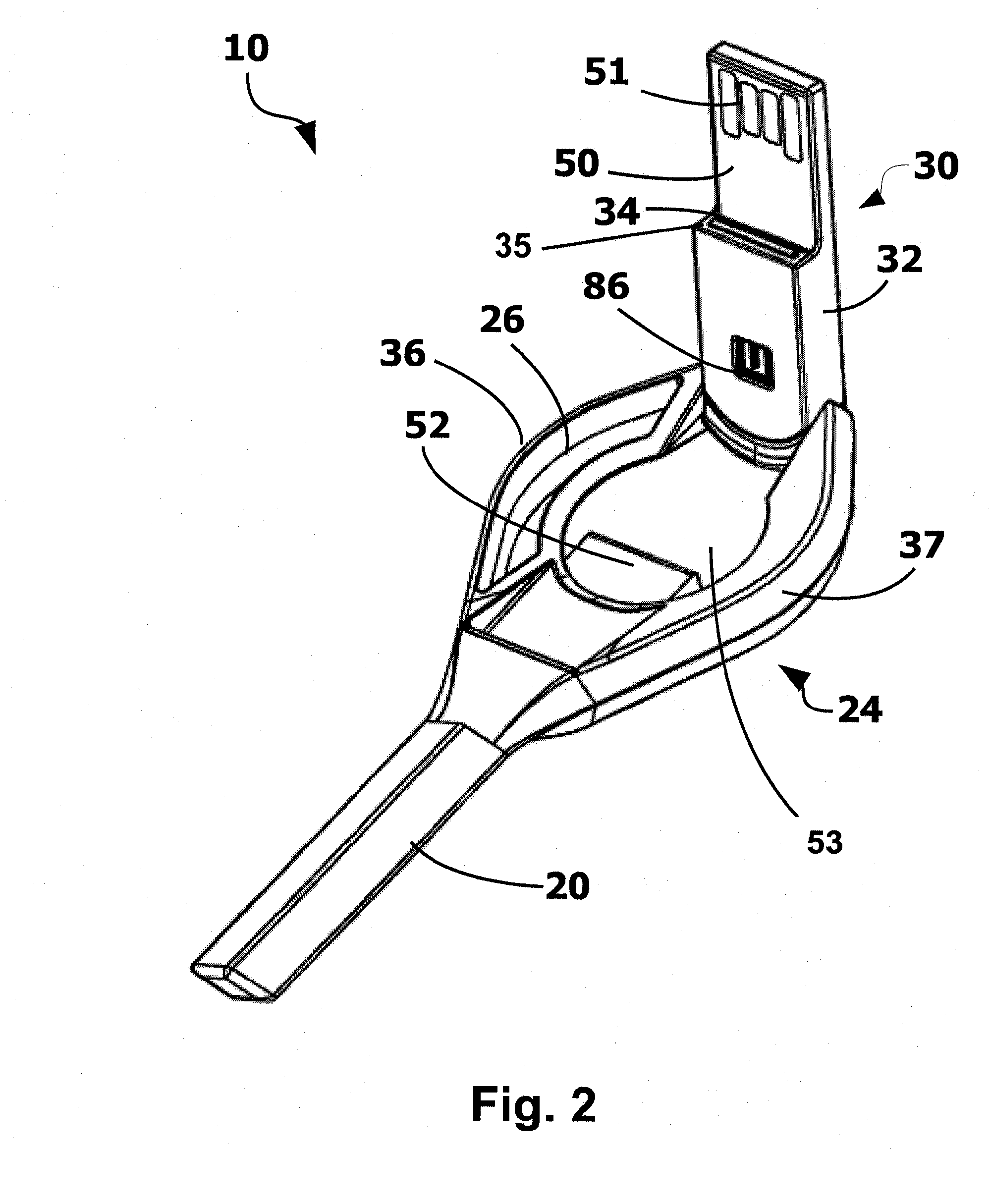

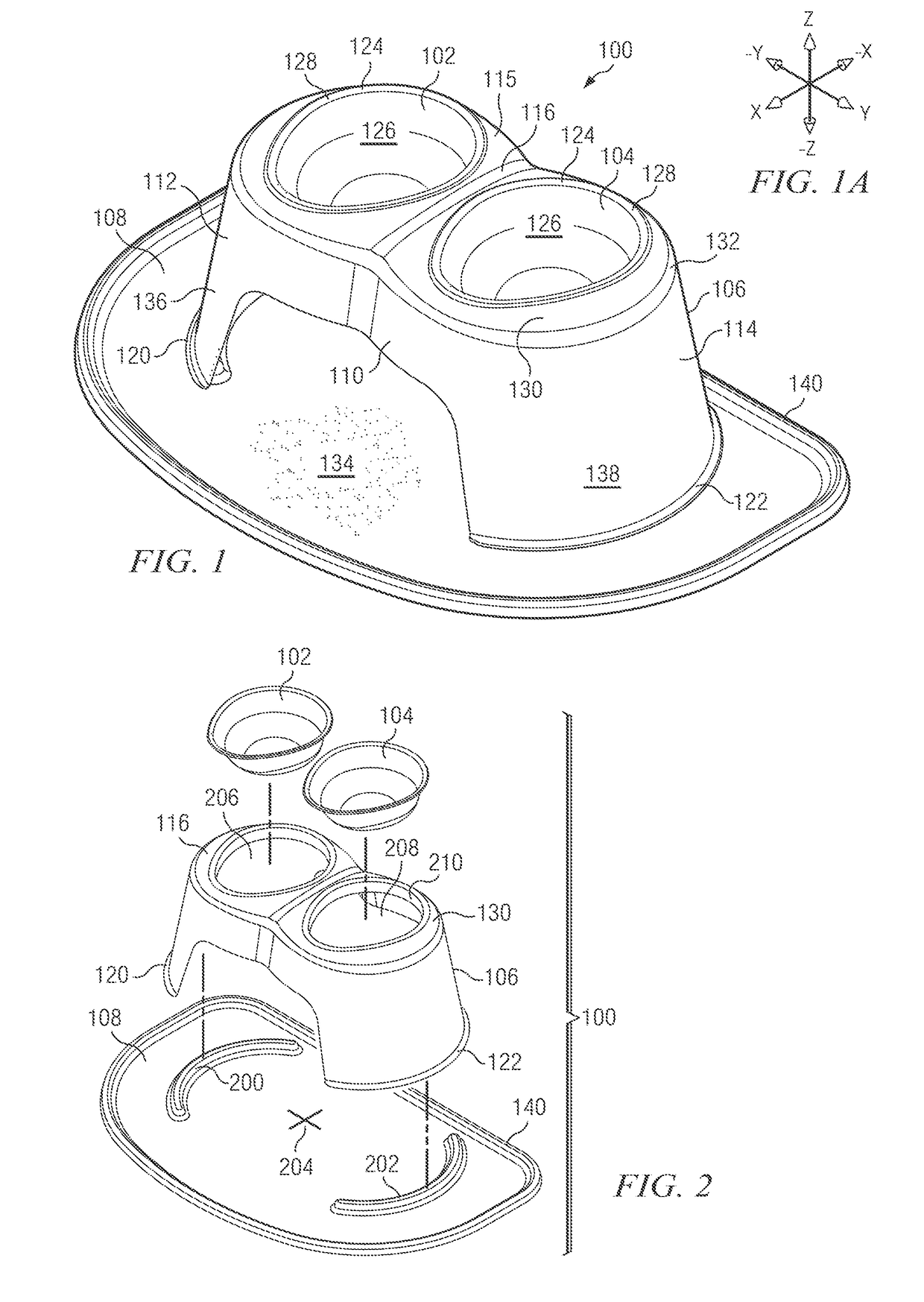

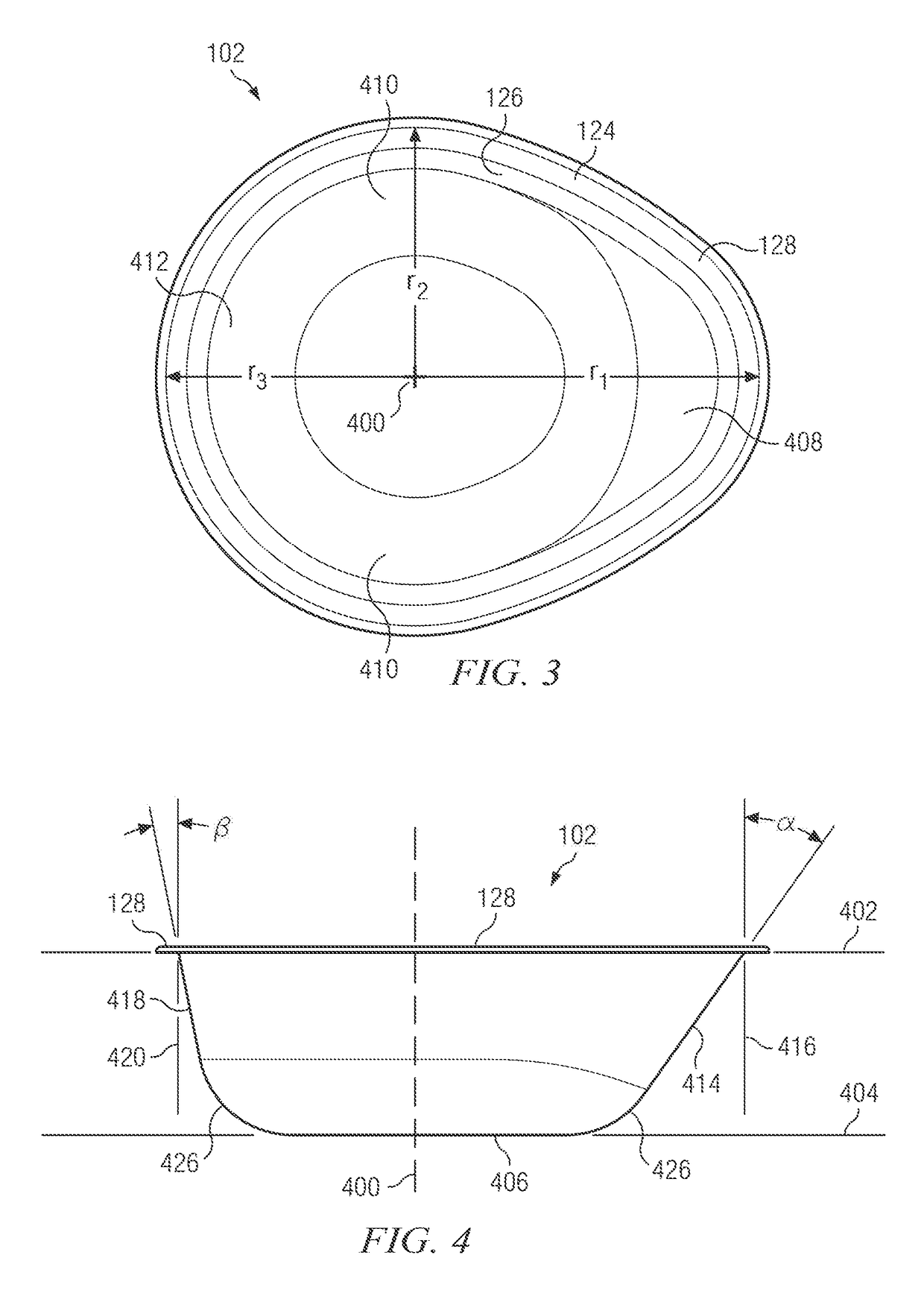

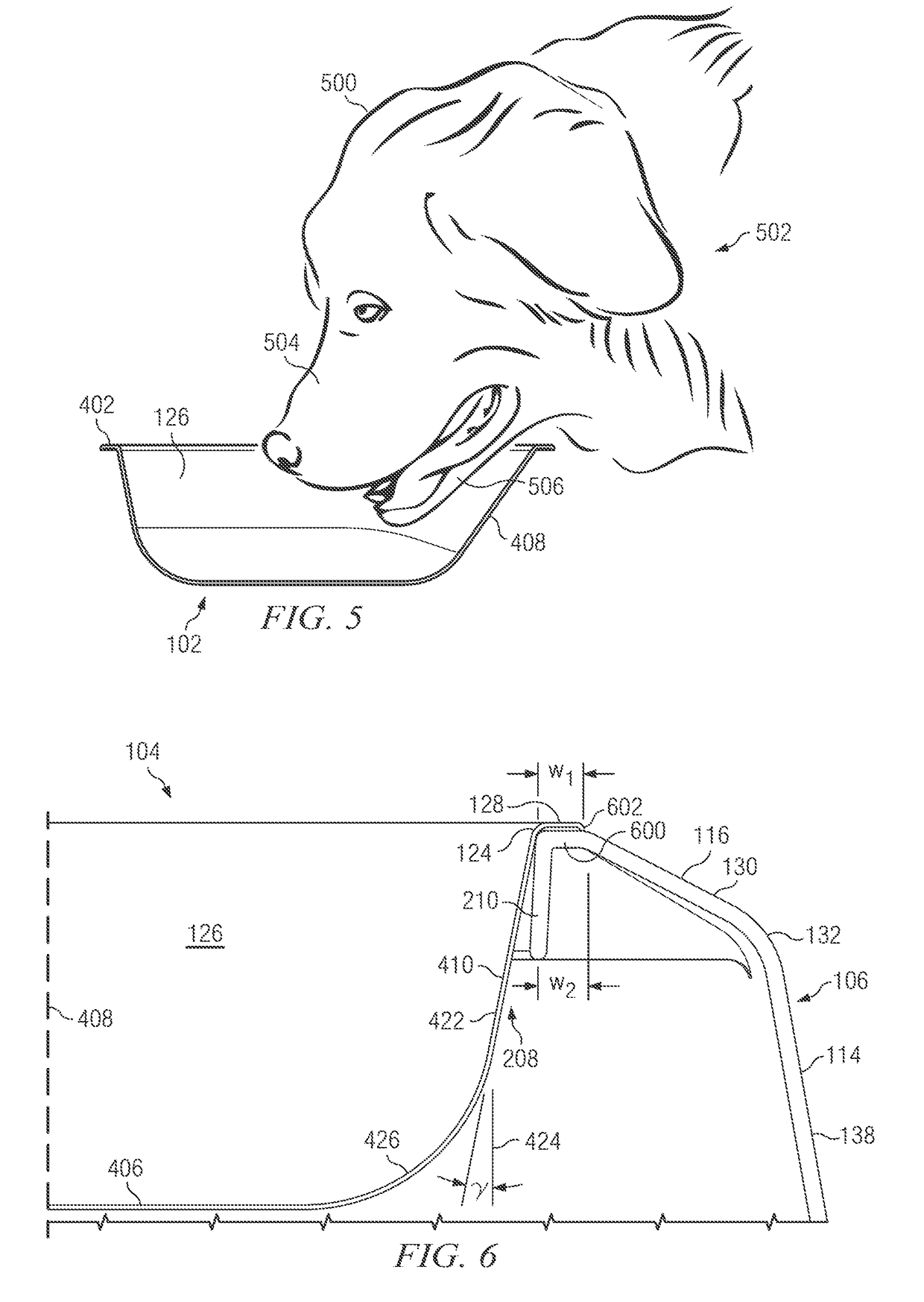

Pet feeding system

InactiveUS20170280675A1Easy to disassembleComfortable accessAnimal watering devicesAnimal feeding devicesEngineeringLateral movement

A top surface of an elevating stand of a pet feeding system defines bowl receptacles into which respective food and water bowls may be removably installed. A first zone of the top surface of the stand includes an upwardly convex ring that laterally surrounds a respective bowl receptacle. A second zone of the top surface of the stand laterally surrounds the first zone, except as interrupted by a finger notch. Each bowl has a peripheral lip with a lower surface formed as a downwardly concave ring that fits over the upwardly convex ring of the stand. An edge of the bowl rests on the second zone at a location below the upper limit of the convex ring. A base of the stand cooperates with upstanding ribs in an elastomeric mat to prevent lateral movement of the stand and to prevent rotation of the stand around the stand center.

