Patents

Literature

48results about How to "Efficiently understood" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

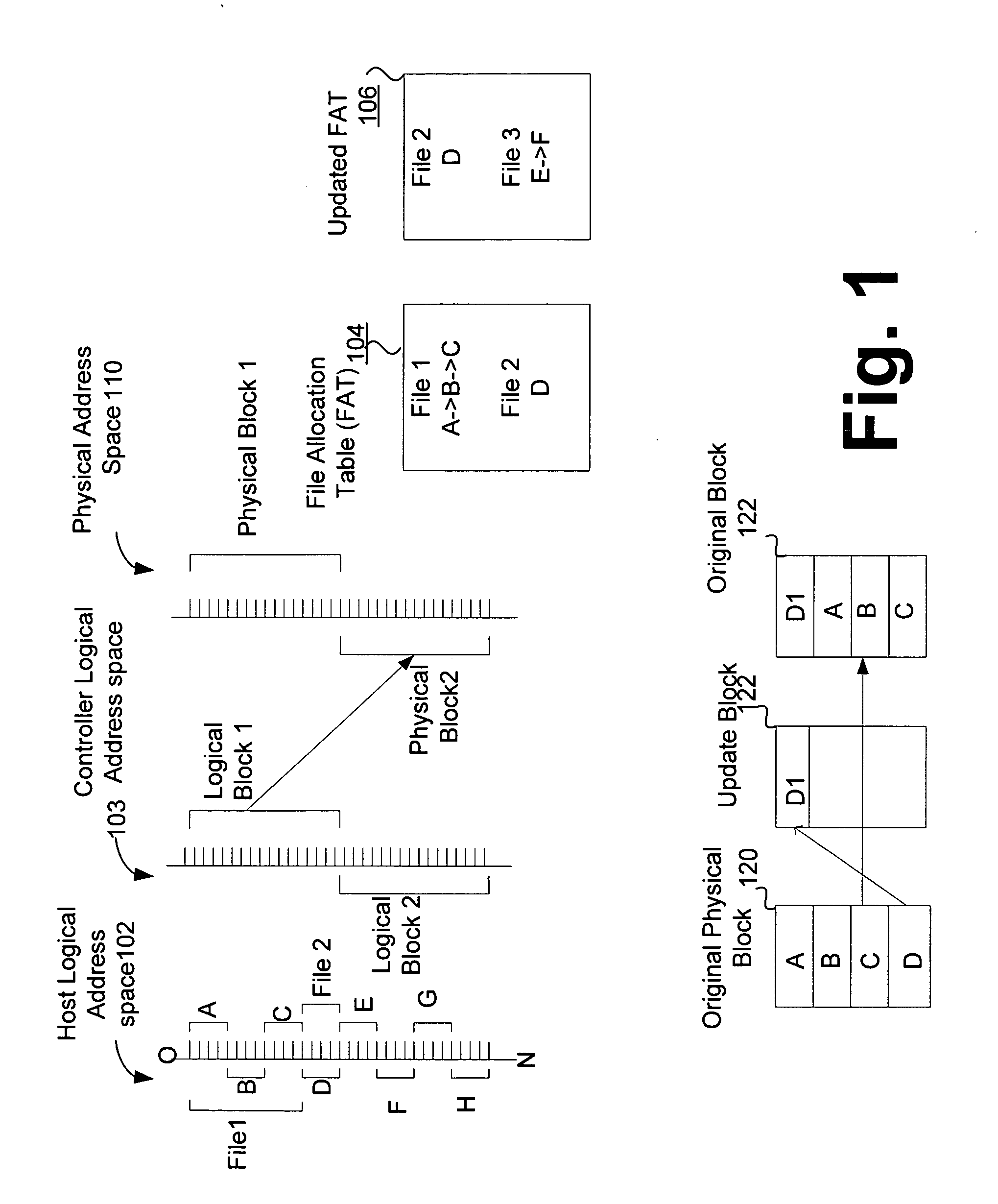

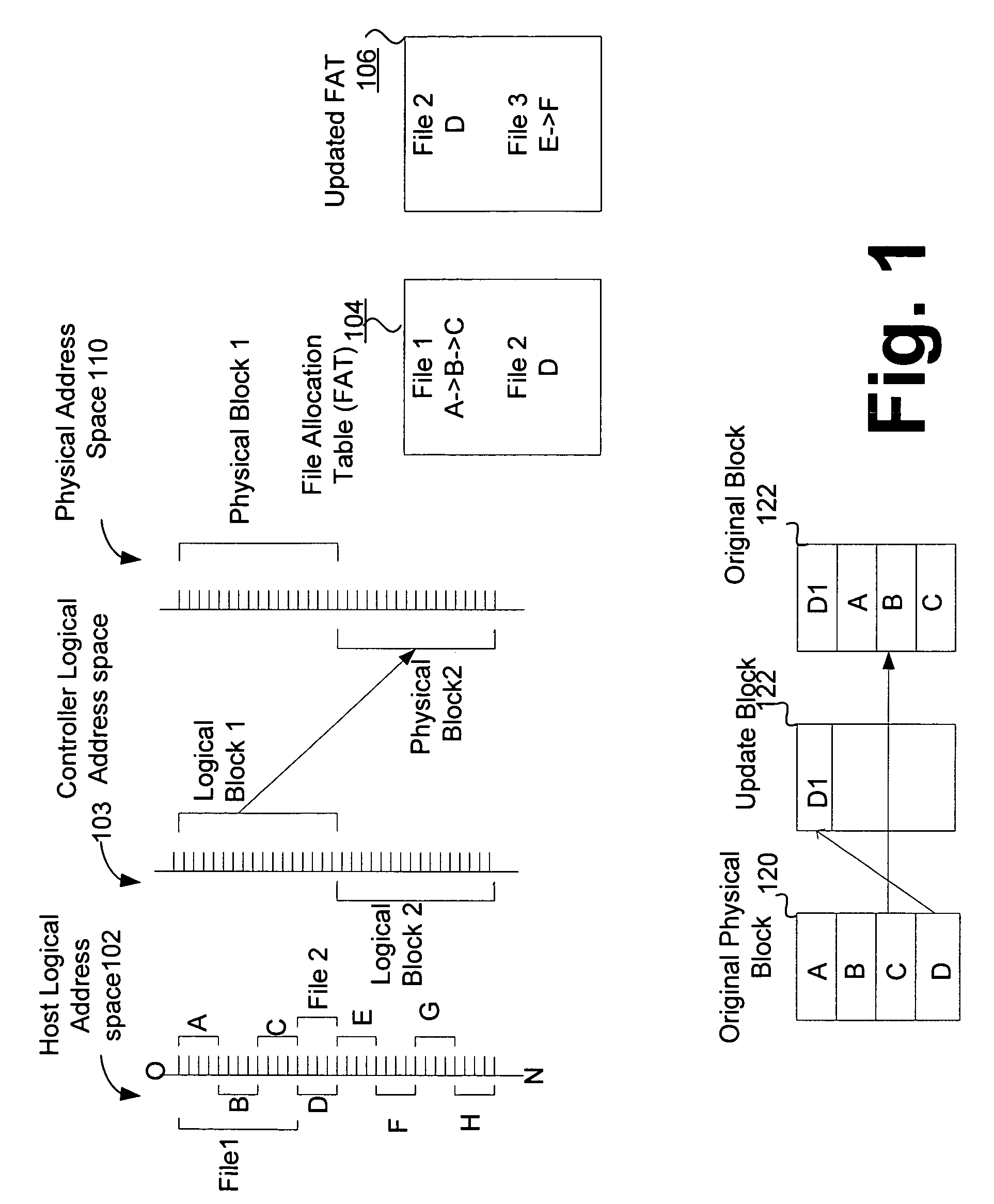

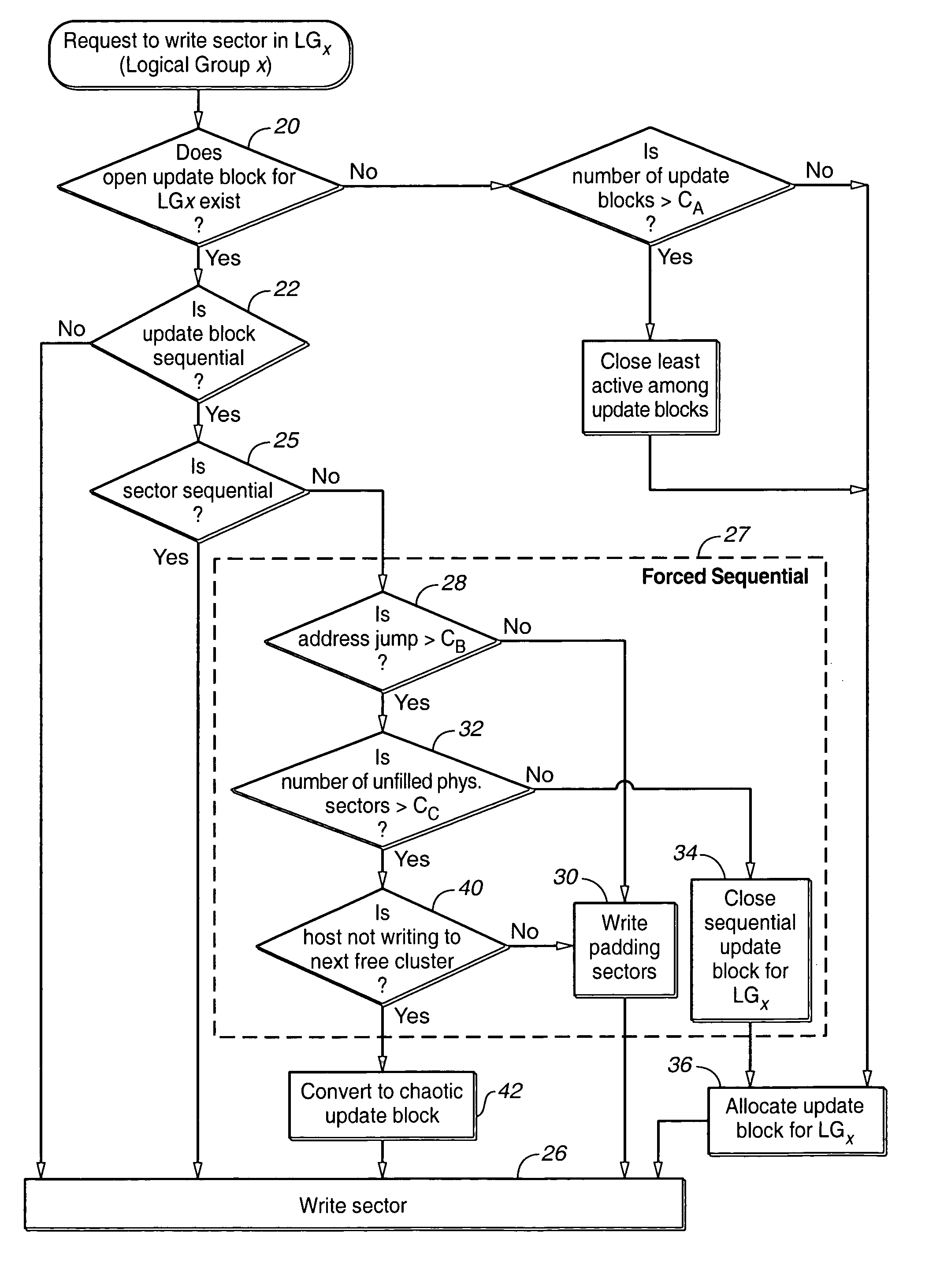

Fat analysis for optimized sequential cluster management

ActiveUS20060020745A1Free spaceEfficient in operationMemory adressing/allocation/relocationSpecial data processing applicationsFile systemVolatile memory

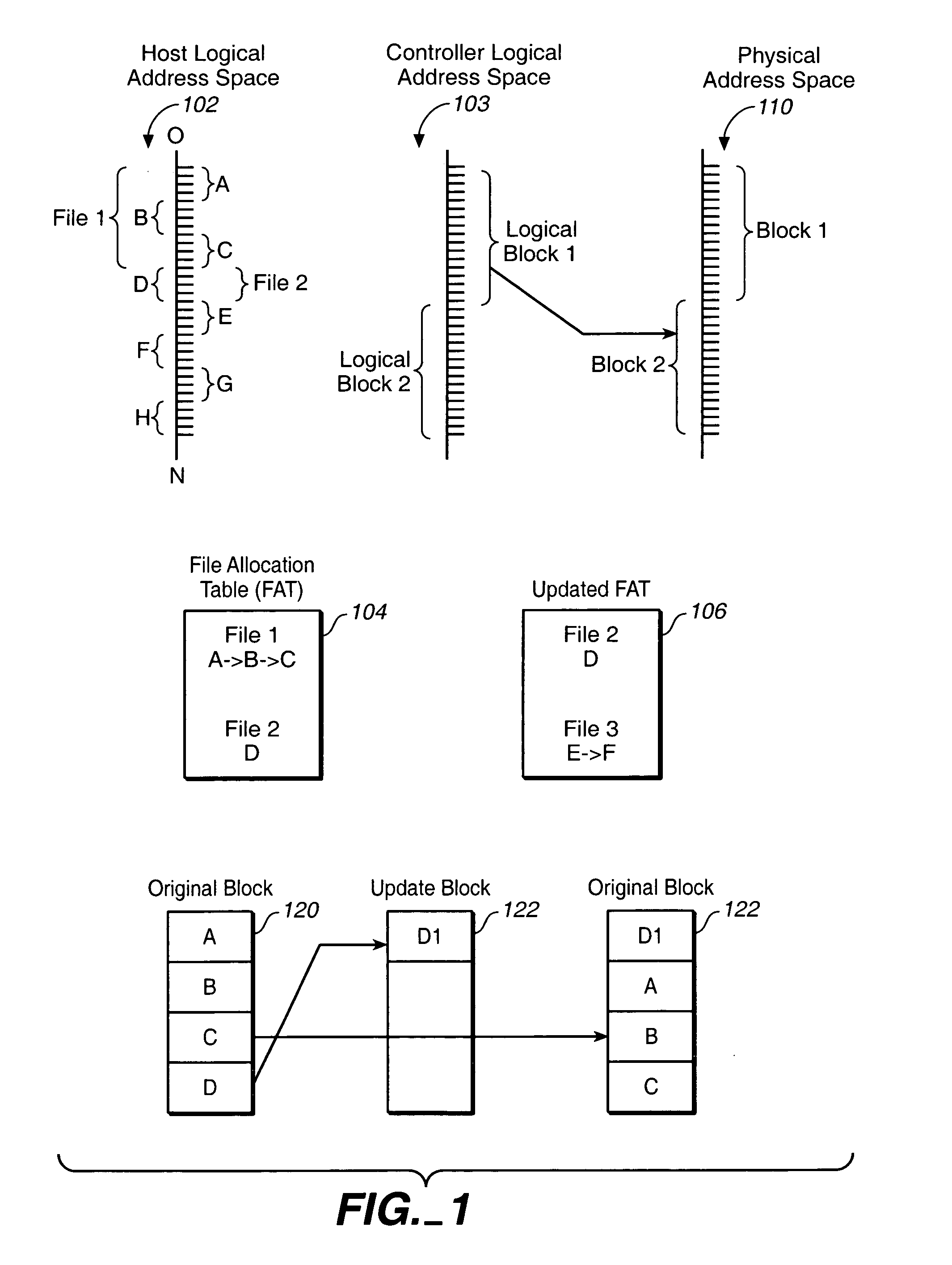

Techniques for managing data in a non-volatile memory system (e.g., Flash Memory) are disclosed. A controller can use information relating to a host's file system, which is stored by the host on non-volatile memory, to determine if one or more clusters (or sectors with clusters) are currently allocated. The controller can use the information relating to the host's file system to identify when the host is sending data to the next free cluster and to store such data in a sequential format by copying data from other locations in the non-volatile memory.

Owner:SANDISK TECH LLC

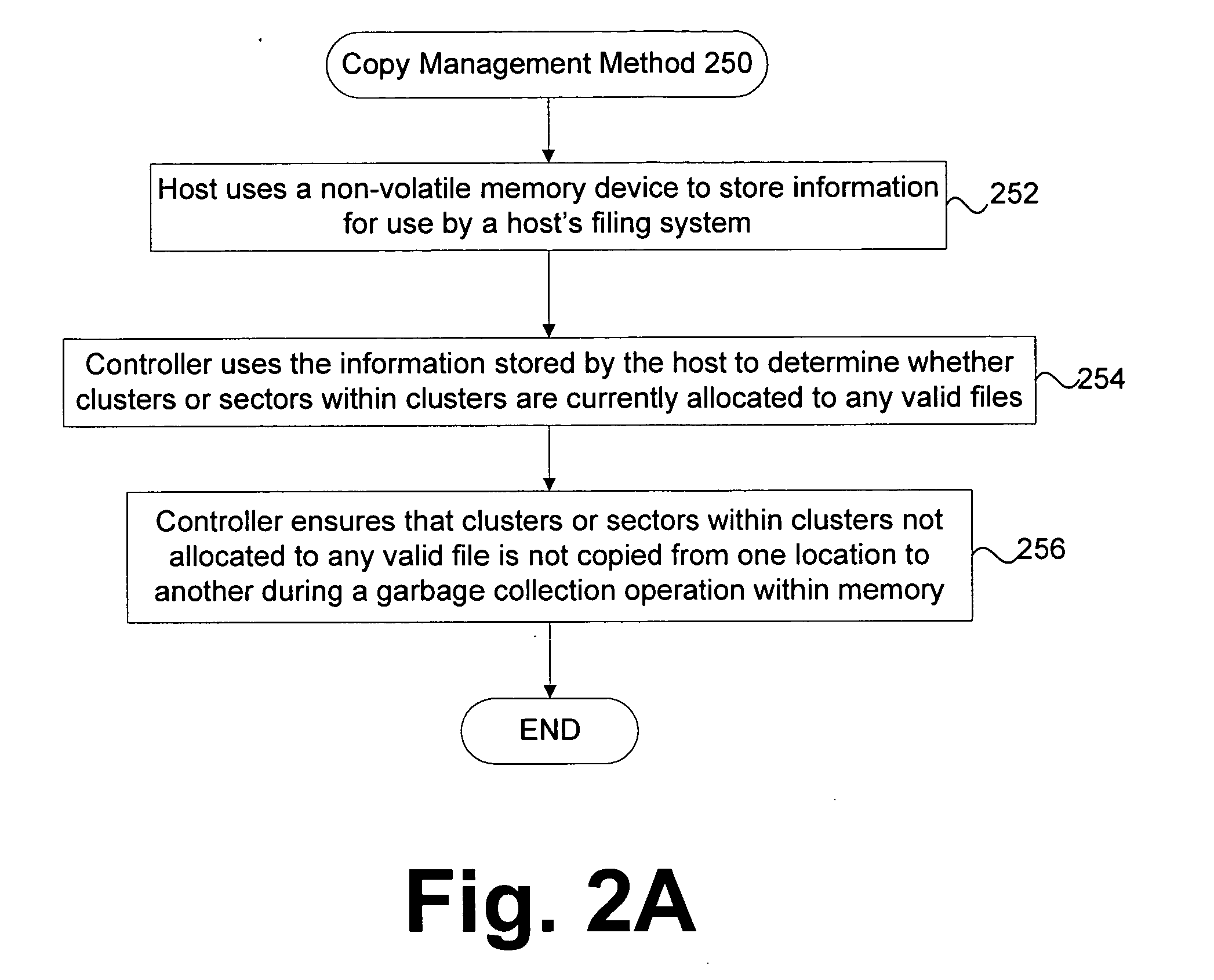

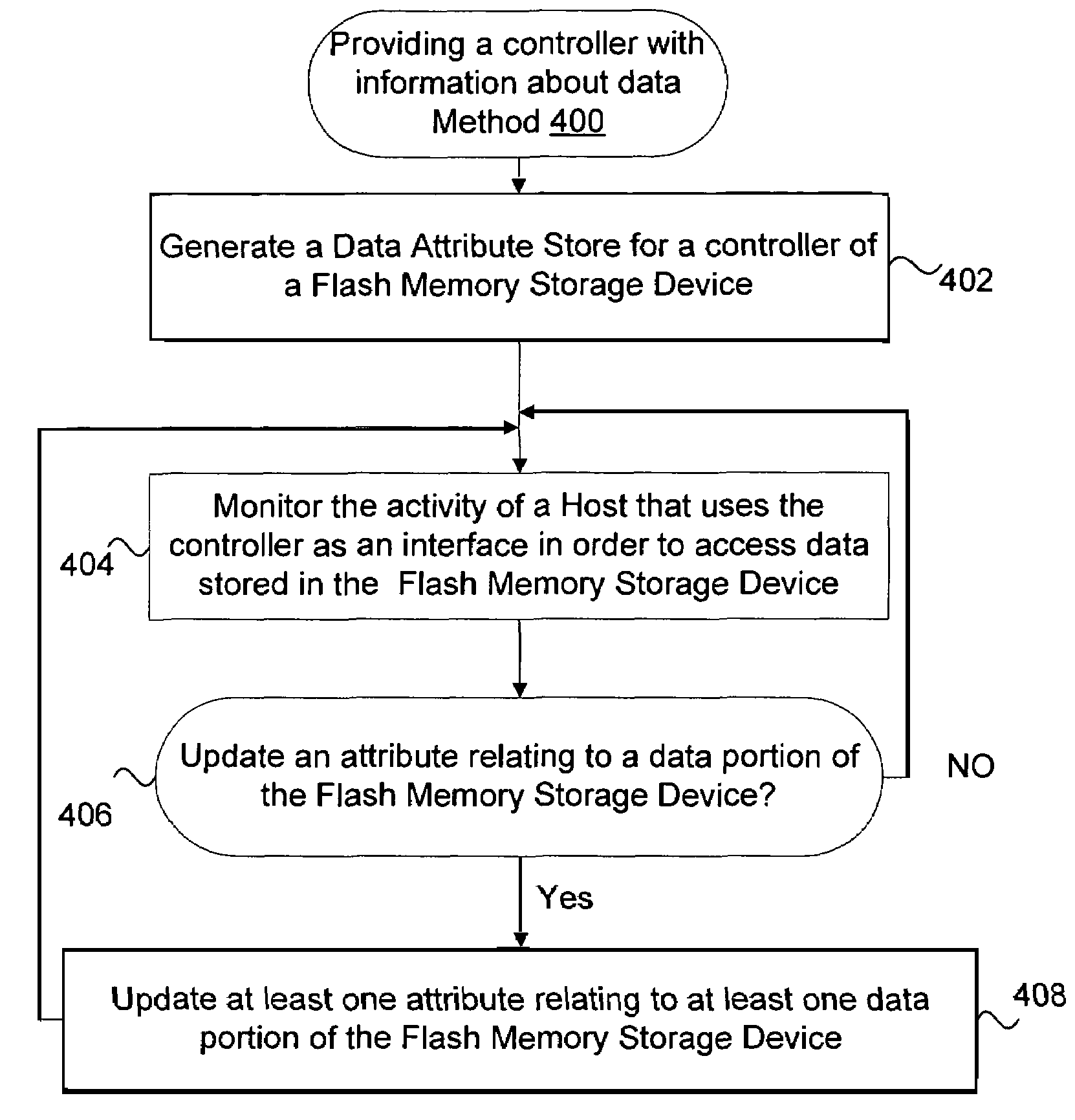

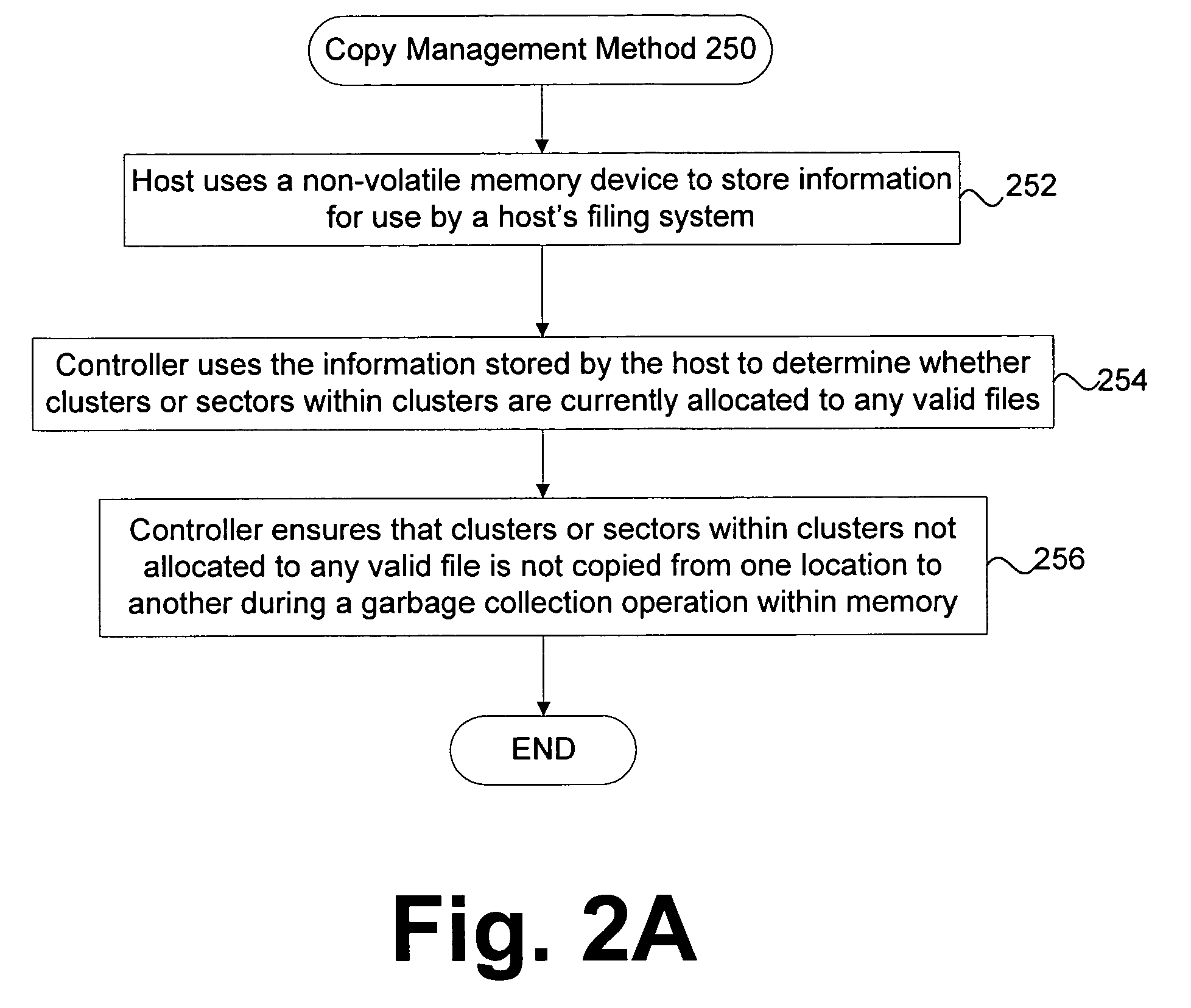

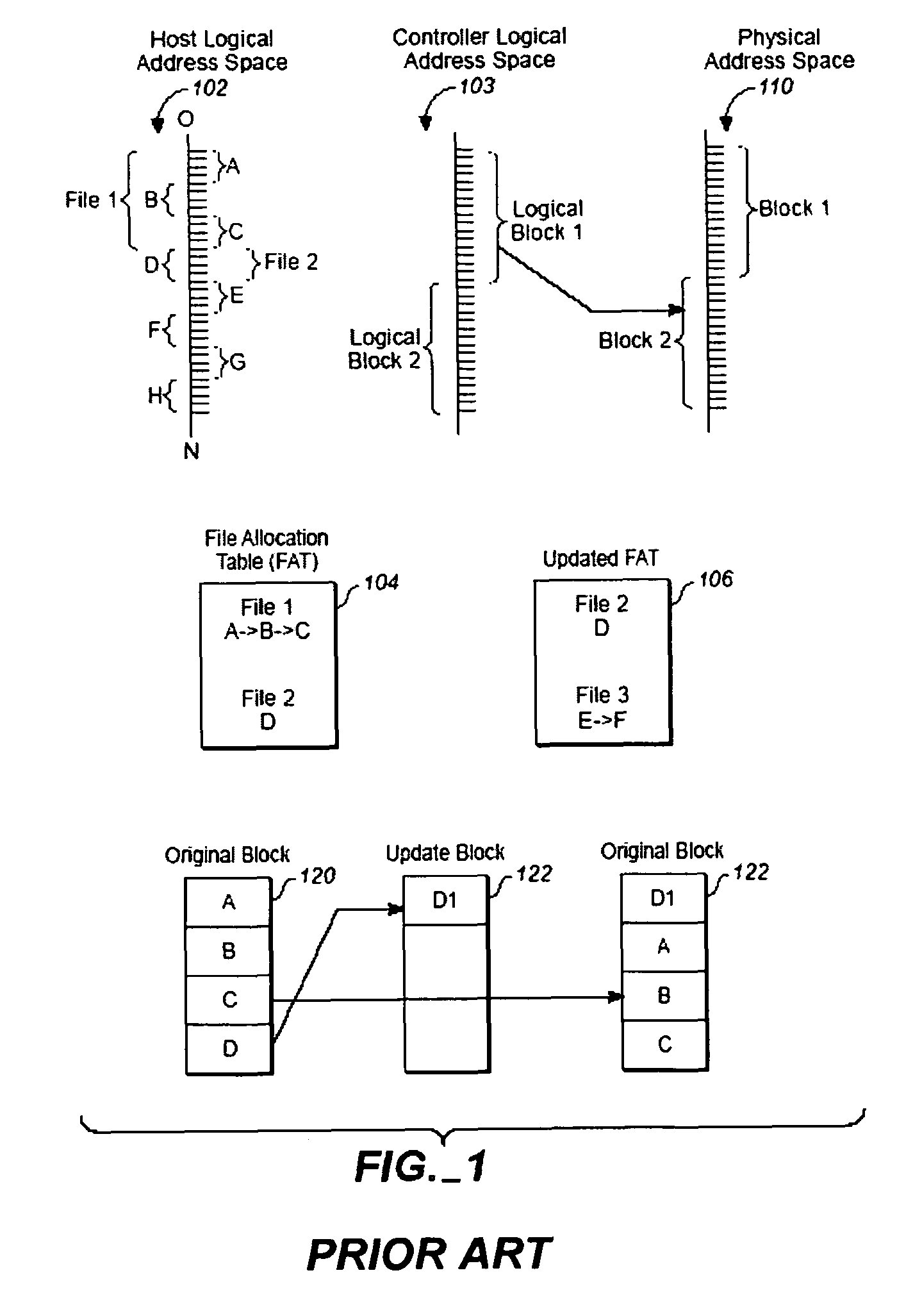

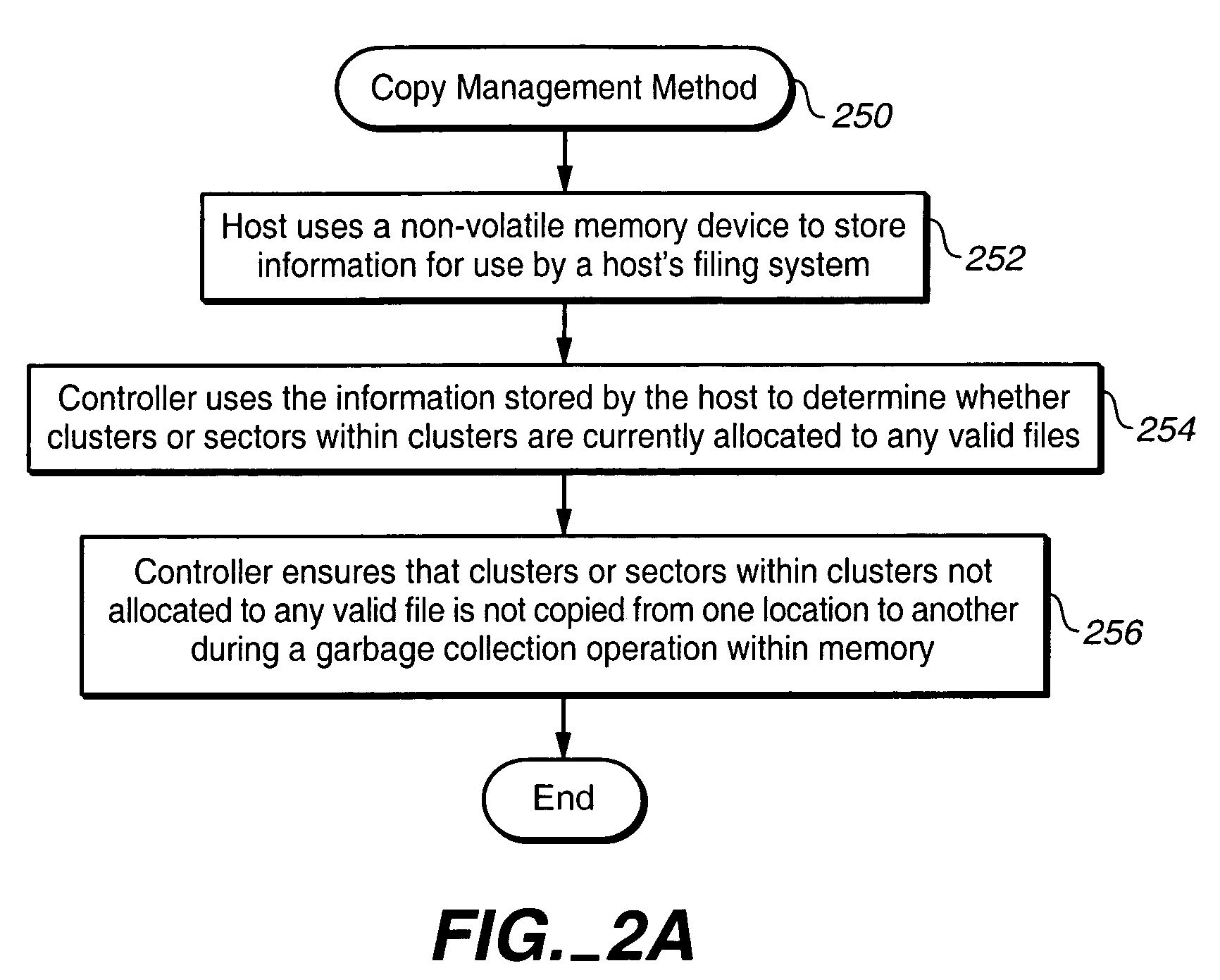

Method and apparatus for maintaining data on non-volatile memory systems

ActiveUS20060020744A1Improve system performanceUnnecessary operationMemory architecture accessing/allocationData processing applicationsCopyingVolatile memory

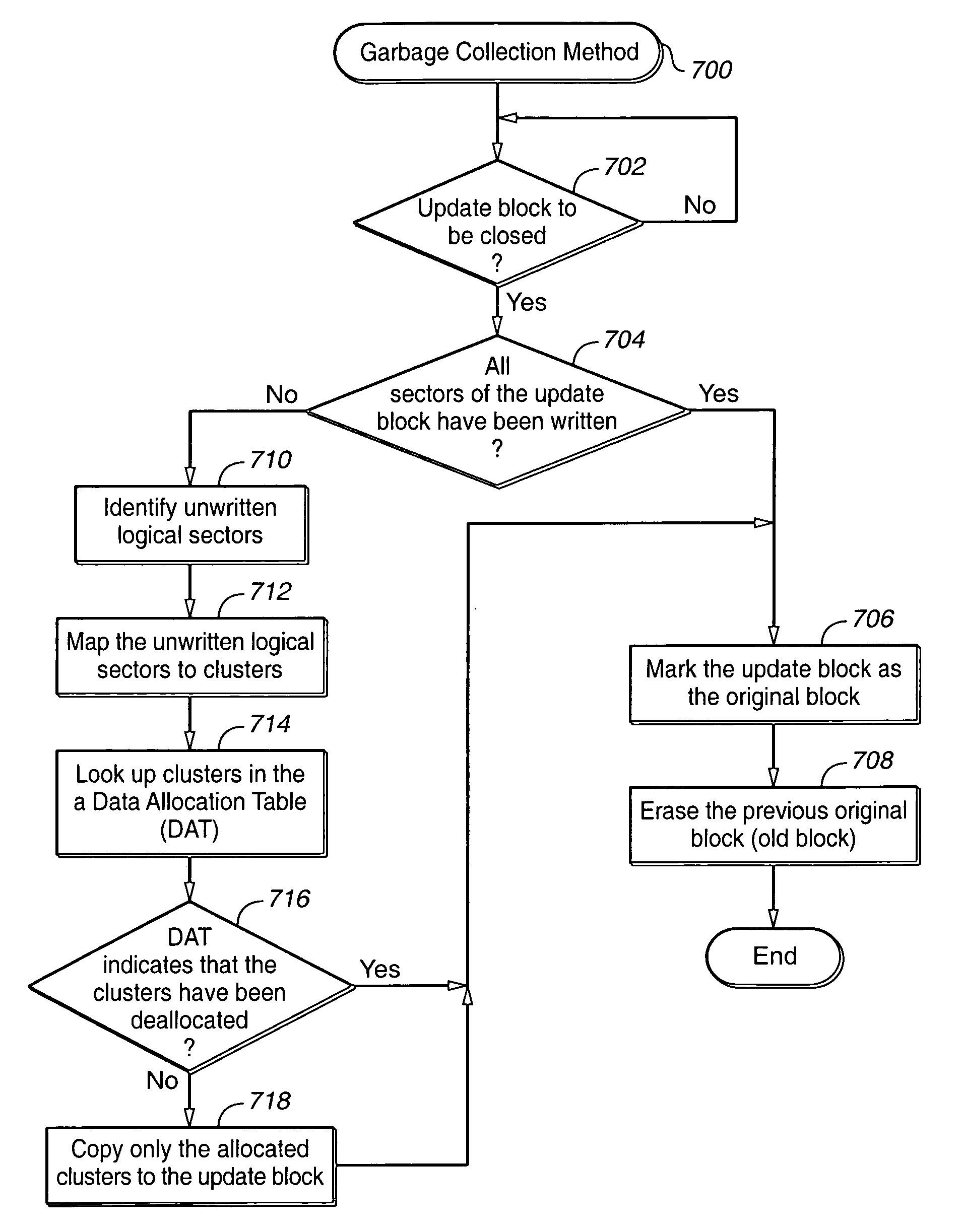

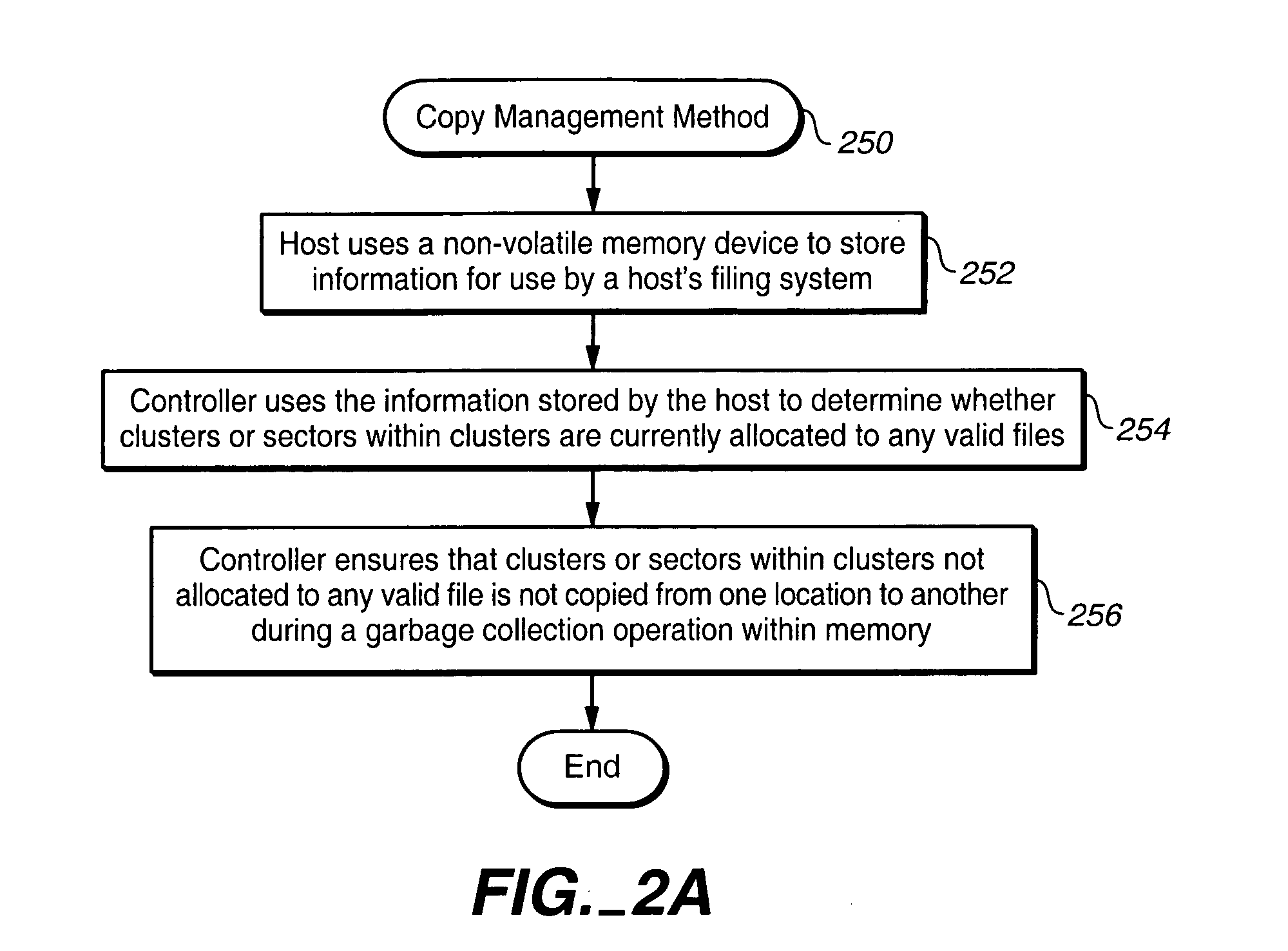

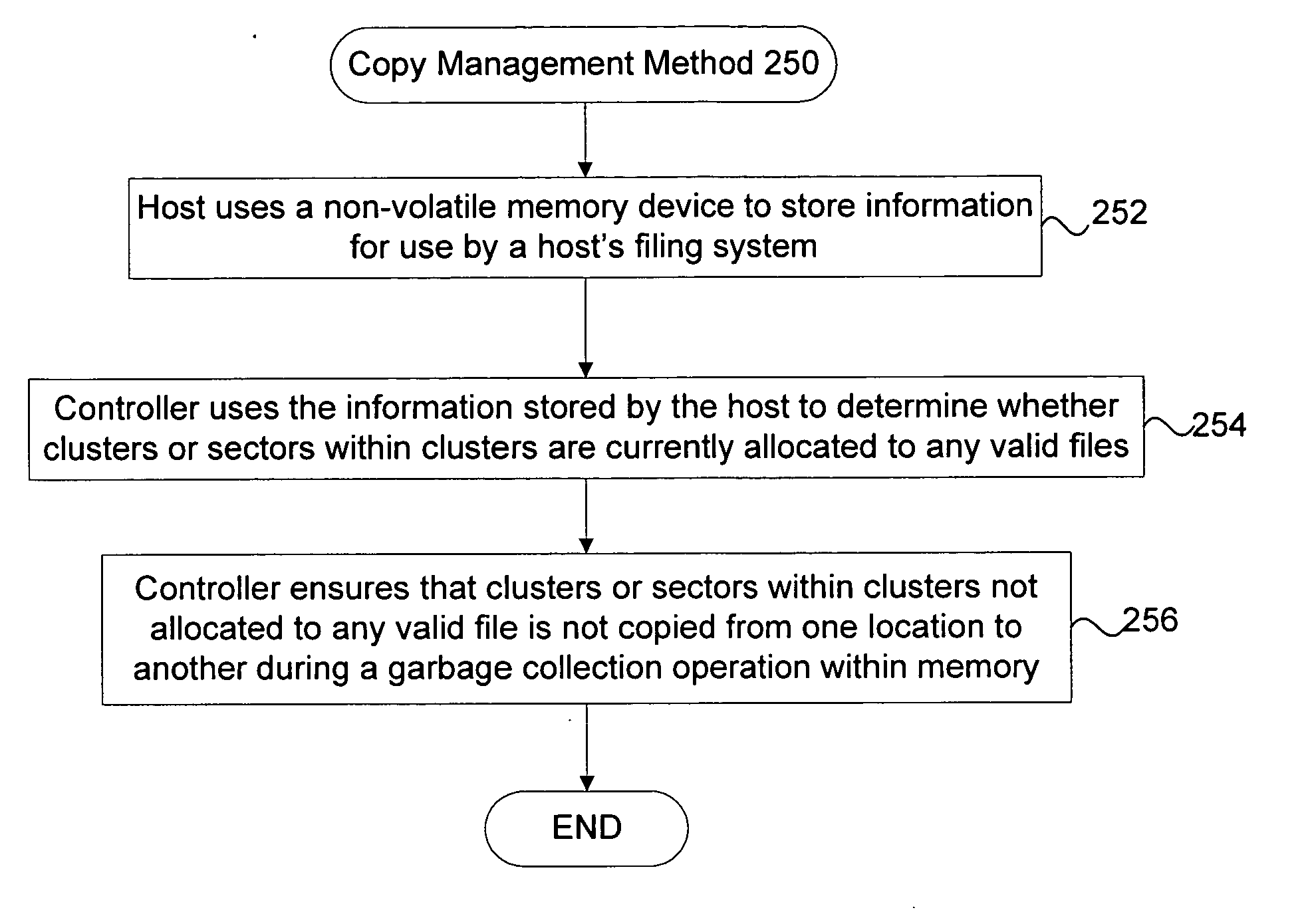

Techniques for managing data in a non-volatile memory system (e.g., Flash Memory) are disclosed. A controller can use information relating to a host's filing system, which is stored by the host on non-volatile memory, to determine if one or more clusters (or sectors with clusters) are currently allocated. The controller can use the information relating to the host's filing system to ensure that one or more clusters (or one or more sectors within a cluster) are not copied from one location to another location in the memory during a garbage collection cycle. As a result, some unnecessary operations (e.g., copying data) which are conventionally performed can be avoided and system performance can be enhanced.

