Patents

Literature

40results about How to "Quick income" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Distillate yield improving vacuum distillation method and device

ActiveCN102311772AAvoid lateral thermal displacementEasy to separateVacuum distillationHydrocarbon oils treatmentLow speedVaporization

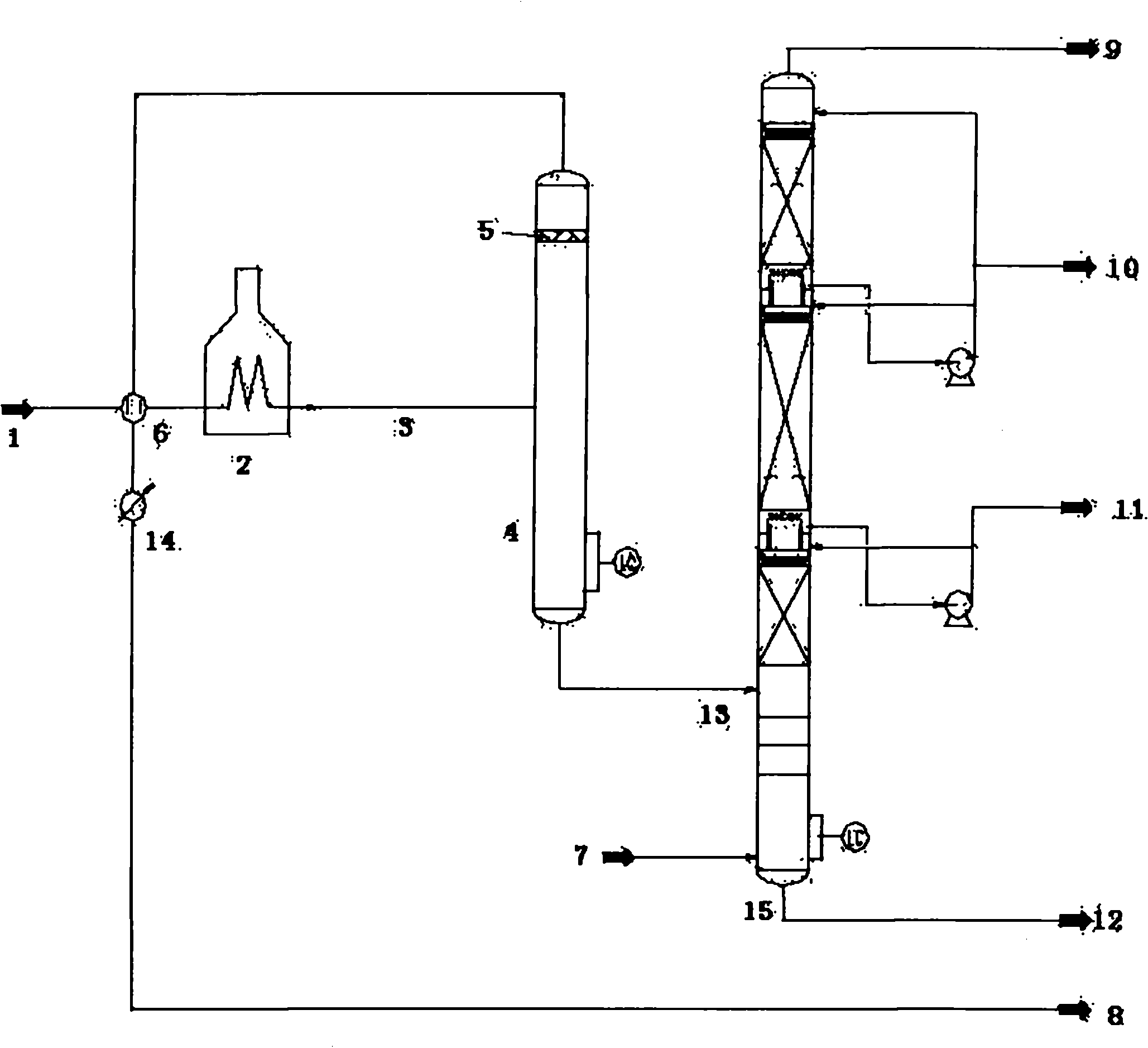

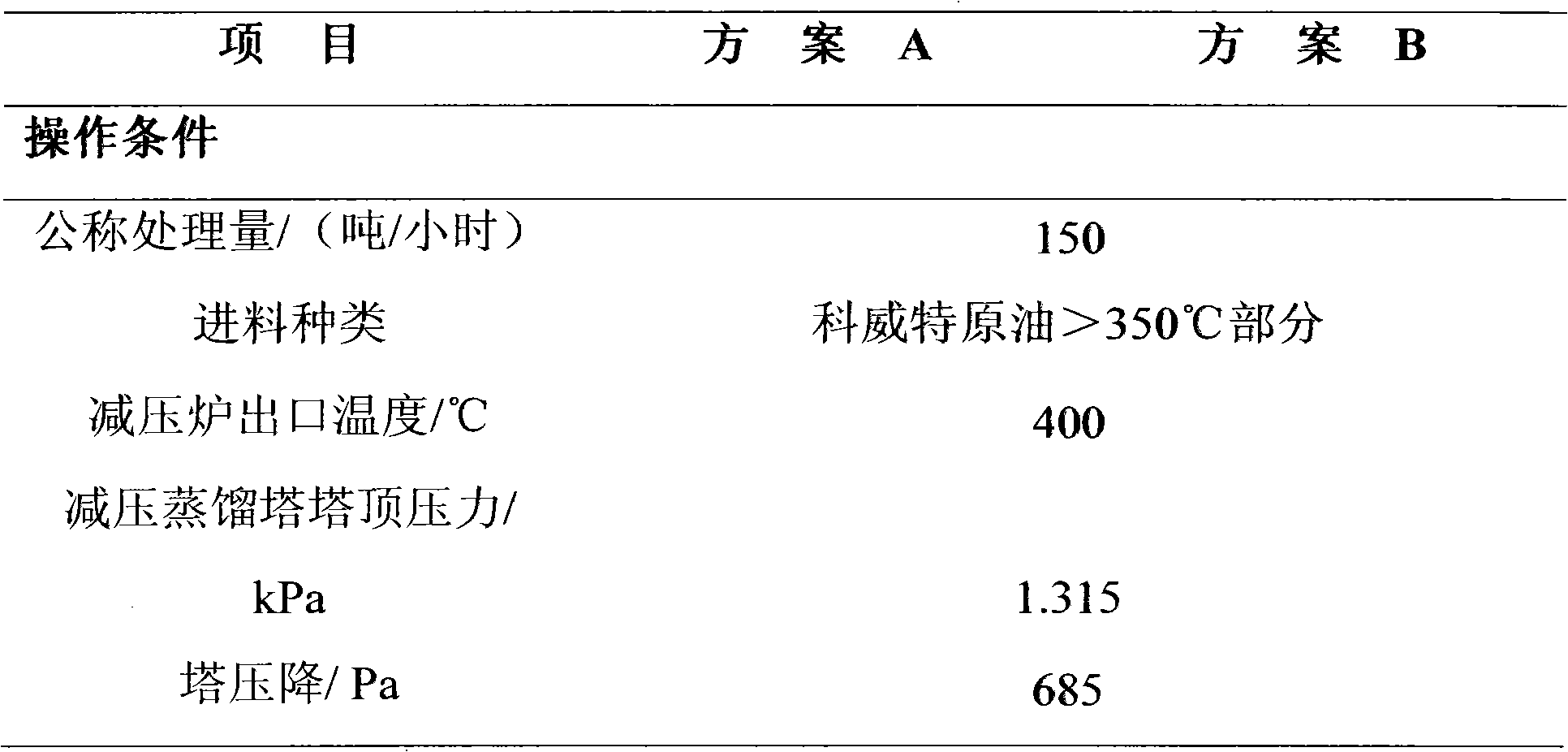

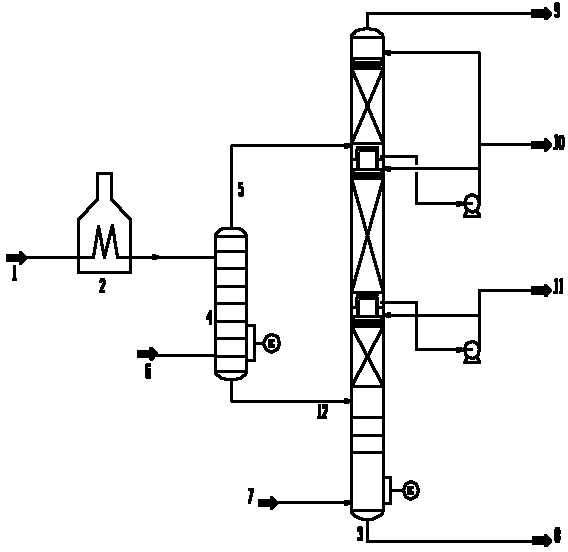

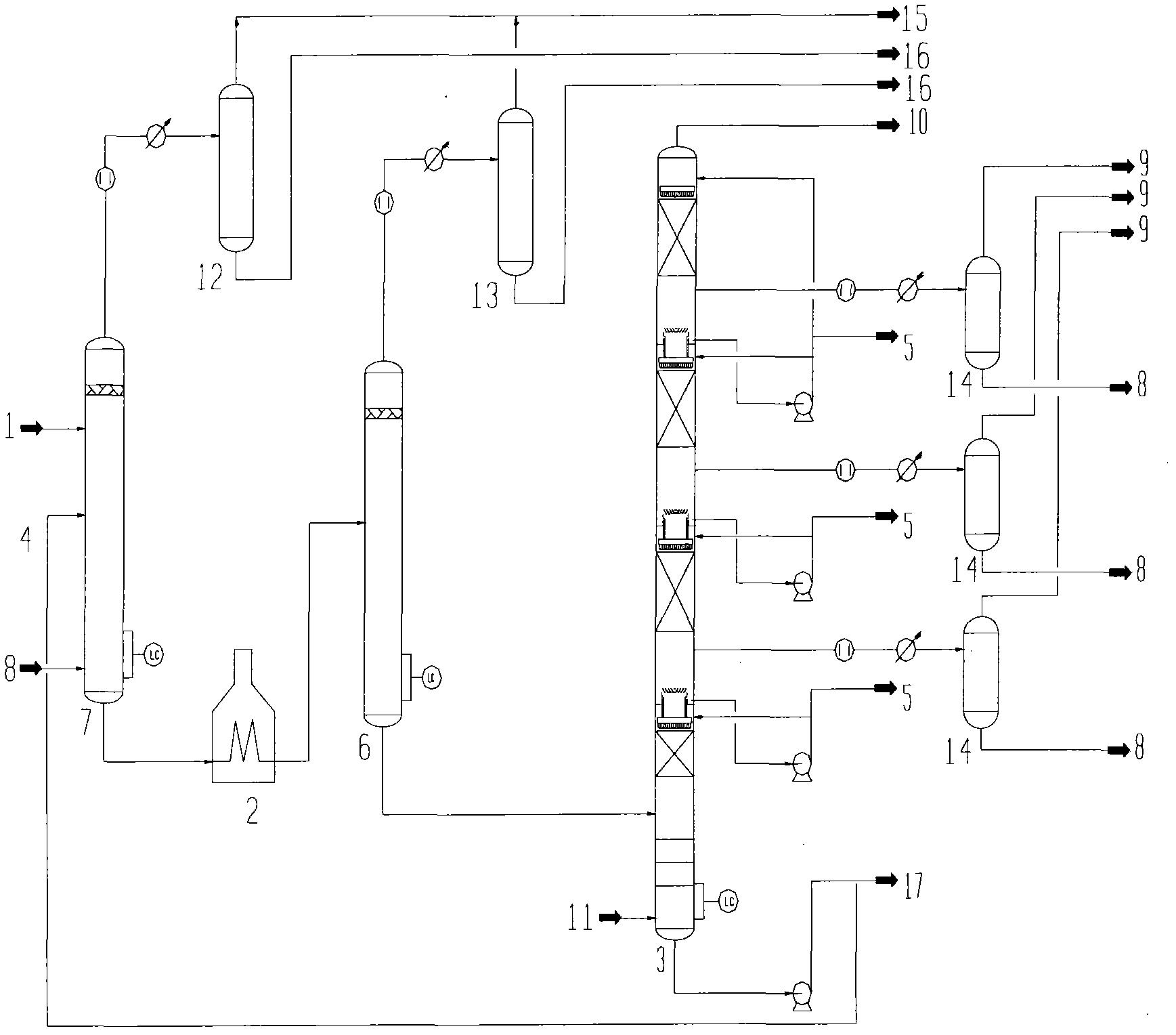

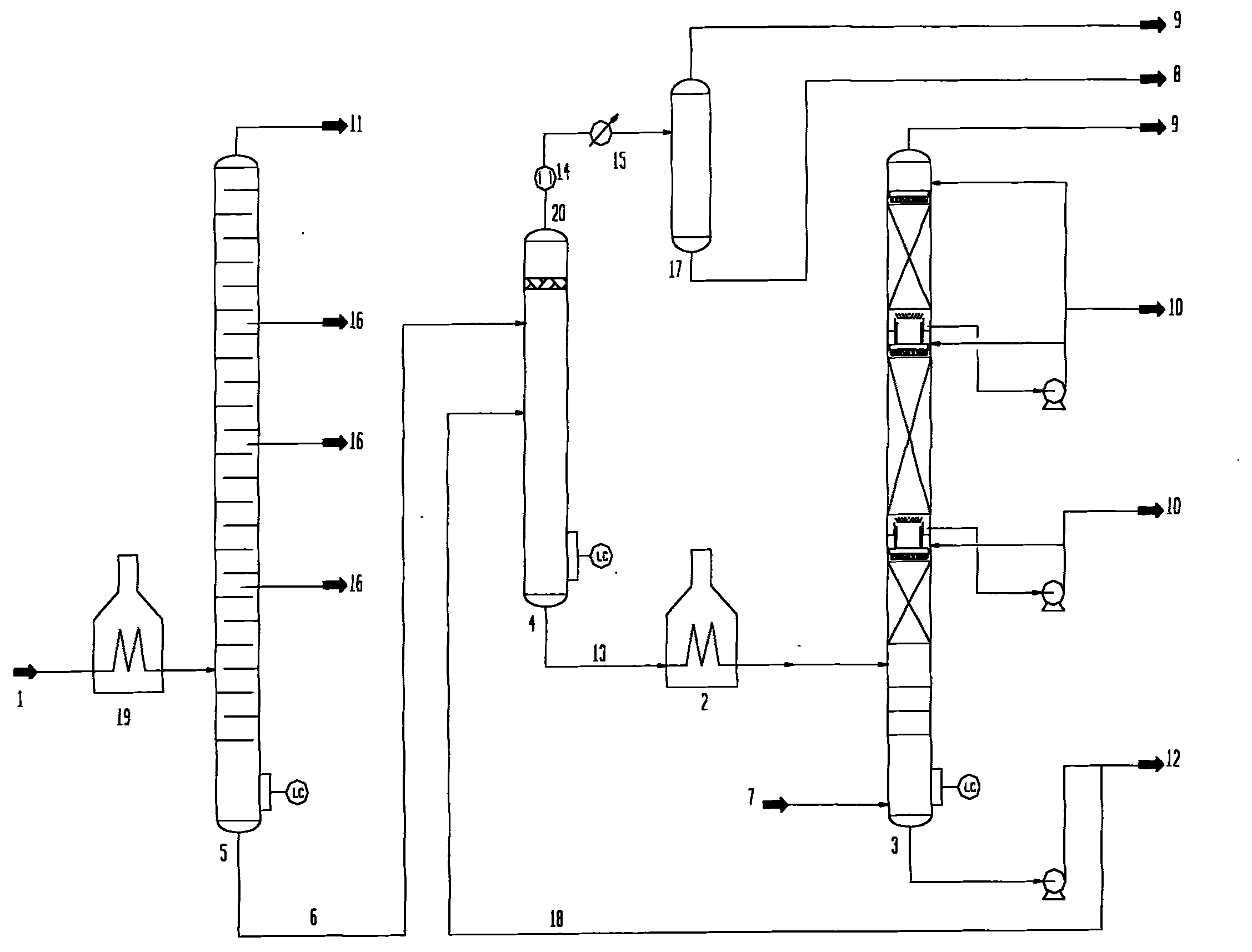

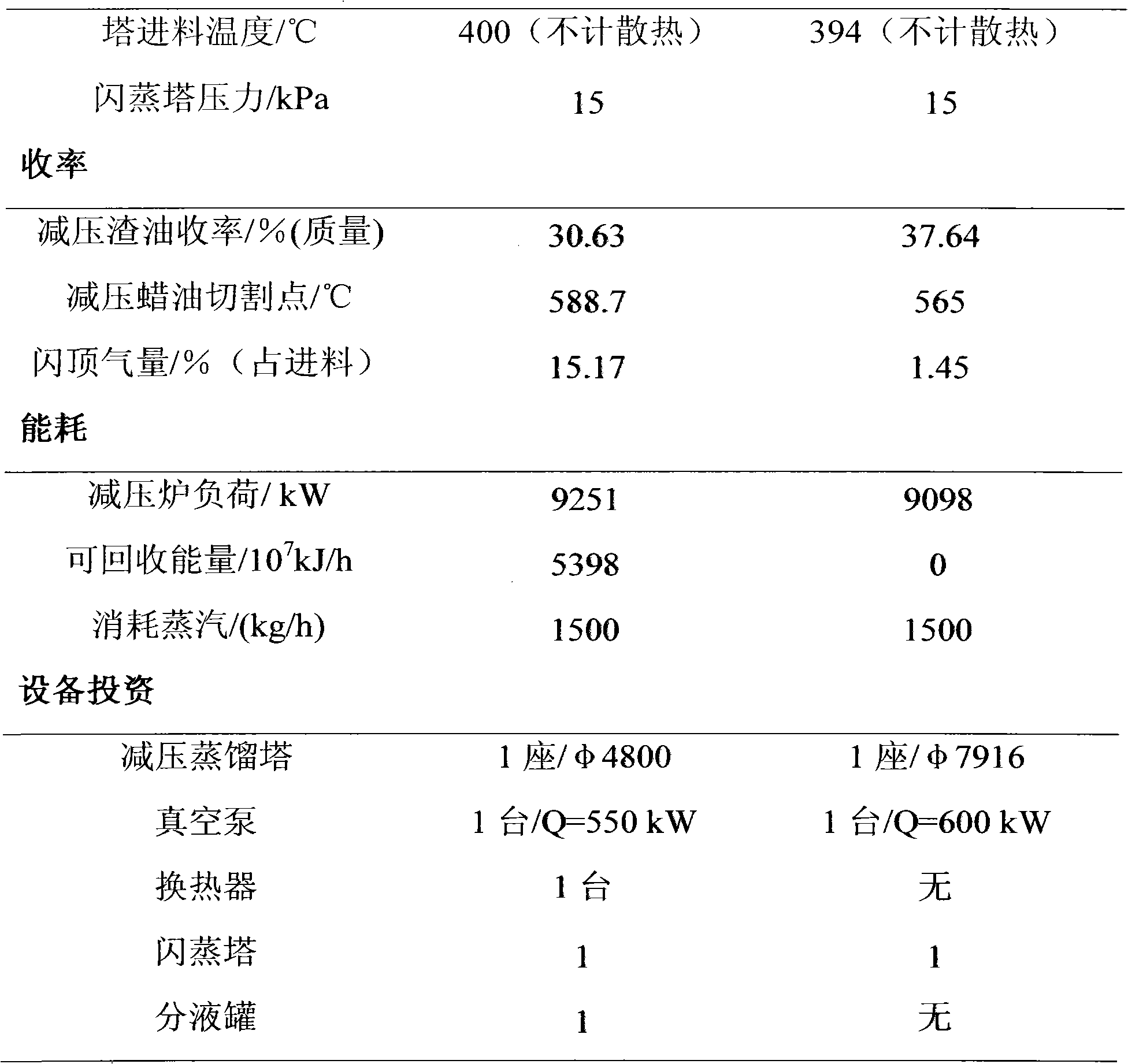

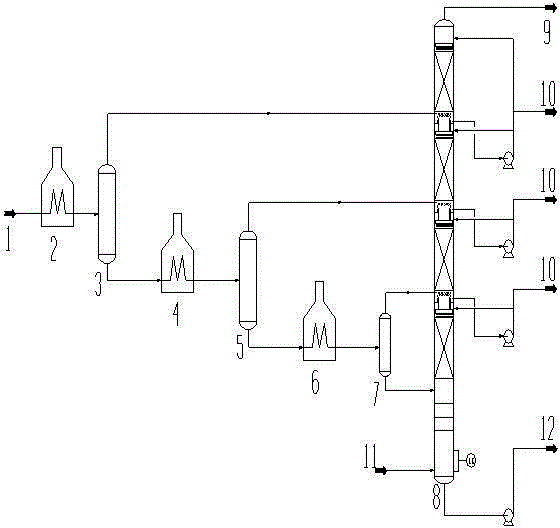

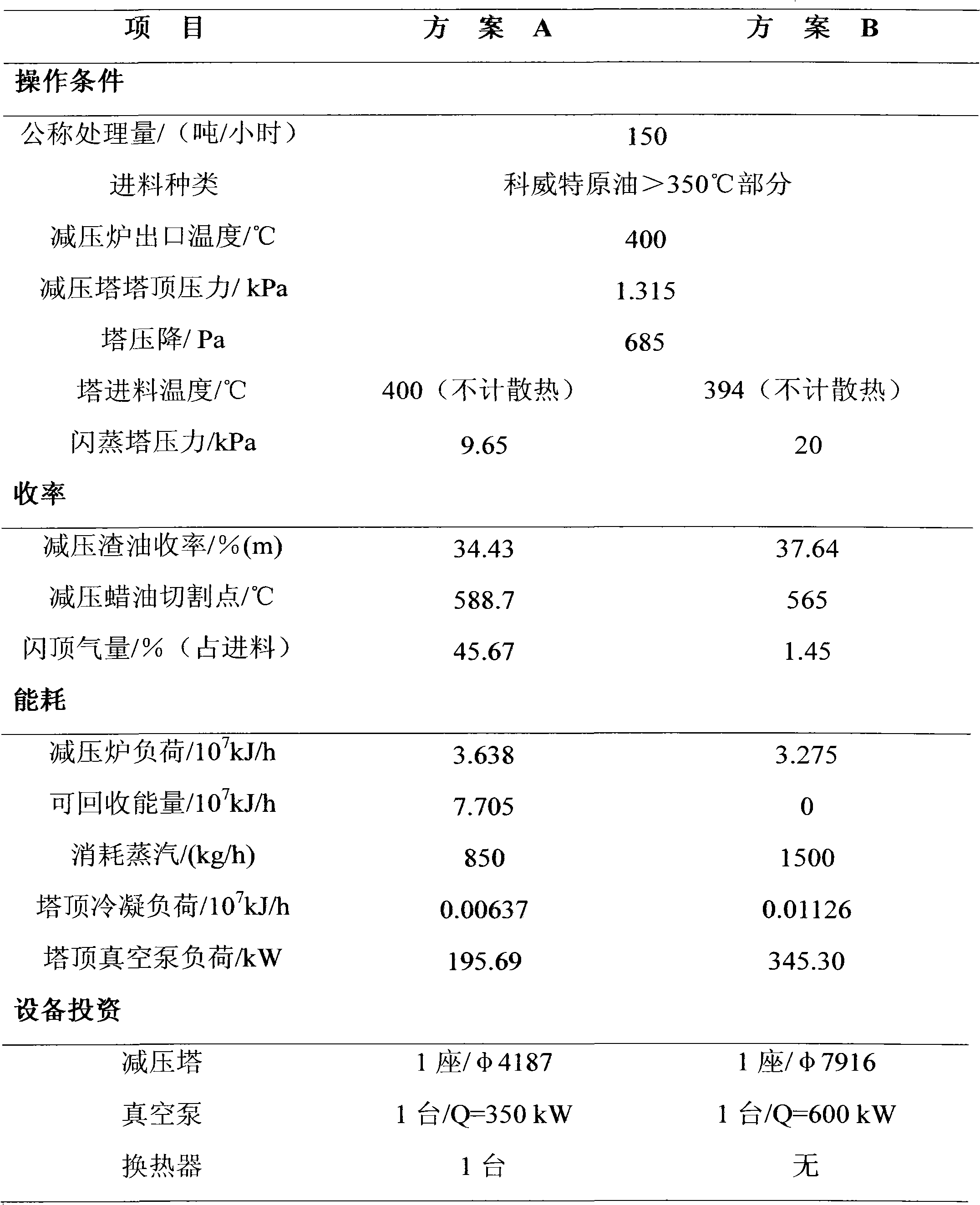

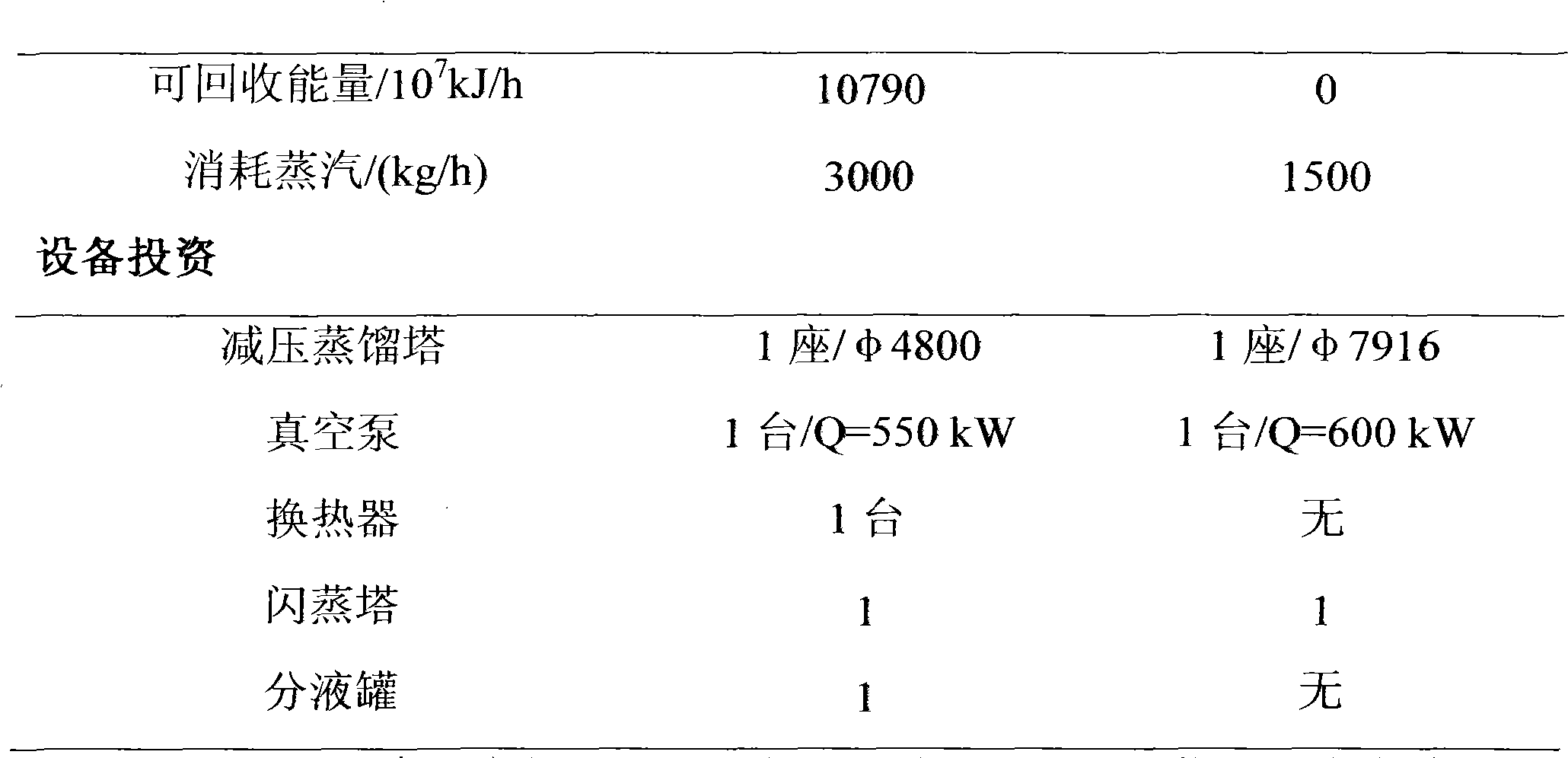

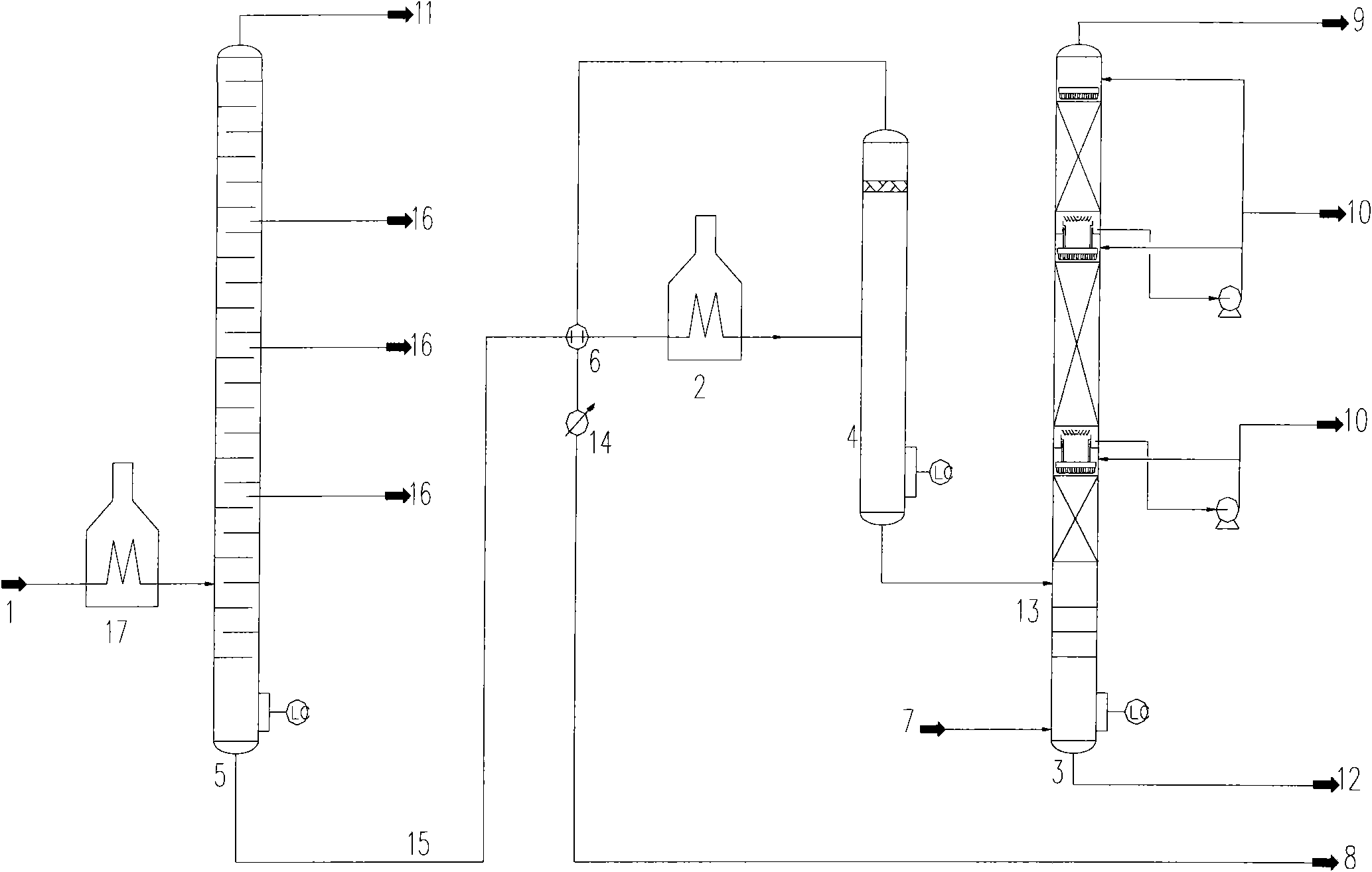

The invention discloses a distillate yield improving vacuum distillation method and device. A flash vaporization vessel is arranged on an oil transfer line between a vacuum furnace and a vacuum distillation tower. Vacuum distillation raw materials enter the oil transfer line and the flash vaporization vessel after being heated by the vacuum furnace. Gas liquid separation is carried out in the flash vaporization vessel: liquid discharged from the bottom of the flash vaporization vessel, namely flash bottom oil, is introduced into the vacuum distillation tower; and gas discharged from the top of the flash vaporization vessel, namely flash top gas, is led out of the device after being condensed into liquid. According to the vacuum distillation method and device with the flash vaporization vessel arranged behind the vacuum furnace, on one hand, the yield of vacuum distillate is increased, on the other hand, a conventional decompression oil transfer line low-speed section is omitted, the operation load of the vacuum tower is reduced, and the diameter of the vacuum tower can be appropriately reduced, so equipment investment is saved, and the operating cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