Owner:MACNEIL IP

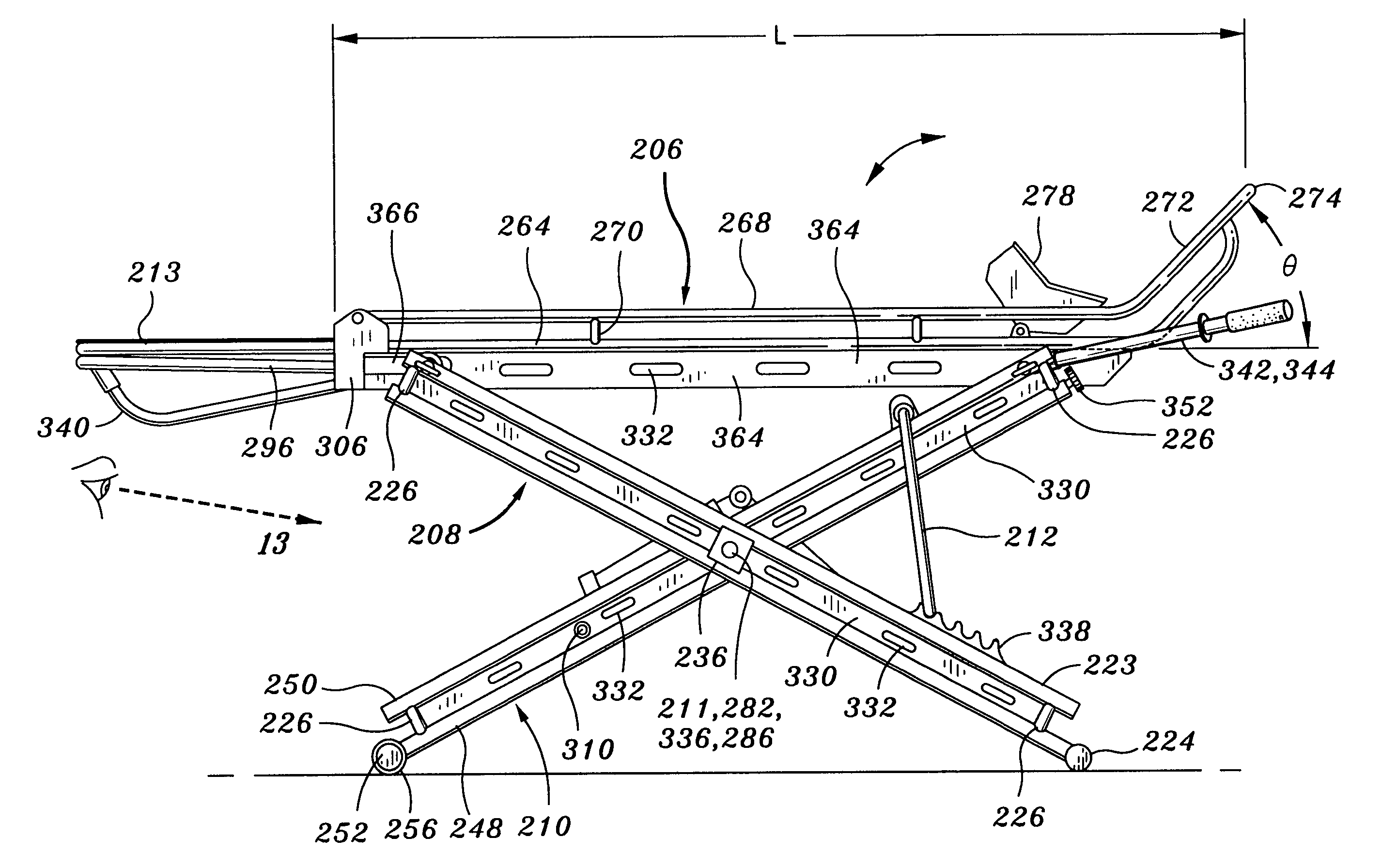

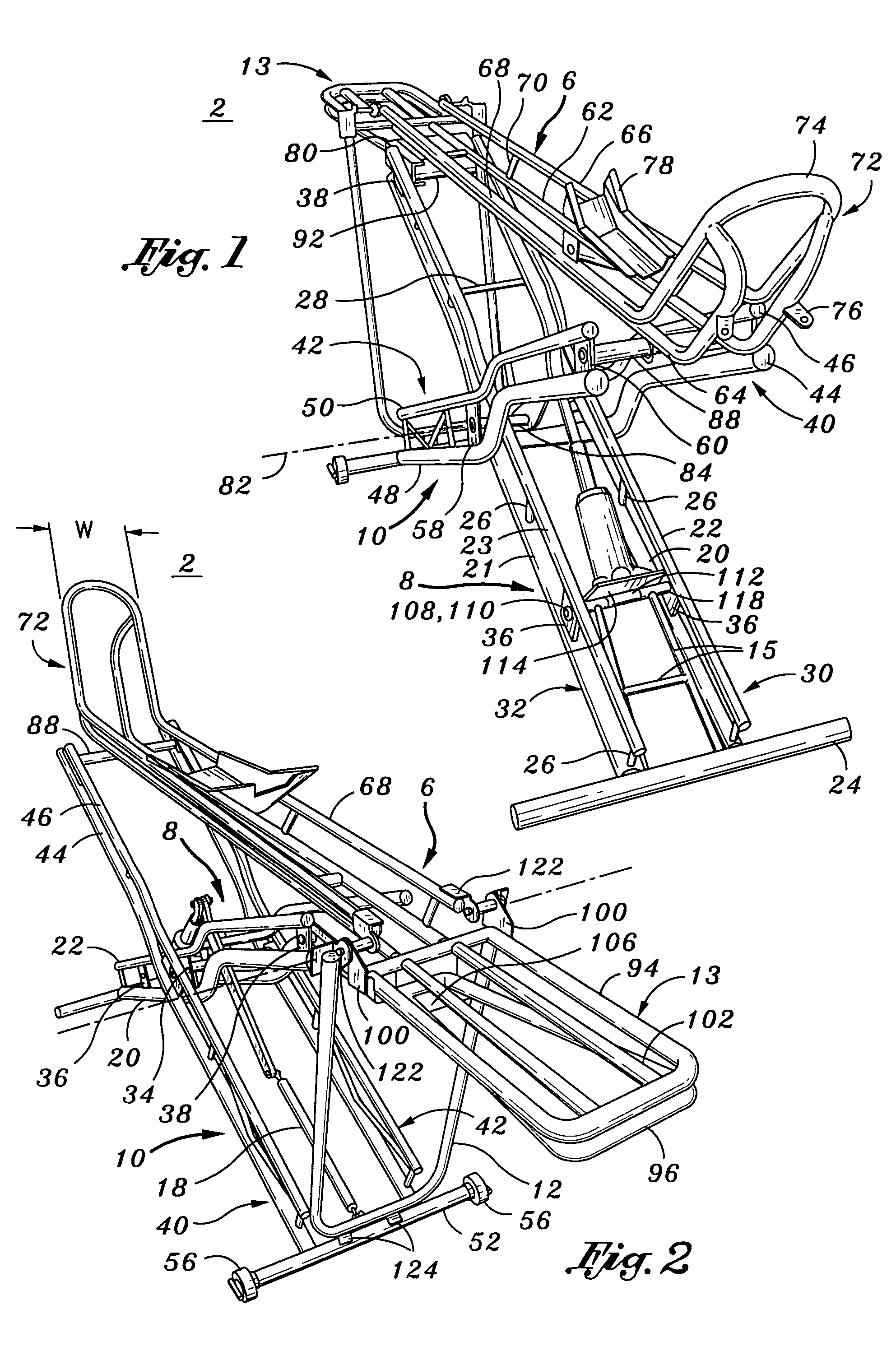

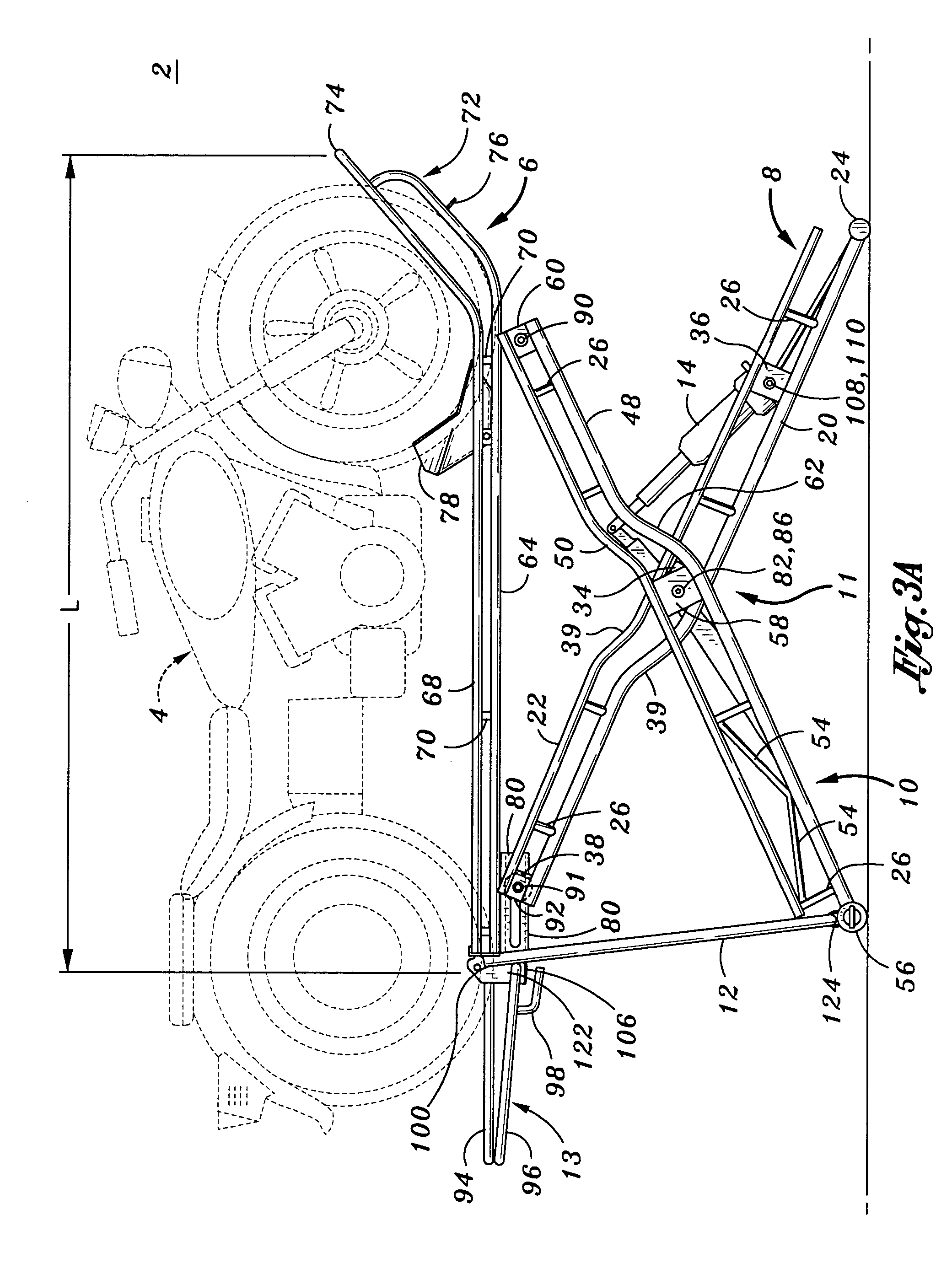

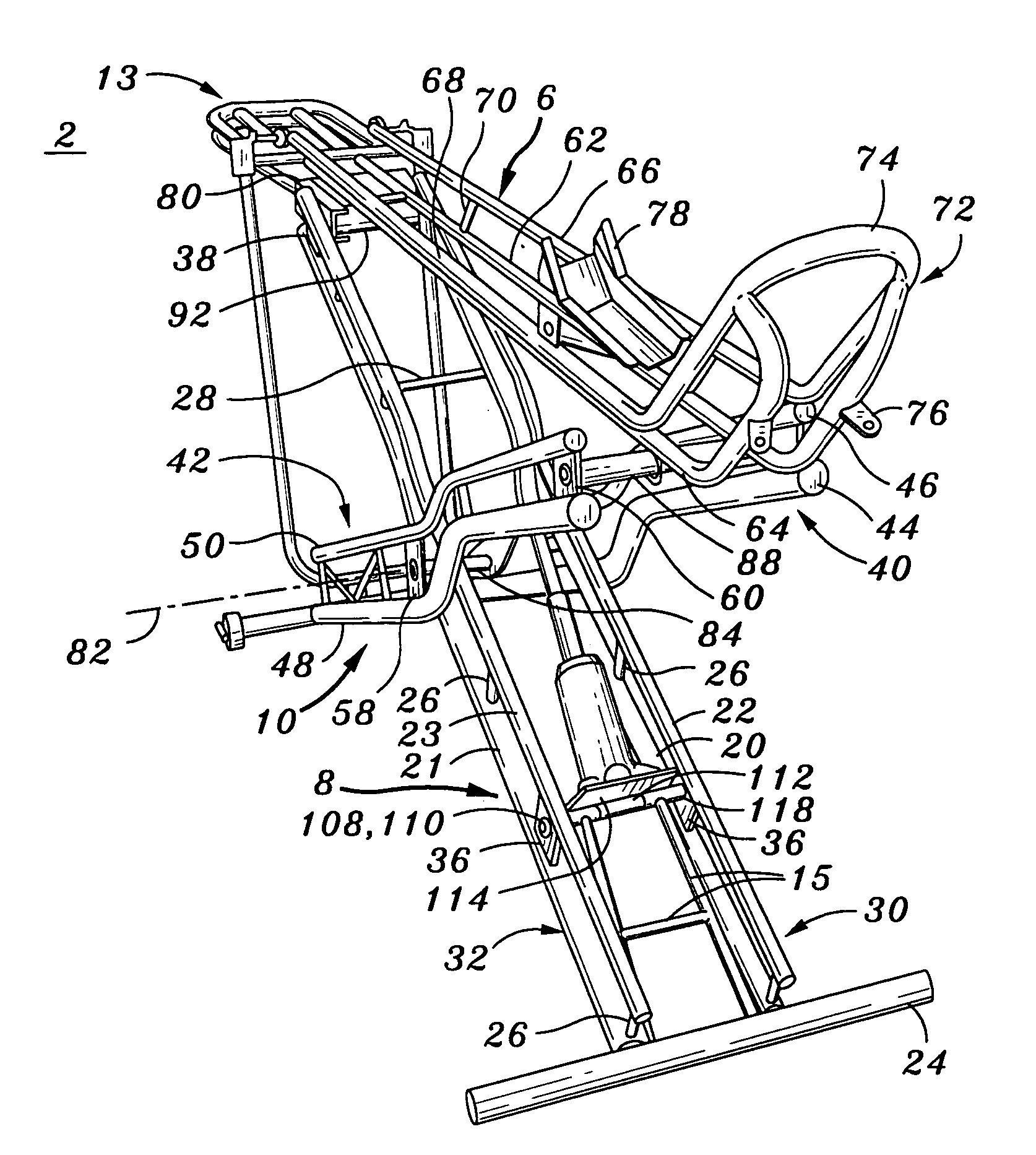

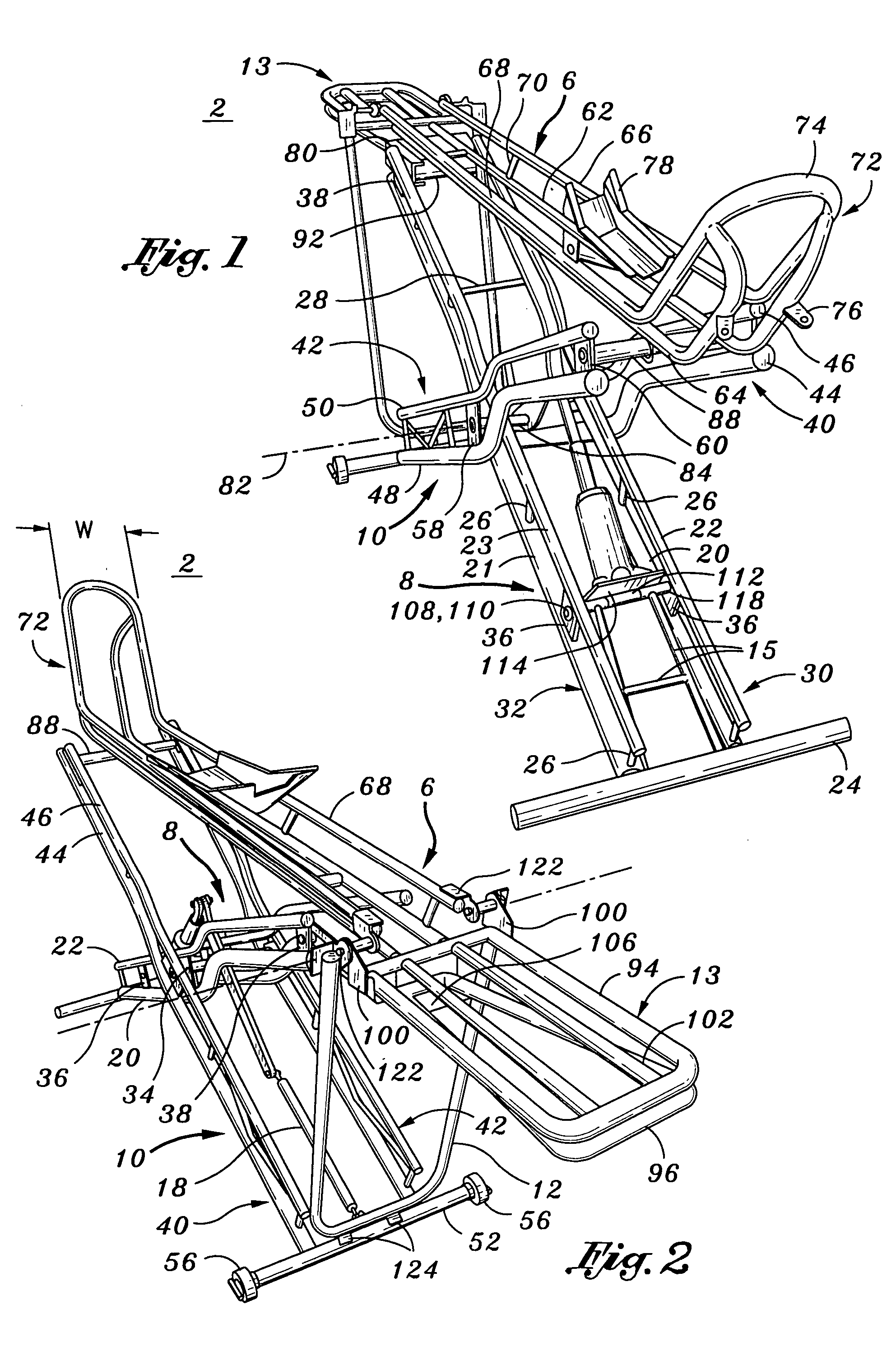

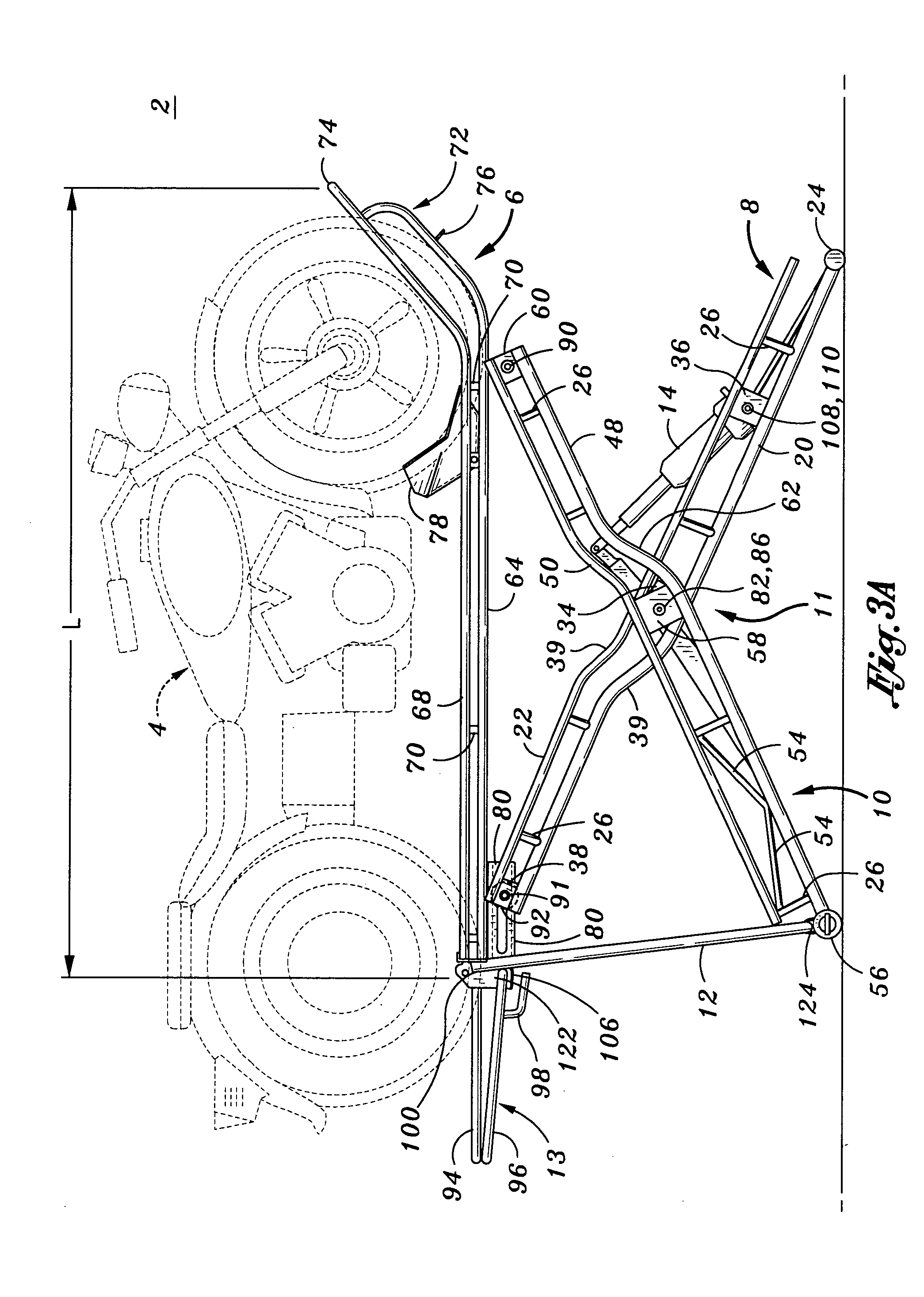

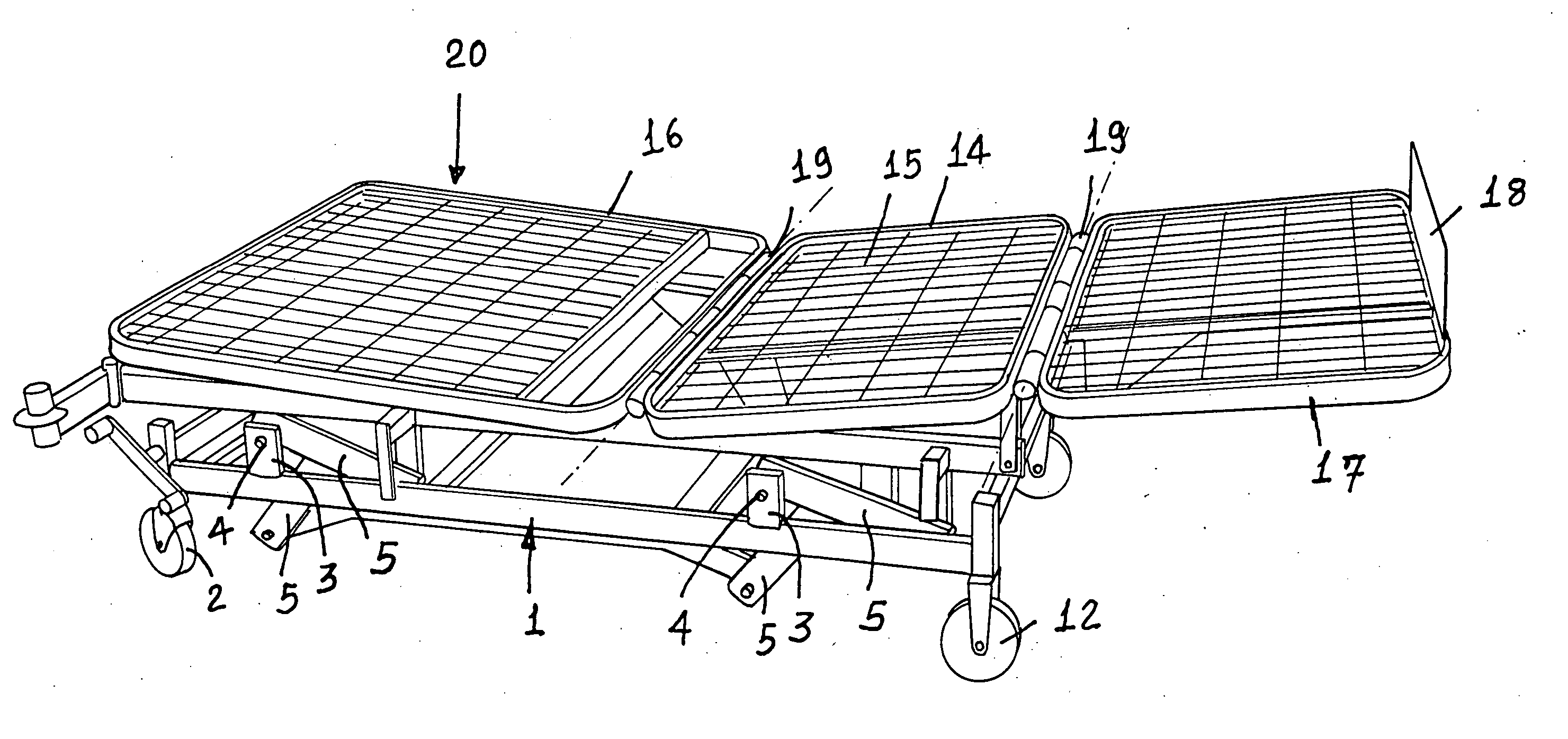

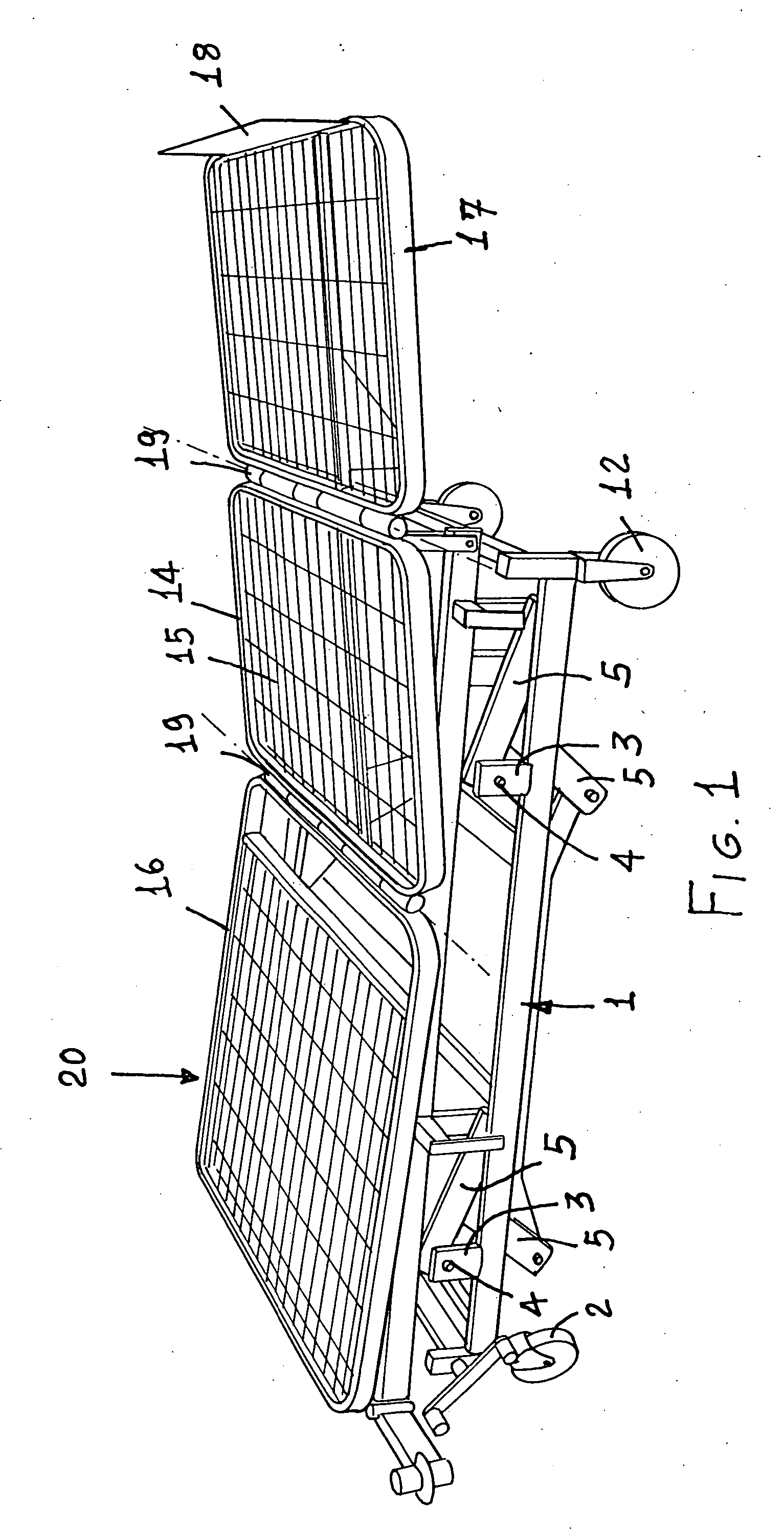

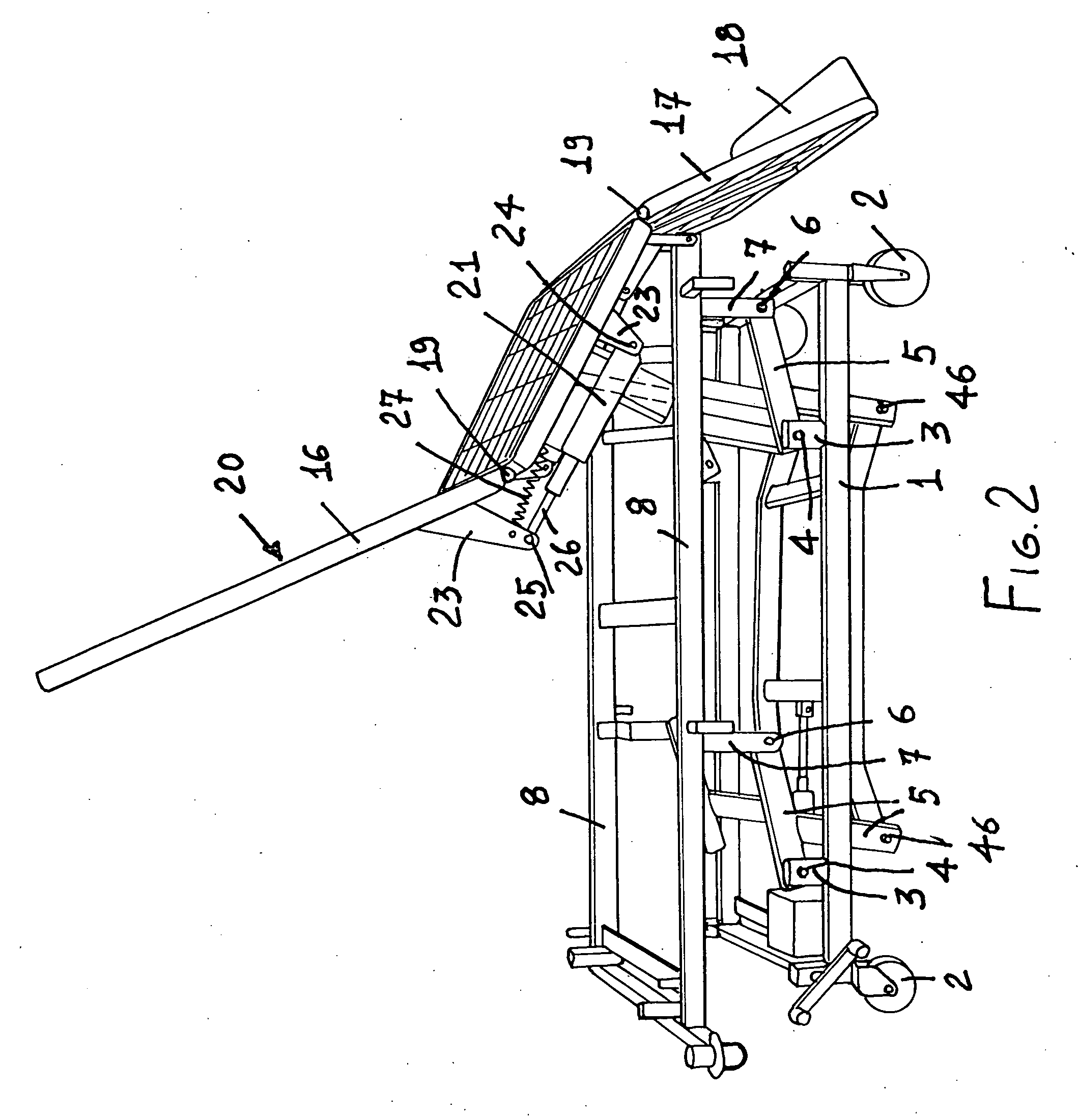

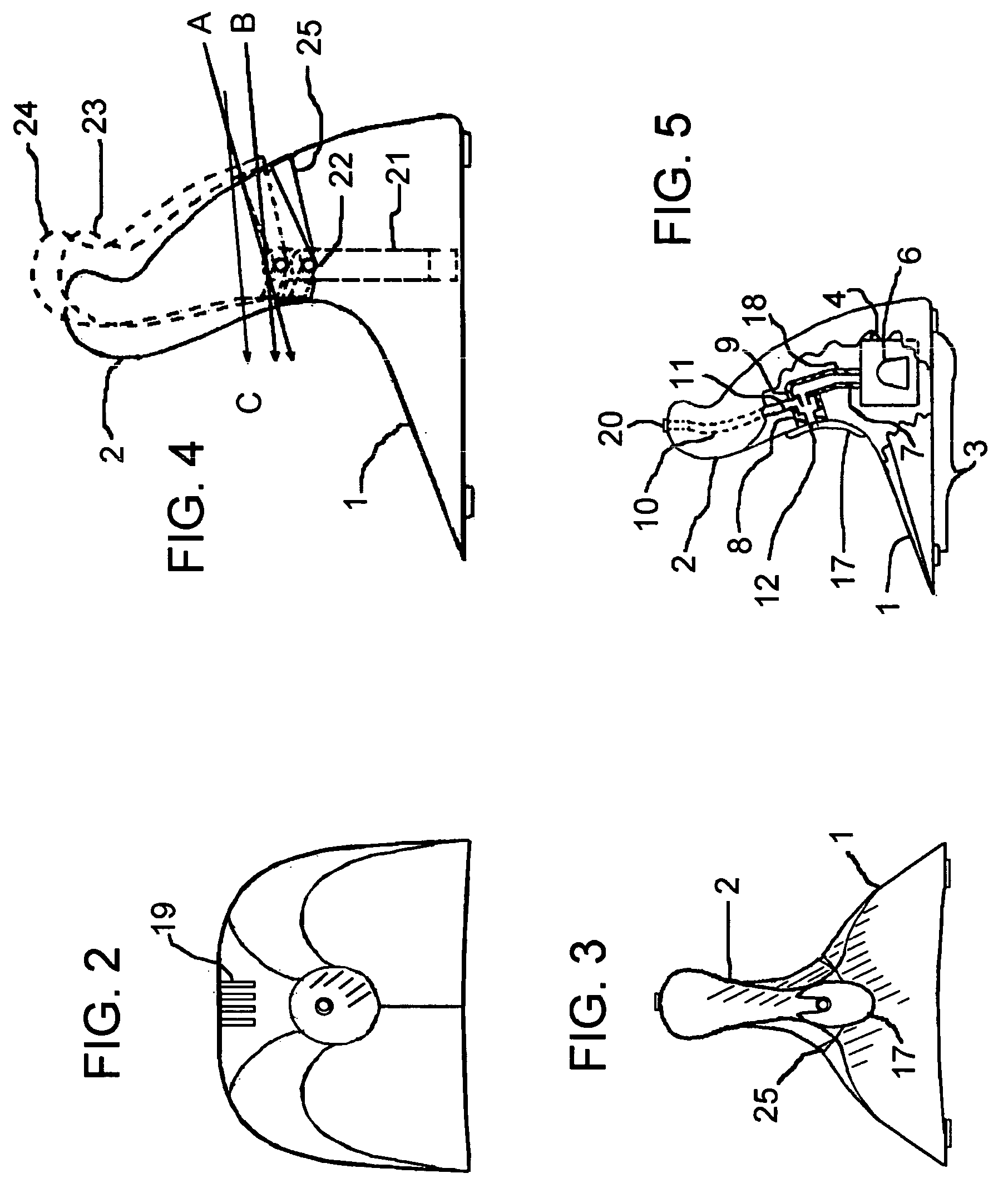

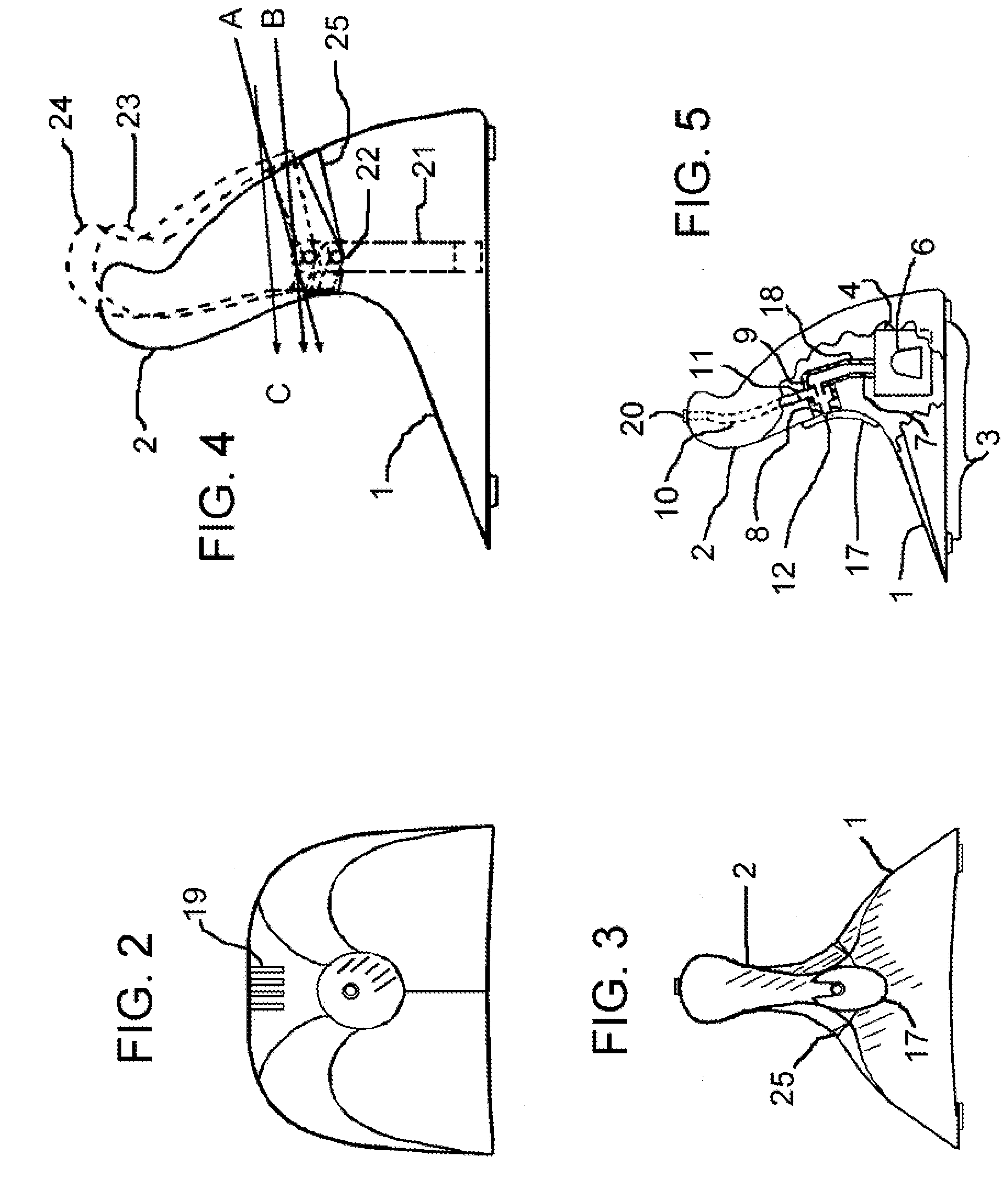

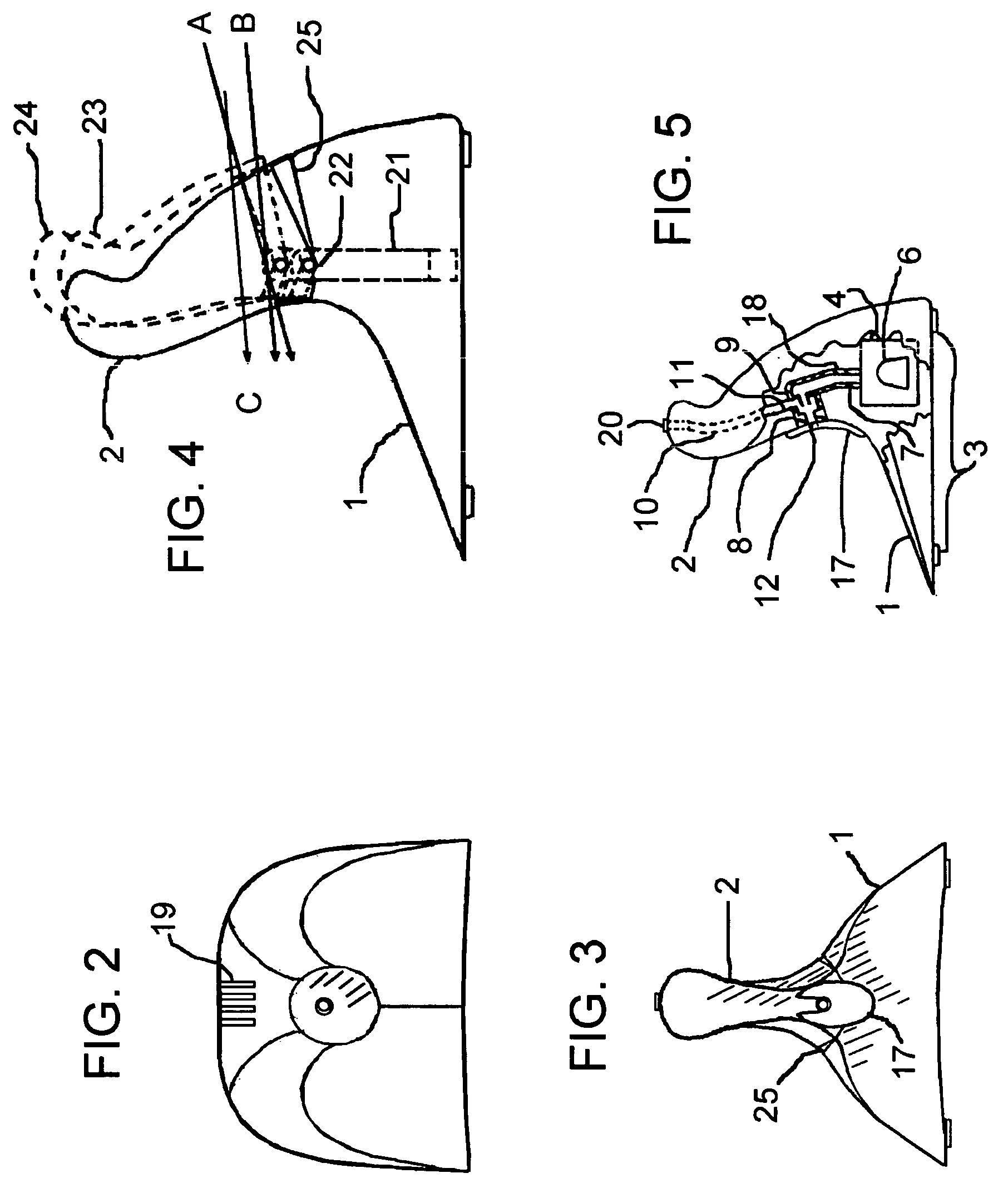

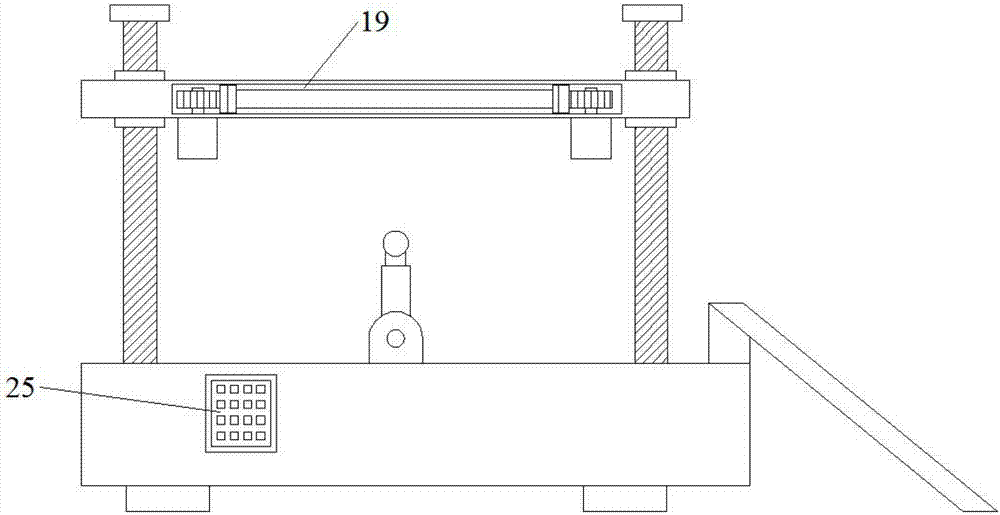

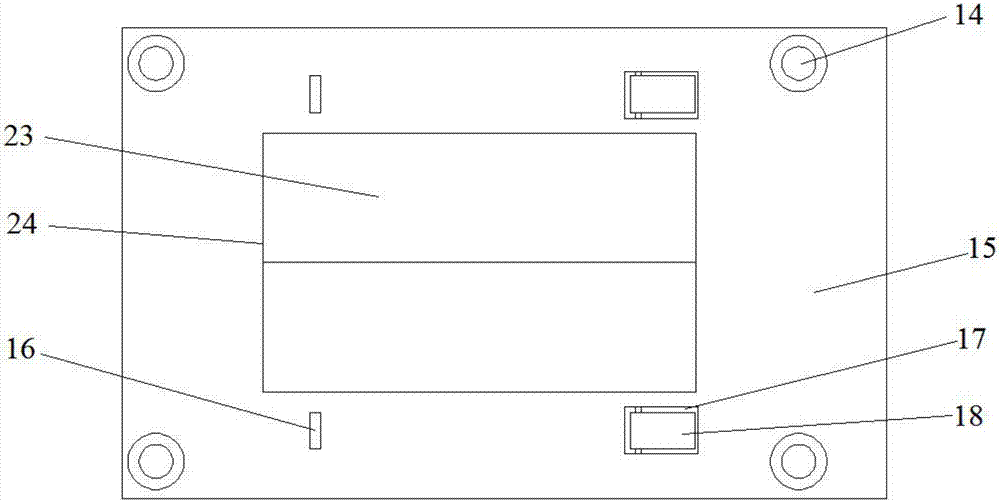

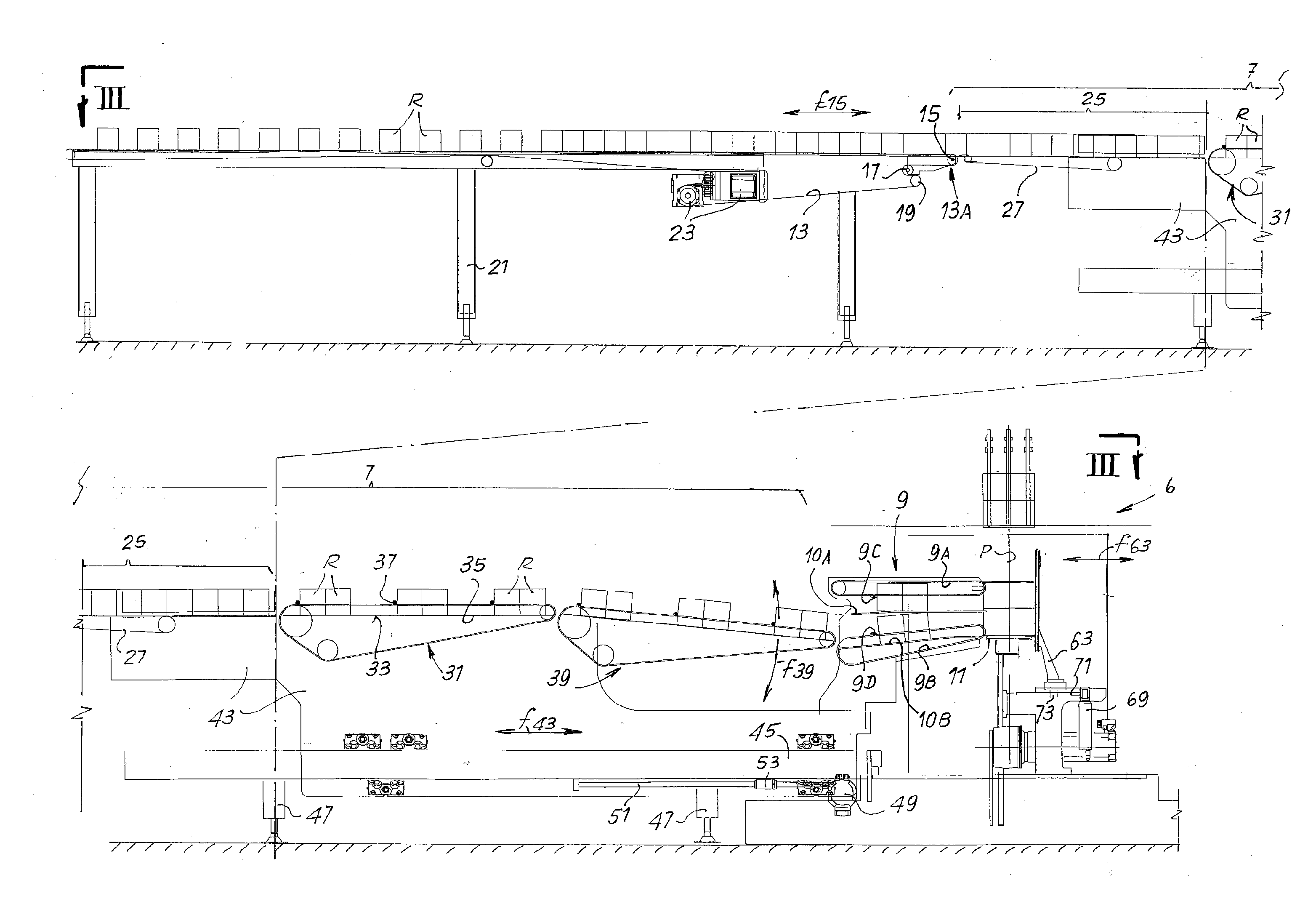

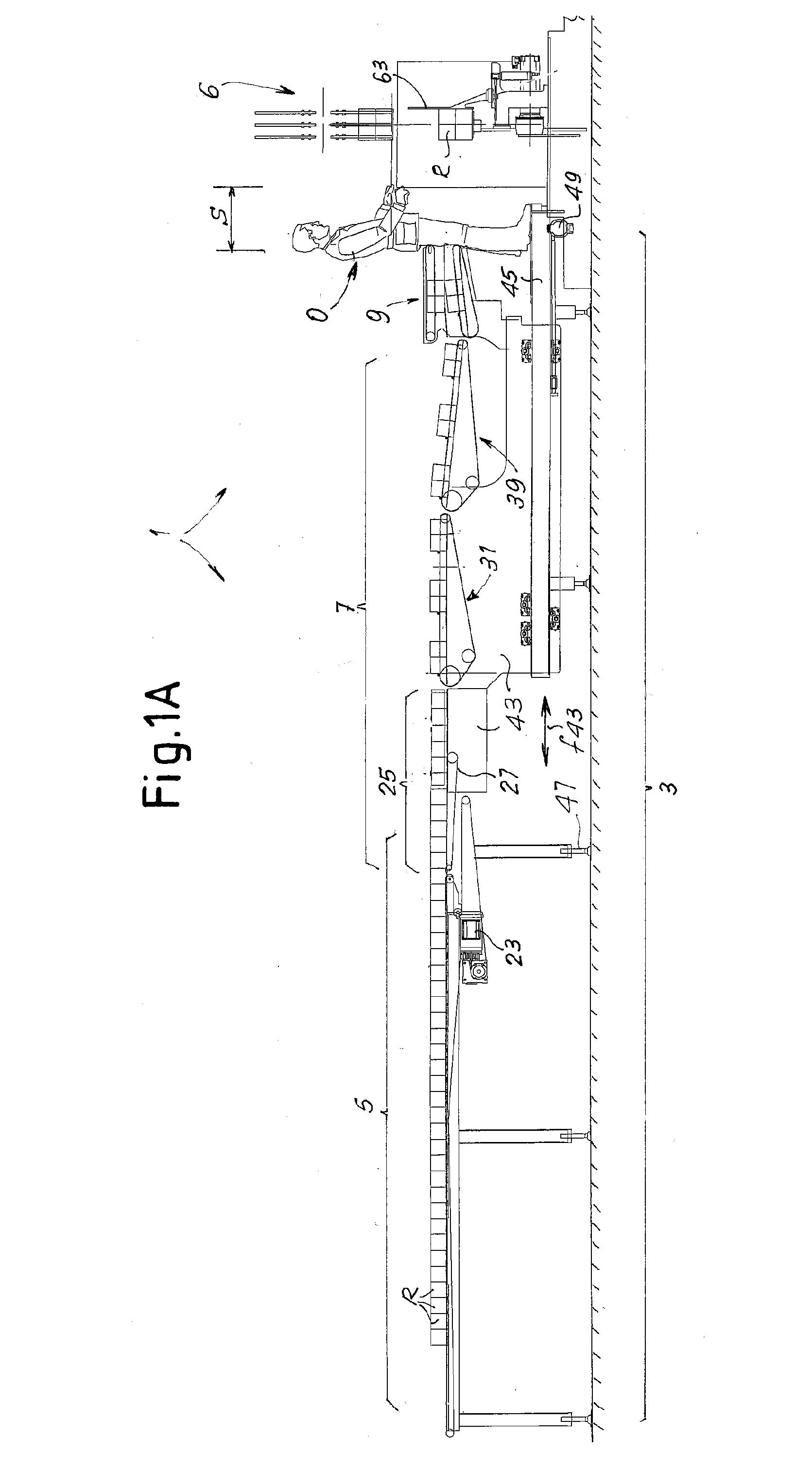

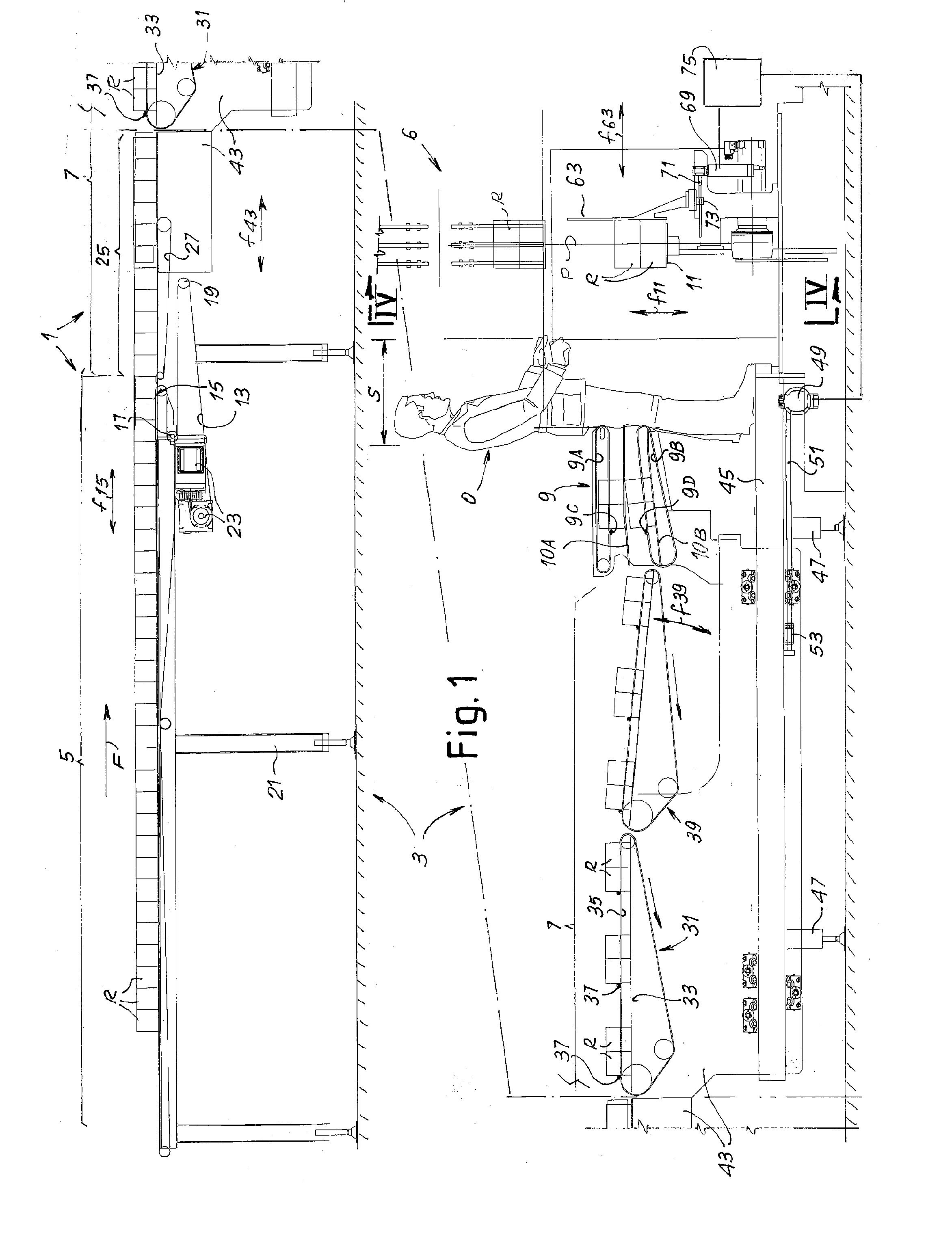

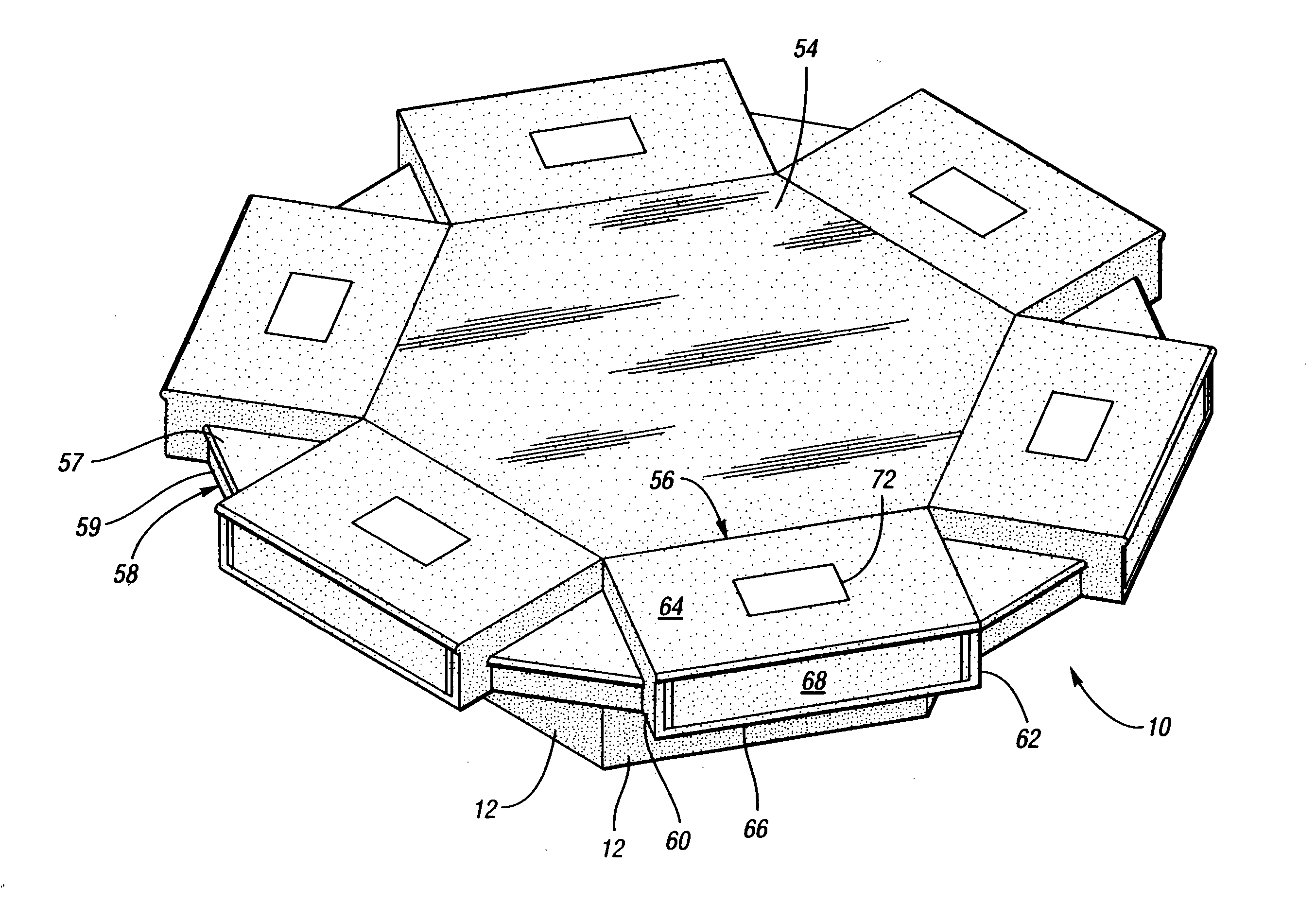

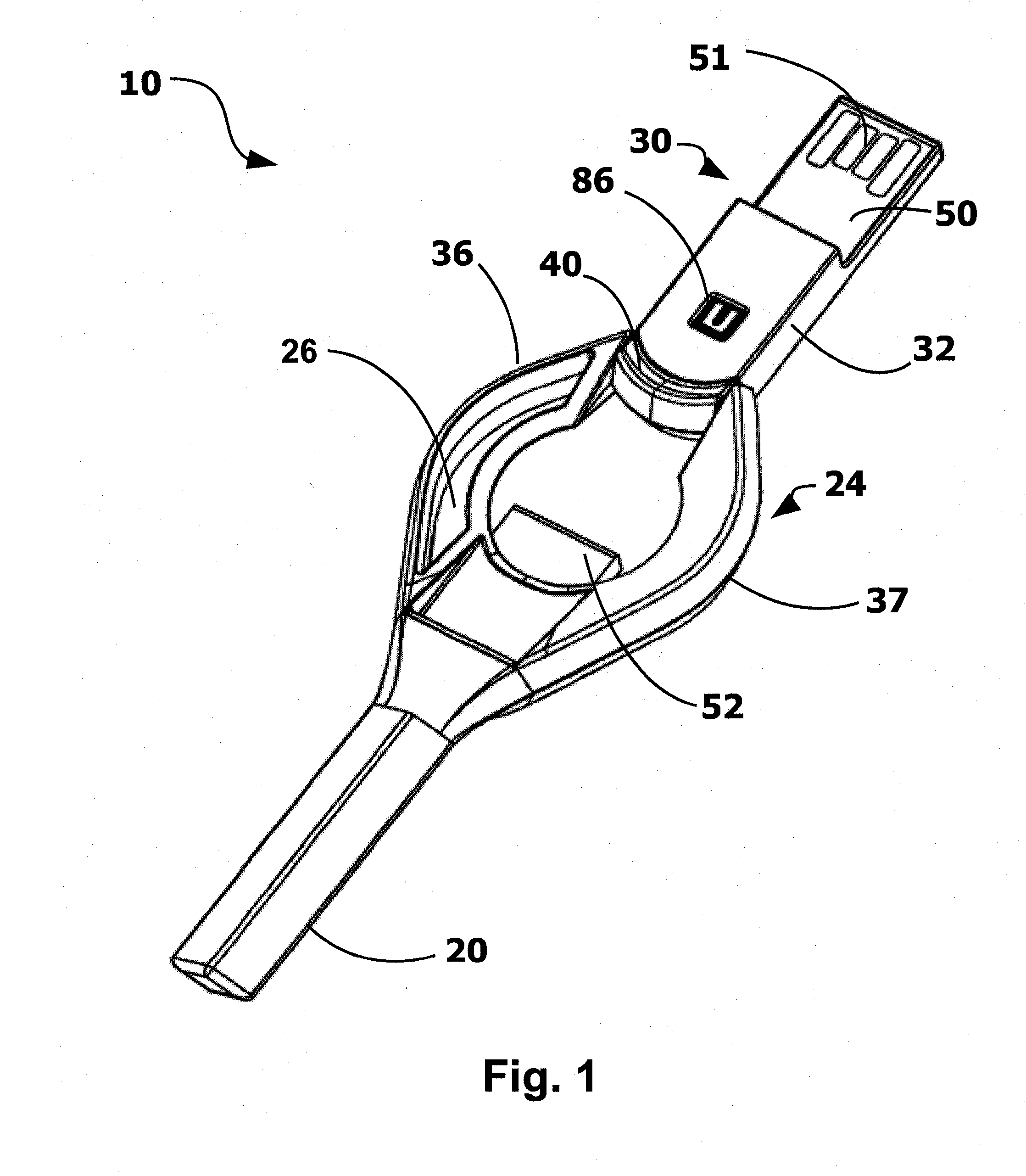

Portable motorcycle lift

InactiveUS7066448B2Comfortable accessReduce the possibilityVehicle with pivoted armsCycle standsEngineeringLift system

Owner:KENDON IND LLC

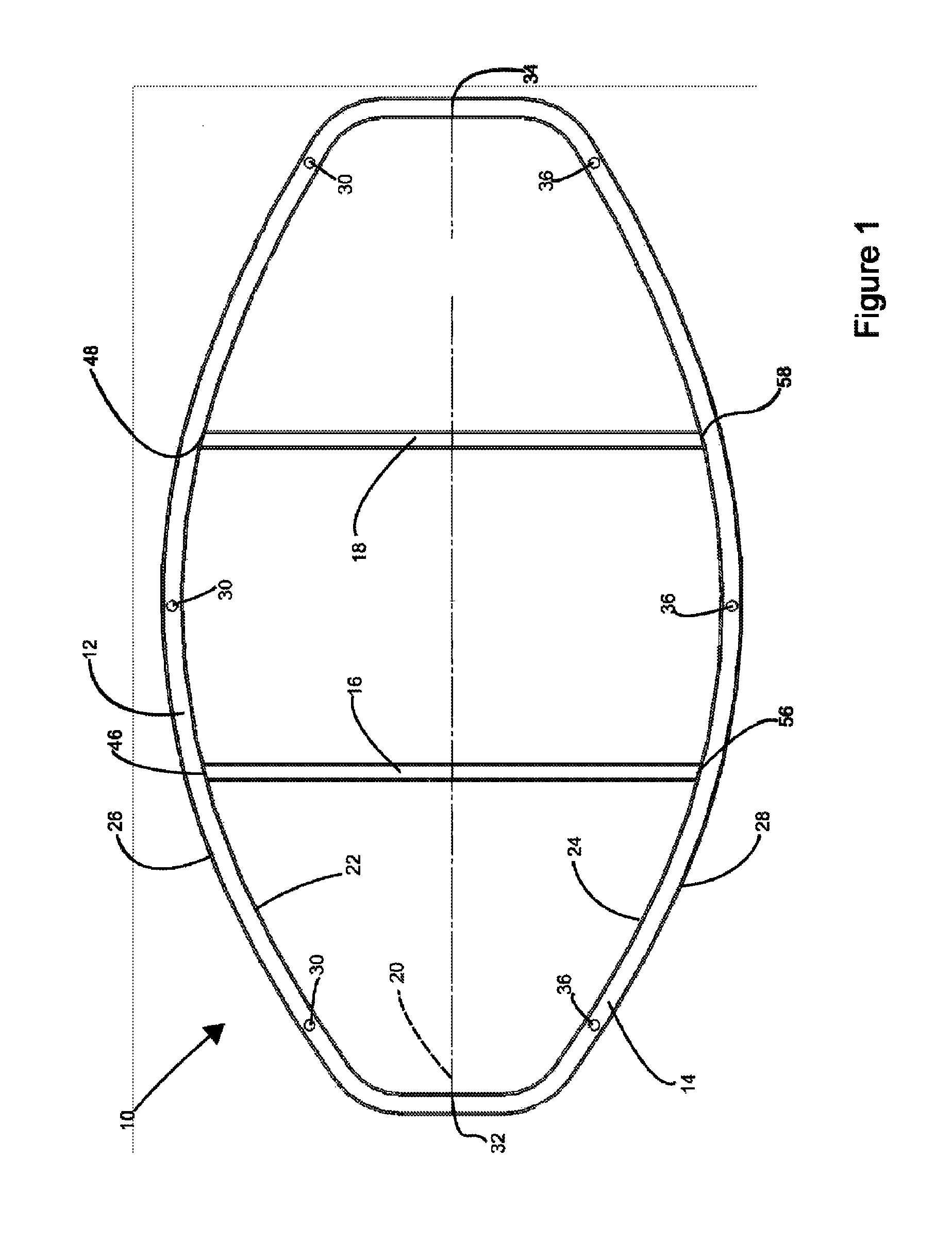

Portable motorcycle lift

ActiveUS20050077505A1Comfortable accessReduce the possibilityCycle standsLifting framesEngineeringLift system

A portable tubular motorcycle lift is provided which utilizes a scissor frame configuration. The scissor frame includes an inner lifting structure and an outer lifting structure rotatably hinged about a common center fulcrum. An upper cradle support is attached to the inner and outer lifting structures. The motorcycle lift has a deployed configuration and a folded, stowable non-deployed configuration which allows the lift to be transported similar to a dolly. To provide the required forces to lift a large motorcycle, an articulated lifting system which includes a jacking device, lifting arm, and linkage arm, is integrated within the inner and outer lifting structures. Other features of the motorcycle lift include a bracing member, rear support section, removable ramp, well chock, remote jacking system, remote pressure release feature, and removable and positionable auxiliary jacking device positioned with the upper cradle support.

Owner:KENDON IND LLC

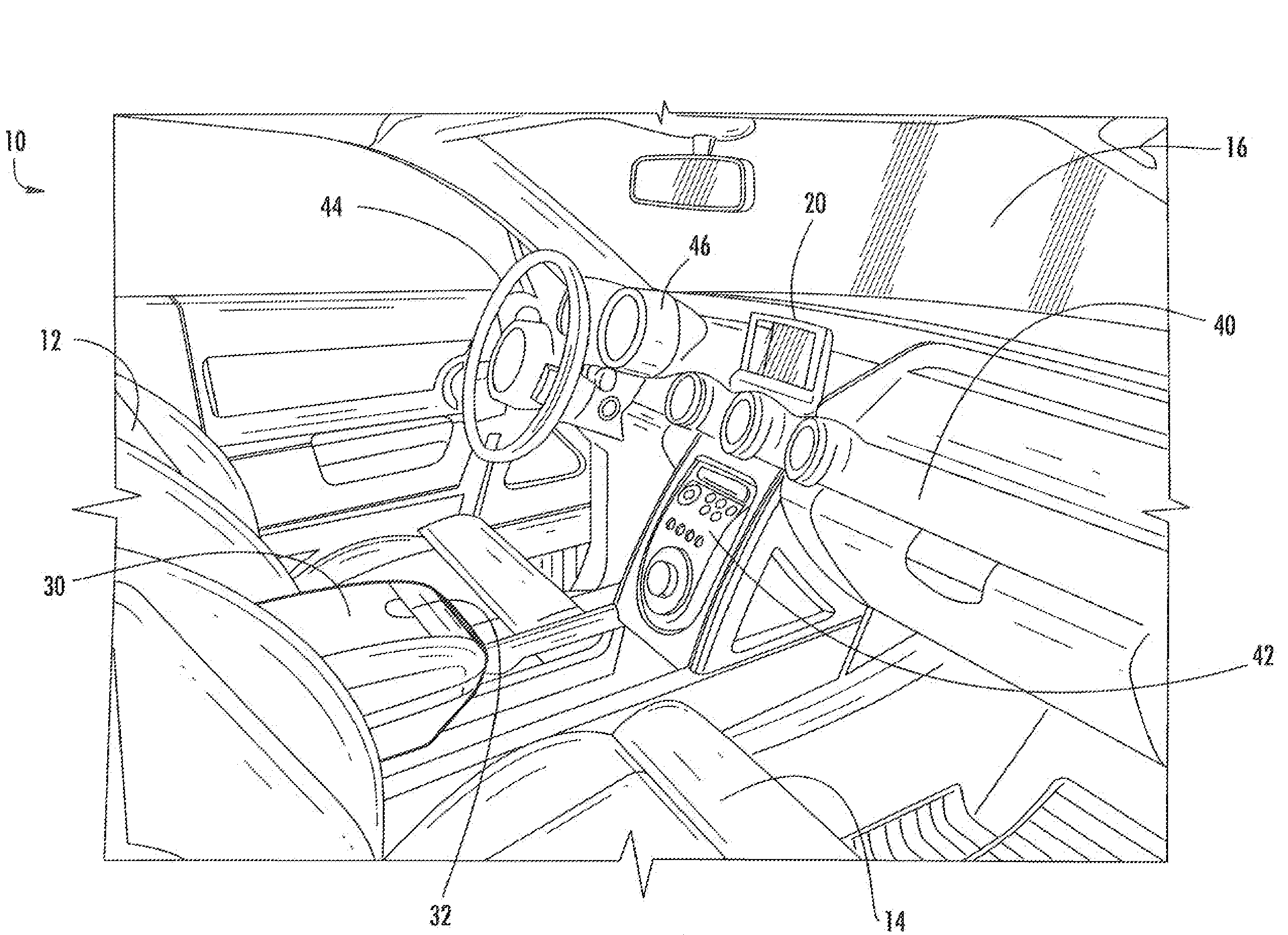