Owner:SANDISK TECH LLC

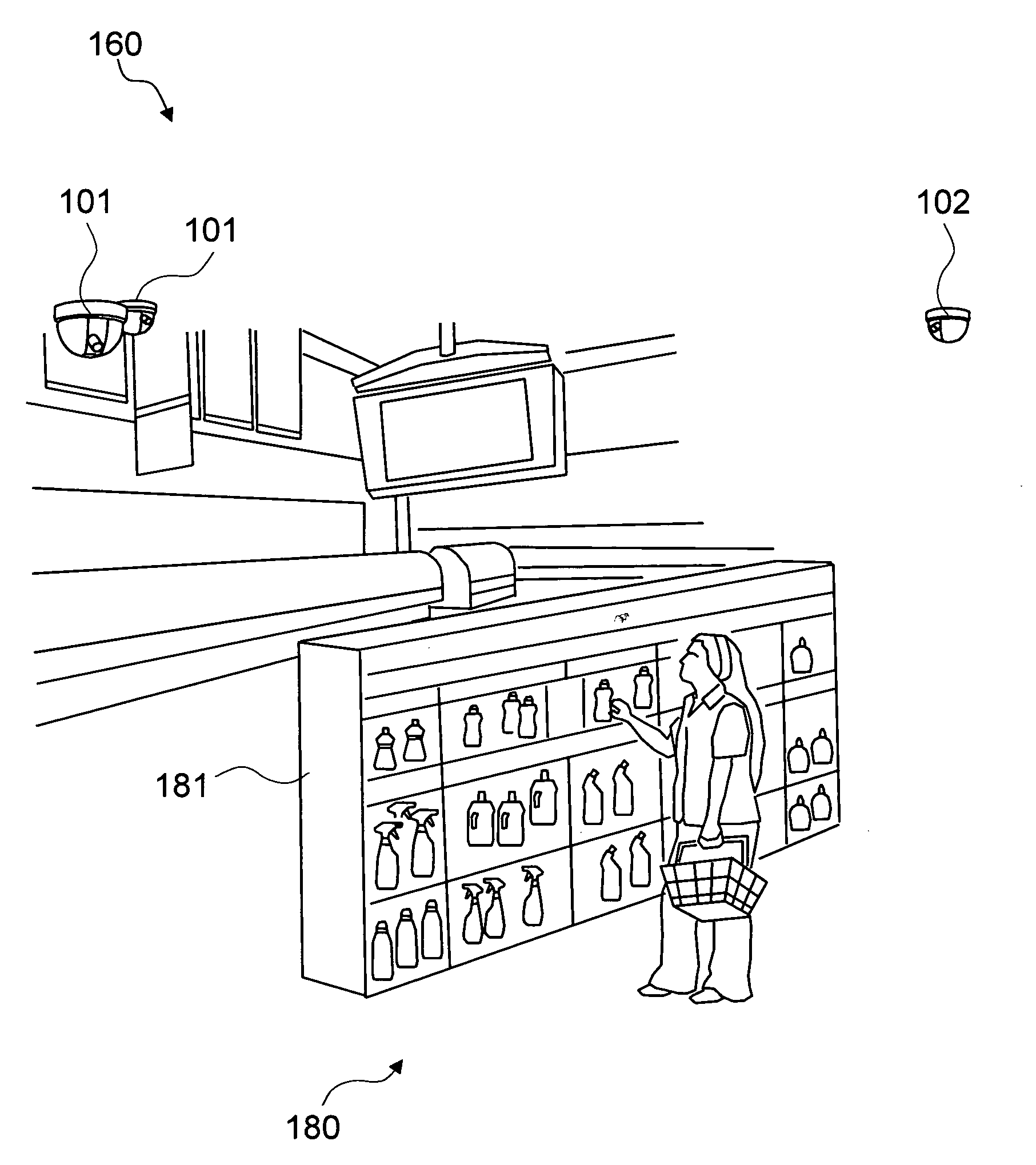

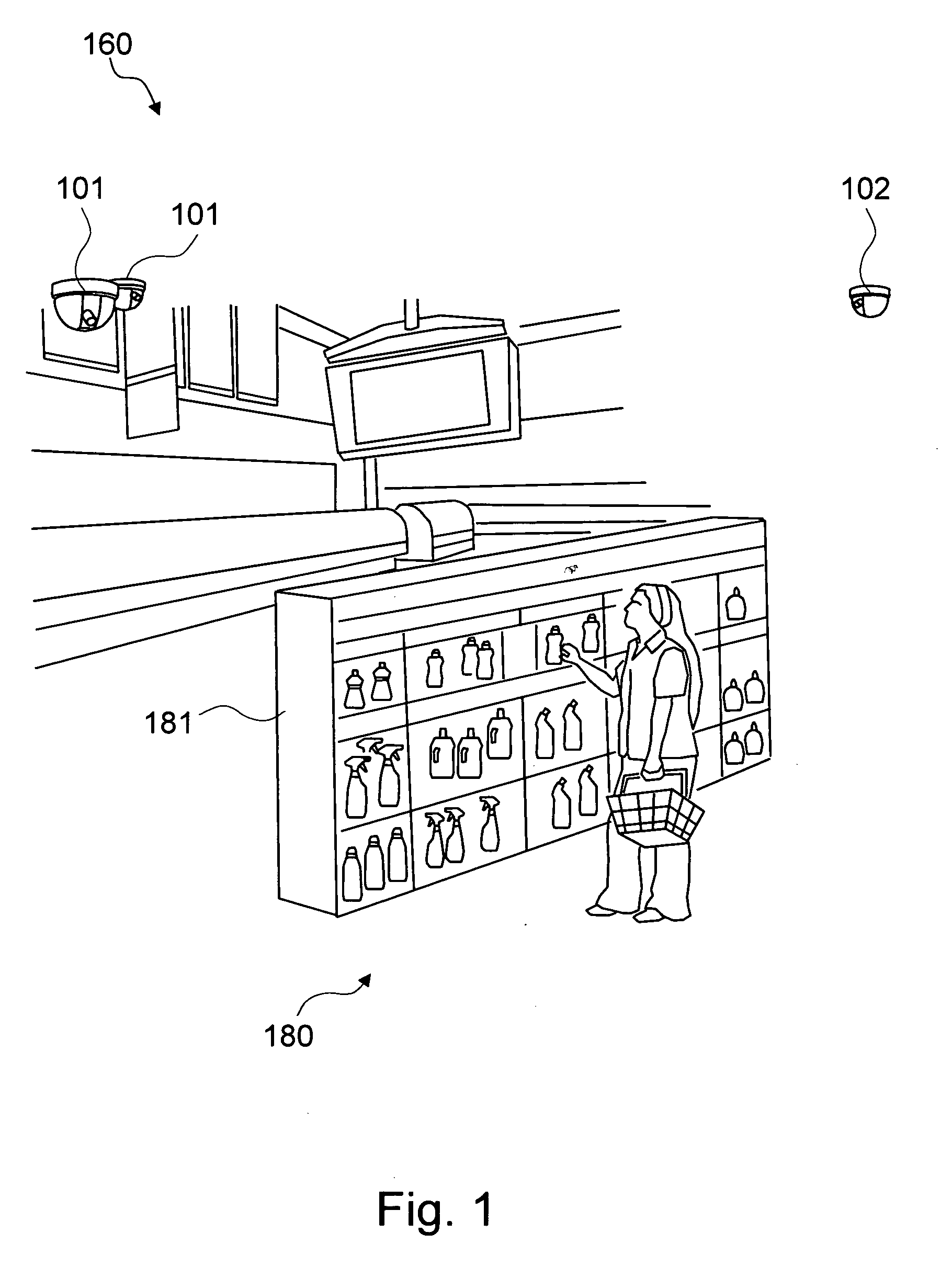

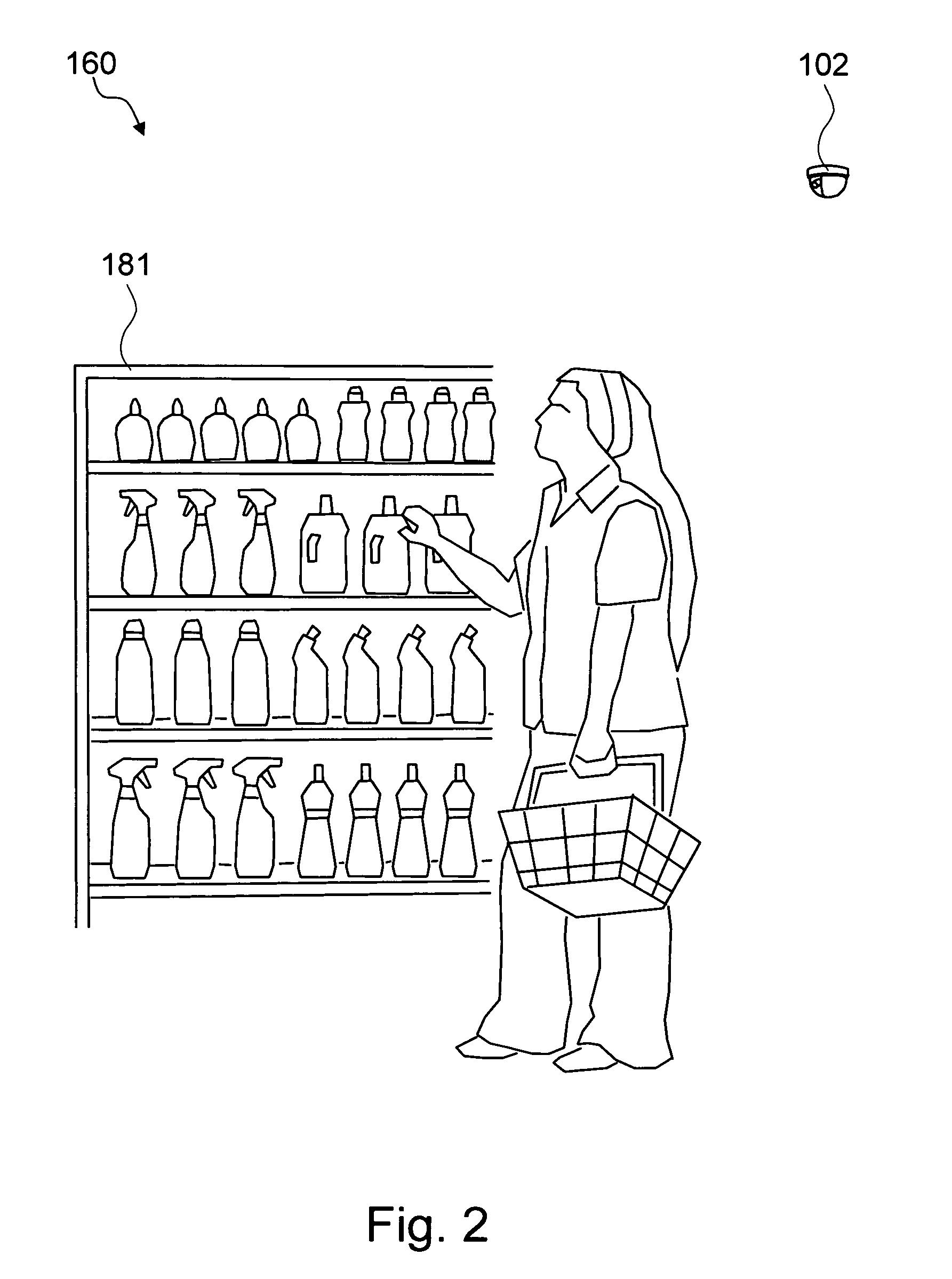

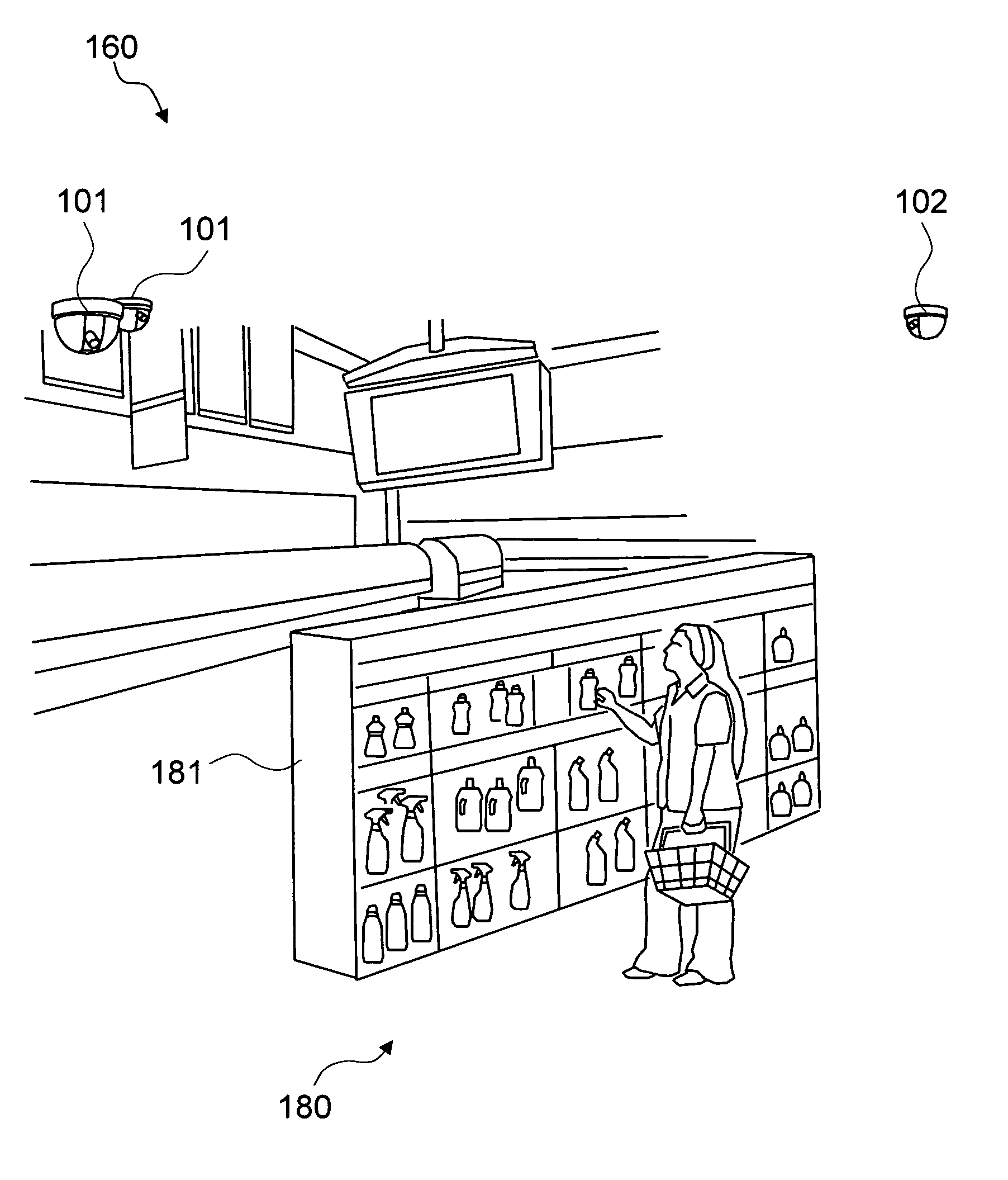

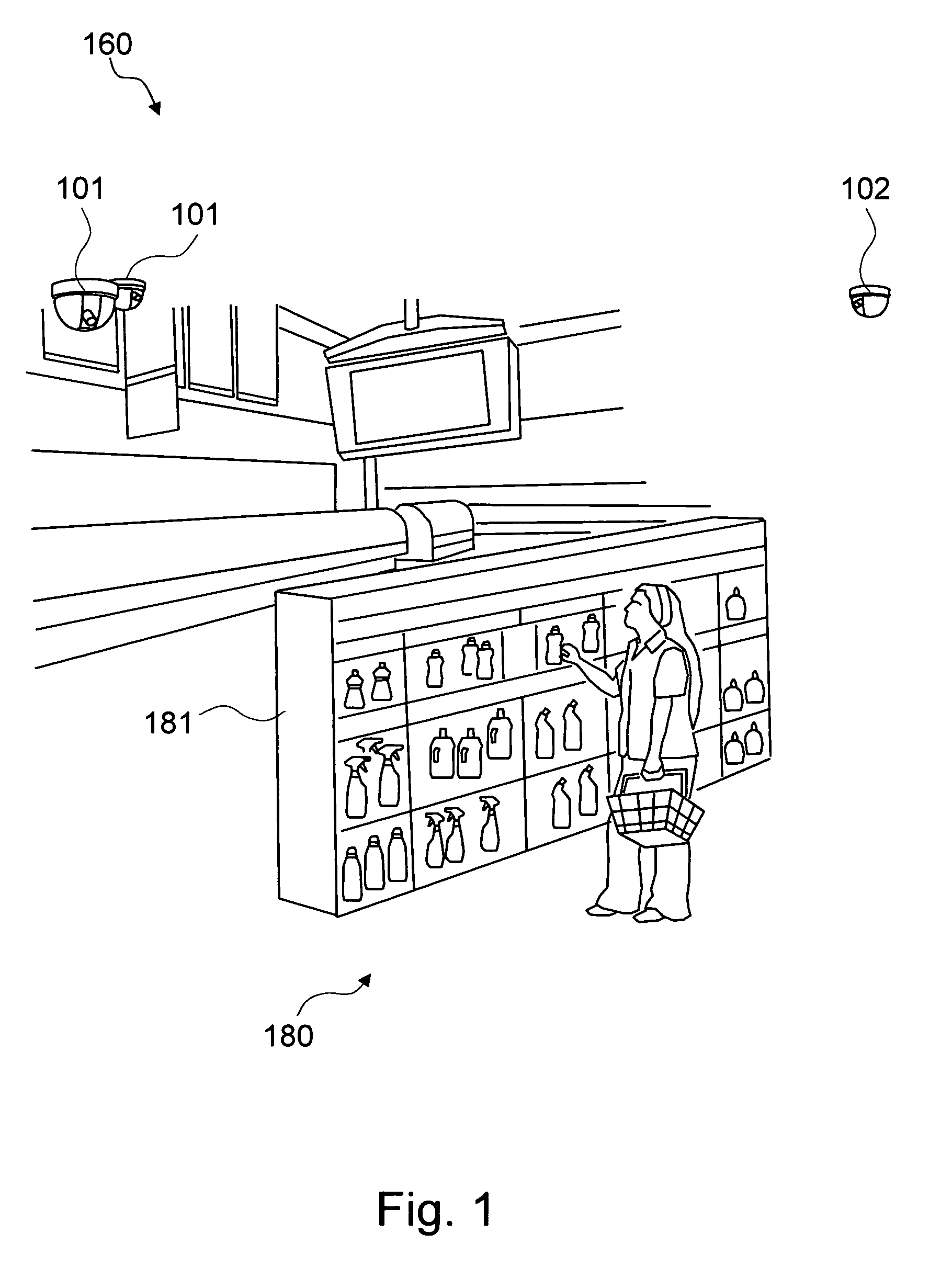

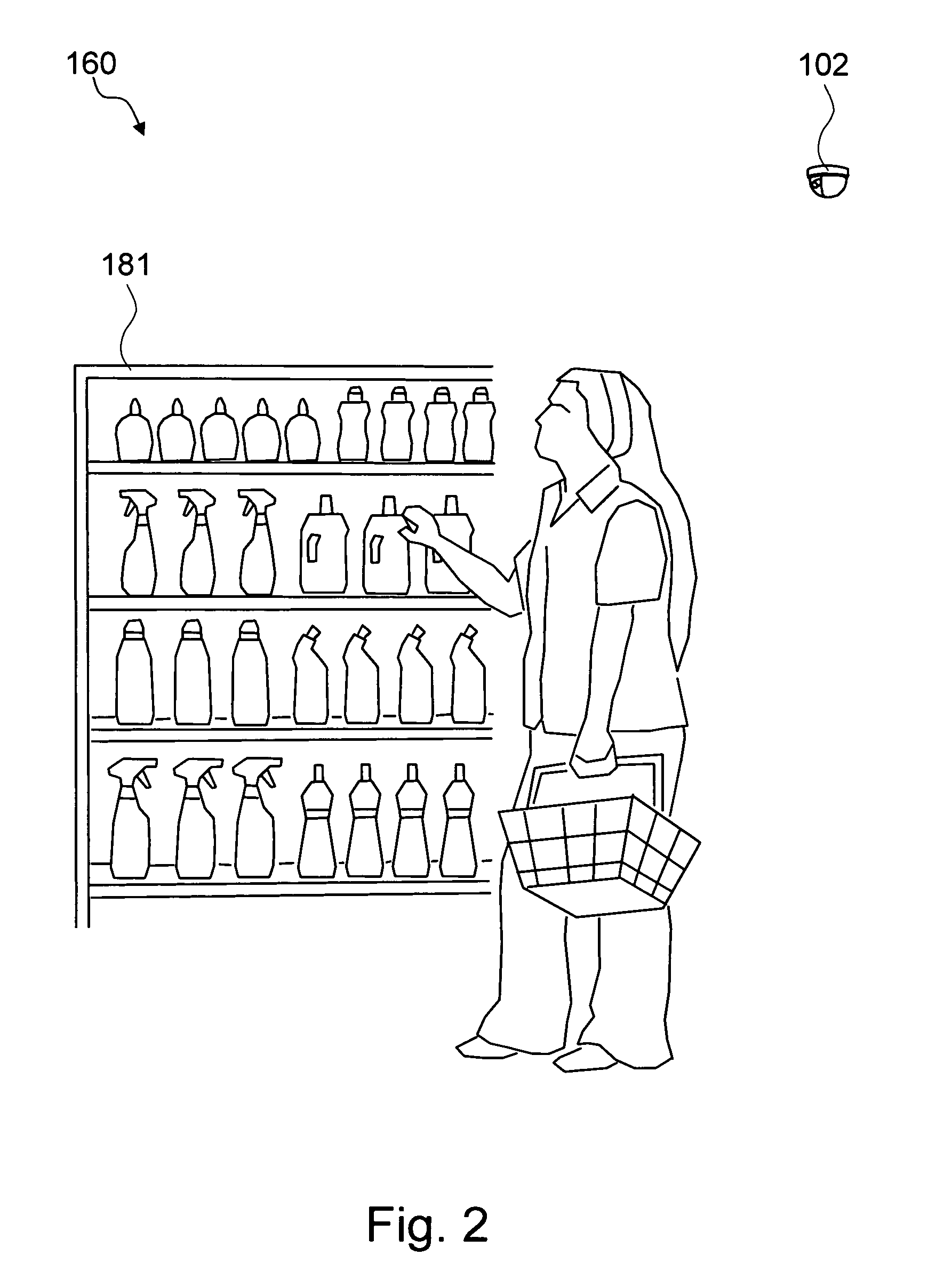

Method and system for automatically analyzing categories in a physical space based on the visual characterization of people

ActiveUS20080159634A1Minimizing number of productMinimizing shelf spaceCharacter and pattern recognitionVisual technologyPhysical space

The present invention is a method and system for automatically analyzing a category in a plurality of the categories in a physical space based on the visual characterization, such as behavior analysis or segmentation, of the persons with regard to the category. The present invention captures a plurality of input images of the persons in the category by a plurality of means for capturing images. The present invention processes the plurality of input images in order to understand the shopping behavior of the persons with the sub-categories of the category and analyzes the level of engagement and decision process at the sub-category level. The processes are based on a novel usage of a plurality of computer vision technologies to analyze the visual characterization of the persons from the plurality of input images. The physical space may be a retail space, and the persons may be customers in the retail space.

Owner:VIDEOMINING CORP

Method and apparatus for maintaining data on non-volatile memory systems

ActiveUS7395384B2Improve system performanceEasy to manageMemory architecture accessing/allocationData processing applicationsWaste collectionCopying

Techniques for managing data in a non-volatile memory system (e.g., Flash Memory) are disclosed. A controller can use information relating to a host's filing system, which is stored by the host on non-volatile memory, to determine if one or more clusters (or sectors with clusters) are currently allocated. The controller can use the information relating to the host's filing system to ensure that one or more clusters (or one or more sectors within a cluster) are not copied from one location to another location in the memory during a garbage collection cycle. As a result, some unnecessary operations (e.g., copying data) which are conventionally performed can be avoided and system performance can be enhanced.

Owner:SANDISK TECH LLC

Method and system for automatically analyzing categories in a physical space based on the visual characterization of people

ActiveUS8189926B2Efficiently understoodIncrease the use of spaceCharacter and pattern recognitionPhysical spaceBehavioral analytics

The present invention is a method and system for automatically analyzing a category in a plurality of the categories in a physical space based on the visual characterization, such as behavior analysis or segmentation, of the persons with regard to the category. The present invention captures a plurality of input images of the persons in the category by a plurality of means for capturing images. The present invention processes the plurality of input images in order to understand the shopping behavior of the persons with the sub-categories of the category and analyzes the level of engagement and decision process at the sub-category level. The processes are based on a novel usage of a plurality of computer vision technologies to analyze the visual characterization of the persons from the plurality of input images. The physical space may be a retail space, and the persons may be customers in the retail space.