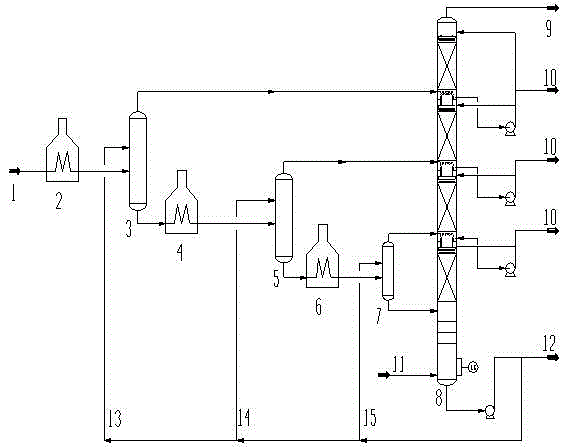

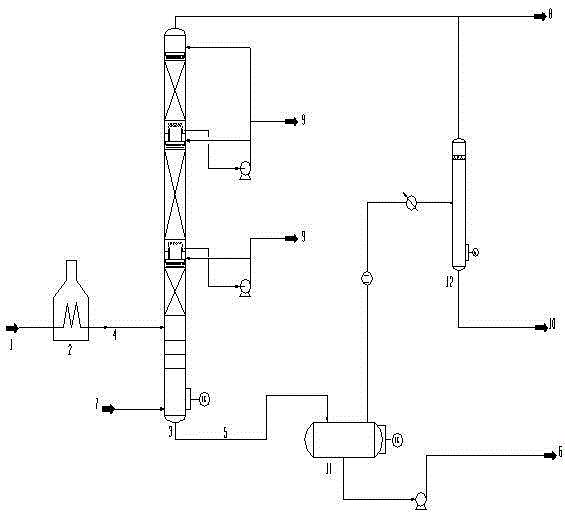

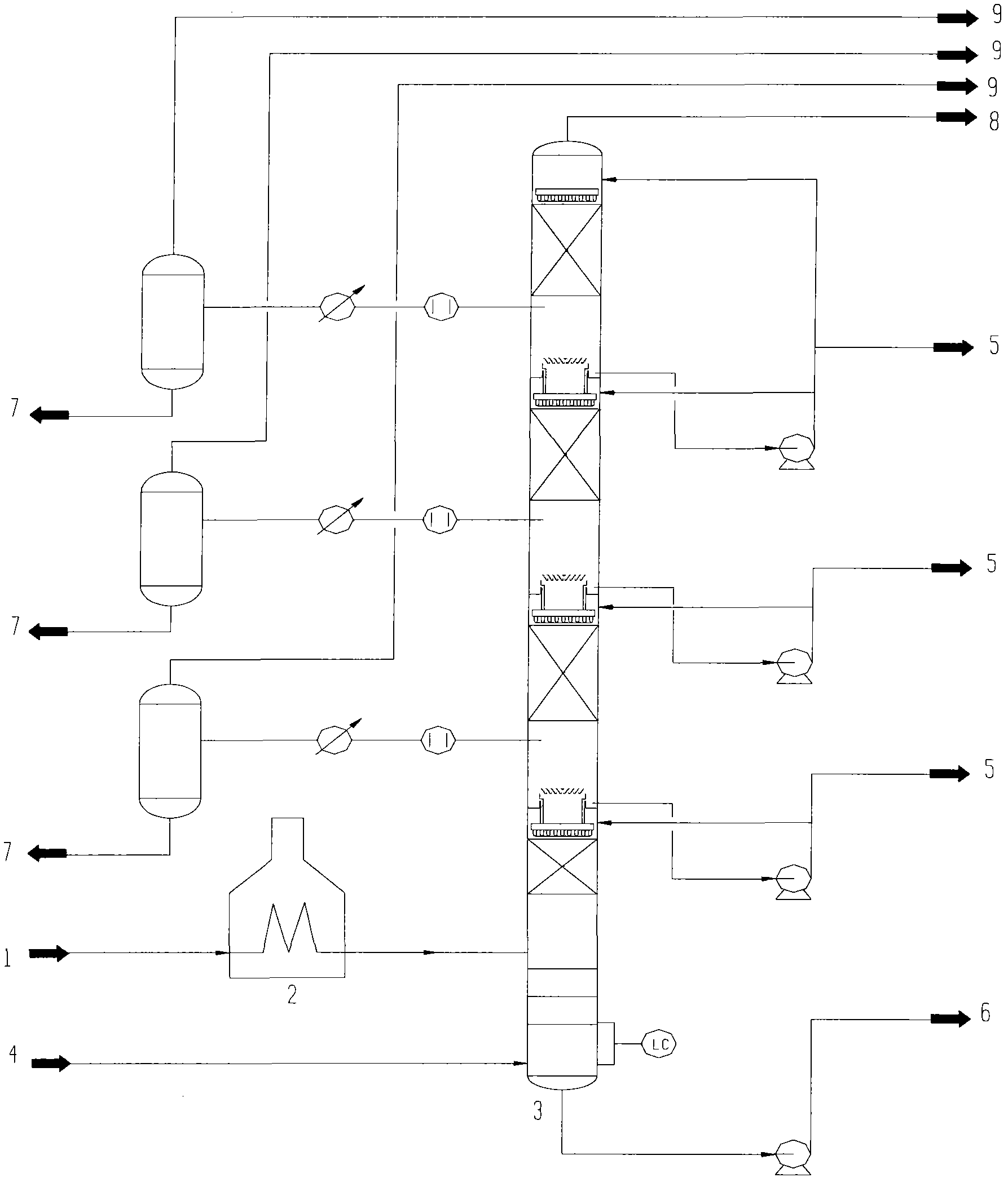

Crude oil processing method

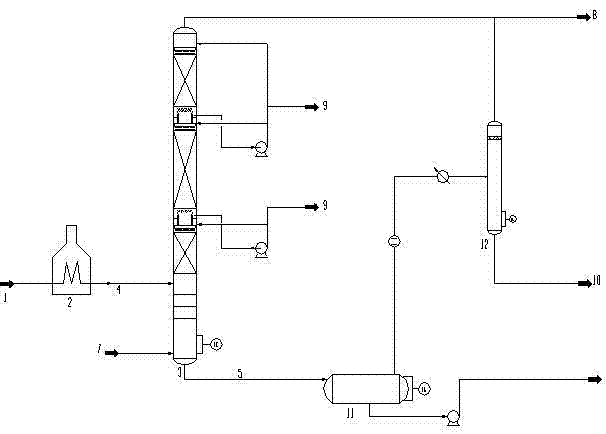

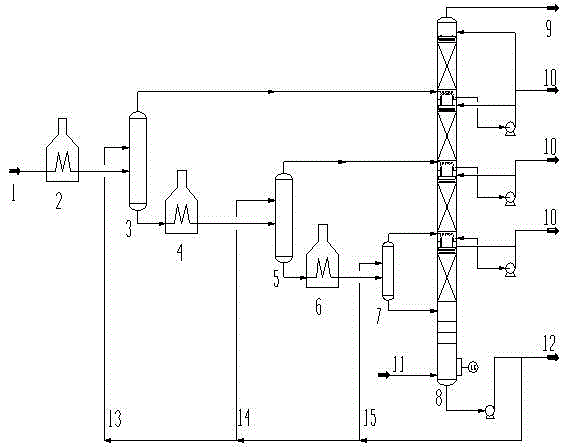

The invention discloses a crude oil processing method, which comprises normal-pressure distillation and reduced-pressure distillation, wherein the heavy oil at the bottom of a normal-pressure distillation tower, namely normal bottom oil, is mixed with part of circular reduced-pressure residual oil at the bottom of a reduced-pressure distillation tower, the mixture enters a flash tower, and a top gas phase, namely flash top gas, of the flash tower undergoes heat exchange and is condensed into a liquid phase to be discharged out of the device as a product; and bottom oil, namely flash bottom oil, of the flash tower, is heated in a reduced-pressure furnace to 390 to 420 DEG C, the heated bottom oil is intruded into a flash section of the reduced-pressure distillation tower from a reduced-pressure oil transfer line for reduced-pressure distillation, proper distillate product is drawn from a side line of the reduced-pressure distillation tower, part of reduced-pressure residual oil drawn out from the bottom of the reduced-pressure distillation tower is circulated, and another part of the reduced-pressure residual oil is discharged of the device. Compared with the prior art, the method can effectively improve the drawing rate of a reduced-pressure distillation process and can reduce the load of the reduced-pressure furnace and the reduced-pressure distillation tower at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Crude oil pressure-reduced distillation method and device