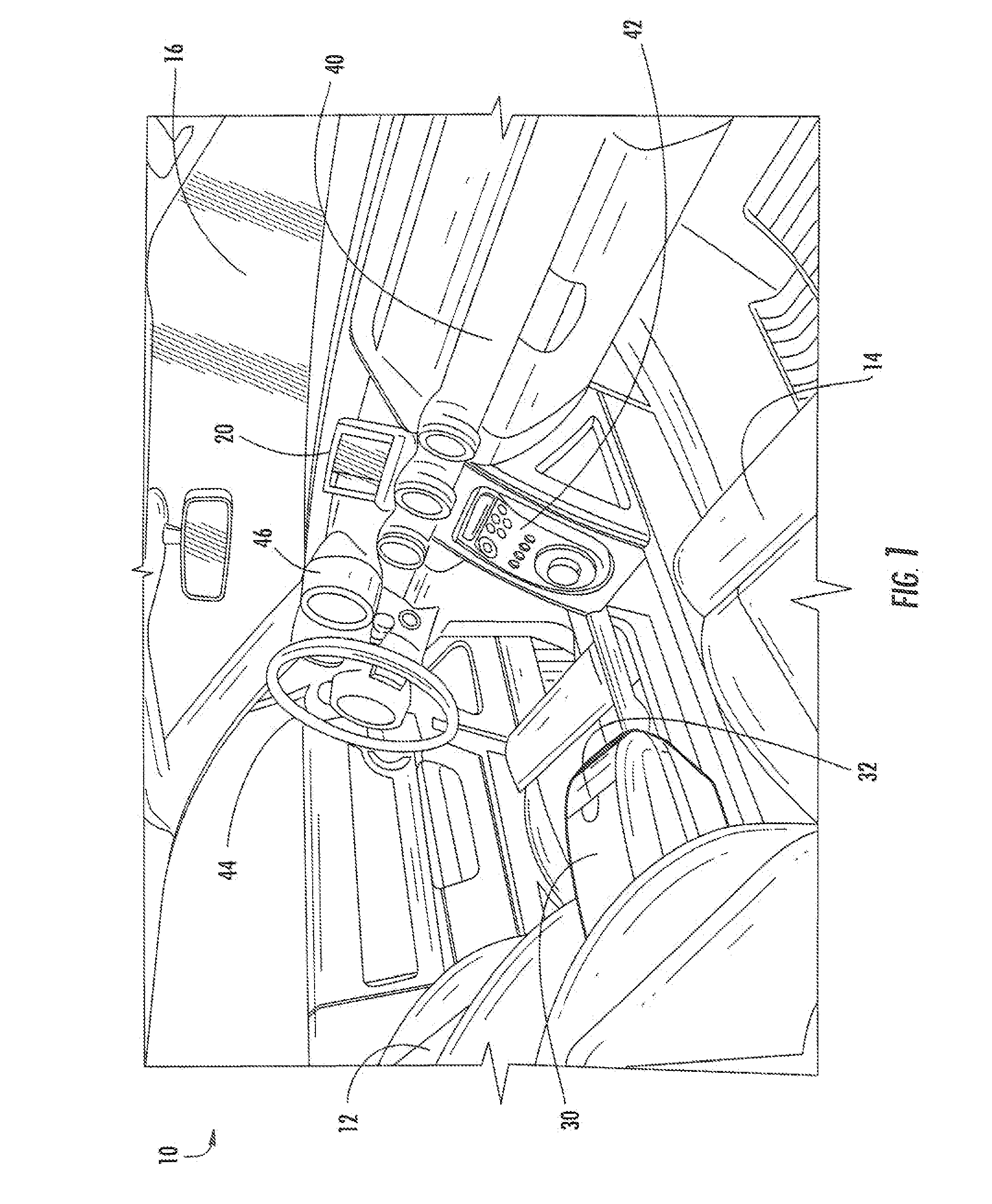

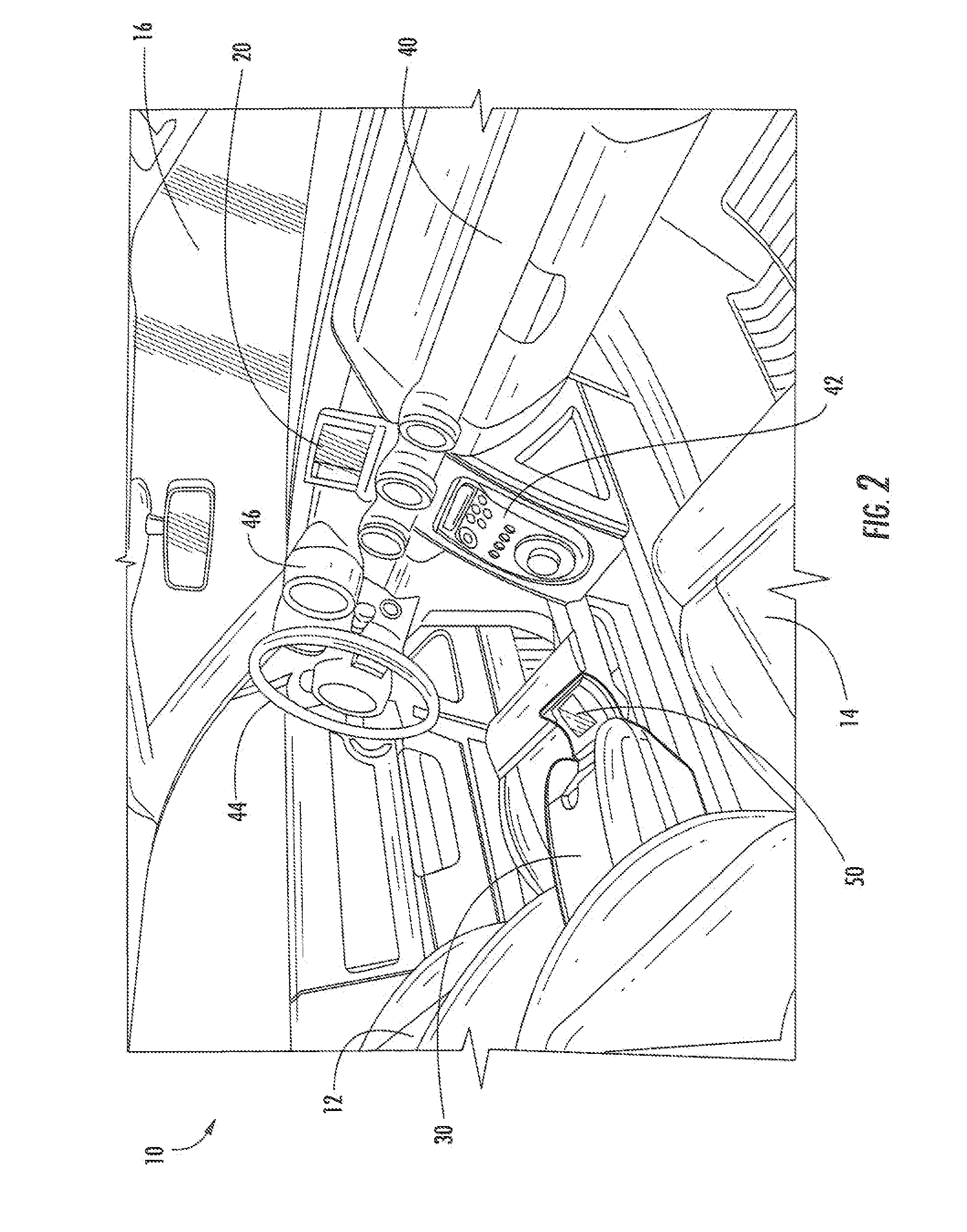

Touch pad control panel located in the center console of a vehicle

ActiveUS20080266265A1Comfortable accessVehicle componentsInput/output processes for data processingDriver/operatorTouchpad

The present disclosure provides a moveable touch pad that opens out of a center console armrest and is operable to control a navigation unit or other vehicle functions. Advantageously, locating a control touch pad unit in the center console armrest provides an ergonomically desirable solution for the vehicle's driver. The touch pad can be stored in the vehicle's center console armrest, and the touch pad is configured to move fore and aft for comfortable driver access. Additionally, the control touch pad unit can be utilized to control other vehicle functions, such as audio, climate settings, odometer settings, lighting, mobile phones, and the like.

Owner:FCA US

Adjustable bed for patients

An improved raisable and adjustable bed, designed for facilitating a patient to access the bed and move away therefrom, is characterized in that said bed comprises a bottom framework, a top framework, and a supporting framework, for supporting a bed base or net including mutually hinged separated portions, actuator means, adapted to be operated by the bed user, for arranging said separated portions at different positions to allow the user to autonomously raise, in a gradual manner, and to assume different slanted positions.

Owner:MOBILSANITAS

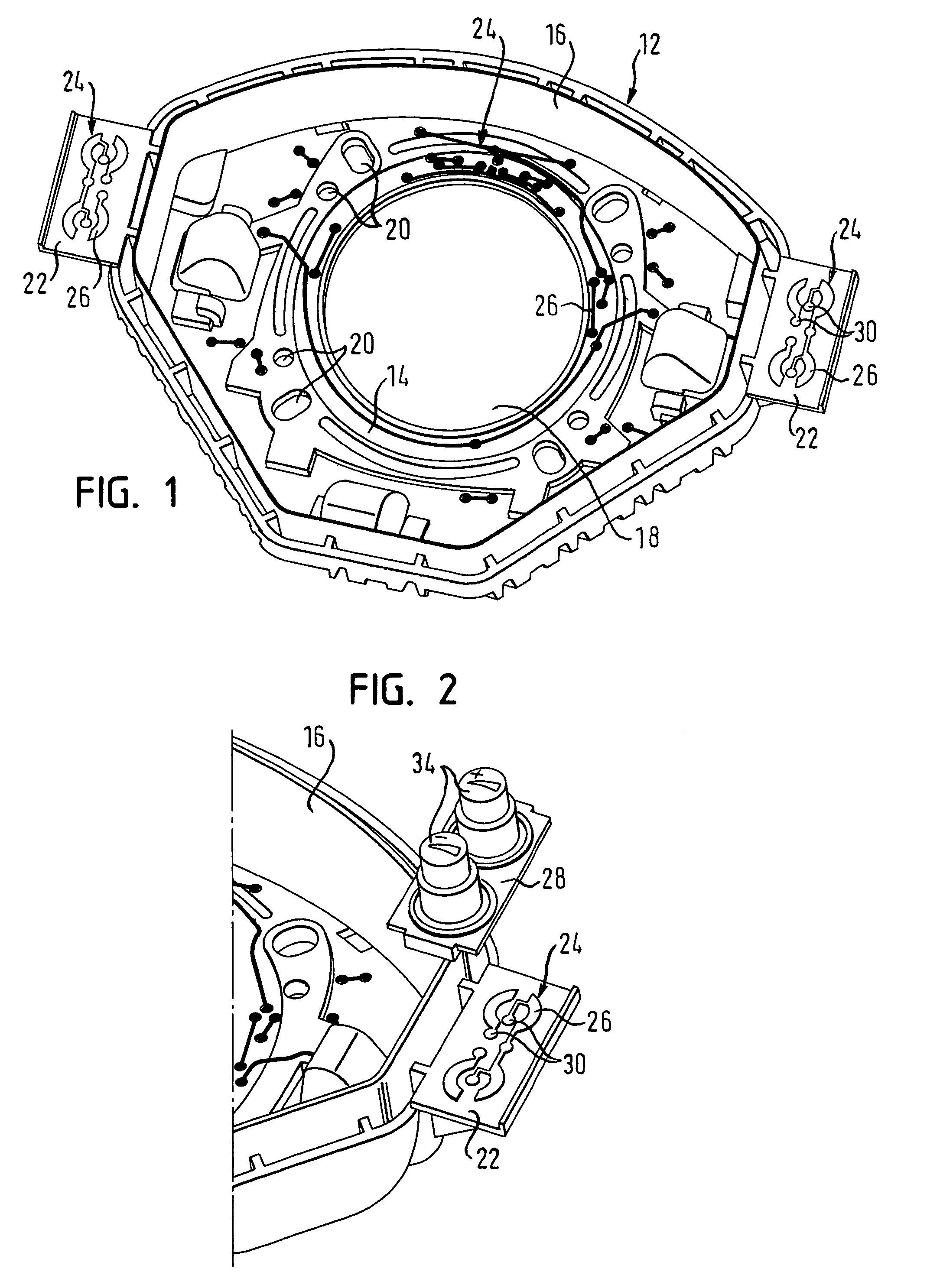

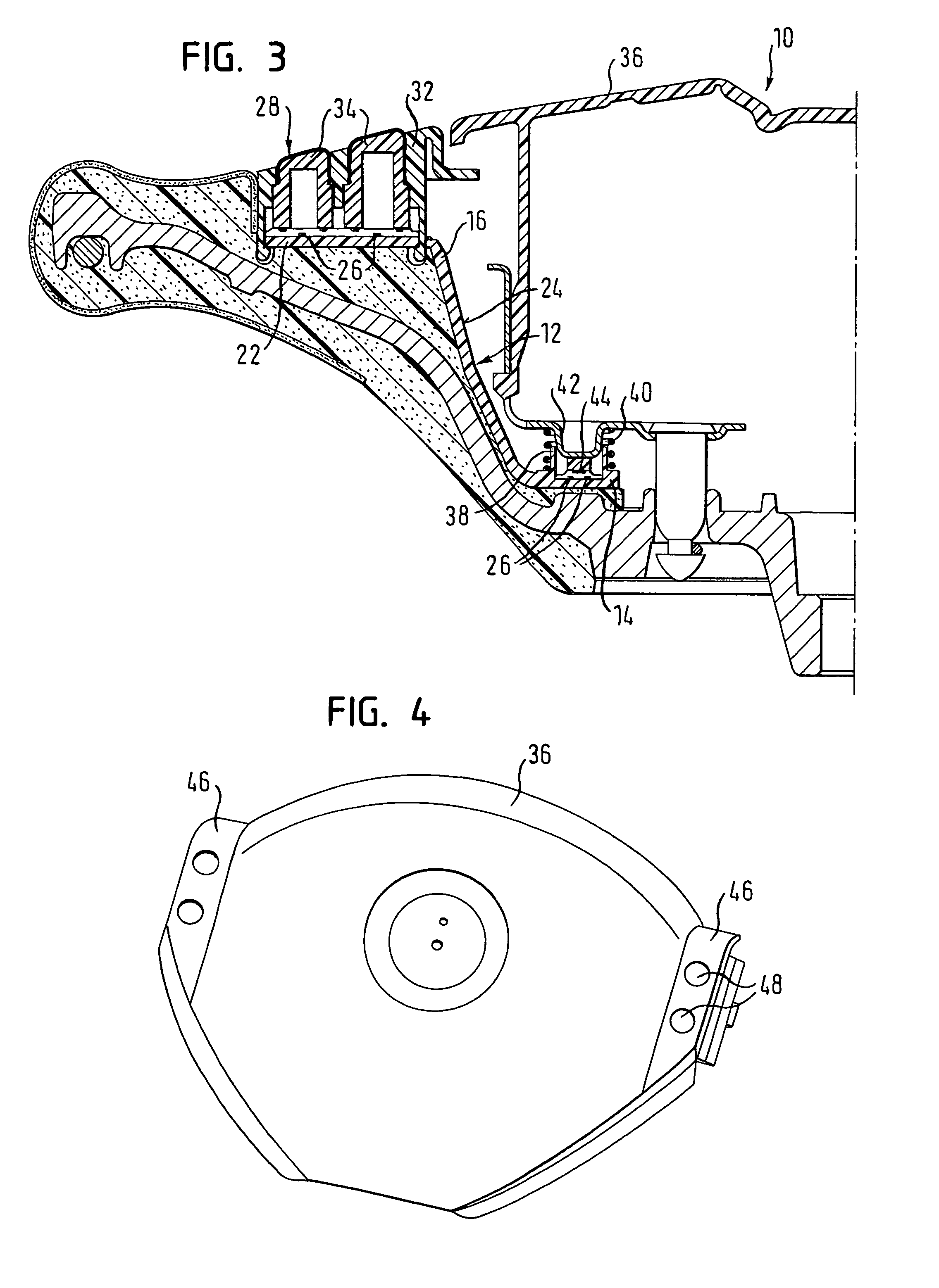

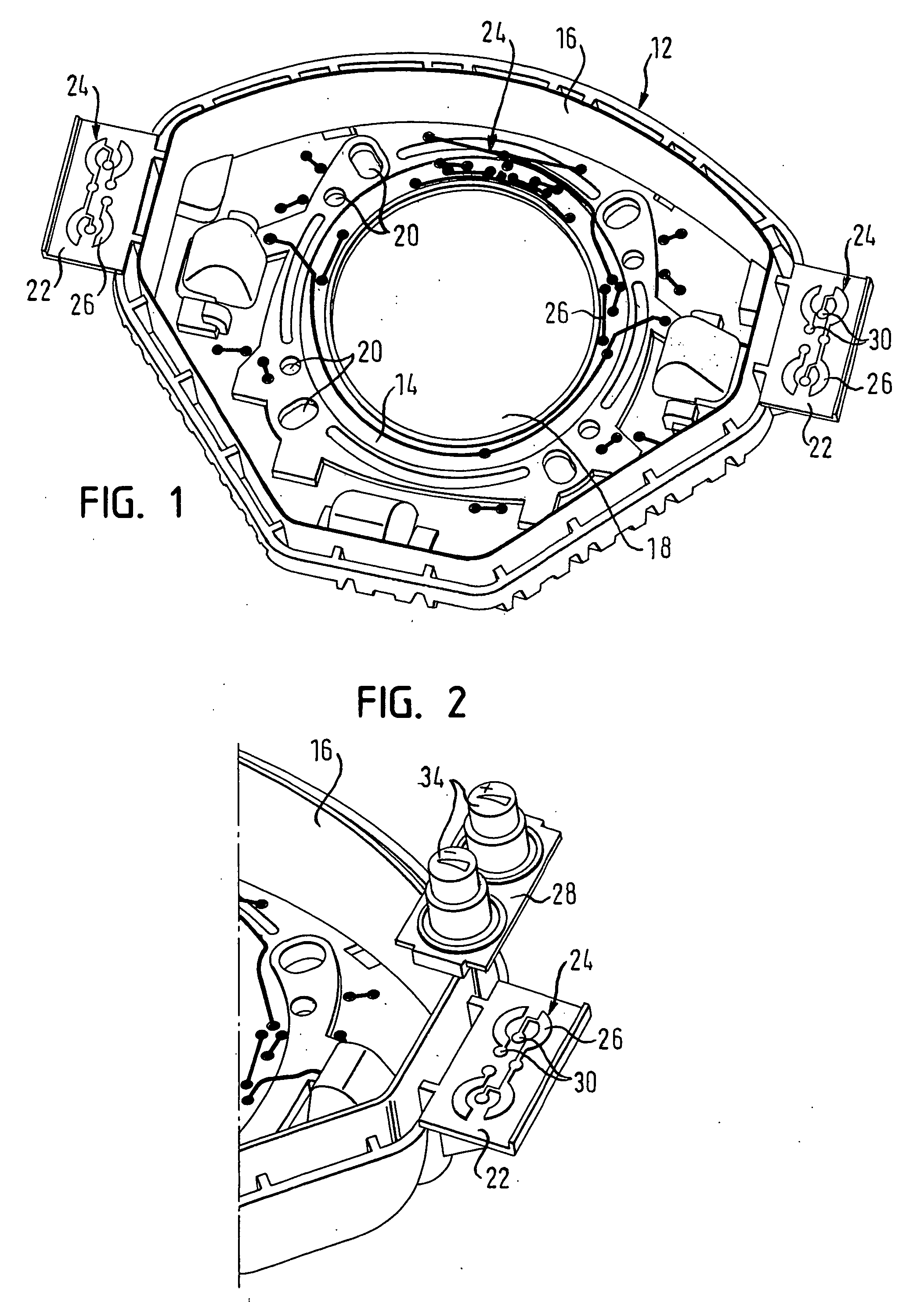

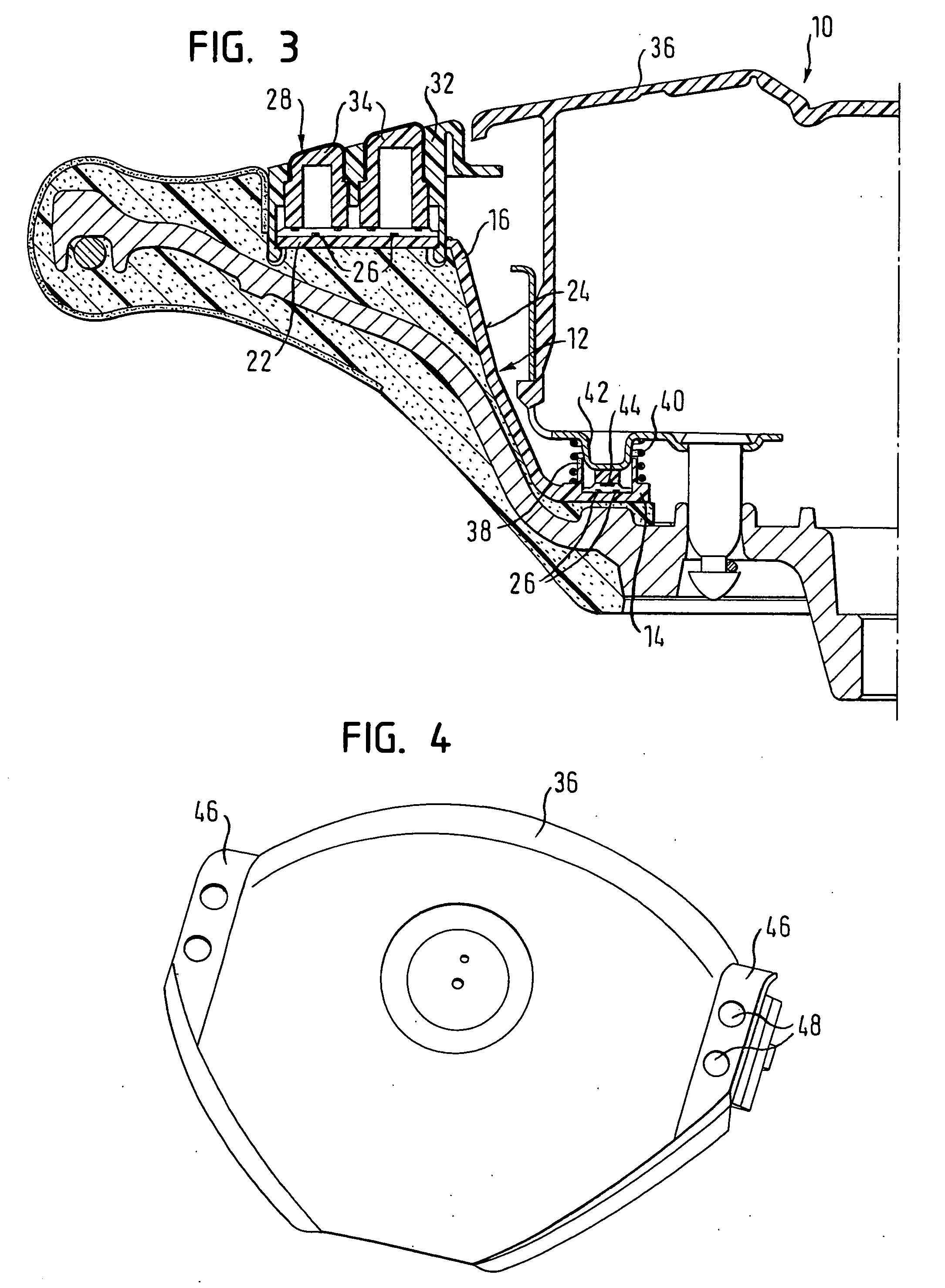

Gas bag module

InactiveUS7053322B2Cost-effectiveReduce weight3D rigid printed circuitsAcoustic signal devicesEngineeringAirbag deployment

A Gas bag module for use in a vehicle occupant restraint device has a plastic generator support. On the generator support a printed circuit is formed by metal deposition. For activating an electrical function element, the printed circuit cooperates with a switching element that is arranged on a section of the generator support.