Owner:VIDEOMINING CORP

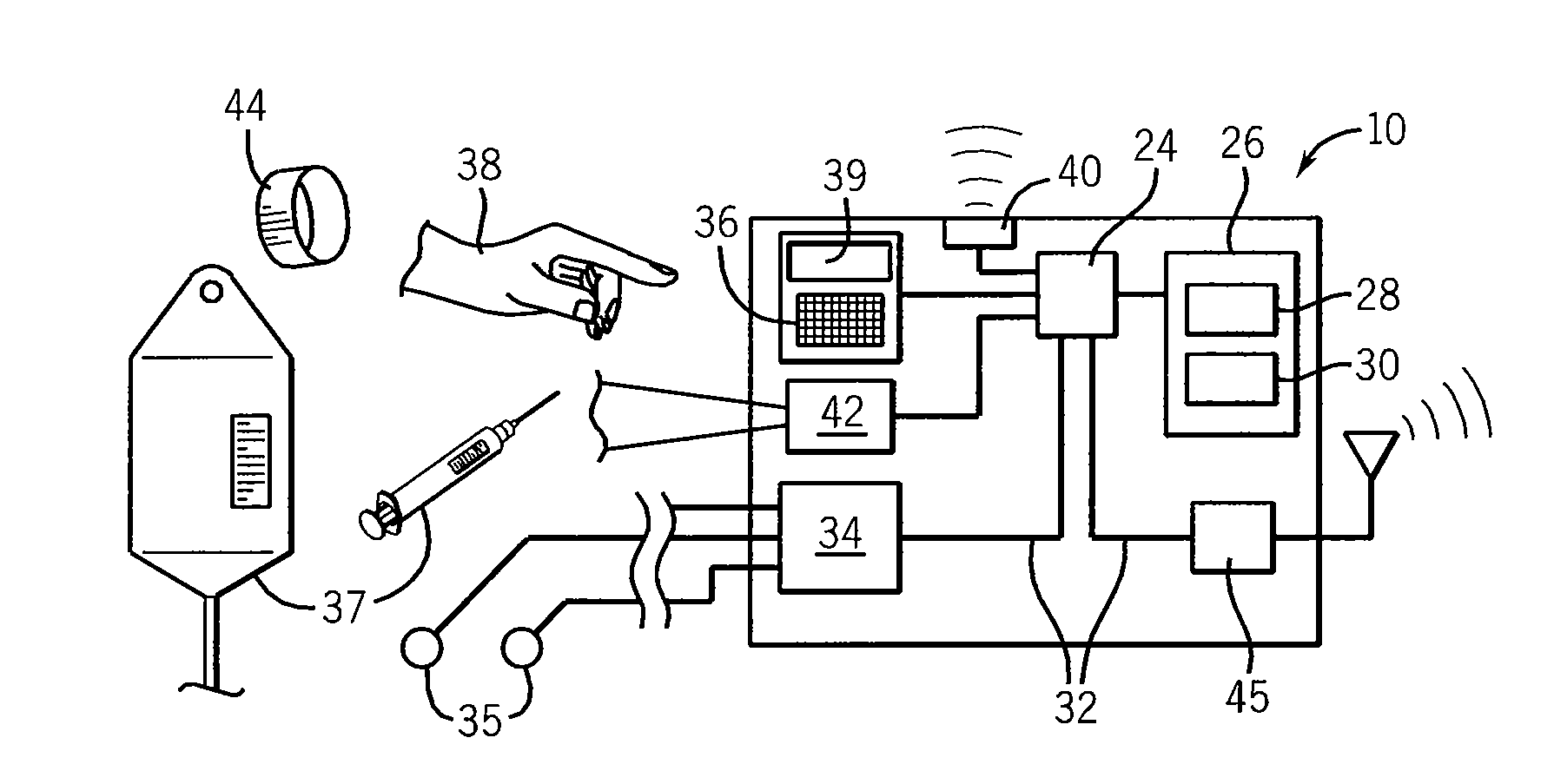

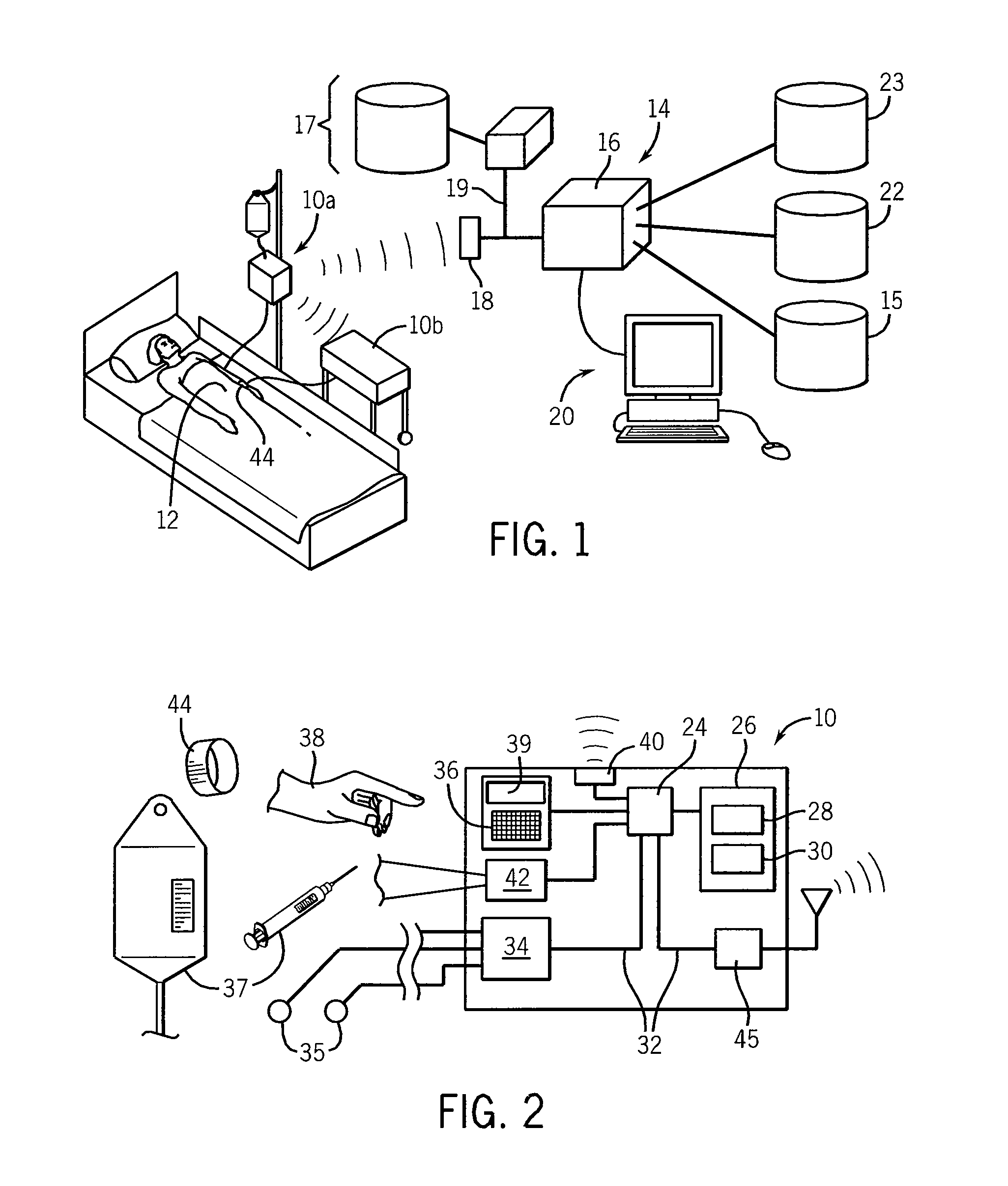

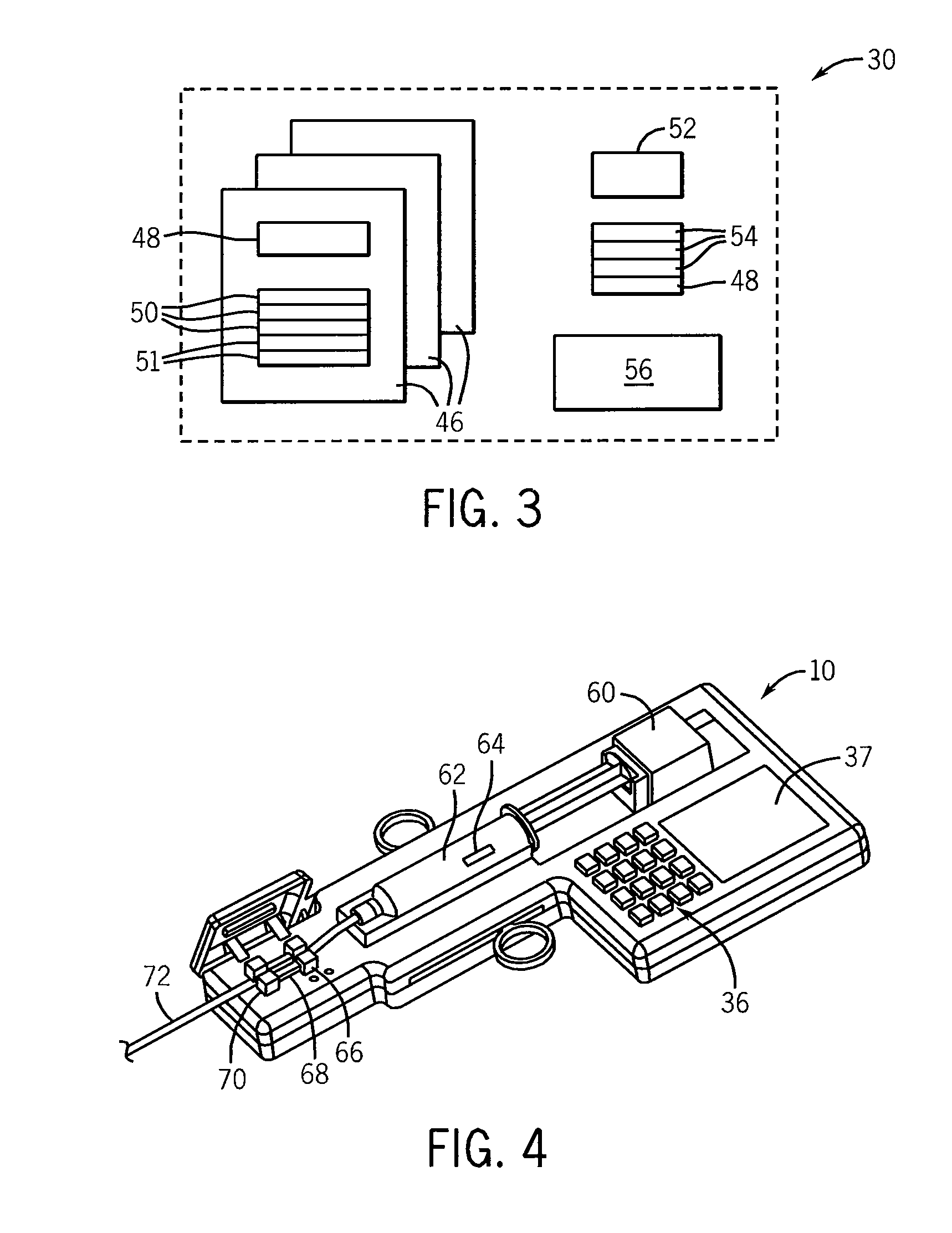

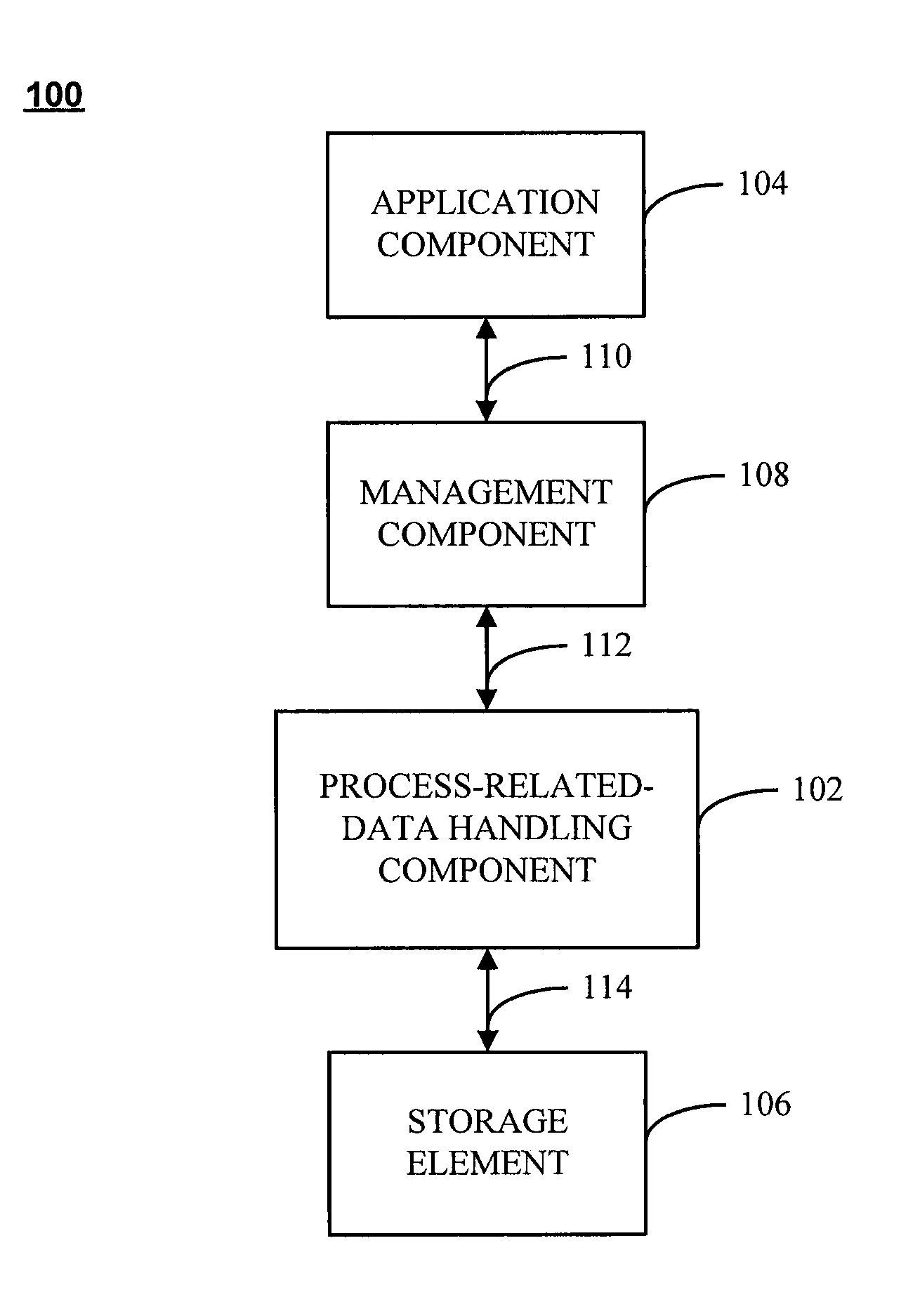

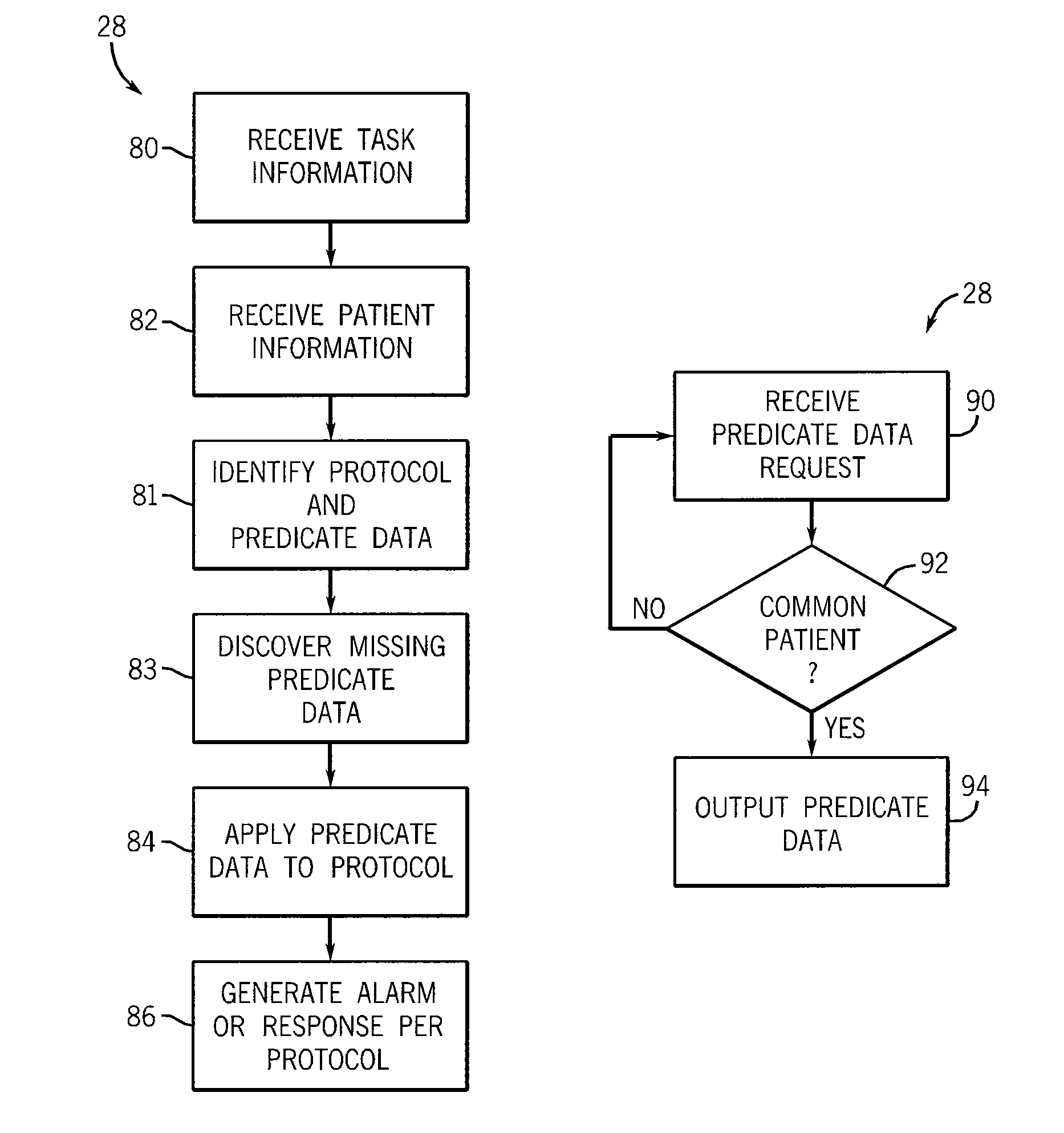

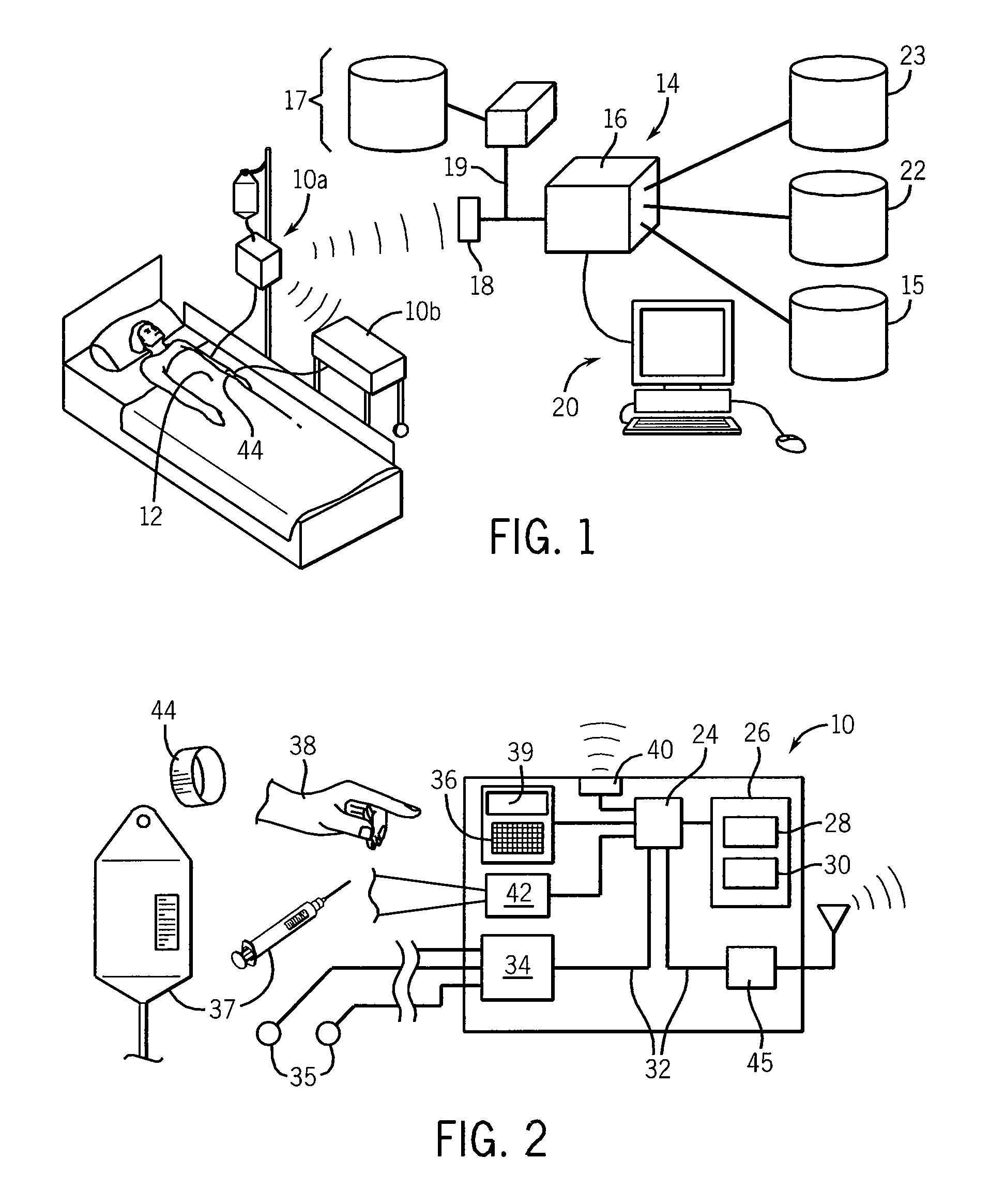

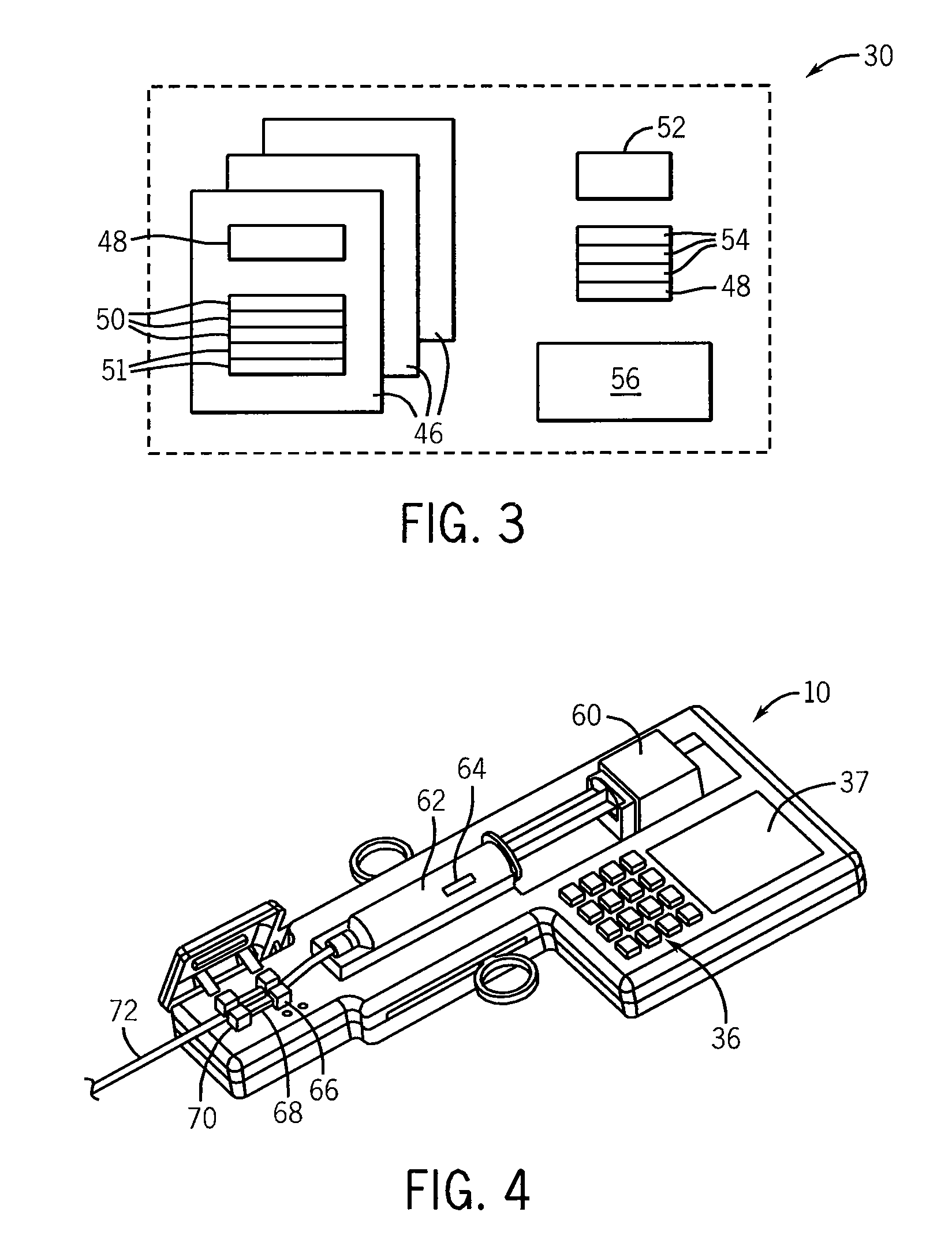

Medical Device With Contextual Awareness

ActiveUS20130144206A1Enhanced contextual understandingEfficiently understoodDrug and medicationsMedical devicesMedical recordElectronic medical record

A medical device, such as an infusion pump, obtains a contextual awareness of its operation by communicating with centralized patient records and or other medical equipment communicating with a common patient, and / or provides real time advisory information, at care point or remotely. A protocol obtained by the medical device from a protocol server provides context-aware protocols and necessary predicate information for those protocols. This predicate information may be discovered by the medical device communicating with electronic medical records and the associated medical equipment.

Owner:ZYNO MEDICAL

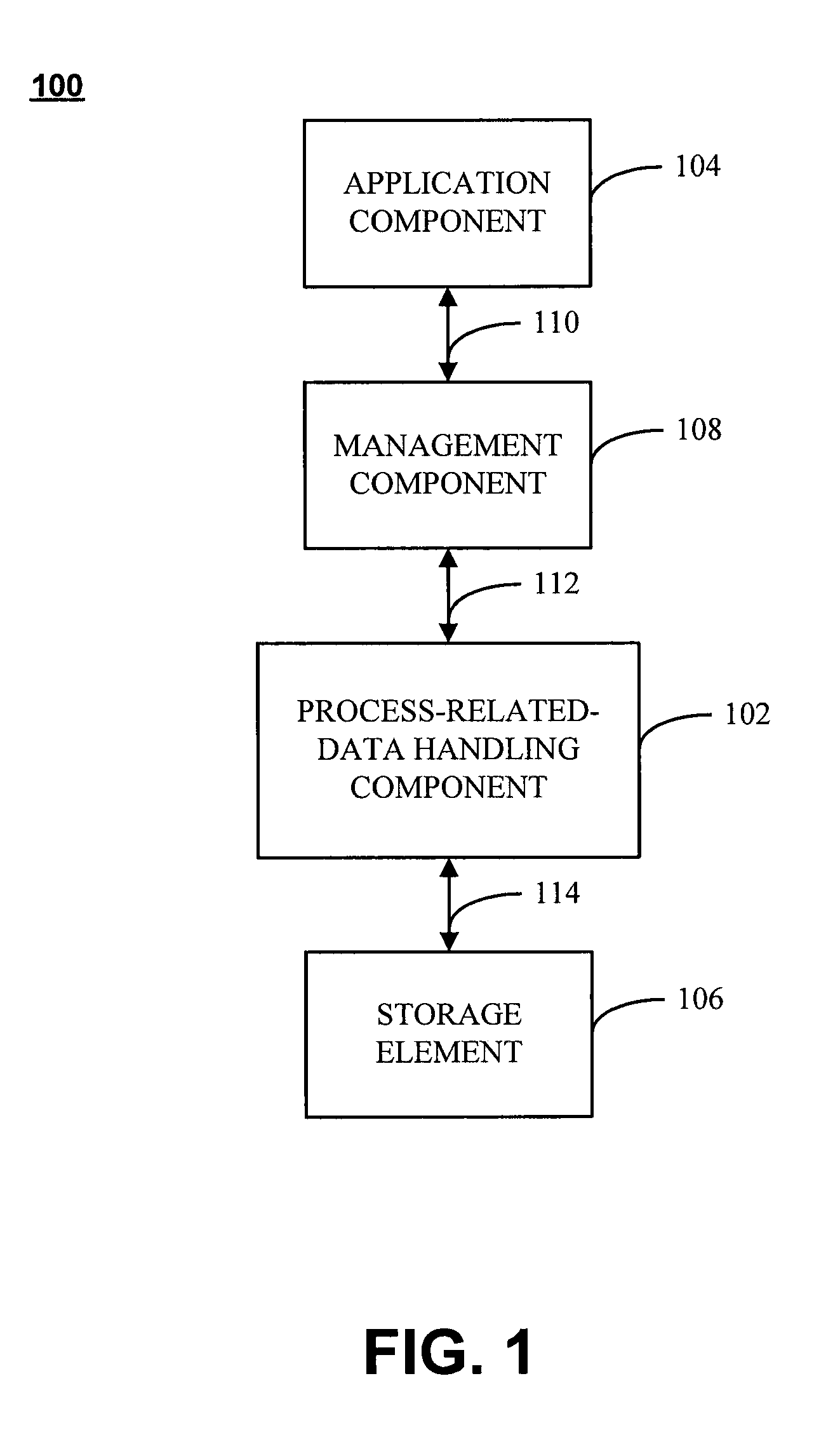

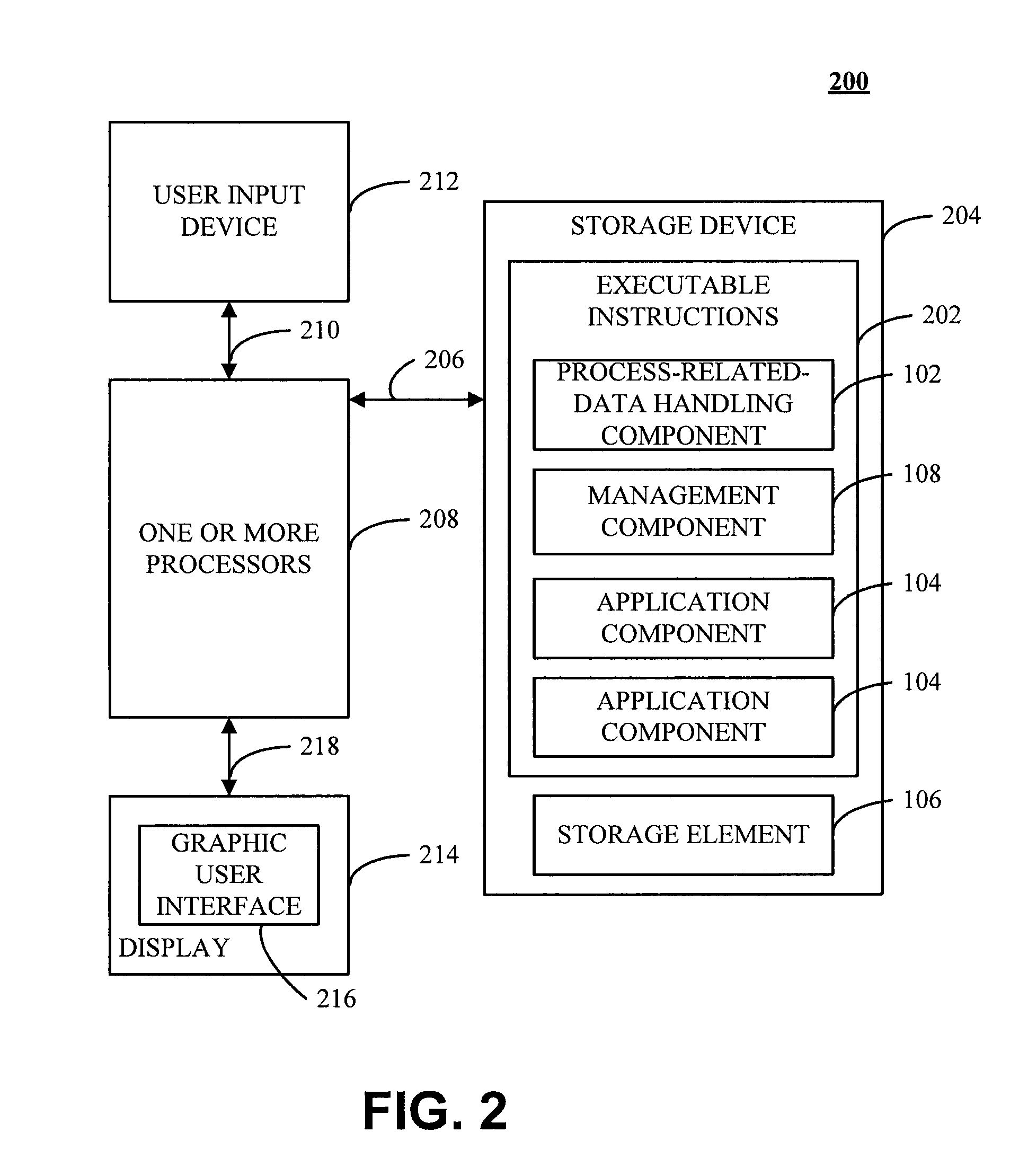

System and method for adding context to the creation and revision of artifacts

ActiveUS20100095298A1Efficiently understoodGreat and efficient understandingDigital data processing detailsText processingData managementApplication software

A system includes a process-related-data handling component operative to handle process-related data corresponding to an operation associated with an artifact, such as the creation or revision of the artifact. An application component is operatively coupled to the process-related-data handling module and is operative to interact with the artifact. A storage element is also operatively coupled to the process-related-data handling module and is operative to store the process-related data. The process-related data may be displayed, created, or otherwise manipulated through a data management tool, which may include, a calendar interface, a task interface, and / or a media capture module. A method is also directed towards establishing process-related context concerning at least one artifact.

Owner:ACCENTURE GLOBAL SERVICES LTD

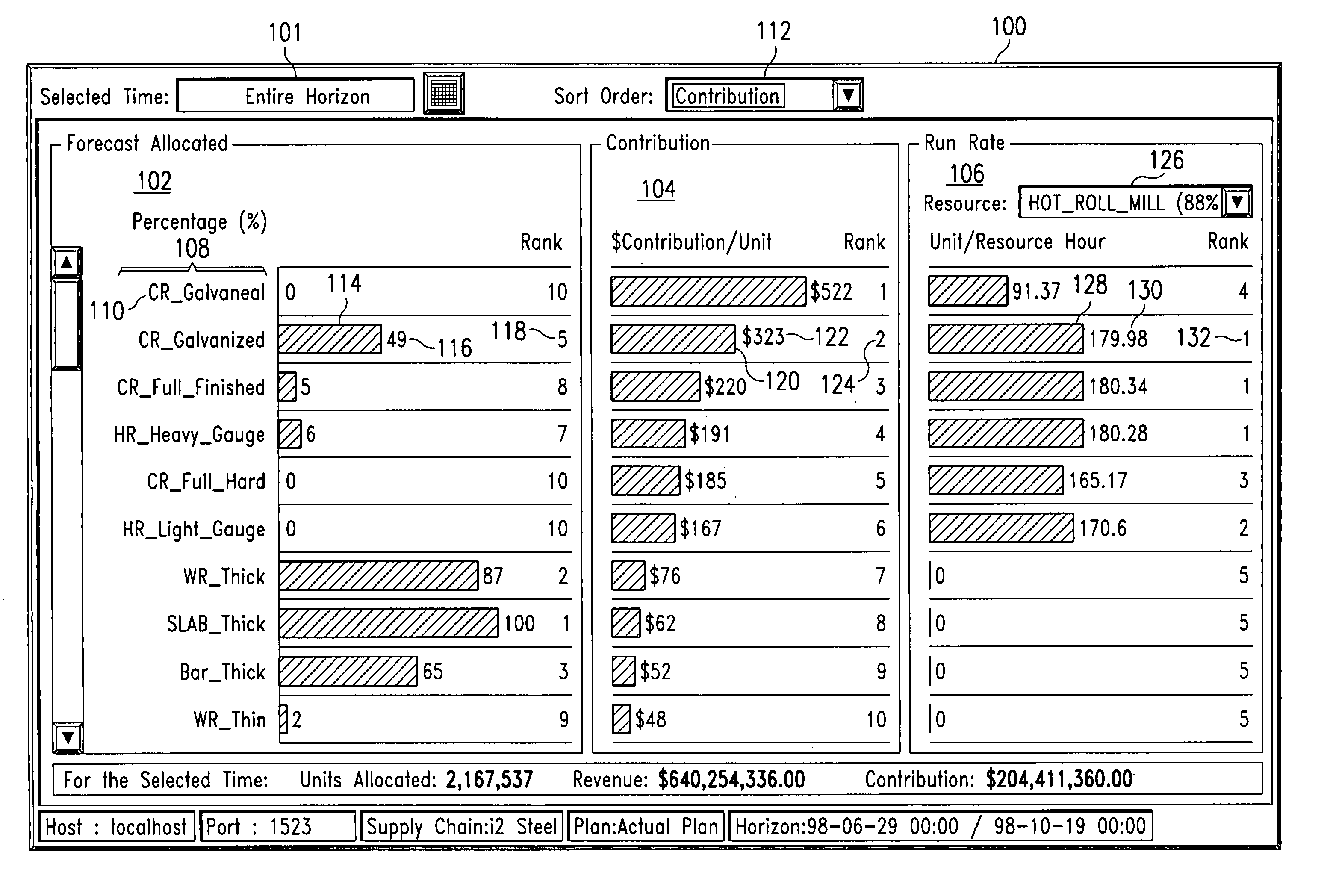

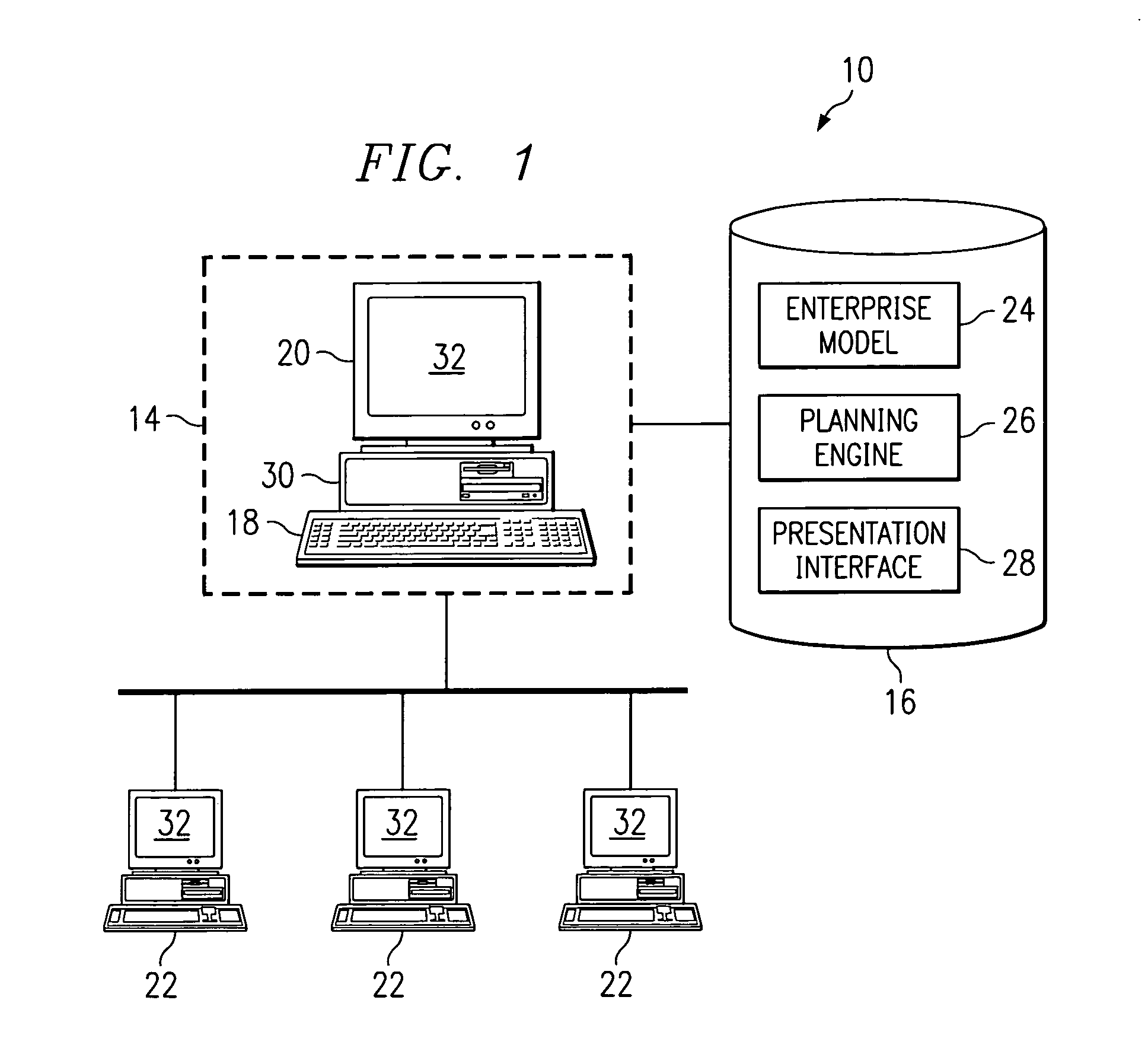

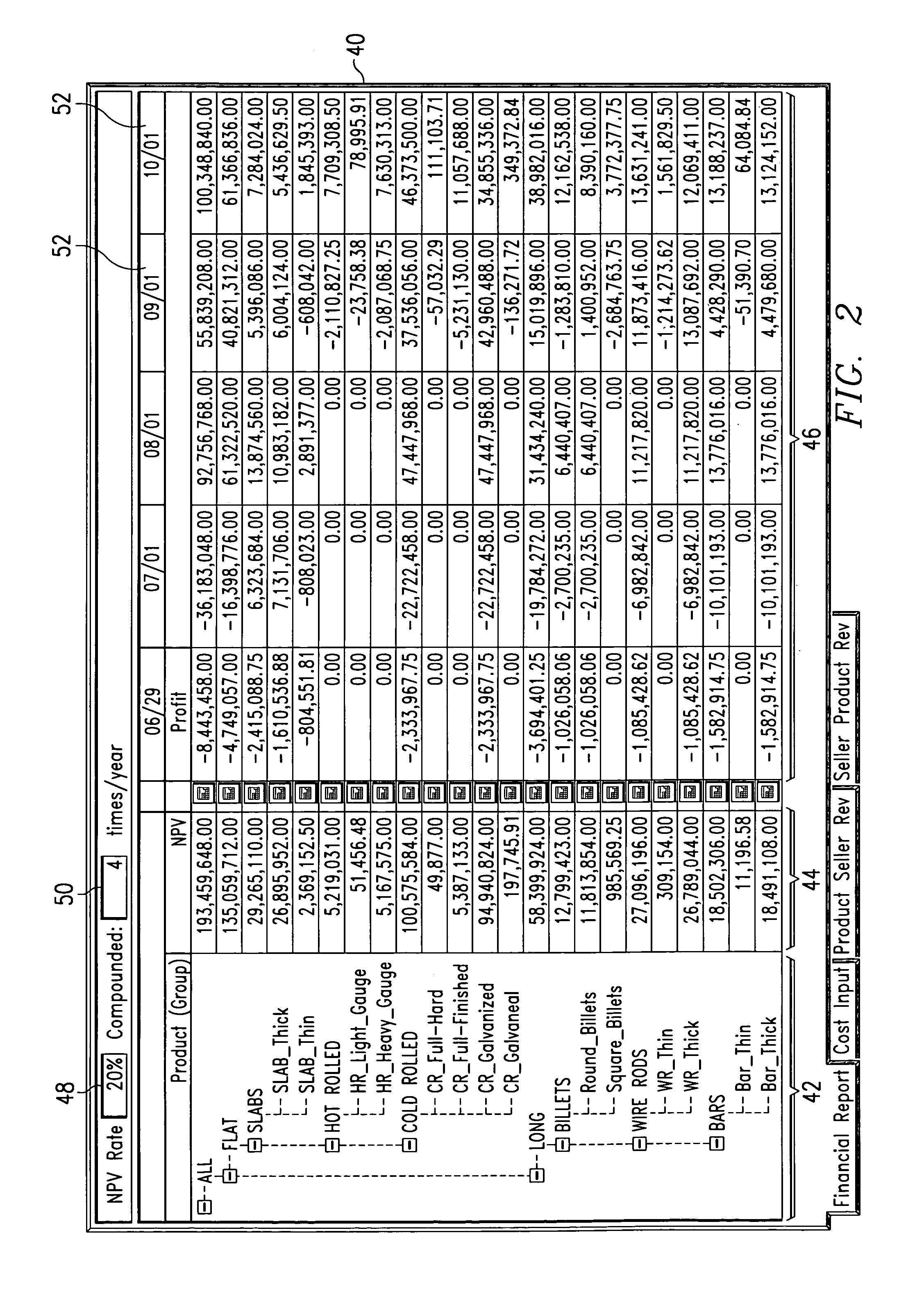

System and method for displaying planning information associated with a supply chain

InactiveUS6947905B1Reduces and eliminates disadvantageReduces and eliminates and problemFinancePayment architectureProgram planningComputer science

A system operating on at least one computer for displaying planning information associated with a supply chain includes an enterprise model, a planning engine, and a presentation interface. The enterprise model represents a supply chain that involves a plurality of products and resources. The planning engine uses the enterprise model to generate planning information for the supply chain according to one or more specified constraints and one or more optimization criteria. The presentation interface generates a first visual display for selected planning information. The first visual display includes a cashflow report providing a net present value for one or more products in the supply chain. Each net present value reflects revenues and expenses associated with a corresponding product according to time periods in which the revenues and expenses occur.

Owner:JDA SOFTWARE GROUP

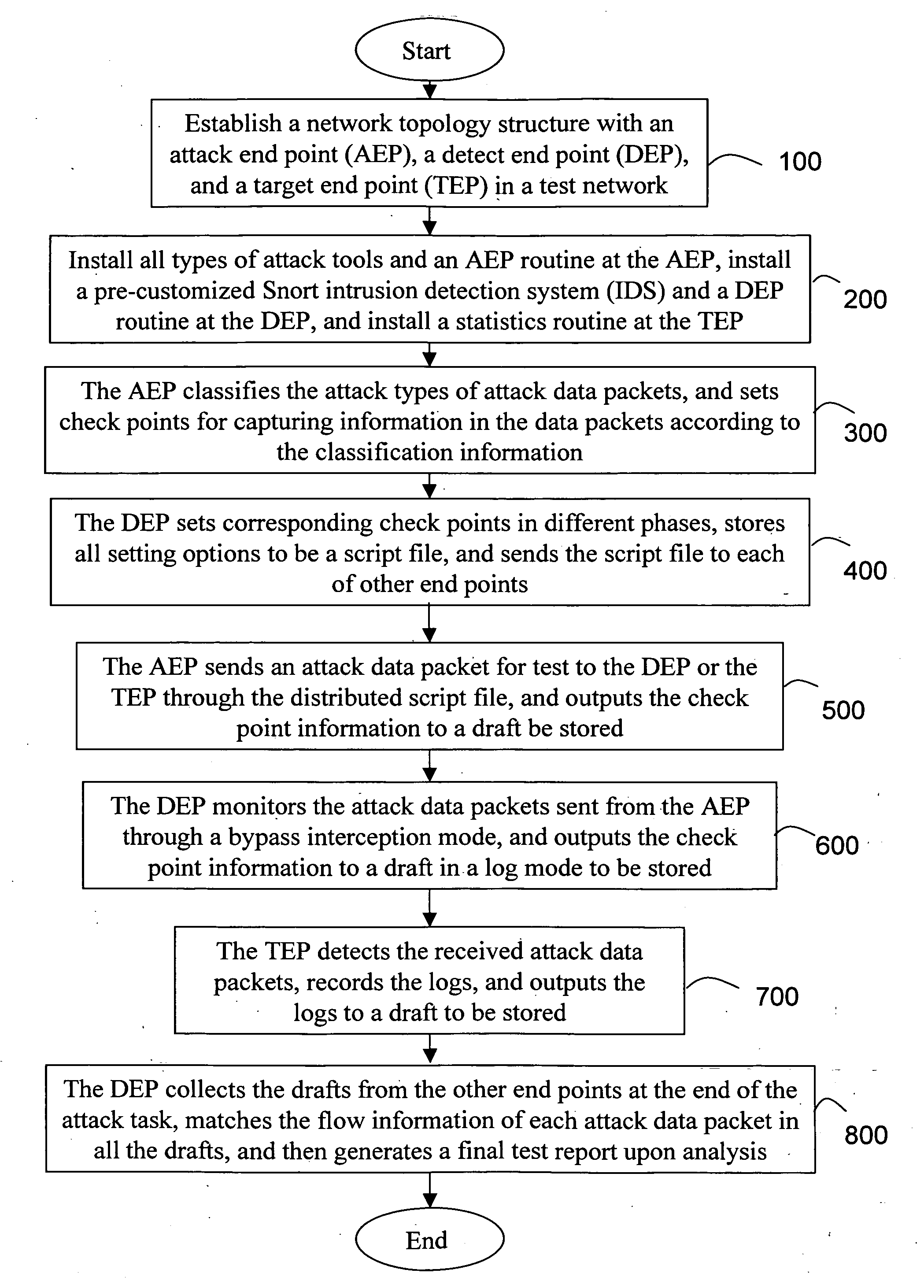

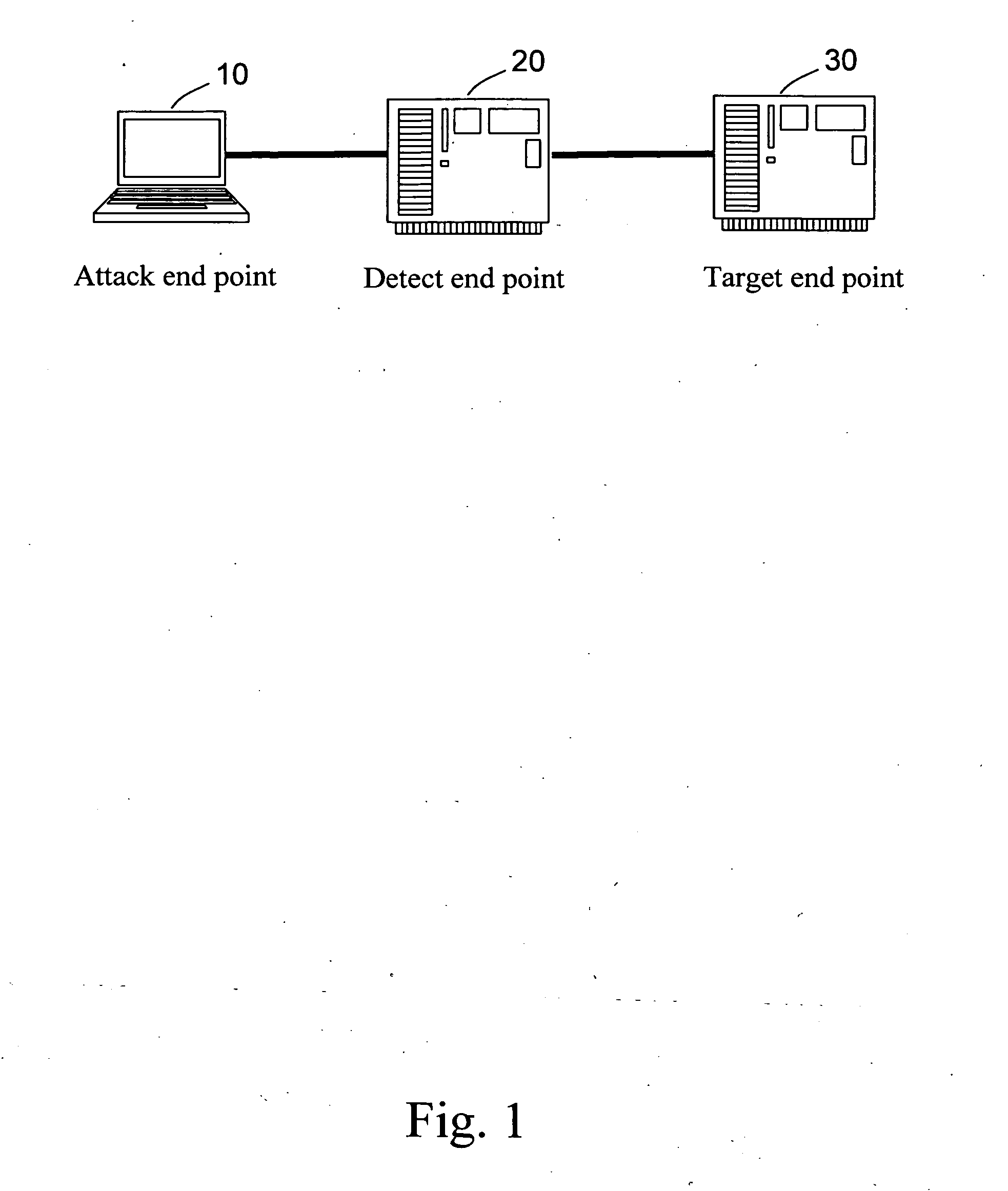

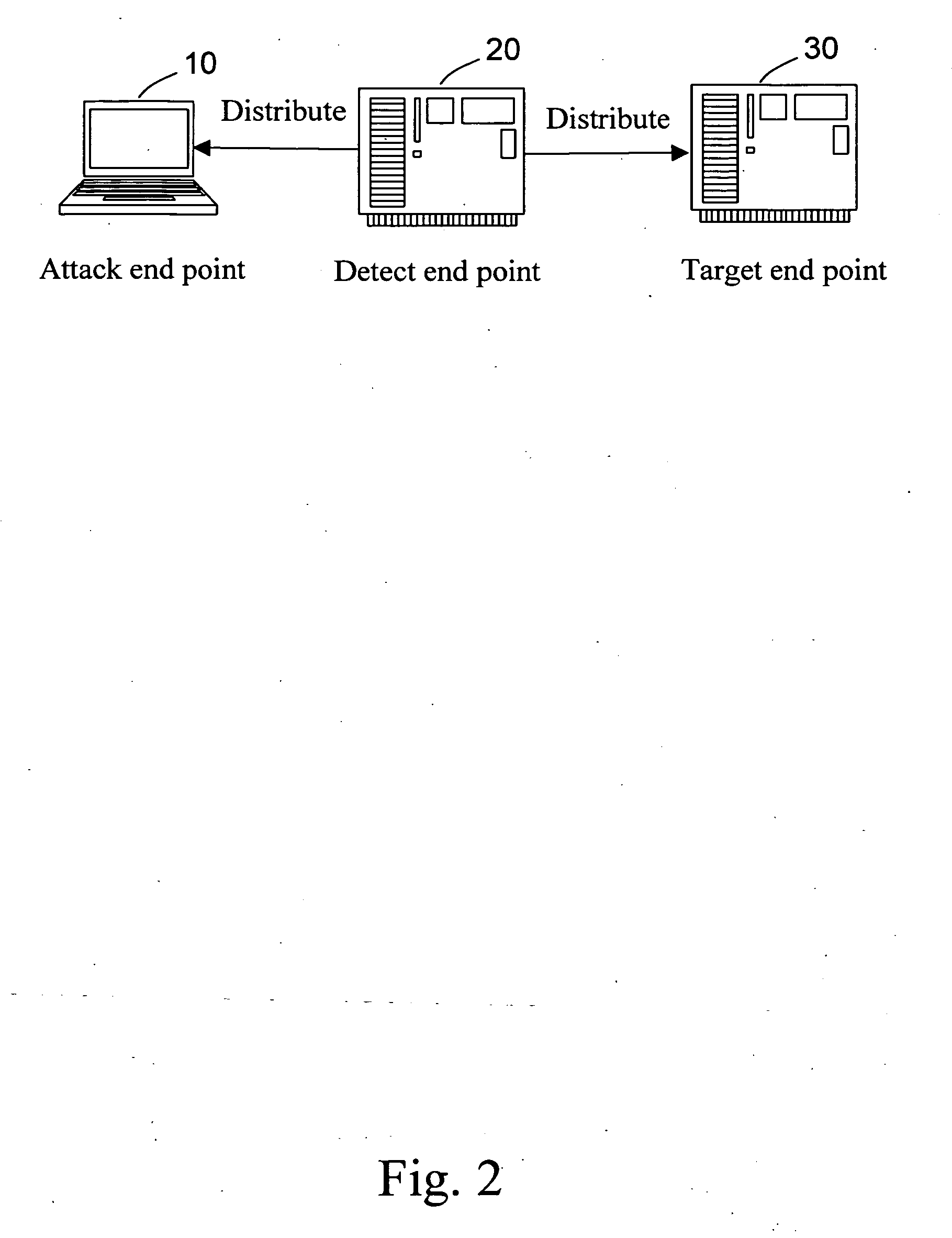

Internal tracing method for network attack detection

InactiveUS20100031093A1Efficiently understoodMemory loss protectionUnauthorized memory use protectionCheck pointThree party

An internal tracing method for network attack detection is used to trace whole life cycle of an attack data packet for test in different phases such as an attacking phase, a defending phase, and an attacked phase through configuring and uniting three parties including an attack end point (AEP), a detect end point (DEP), and a target end point (TEP) and setting a corresponding internal check point in each part when testing a network intrusion detection system (IDS). In other words, when testing the network IDS, in a whole period that the attack data packet for test is attacking, filtered, detected, and finally transmitted to a target host, a tester may clearly know the statuses and information of the data packet in each important phase, thereby generating a test report conveniently, quickly, and accurately.