InactiveCN102311754AEasy to separateGood stripping effectVacuum distillation separationVacuum distillationHydrogenGas phase

The invention discloses a crude oil pressure-reduced distillation method and a crude oil pressure-reduced distillation device. A flash tower is arranged between a reduced-pressure furnace and a reduced-pressure distillation tower, an oil transfer line is eliminated, a reduced-pressure distillation raw material is heated in the reduced-pressure furnace and directly enter the flash tower, a small amount of stripping gas is introduced into the flash tower, and the liquid phase, namely flash bottom oil, obtained by gas-liquid separation in the flash tower is introduced into the reduced-pressure distillation tower; and a gas phase, namely flash top gas, discharged from the top of the flash tower is condensed into a liquid phase to be led out of the device. A high-temperature hydrogen or inert gas is introduced into the bottom of the flash tower. When the pressure-reduced distillation method and the pressure-reduced distillation device, in which the flash tower for high-temperature hydrogen or inert gas stripping flash tower is arranged behind the reduced-pressure furnace, are used, the yield of a reduced-pressure fraction oil is increased, the conventional reduced-pressure oil transfer line is not used, the operation load of the reduced-pressure furnace is lowered, and the tower diameter of the reduced-pressure tower can be reduced properly; therefore, equipment investment is reduced, and operation cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

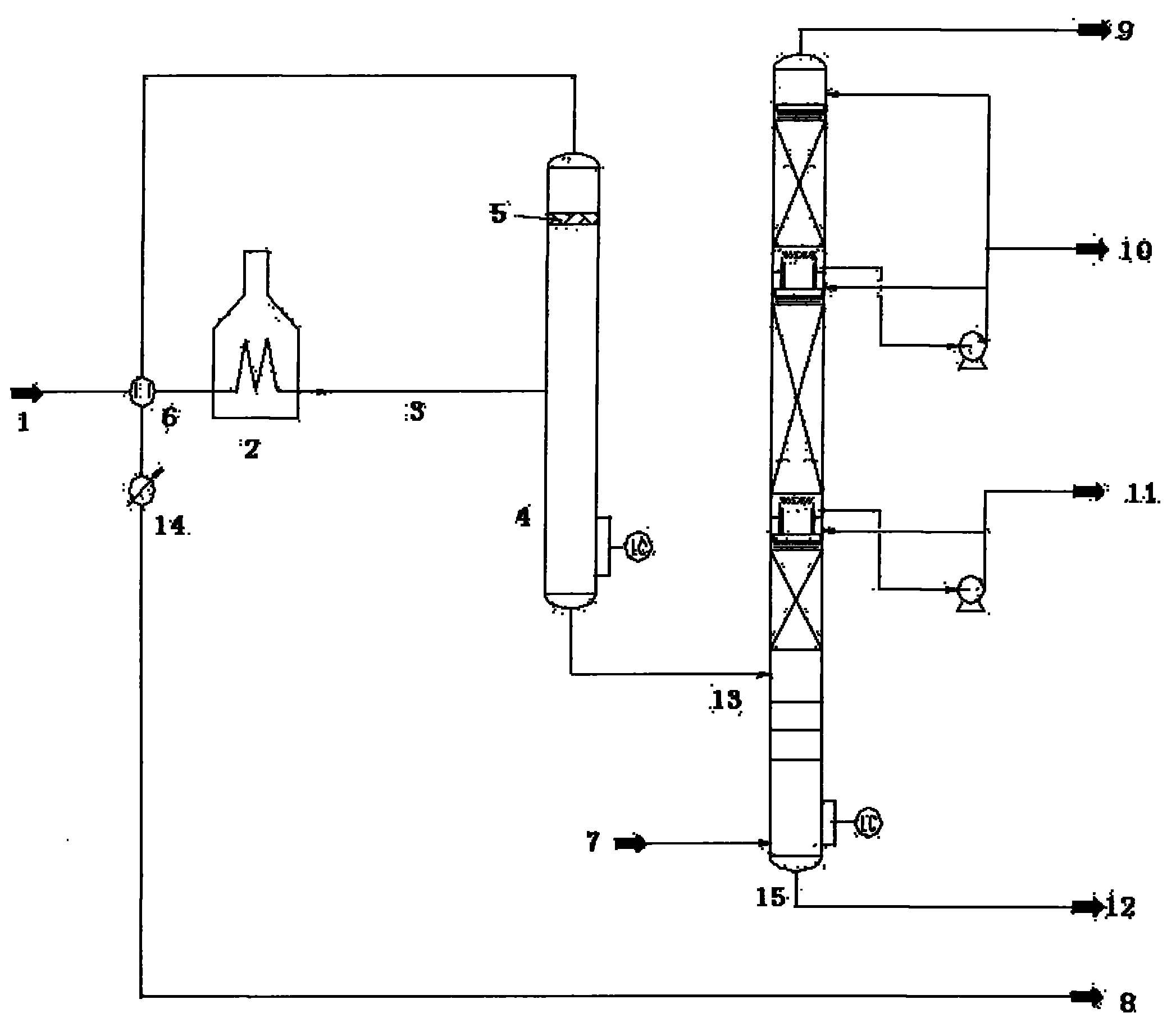

Crude oil distillation method

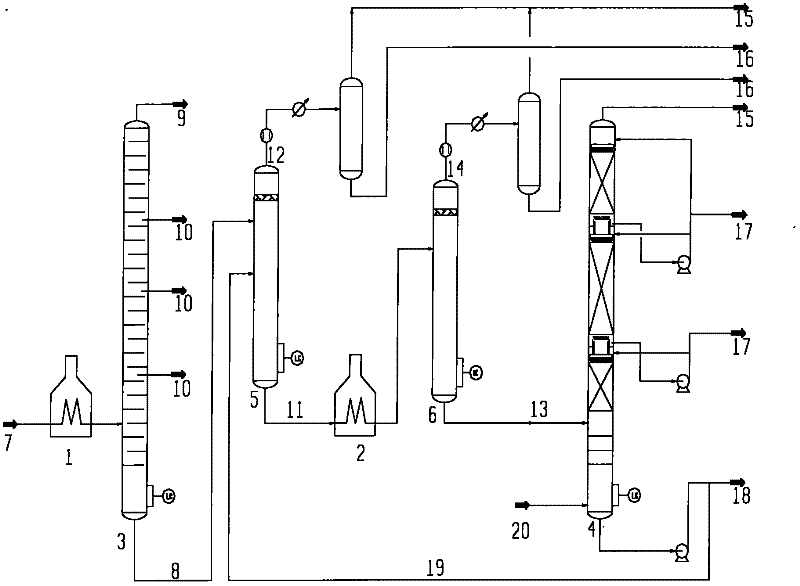

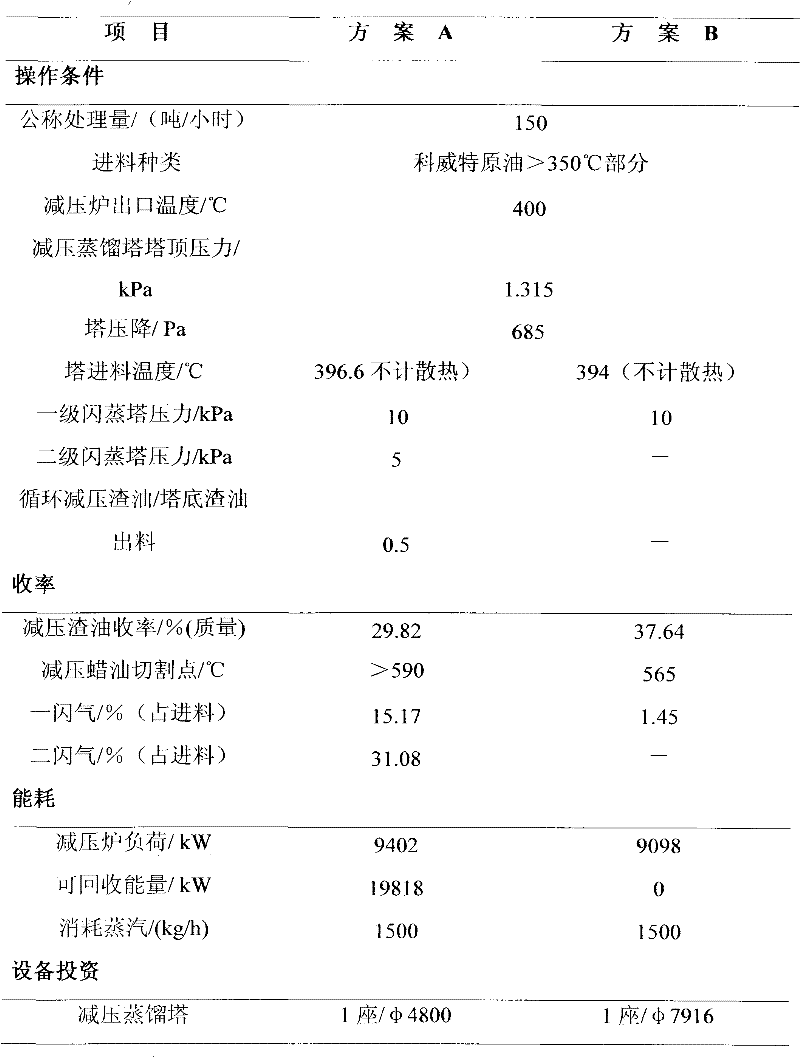

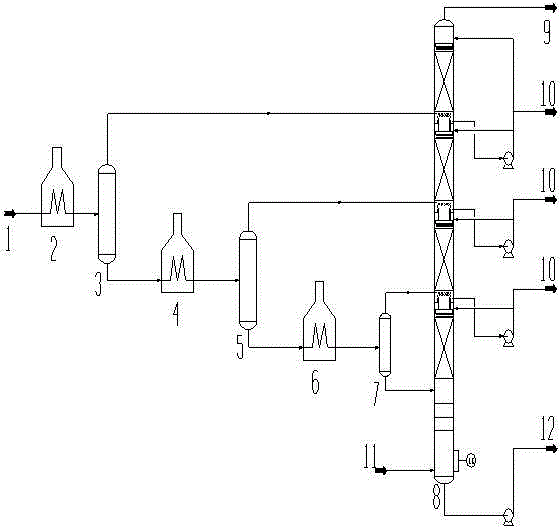

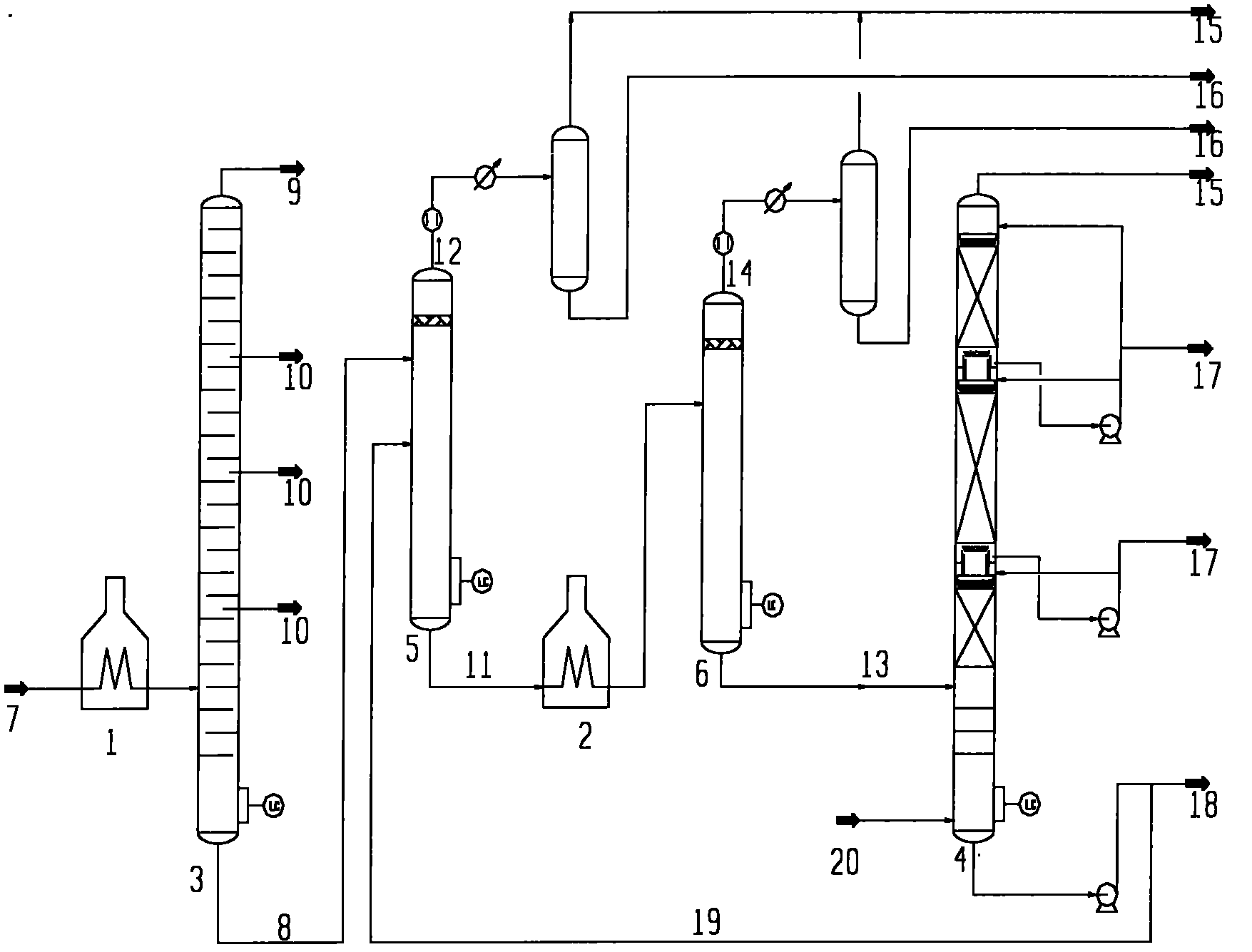

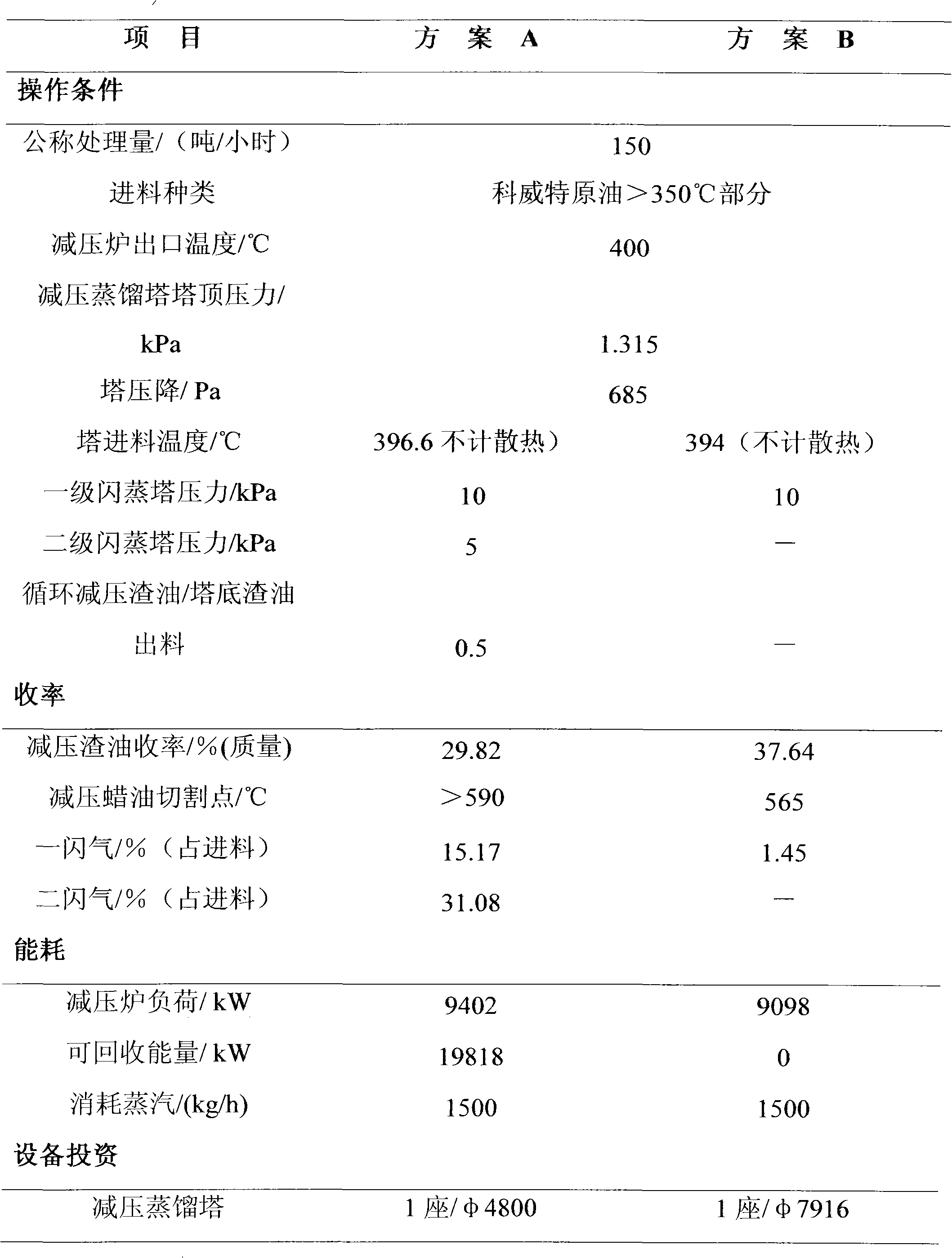

The invention discloses a crude oil distillation method. A primary flash distillation tower is arranged between a normal pressure distillation tower and a pressure reduction furnace, a pressure reduction oil line from an outlet of the pressure reduction furnace to a pressure reduction distillation tower is omitted, a secondary flash distillation tower is arranged between the pressure reduction furnace and the pressure reduction distillation tower, tower bottom heavy oil of the normal pressure distillation tower, i.e. normal bottom oil enters the primary flash distillation tower after being mixed with cyclic pressure reduction slag oil, the tower top gas phase of the primary flash distillation tower is converted into a liquid phase to be used as products through heat exchange and condensing, bottom oil of the primary flash distillation tower enters the secondary flash distillation tower through being heated by the pressure reduction furnace, the tower top gas phase of the secondary flash distillation tower is converted into a liquid phase to be used as products through heat exchange and condensing, and bottom oil of the secondary flash distillation tower is introduced into a flash distillation section of the pressure reduction distillation tower for pressure reduction distillation. Compared with the prior art, the method has the advantages that on one hand, the yield of the pressure reduction slag oil is reduced, and the economic benefits of devices are improved; and on the other hand, the load of the pressure reduction furnace and the pressure reduction distillation tower is reduced, the device investment is saved, and the energy consumption of the devices is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reduced pressure distillation method with low energy consumption and deep total distillation rate