Owner:TRW AUTOMOTIVE SAFETY SYST

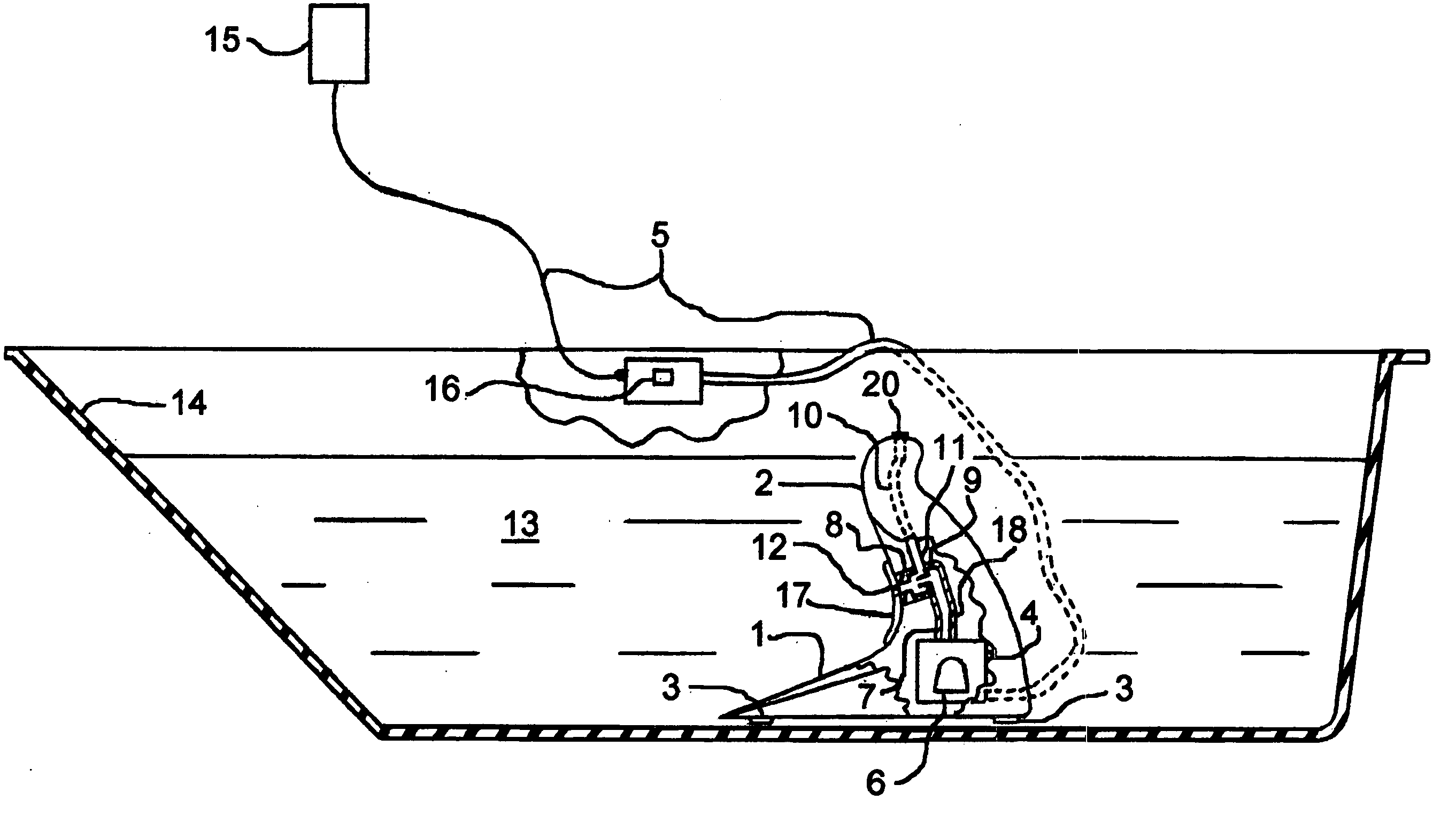

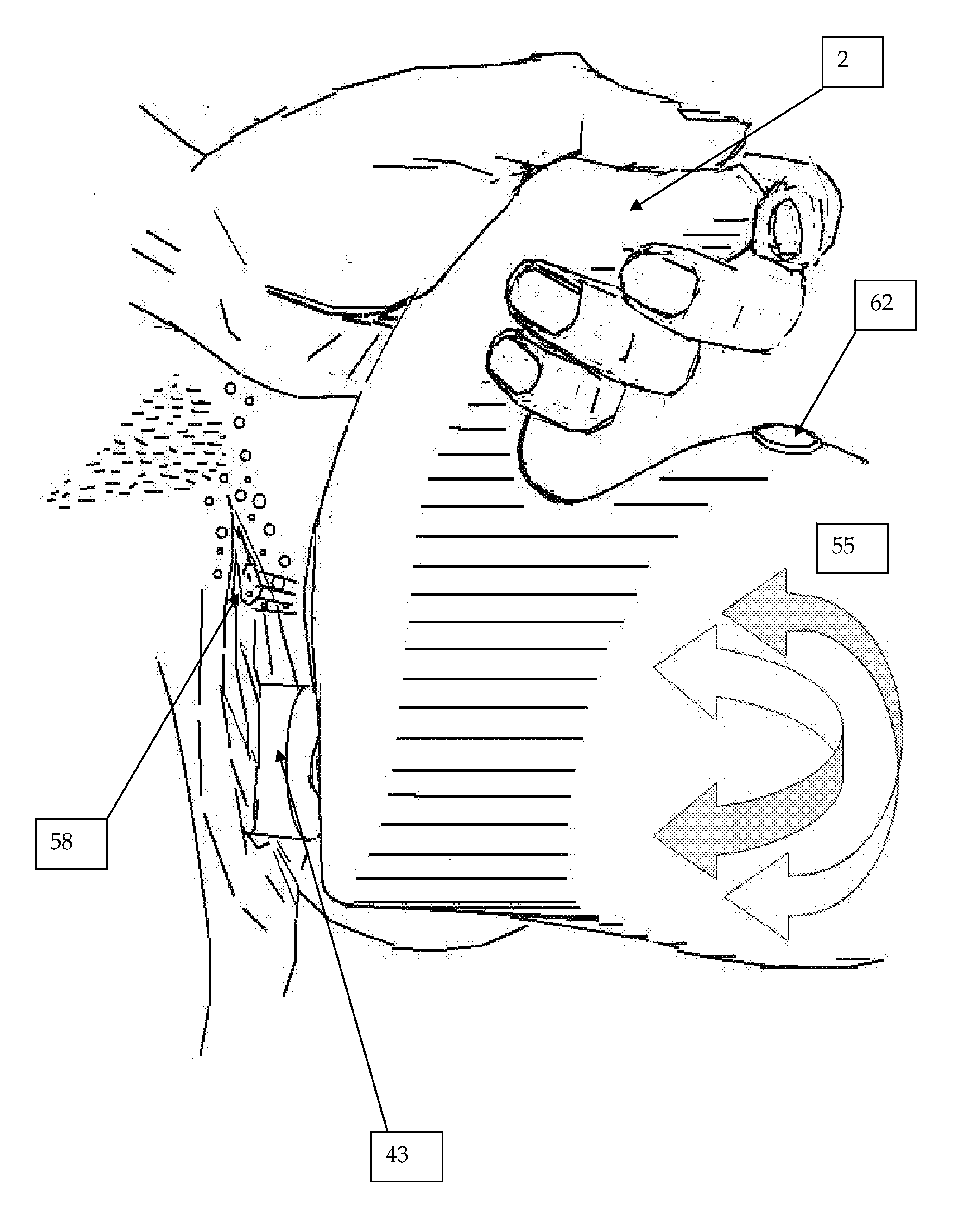

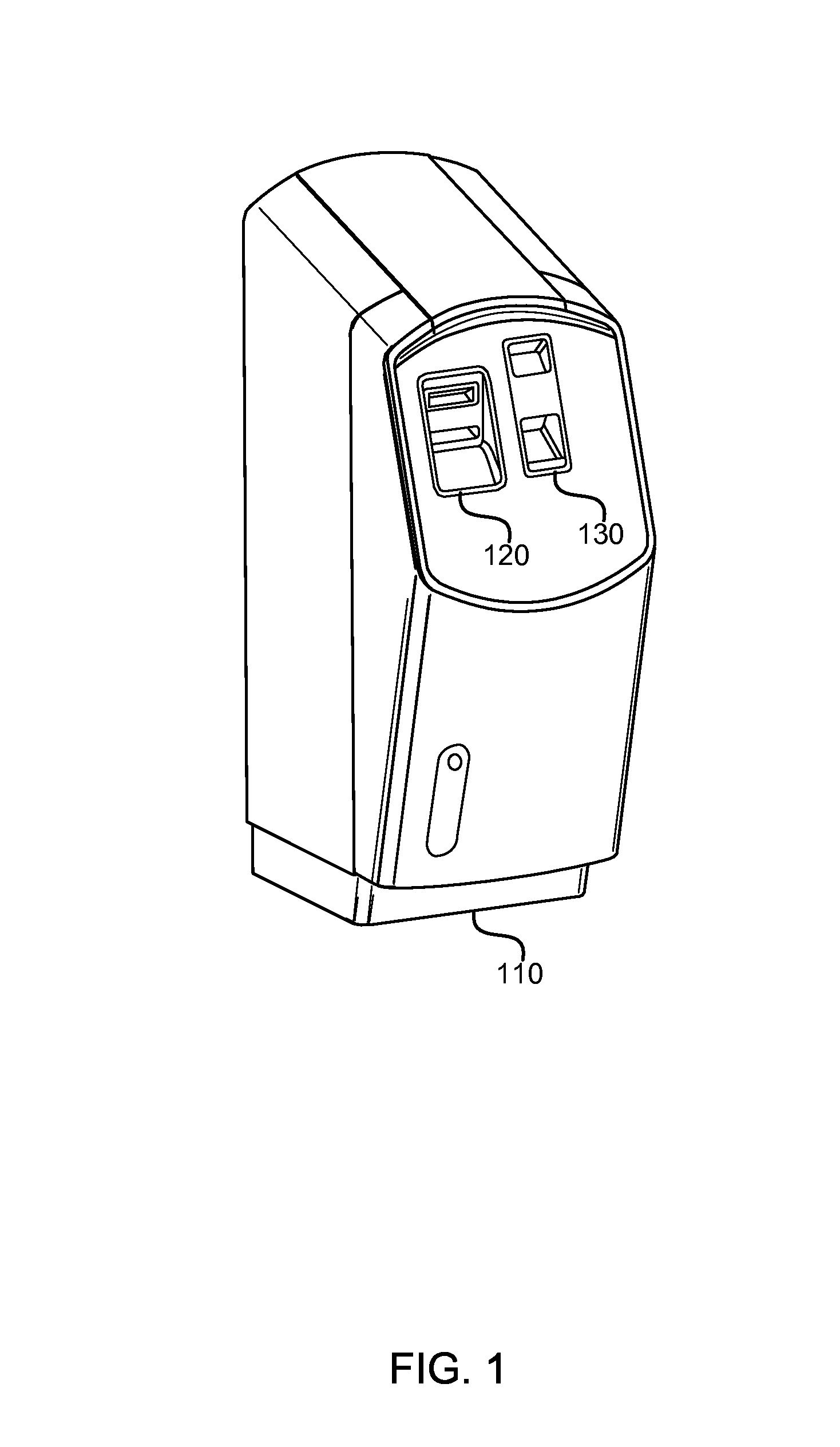

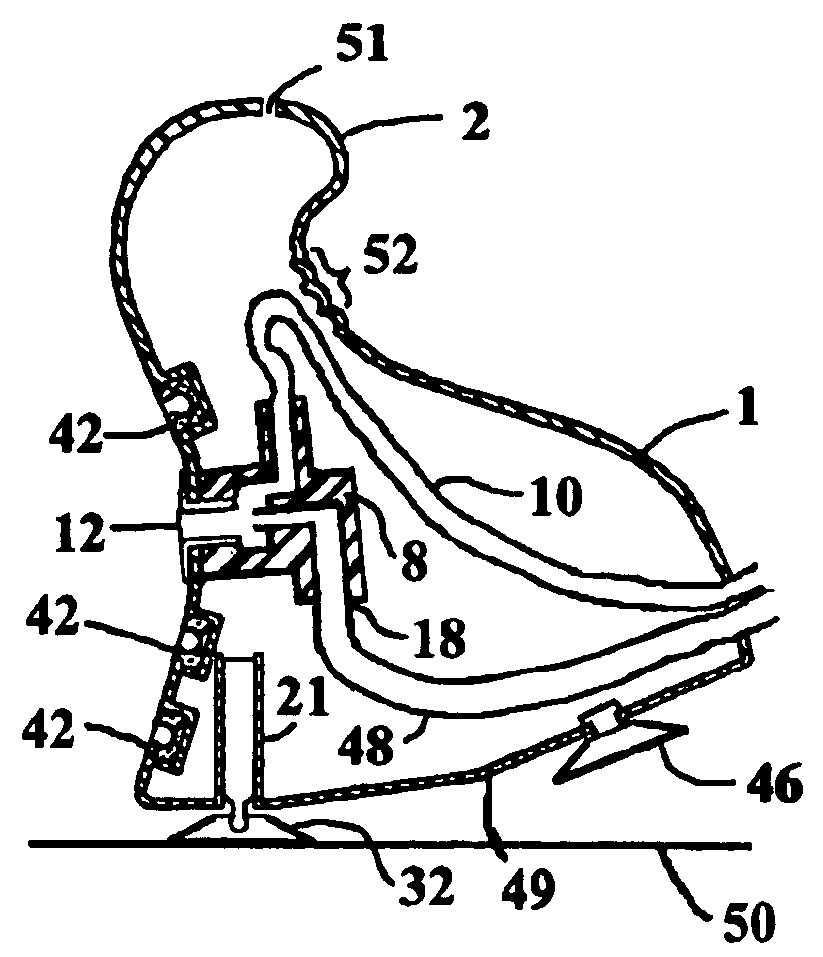

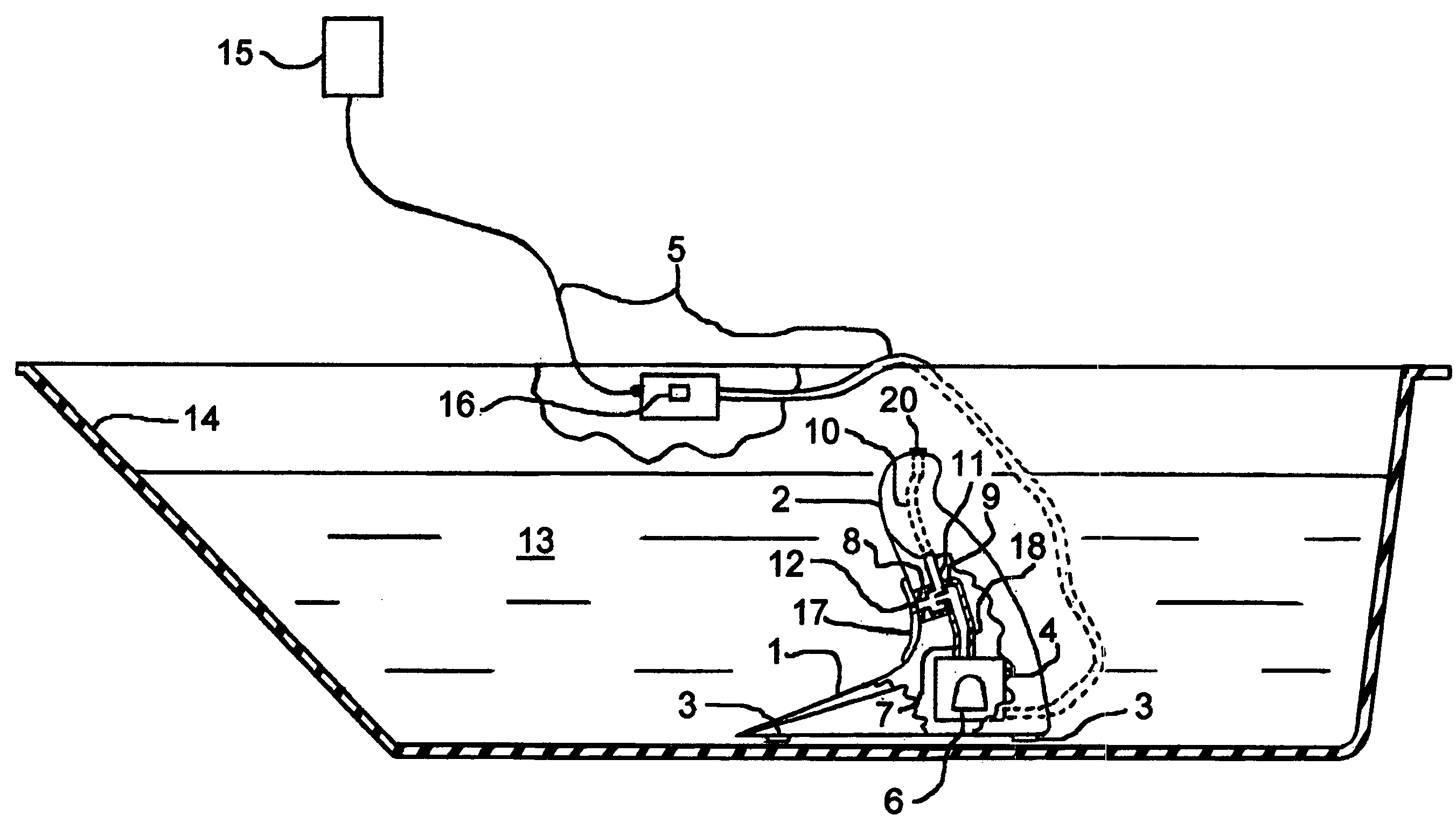

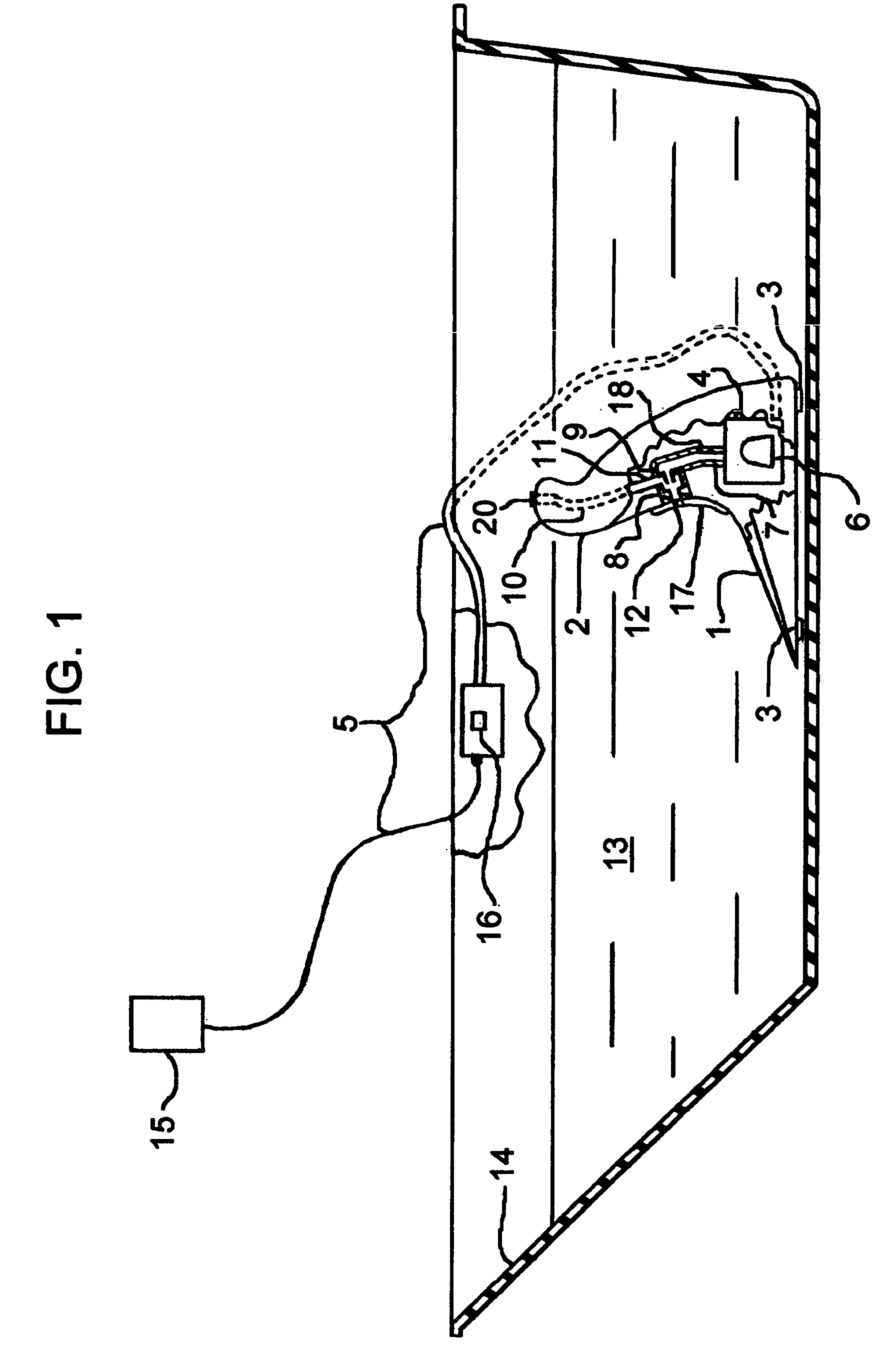

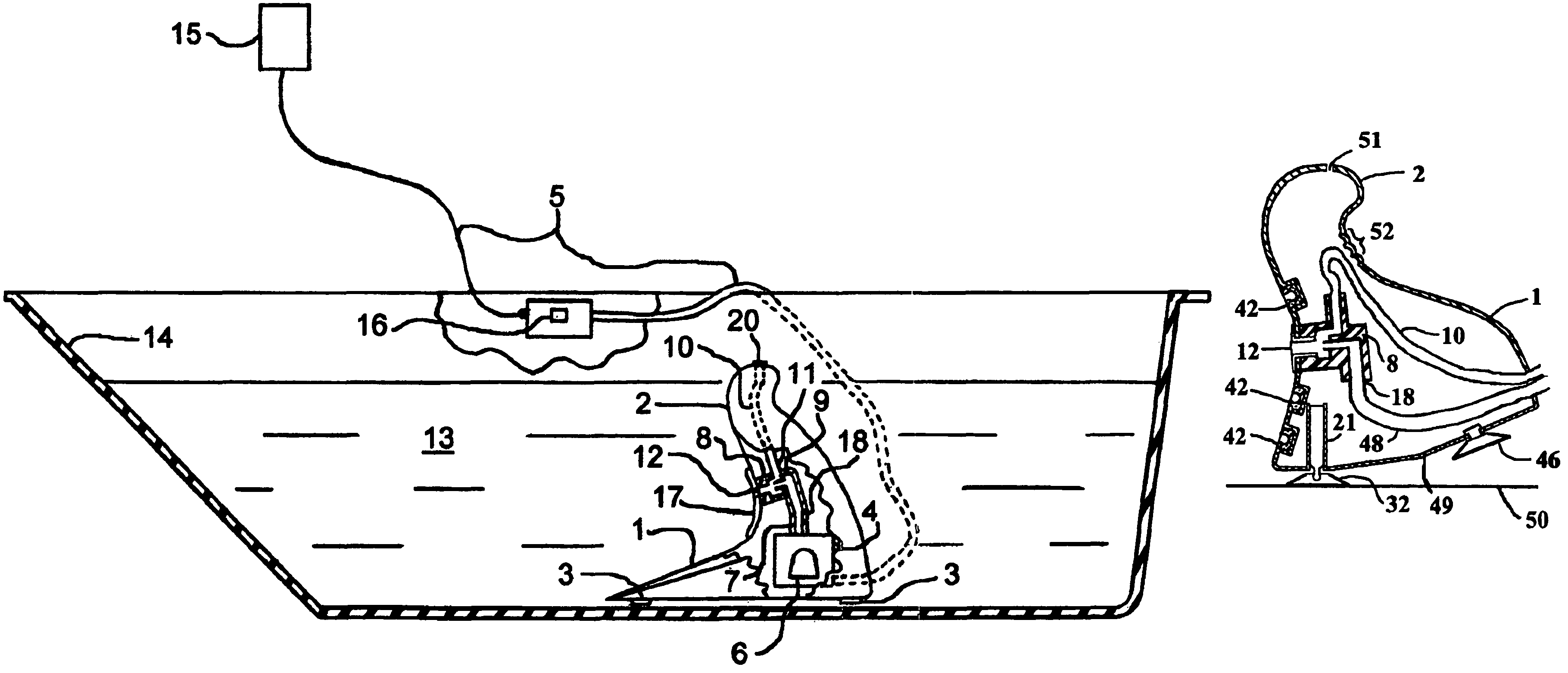

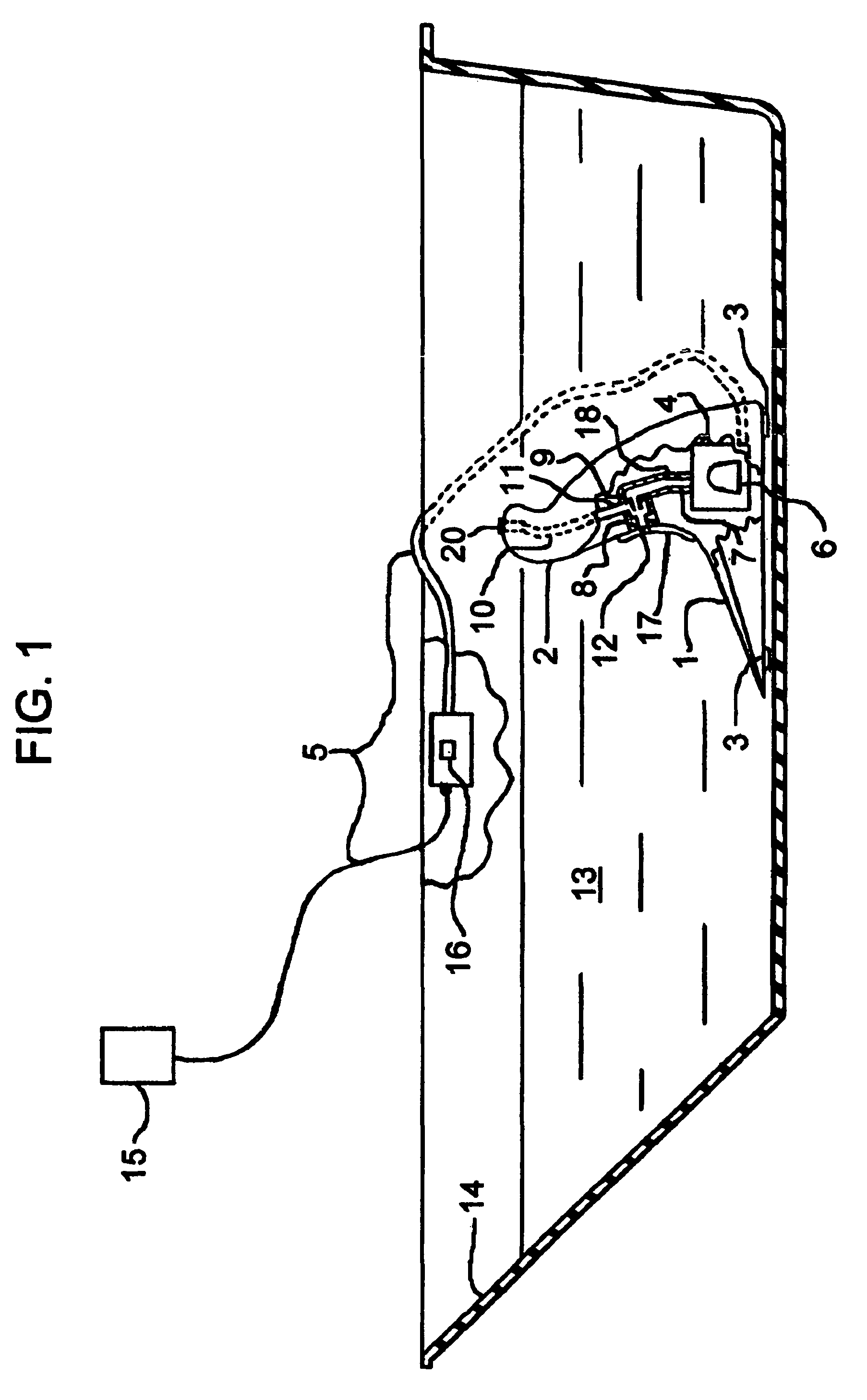

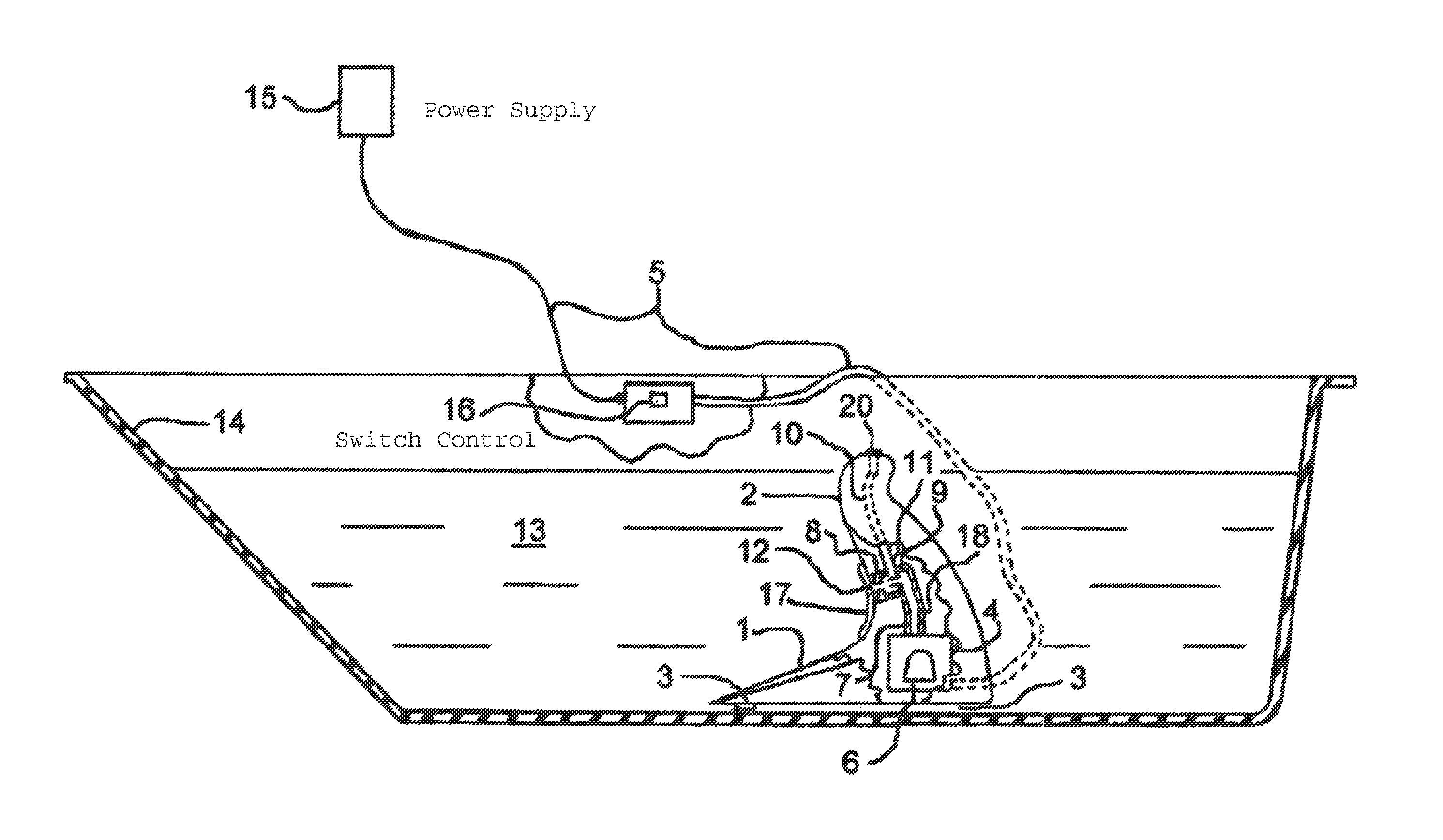

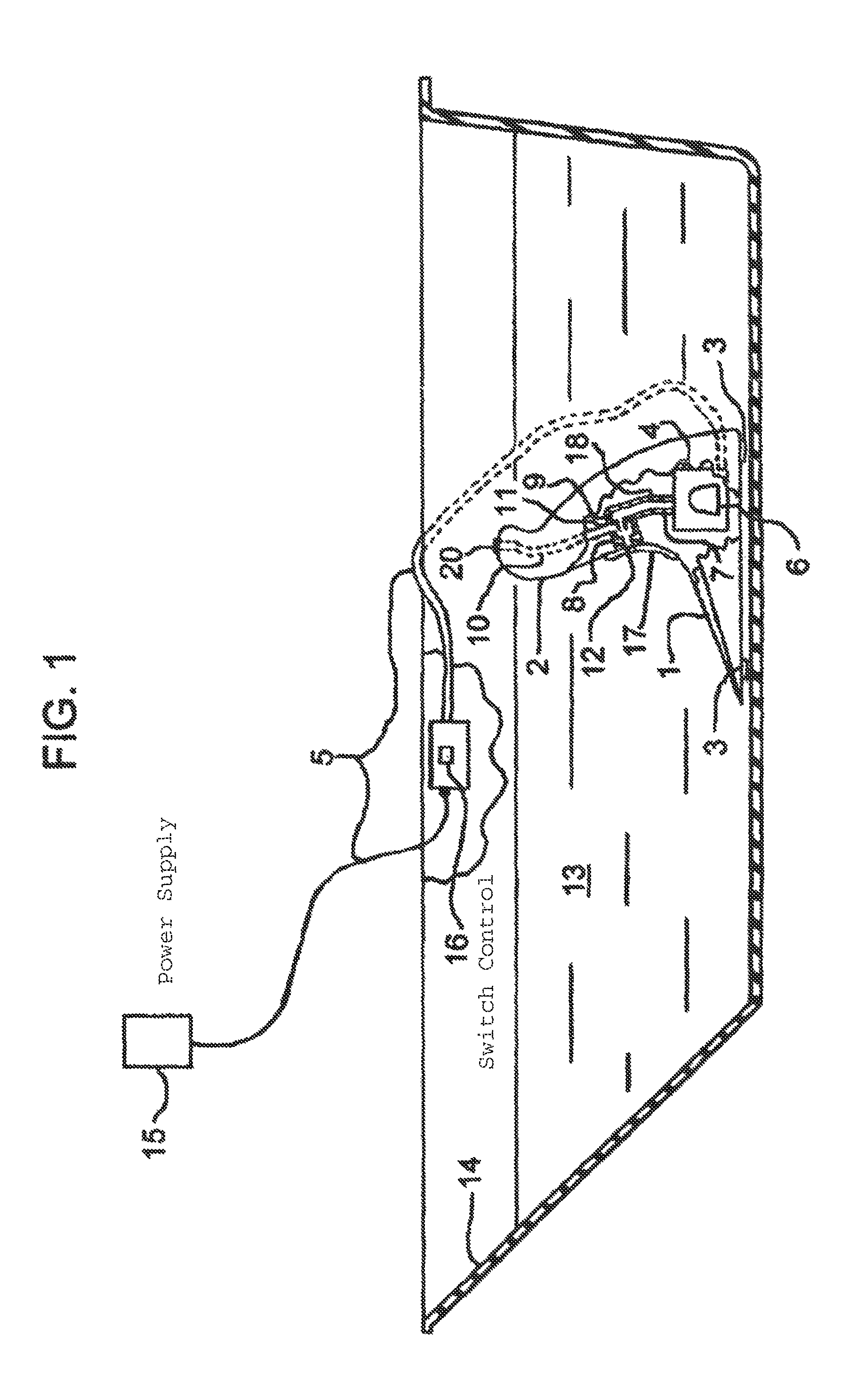

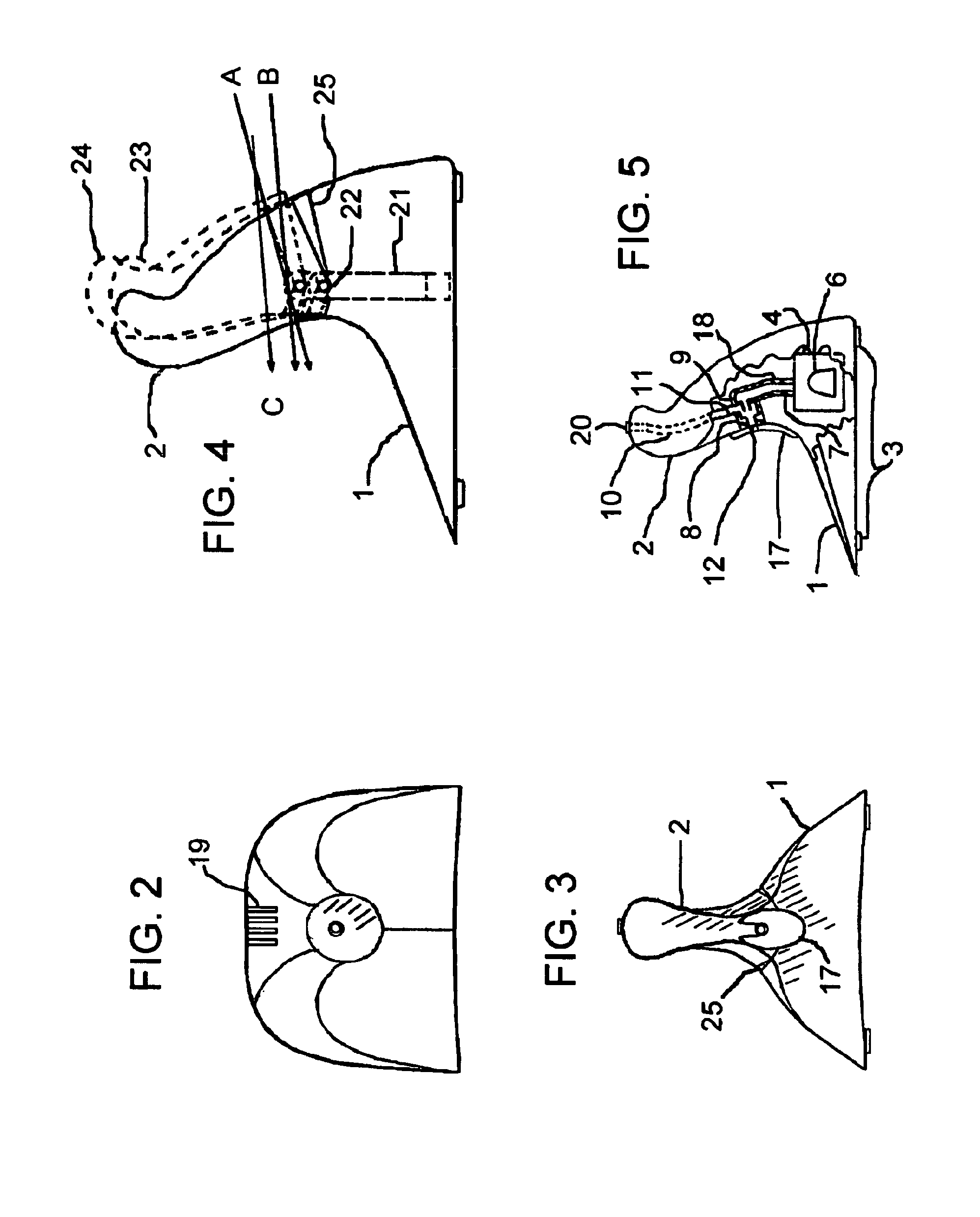

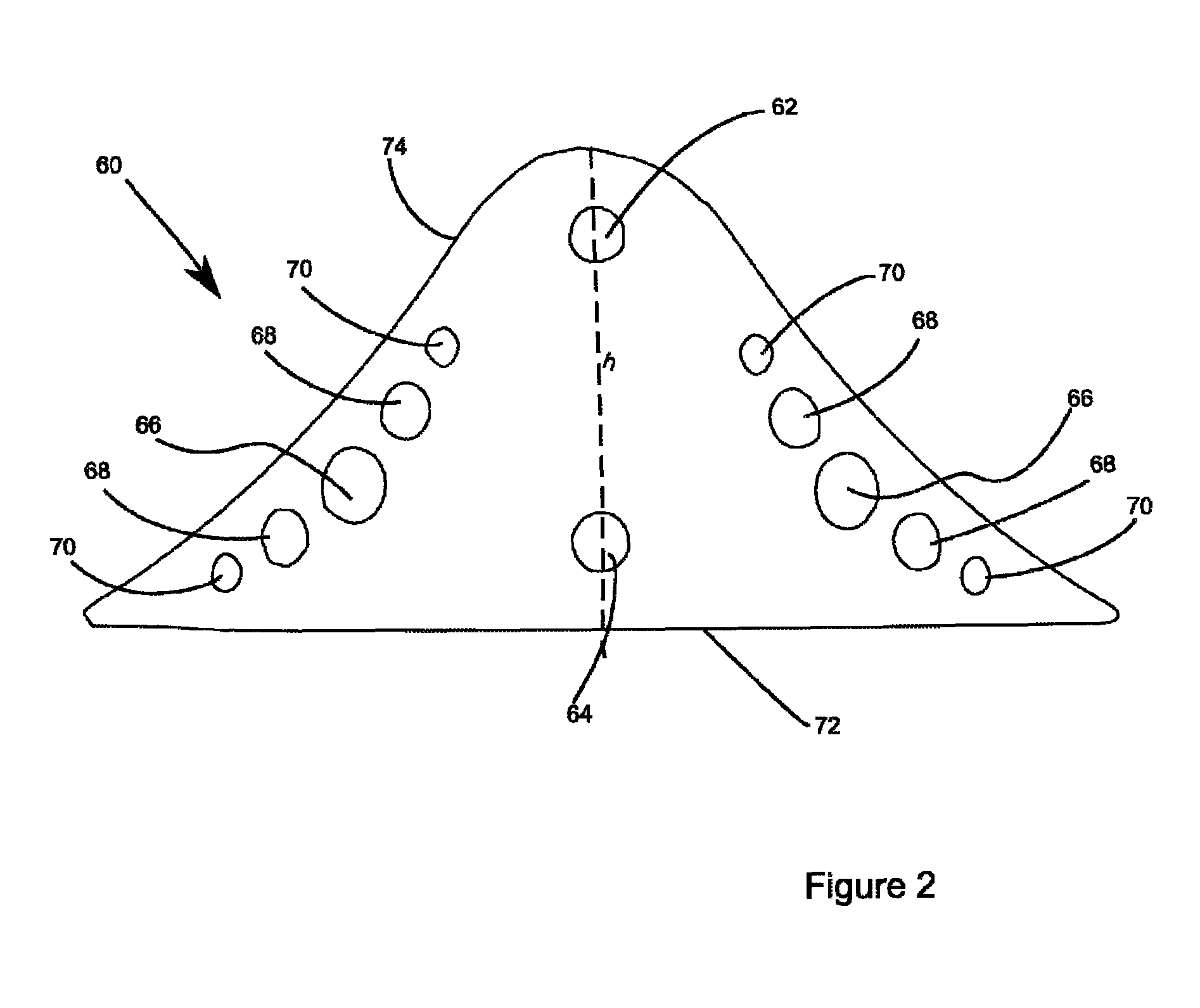

Feminine hydro-therapeutic massage device

InactiveUS20050197604A1Change is minimalImproves hydrotherapy stimulation deviceBathing devicesGenitals massagePelvic regionButtocks

A portable hydro massage device for submersion in a body of water containing a female user, i.e. a bathtub, provides a local massage to the labium region and a focused stimulant to the female user's clitoris thereby resulting in a superior sensation to the entire body promoting an overall euphoric state and calming effect. The apparatus employs a saddle shaped housing, where the buttocks are placed, and a saddle horn for controlling the stimulus. Disposed within the midsection of the saddle horn is a hydro jet with a driven flow from a circulating water pump that draws suction from the main body of water. The hydro jet is adjustable in pressure and a method is provided for aeration of the water discharged to allow for a rhythmic pulsation effect. The saddle horn may be held and the lower body positioned as needed to focus the discharged stream from the hydro jet to the desired point of the pelvic region.

Owner:BUBBLE LOVE

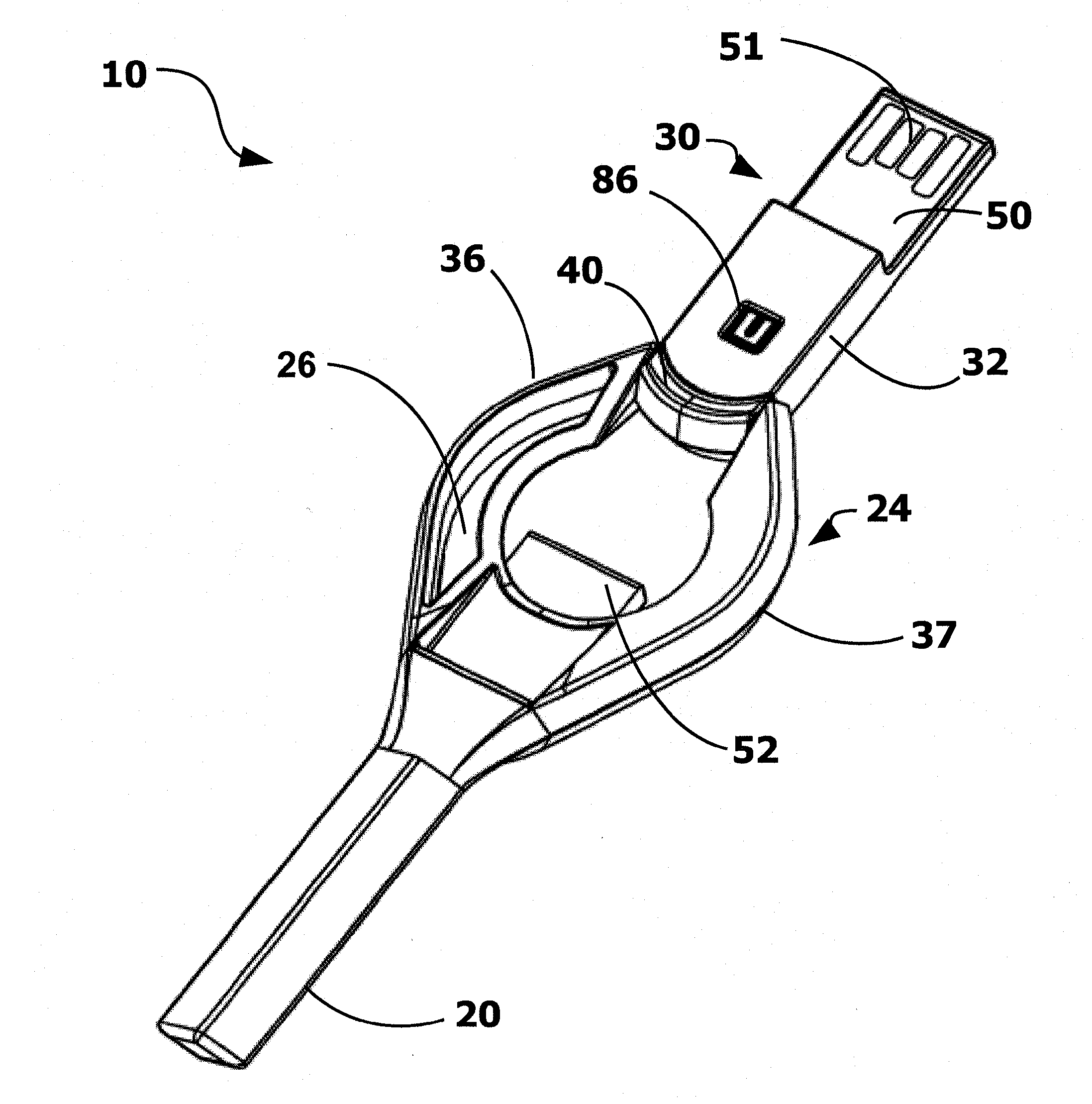

Hydro-therapeutic massage device

InactiveUS20090038069A1Improves hydrotherapy stimulation deviceImprove comfortVibration massageBathing devicesWater flowEngineering

Method and apparatus for hydrotherapeutic stimulation having a handle with housing with exterior engagement surfaces for contacting a user's lower body. An air-water stream generator, coupled to a water inlet and an air inlet, positioned in housing and a pump means imparts an increase in pressure and flow of water within housing to outlet nozzle. An electrical source is electrically connected to the pump means within the housing. An air-water stream outlet nozzle located within the fore portion of the housing and connected to air-water stream generator for transmission of air-water stream onto user's lower body positioned fore of air-water stream outlet nozzle. Either distended portion or attachment at fore portion of housing, upon insertion in an anal or a vaginal orifice in the user fixes the position of housing in relation to user's lower body thereby allowing handle further control of air-water stream outlet nozzle and stimulation.