Owner:INVENTEC CORP

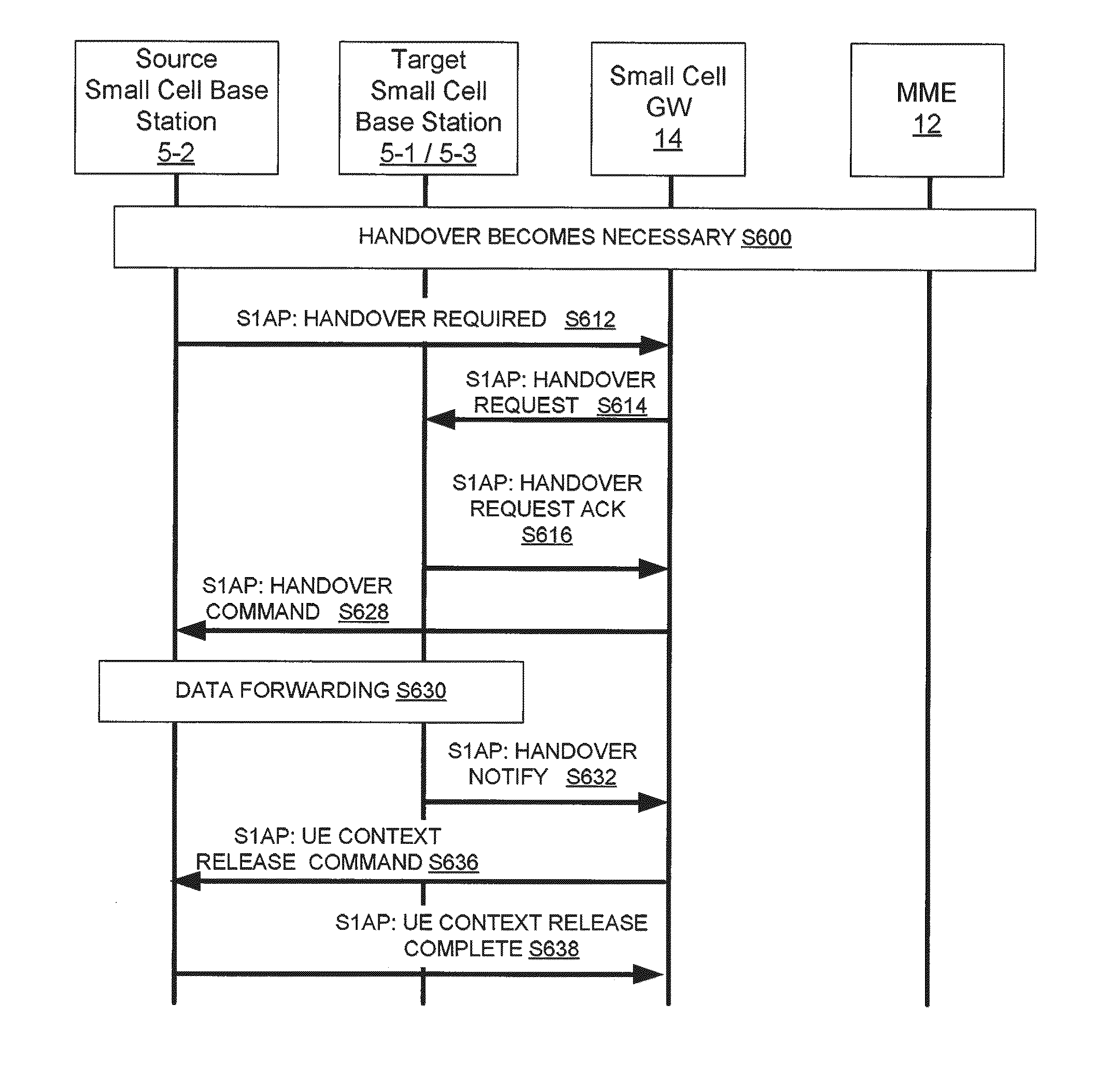

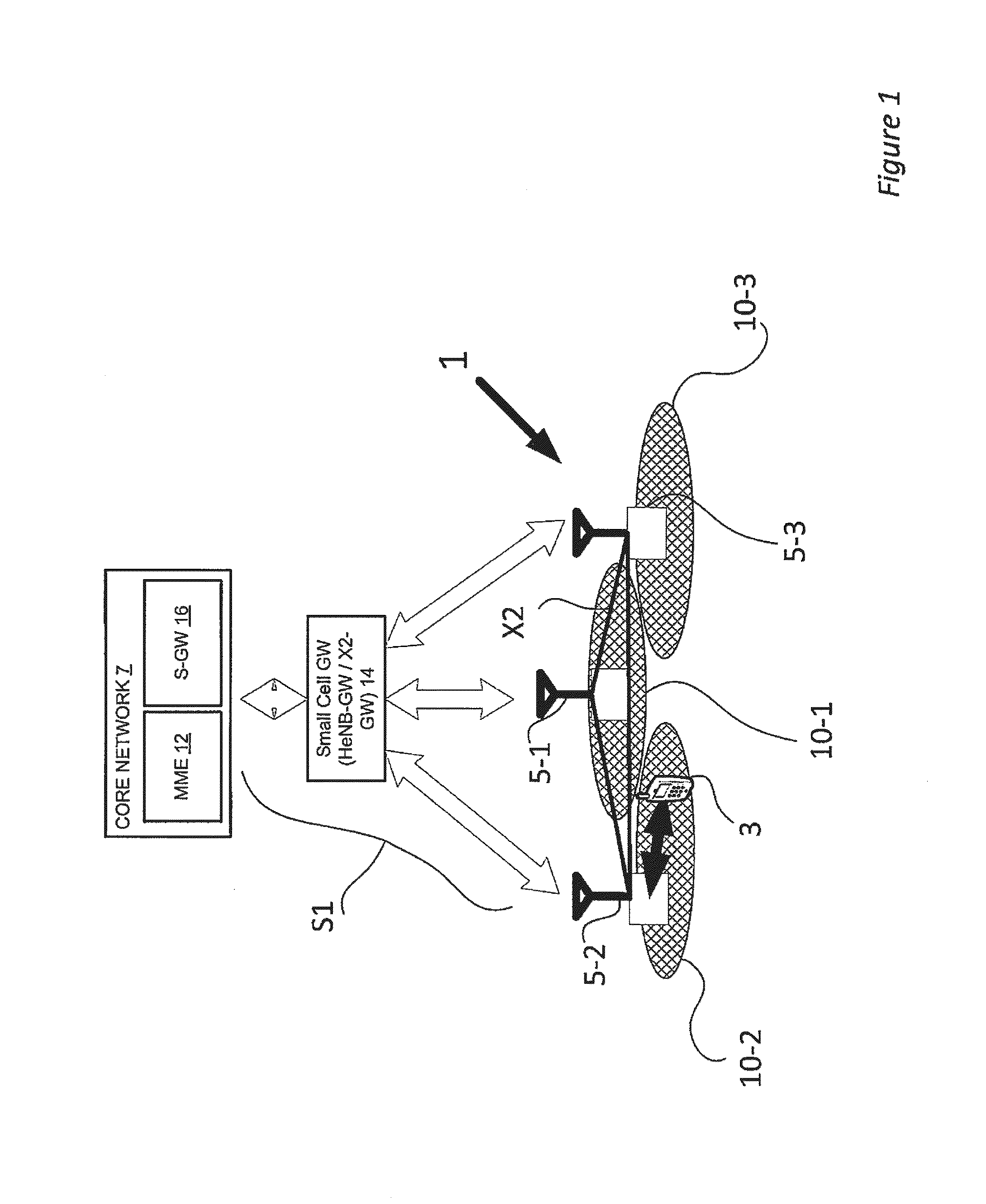

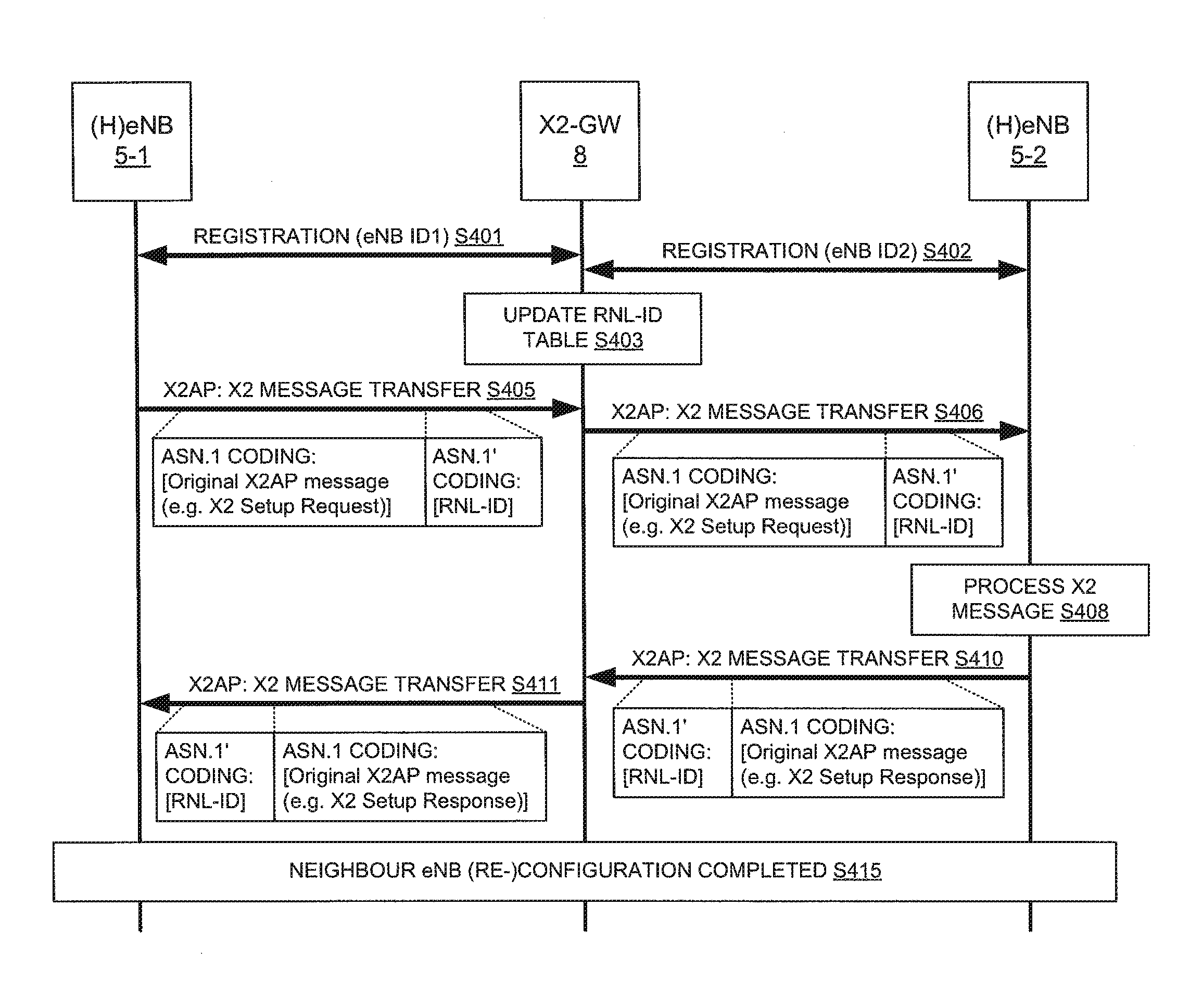

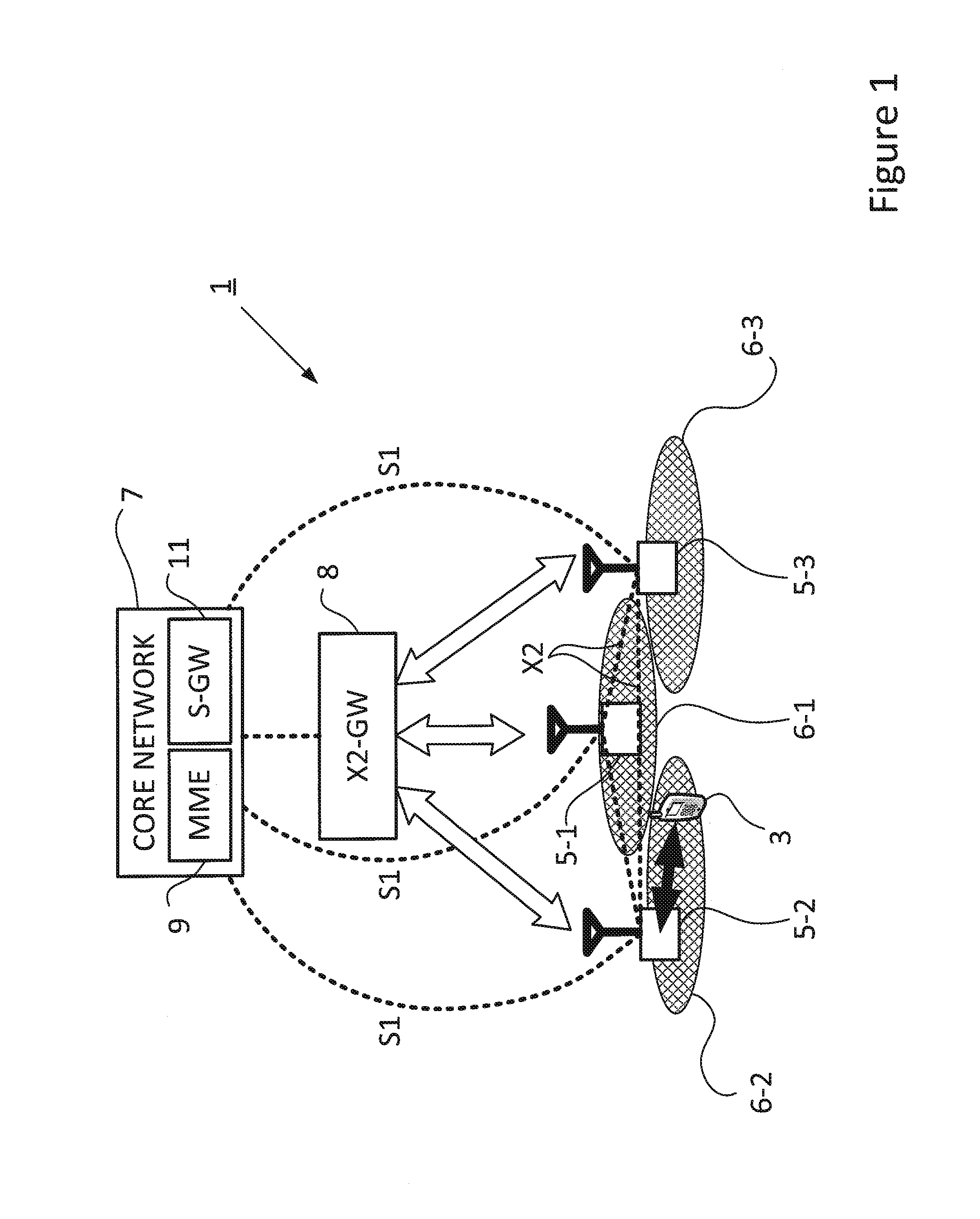

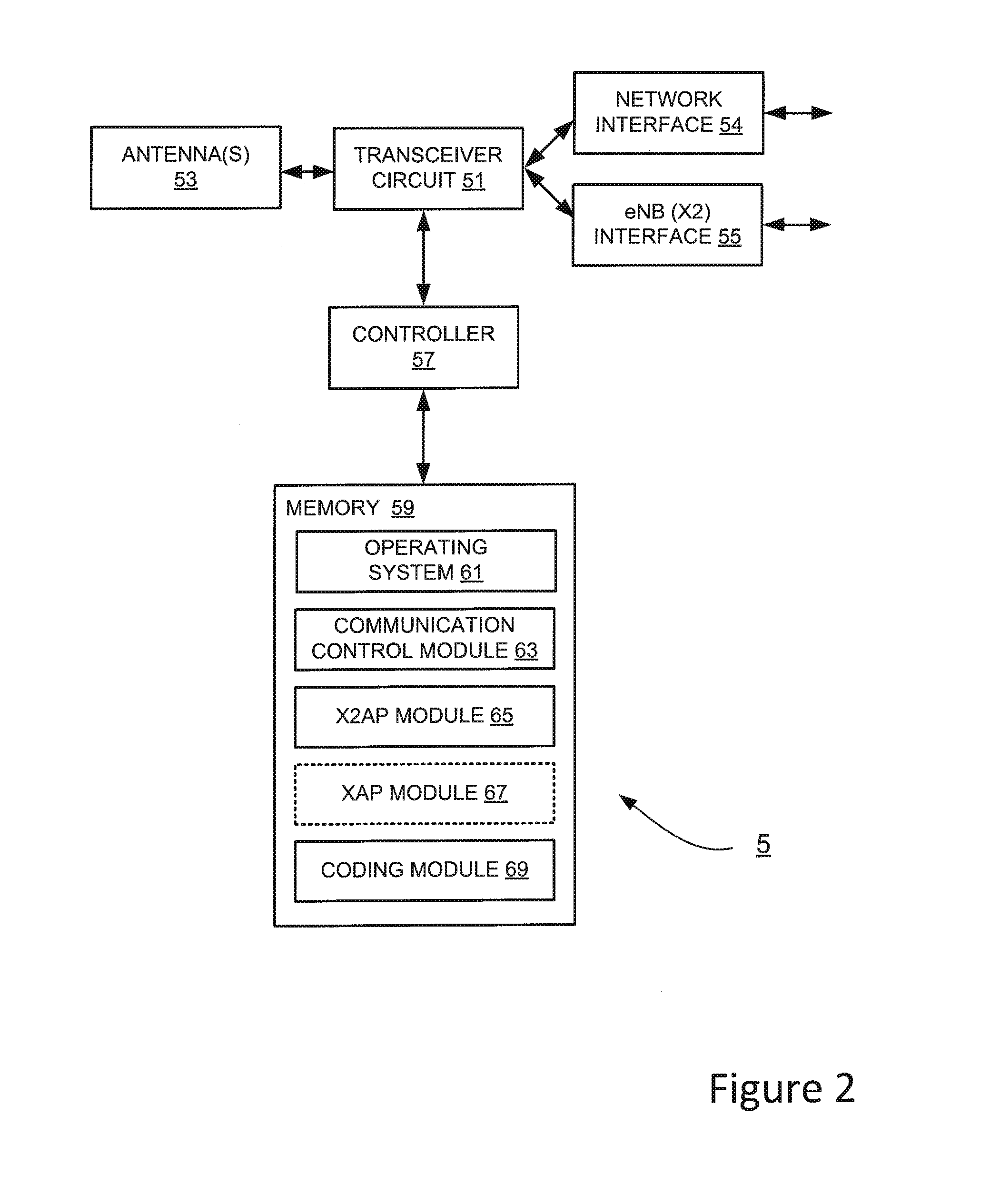

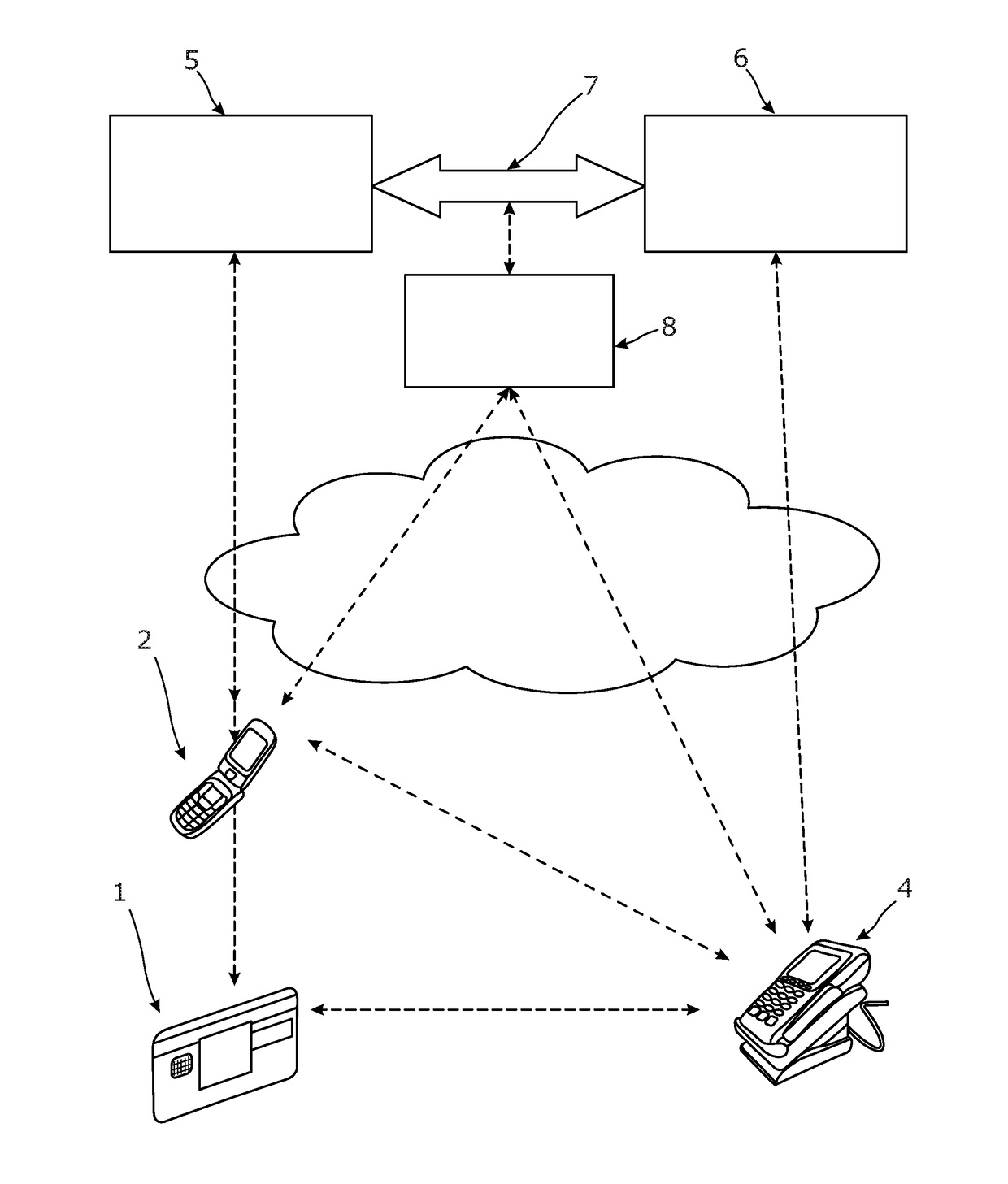

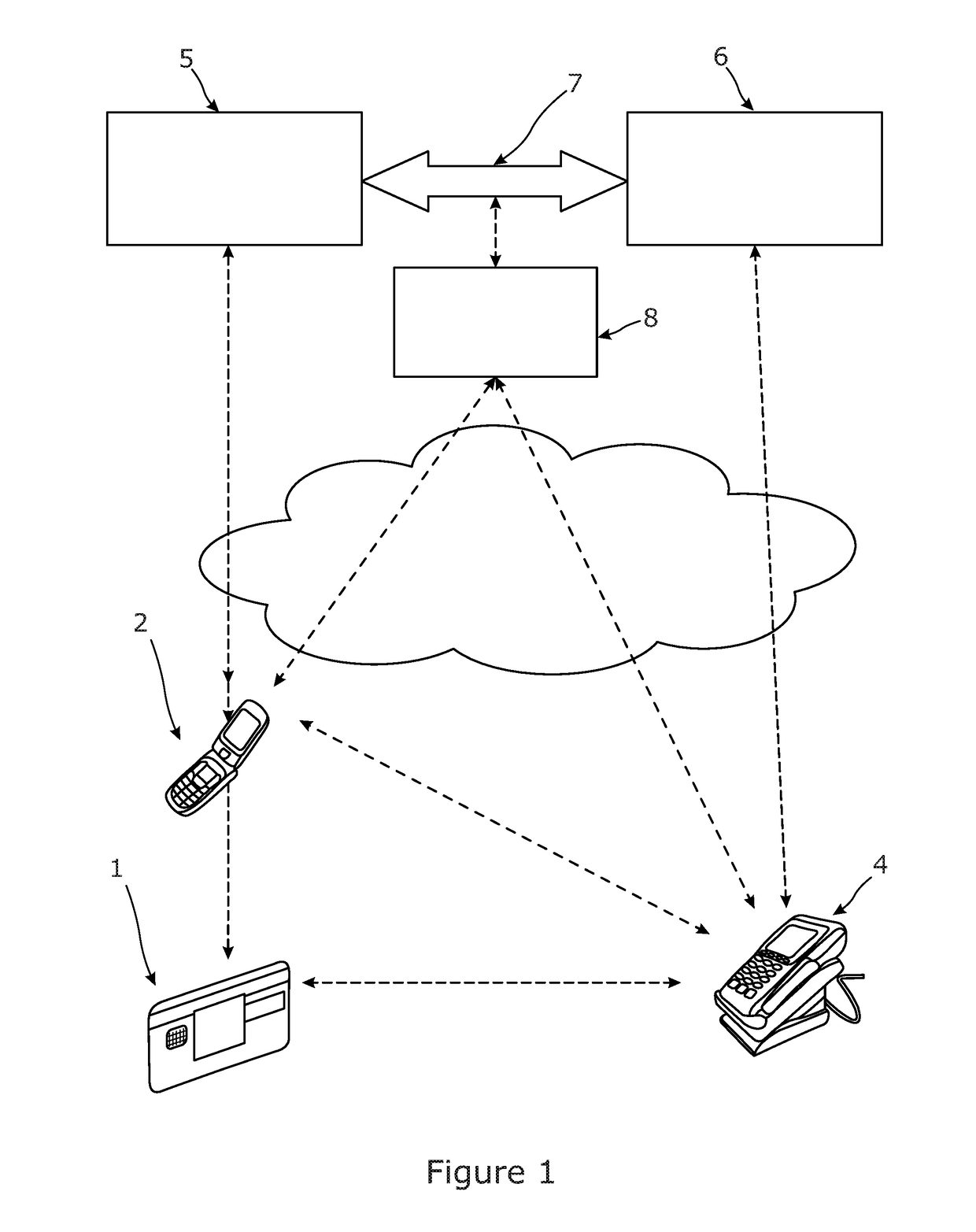

Communication system

InactiveUS20160007255A1Efficiently understoodNetwork topologiesWireless commuication servicesCommunications systemMobile device

A gateway is described which facilitates a change of communication cell for a mobile device in a communication system, which includes a core network. The gateway receives messages from a base station operating a cell and forwards the messages received from the base station to the core network. The gateway intercepts a message relating to a change of communication cell, from a source cell in which the mobile communication device is located to a target cell, to determine if the core network needs to be notified of the change of cell. When it is determined that the core network needs to be notified, the gateway generates a message for providing information relating to the change of cell to the core network and transmits the message to the core network.

Owner:NEC CORP

Medical device with contextual awareness

ActiveUS8945043B2Efficiently understoodReduce deliveryDrug and medicationsMedical devicesElectronic medical recordComputer science

A medical device, such as an infusion pump, obtains a contextual awareness of its operation by communicating with centralized patient records and or other medical equipment communicating with a common patient, and / or provides real time advisory information, at care point or remotely. A protocol obtained by the medical device from a protocol server provides context-aware protocols and necessary predicate information for those protocols. This predicate information may be discovered by the medical device communicating with electronic medical records and the associated medical equipment.

Owner:ZYNO MEDICAL

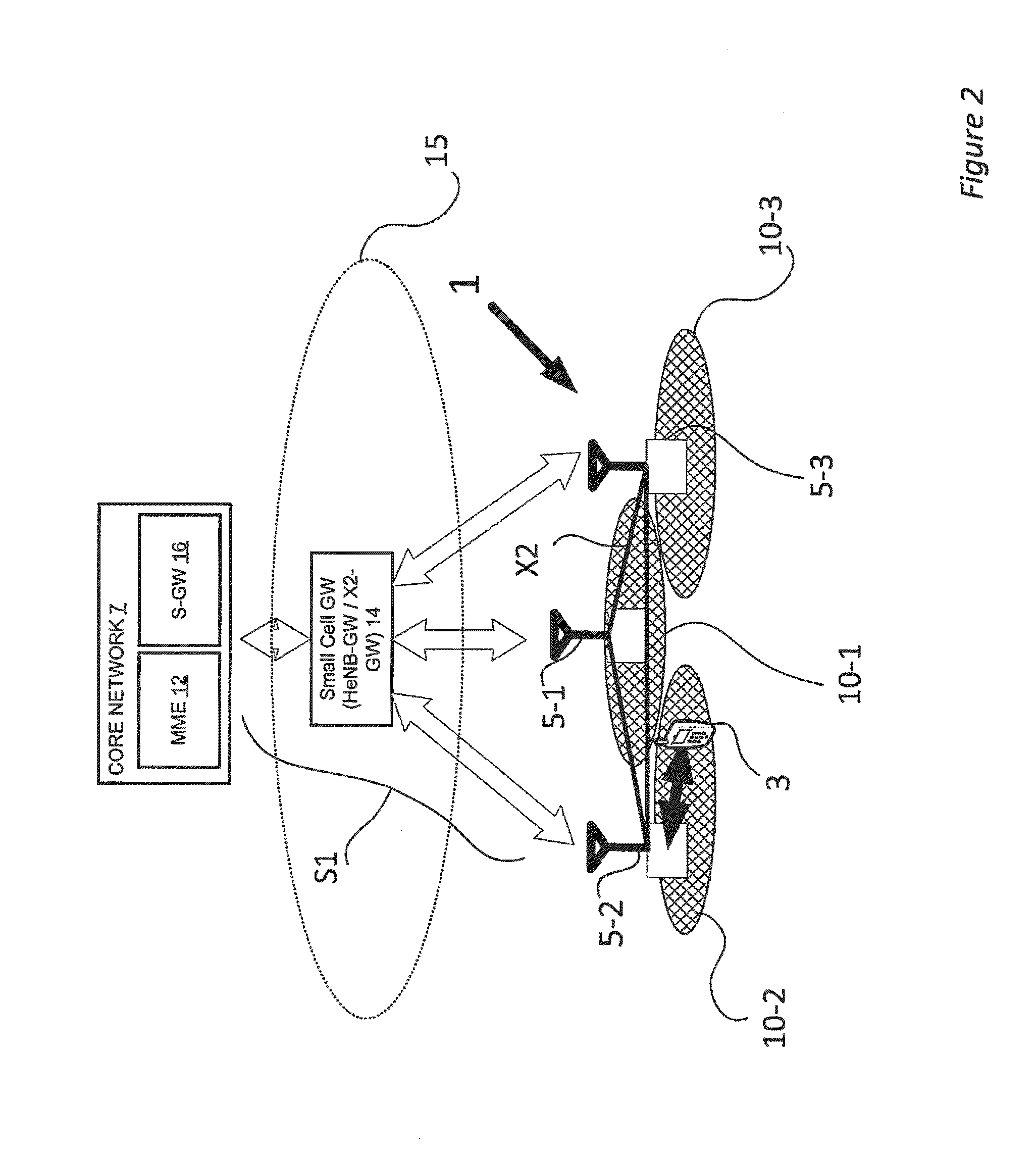

Communication system

ActiveUS20160227449A1Efficiently understoodFacilitate information exchangeNetwork topologiesCommunications systemComputer science

A communication system is disclosed comprising a gateway and a number of base stations communicating, via the gateway, in accordance with a base station to base station application protocol. The gateway receives a message from a first base station, destined for a second base station. The message comprises (a) information for the second base station, in a first part of the message; and (b) an identifier of the second base station, in a second part of the message other than the first part. The gateway can obtain from the received message the second base station's identifier without the gateway being required to obtain the information from the first part of the message. The gateway routes the message to the second base station identified by the obtained identifier.

Owner:NEC CORP

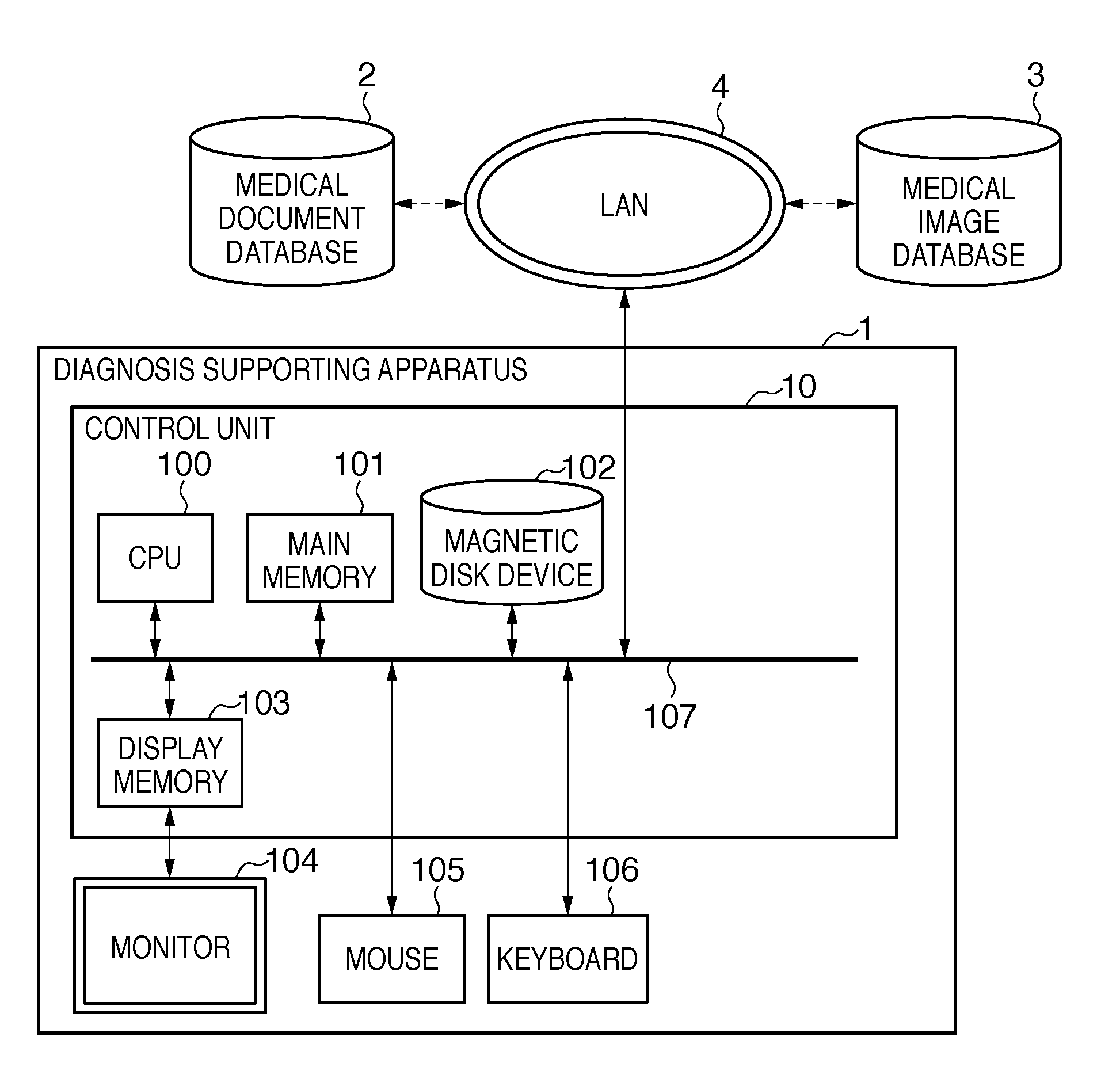

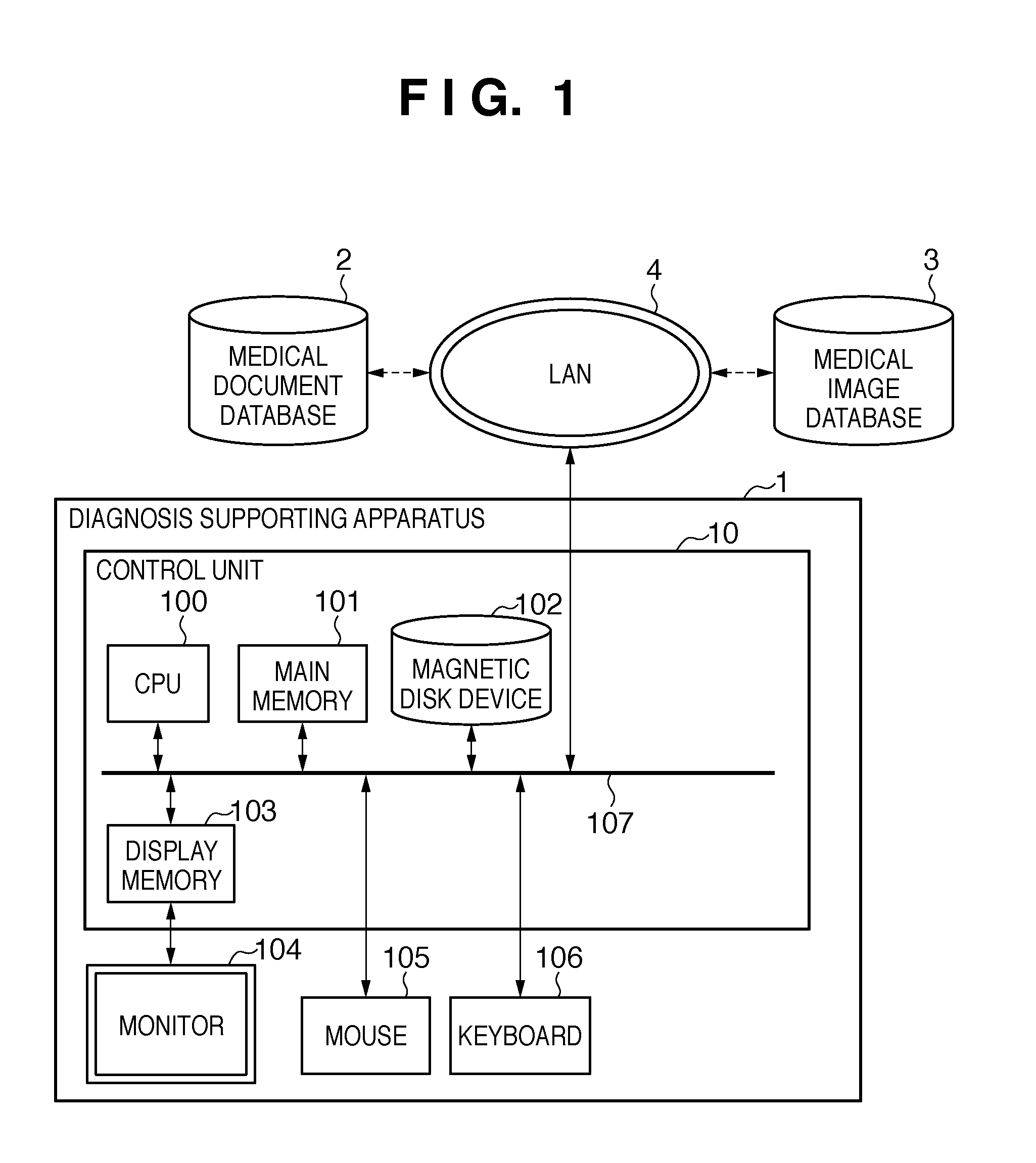

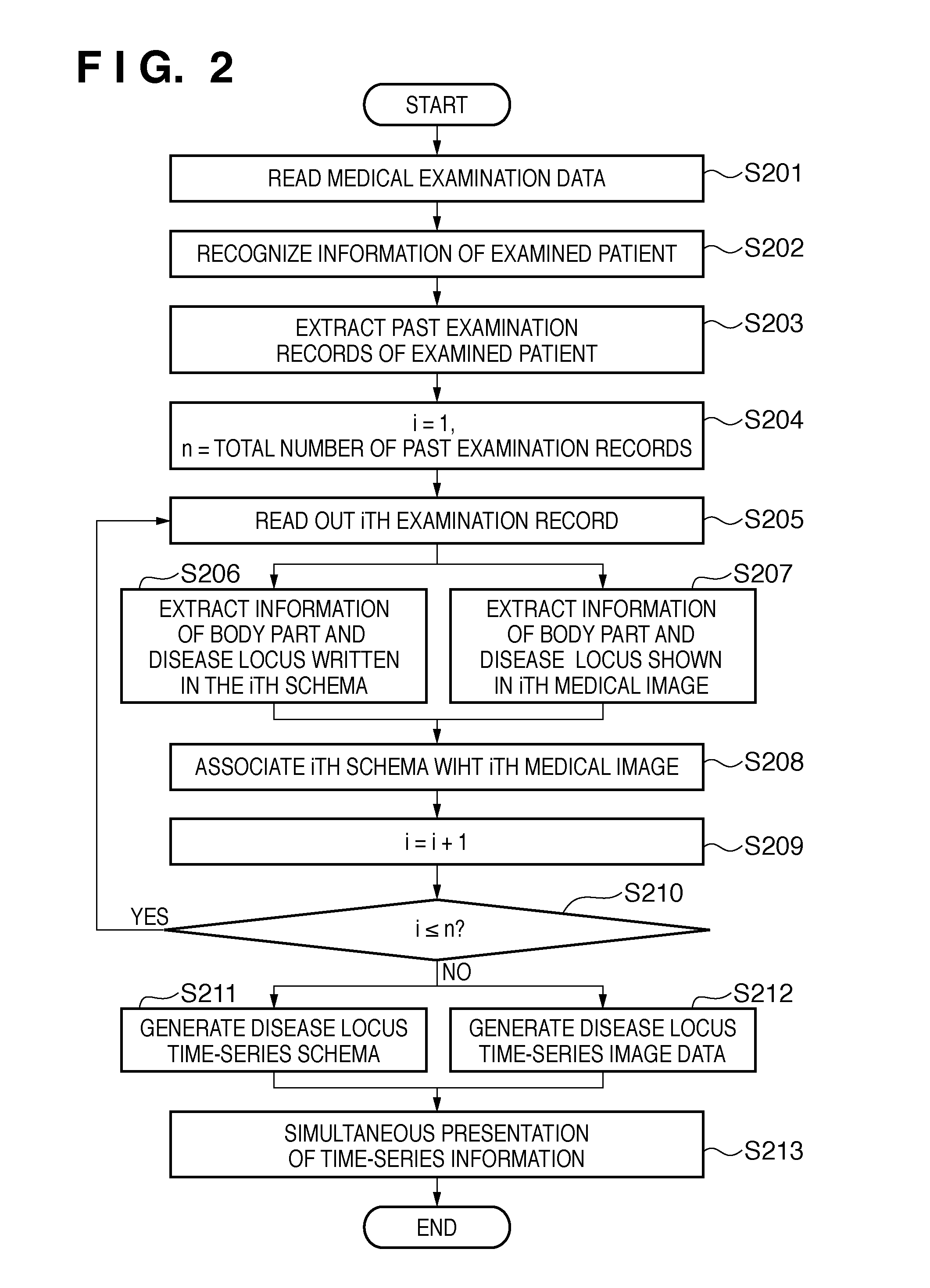

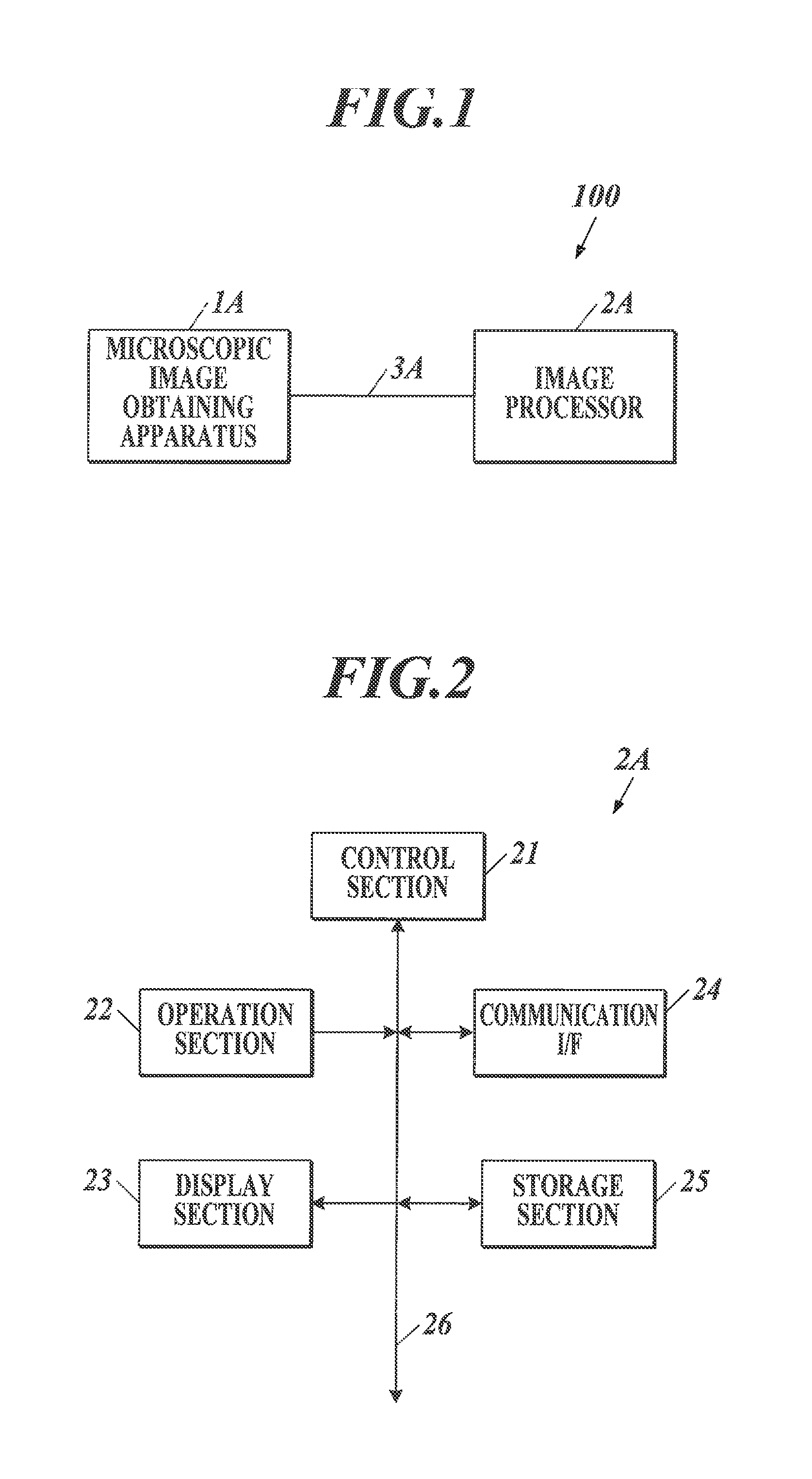

Information processing apparatus and its control method and data processing system

InactiveUS20100082699A1Efficiently understoodImage analysisDigital data processing detailsDiseaseInformation processing

In order to provide a technology which allows efficient understanding of images of a disease locus and diagnosis supporting information for the images, an information processing apparatus comprises: an input unit which inputs object identification information for identifying an object; an acquiring unit which acquires one or more schemas related to the object and medical image data related to the schema, an identification unit which identifies a disease locus region in medical image data respectively related to each of the one or more schemas, a time-series schema generating unit which generates a time-series schema of the disease locus, a time-series image data generating unit which generates time-series image data of the disease locus, and a display output unit which synchronizes and outputs the time-series schema of the disease locus and the time-series image data of the disease locus.