ActiveCN103242896AIncrease gasification rateReduce pressure drop lossTreatment with plural serial refining stagesThermodynamicsEconomic benefits

The invention discloses a reduced pressure distillation method with low energy consumption and deep total distillation rate. By arranging a reduced pressure flashing tower behind a reduced pressure heating furnace, light fractions vaporized by heat are separated out, load of a reduced pressure distillation tower is reduced and energy consumption of an apparatus is reduced; by arranging a reduced pressure flashing tank behind the reduced pressure distillation tower, relatively light fractions in reduced pressure residues can be further flashed under a vacuum degree higher than that of the bottom of a reduced pressure distillation tower, yield of reduced pressure distillate oil is increased, and thus a reduced pressure distillation operation with low energy consumption and deep total drawing rate can be realized. With the reduced pressure distillation method, the content of fractions with a temperature lower than 500 DEG C in the reduced pressure residues can be reduced to the minimum, so that the distillation rate of the reduced pressure distillation is increased and economic benefits of the apparatus can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

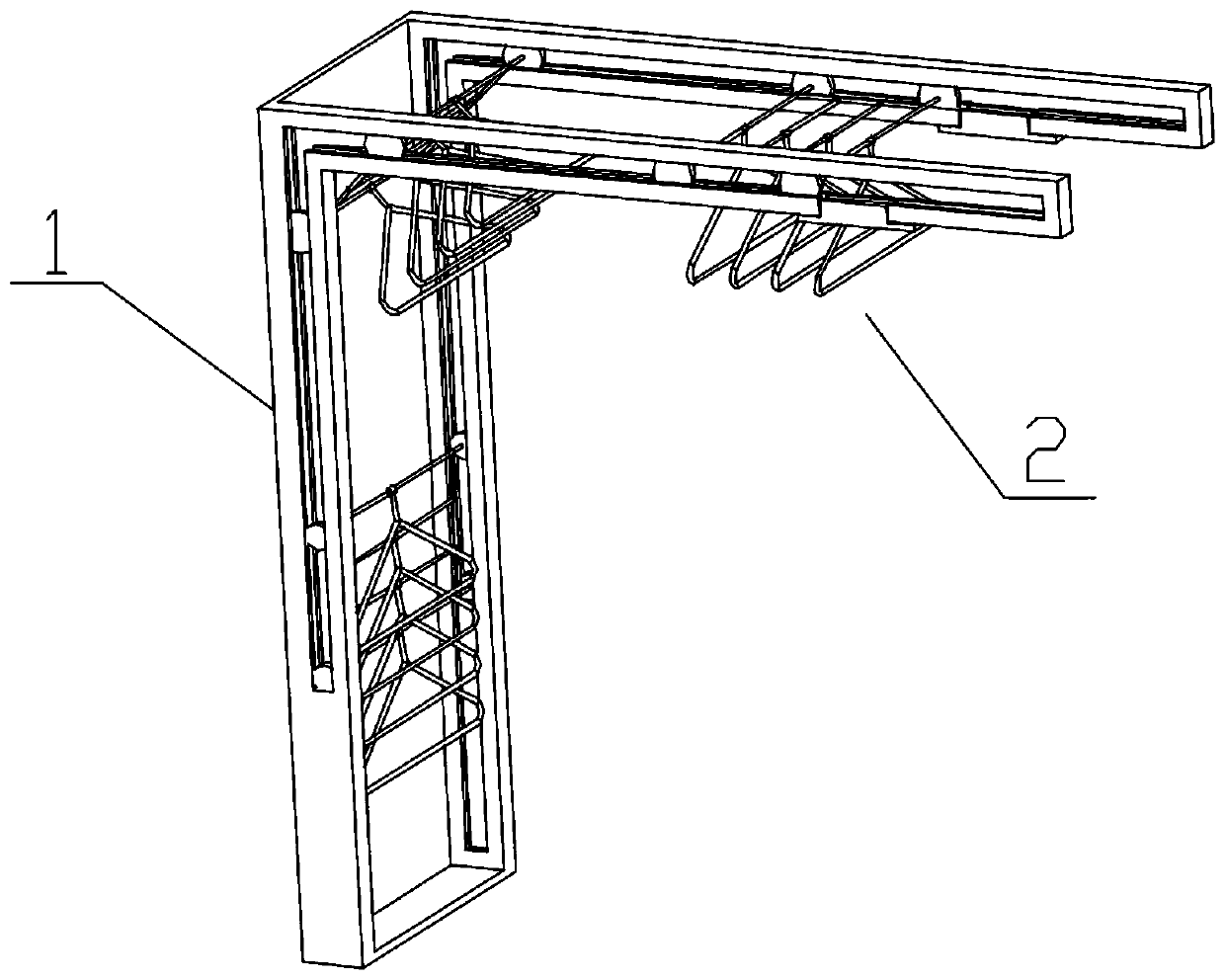

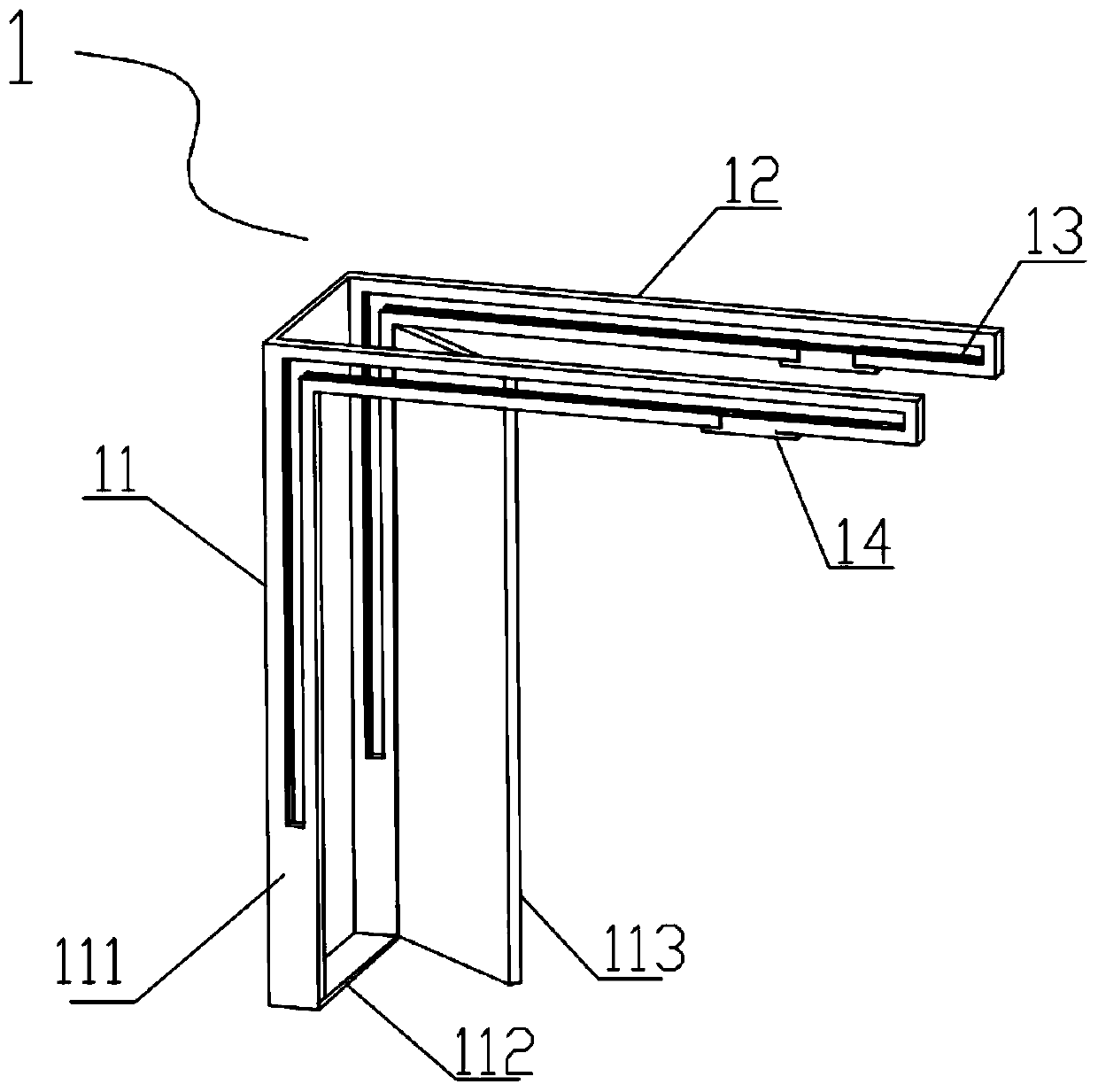

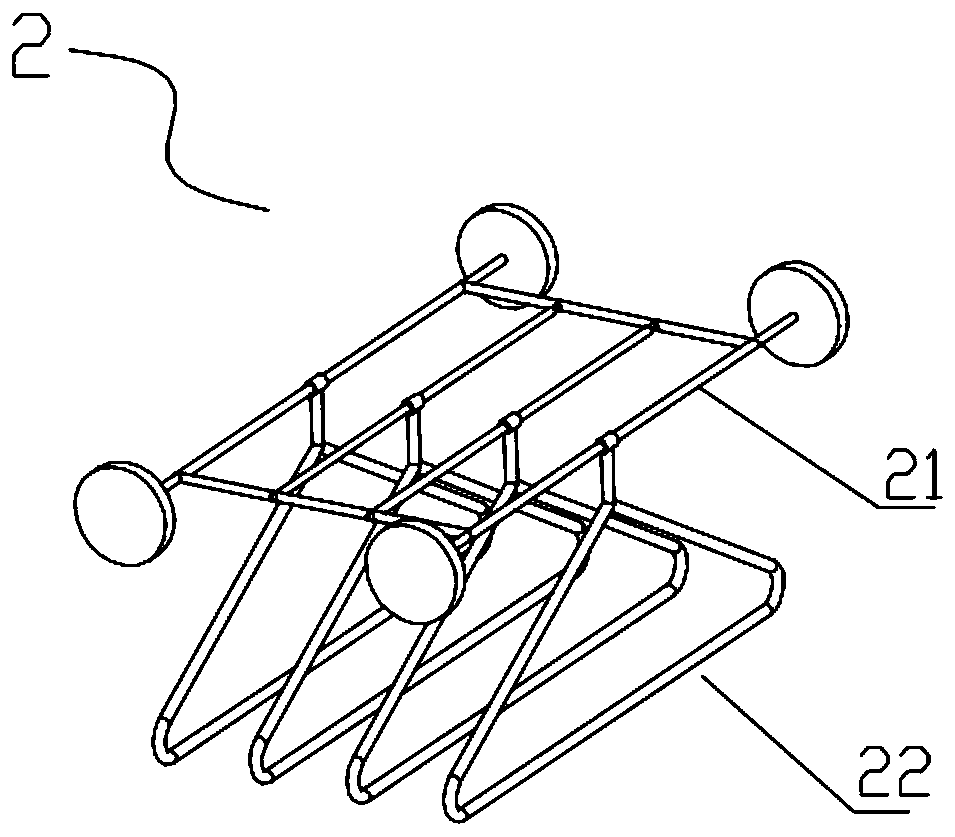

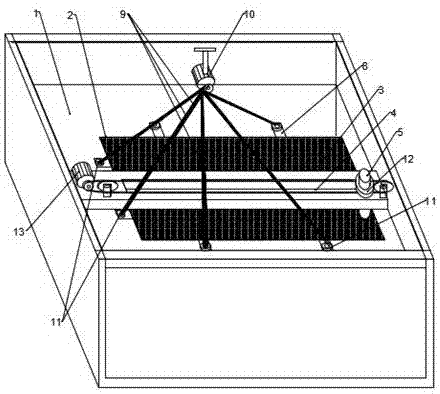

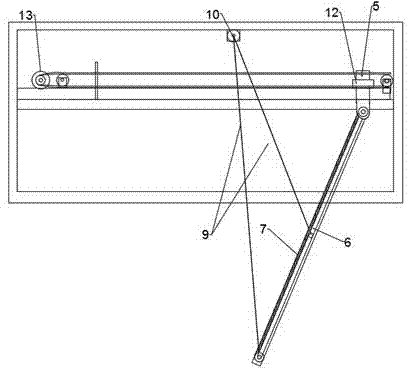

Multifunctional wardrobe placed in bay windows

The invention discloses a multifunctional wardrobe placed in bay windows. The multifunctional wardrobe includes a wardrobe body and a hanger assembly; the wardrobe body includes a box body and horizontal rail crossbars connected to the top of the box body in parallel, and continuous rails both are arranged on side frames of the box body and the rail crossbars at two sides of the wardrobe body; andthe size of the hanger assembly is equal to that of the rails, the hanger assembly can freely transfer on the rails, and the rail crossbars are provided with installing mouths. According to the multifunctional wardrobe placed in the bay windows, the hanger assembly can freely transfer on the rails, clothes aired on the rail crossbars can be rapidly collected into the box body; and in addition, included angles are designed between the rails at the side frame parts of the box body and in the vertical directions, so that the clothes hanged on hangers of the hanger assembly naturally fall and donot stack together.

Owner:何海华

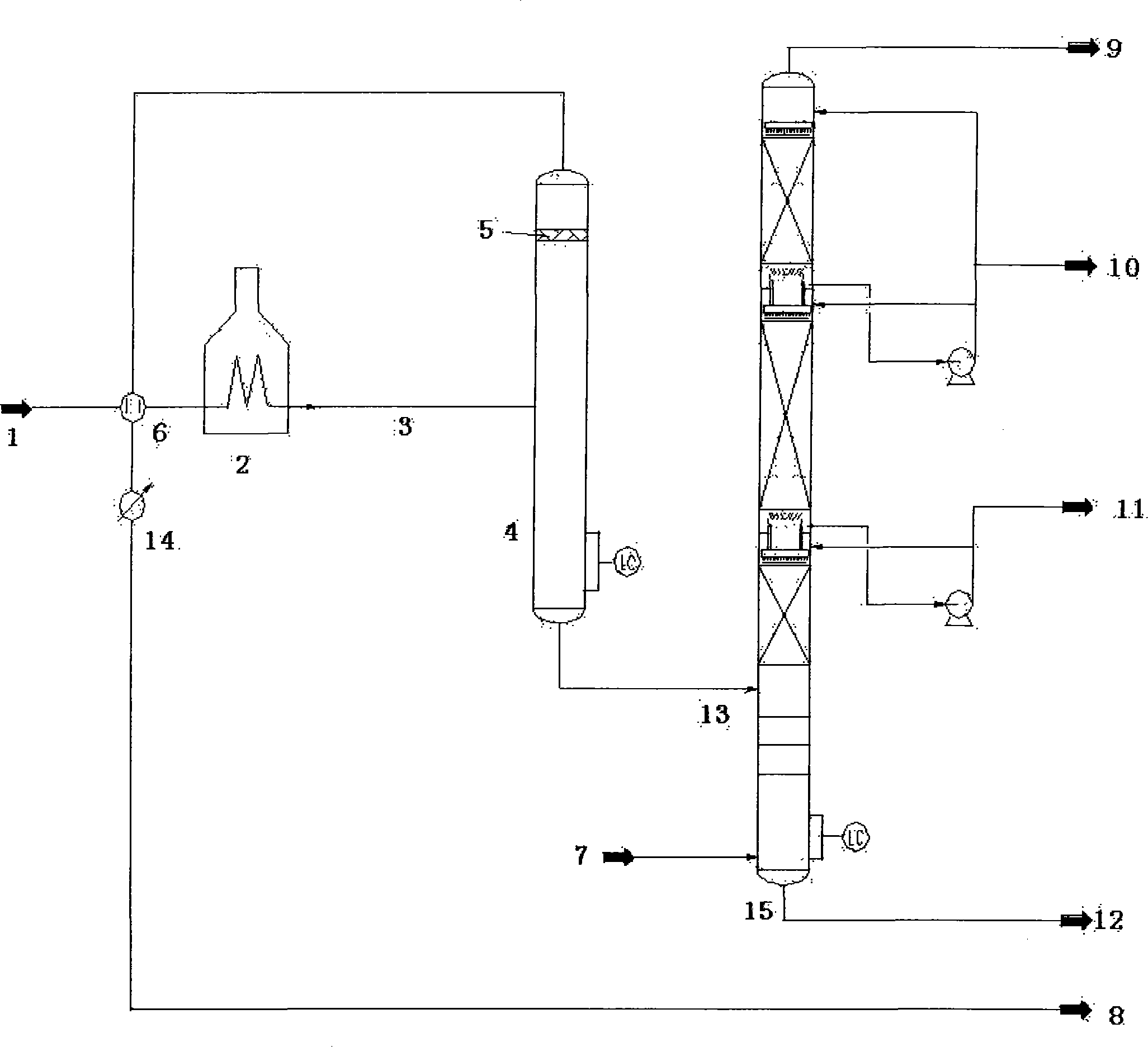

Sectional feeding vacuum distillation method and apparatus for crude oil

InactiveCN102911716AAvoid lateral thermal displacementLess investmentTreatment with plural serial refining stagesProcess engineeringSuperheated steam

The invention discloses a sectional feeding vacuum distillation method and an apparatus for crude oil. The method comprises the steps of omitting relatively long transfer line from the outlet of a vacuum furnace to the vacuum tower; arranging a flashing tower between the vacuum tower and a vacuum distillation tower; passing superheated steam through the bottom of the flashing tower; introducing the raw materials of vacuum distillation to the flashing tower through the vacuum furnace after being heated; educing relative light components (hereinafter referred to flashing top gas) in the flashing tower from the tower top after steam stripping evaporation; entering below a packing layer of some fractioning section of the vacuum distillation tower; and introducing the liquid phase (hereinafter referred to flashing bottom oil) educed from the bottom of the flashing tower to the feeding section of the vacuum distillation tower to perform vacuum distillation. The sectional feeding vacuum distillation method and the apparatus for the crude oil can obviously increase pull-out rate of the vacuum distillation process and improve the quality of the vacuum distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