Owner:BUBBLE LOVE

Sanitary pet feeding system

InactiveUS20180020637A1Easy to disassembleComfortable accessAnimal watering devicesAnimal feeding devicesEngineeringFungal contamination

A top surface of an elevating stand of a pet feeding system defines bowl receptacles into which respective food and water bowls may be removably installed. A first zone of the top surface of the stand includes an upwardly convex ring that laterally surrounds a respective bowl receptacle. A second zone of the top surface of the stand laterally surrounds the first zone, except as interrupted by a finger notch. Each bowl has a peripheral lip with a lower surface formed as a downwardly concave ring that is spaced over the upwardly convex ring of the stand. An edge of the bowl rests on the second zone at a location below the upper limit of the convex ring, thereby supporting the entire weight of the bowl and its contents on the stand. A base of the stand cooperates with upstanding ribs in an elastomeric mat to prevent lateral movement of the stand and to prevent rotation of the stand around the stand center. Compositions and shapes of the stand, bowls and mat are chosen to make them easy to clean and to reduce bacterial and fungal contamination.

Owner:MACNEIL IP

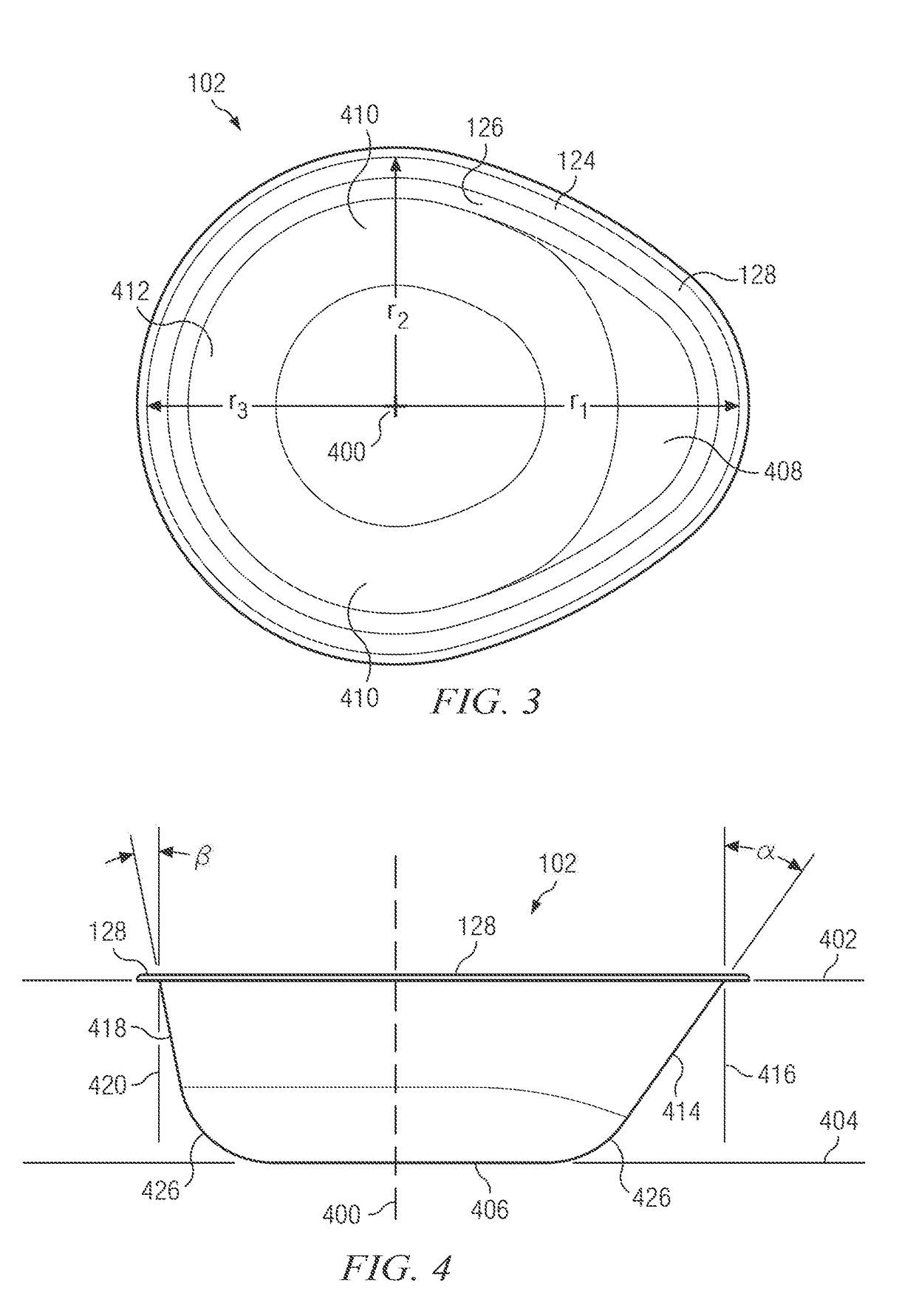

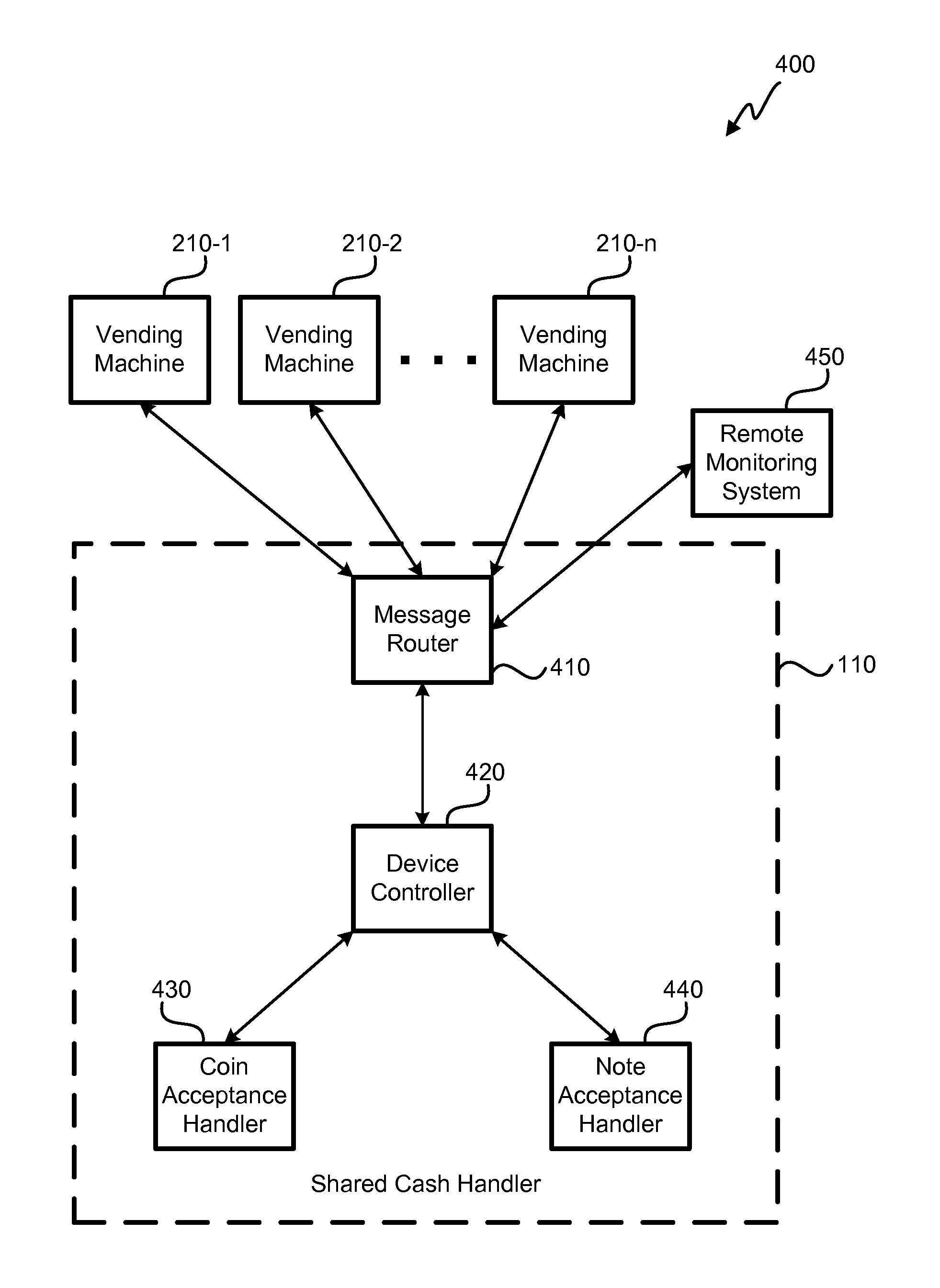

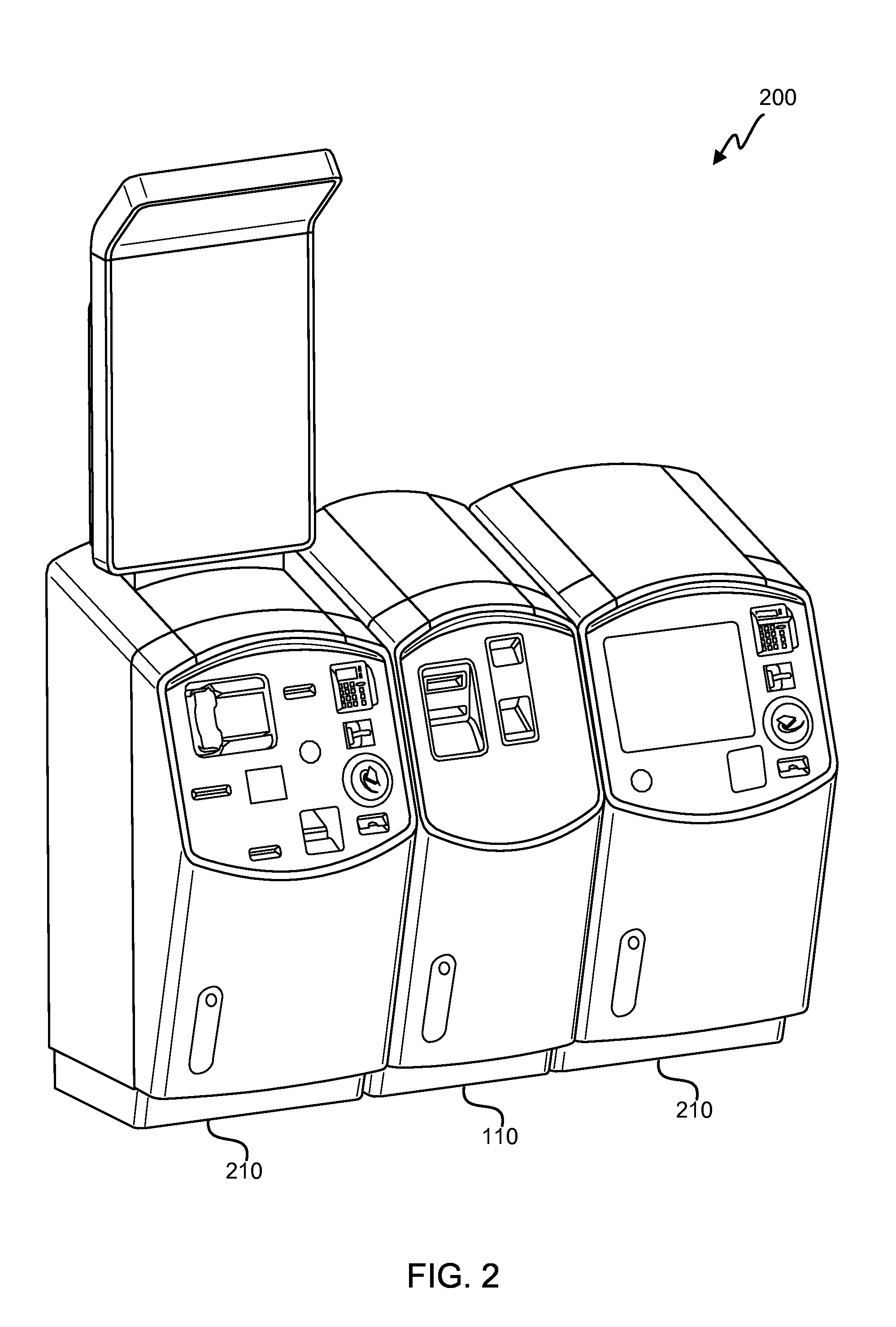

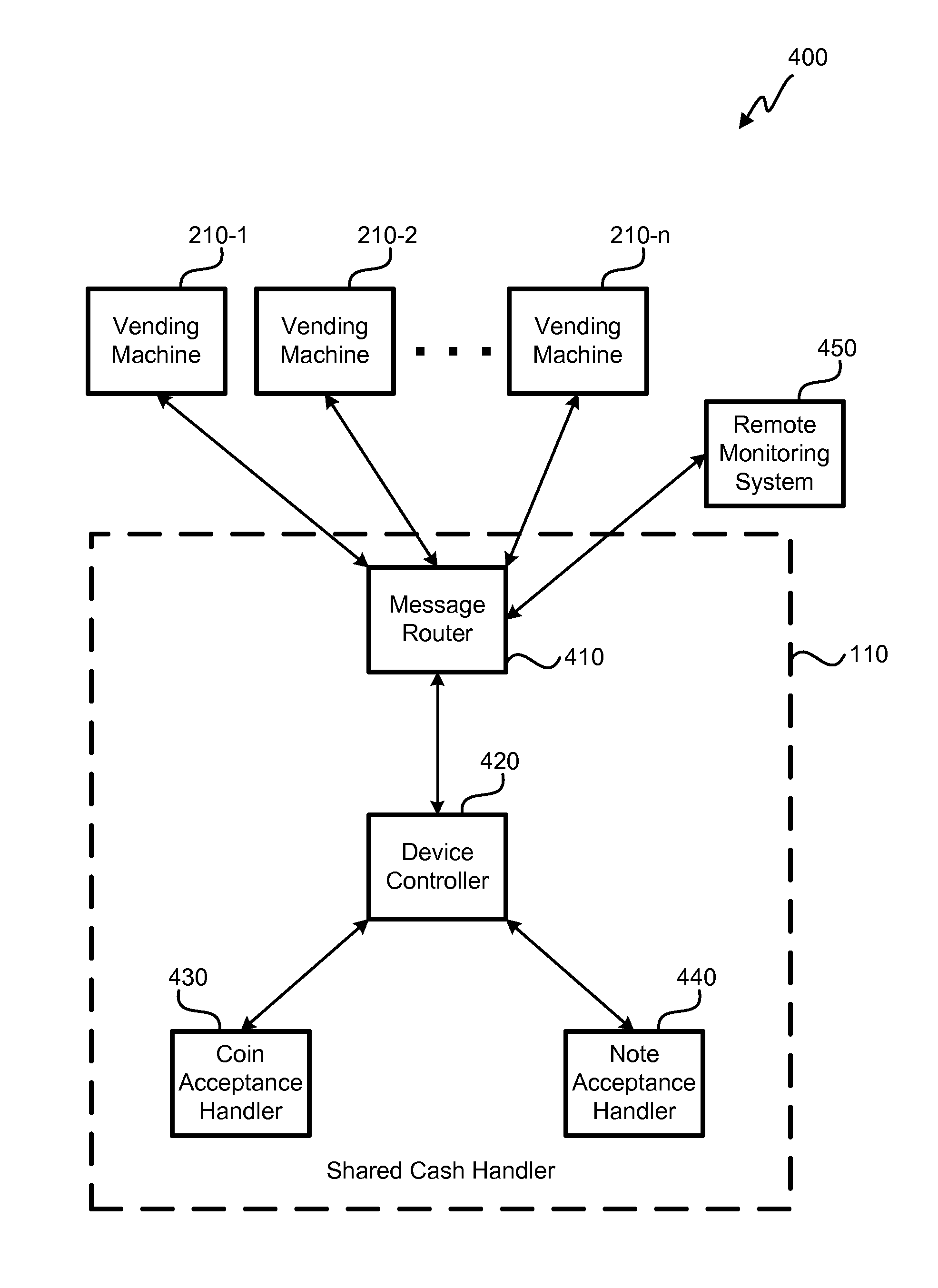

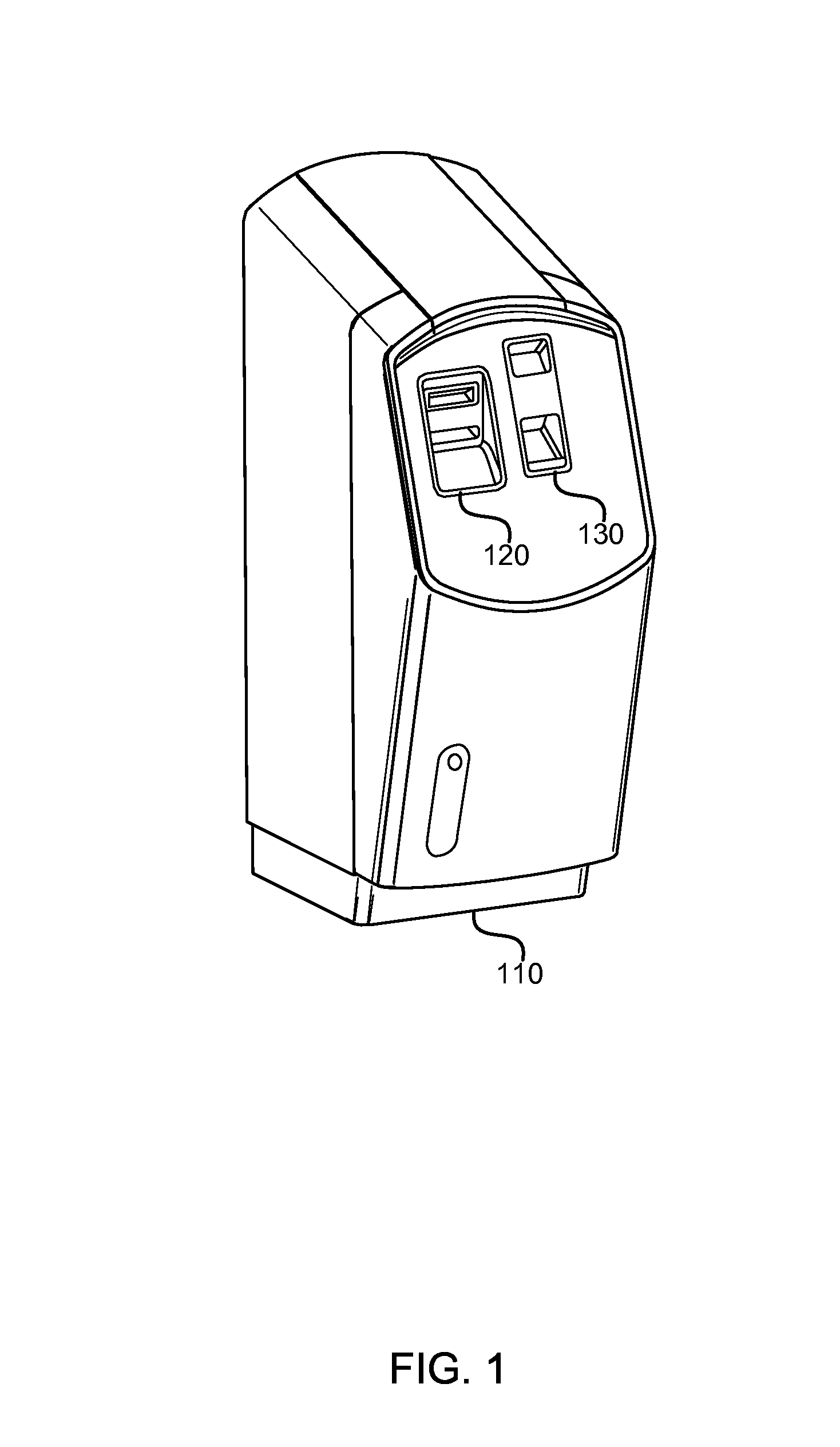

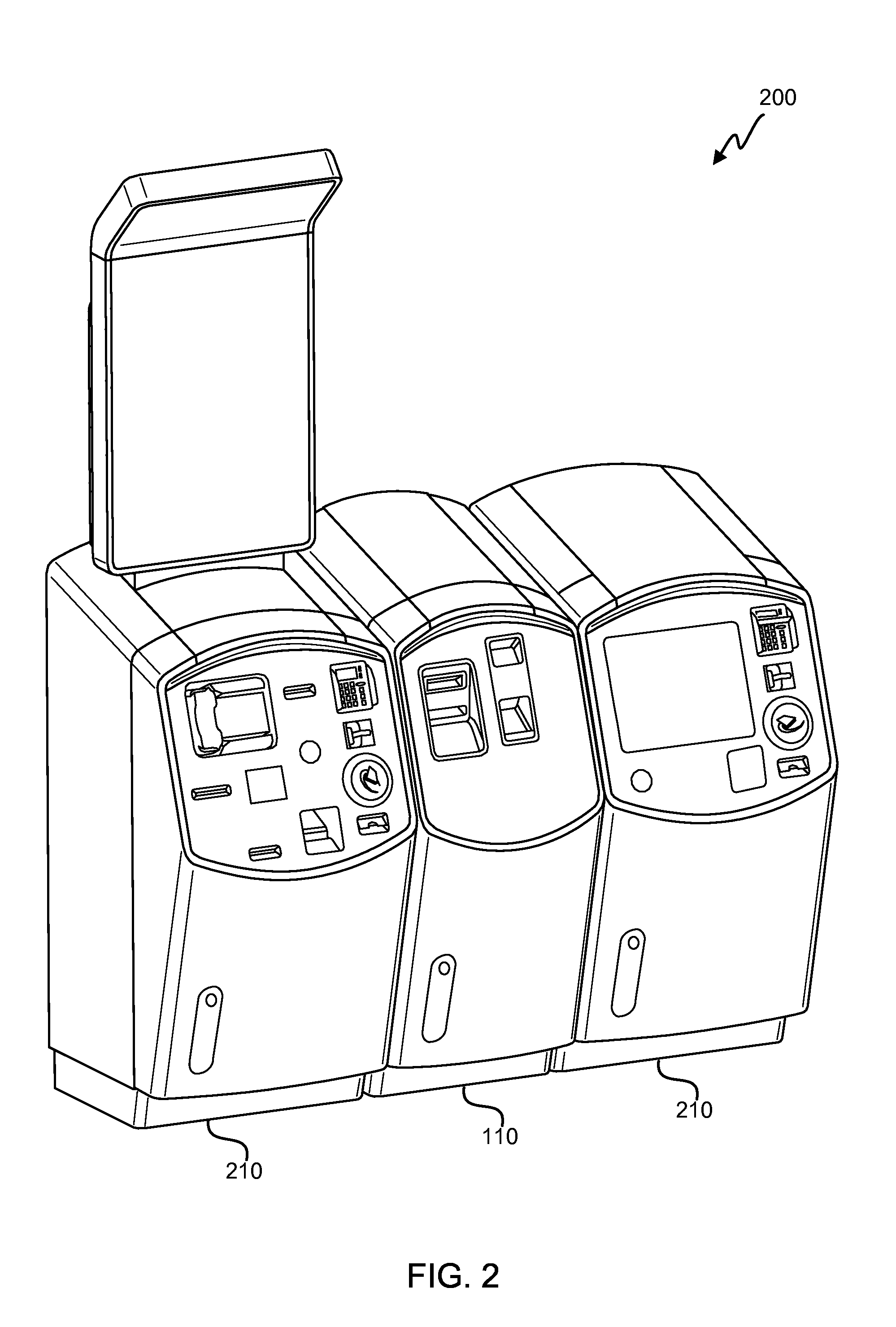

Shared cash handler

InactiveUS20140025200A1Increase availabilityExtra costControlling coin-freed apparatusCoin-freed apparatus detailsData mining

A cash hander can be coupled with multiple vending machines or other devices to enable the vending machines to accept cash. Through various interactions, the cash handler can provide status updates to the vending machines and relinquish control a particular vending machine to accept cash for that vending machine. The cash handler can also maintain a queue to manage and / or prioritize requests from vending machines to accept cash.