Owner:CANON KK

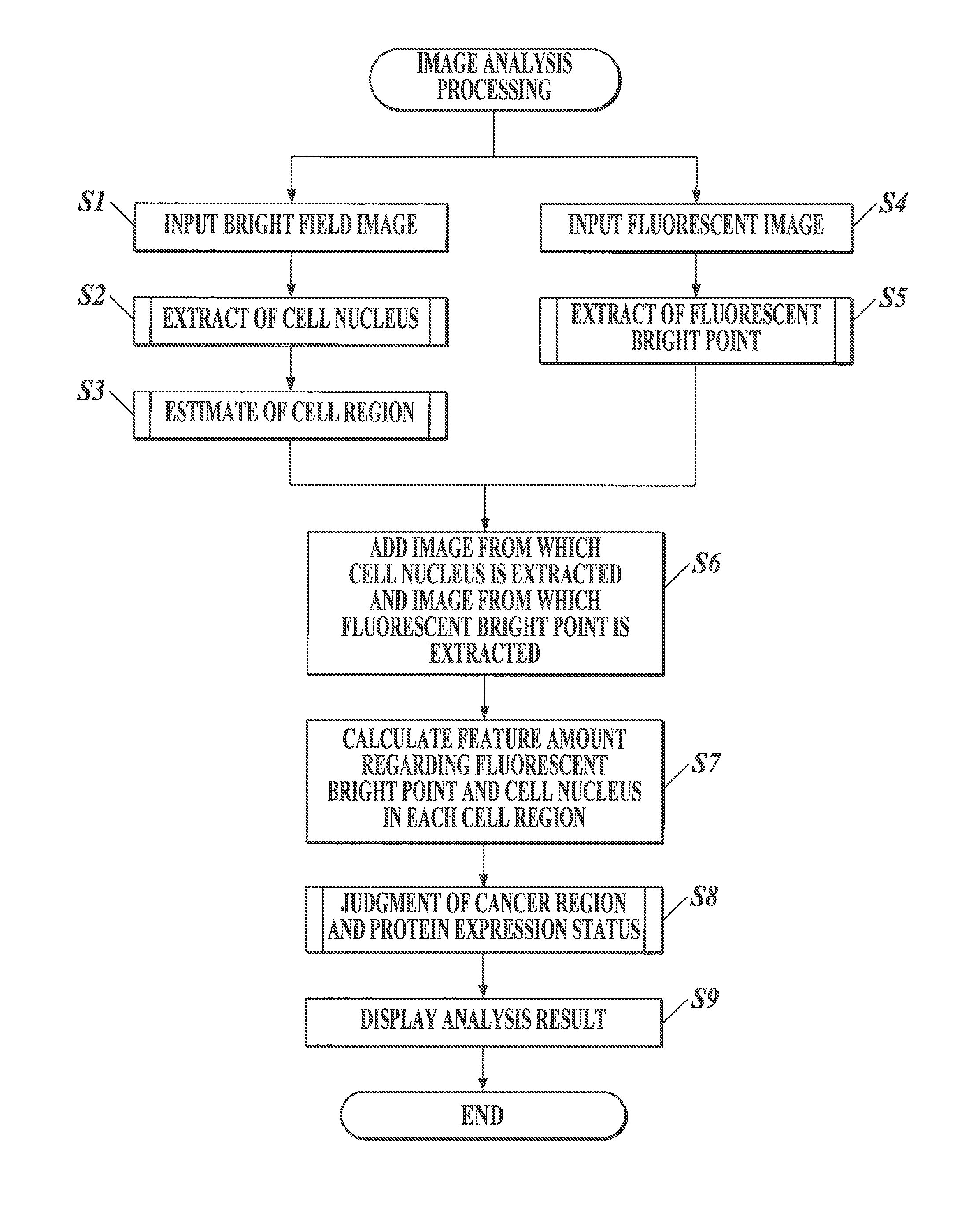

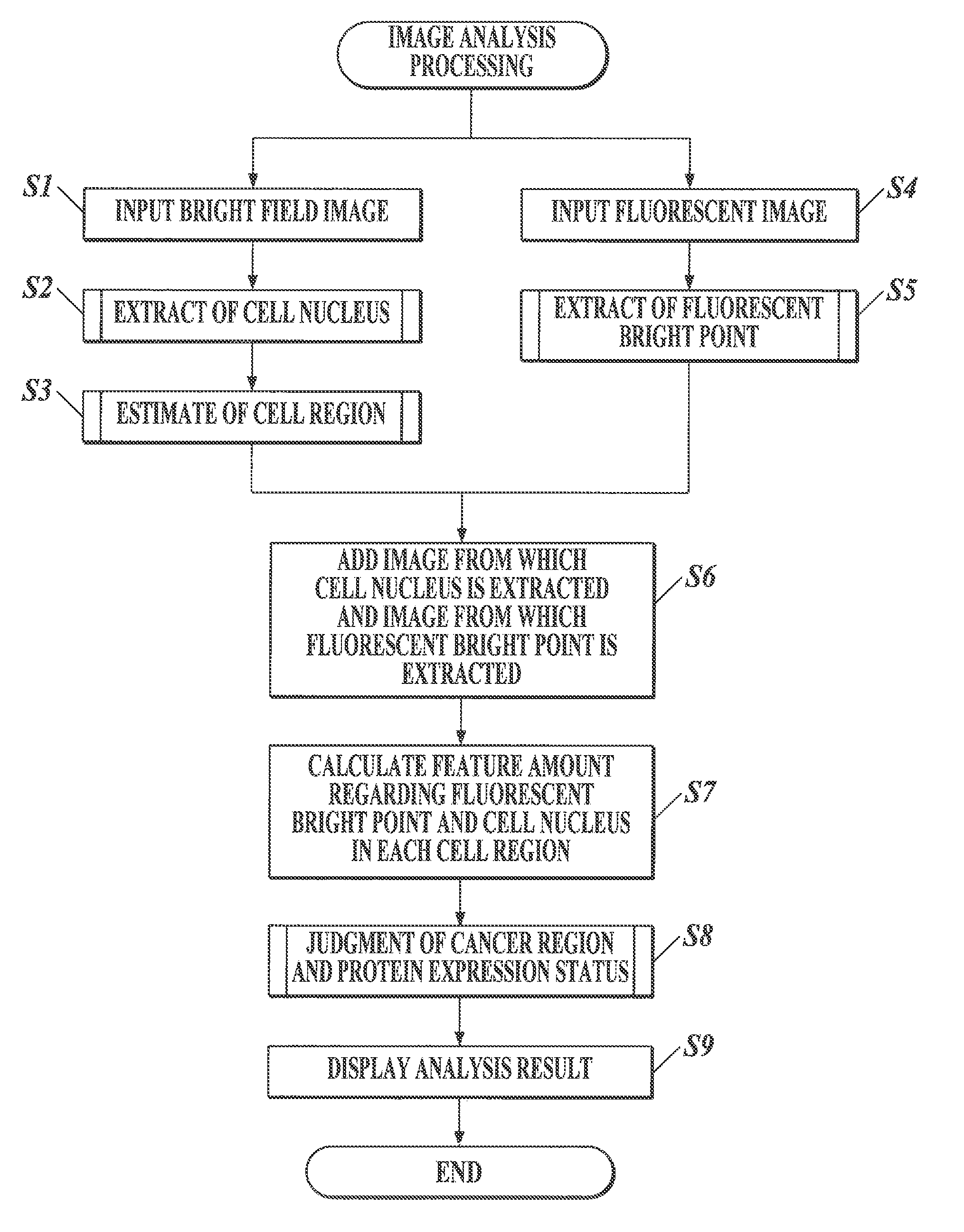

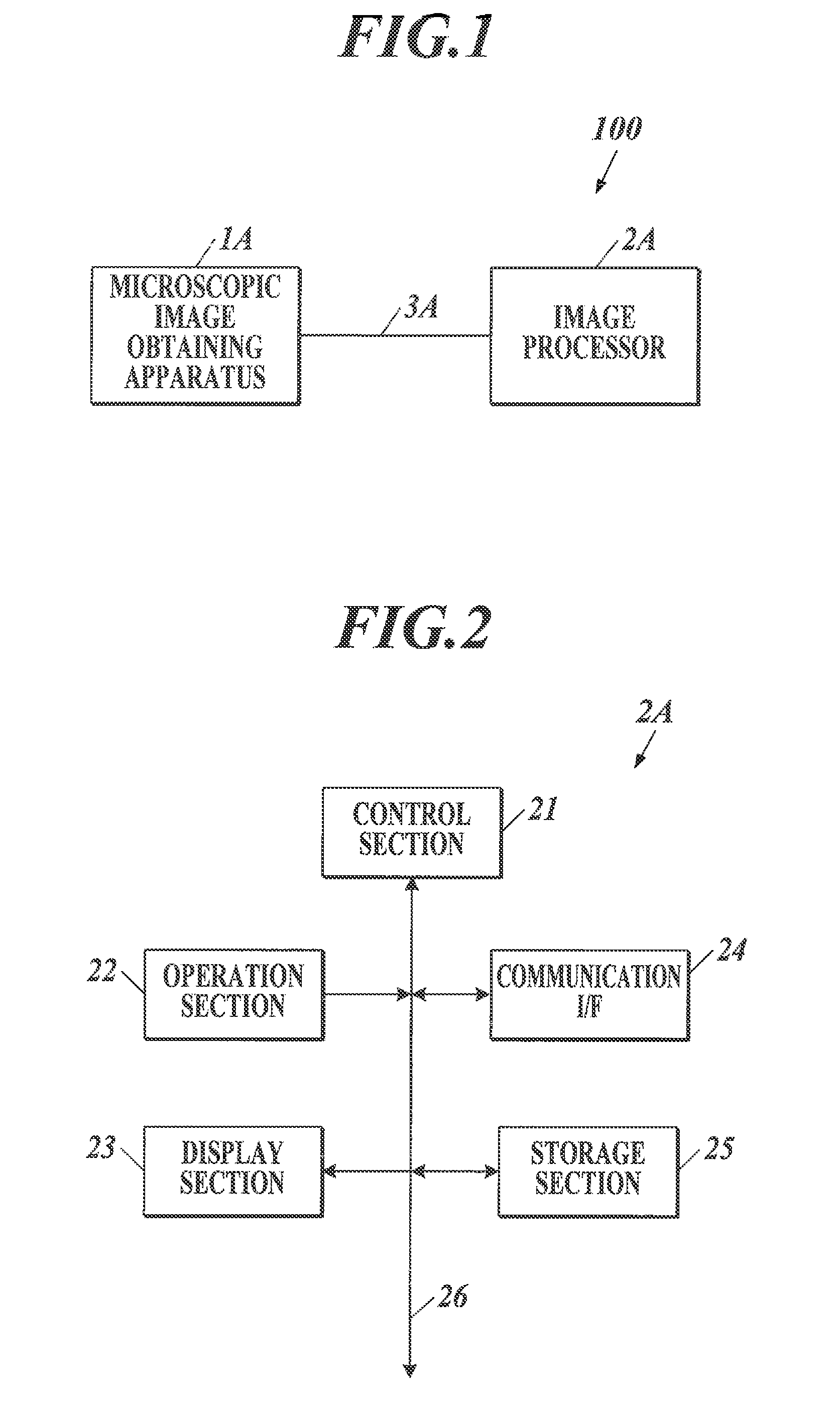

Medical image processor and storage medium

ActiveUS20150086103A1Efficiently understoodImage enhancementImage analysisPattern recognitionCell region

A medical image processor and a storage medium are shown. According to one implementation, the medical image processor includes the following. An input unit is used to input a cell shape image and a fluorescent image showing expression of a specific protein. A cell nucleus extracting unit extracts a cell nucleus. A fluorescent bright point extracting unit extracts a fluorescent bright point. A region estimating unit sets a predetermined region. When the set region does not overlap with another, it is estimated to include one cell. When a plurality of the set regions overlap, it is estimated to include a plurality of cells. A feature amount calculating unit calculates a feature amount. A determining unit determines whether each estimated cell region is cancer and determines an expression status in the region based on the calculated feature amount. An output unit outputs a determination result.

Owner:KONICA MINOLTA INC

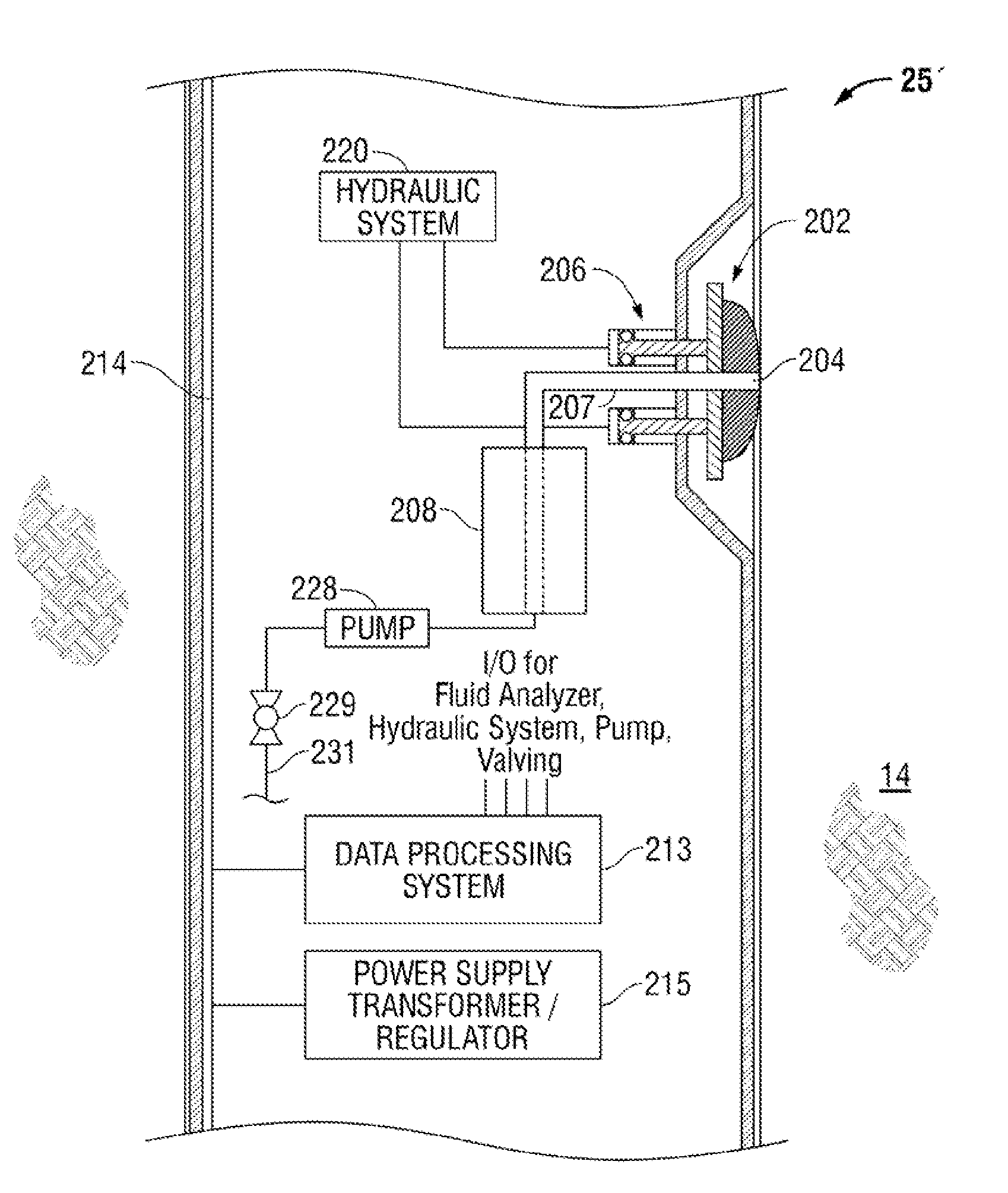

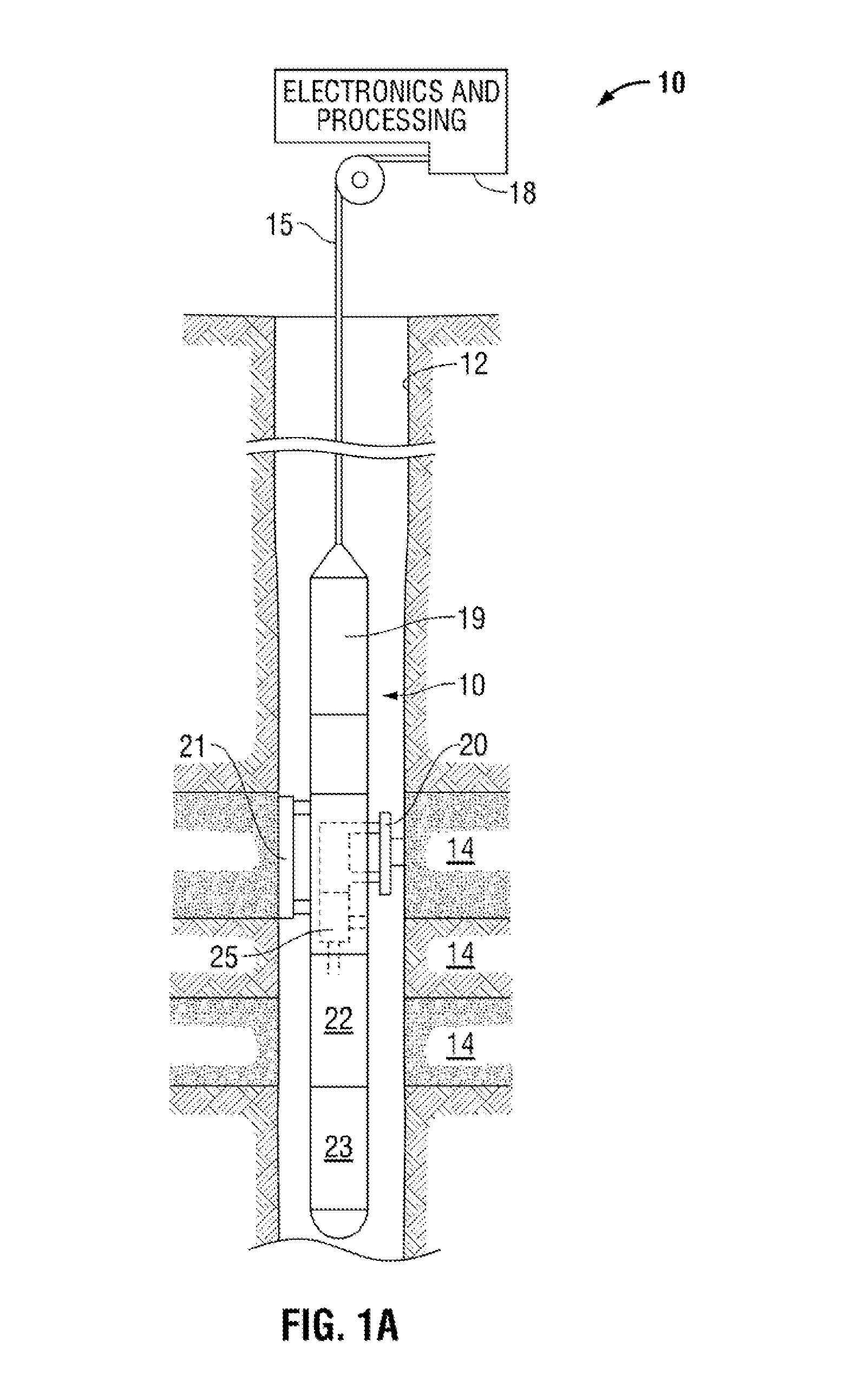

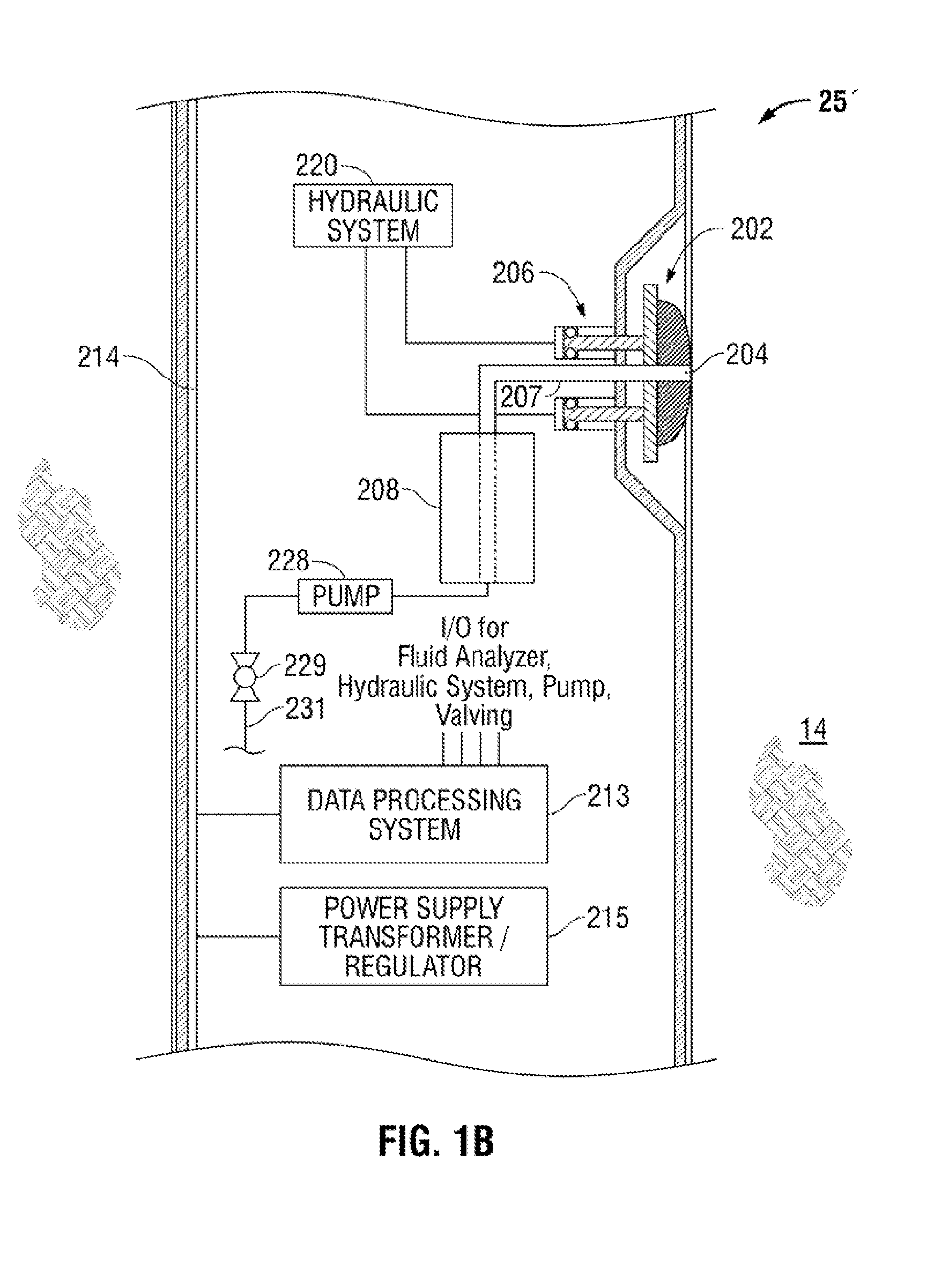

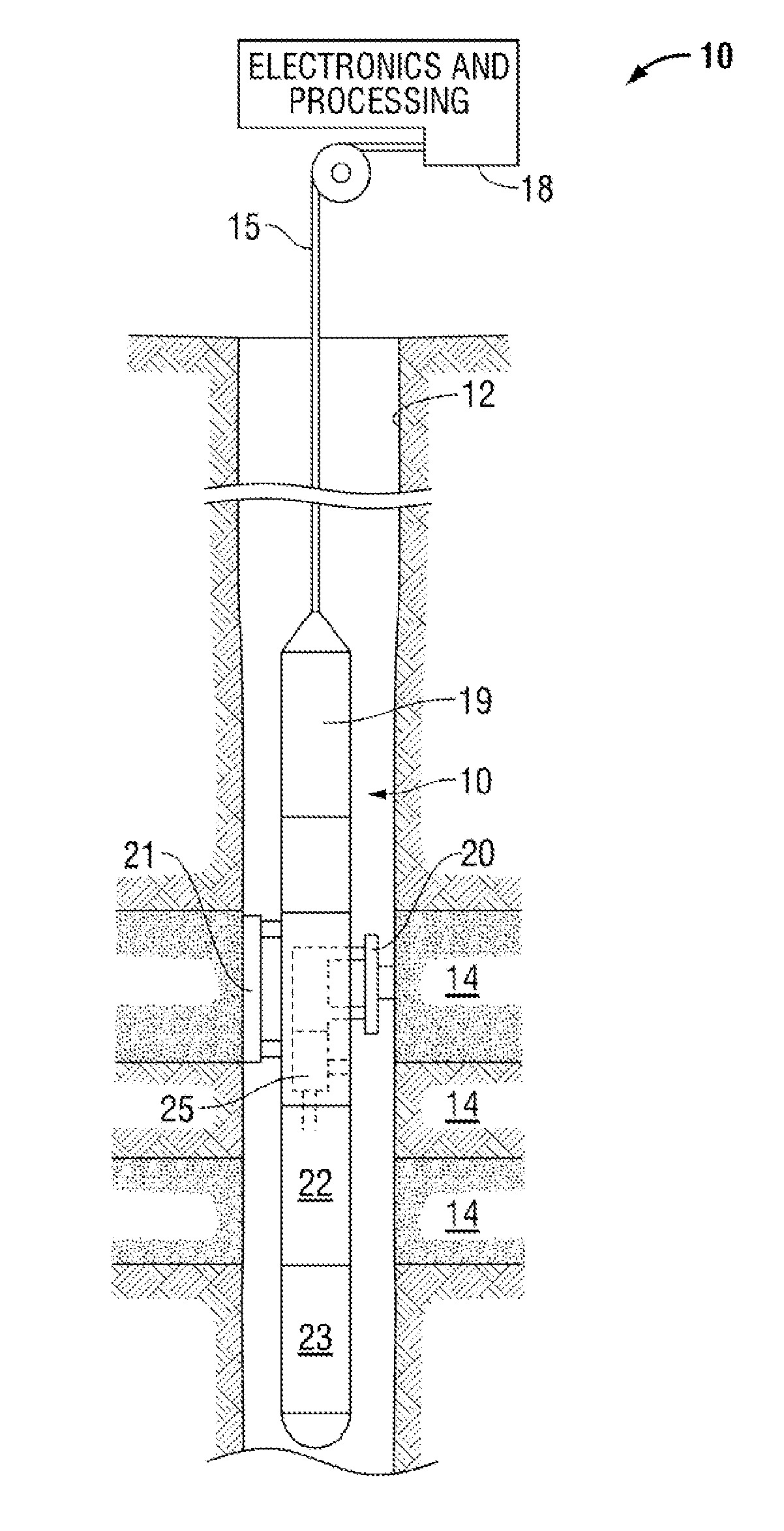

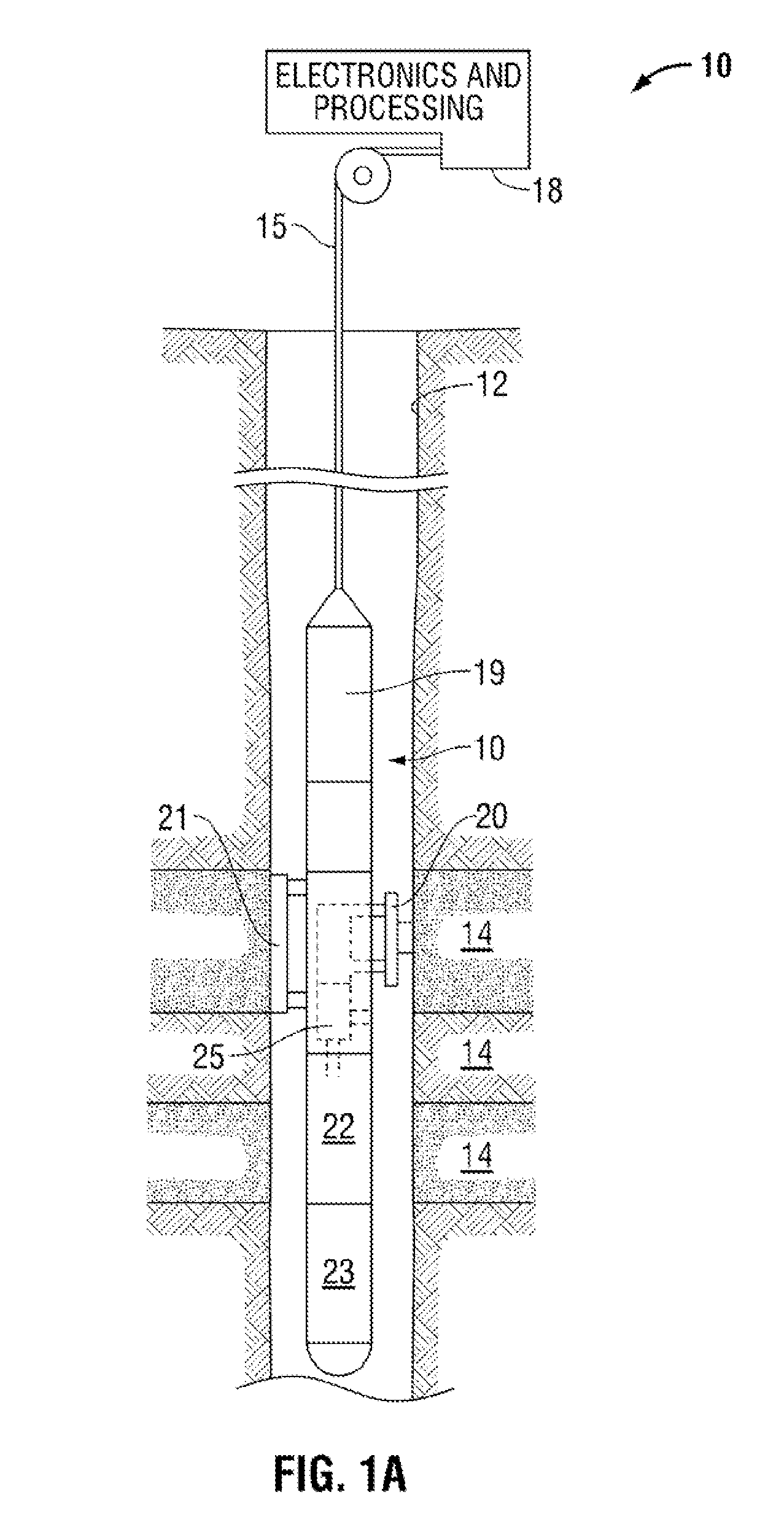

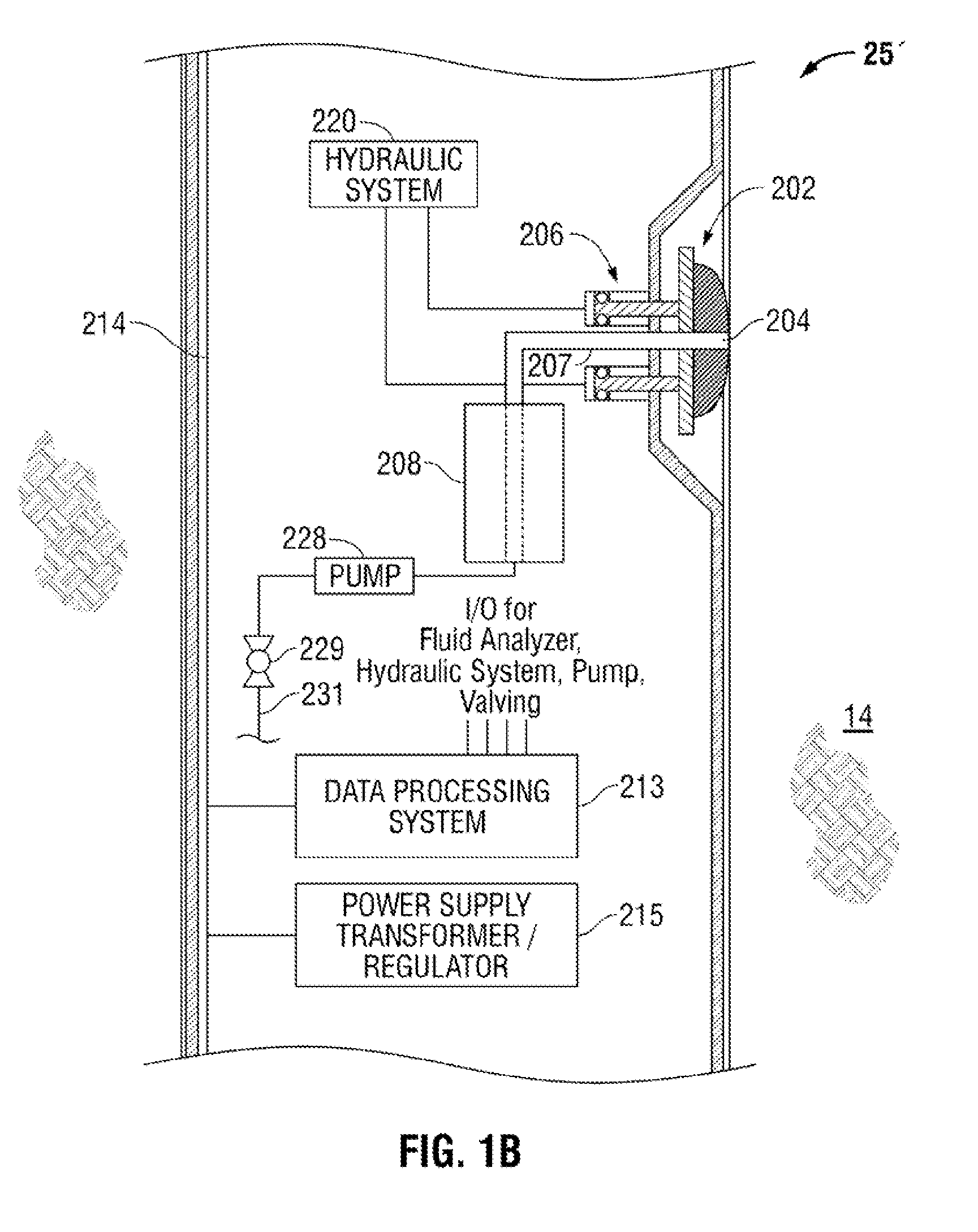

Methods For Reservoir Evaluation Employing Non-Equilibrium Compositional Gradients

ActiveUS20140200810A1Efficiently understoodElectric/magnetic detection for well-loggingConstructionsCarbon dioxideEngineering

A method for determining reservoir architecture using modeling of a non-equilibrium distribution of at least one analyte in reservoir fluids. The analyte(s) of the analysis preferably has (have) significant compositional variation in the reservoir. For example, the analyte can be a later charging single gas component (such as methane, carbon dioxide, or hydrogen sulfide) in a multi-component fluid system. In this case, the model can assume that the components of the early charge are in a stationary state or in equilibrium, whereas the later charge is in a state of non-equilibrium. The non-equilibrium distribution of the analyte(s) derived from the model is compared to the distribution of the analyte(s) derived from downhole or laboratory fluid analysis of reservoir fluid, and the architecture of the reservoir is determined based upon such comparison.