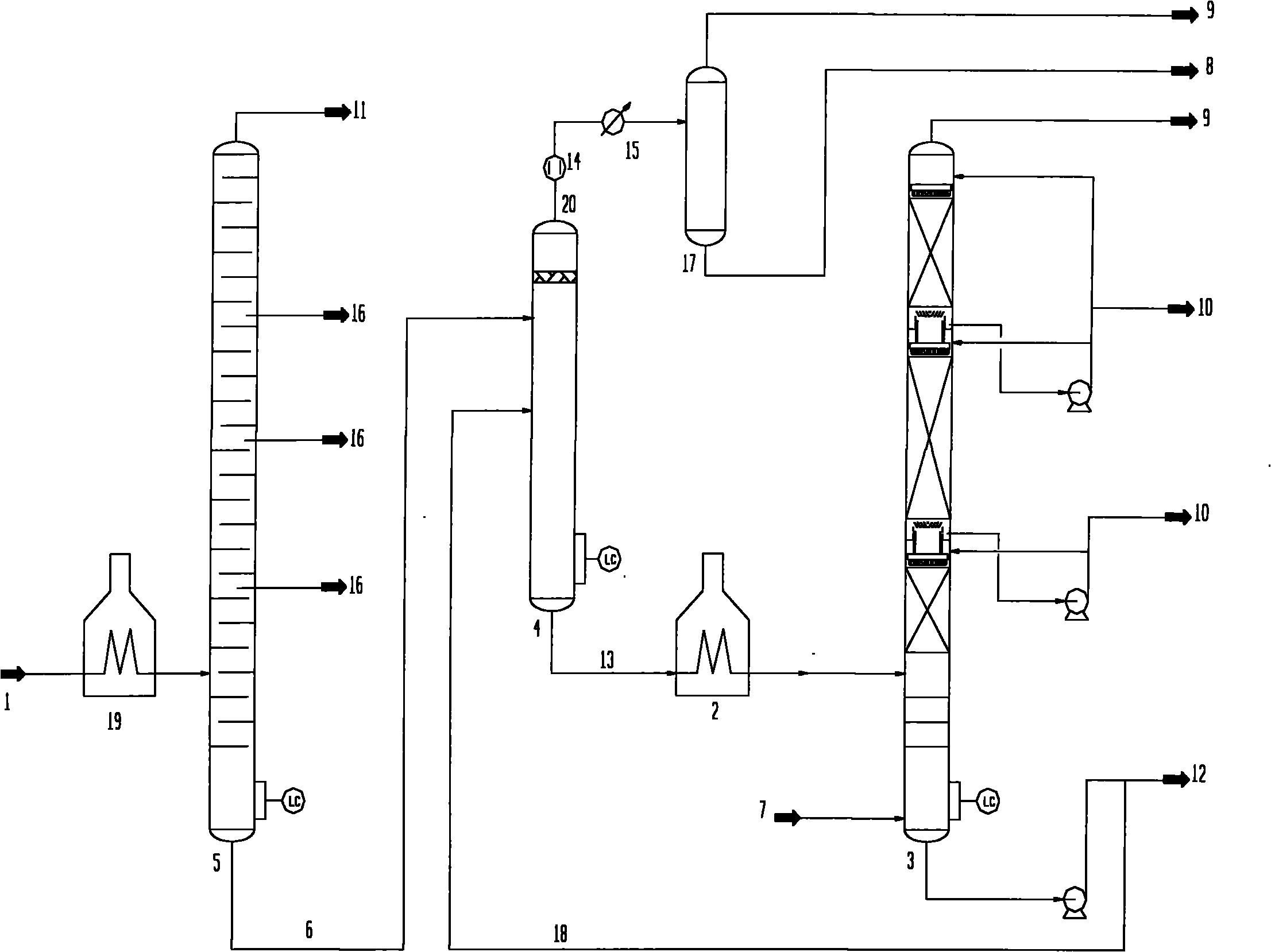

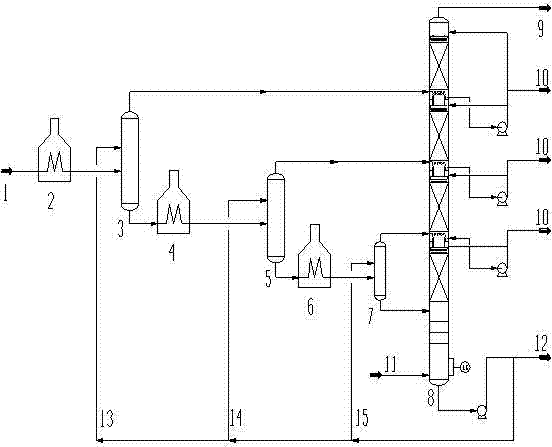

Vacuum distillation method for gradual gasification segmented feed

ActiveCN103059918AIncrease gasification rateRelieve pressureTreatment with plural serial refining stagesFluid phaseProcess engineering

The invention discloses a vacuum distillation method for gradual gasification segmented feed. The method includes: making atmospheric tower bottom oil enter a first stage gasification furnace, conducting heating to make the tower bottom oil enter a first stage flash tank to perform separation, leaving a gas phase to enter an upper fractionation segment of a vacuum tower, and leaving a liquid phase to enter a second stage gasification furnace; heating the liquid phase and making it enter a second stage flash tank, letting the generated gas phase enter a middle fractionation segment of the vacuum tower, and letting the generated liquid phase enter a third stage gasification furnace; heating the liquid phase and making it enter a third stage flash tank, letting the generated gas phase enter a lower fractionation segment of the vacuum tower, and letting the generated liquid phase enter a flash segment of the vacuum tower; and subjecting the feed of each segment to vacuum distillation in the vacuum tower, extracting a lateral line product from a vacuum tower lateral line, and extracting vacuum residue from the tower bottom. The method provided in the invention can substantially enhance the distillate yield of a crude oil vacuum distillation process, reduce equipment energy consumption, increase equipment economic benefits, and save equipment investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

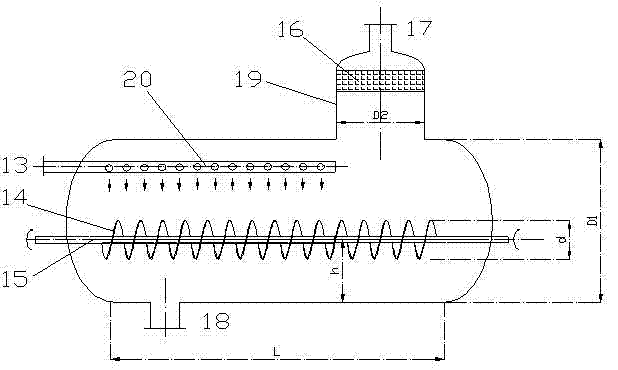

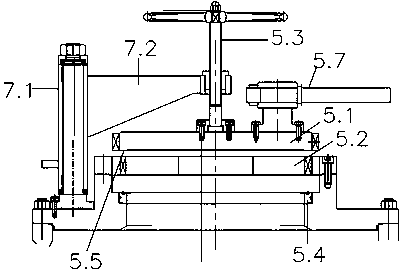

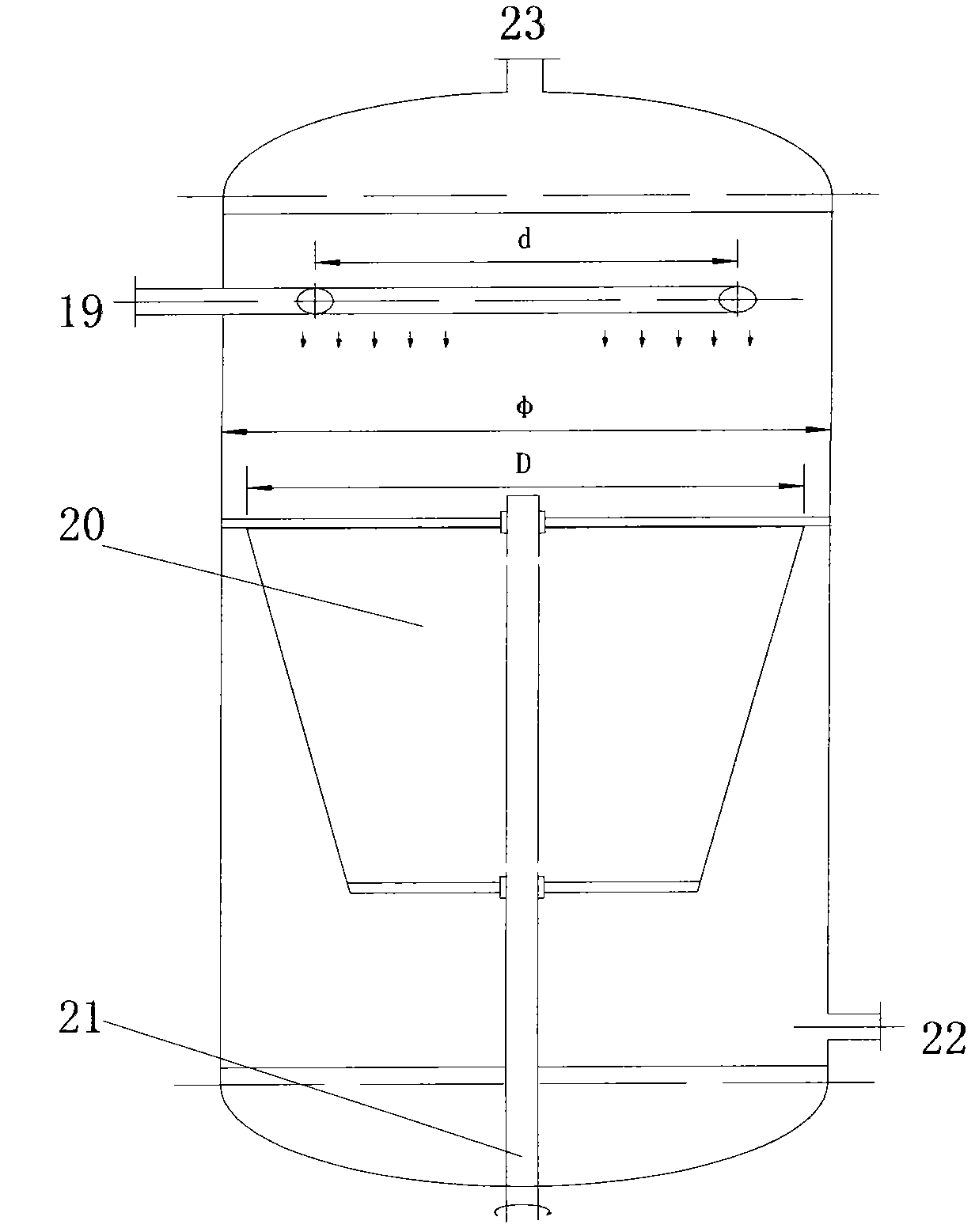

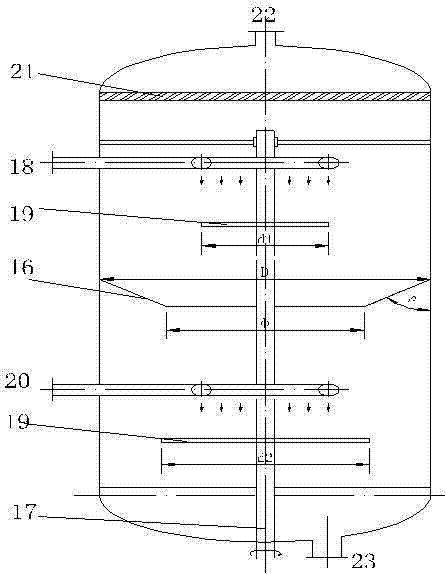

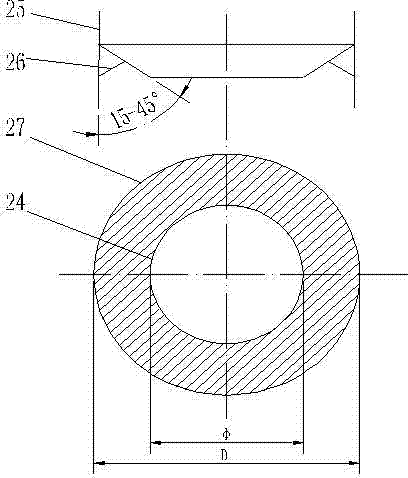

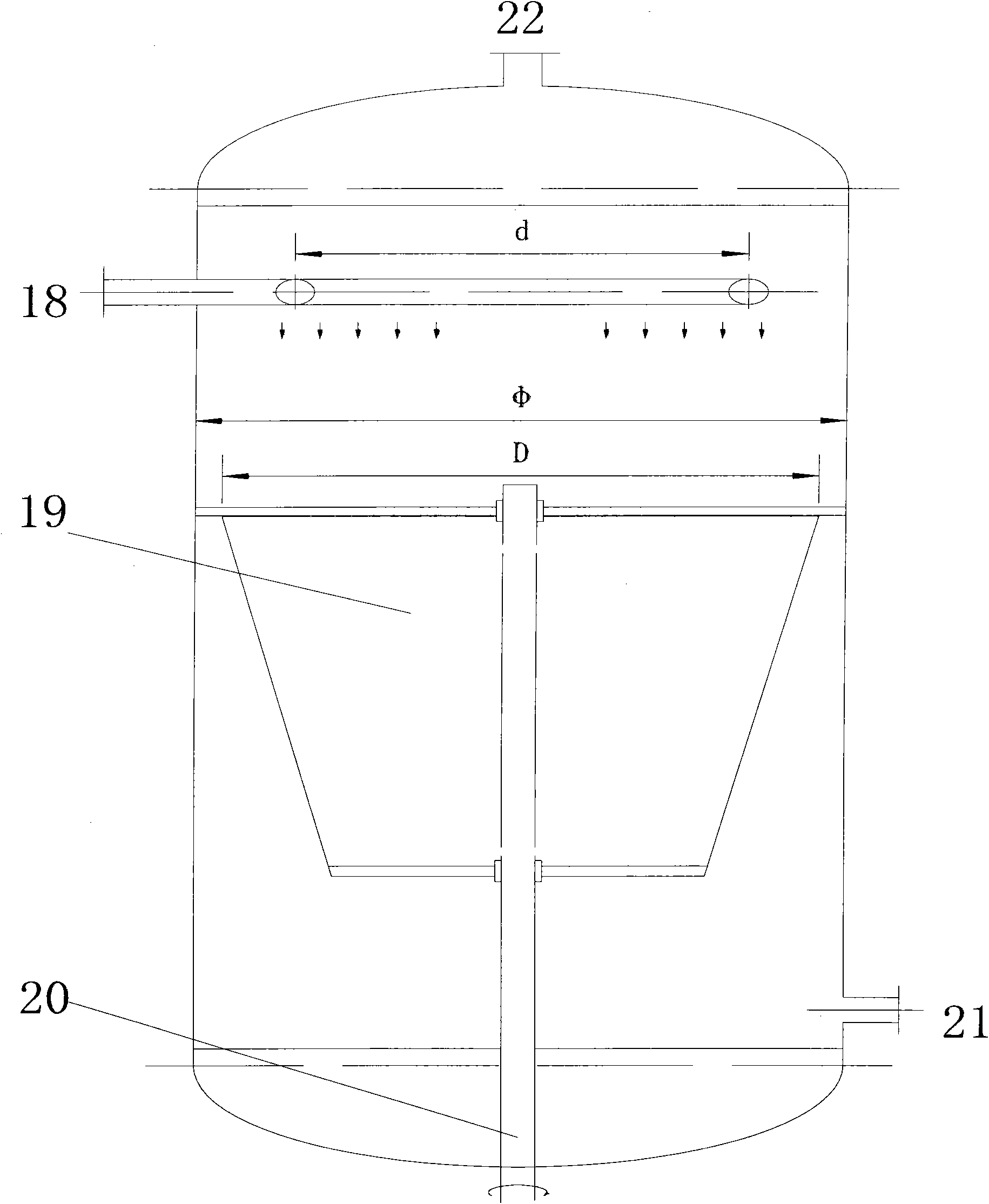

Deep reduced pressure flash tank and reduced pressure deep distillation method

ActiveCN103242886AReduce cracking lossImprove decompression yieldVacuum distillationGas phaseEngineering

The invention discloses a deep reduced pressure flash tank and a reduced pressure deep distillation method. The reduced pressure flash tank comprises a tank body and internal members of the tank. The internal members comprises a feeding inlet distributor arranged in a gas phase zone at the upper part of the reduced flash tank and a rotary disk arranged above a liquid surface of the lower part liquid phase zone, wherein the rotary disk is fixed on a rotary shaft arranged in an axis direction of the tank body. In the reduced pressure deep distillation method, the reduced pressure flash tank is arranged behind the reduced pressure tower; the atmospheric pressure bottom oil is heated by a reduced pressure furnace and introduced to the reduced pressure tower through a reduced pressure transfer line; reduced pressure light fraction oil is pumped out from the lateral line of the reduced pressure tower; reduced pressure heavy oil is pumped out from the bottom of the tower and introduced to the reduced pressure flash tank; the obtained gas phase is introduced to a gas-liquid separation tank; the reduced pressure light fraction oil is discharged from the bottom of the gas-liquid separation tank; and the flashed reduced pressure residual oil is discharged from the bottom of the reduced pressure flash tank. The deep reduced pressure flash tank and the reduced pressure deep distillation method can obviously increase distillation yield during a distillation process of crude oil, reduce energy consumption during the process and increase economic benefits of the apparatus.

Owner:CHINA PETROLEUM & CHEM CORP +1

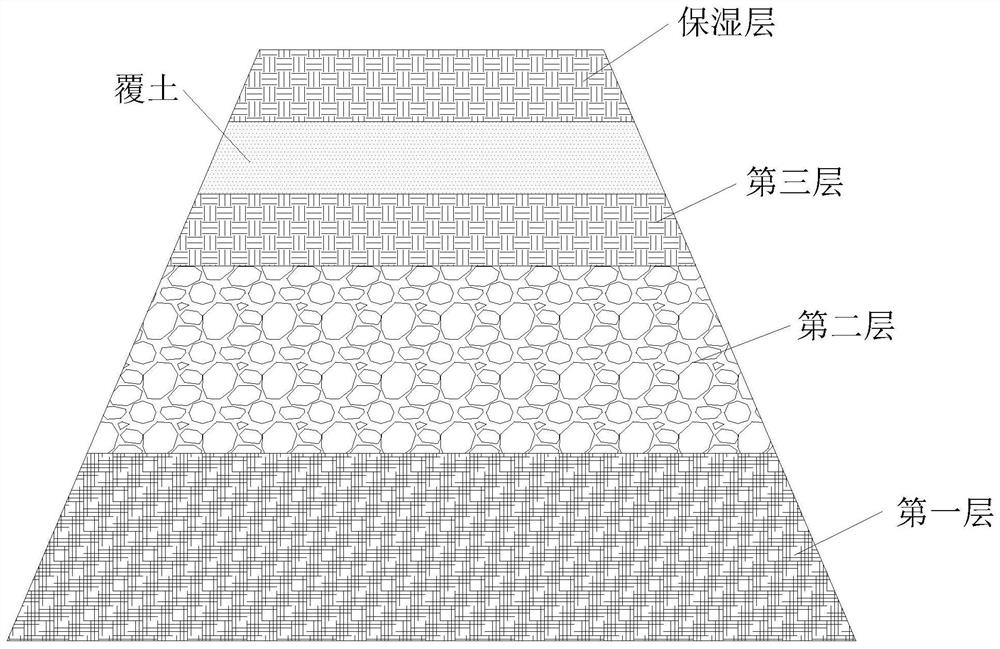

Novel method for cultivating stropharia rugosoannulata under poor mountainous area forest

PendingCN112690168AHigh in nutrientsPromote growthCultivating equipmentsMushroom cultivationMildewBedding

The invention provides a new method for cultivating stropharia rugosoannulata under a poor mountainous area forest, and relates to the technical field of mushroom planting. The new method for cultivating the stropharia rugosoannulata under the poor mountainous area forest comprises the following steps of weighing the following raw materials in parts by weight of 264-314 parts of rice husk, 140-190 parts of sawdust, 10-60 parts of wheat bran, 90-140 parts of cornstalk, 50-100 parts of soybean stalk and 40-90 parts of straw, drying the sawdust, the cornstalk, the wheat bran, the straw, the soybean stalk and the rice husk without mildew, and performing smashing before use. The specific cultivation method comprises the following steps that firstly, materials are treated, the treated materials are piled, then a cultivation field is selected, soil preparation and bedding are conducted on the cultivation field, a fungus bed is manufactured for sowing, and the stropharia rugosoannulata which grows maturely is collected. The method has the characteristics of low stropharia rugosoannulata planting investment, high effect taking speed, high income and the like.