Owner:CUBIC CORPORATION

Feminine hydro-therapeutic massage device

InactiveUS20080091060A1Change is minimalImproves hydrotherapy stimulation deviceDomestic plumbingBathing devicesButtocksPelvic region

A portable hydro massage device for submersion in a body of water containing a female user, i.e. a bathtub, provides a local massage to the labium region and a focused stimulant to the female user's clitoris thereby resulting in a superior sensation to the entire body promoting an overall euphoric state and calming effect. The apparatus employs a saddle shaped housing, where the buttocks are placed, and a saddle horn for controlling the stimulus. Disposed within the midsection of the saddle horn is a hydro jet with a driven flow from a circulating water pump that draws suction from the main body of water. The hydro jet is adjustable in pressure and a method is provided for aeration of the water discharged to allow for a rhythmic pulsation effect. The saddle horn may be held and the lower body positioned as needed to focus the discharged stream from the hydro jet to the desired point of the pelvic region.

Owner:BUBBLE LOVE

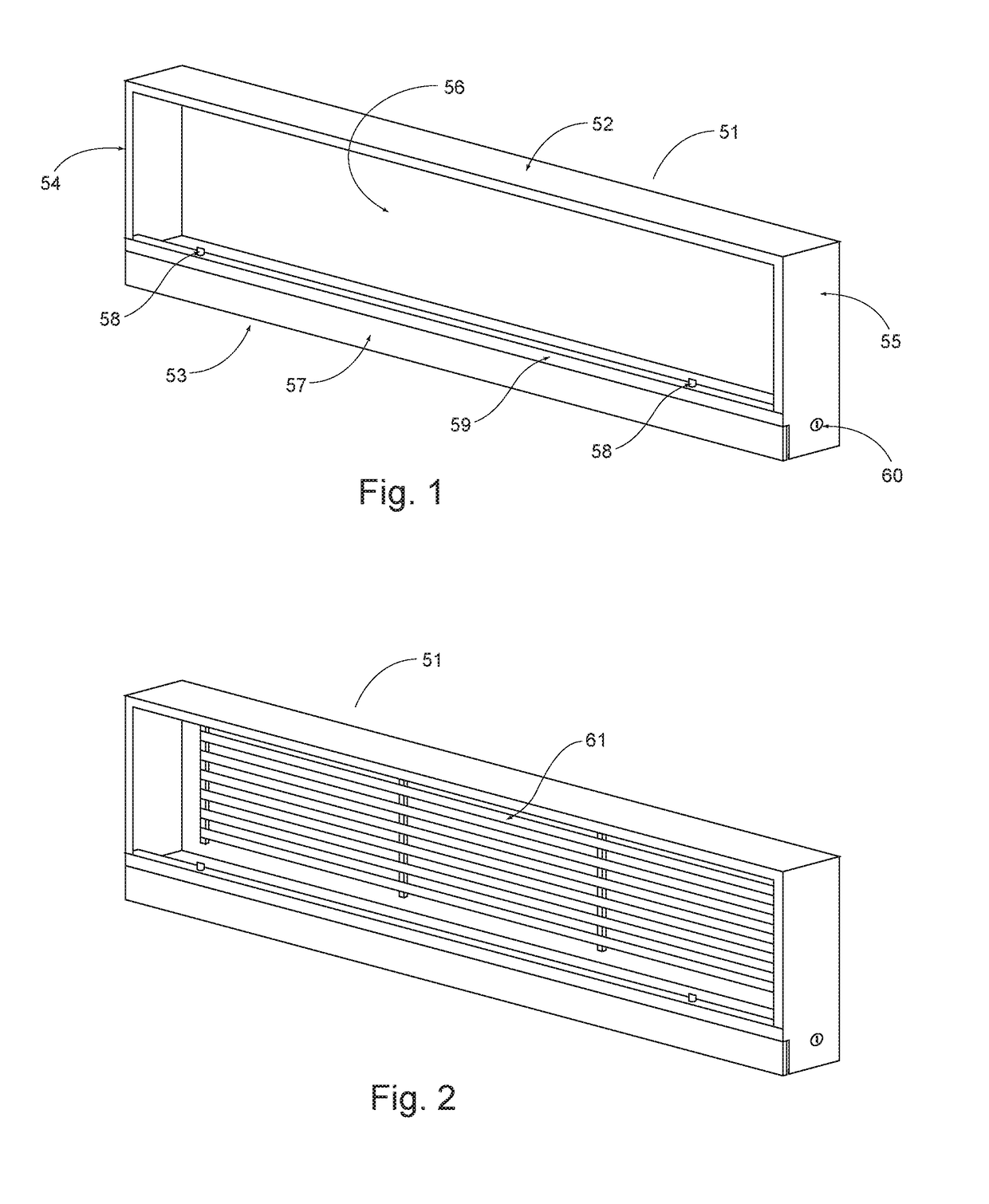

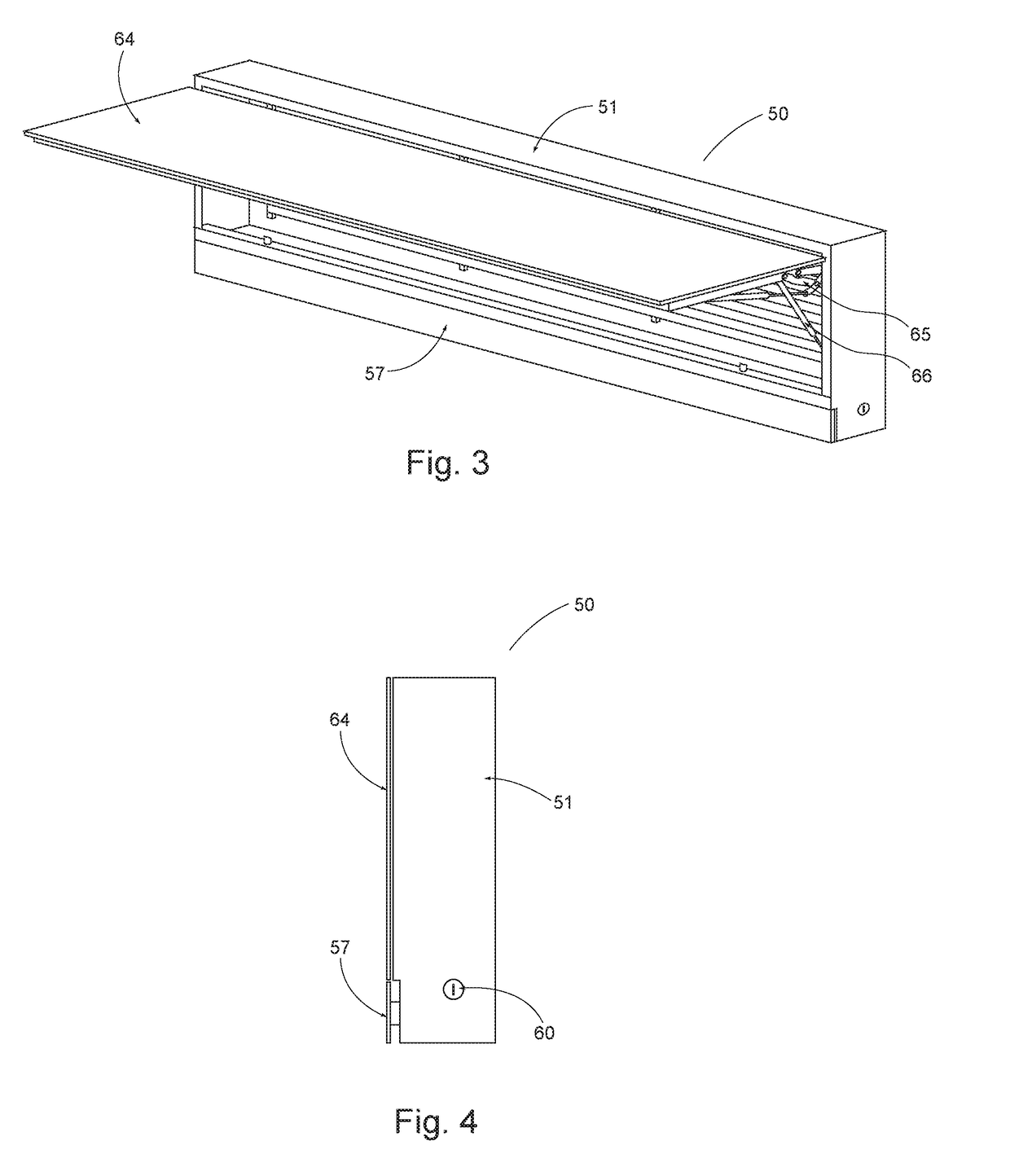

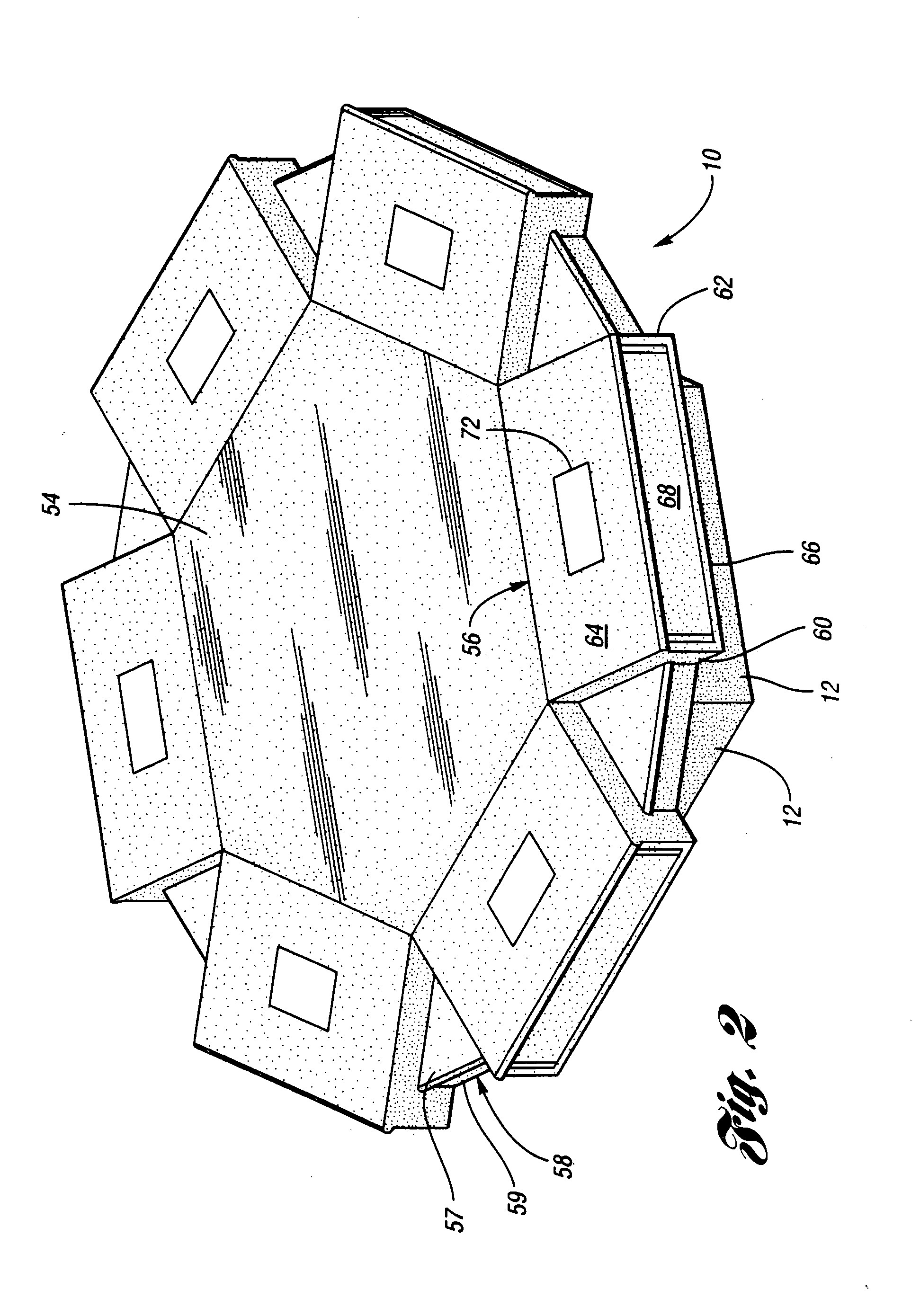

Secure enclosure for the storage and rapid retrieval of self-defense weapons

InactiveUS20190038024A1Comfortable accessDifficult to accessSofasBedsFasciaElectrical and Electronics engineering

A storage enclosure of ample size to contain common firearms within, comprising a box with a door attached to the top of the box with articulating hinges, that latches at the bottom of the box. A latch release mechanism at the bottom of the box, with a release bar on the exterior of the bottom of the box, which when pressed inward, releases the latches and allows the door to open unassisted by the user via the force of compression springs. Within the interior of the storage enclosure are slatted attachment structures—both on the interior of the box and the interior of the door—to which a vast array of self-defense weapons can be mounted with retaining devices of various type (hooks, pegs, etc.). To the storage enclosure assembly is attached cladding elements—legs, panels, fascia—to make a bed headboard.

Owner:COONS SCOTT WARREN

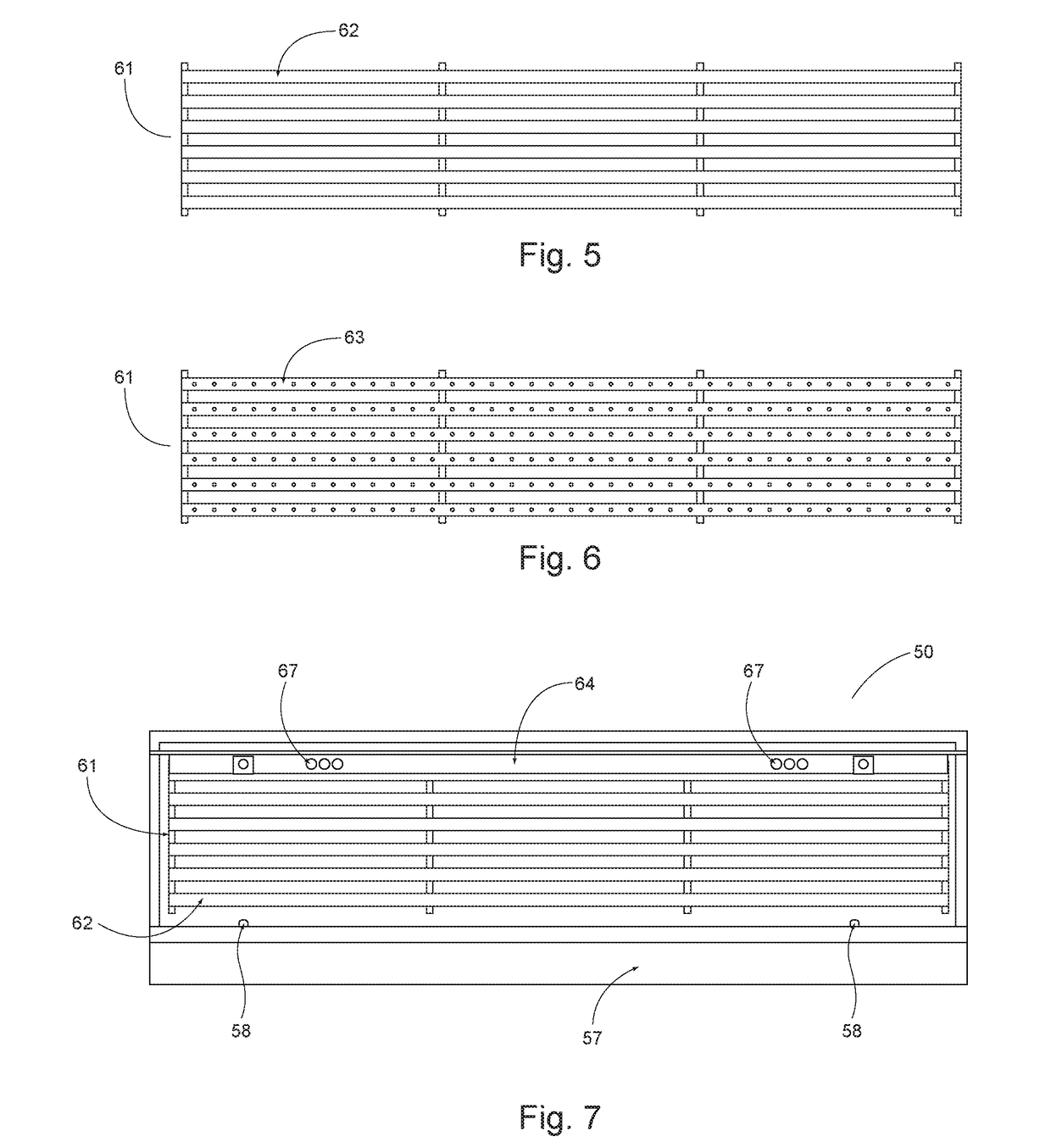

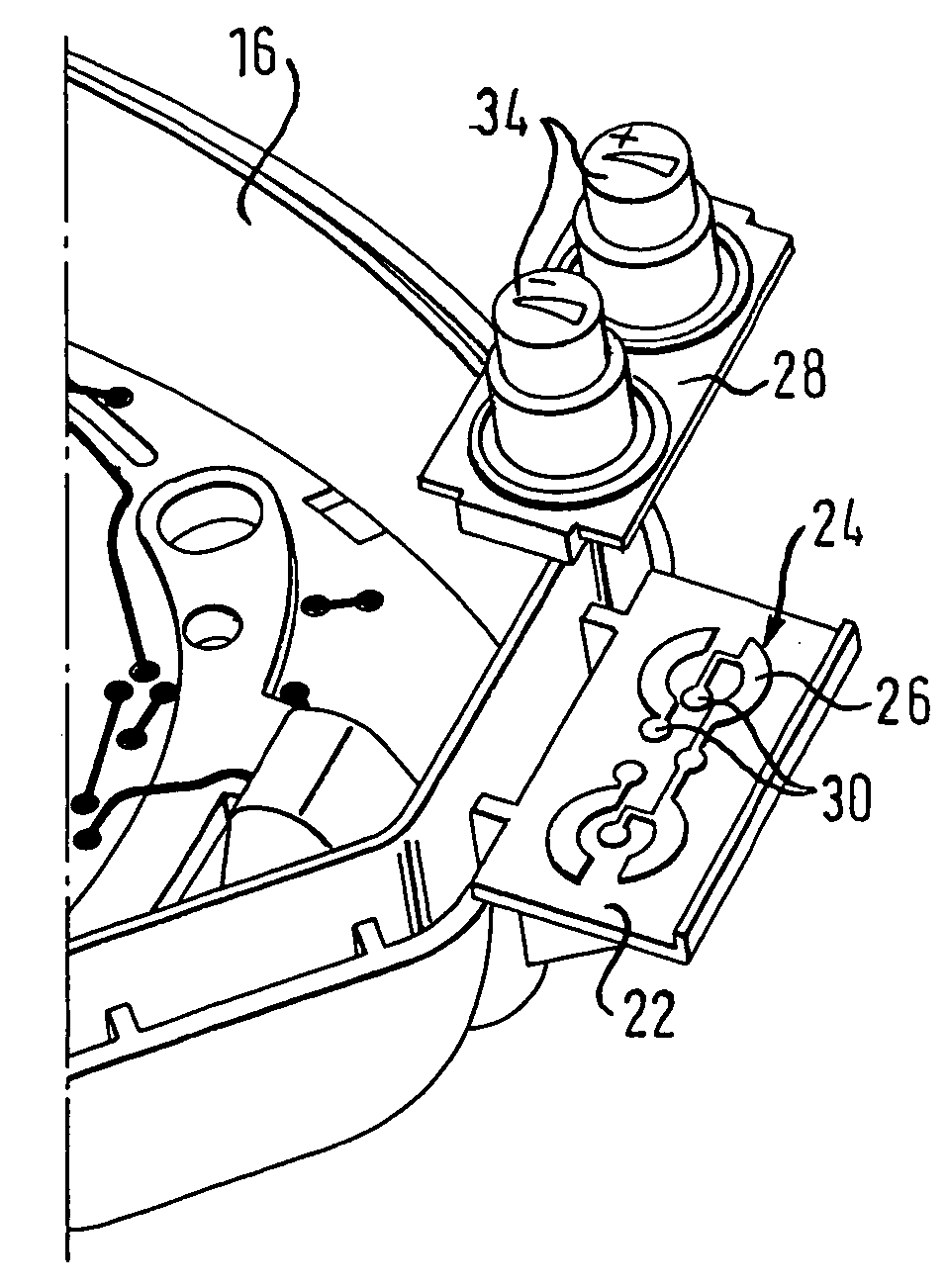

Gas bag module

InactiveUS20060027448A1Reduce weightSave space3D rigid printed circuitsAcoustic signal devicesElectrical and Electronics engineeringMetal deposition

A Gas bag module for use in a vehicle occupant restraint device has a plastic generator support. On the generator support a printed circuit is formed by metal deposition. For activating an electrical function element, the printed circuit cooperates with a switching element that is arranged on a section of the generator support.