Owner:SCHLUMBERGER TECH CORP

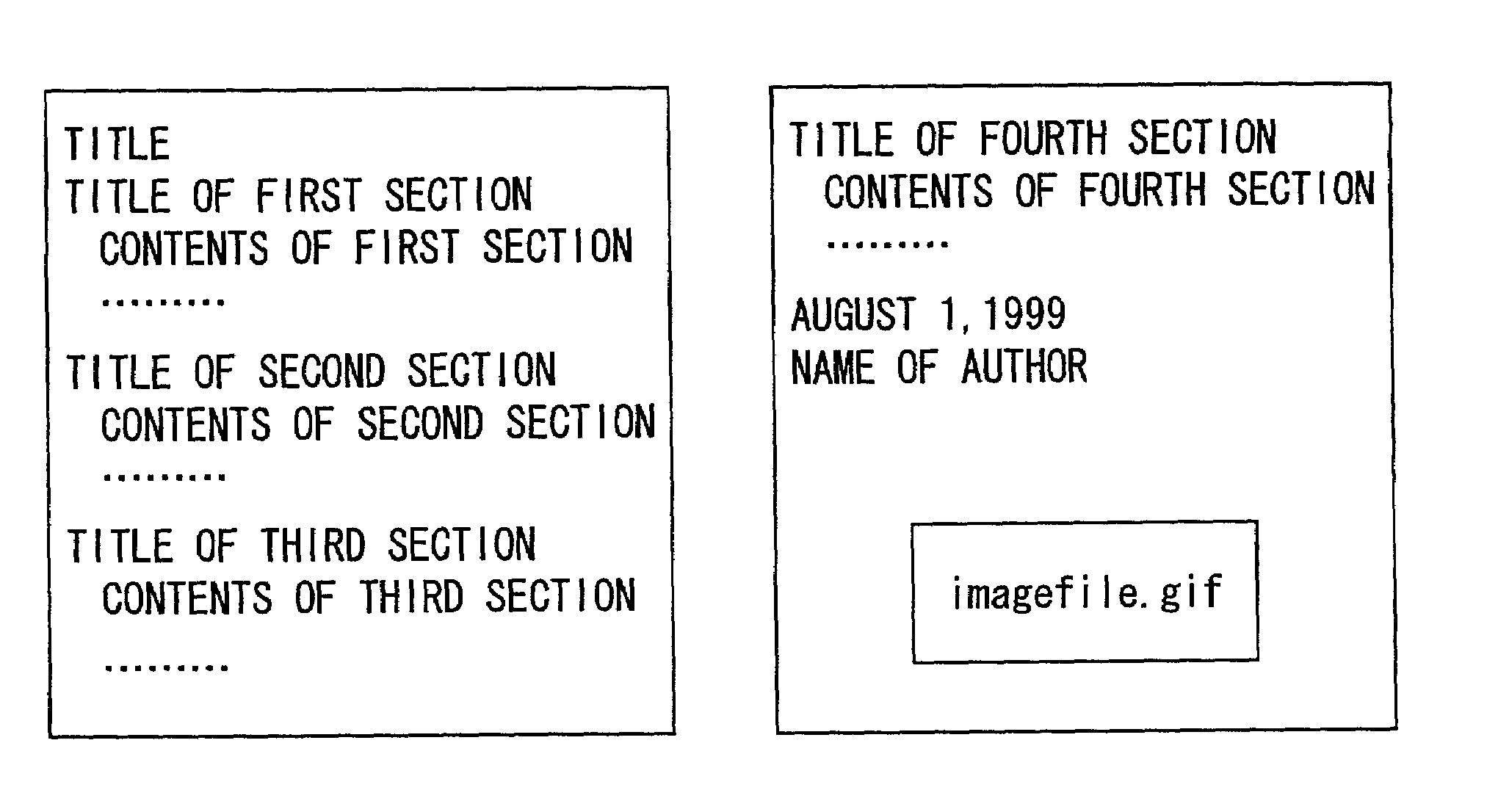

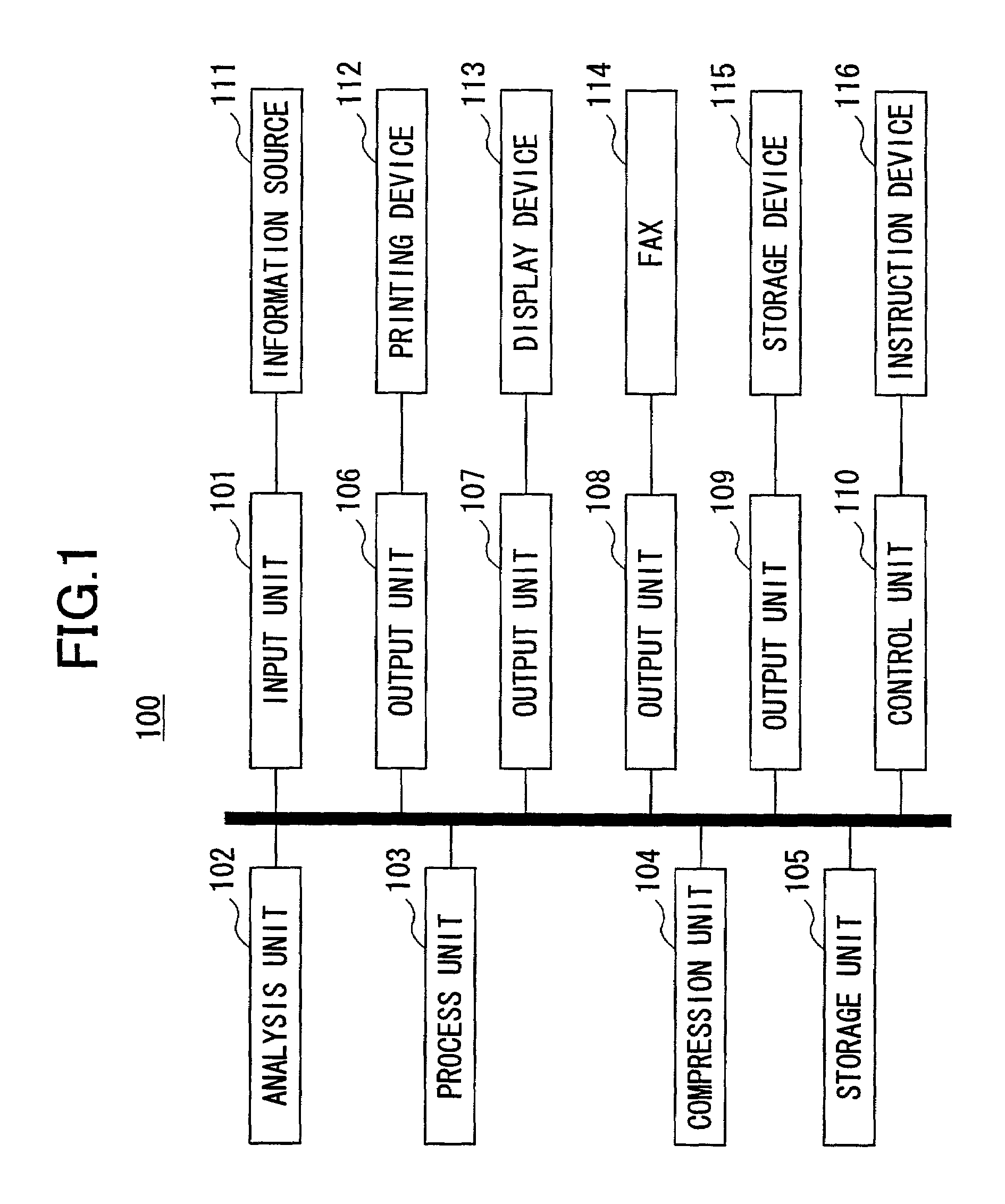

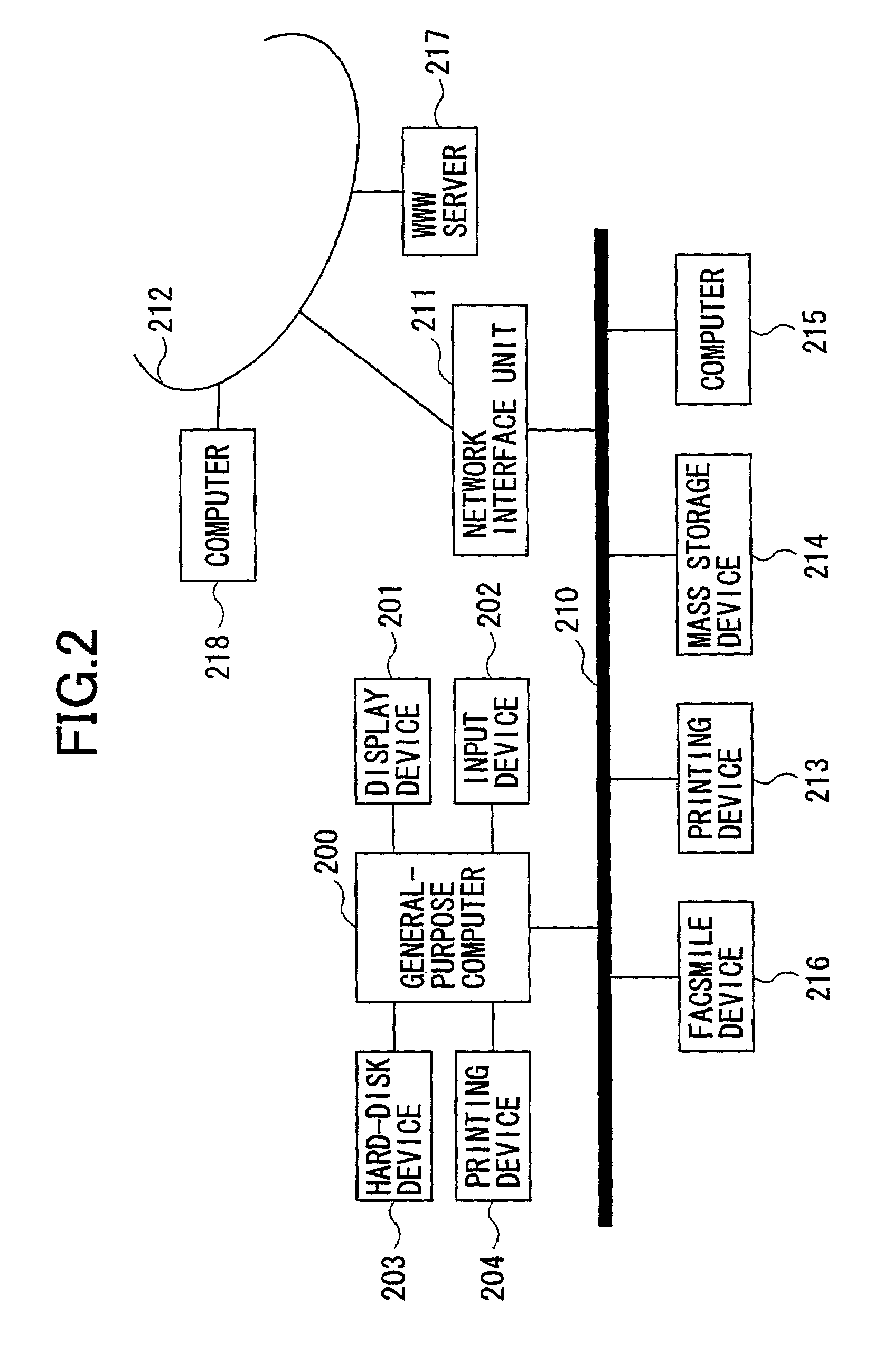

Document information processing device that achieves efficient understanding of contents of document information

InactiveUS7257770B2Efficiently understoodSmall sizeDigital computer detailsCharacter and pattern recognitionInformation processingDocumentation

A document-information processing device includes an analysis unit and a process unit. The analysis unit analyzes construction of document information that is composed of a plurality of elements, and evaluates a degree of significance of each element included in the document information. The process unit selects an element sequentially from the plurality of elements, starting from an element whose degree of significance is the highest and ending with an element whose degree of significance is the lowest, and places a selected element on an output document. Alternatively, the process unit reduces an information content of the document information by eliminating or compressing an element whose degree of significance is low.

Owner:RICOH KK

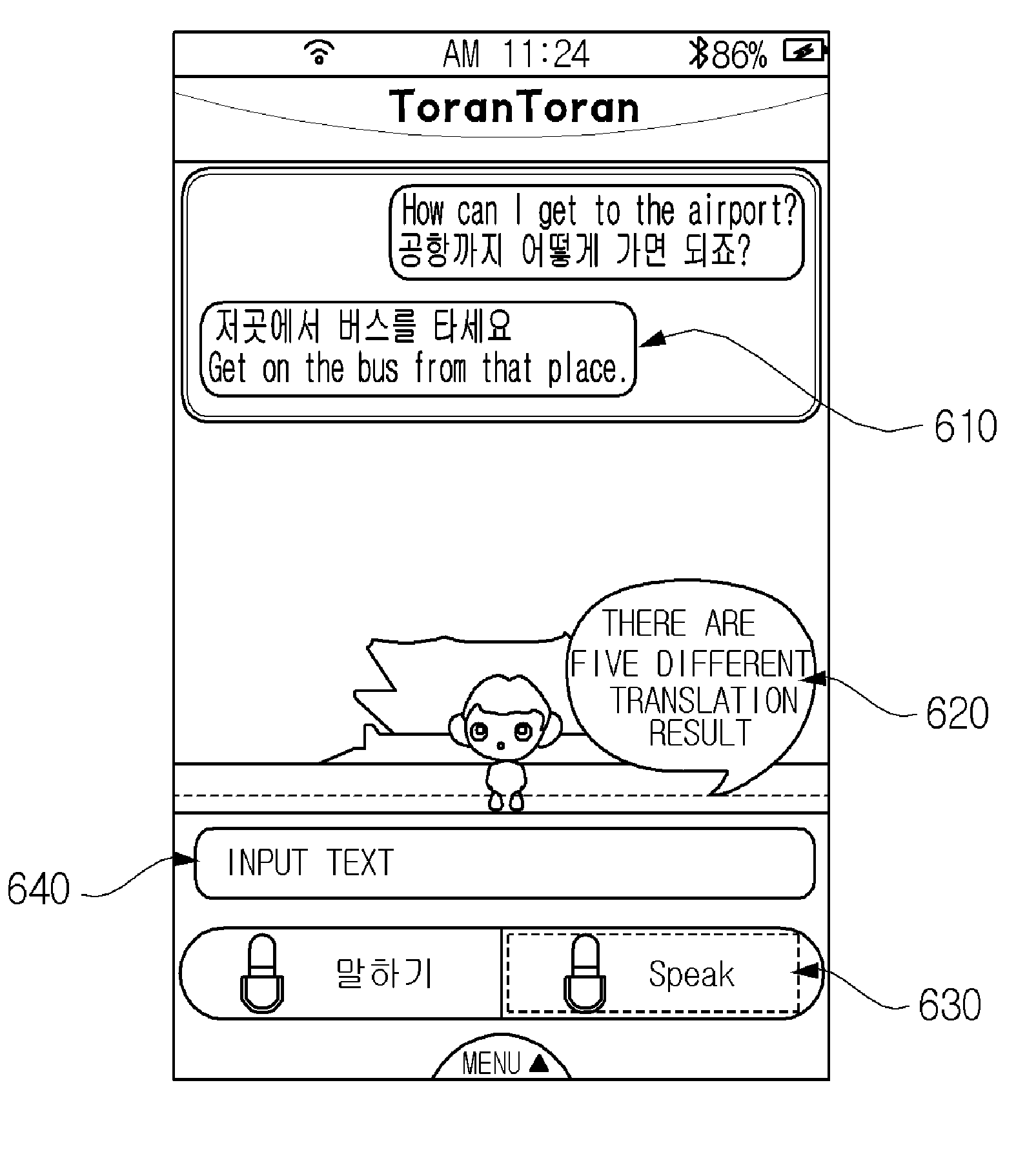

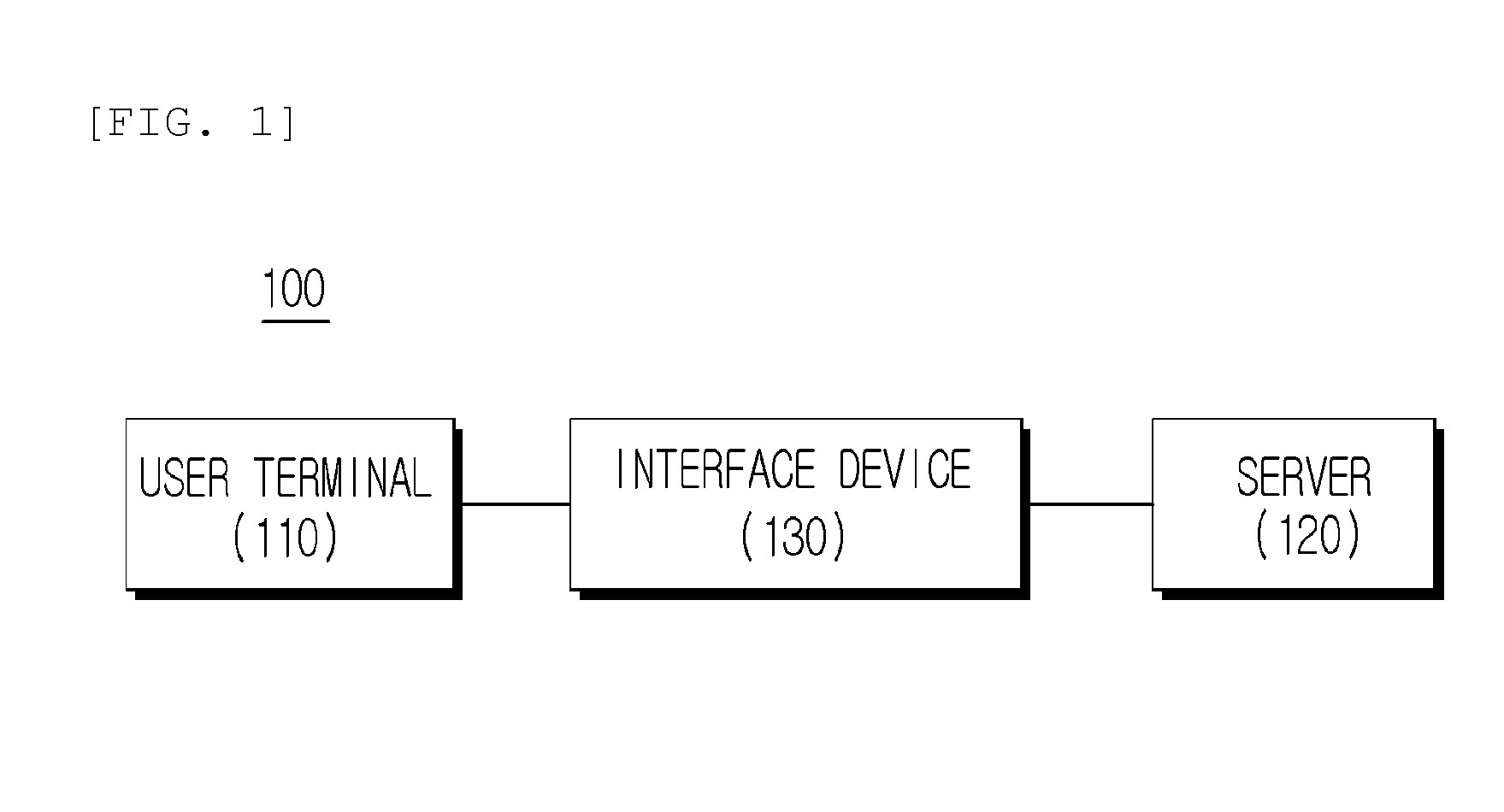

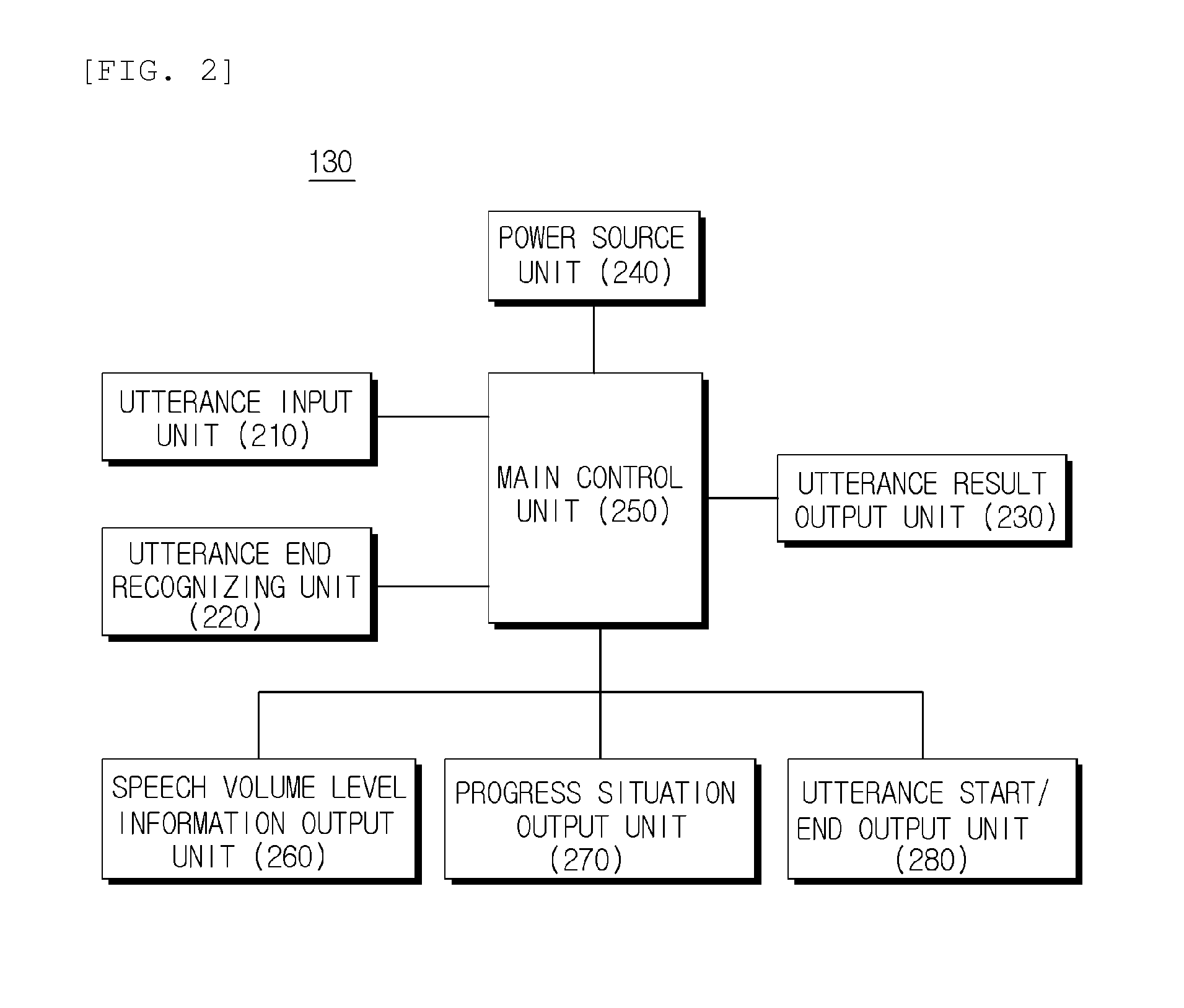

Interface device for processing voice of user and method thereof

InactiveUS20140156256A1Efficient outputImprove accuracyNatural language translationSpeech recognitionSpeech inputSpeech sound

The present invention suggests an interface device for processing a voice of a user which efficiently outputs various information so as to allow a user to contribute to the voice recognition or the automatic interpretation and a method thereof. For this purpose, the present invention suggests an interface device for processing a voice of a user which includes an utterance input unit configured to input utterance of a user, an utterance end recognizing unit configured to recognize the end of the input utterance; and an utterance result output unit configured to output at least one of a voice recognition result, a translation result, and an interpretation result of the ended utterance.

Owner:ELECTRONICS & TELECOMM RES INST

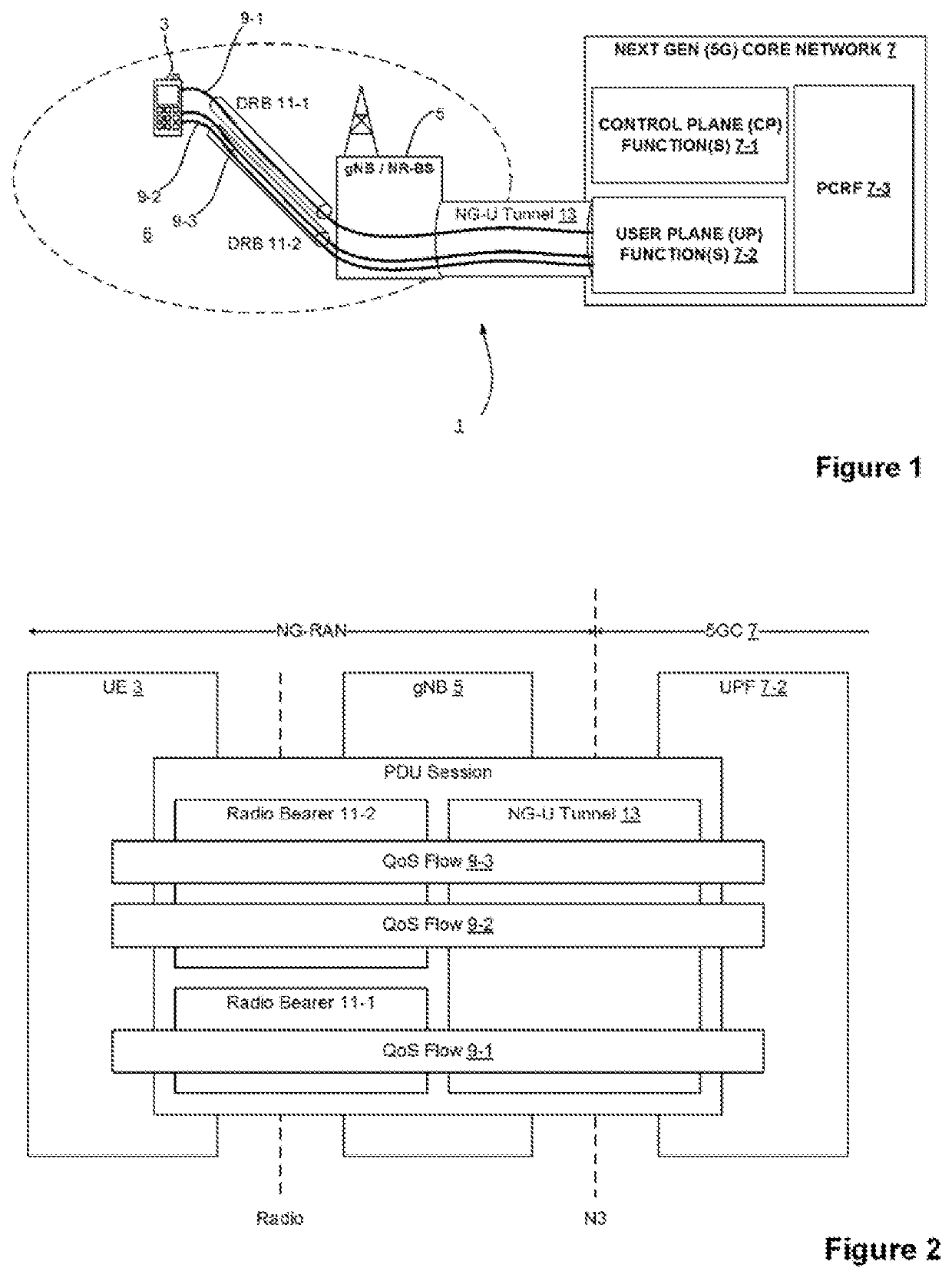

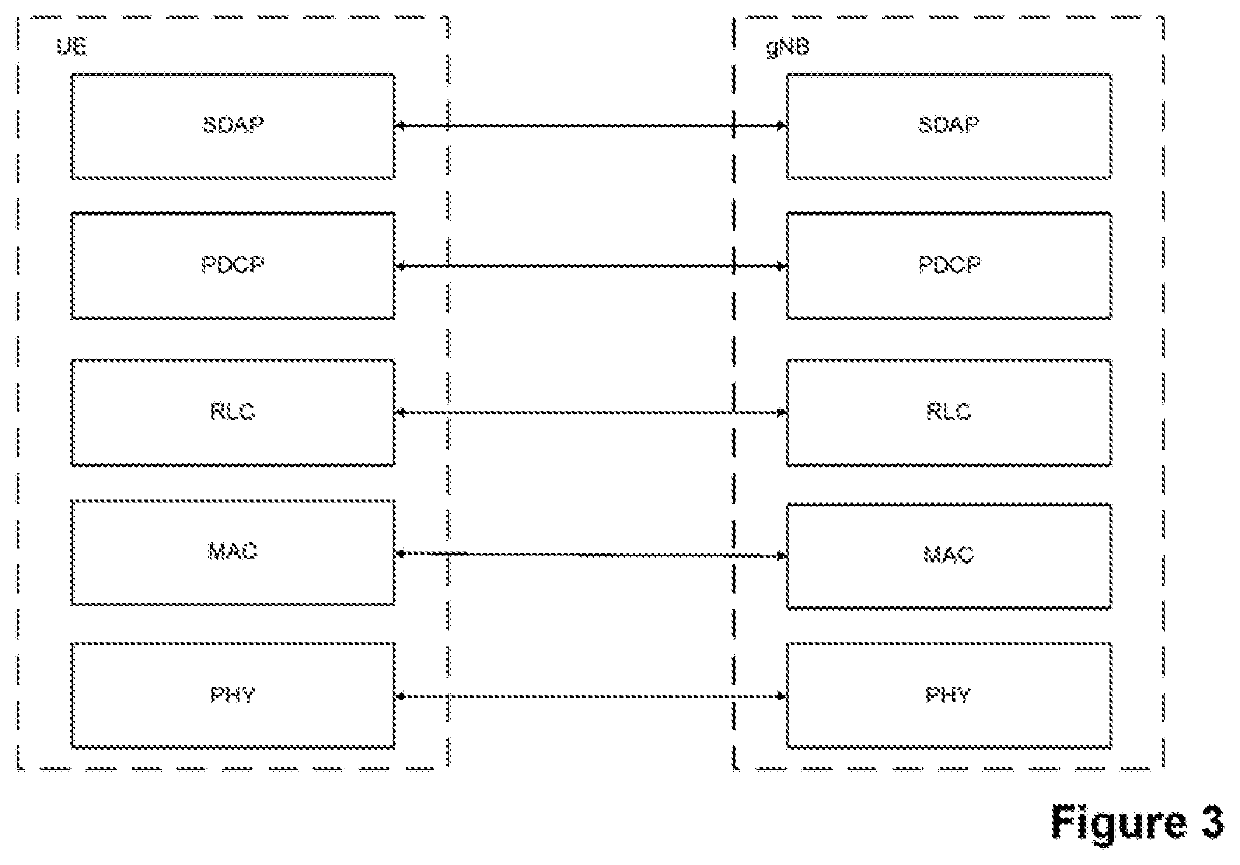

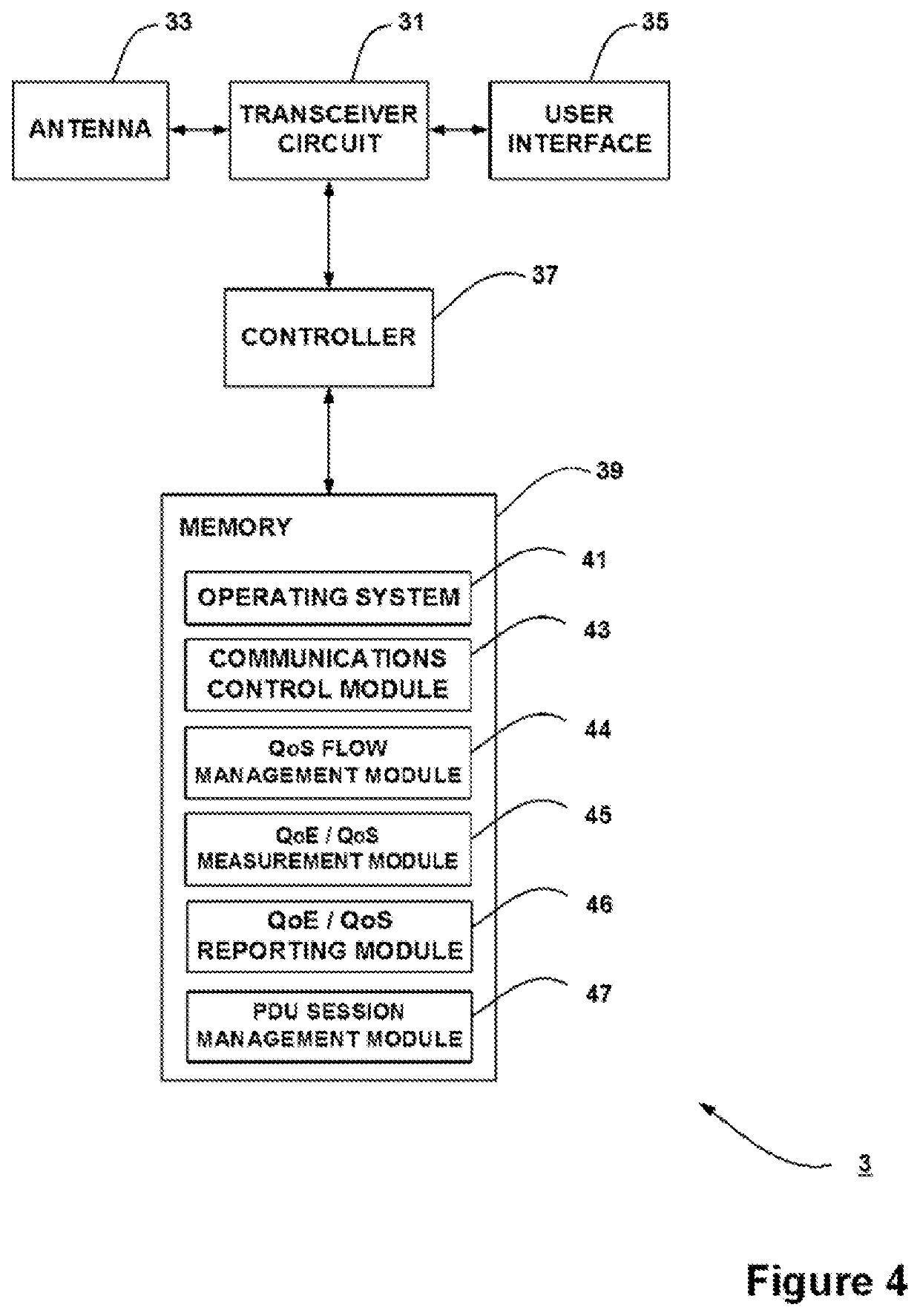

Optimization of resource allocation based on received quality of experience information

PendingUS20200280871A1Efficiently understoodNetwork traffic/resource managementQos quality of serviceData stream

A method performed by a user equipment in a communication system is disclosed in which the user equipment communicates data with a base station using at least one data radio bearer (DRB). The data is communicated using a plurality of data flows that are mapped to a single DRB. Each data flow is configured to have a respective set of quality of service (QoS) characteristics specific to that data flow. The user equipment measures quality of experience (QoE) parameters for the data flows and reports QoE information to the base station based on the measurement of the QoE parameters.

Owner:NEC CORP

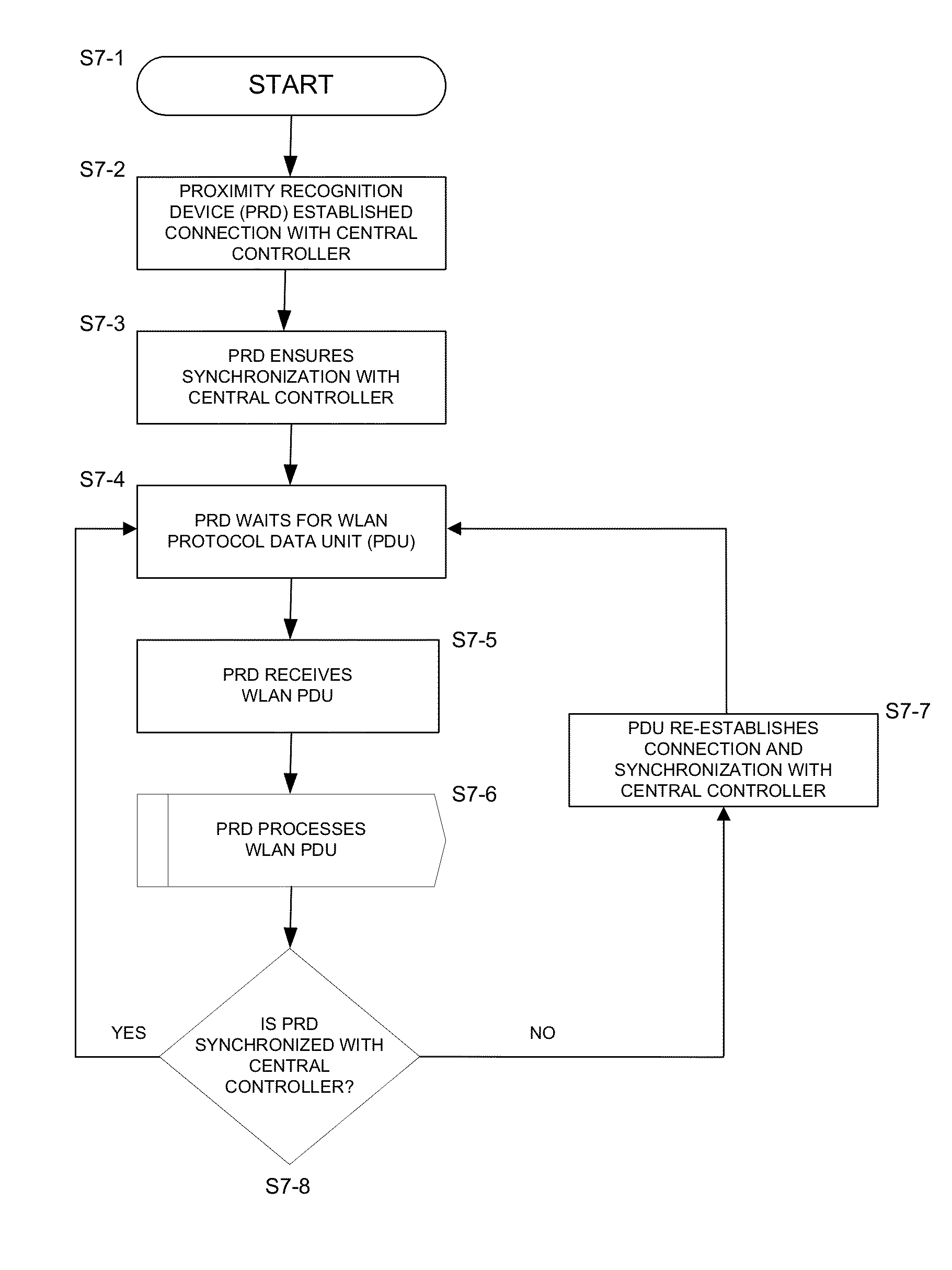

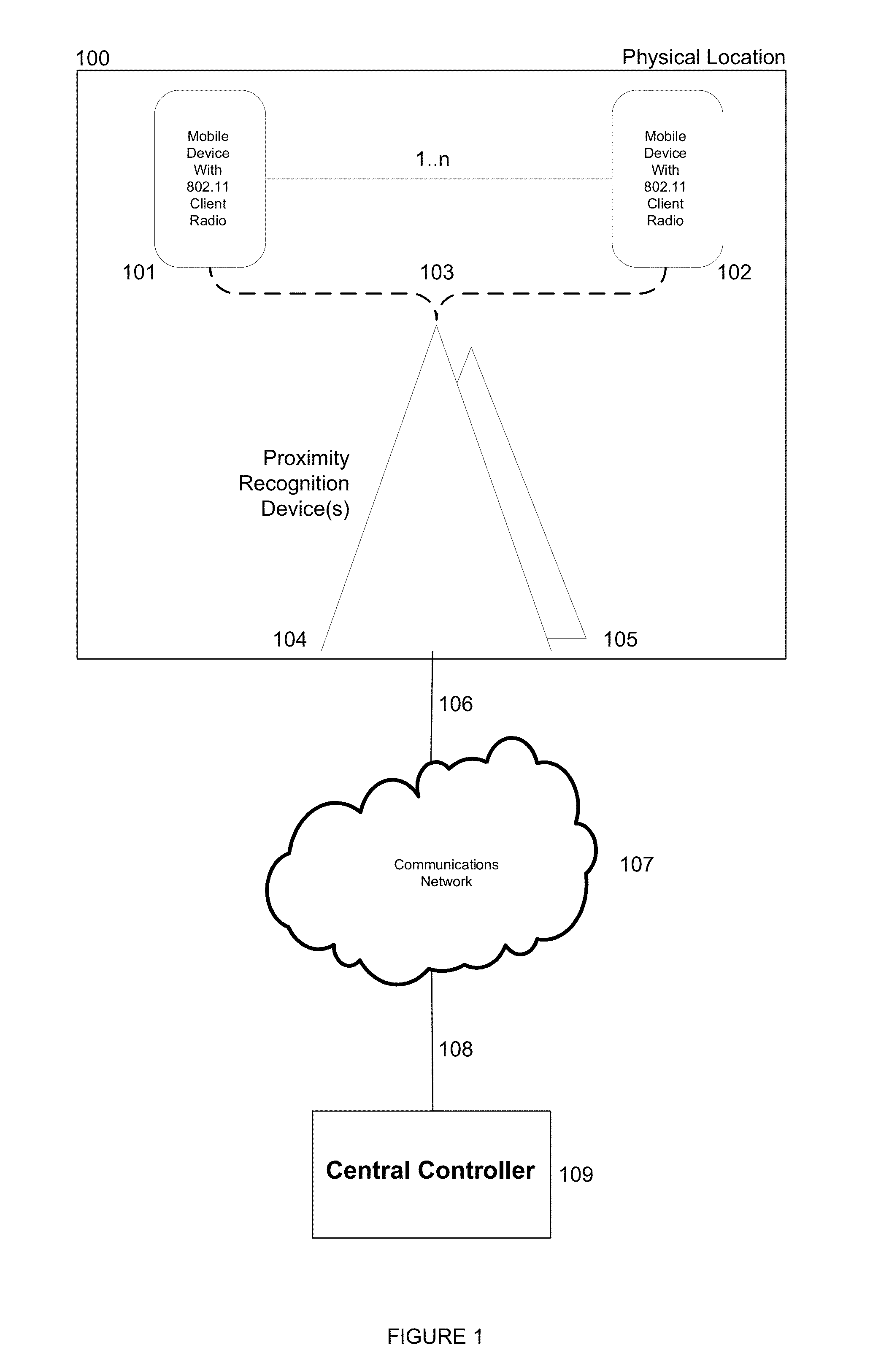

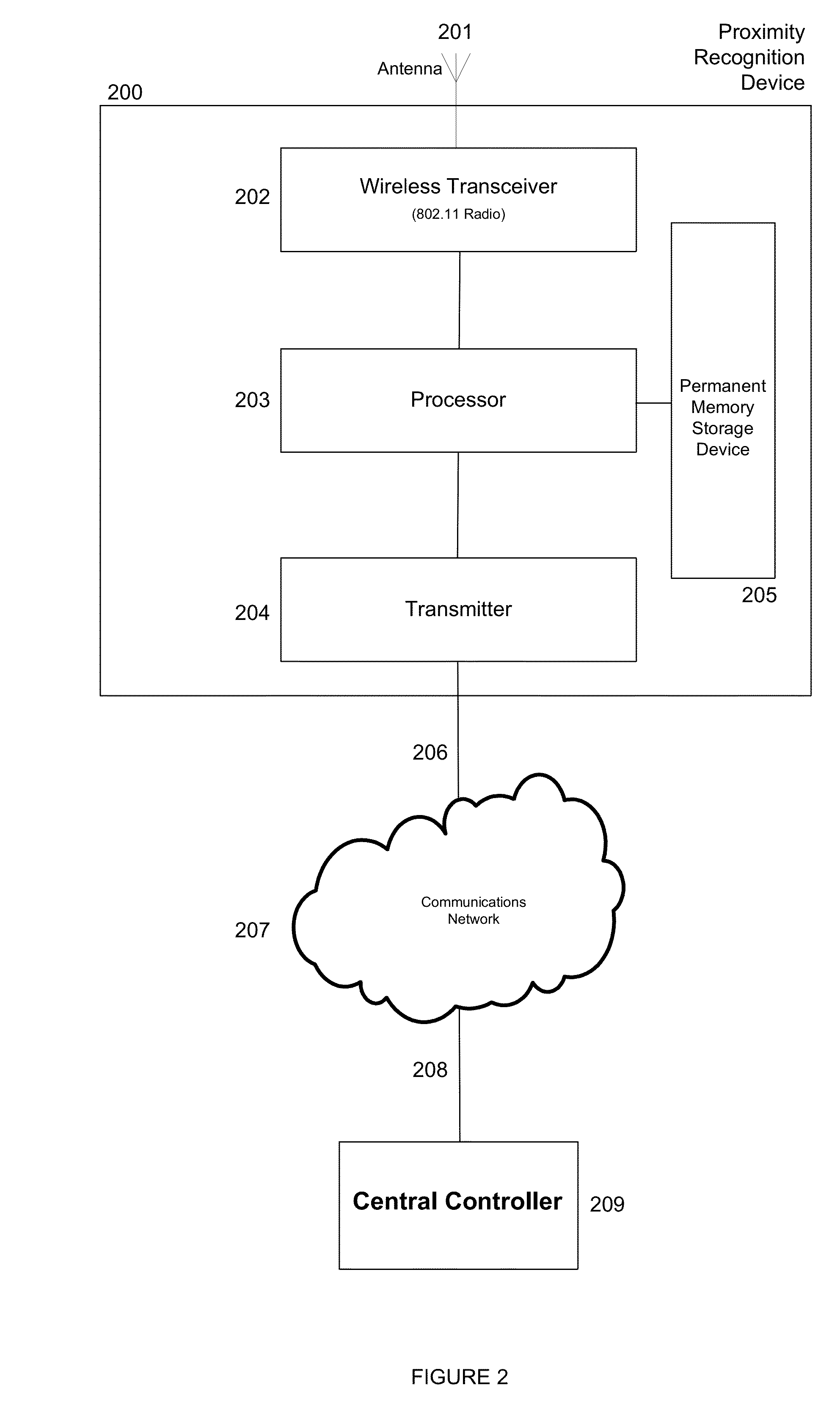

Method and System for Wireless local area network Proximity Recognition

ActiveUS20140169352A1Efficiently understoodHigh positioning accuracyWireless commuication servicesLocation information based serviceProtocol for Carrying Authentication for Network AccessMobile device

A method and system for proximity detection, recognition and classification of a wireless local area network (WLAN) enabled device without a WLAN infrastructure. The proximity recognition system monitors WLAN communications at one or more known locations. The proximity of a transmitter is sensed by examining receive signal strength as the mobile device engages in a sequence of protocol data unit exchanges requesting WLAN association. An identifier of the mobile device may be provided in this association request. Association requests may be periodic or may be prompted by a specific response from the WLAN proximity recognition device which may operate on one or a plurality of WLAN channels.