Owner:昭通学院 +1

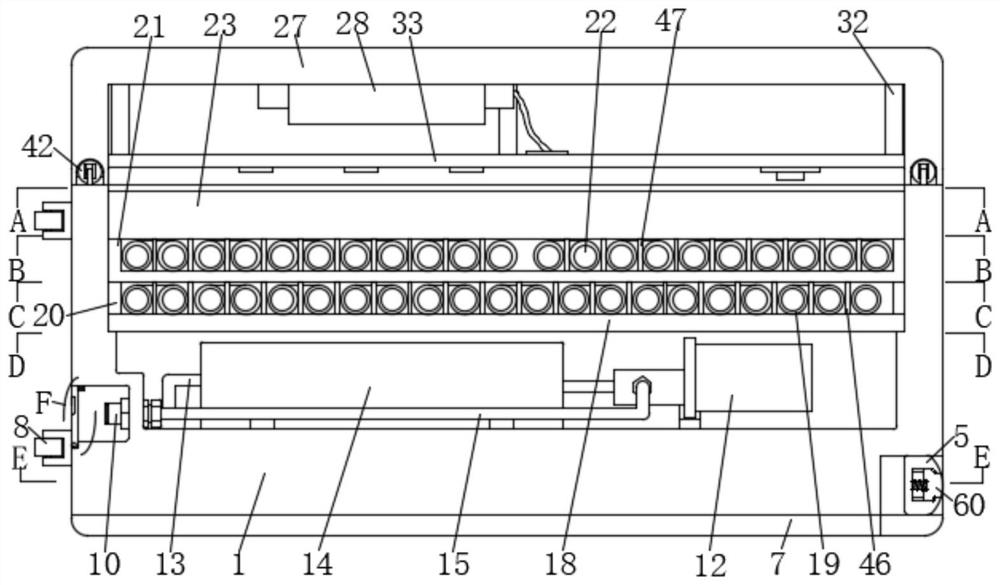

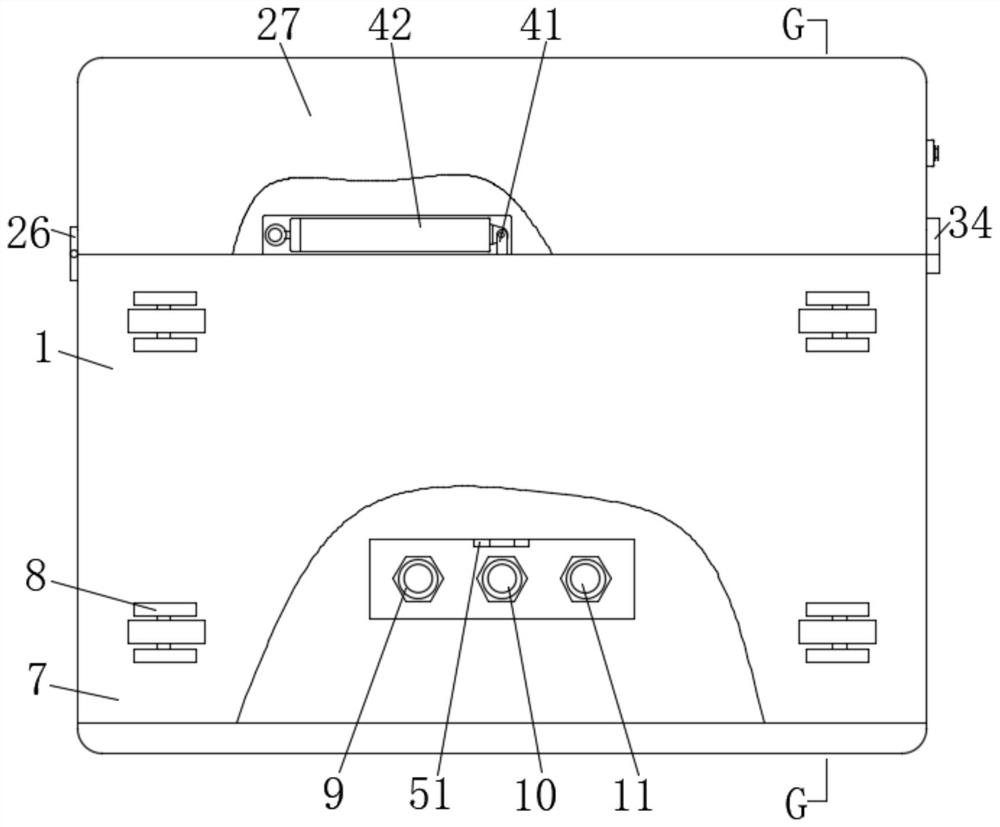

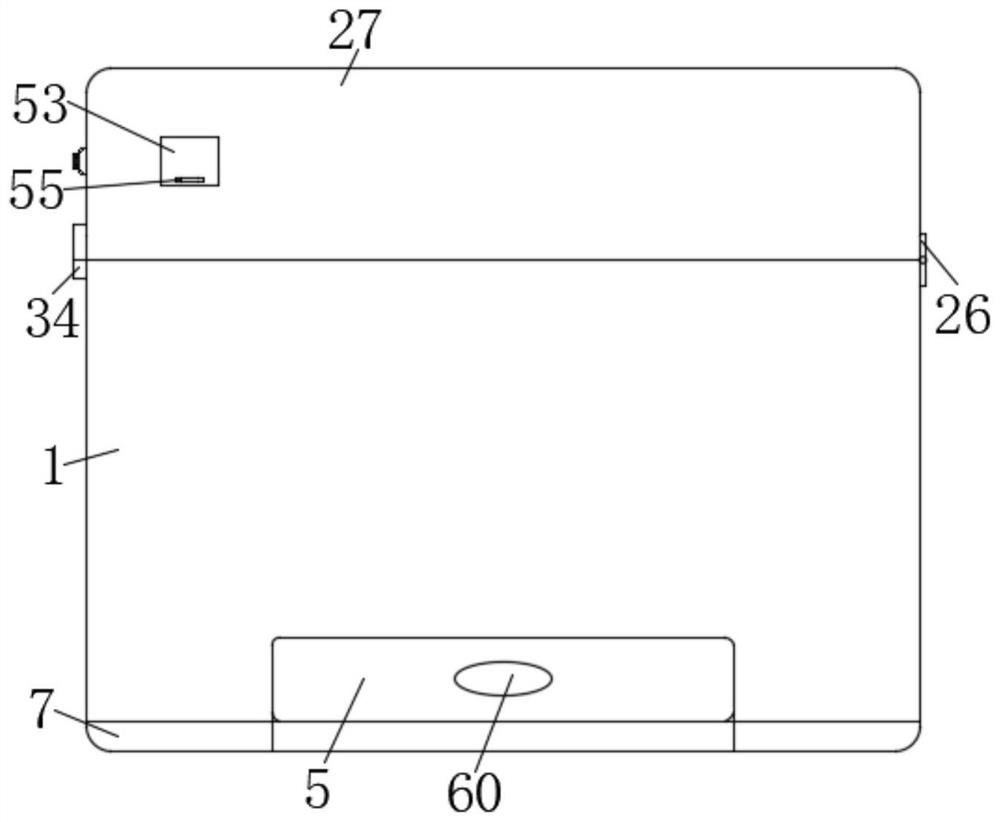

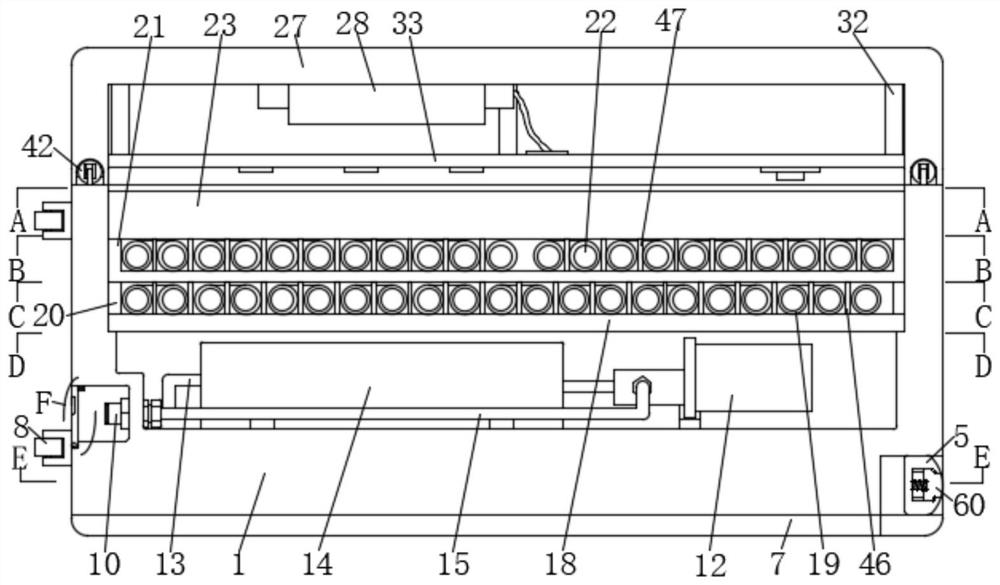

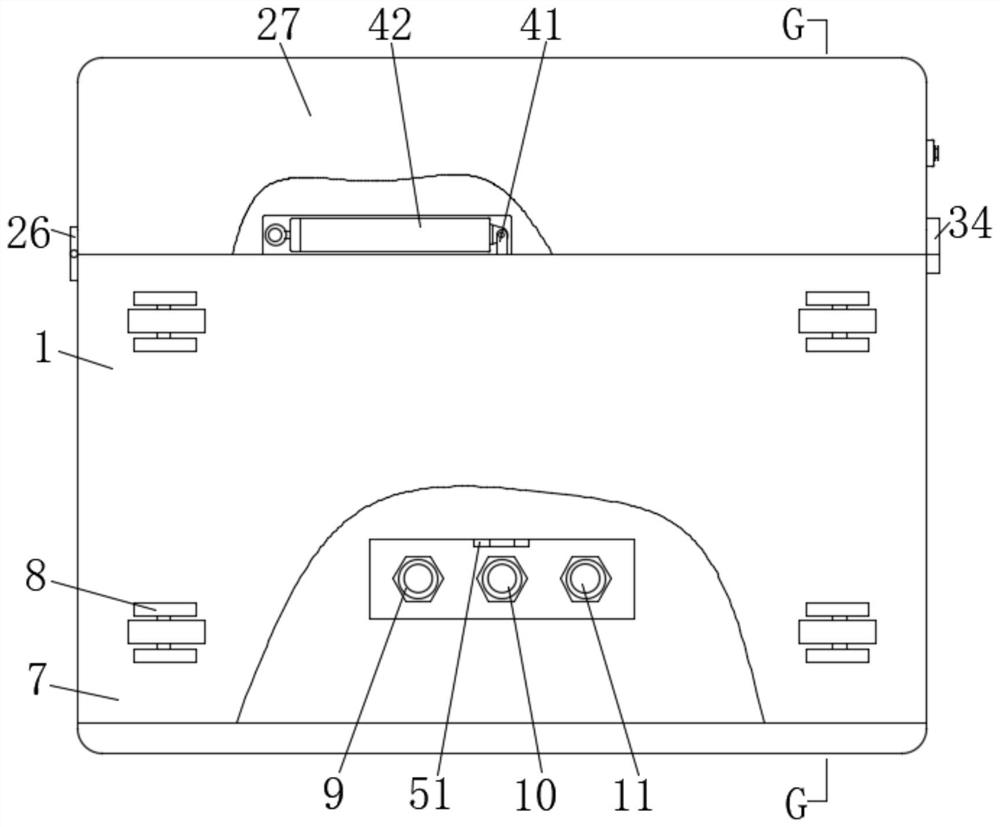

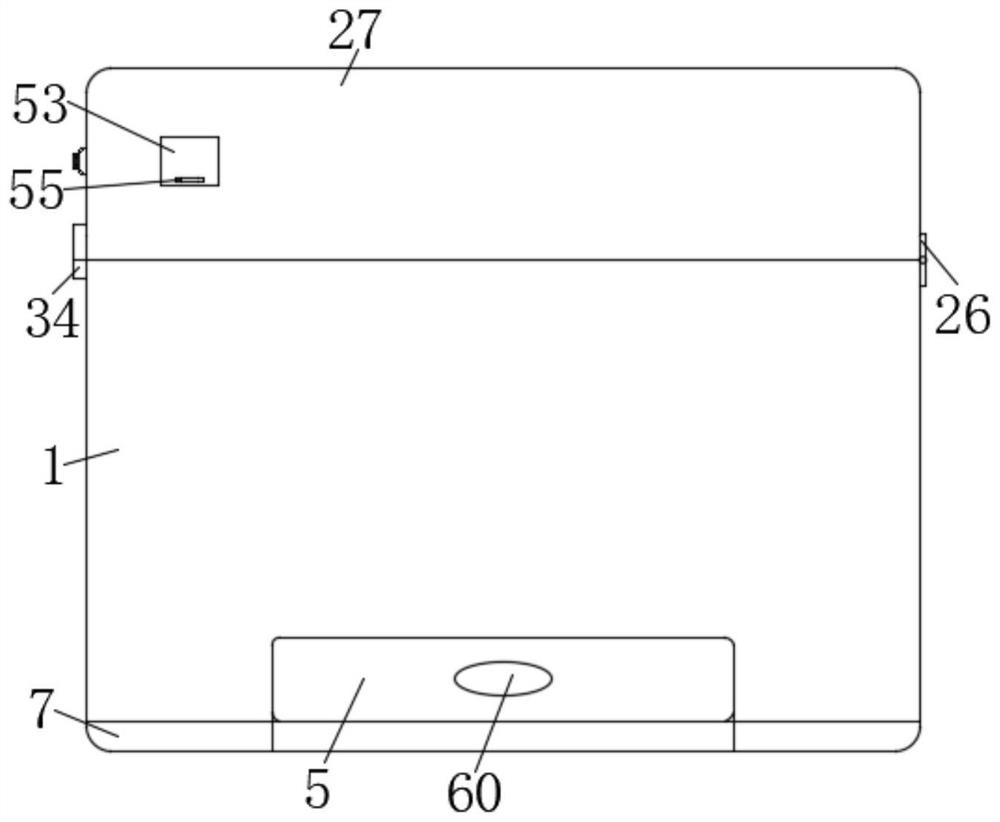

Intelligent household appliance deep cleaning and disinfecting integrated machine

ActiveCN112387670AExtended service lifeEasy to carryPortable framesLavatory sanitoryMechanical engineering

The invention relates to the technical field of household appliance cleaning equipment, in particular to an intelligent household appliance deep cleaning and disinfecting integrated machine. The intelligent household appliance deep cleaning and disinfecting integrated machine comprises a box body, sliding grooves are symmetrically formed in the lower surface of the box body, a second inserting rodis inserted into each of two first inserting rods, a limiting sleeve is arranged on the outer side of each of the two second inserting rods in a sleeving mode, a handle is arranged between the two second inserting rods, and a locking mechanism is arranged on the side, away from the second inserting rods, of the handle; and baffles matched with the first inserting rods are arranged on the lower portion of the box body, rolling wheels are arranged at four corners of the left side of the box body, a first groove is formed in the lower portion of the left side of the box body, a water inlet connector, a water outlet connector and an ozone outlet connector are arranged in the first groove, a water pump is arranged in an inner cavity of the box body, a water inlet of the water pump is connectedwith the water inlet connector through a first heat preservation pipe, and a steam generator is connected to the heat preservation pipe. According to the intelligent household appliance deep cleaningand disinfecting integrated machine, damage of heating electrical elements to a control panel is avoided, the service life of the cleaning and disinfecting integrated machine is prolonged, and meanwhile, carrying of the cleaning and disinfecting integrated machine is facilitated.

Owner:温州雪榕机械科技有限公司

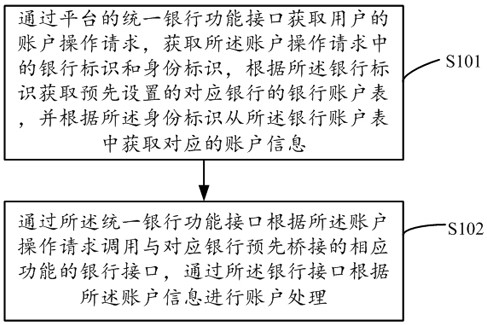

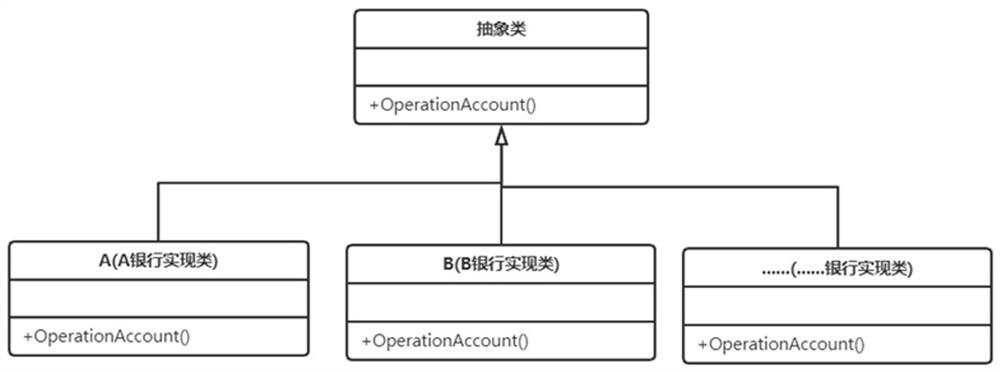

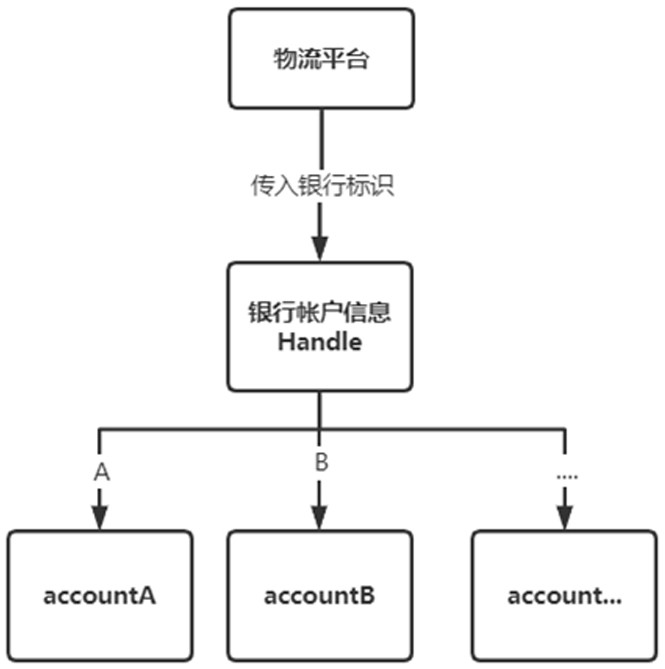

Platform multi-bank access calling method, system and device

The invention discloses a platform multi-bank access calling method, system and device; and the method comprises the steps: obtaining an account operation request of a user through a unified bank function interface of a platform, obtaining a bank identifier and an identity identifier in the account operation request, obtaining a preset bank account table corresponding to a bank according to the bank identifier; obtaining corresponding account information from the bank account table according to the identity identifier; calling a bank interface with a corresponding function bridged with the corresponding bank in advance through the unified bank function interface according to the account operation request, and carrying out account processing through the bank interface according to the account information. According to the invention, the platform can be quickly accessed to a bank system, so that earnings are created for enterprises more quickly, and the production efficiency is improved.