Owner:TRW AUTOMOTIVE SAFETY SYST

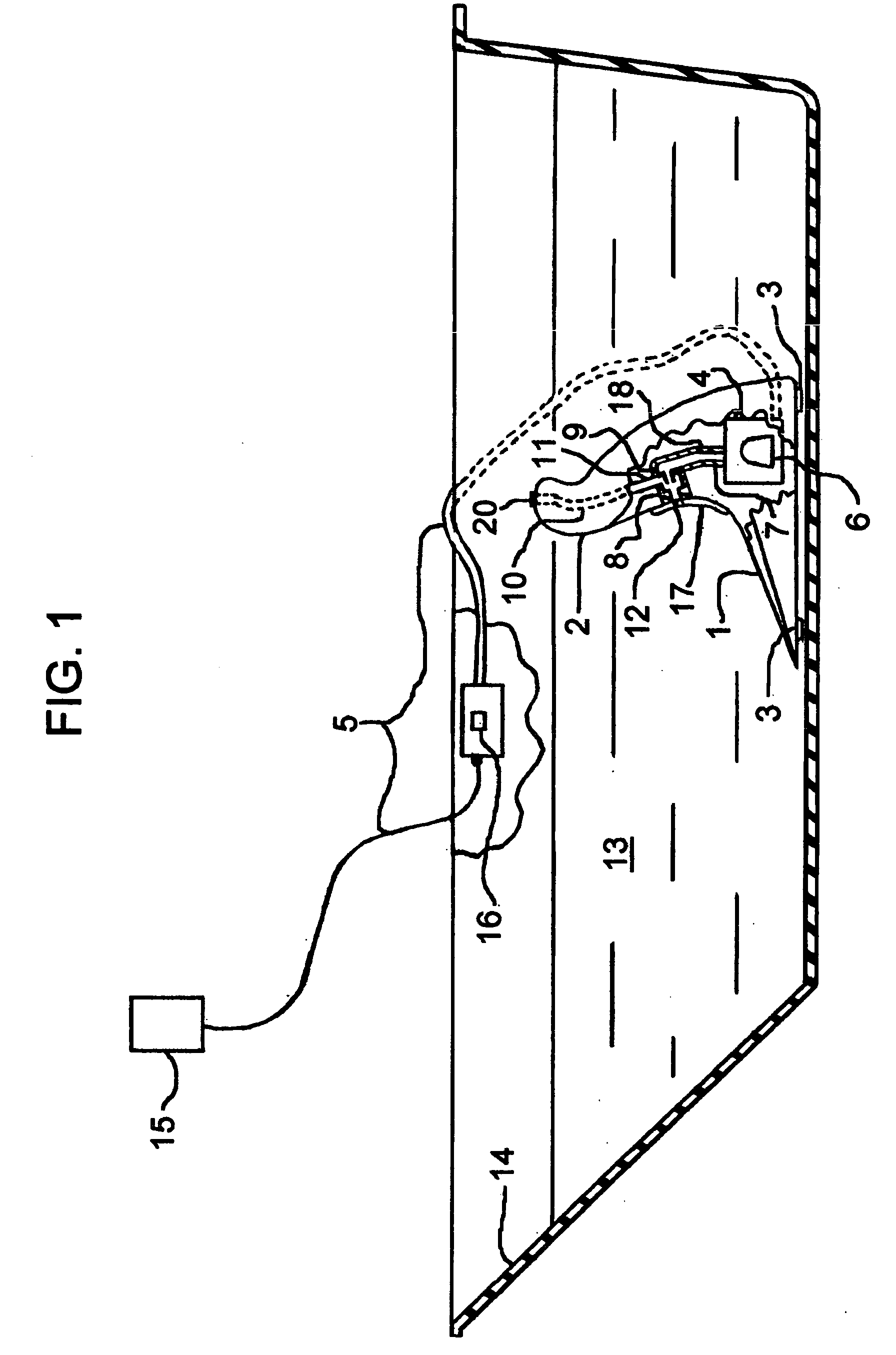

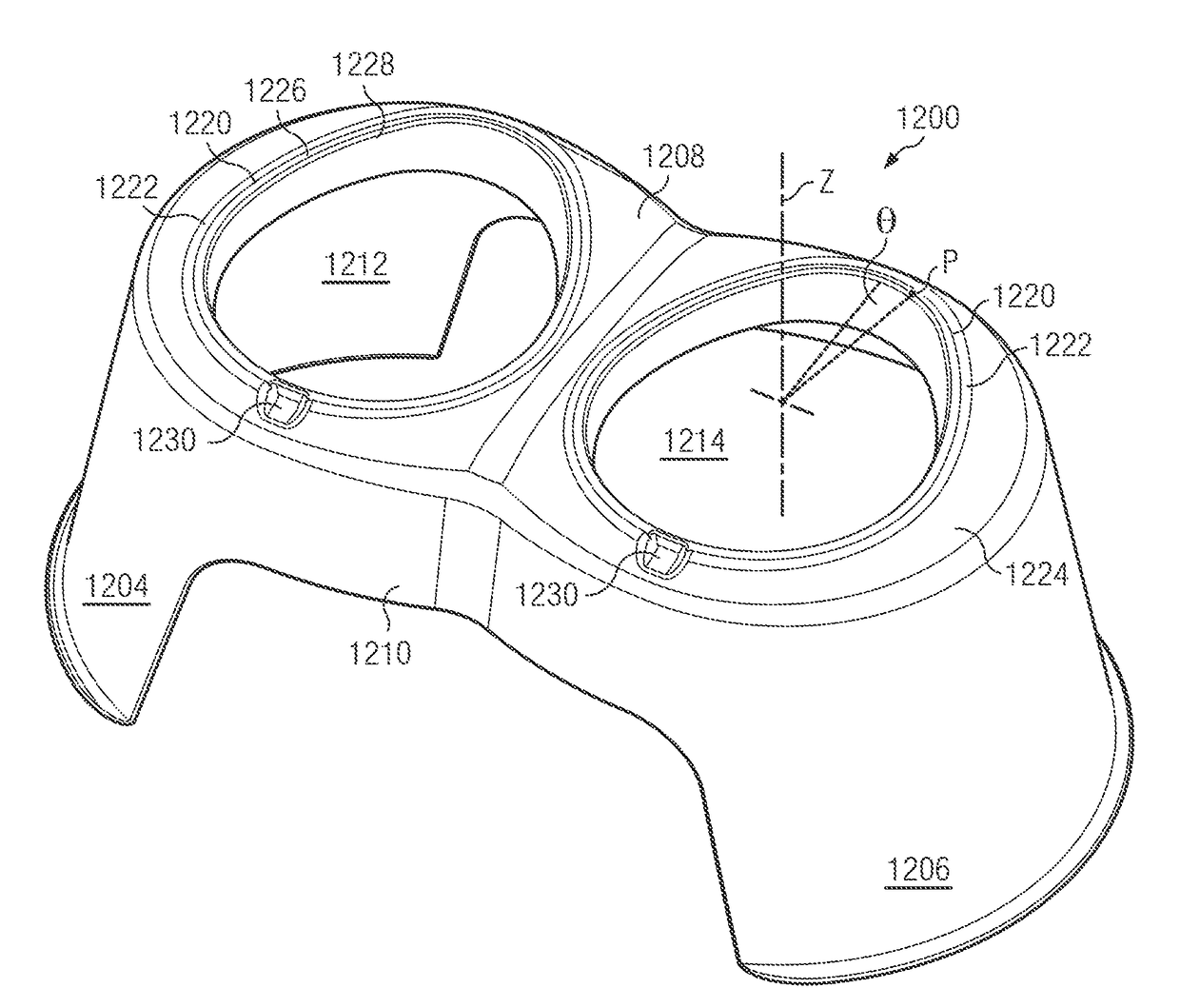

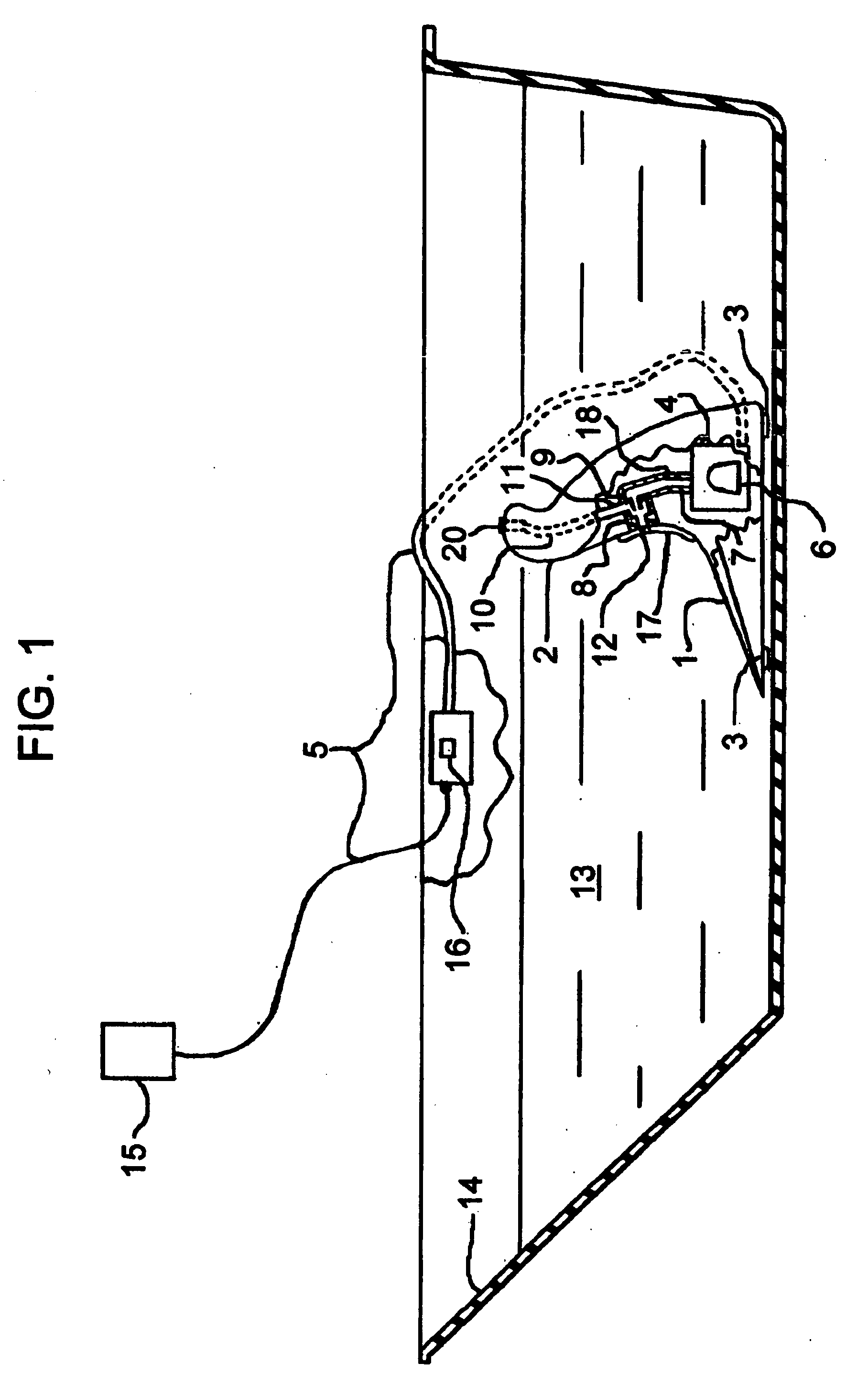

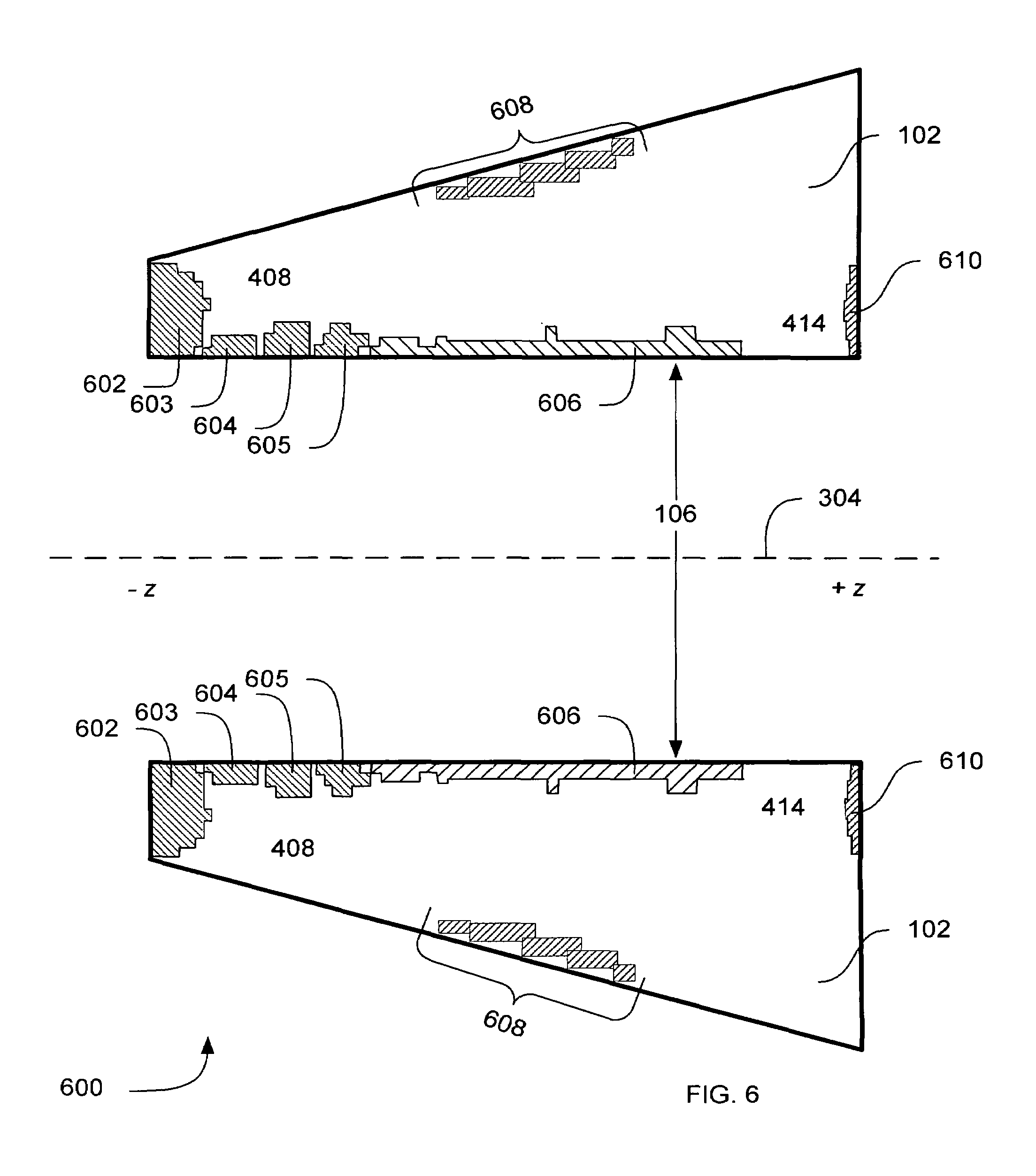

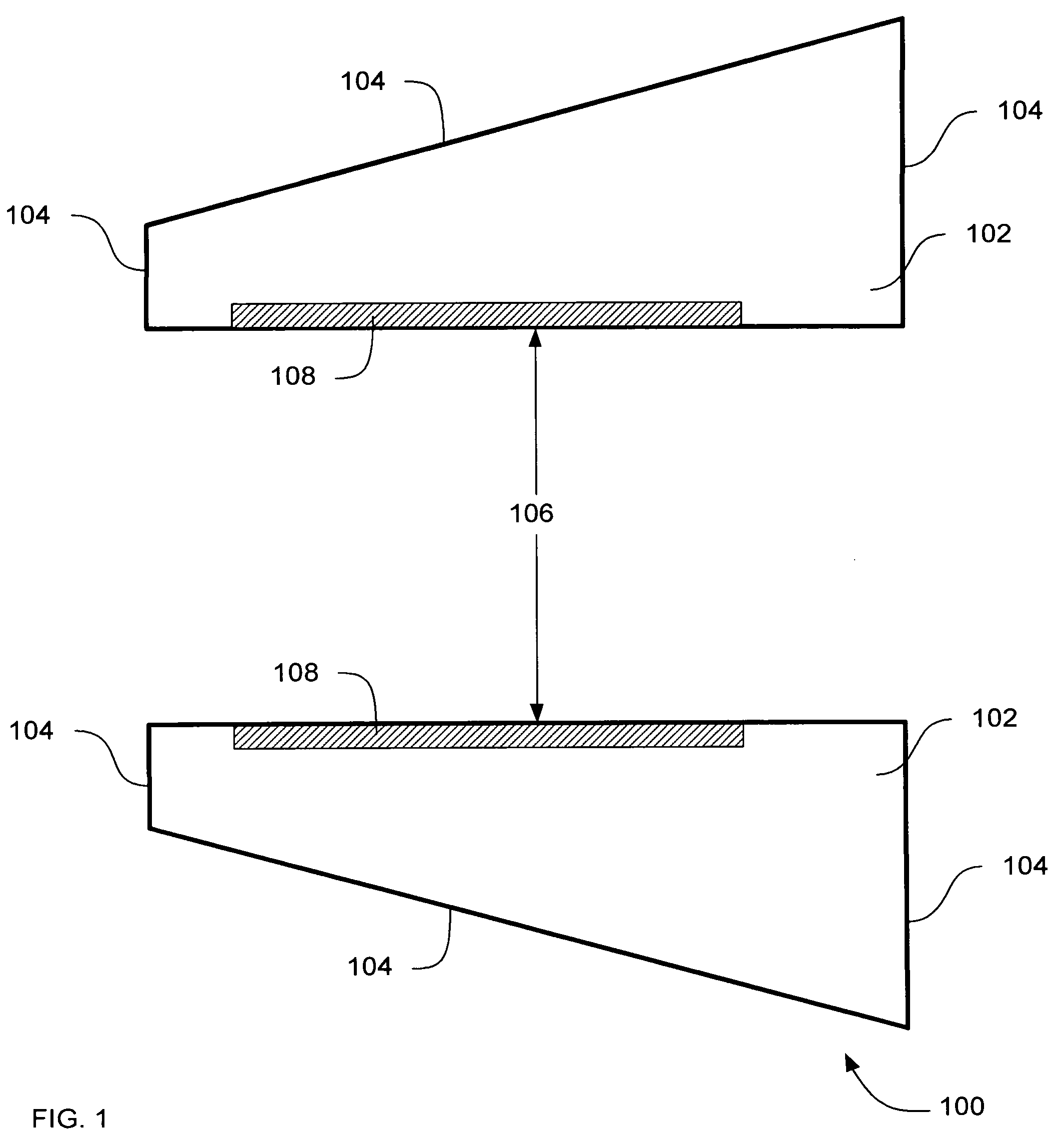

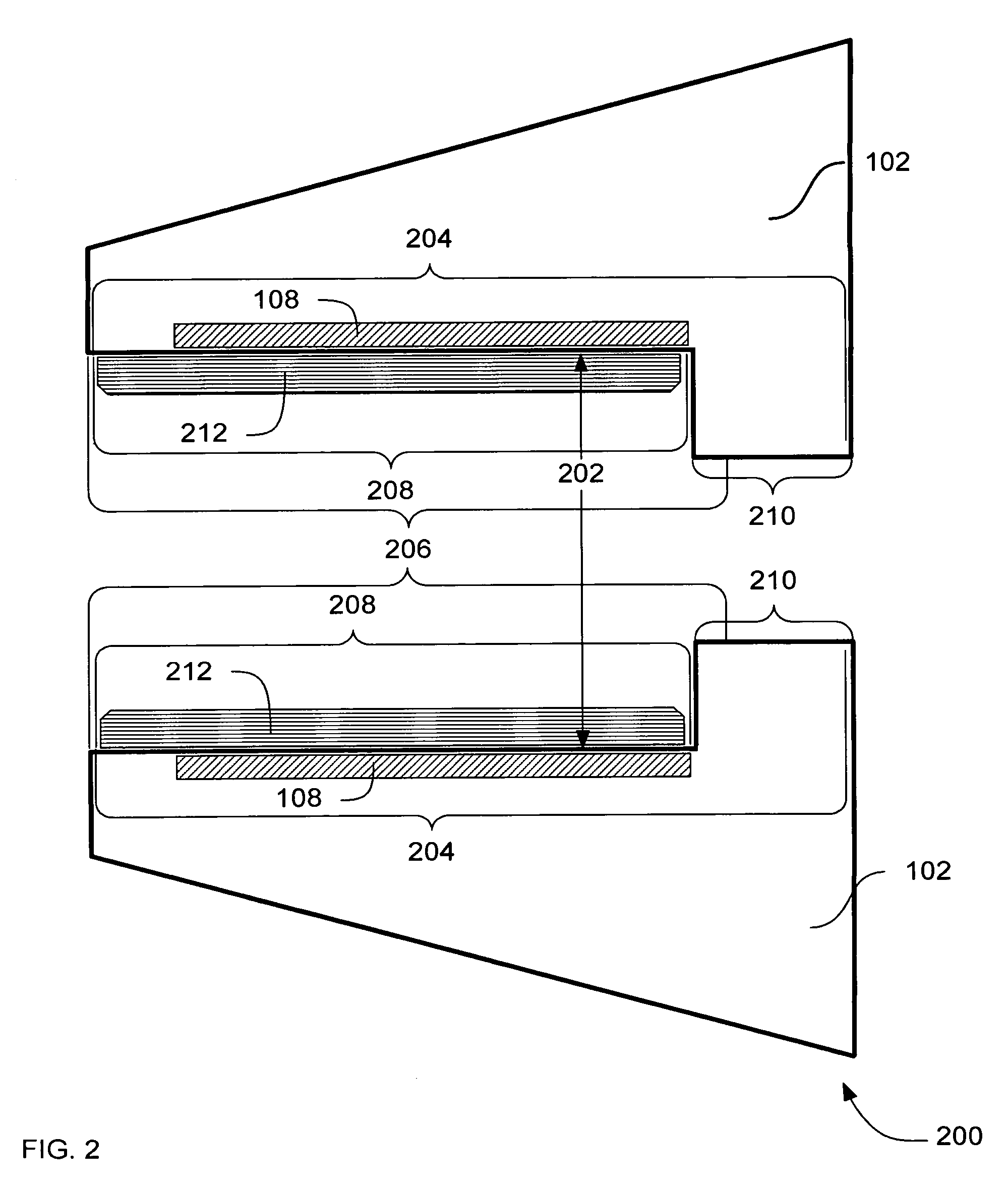

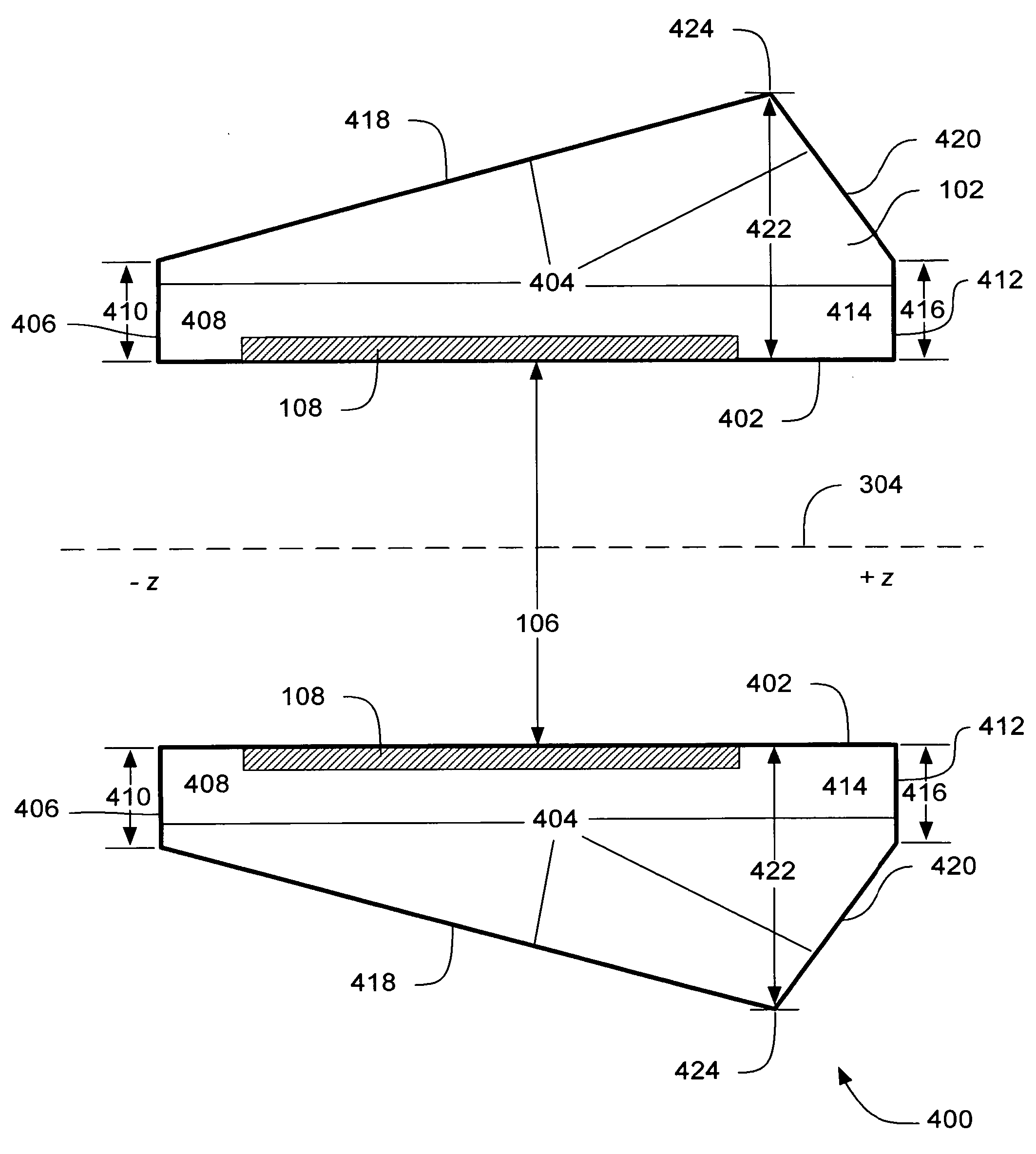

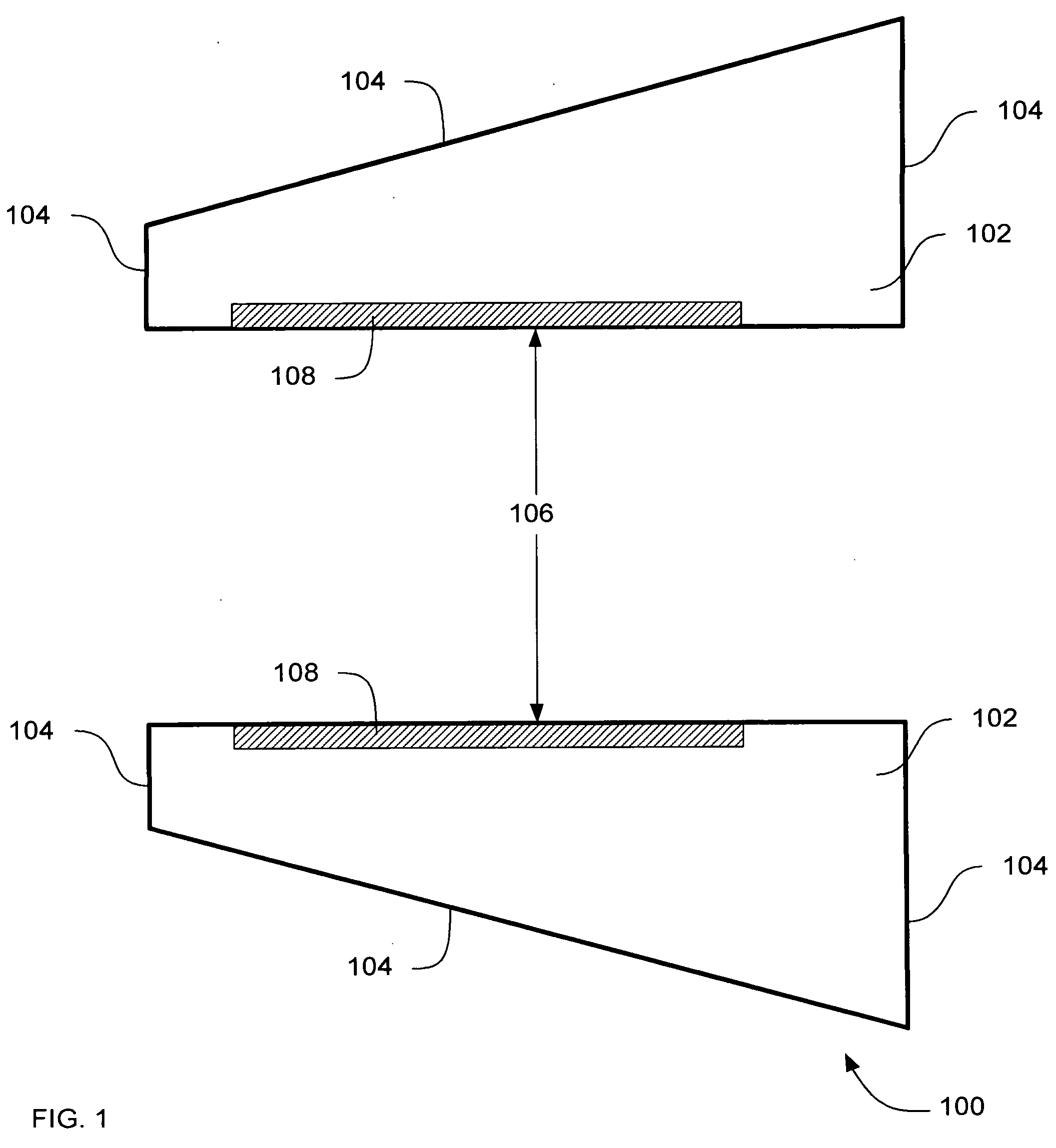

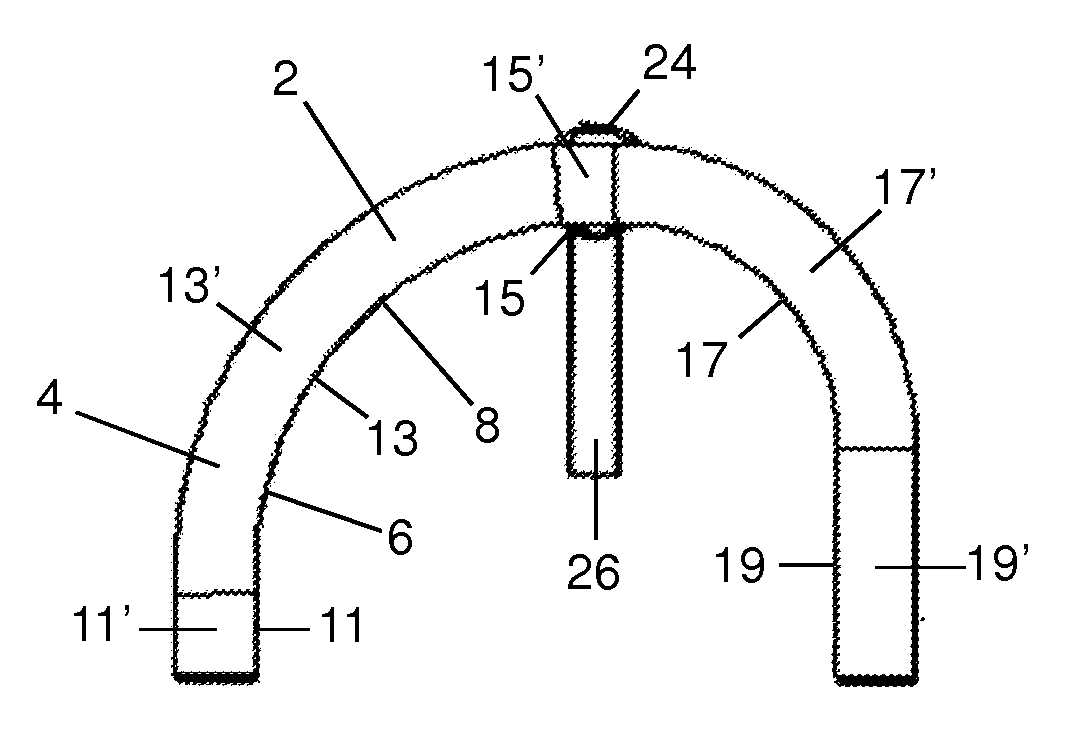

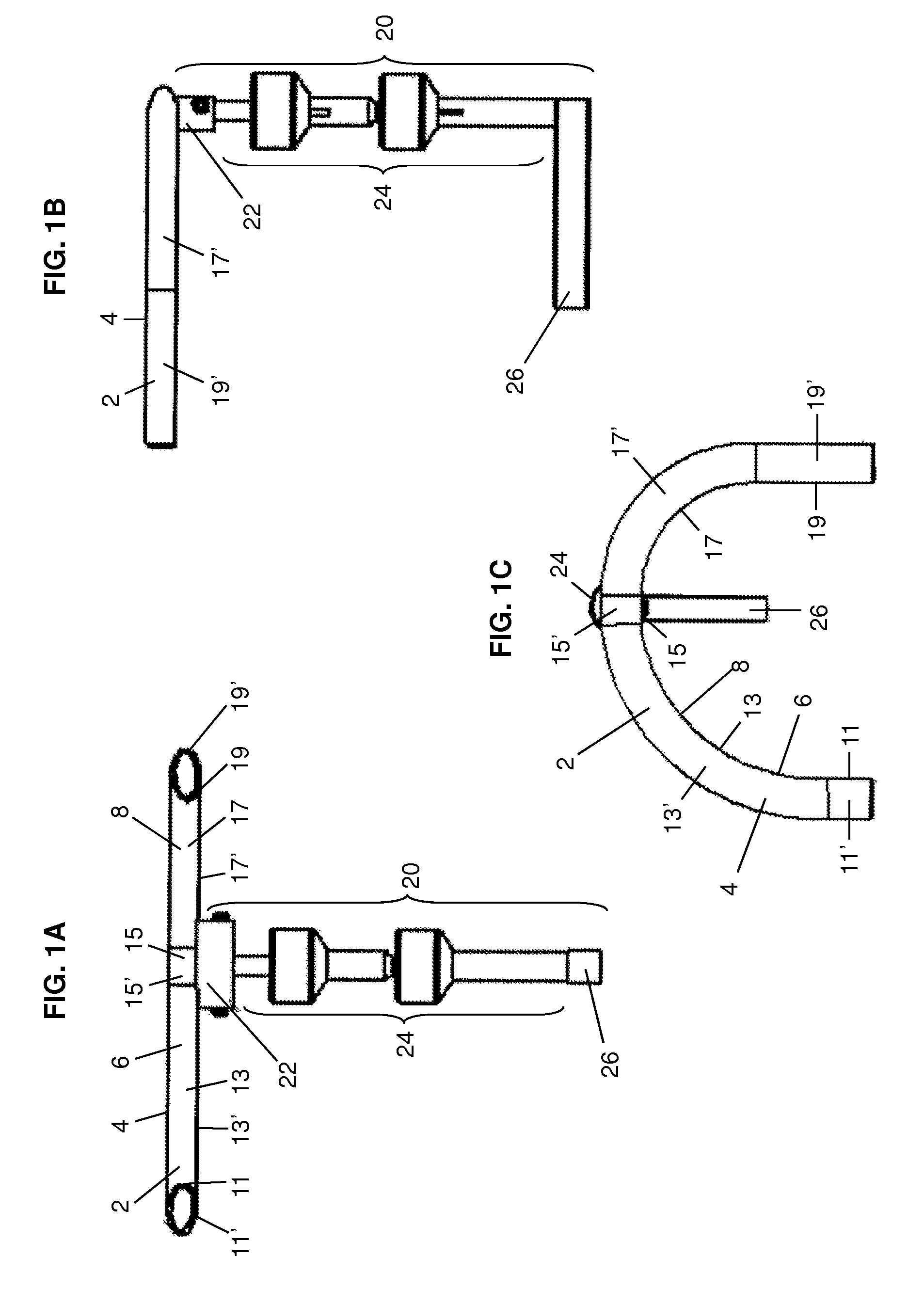

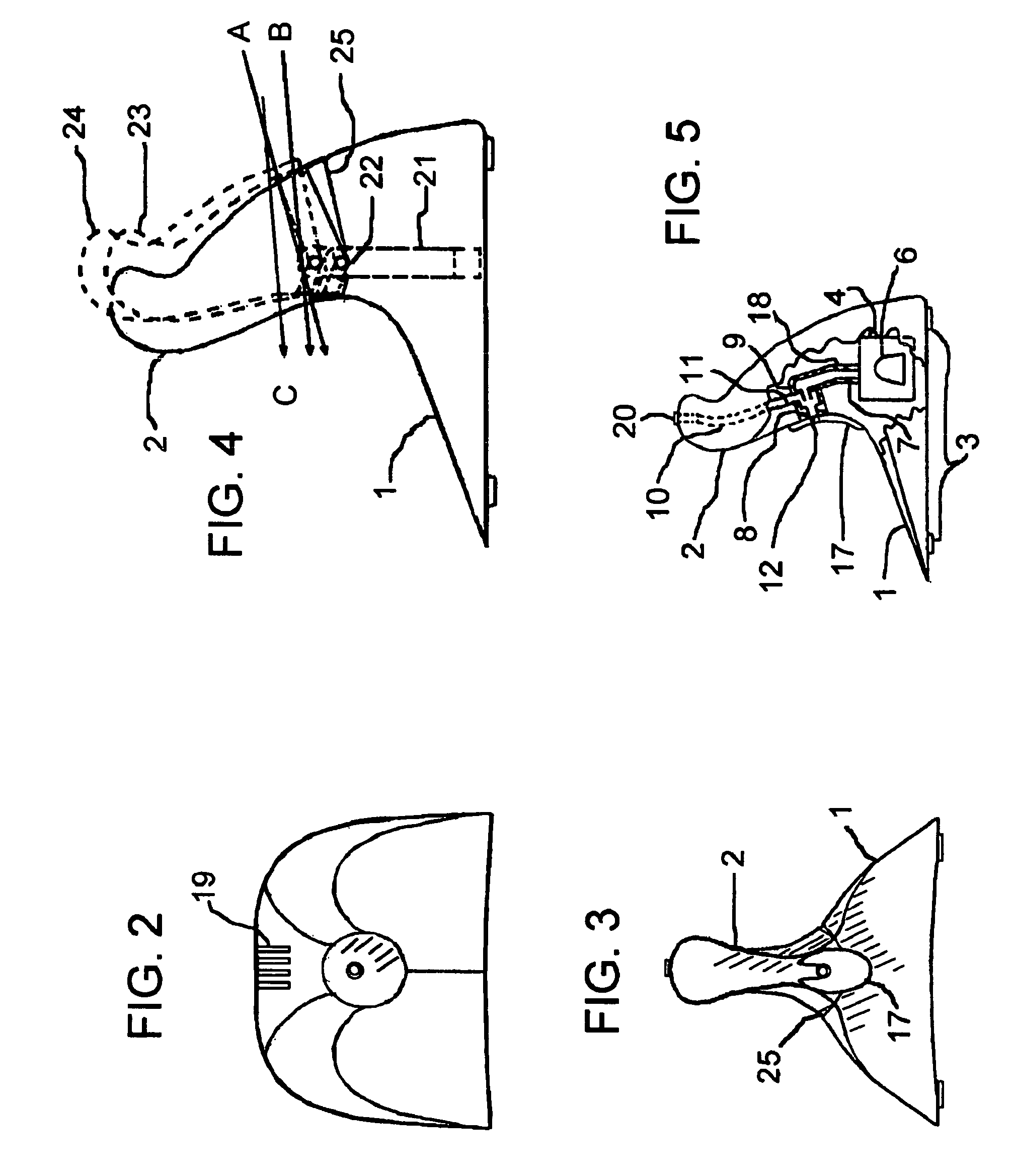

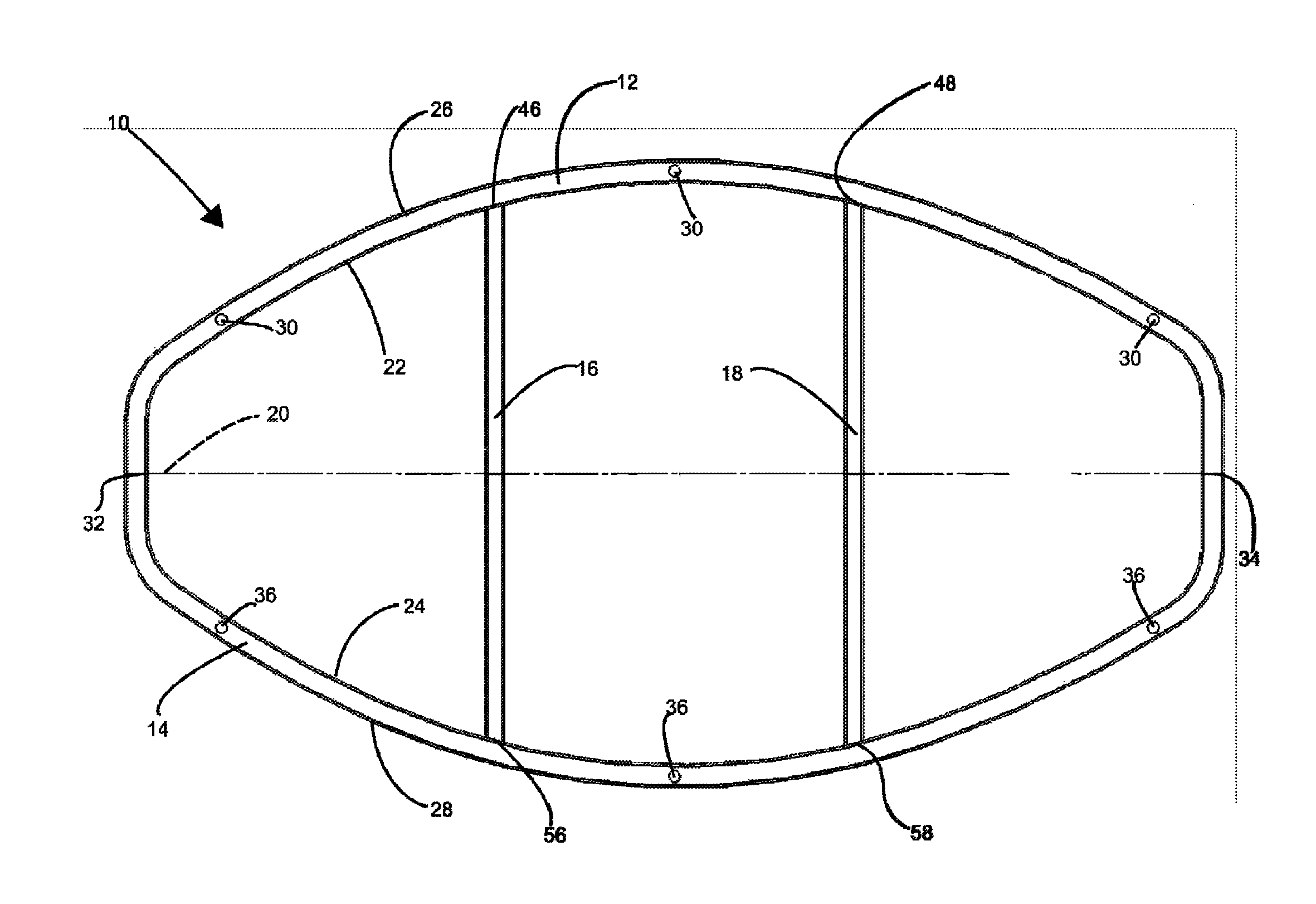

Systems, methods and apparatus of a magnetic resonance imaging magnet to produce an asymmetrical stray field

InactiveUS7109708B2Reduced footprint requirementsComfortable accessDiagnostic recording/measuringSensorsEngineeringSystems approaches

Systems, methods and apparatus are provided through which in some embodiments a magnetic resonance imaging (MRI) system includes an asymmetrical magnet to generate an asymmetrical stray field that is particularly well suited to imaging limbs. In some other embodiments, a MRI system includes a conically-shaped casing that allows a patient to more readily access a field-of-view (FOV) in the interior of the MRI system during imaging of limbs. In some embodiments, a MRI system includes a stepped inner bore that has a stepped shape that focuses the FOV in an inner bore of the MRI system on a smaller area that is closer to where a patient accesses the FOV in the MRI that is particularly well suited to imaging a limb in the FOV.

Owner:GENERAL ELECTRIC CO

Feminine hydro-therapeutic massage device

InactiveUS7335175B2Improves hydrotherapy stimulation deviceImprove comfortBathing devicesGenitals massageButtocksPelvic region

A portable hydro massage device for submersion in a body of water containing a female user, i.e. a bathtub, provides a local massage to the labium region and a focused stimulant to the female user's clitoris thereby resulting in a superior sensation to the entire body promoting an overall euphoric state and calming effect. The apparatus employs a saddle shaped housing, where the buttocks are placed, and a saddle horn for controlling the stimulus. Disposed within the midsection of the saddle horn is a hydro jet with a driven flow from a circulating water pump that draws suction from the main body of water. The hydro jet is adjustable in pressure and a method is provided for aeration of the water discharged to allow for a rhythmic pulsation effect. The saddle horn may be held and the lower body positioned as needed to focus the discharged stream from the hydro jet to the desired point of the pelvic region.

Owner:BUBBLE LOVE

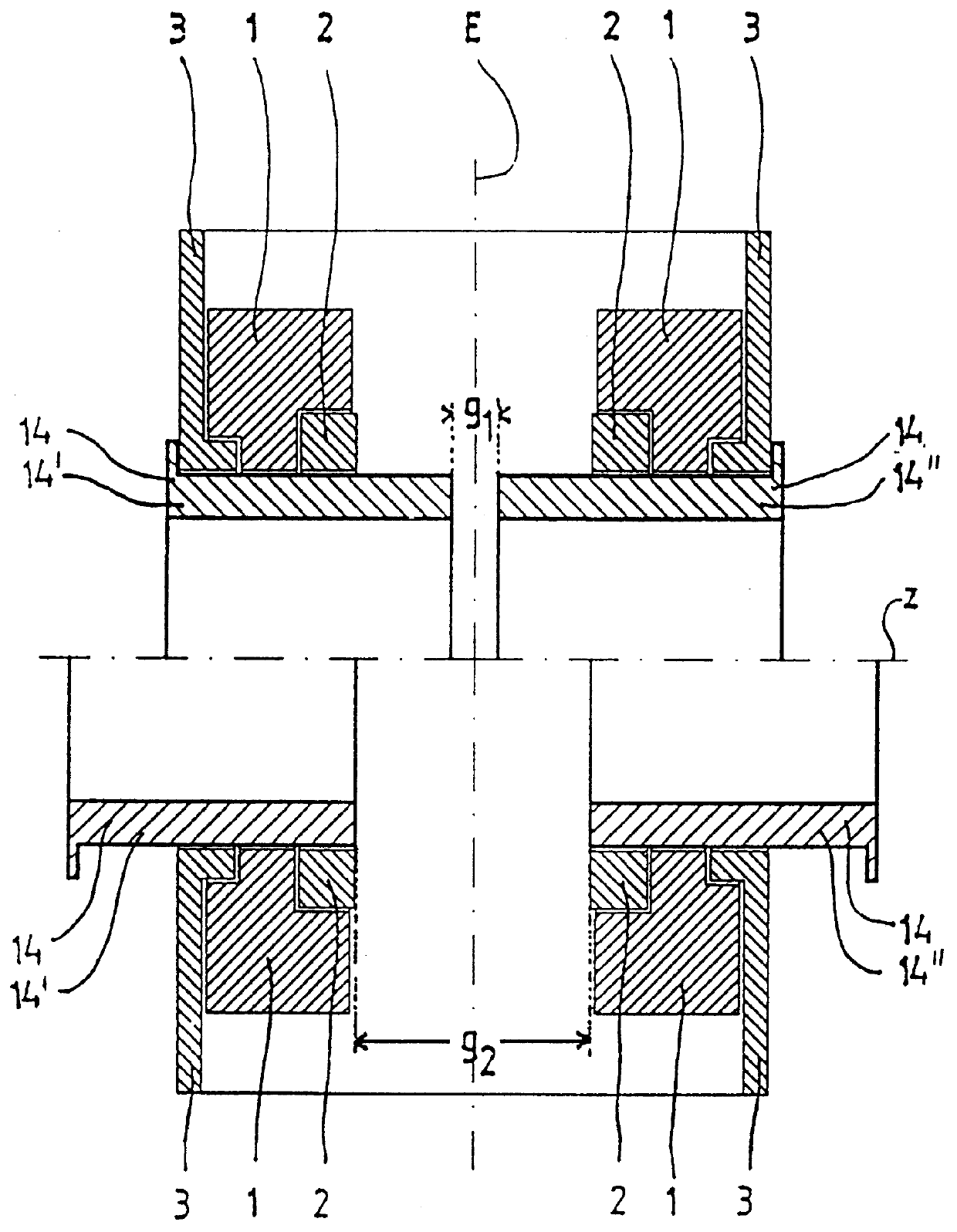

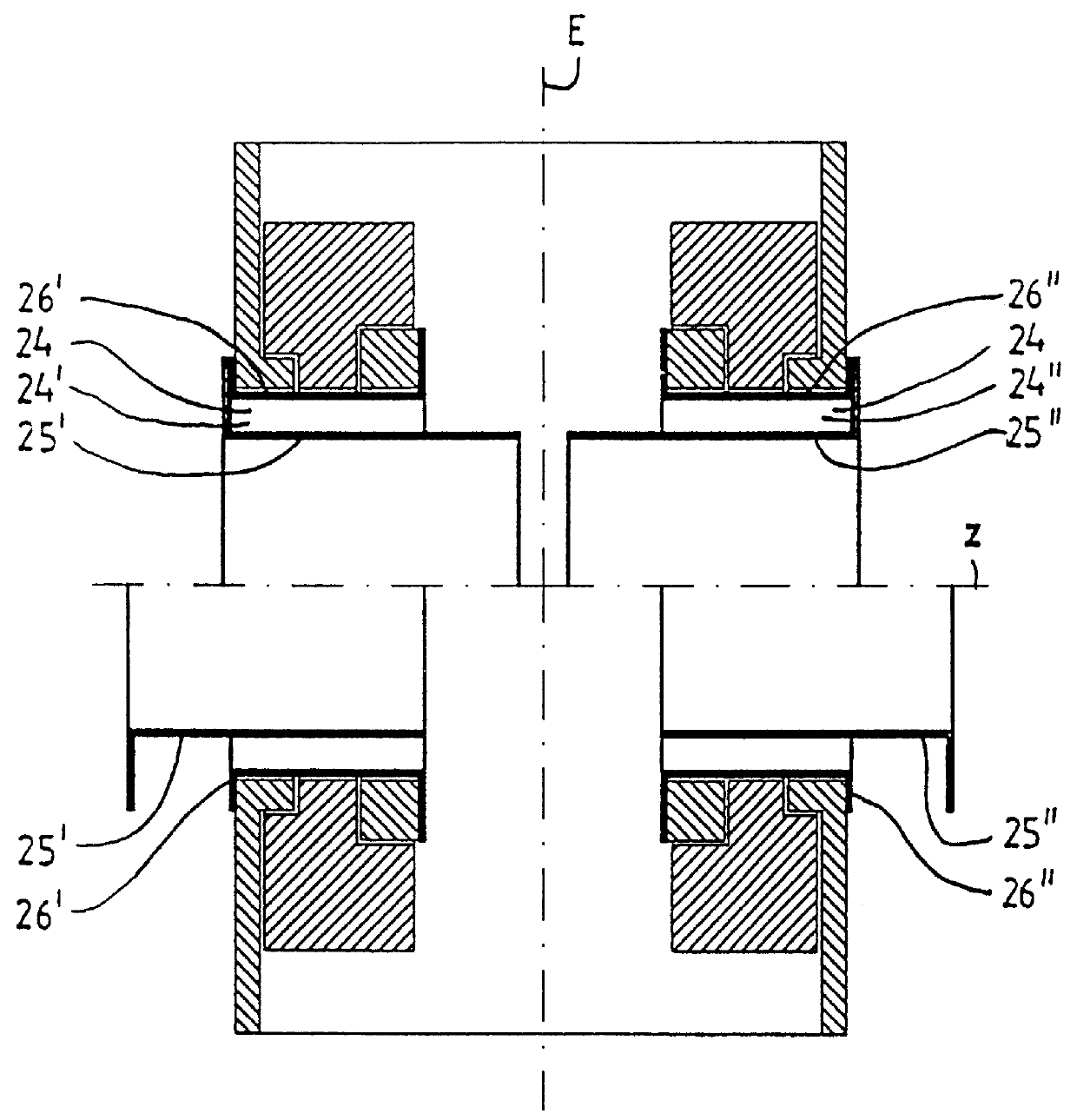

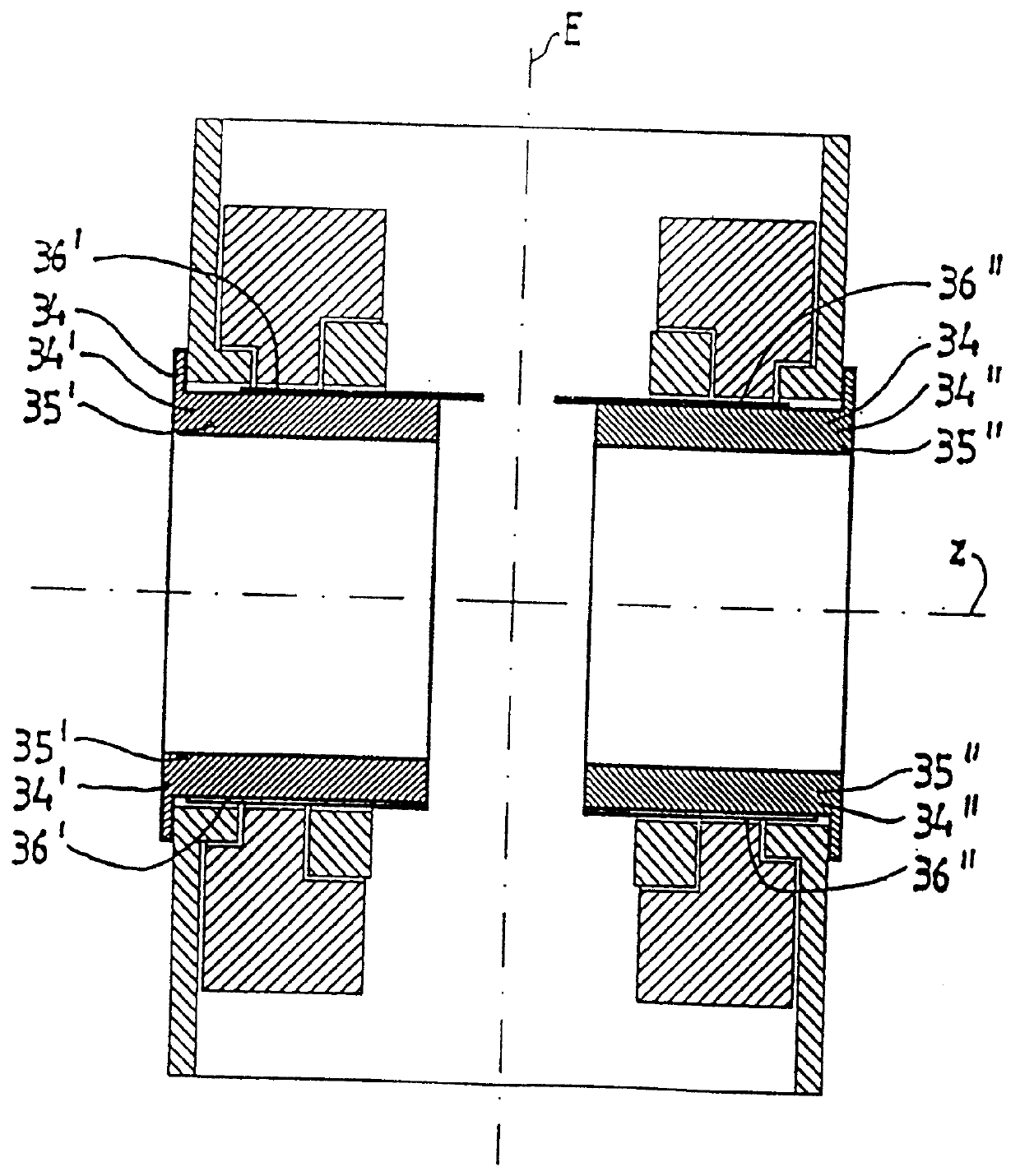

Gradient system for an NMR tomograph

InactiveUSRE36881E1The production process is simpleImprove performanceMagnetic measurementsDiagnostic recording/measuringElectrical conductorLinearity

A gradient system for a nuclear spin resonance (NMR) tomograph with a main magnet system producing a homogeneous magnetic field directed along a z-axis inside a measuring volume, wherein the main magnet system provides access to the measuring volume along the z-axis and transversely to the z-axis, and wherein the gradient system comprises two first partial gradient systems which are located at opposite sides of a central plane perpendicular to the z-axis, across the measuring volume. At least one of the two partial gradient systems is movable between at least two positions along the z-axis. In this way, with a small constructional size and with a simple manufacturing procedure, a gradient system is obtained with high performance capability with respect to generated gradient strength for given ampere turns, high linearity of the generated gradient fields, minimum inductance and minimum electrical resistance of the conductor segments.