Owner:INPIXON

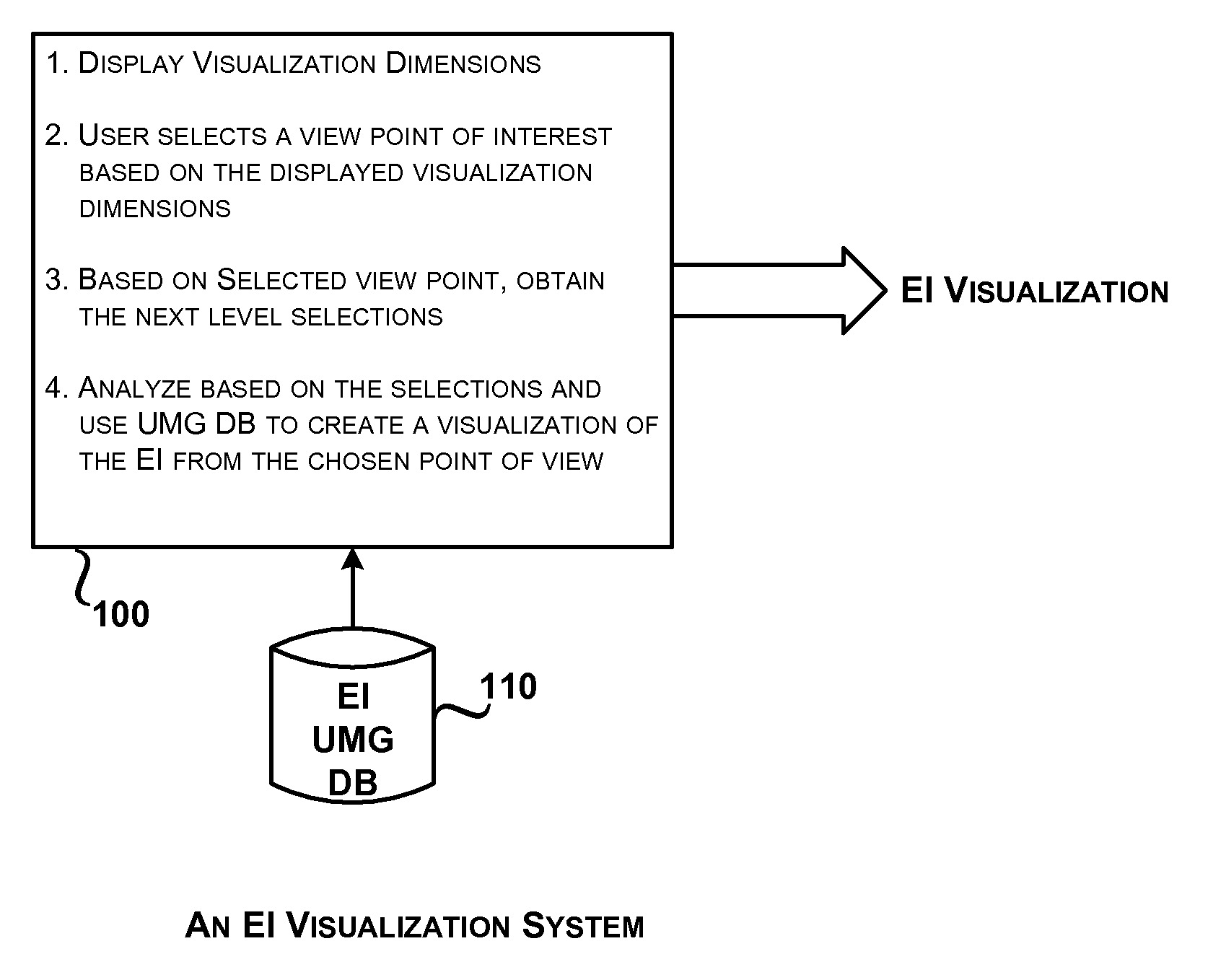

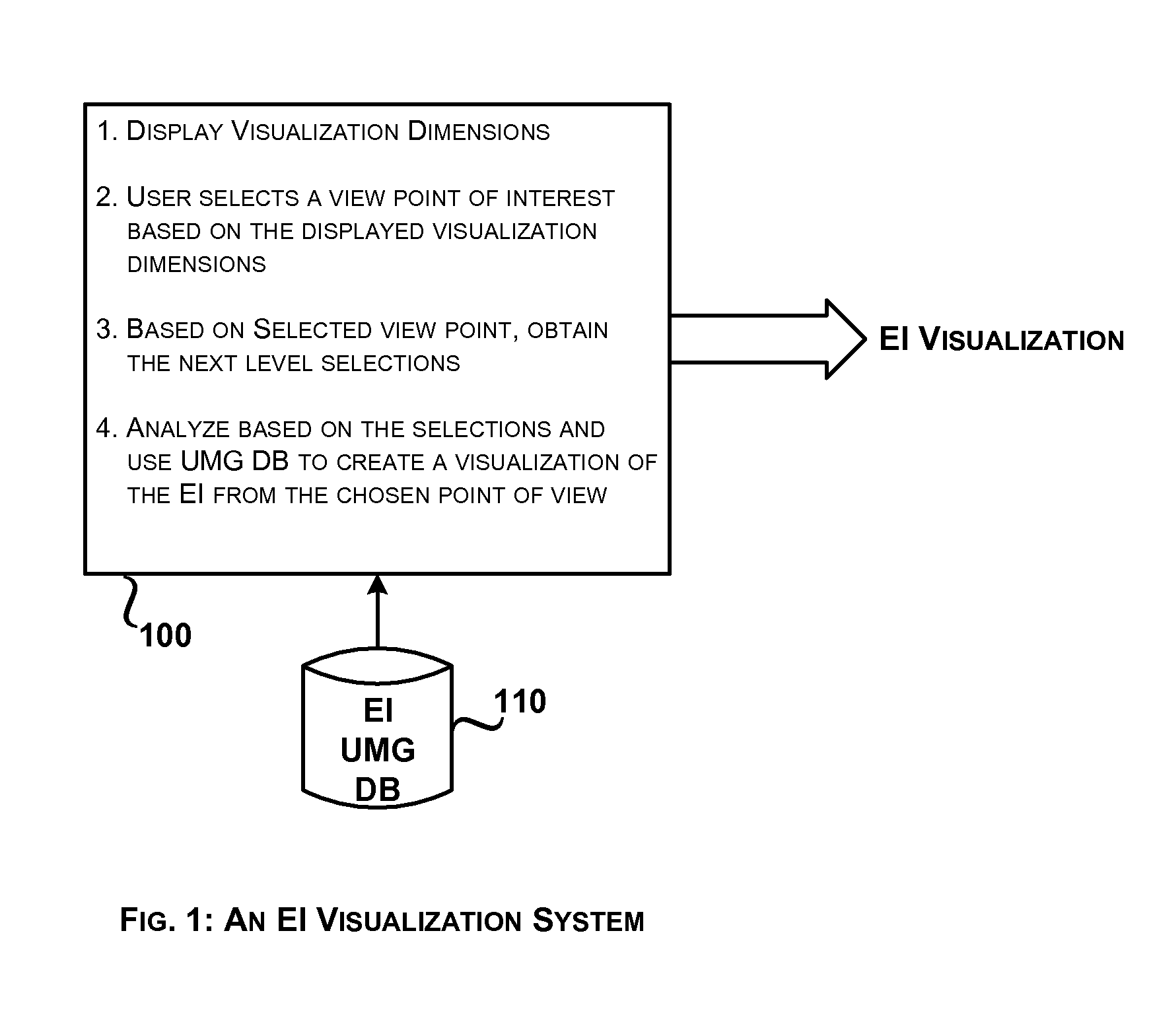

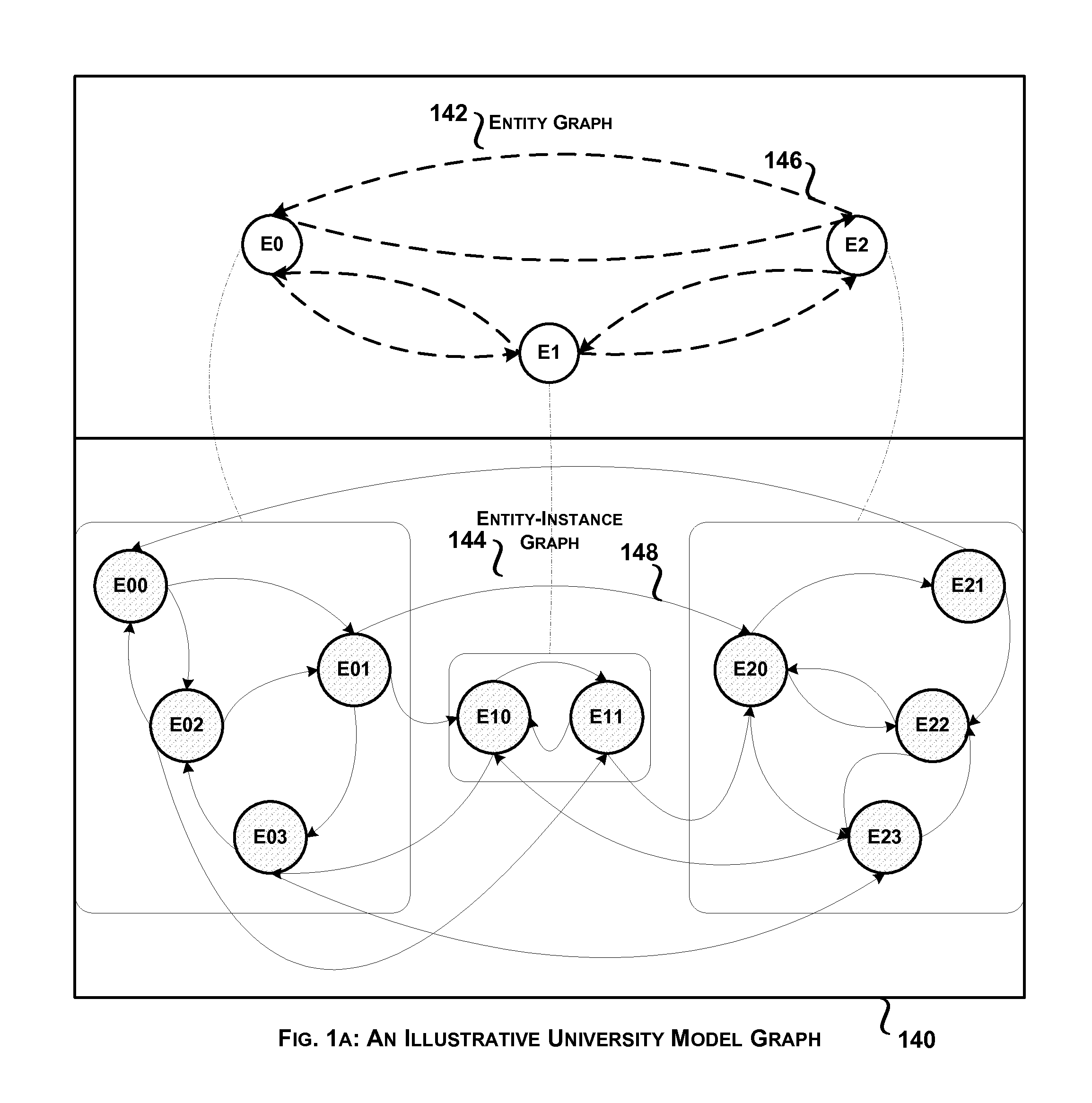

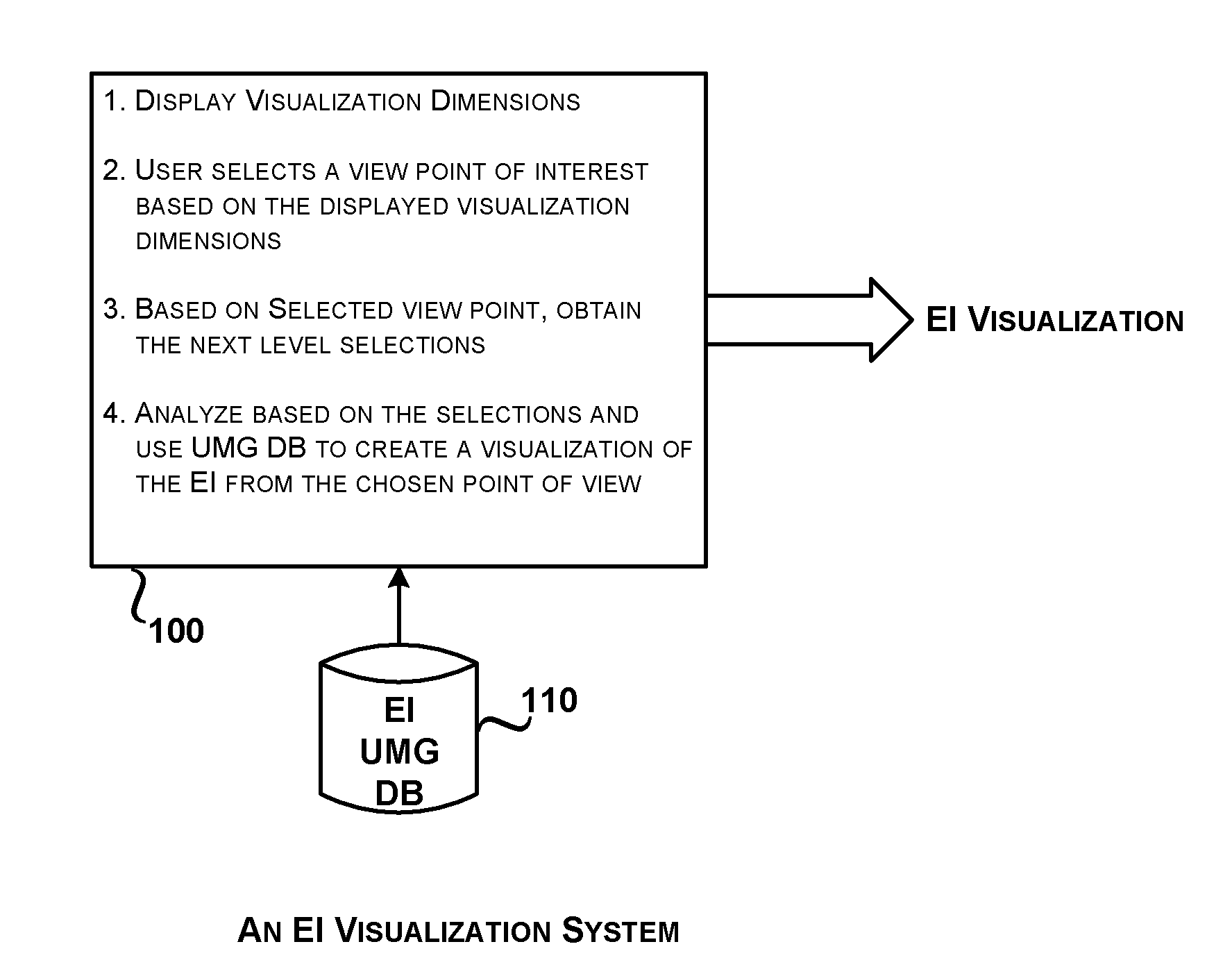

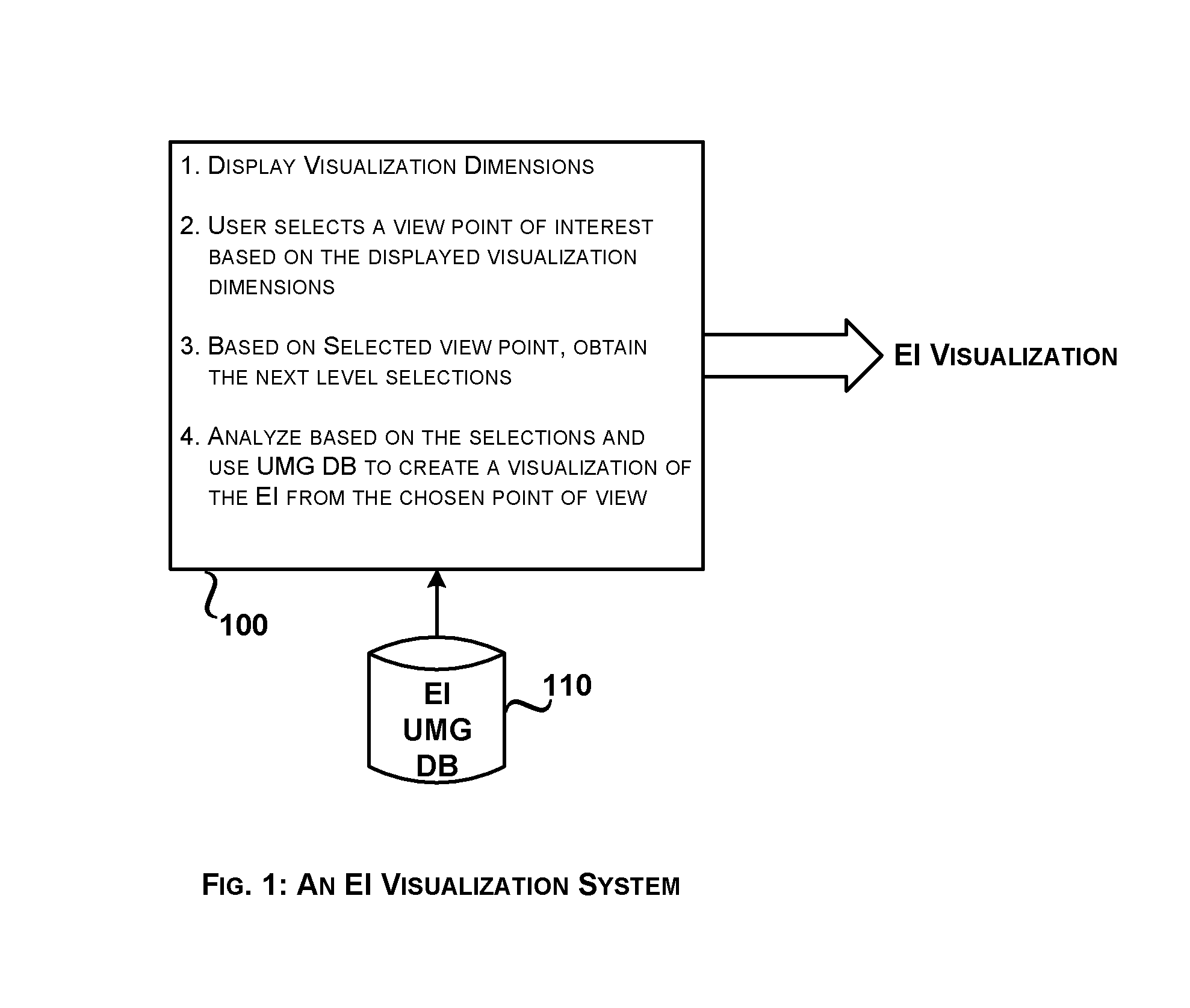

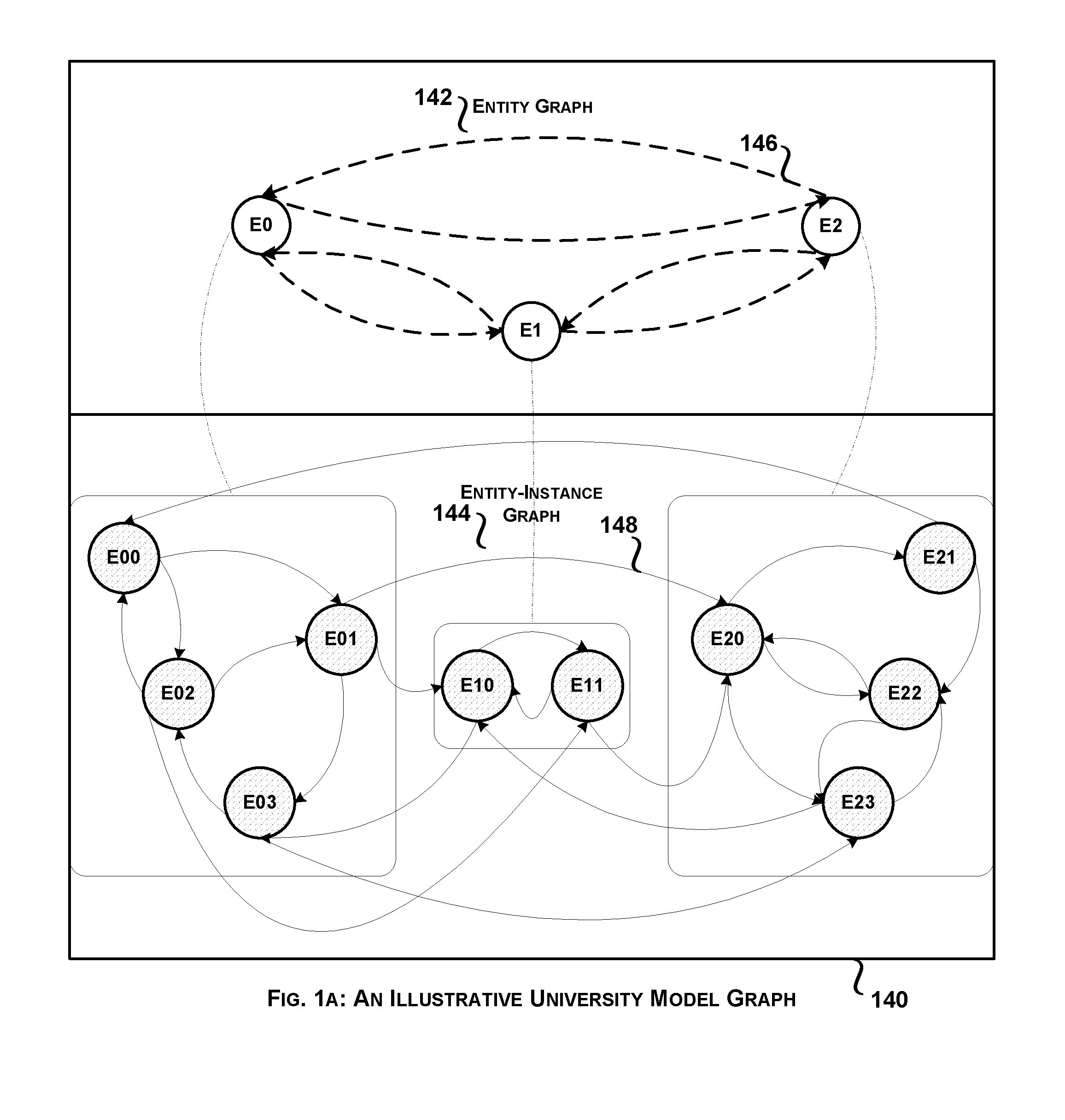

System and method for university model graph based visualization

InactiveUS20110276509A1Efficiently understoodData processing applicationsStructural representationData science

An educational institution (also referred as a university) is rich with multiple kinds of data: students, faculty members, departments, divisions, and at university level. A structural representation that captures the essence of all of the relationships in a unified manner has concise information about the educational institution, and visualization is a way to bring out all this information in an explicit manner so that the various of the users of the educational institution system understand effectively their system. A system and method for visualization based on the structural representation of a university along a variety of dimensions is discussed.

Owner:SRM INST OF SCI & TECH

Methods for reservoir evaluation employing non-equilibrium compositional gradients

ActiveUS9322268B2Efficiently understoodConstructionsDesign optimisation/simulationAnalyteEngineering

A method for determining reservoir architecture using modeling of a non-equilibrium distribution of at least one analyte in reservoir fluids. The analyte(s) of the analysis preferably has (have) significant compositional variation in the reservoir. For example, the analyte can be a later charging single gas component (such as methane, carbon dioxide, or hydrogen sulfide) in a multi-component fluid system. In this case, the model can assume that the components of the early charge are in a stationary state or in equilibrium, whereas the later charge is in a state of non-equilibrium. The non-equilibrium distribution of the analyte(s) derived from the model is compared to the distribution of the analyte(s) derived from downhole or laboratory fluid analysis of reservoir fluid, and the architecture of the reservoir is determined based upon such comparison.

Owner:SCHLUMBERGER TECH CORP

Medical image processor and storage medium

ActiveUS9189678B2Efficiently understoodImage enhancementImage analysisPattern recognitionFluorescence

A medical image processor and a storage medium are shown. According to one implementation, the medical image processor includes the following. An input unit is used to input a cell shape image and a fluorescent image showing expression of a specific protein. A cell nucleus extracting unit extracts a cell nucleus. A fluorescent bright point extracting unit extracts a fluorescent bright point. A region estimating unit sets a predetermined region. When the set region does not overlap with another, it is estimated to include one cell. When a plurality of the set regions overlap, it is estimated to include a plurality of cells. A feature amount calculating unit calculates a feature amount. A determining unit determines whether each estimated cell region is cancer and determines an expression status in the region based on the calculated feature amount. An output unit outputs a determination result.

Owner:KONICA MINOLTA INC

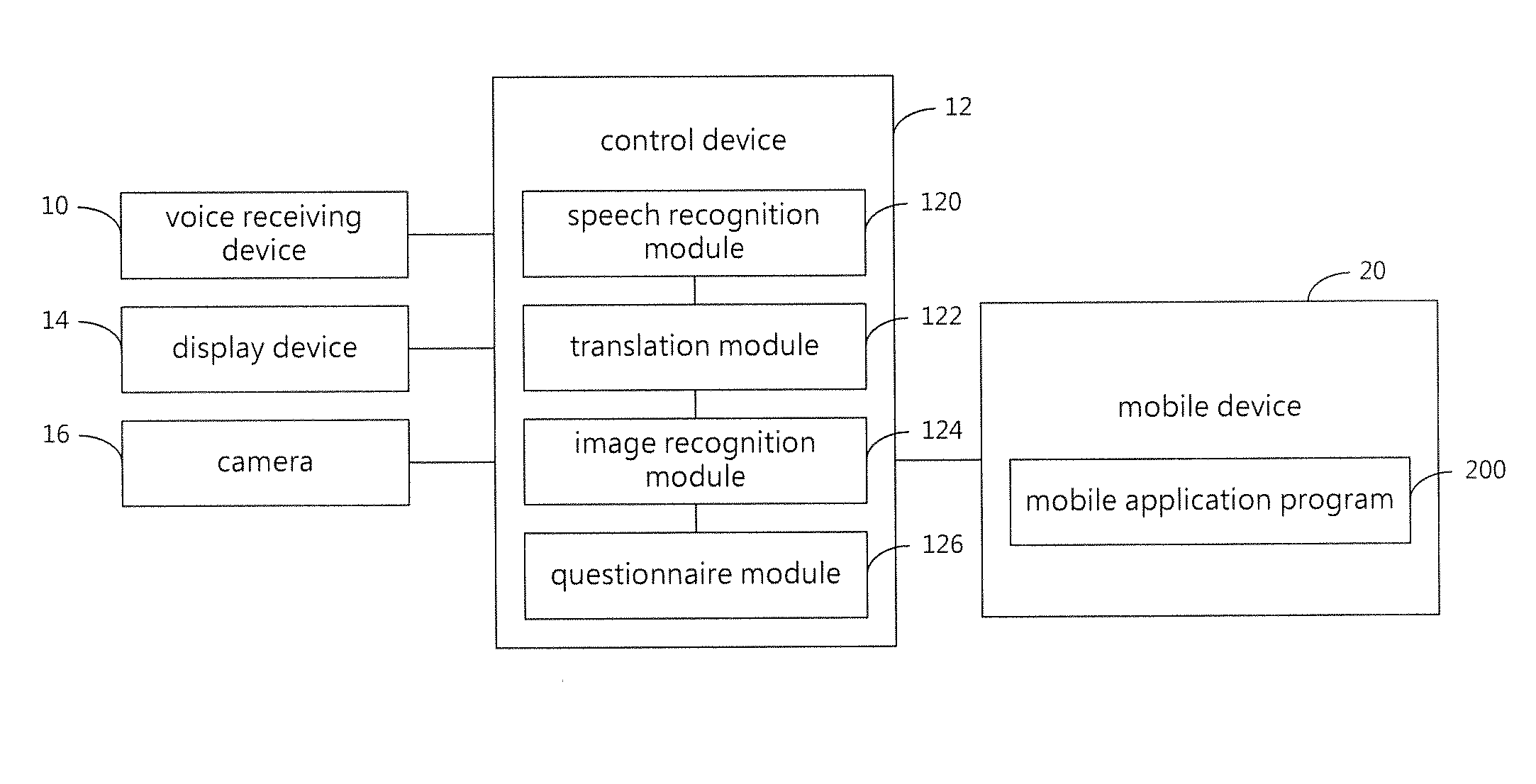

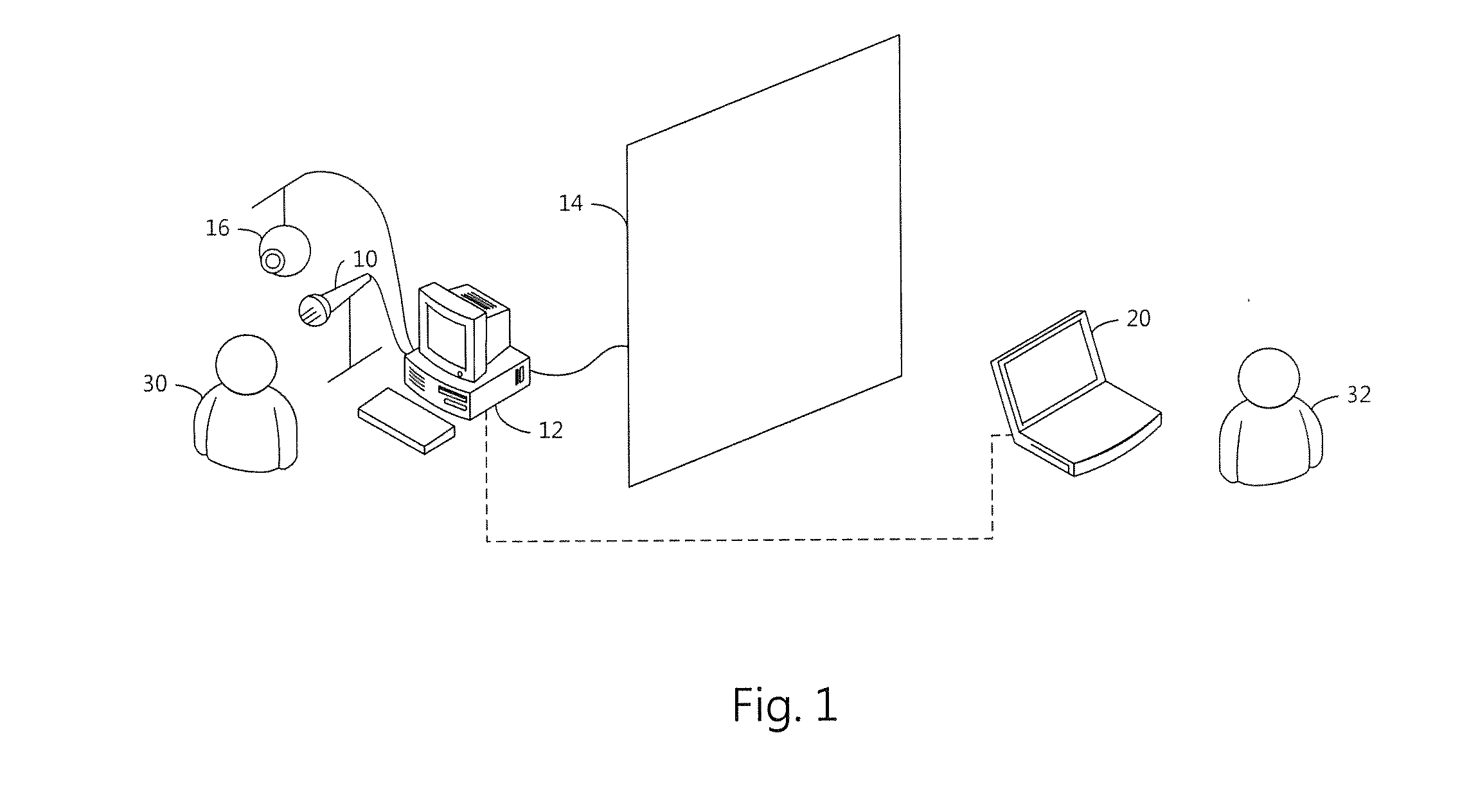

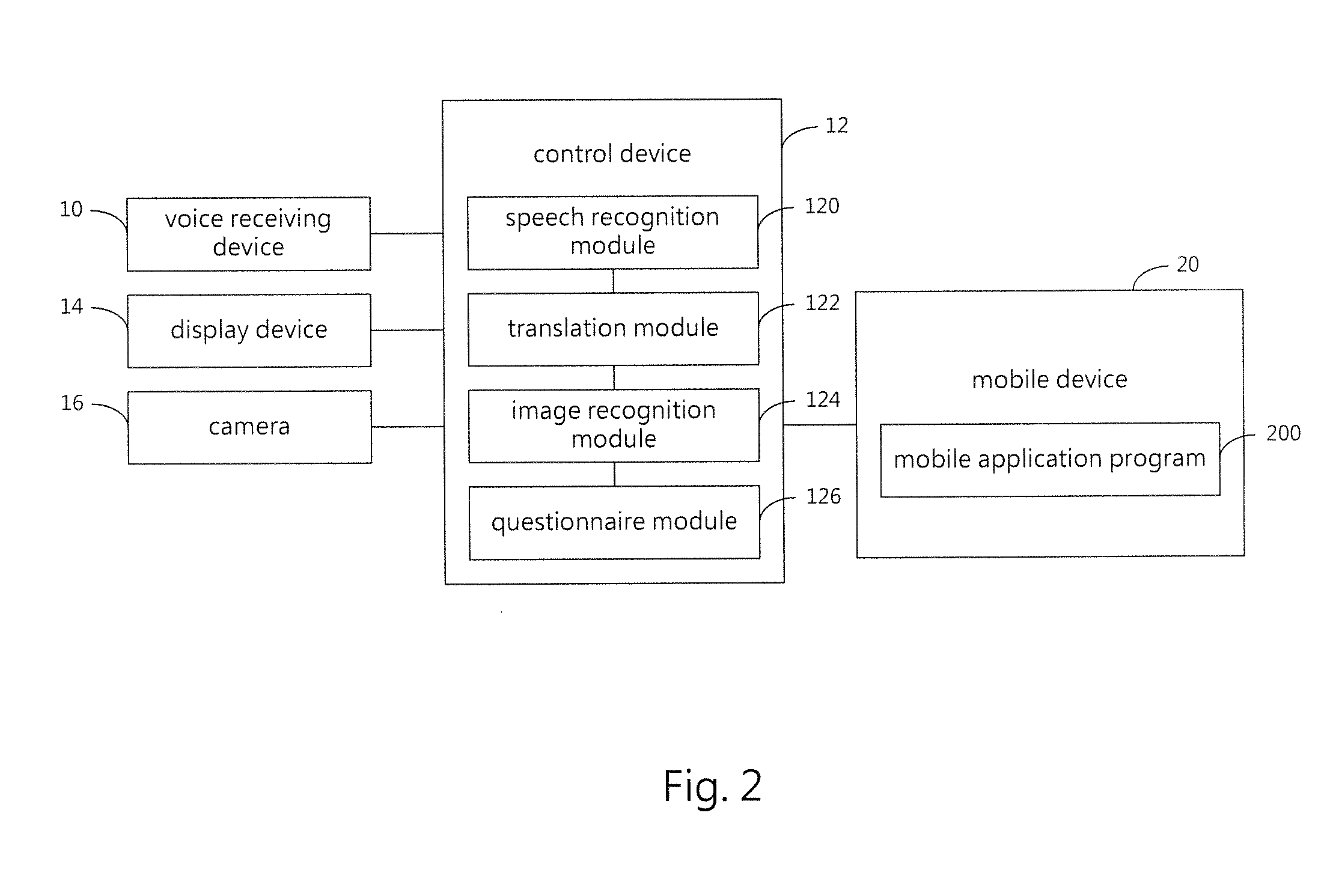

Speech assistance system in combination with mobile device

InactiveUS20160048503A1Efficiently understoodNatural language translationSpeech recognitionDisplay deviceSpeech identification

A speech assistance system in combination with at least one mobile device is revealed. While a speaker is delivering a speech. a speech assistant image is shown on a display under control of a control device. At the same time, the speech is received and delivered to the control device by a voice receiving device in a real-time manner. After the control device receiving the speech, the speech is immediately converted to a first speech text by a speech recognition module. Then a translation module translates the first speech text into a first translated text of the speech. An audience uses a mobile device to show the first speech text or play the speech of the first translated text to have a better understanding of content of the speech.

Owner:YINGQIDA INFORMATION

System and method for university model graph based visualization

An educational institution (also referred as a university) is rich with multiple kinds of data: students, faculty members, departments, divisions, and at university level. A structural representation that captures the essence of all of the relationships in a unified manner has concise information about the educational institution, and visualization is a way to bring out all this information in an explicit manner so that the various of the users of the educational institution system understand effectively their system. A system and method for visualization based on the structural representation of a university along a variety of dimensions is discussed.