Owner:北京快成科技有限公司

Method and device for crude oil deep vacuum distillation

ActiveCN103059920AIncrease gasification rateRelieve pressureTreatment with plural serial refining stagesFluid phaseResidual oil

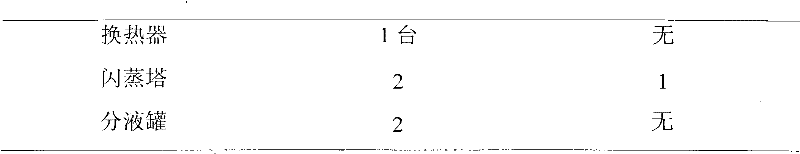

The invention discloses a method and a device for crude oil deep vacuum distillation. The method disclosed in the invention includes: introducing atmospheric tower bottom oil into a primary gasification furnace, conducting heating and leaving the oil to enter a primary flash tank to undergo separation, making the obtained gas phase enter a vacuum tower upper fractionation section, and letting the liquid phase enter a second stage gasification furnace; heating the liquid phase and making it enter a second-stage flash tank, leaving the obtained gas phase to enter a vacuum tower middle fractionation section, and making the obtained liquid phase enter a third-stage gasification furnace; heating the liquid phase and making it enter a third-stage flash tank, letting the obtained gas phase enter a vacuum tower lower fractionation section, and leaving the obtained liquid phase to enter a vacuum tower flash section; subjecting the feed of each section to vacuum distillation is the vacuum, extracting a lateral line product from a vacuum tower lateral line, and extracting vacuum residual oil from the tower bottom; and introducing part of the vacuum residual oil into the flash tanks of different stages respectively. The method provided in the invention can significantly improve the distillate yield of the crude oil in the distillation process, reduce device energy consumption, increase device economic benefits, and save device investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Distillate yield improving vacuum distillation method and device

ActiveCN102311772BAvoid lateral thermal displacementEasy to separateVacuum distillationHydrocarbon oils treatmentLow speedVaporization

The invention discloses a distillate yield improving vacuum distillation method and device. A flash vaporization vessel is arranged on an oil transfer line between a vacuum furnace and a vacuum distillation tower. Vacuum distillation raw materials enter the oil transfer line and the flash vaporization vessel after being heated by the vacuum furnace. Gas liquid separation is carried out in the flash vaporization vessel: liquid discharged from the bottom of the flash vaporization vessel, namely flash bottom oil, is introduced into the vacuum distillation tower; and gas discharged from the top of the flash vaporization vessel, namely flash top gas, is led out of the device after being condensed into liquid. According to the vacuum distillation method and device with the flash vaporization vessel arranged behind the vacuum furnace, on one hand, the yield of vacuum distillate is increased, on the other hand, a conventional decompression oil transfer line low-speed section is omitted, the operation load of the vacuum tower is reduced, and the diameter of the vacuum tower can be appropriately reduced, so equipment investment is saved, and the operating cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Display suspended ceiling with rotation angle capable of being adjusted

PendingCN107975180AAdjust directionAdjust the direction arbitrarilyCeilingsLiving roomDisplay device

The invention discloses a display suspended ceiling with the rotation angle capable of being adjusted. The display suspended ceiling comprises rectangular square holes formed in a suspended ceiling plate surface; a transverse plate is arranged on the upper end surfaces of the rectangular square holes; a sliding groove is formed in the transverse plate, and a rotating shaft in the vertical direction is mounted in the sliding groove; a motor which can control the rotating shaft to move leftwards and rightwards along the sliding groove is arranged on the rotating shaft; a movable suspended ceiling face plate which can be inlaid on the rectangular square holes is hinged to the lower end of the rotating shaft; a display screen is arranged on the upper surface of the movable suspended ceiling face plate, and a suspended ceiling decoration surface is arranged on the lower surface of the movable suspended ceiling face plate; hanging rings are arranged on the periphery of the movable suspendedceiling face plate and connected with steel wire ropes; and the steel wire ropes are connected with a rope winding and unwinding device. The suspended ceiling and a large-screen display can be effectively combined, the defects that when families watch a film together, the picture of a projector is not clear, the color is poor, and the seismic effect is poor are overcome, the direction of the display can also be adjusted at random according to the household living room structure, and thus the watching suitable distance is conveniently adjusted.

Owner:贵州纵横合一电子商务股份有限公司

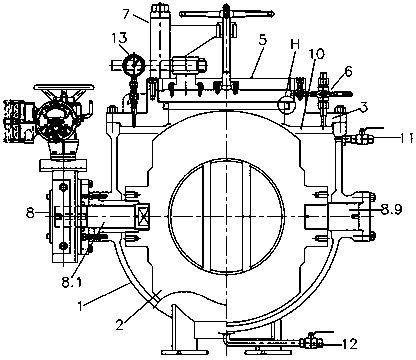

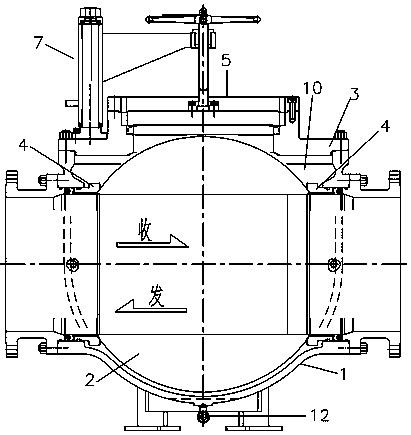

Horizontal shaft top mounted pipe cleaning valve

PendingCN110206910ASimple structureRealize top loadingPlug valvesOperating means/releasing devices for valvesPiggingEngineering

The invention discloses a horizontal shaft top mounted pipe cleaning valve. The horizontal shaft top mounted pipe cleaning valve comprises a valve body, a ball body, a valve cover, a valve base, an opening / closing sealing mechanism, an opening / closing interlocking mechanism, a rotating mechanism and a ball body control mechanism; a loading / unloading port is formed in the upper end of the valve body; the ball body and the valve base are mounted in the valve body through the loading / unloading port; the valve cover is fixed on the valve body, and is provided with an opening / closing hole; the opening / closing sealing mechanism is fixed on the valve cover; the opening / closing interlocking mechanism is fixed on the valve cover; the rotating mechanism is fixed on the valve cover; the ball body control mechanism comprises a valve rod and a fixed shaft; and the valve rod is matched with the fixed shaft to control the ball body to rotate. The ball body, a pipe cleaner and a valve inner part all can be mounted in the valve body from the top, so that the top mounting structure is really realized, meanwhile, the structure of the pipe cleaning valve is simplified, the total weight of the pipe cleaning valve is reduced, the overall sealing performance of the pipe cleaning valve is improved, the convenient collecting and releasing operations of pipe cleaners with various sizes and weights is achieved, and meanwhile, the real on-line maintenance function is achieved.

Owner:ZIGONG ZIGAO VALVE

Crude oil distillation method

The invention discloses a crude oil distillation method. A primary flash distillation tower is arranged between a normal pressure distillation tower and a pressure reduction furnace, a pressure reduction oil line from an outlet of the pressure reduction furnace to a pressure reduction distillation tower is omitted, a secondary flash distillation tower is arranged between the pressure reduction furnace and the pressure reduction distillation tower, tower bottom heavy oil of the normal pressure distillation tower, i.e. normal bottom oil enters the primary flash distillation tower after being mixed with cyclic pressure reduction slag oil, the tower top gas phase of the primary flash distillation tower is converted into a liquid phase to be used as products through heat exchange and condensing, bottom oil of the primary flash distillation tower enters the secondary flash distillation tower through being heated by the pressure reduction furnace, the tower top gas phase of the secondary flash distillation tower is converted into a liquid phase to be used as products through heat exchange and condensing, and bottom oil of the secondary flash distillation tower is introduced into a flash distillation section of the pressure reduction distillation tower for pressure reduction distillation. Compared with the prior art, the method has the advantages that on one hand, the yield of the pressure reduction slag oil is reduced, and the economic benefits of devices are improved; and on the other hand, the load of the pressure reduction furnace and the pressure reduction distillation tower is reduced, the device investment is saved, and the energy consumption of the devices is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Crude oil deep vacuum distillation process and system

ActiveCN102443420BLow yieldHigh yieldVacuum distillationHydrocarbon oils treatmentVacuum pumpingGas phase

Owner:CHINA PETROLEUM & CHEM CORP +1

A vacuum distillation method and device for improving extraction rate

ActiveCN103059919BReduce cracking lossImprove decompression yieldTreatment with plural serial refining stagesResidual oilFuel oil

The invention discloses a crude oil vacuum distillation method and a device. According to the invention, a vacuum flash tank is added to a vacuum heavy oil outlet at a vacuum distillation tower bottom so as to make the vacuum heavy oil flowing out of the vacuum tower bottom undergo flashing in the vacuum flash tank under the condition of a vacuum degree higher than that of the vacuum tower bottom. A vacuum flash tank top gas enters a gas-liquid separation tank after heat exchange and cooling. The top of the gas-liquid separation tank is in connection with a vacuum-pumping system to maintain the vacuum degree of the flash tank. The vacuum distillate oil extracted from the bottom is taken as a product, and vacuum residual oil is extracted from the vacuum flash tank bottom. The vacuum distillation method disclosed in the invention improves the crude oil vacuum distillation process, and makes the vacuum heavy oil enter the vacuum flash tank with a high vacuum degree to undergo further flashing, thus acquiring relatively light distillate from the vacuum heavy oil by flashing completely and ensuring that the content of distillate lower than 500DEG C in vacuum residual oil is reduced to a minimum. Therefore, the distillate yield of vacuum distillation can be improved, and the economic benefits of the device can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

An all-in-one machine for deep cleaning and disinfection of smart home appliances

ActiveCN112387670BAvoid damageExtended service lifePortable framesLavatory sanitoryEnvironmental engineeringHome appliance

The present invention relates to the technical field of cleaning equipment for household appliances, in particular to an integrated machine for deep cleaning and disinfection of intelligent household appliances. The outer sleeves of the two second insertion rods are provided with limit sleeves, a handle is provided between the two second insertion rods, and a locking mechanism is provided on the side away from the second insertion rod. The lower part of the box is provided with the first The baffle plate matched with the insertion rod, the four corners on the left side of the box are equipped with rollers, the lower part of the left side of the box is provided with a first groove, and the first groove is provided with a water inlet joint, a water outlet joint and an ozone outlet joint A water pump is installed in the inner cavity of the box body, the water inlet of the water pump is connected to the water inlet joint through a first heat preservation pipe, and a steam generator is connected to the heat preservation pipe. The invention prevents the heating electrical components from causing damage to the control panel, improves the service life of the cleaning and disinfecting integrated machine, and facilitates the handling of the cleaning and disinfecting integrated machine.

Owner:温州雪榕机械科技有限公司

Crude oil reduced pressure distillation method and apparatus for reducing yield of residual oil

The invention discloses a crude oil reduced pressure distillation method for reducing yield of residual oil. Atmospheric tower bottom oil is introduced into a first stage flash tank for separation after being heated in a first stage gasifier; a liquid phase is introduced to a second stage gasifier and then to a second stage flash tank after being heated; the liquid phase is introduced to a third stage gasifier and then to a third stage flash tank after being heated; the liquid phase is introduced to a reduced pressure flash section; gas phases obtained in various stages are introduced to the upper, the middle and the lower fractional distillation sections of reduced pressure tower; lateral line products are pumped out from lateral lines of the reduced pressure tower; a part of residues at the bottom of the tower is introduced to the flash tanks in the various stages, wherein at least two rotary evaporation coils are arranged in a gas phase zone in the upper part of the reduced pressure flash tower; tank walls between the two rotary evaporation coils are provided with baffle plates for preventing wall flows; and the rotary evaporation coils are fixed on a rotary shaft at a longitudinal shaft center position of the tank body. The method provided by the invention can obviously reduce the yield of the reduced pressure residual oil, increase economic benefits of the apparatus, reduce energy consumption of the apparatus, and save investment for the apparatus.

Owner:CHINA PETROLEUM & CHEM CORP +1

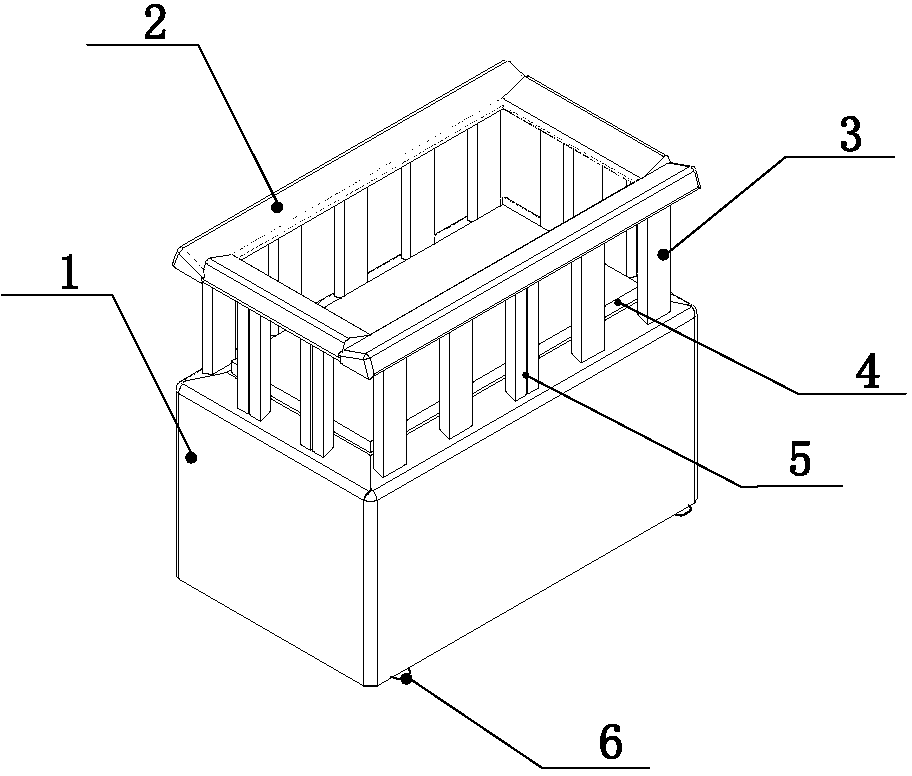

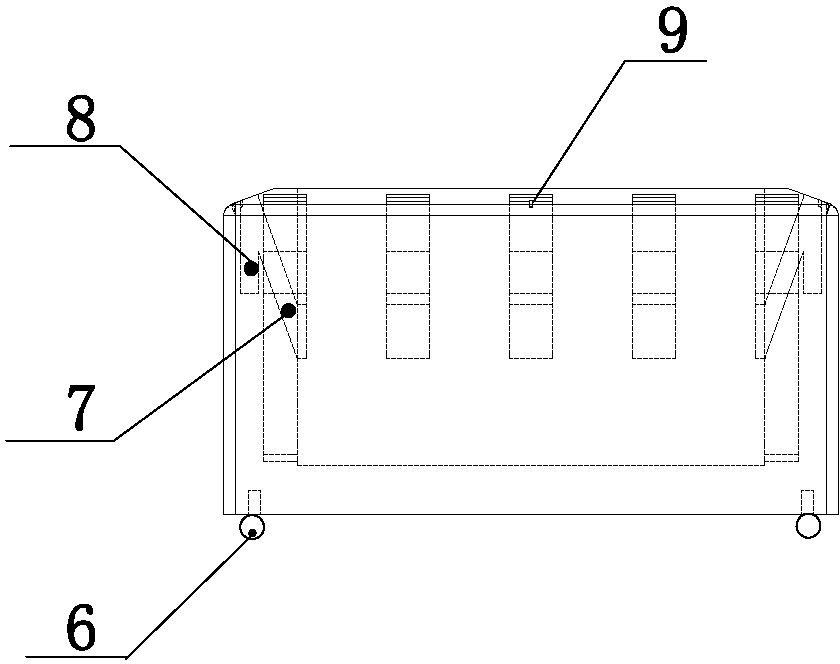

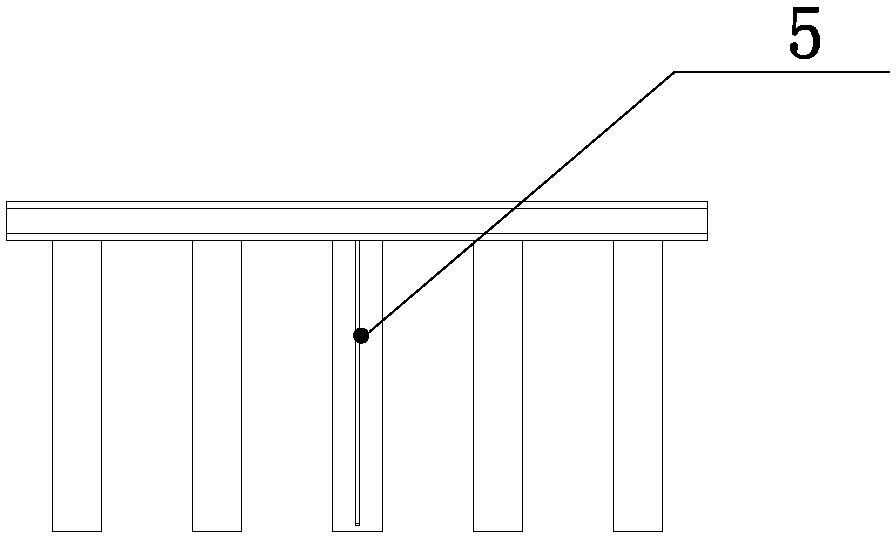

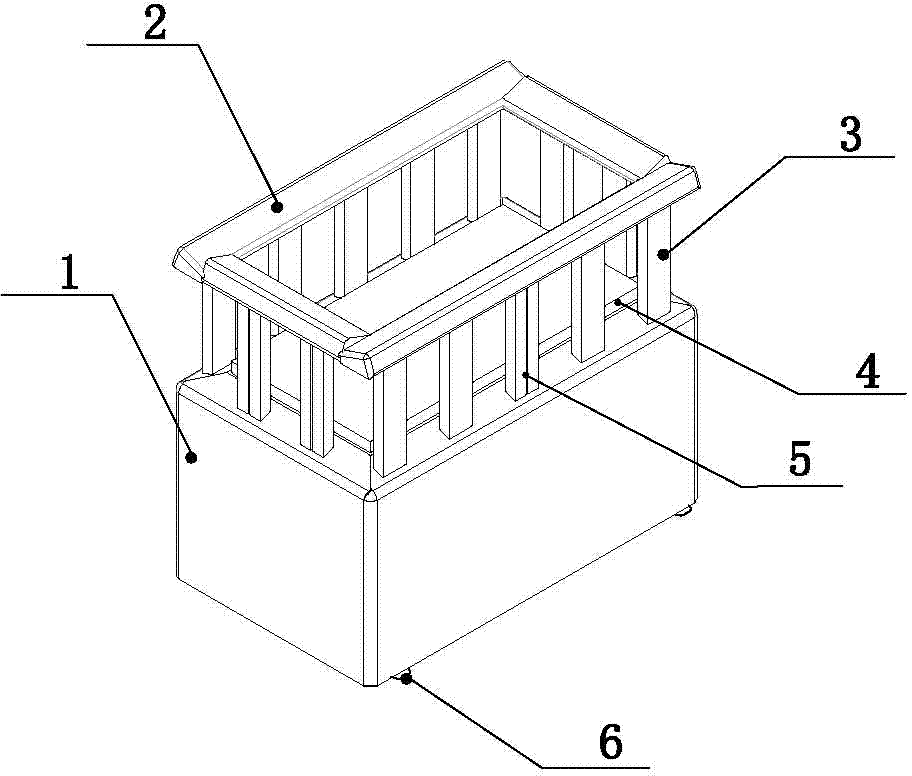

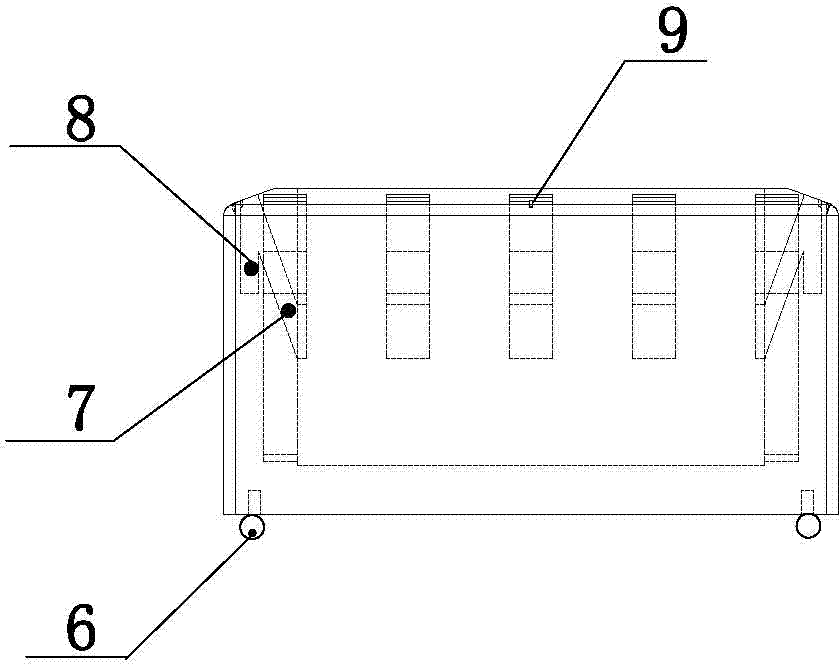

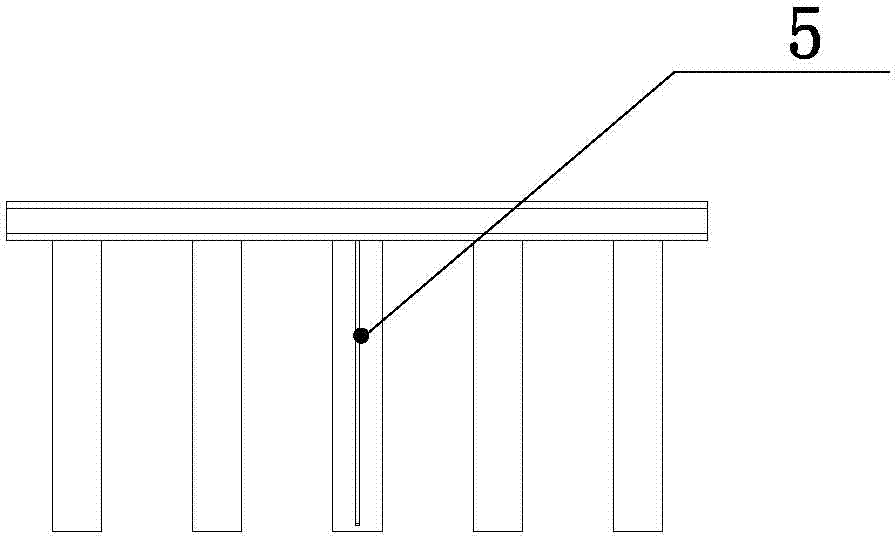

Crib capable of containing fences

The invention relates to a crib capable of containing fences. The crib comprises a box-type bed body, a bed cover and the fences, wherein the fences are formed by transverse rods and vertical handrails. Inserted ports for insertion and installation of the handrails are arranged in upper edges of the periphery of the bed body, and sliding groove sets corresponding to the handrails are vertically arranged in the wall of the bed body. Each sliding groove set comprises a straight sliding groove and an oblique sliding groove, wherein the straight sliding groove and the oblique sliding groove are intersected in the inserted port of the handrails in a herringbone mode. The fences are four in the number and are mutually separated, and each piece can slip into the bed body or slip out of the bed body along the sliding groove independently. The crib is reasonable in structure and convenient to operate, the fences can be taken in the bed body rapidly or can be pulled out of the bed body and fixed, the crib can be conveniently and flexibly placed according to needs of families, and practicability of the crib is improved.