Owner:BRUKER ANALYTISCHE MESSTECHN

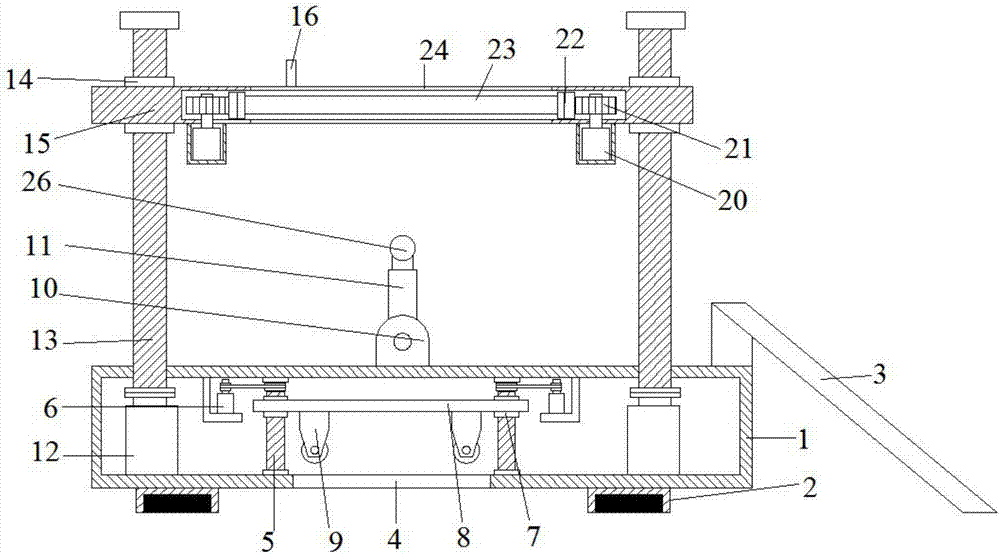

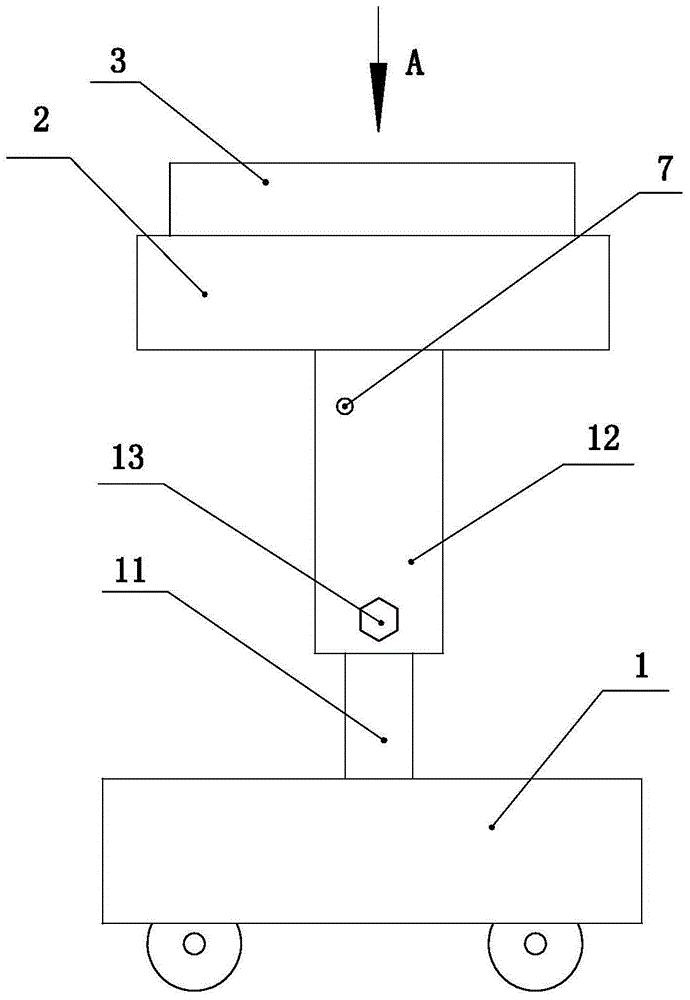

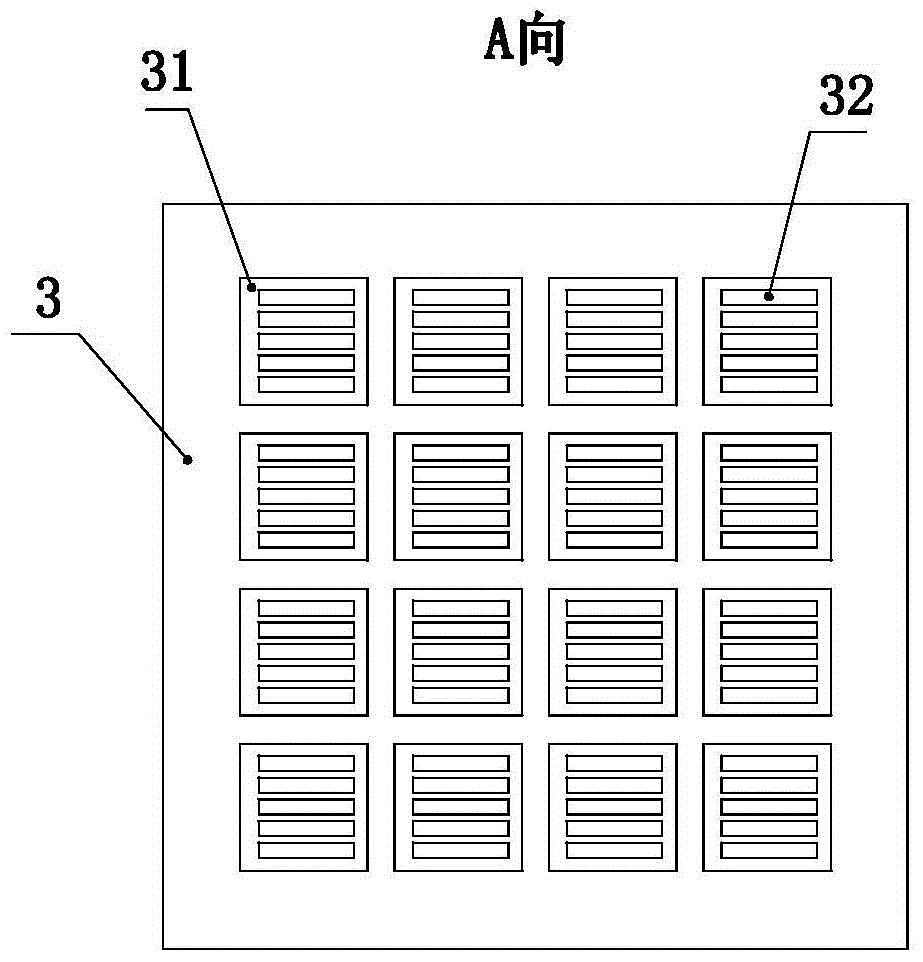

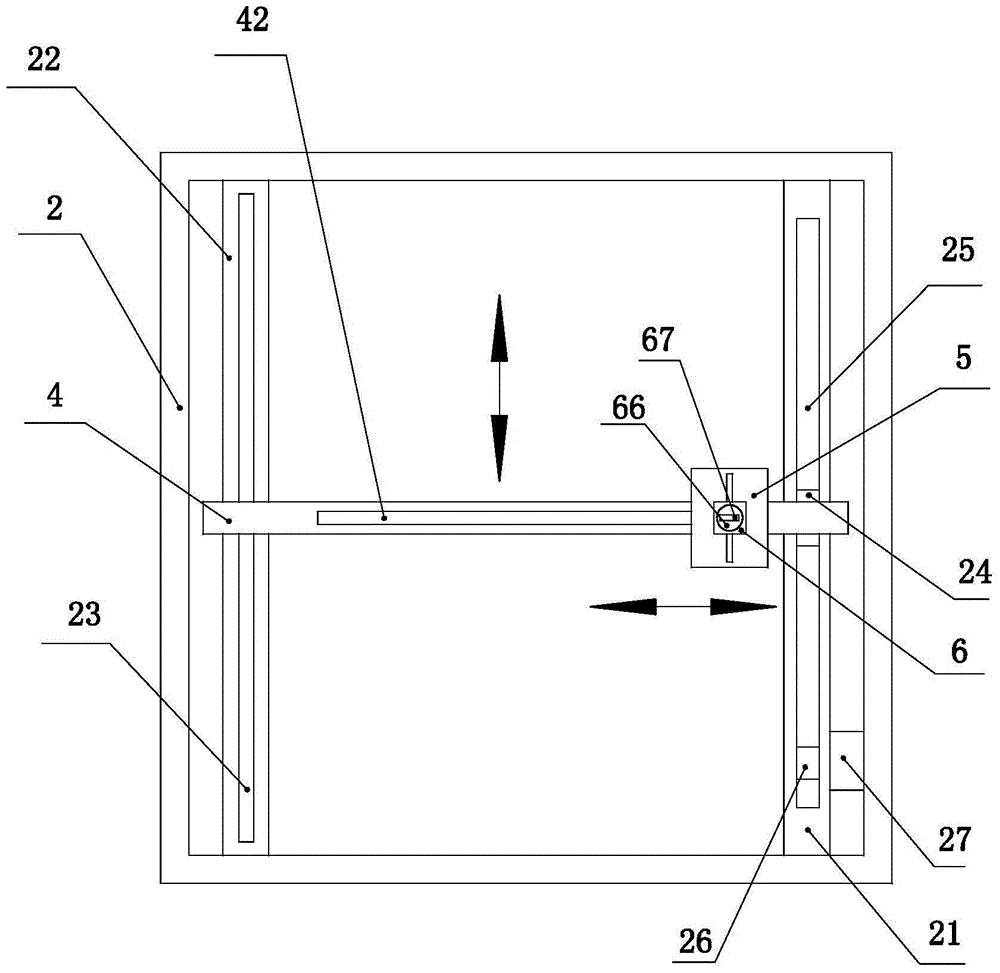

Mechanical equipment maintenance device

InactiveCN107458679AEasy maintenanceConvenience to workPackaging machinesDrive wheelElectric machine

The invention discloses a mechanical equipment maintenance device, which comprises a base. Supporting seats are arranged at four corners of the lower side of the base; an inclined table surface is arranged at the right end of the upper side of the base; a first opening is formed in the lower side inside the base; first screw rods are arranged at the left end and the right end of the upper side of the first opening; a first inner threaded sleeve is arranged at the upper side of each first screw rod; a connecting plate is arranged at the outer side of each first inner threaded sleeve; drive wheels are arranged at four corners of the lower side of each connecting plate; second motors are arranged at four corners in the base; a second screw rod is arranged at the upper side of each second motor; a second inner threaded sleeve is arranged on each second screw rod; a maintenance platform is arranged at the outer side of each second inner threaded sleeve; a notch is formed in each maintenance platform; third motors are arranged at four corners of the lower side of each notch; a drive gear is arranged at the upper side of each third motor; a rack is arranged at the inner side of each drive gear; a seal plate is arranged between the racks; and second openings are formed in the upper side and the lower side of the seal plate. According to the mechanical equipment maintenance device provided by the invention, equipment can be effectively and conveniently moved and fixed, and a motor vehicle can be effectively and conveniently maintained.

Owner:HEFEI TOTEM LONG MACHINERY DESIGN CO LTD

Systems, methods and apparatus of a magnetic resonance imaging magnet to produce an asymmetrical stray field

InactiveUS20060038565A1Reduced footprint requirementsComfortable accessDiagnostic recording/measuringSensorsEngineeringSystems approaches

Systems, methods and apparatus are provided through which in some embodiments a magnetic resonance imaging (MRI) system includes an asymmetrical magnet to generate an asymmetrical stray field that is particularly well suited to imaging limbs. In some other embodiments, a MRI system includes a conically-shaped casing that allows a patient to more readily access a field-of-view (FOV) in the interior of the MRI system during imaging of limbs. In some embodiments, a MRI system includes a stepped inner bore that has a stepped shape that focuses the FOV in an inner bore of the MRI system on a smaller area that is closer to where a patient accesses the FOV in the MRI that is particularly well suited to imaging a limb in the FOV.

Owner:GENERAL ELECTRIC CO

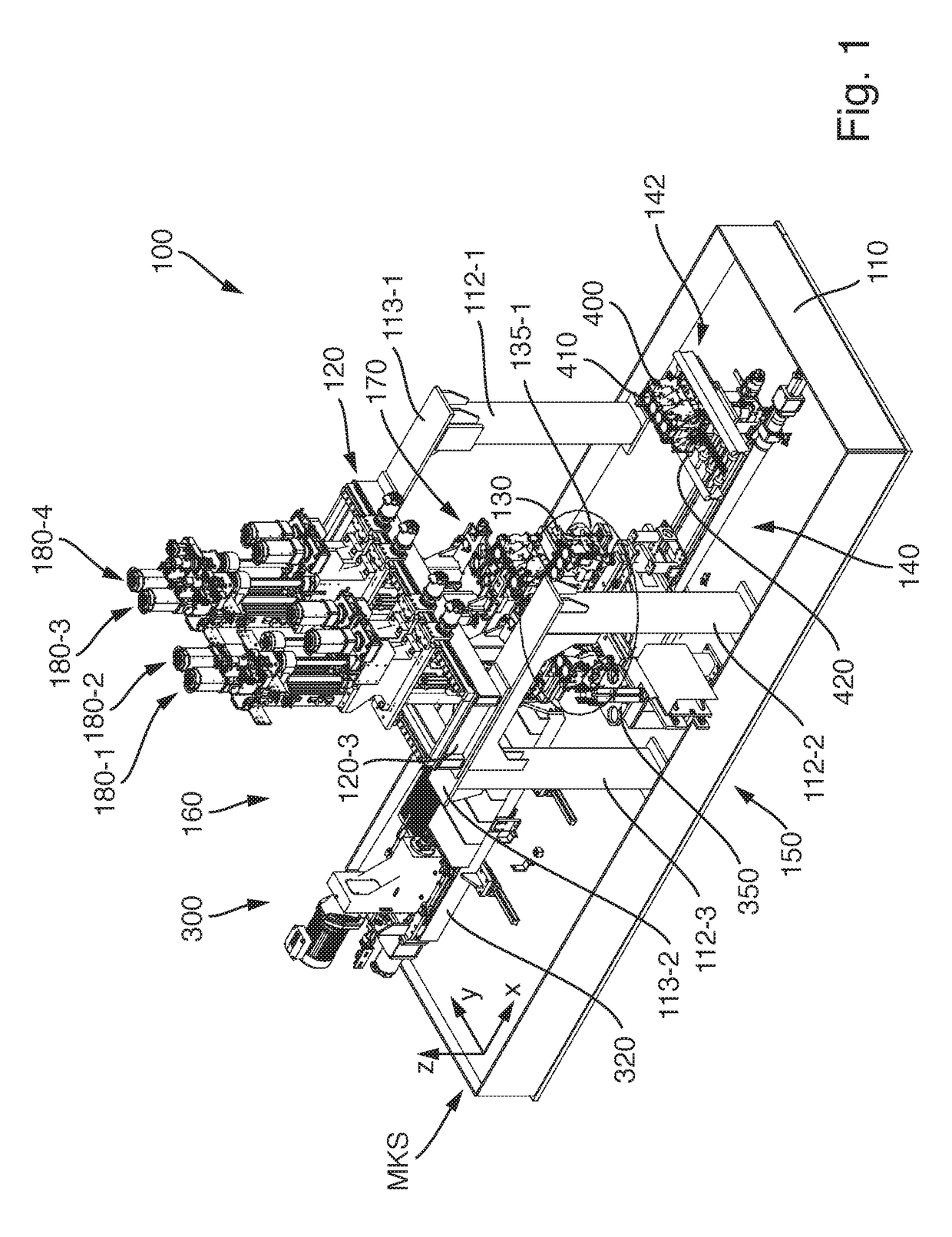

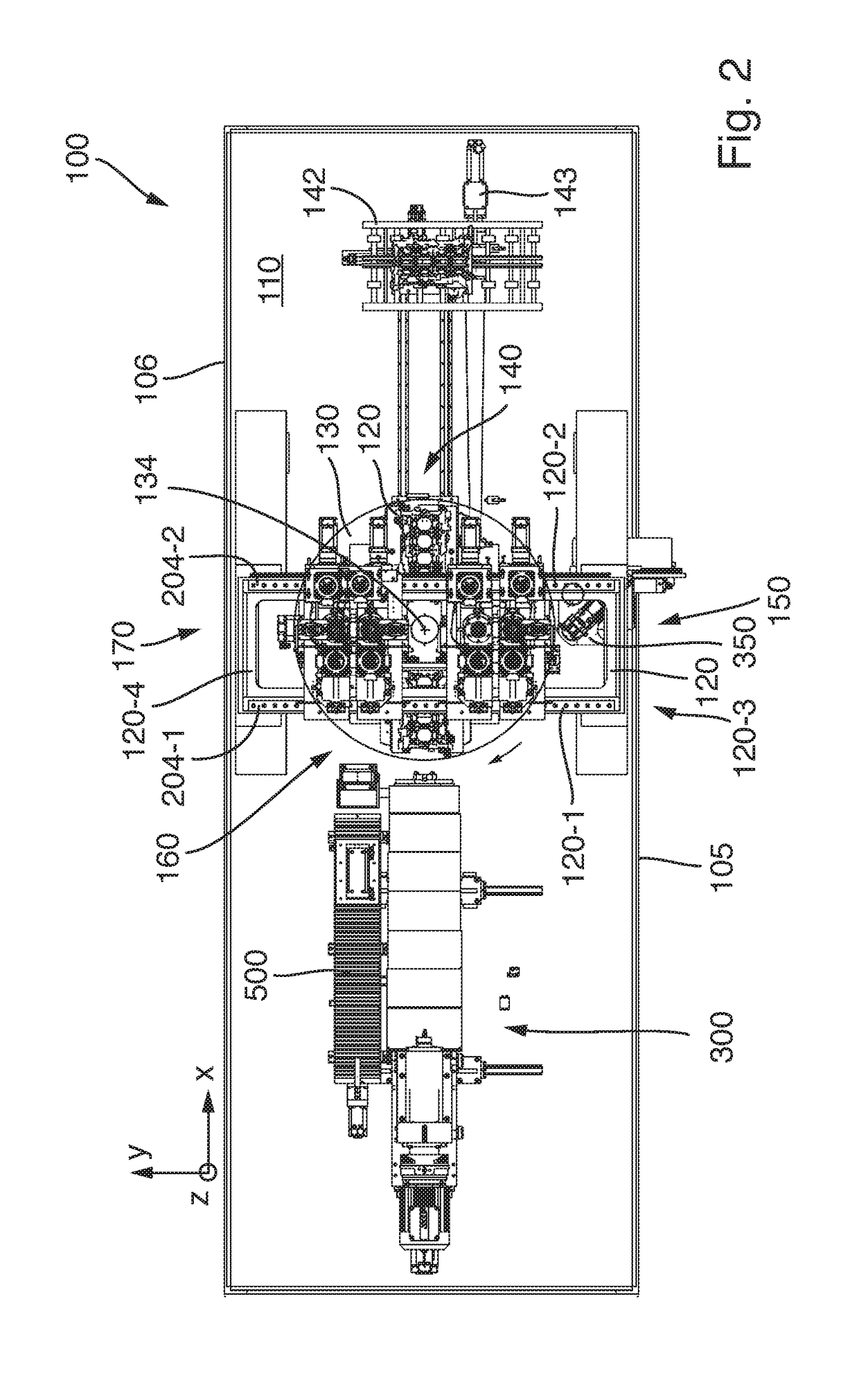

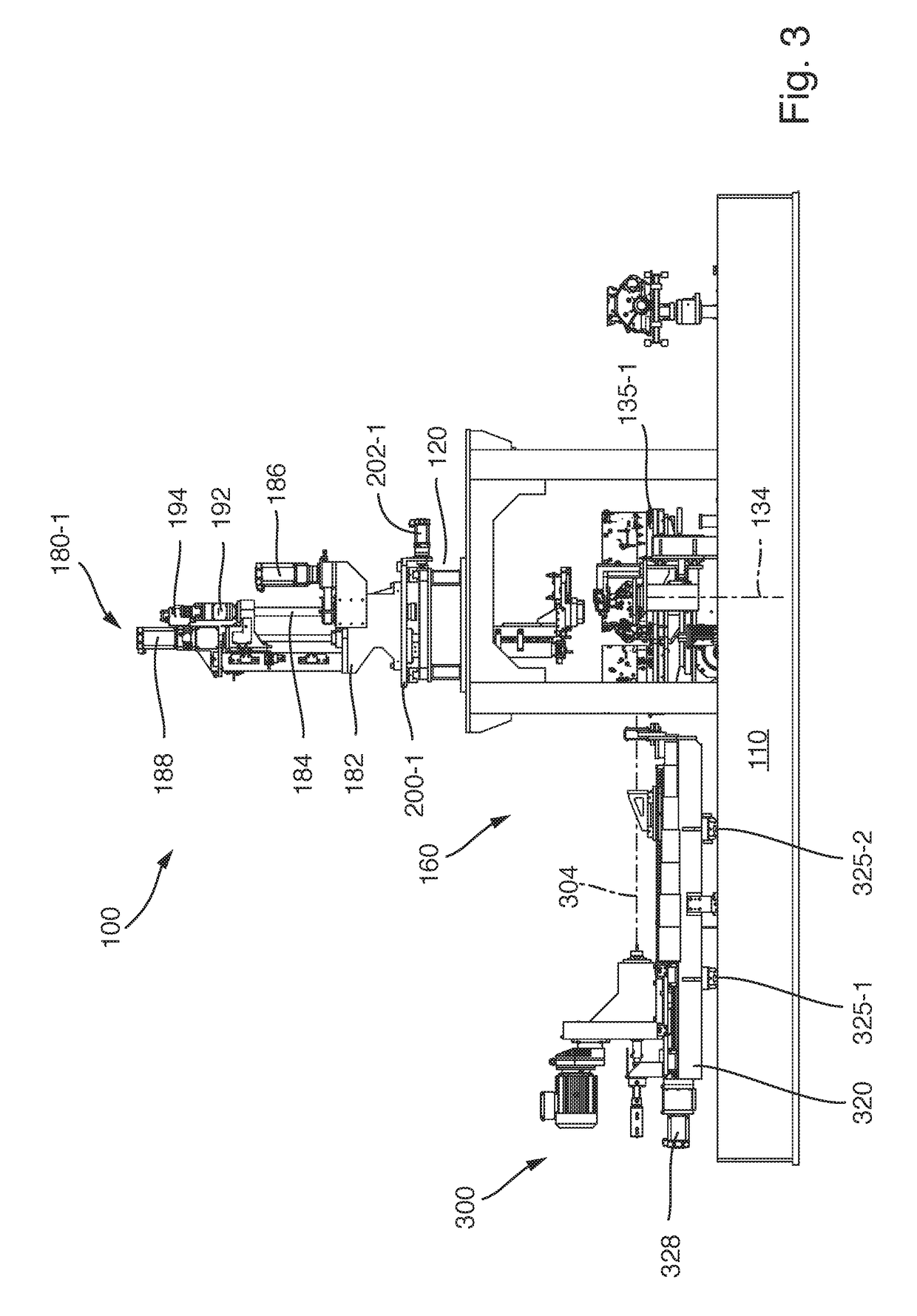

Honing machine with multiple workstations

A honing machine (100) for carrying out honing operations on boreholes, oriented orthogonally with respect to one another, in a workpiece (102), in particular for honing processing of cylinder boreholes and a bearing gate borehole in a cylinder crank casing, comprises a machine base (110) and a round table (130) which is arranged on the machine base and which can rotate about a vertical round table axis (134) and has a plurality of workpiece receptacles which are arranged offset with respect to one another in a circumferential direction at a radial distance from the round table axis, in such a way that a workpiece which is held in a workpiece receptacle can be transported successively to different workstations (140, 150, 160, 170) of the honing machine by rotating the round table. At least one of the workstations is a vertical honing station (150, 170) which has at least one vertical honing unit (180) which has a honing spindle which can move back and forth in the direction of a spindle axis which is oriented parallel to the round table axis, rotatably about said spindle axis. Furthermore, at least one of the workstations is a horizontal honing station (160) which has at least one horizontal honing unit (300) which has a honing spindle which can move back and forth in the direction of a horizontal spindle axis (304), rotatable about said spindle axis. The horizontal honing unit (300) is or can be positioned with respect to the round table (130) in such a way that the horizontal honing unit assumes a processing position in which the horizontal spindle axis (304) is oriented radially with respect to the round table axis (134).

Owner:NAGEL MASCHEN UND WERKZEUGFAB

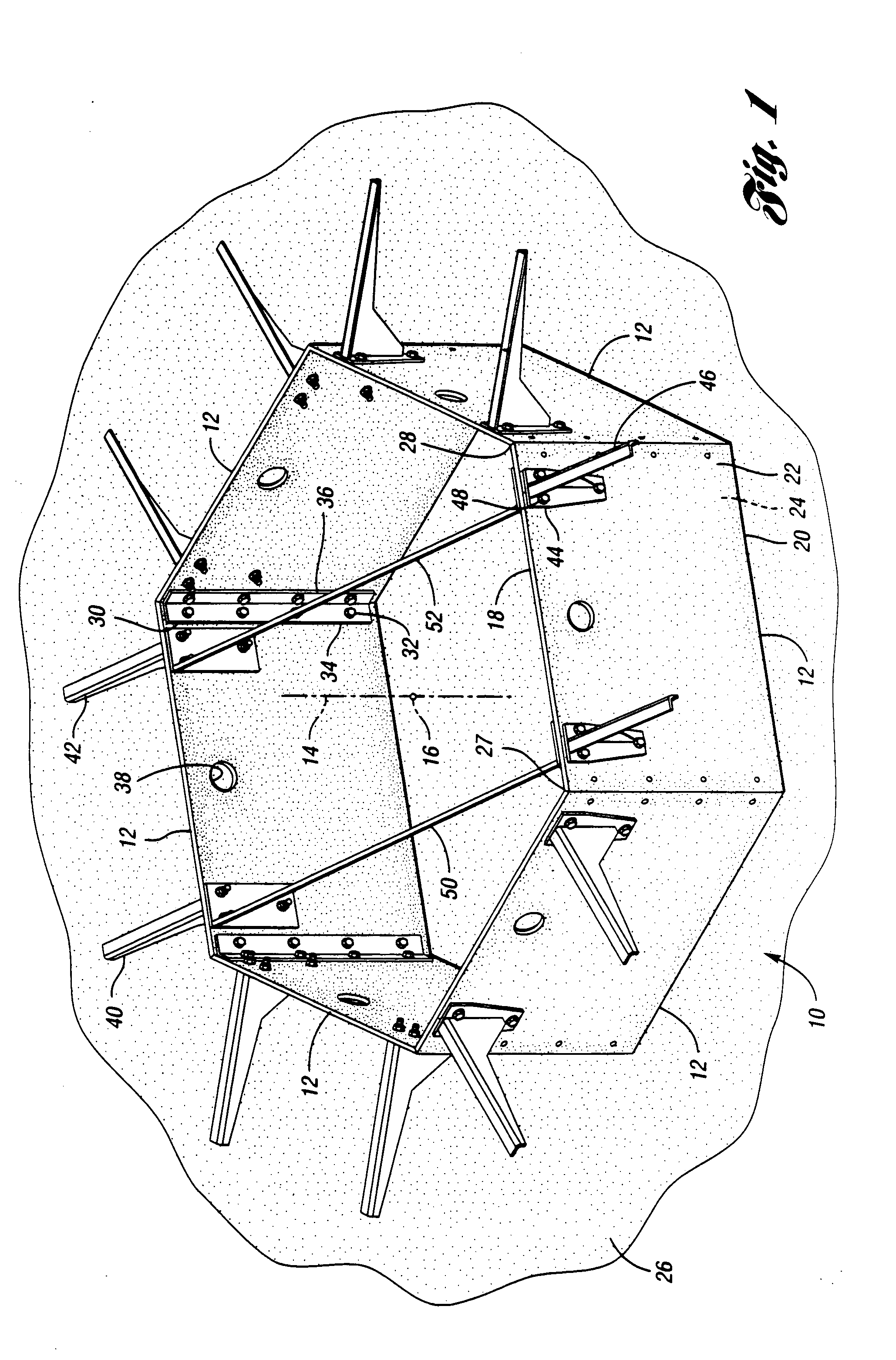

Asymmetrical surgical wrist rest

Wrist, hand, or arm support devices are provided. The support devices include a support member having a top surface and a front surface. The top surface is oriented at either a parallel angle or a non-parallel angle with respect to a work surface. The front surface curves upon itself to form either a symmetric or an asymmetric arc. Preferred versions of the support devices described herein include at least one of a top surface oriented at a non-parallel angle with respect to the work surface or a front surface that curves upon itself to define an asymmetric arc. Mounting members for connecting the support member to an operating surface are also provided. The support devices described herein permit an operator to comfortably rest his or her hand on the support devices while directing procedures toward non-centered portions of work objects.

Owner:WOLF BENJAMIN +3

Gaming device stand

InactiveUS20070045960A1Comfortable accessSecure supportCard gamesApparatus for meter-controlled dispensingEngineeringCantilever

Owner:GREAT AMERICAN BASE

Feminine hydro-therapeutic massage device

InactiveUS7824351B2Improves hydrotherapy stimulation deviceImprove comfortDomestic plumbingBathing devicesPelvic regionButtocks

A portable hydro massage device for submersion in a body of water containing a female user, i.e. a bathtub, provides a local massage to the labium region and a focused stimulant to the female user's clitoris thereby resulting in a superior sensation to the entire body promoting an overall euphoric state and calming effect. The apparatus employs a saddle shaped housing, where the buttocks are placed, and a saddle horn for controlling the stimulus. Disposed within the midsection of the saddle horn is a hydro jet with a driven flow from a circulating water pump that draws suction from the main body of water. The hydro jet is adjustable in pressure and a method is provided for aeration of the water discharged to allow for a rhythmic pulsation effect. The saddle horn may be held and the lower body positioned as needed to focus the discharged stream from the hydro jet to the desired point of the pelvic region.

Owner:BUBBLE LOVE

Feminine hydro-therapeutic massage device

InactiveUS8992450B1Improves hydrotherapy stimulation deviceImprove comfortBathsDouchesButtocksWater discharge

A portable hydro massage device for submersion in a body of water containing a female user, i.e. a bathtub, provides a local massage to the labium region and a focused stimulant to the female user's clitoris thereby resulting in a superior sensation to the entire body promoting an overall euphoric state and calming effect. The apparatus employs a saddle shaped housing, where the buttocks are placed, and a saddle horn for controlling the stimulus. Disposed within the midsection of the saddle horn is a hydro jet with a driven flow from a circulating water pump that draws suction from the main body of water. The hydro jet is adjustable in pressure and a method is provided for aeration of the water discharged to allow for a rhythmic pulsation effect. The saddle horn may be held and the lower body positioned as needed to focus the discharged stream from the hydro jet to the desired point of the pelvic region.

Owner:BUBBLE LOVE

A portable electronic device integrated with a key

InactiveUS20160251875A1Comfortable accessKeysDigital processing power distributionEngineeringMechanical engineering

Owner:SHABTAY LIOR +2

Pet feeding system

ActiveUS20190000035A1Comfortable accessEasy accessAnimal watering devicesAnimal feeding devicesEngineeringLateral movement

Owner:MACNEIL IP

A device convenient for salespersons to take receipts

Owner:STATE GRID SHANDONG JIYANG POWER SUPPLY +1

Shared cash handler

InactiveUS8827063B2Improve usabilityLow costControlling coin-freed apparatusCoin-freed apparatus detailsData mining

A cash hander can be coupled with multiple vending machines or other devices to enable the vending machines to accept cash. Through various interactions, the cash handler can provide status updates to the vending machines and relinquish control a particular vending machine to accept cash for that vending machine. The cash handler can also maintain a queue to manage and / or prioritize requests from vending machines to accept cash.

Owner:CUBIC CORP

Multi-section vehicle chassis access and inspection platform

InactiveUS8708347B1Comfortable to useMinimal vertical profileHarvestersSledge wheelsCushionRolling chassis

A vehicle chassis inspection platform, or creeper, comprising a frame, a cushion layer, and several wheel assemblies is disclosed. The creeper includes a wheel assembly designed to minimize vertical clearance of the creeper wherein the wheel assembly includes a wheel platform with multiple possible positions for joining of the wheel platform to the creeper.

Owner:POOLE HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com