Owner:SRM INST OF SCI & TECH

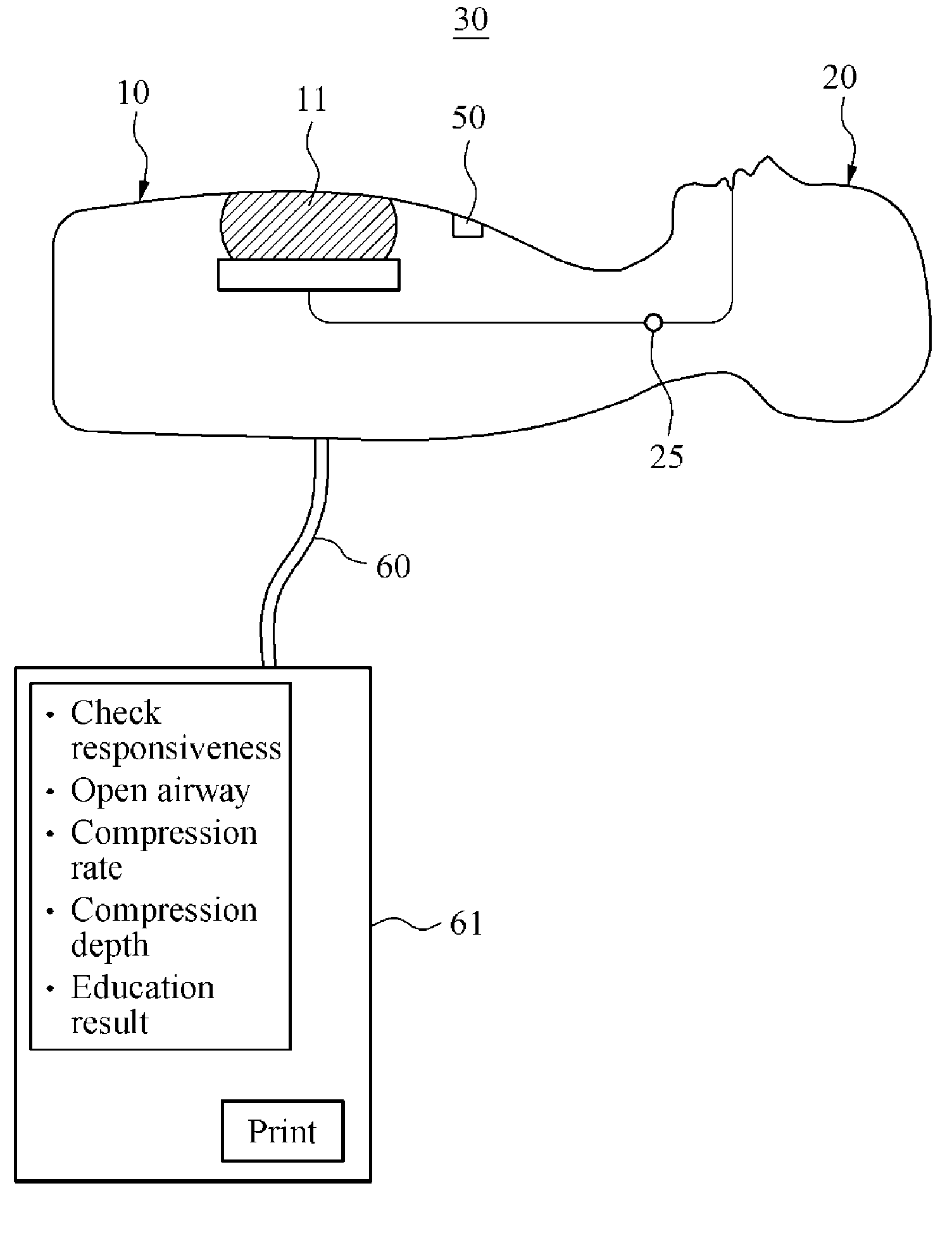

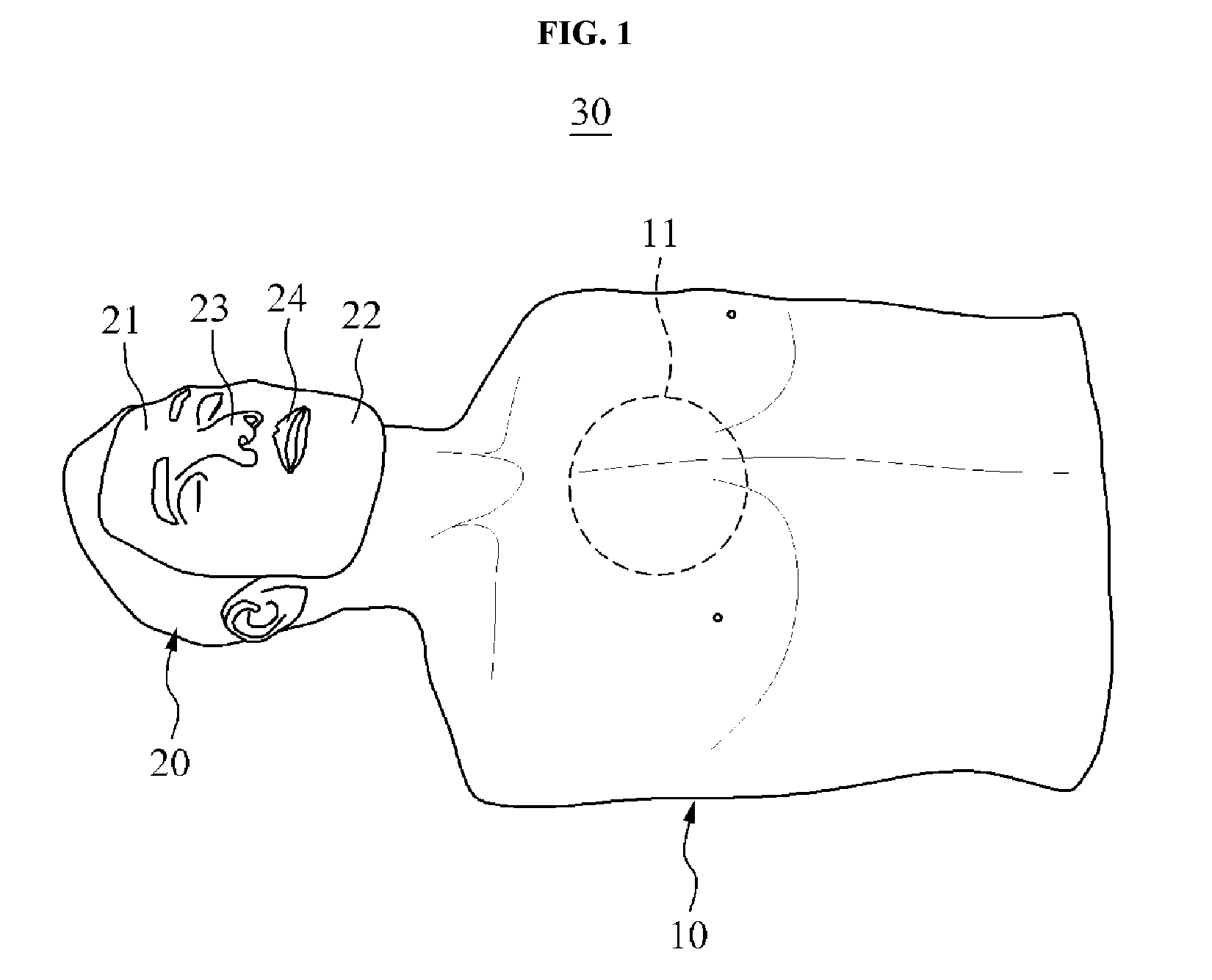

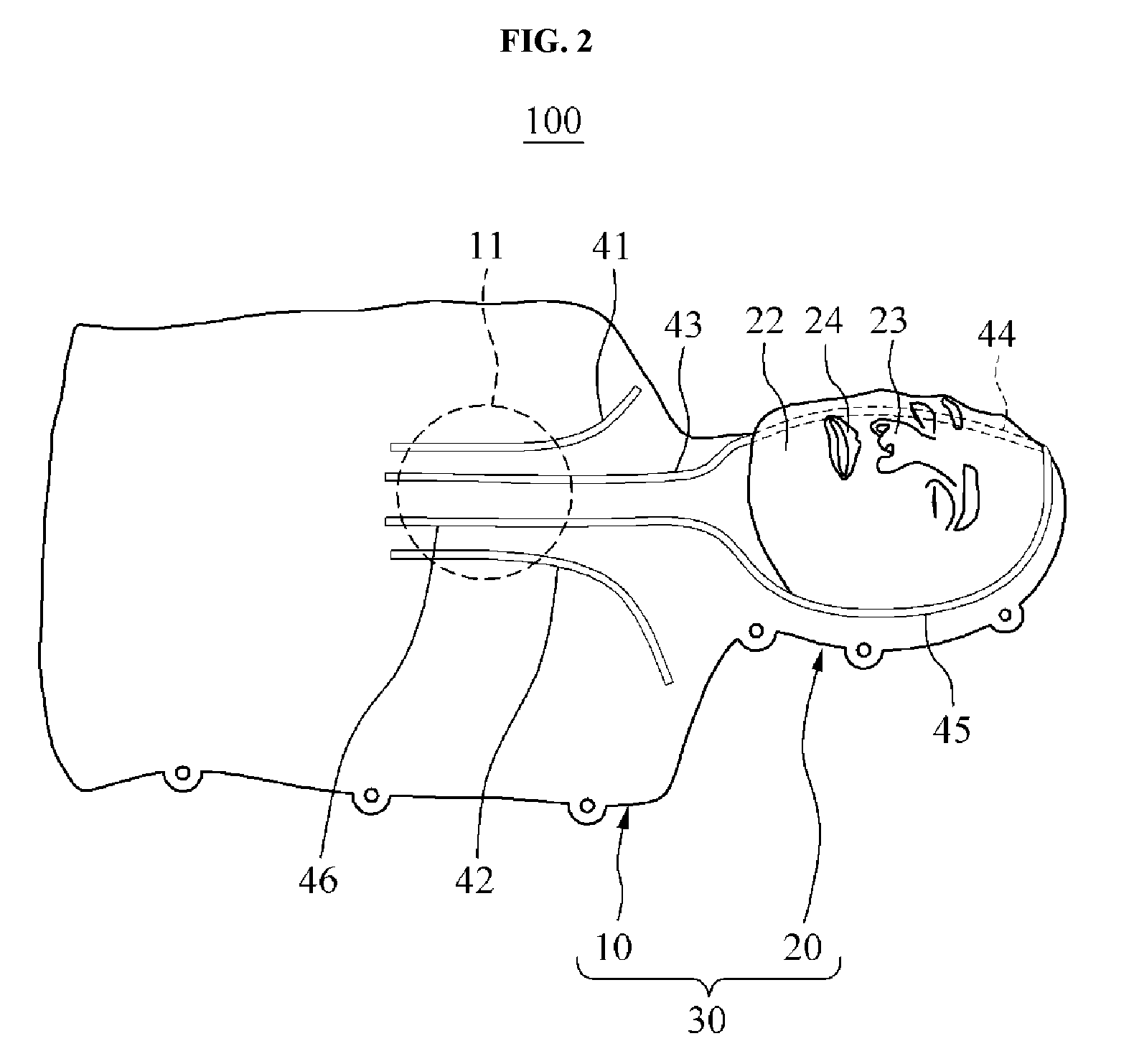

Cardiopulmonary resuscitation training apparatus

ActiveUS20160335921A1Effective trainingAccurate compression rateEducational modelsElectrical appliancesEmergency medicineCardiopulmonary resuscitation

Disclosed is a cardiopulmonary resuscitation training apparatus. The cardiopulmonary resuscitation training apparatus comprises: a mannequin; a compression plate which is provided towards the chest area of the mannequin and generates a return force; and a display unit which displays the state of the mannequin and shows blood circulation movement in light-emitting lines, in accordance with the pressing of the compression plate. The display unit can be constituted in such a way that the blood circulation movement in the mannequin is displayed by means of LEDs, and the LED movement rate is varied or the LEDs emit light in different colours in accordance with the depth of pressing or the pressing rate of the compression plate. This gives the advantage that the user can implement cardiopulmonary resuscitation close to reality while being made aware of the compression depth and the compression rate.

Owner:INNOSONIAN

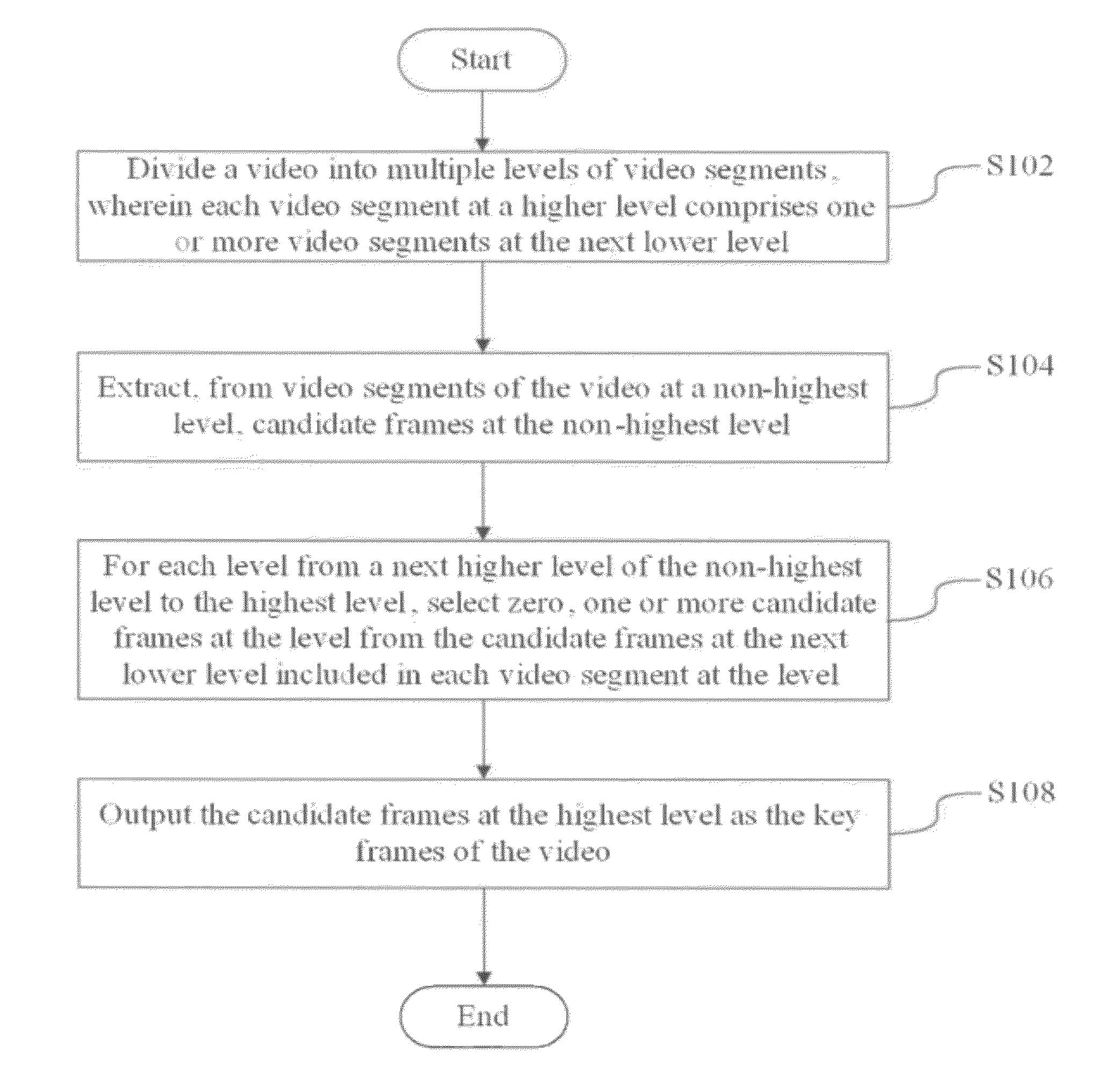

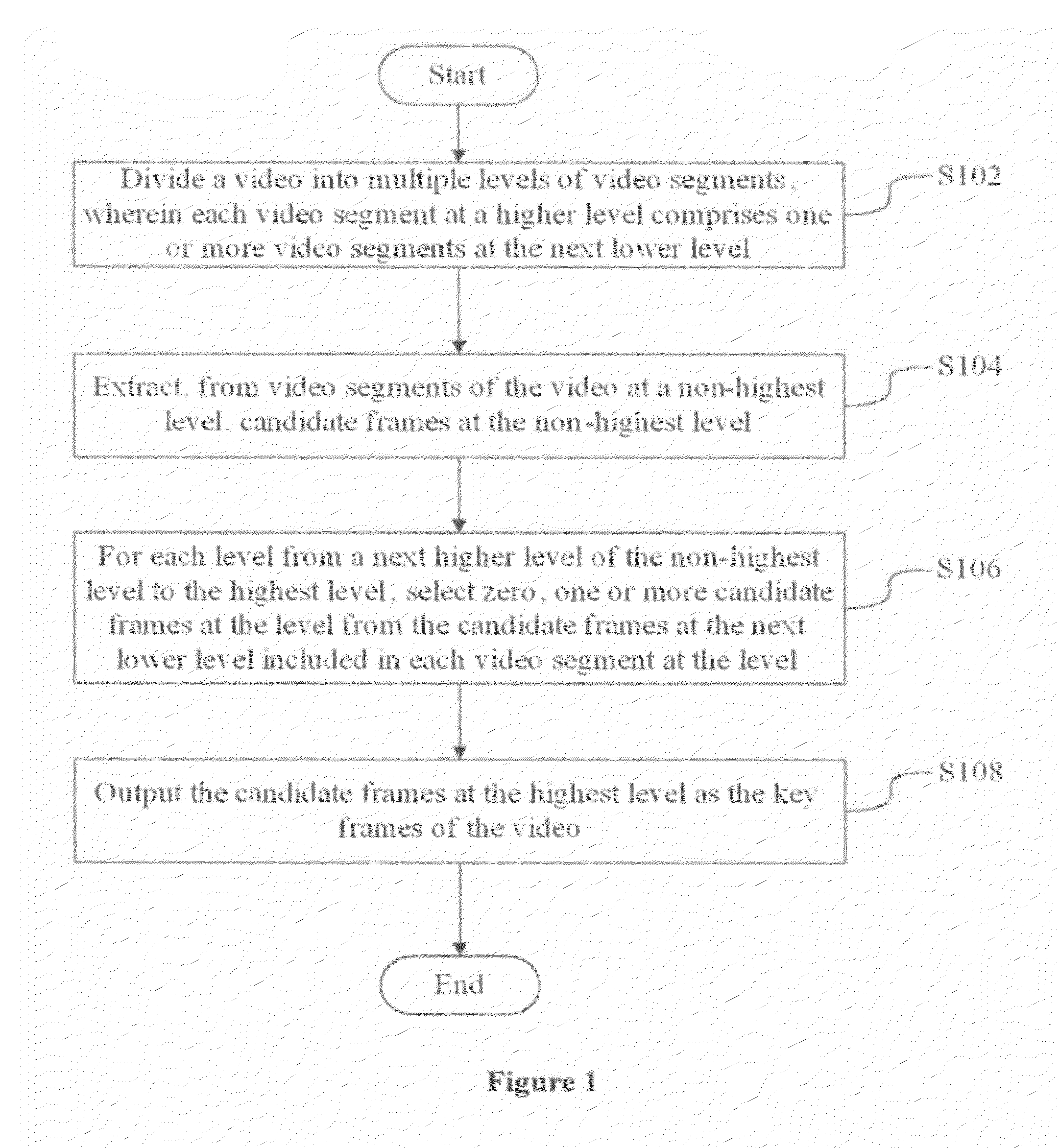

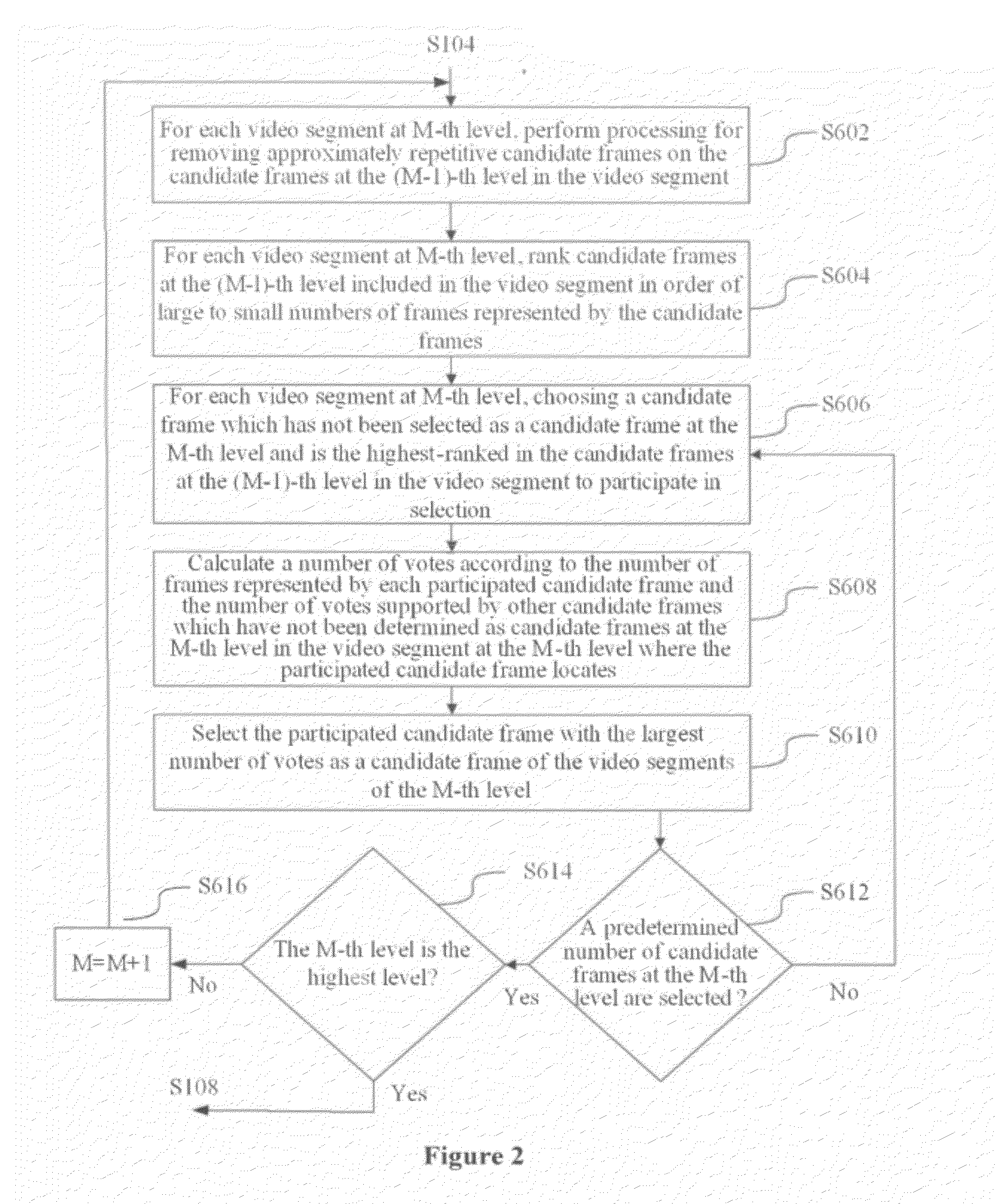

Method and apparatus for extracting key frames from a video

InactiveUS20120063746A1Effectively understood previewEfficiently understoodTelevision system detailsRecording carrier detailsKey frame

Owner:SONY CORP

Mobile application performance

InactiveUS20170091752A1Effective monitoringEfficiently understoodError detection/correctionPayment architectureService provisionFinancial transaction

A method of monitoring performance for transactions performed by a mobile computing device with a transaction system is described. A set of performance metrics related to a transaction is defined. For a transaction, at least some of the set of performance metrics from that transaction are captured at the mobile computing device and provided so that a report on the set of performance metrics can be provided for the transaction. This report may be provided by a monitoring service external to the mobile computing device.

Owner:MASTERCARD INT INC

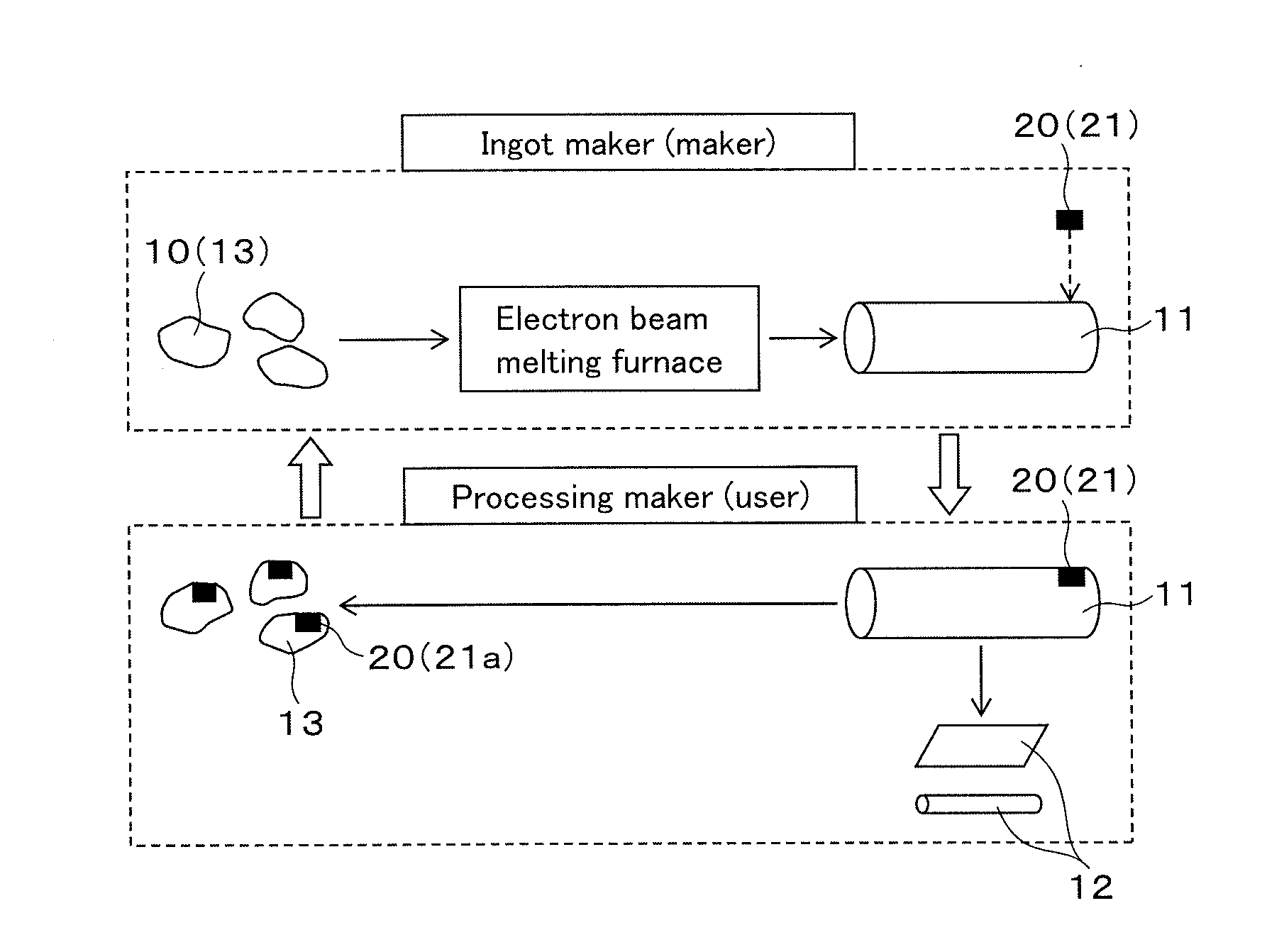

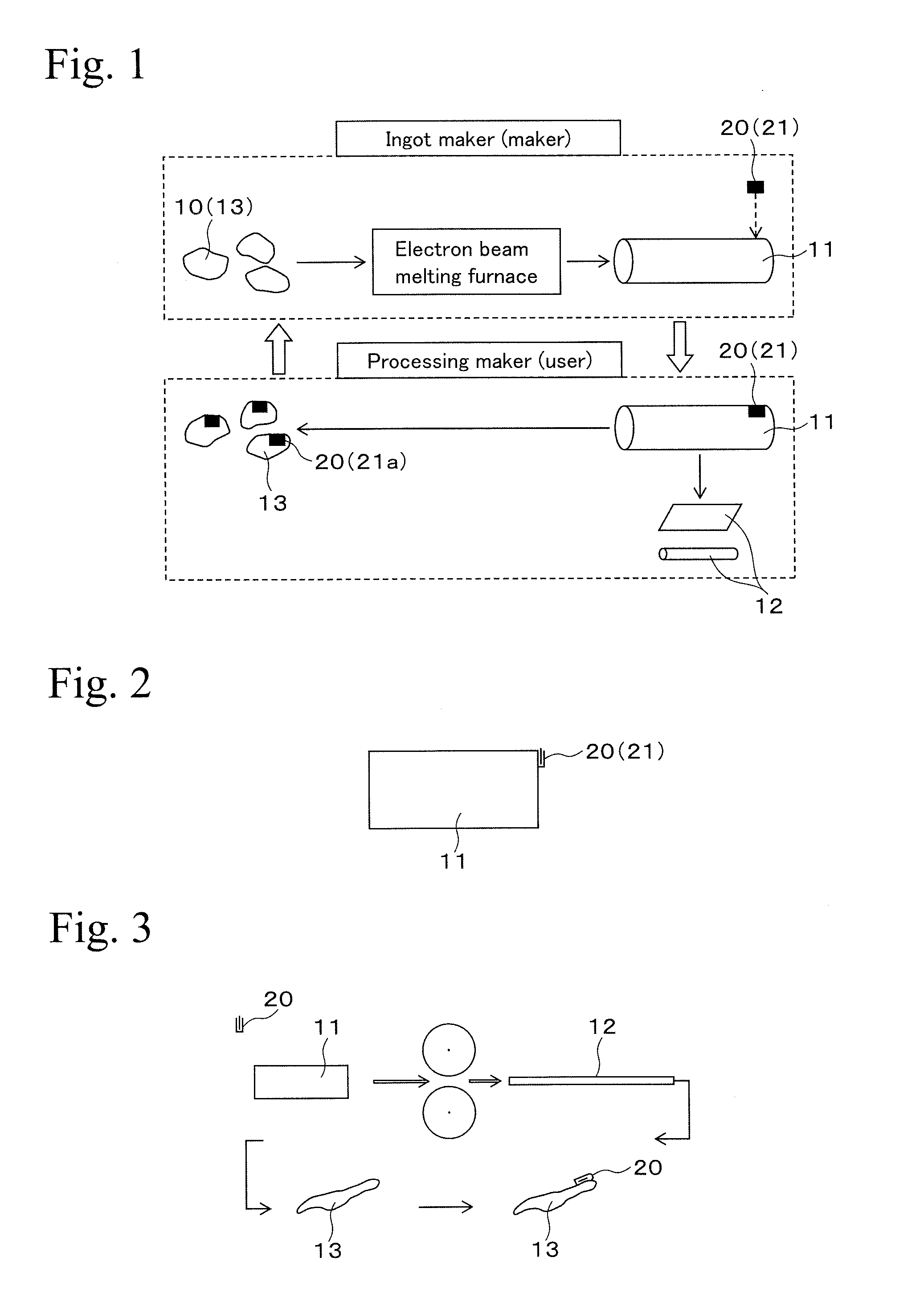

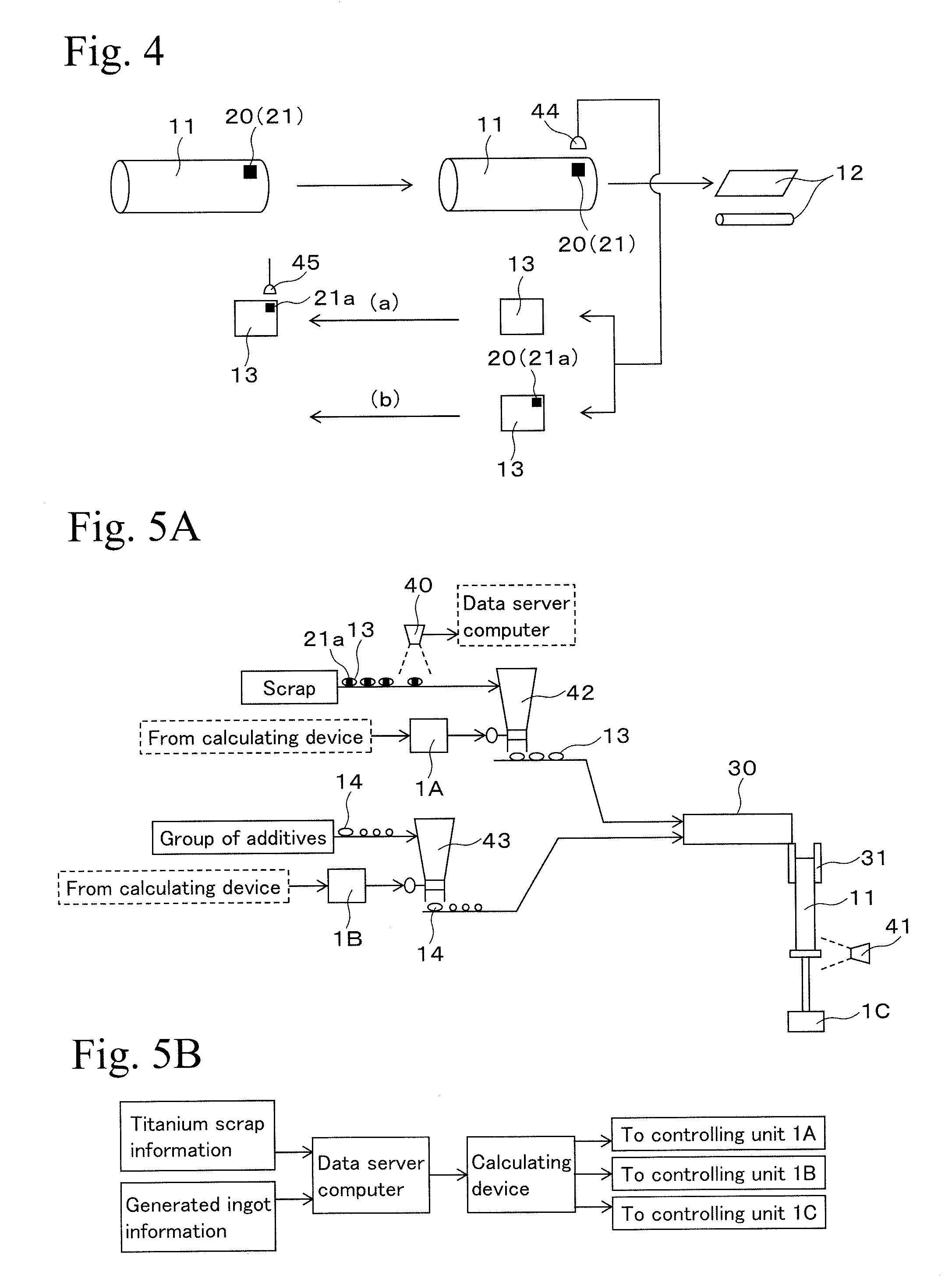

Method for production of titanium ingot using scrap and apparatus therefor

ActiveUS20140121815A1Low production costQuality improvementCasting safety devicesProcess efficiency improvementProduction rateChemical composition

High quality titanium ingot is produced by using recovered titanium scrap as a raw material and adding additives. Scrap, each having individual information of identification and process profile information, is passed through automatic reading means to obtain the information and to store it in a data server. A calculating means calculates a combination of the scrap, titanium sponge and additives and feed rate of each of them so as to satisfy chemical composition and producing rate of a target ingot product using the individual identification pieces of information stored in the data server, during a beginning step of the ingot production, and transmits electrical signals corresponding to calculated results of the combination and the feed rates from the calculating means to a feed rate controlling means of each feed means of the titanium scrap, titanium sponge, and additives and then starting supply of them, and detecting means equipped at an extracting part of the ingot product reads actual producing rate of the ingot product, after the beginning step of the ingot production. The calculating means controls feed rate of the titanium scrap, titanium sponge, and / or additives based on the actual producing rate.

Owner:TOHO TITANIUM CO LTD

FAT analysis for optimized sequential cluster management

ActiveUS8607016B2Improve system performanceEasy to manageMemory adressing/allocation/relocationSpecial data processing applicationsFile systemVolatile memory

Techniques for managing data in a non-volatile memory system (e.g., Flash Memory) are disclosed. A controller can use information relating to a host's file system, which is stored by the host on non-volatile memory, to determine if one or more clusters (or sectors with clusters) are currently allocated. The controller can use the information relating to the host's file system to identify when the host is sending data to the next free cluster and to store such data in a sequential format by copying data from other locations in the non-volatile memory.

Owner:SANDISK TECH LLC

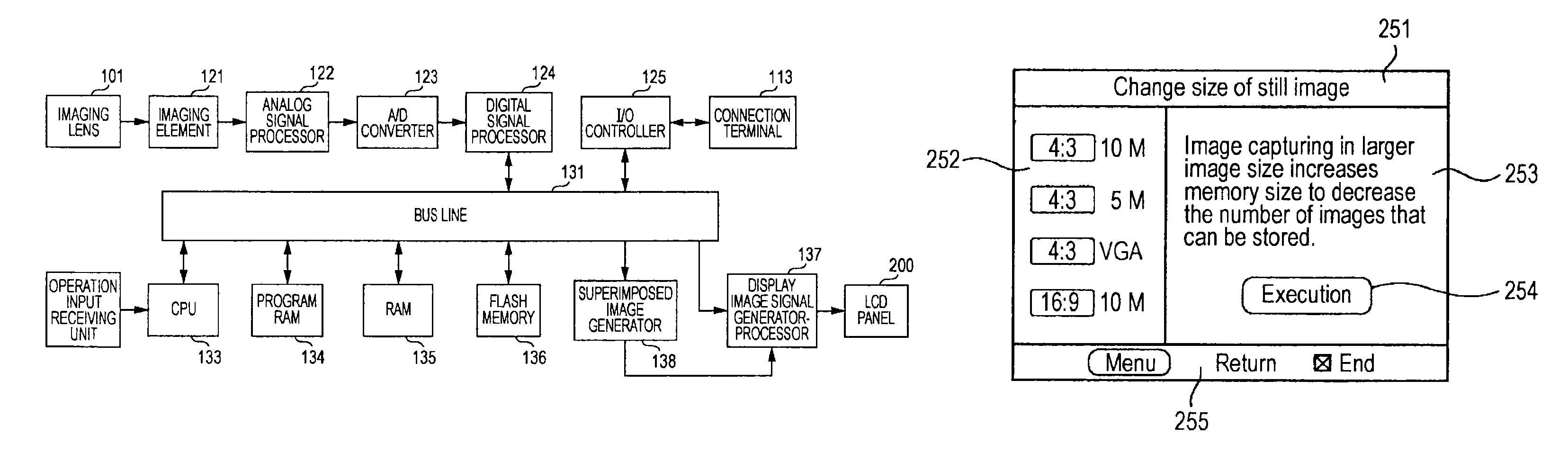

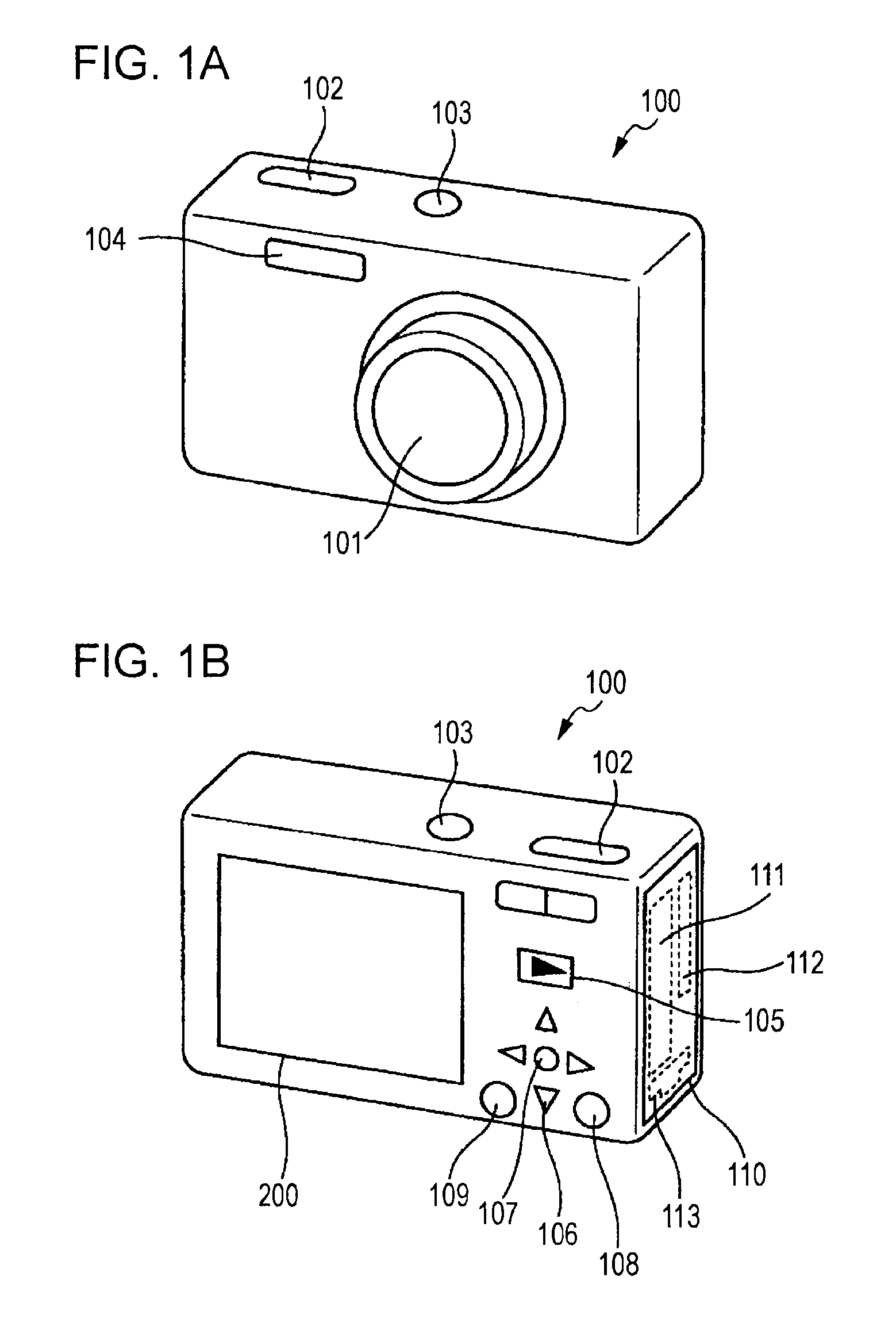

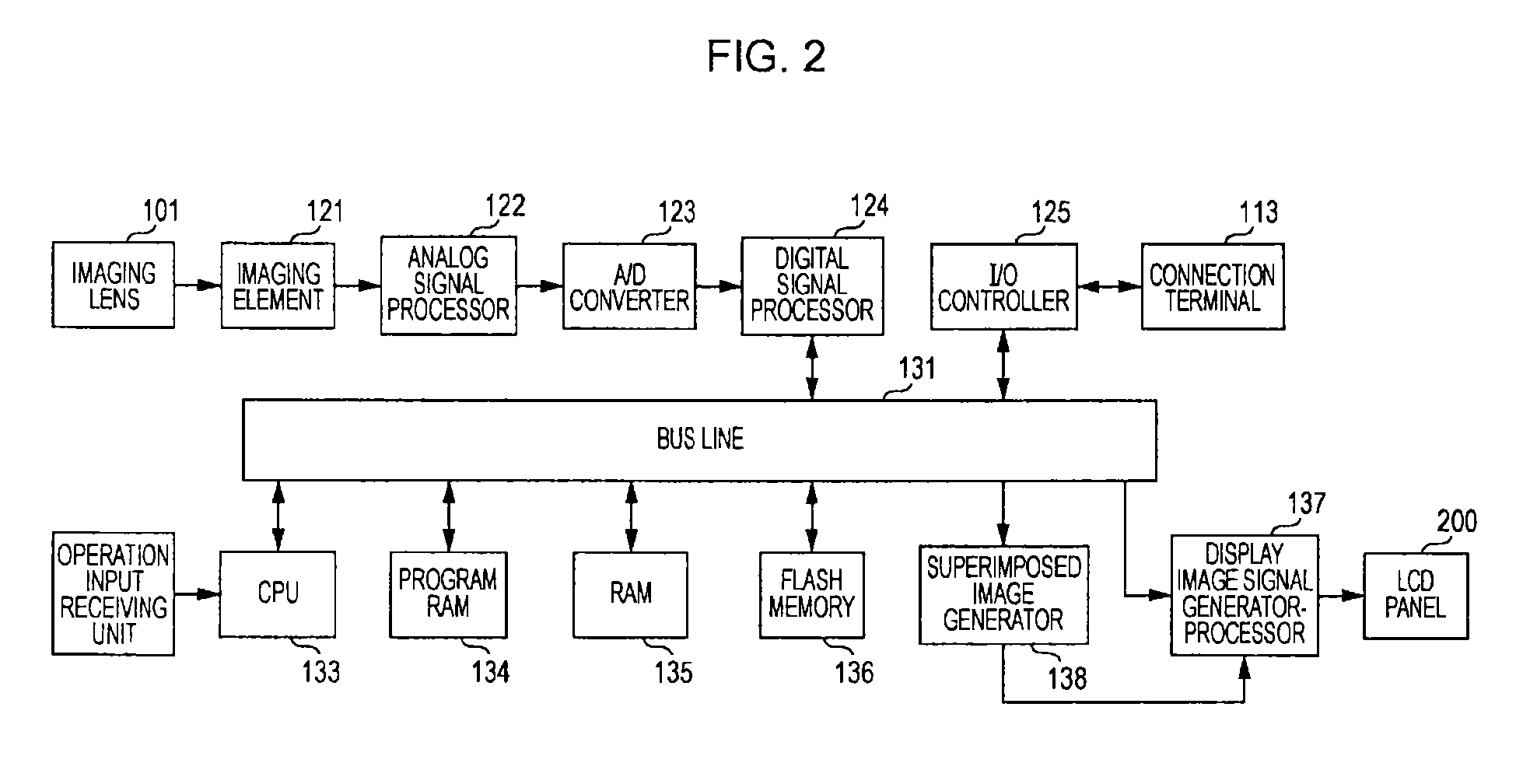

Image processing apparatus and image processing method

ActiveUS9575630B2Easy to displayEfficiently understoodTelevision system detailsColor television detailsImaging processingComputer graphics (images)

An image processing apparatus includes an operation receiving unit; and a control unit configured to perform a normal mode display process of displaying icon images of kinds corresponding to an operation status of the apparatus in a display unit and an icon description display process of displaying an icon selection image for selecting an icon image that is being displayed in the display unit upon reception of an operation input to activate an icon description mode by the operation receiving unit during the normal mode display process in the display unit and displaying a description image for an icon image selected upon reception of an operation input by the operation receiving unit while the icon selection image is being displayed in the display unit.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com