Owner:JINLING INST OF TECH

Crib capable of containing fences

The invention relates to a crib capable of containing fences. The crib comprises a box-type bed body, a bed cover and the fences, wherein the fences are formed by transverse rods and vertical handrails. Inserted ports for insertion and installation of the handrails are arranged in upper edges of the periphery of the bed body, and sliding groove sets corresponding to the handrails are vertically arranged in the wall of the bed body. Each sliding groove set comprises a straight sliding groove and an oblique sliding groove, wherein the straight sliding groove and the oblique sliding groove are intersected in the inserted port of the handrails in a herringbone mode. The fences are four in the number and are mutually separated, and each piece can slip into the bed body or slip out of the bed body along the sliding groove independently. The crib is reasonable in structure and convenient to operate, the fences can be taken in the bed body rapidly or can be pulled out of the bed body and fixed, the crib can be conveniently and flexibly placed according to needs of families, and practicability of the crib is improved.

Owner:JINLING INST OF TECH

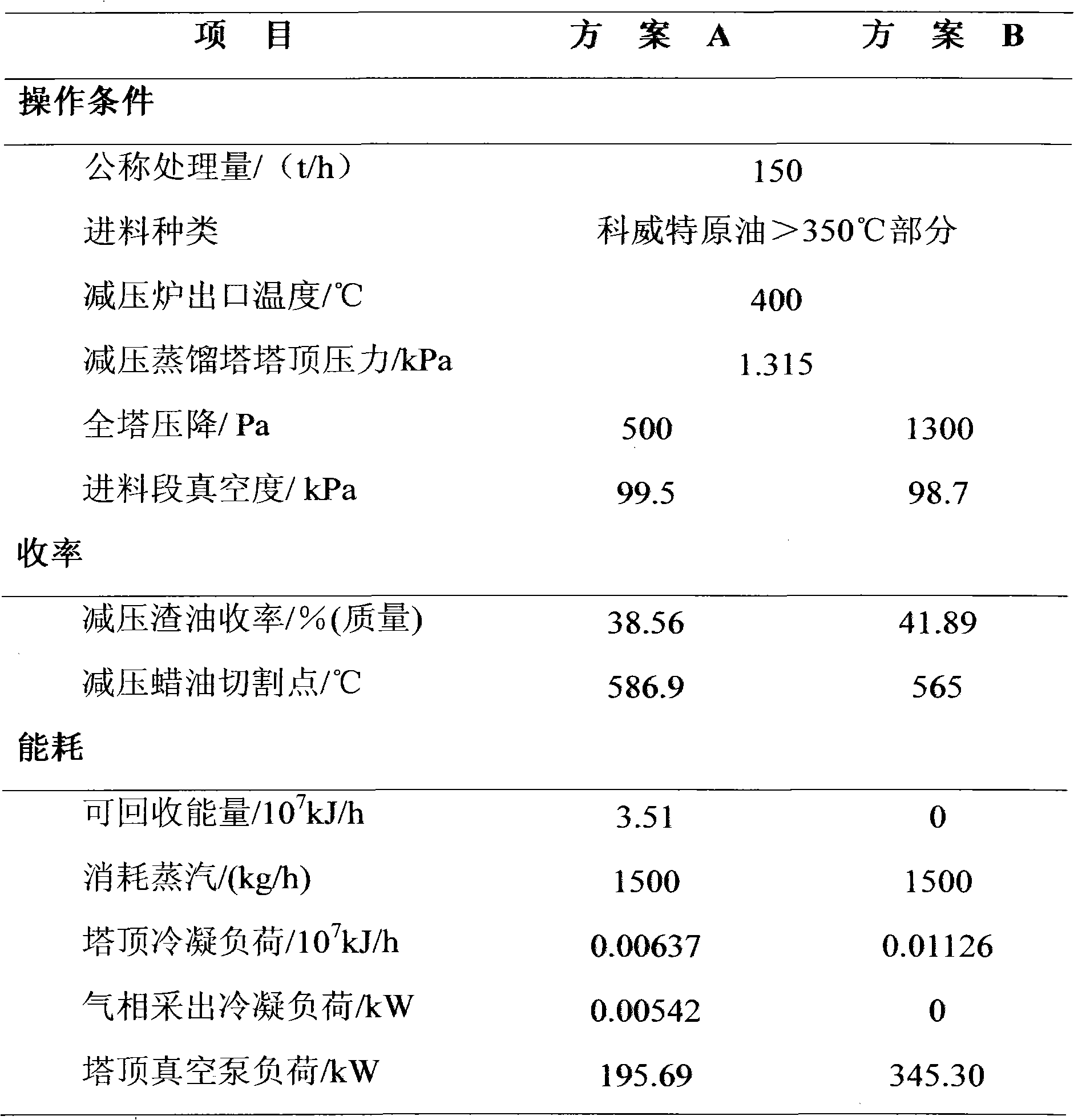

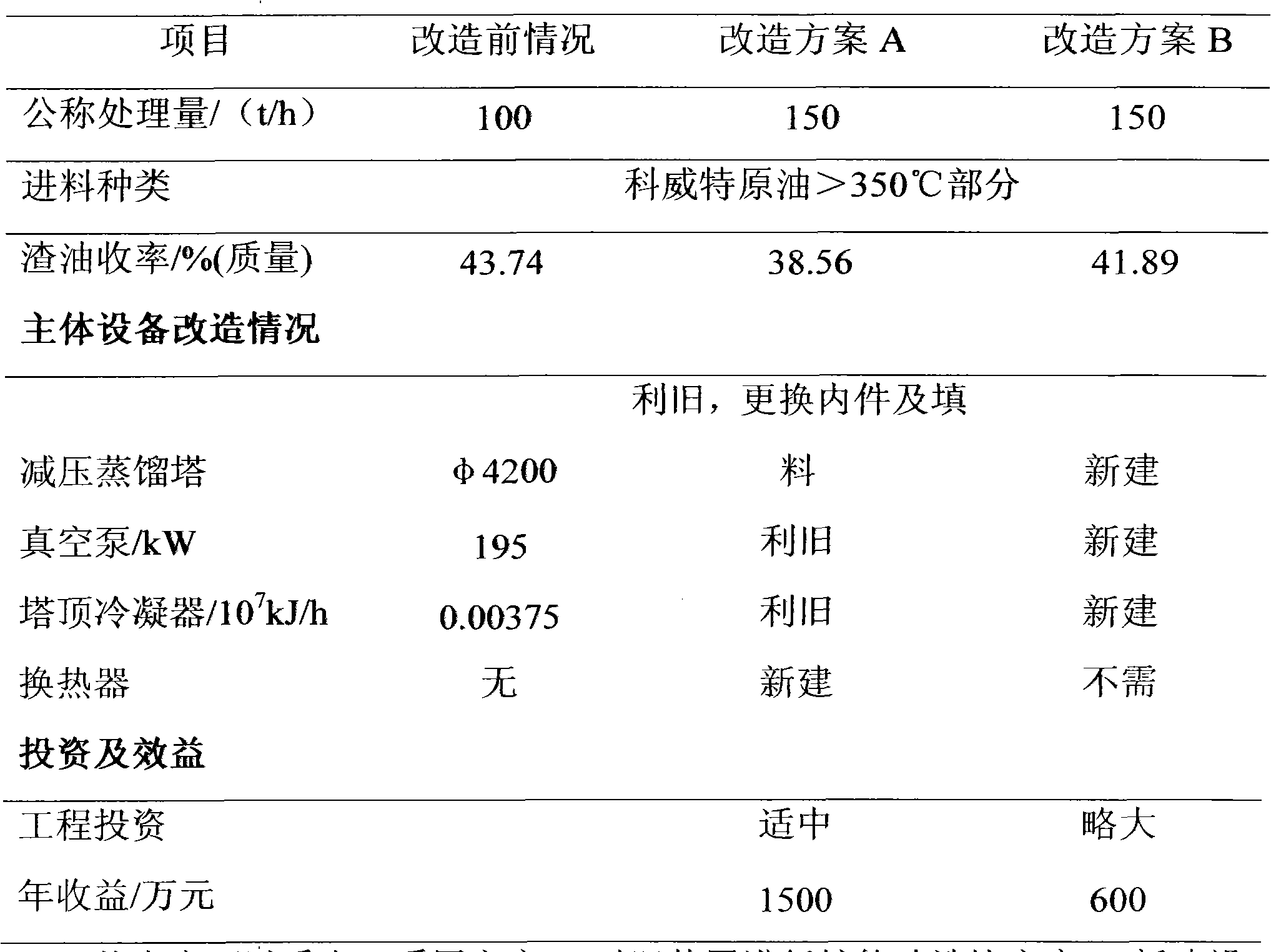

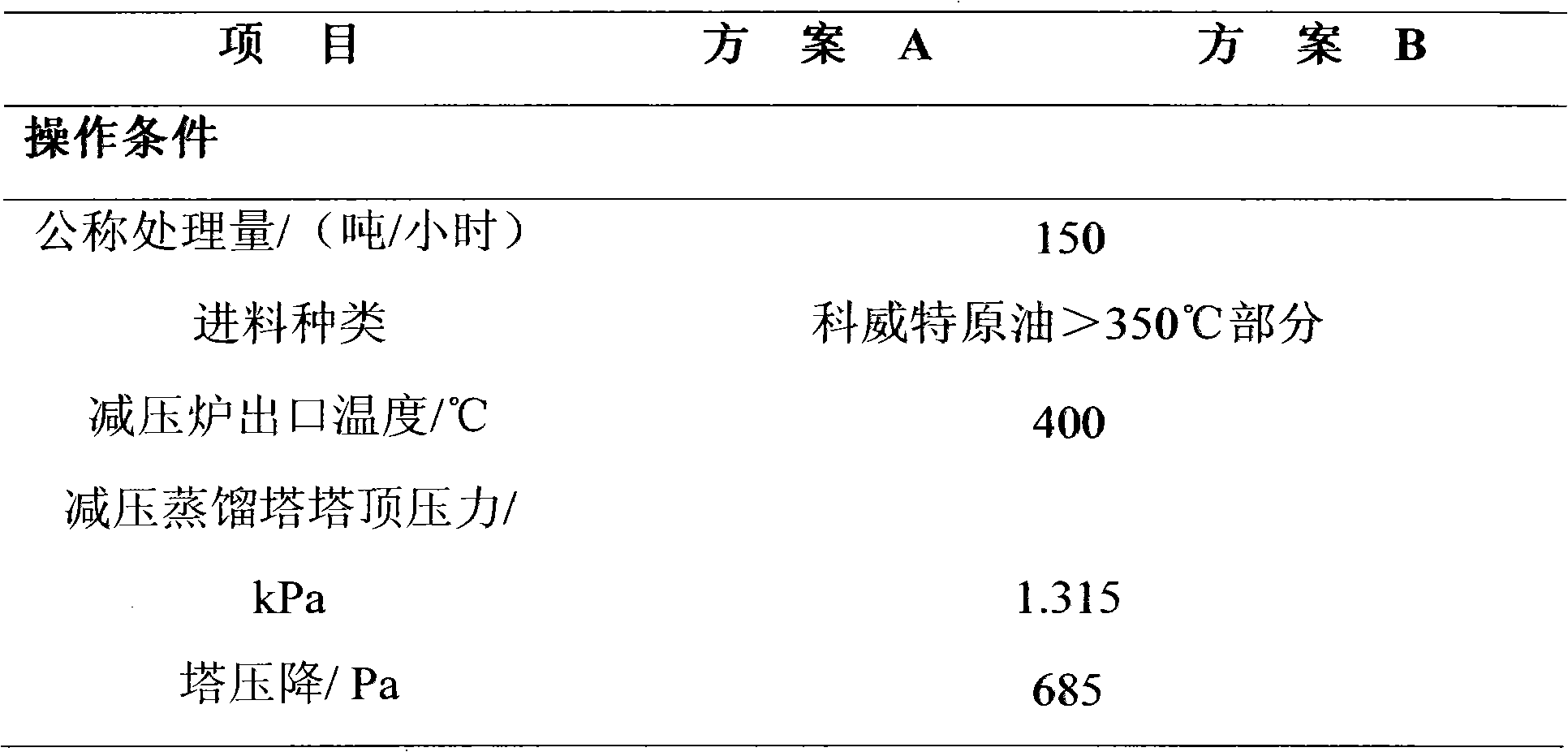

Pressure reduction distillation process method

ActiveCN102443408BFacilitate capacity expansionReduce gas loadVacuum distillationVacuum pumpingDistillation

The invention discloses a pressure reduction distillation process method, in particular to a pressure reduction distillation process applicable to the pressure reduction deep drawing treatment of crude oil pressure reduction distillation. A gas phase extraction opening is arranged in a gas phase region above at least one side line outlet material liquid phase region, and the gas phase extraction opening is connected with a vacuum pumping system. The pressure reduction distillation process method is characterized in that the in-tower sectional vacuum pumping operation is carried out on the gas phase region above each condensing section in a pressure reduction distillation tower, so the vacuum degree in the pressure reduction distillation tower is improved, and further, the vacuum degree of the flash distillation section and the steam extraction section is improved, so more light ingredients in pressure reduction slag oil are evaporated out, and the drawing rate in the crude oil pressure reduction distillation process is obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Crude oil processing method

The invention discloses a crude oil processing method, which comprises normal-pressure distillation and reduced-pressure distillation, wherein the heavy oil at the bottom of a normal-pressure distillation tower, namely normal bottom oil, is mixed with part of circular reduced-pressure residual oil at the bottom of a reduced-pressure distillation tower, the mixture enters a flash tower, and a top gas phase, namely flash top gas, of the flash tower undergoes heat exchange and is condensed into a liquid phase to be discharged out of the device as a product; and bottom oil, namely flash bottom oil, of the flash tower, is heated in a reduced-pressure furnace to 390 to 420 DEG C, the heated bottom oil is intruded into a flash section of the reduced-pressure distillation tower from a reduced-pressure oil transfer line for reduced-pressure distillation, proper distillate product is drawn from a side line of the reduced-pressure distillation tower, part of reduced-pressure residual oil drawn out from the bottom of the reduced-pressure distillation tower is circulated, and another part of the reduced-pressure residual oil is discharged of the device. Compared with the prior art, the method can effectively improve the drawing rate of a reduced-pressure distillation process and can reduce the load of the reduced-pressure furnace and the reduced-pressure distillation tower at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vacuum distillation method for gradual gasification segmented feed

ActiveCN103059918BIncrease gasification rateRelieve pressureTreatment with plural serial refining stagesFluid phaseProcess engineering

The invention discloses a vacuum distillation method for gradual gasification segmented feed. The method includes: making atmospheric tower bottom oil enter a first stage gasification furnace, conducting heating to make the tower bottom oil enter a first stage flash tank to perform separation, leaving a gas phase to enter an upper fractionation segment of a vacuum tower, and leaving a liquid phase to enter a second stage gasification furnace; heating the liquid phase and making it enter a second stage flash tank, letting the generated gas phase enter a middle fractionation segment of the vacuum tower, and letting the generated liquid phase enter a third stage gasification furnace; heating the liquid phase and making it enter a third stage flash tank, letting the generated gas phase enter a lower fractionation segment of the vacuum tower, and letting the generated liquid phase enter a flash segment of the vacuum tower; and subjecting the feed of each segment to vacuum distillation in the vacuum tower, extracting a lateral line product from a vacuum tower lateral line, and extracting vacuum residue from the tower bottom. The method provided in the invention can substantially enhance the distillate yield of a crude oil vacuum distillation process, reduce equipment energy consumption, increase equipment economic benefits, and save equipment investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for crude oil deep vacuum distillation

ActiveCN103059920BIncrease gasification rateRelieve pressureTreatment with plural serial refining stagesFluid phaseResidual oil

The invention discloses a method and a device for crude oil deep vacuum distillation. The method disclosed in the invention includes: introducing atmospheric tower bottom oil into a primary gasification furnace, conducting heating and leaving the oil to enter a primary flash tank to undergo separation, making the obtained gas phase enter a vacuum tower upper fractionation section, and letting the liquid phase enter a second stage gasification furnace; heating the liquid phase and making it enter a second-stage flash tank, leaving the obtained gas phase to enter a vacuum tower middle fractionation section, and making the obtained liquid phase enter a third-stage gasification furnace; heating the liquid phase and making it enter a third-stage flash tank, letting the obtained gas phase enter a vacuum tower lower fractionation section, and leaving the obtained liquid phase to enter a vacuum tower flash section; subjecting the feed of each section to vacuum distillation is the vacuum, extracting a lateral line product from a vacuum tower lateral line, and extracting vacuum residual oil from the tower bottom; and introducing part of the vacuum residual oil into the flash tanks of different stages respectively. The method provided in the invention can significantly improve the distillate yield of the crude oil in the distillation process, reduce device energy consumption, increase device economic benefits, and save device investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reduced pressure distillation method and device

ActiveCN102309863BIncrease gasification rateShort processVacuum distillation separationVacuum distillationGas phaseTower

Owner:CHINA PETROLEUM & CHEM CORP +1

Crude oil deep drawing process method

Owner:CHINA PETROLEUM & CHEM CORP +1

Reduced-pressure flash tank and reduced-pressure distillation method

ActiveCN102311770BEasy to separateIncrease evaporation rateVacuum distillation separationDistillation in rotating vesselsGas phaseEvaporation

The invention discloses a reduced-pressure flash tank and a crude oil reduced-pressure distillation method. The reduced-pressure flash tank comprises a tank body, a supergravity rotating evaporator is arranged in a gas phase area in the upper part of the reduced-pressure flash tank, and the rotating evaporator is fixed on a rotating shaft arranged at a longitudinal axial center position of the tank body. In the crude oil reduced-pressure distillation method, the reduced-pressure flash tank is arranged between a reduced-pressure furnace and a reduced-pressure distillation tower, a reduced-pressure distillation raw material is heated in the reduced-pressure furnace and then enters the reduced-pressure flash tank for evaporation and gas-liquid separation, a liquid phase, namely bottom oil, discharged from the bottom of the reduced-pressure flash tank is introduced into the reduced-pressure distillation tower, and a gas phase, namely a top gas, discharged from the top of the reduced-pressure flash tank is discharged from the flash tank and is condensed into a liquid phase to be led out of the device. When the reduced-pressure flash tank and the crude oil reduced-pressure distillation method are used, the drawing rate of a crude oil reduced-pressure distillation process can be increased obviously, and the energy consumption of the device can be lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com